Abstract

4D printing polymeric biomaterials can change their morphology or performance in response to stimuli from the external environment, compensating for the shortcomings of traditional 3D-printed static structures. This paper provides a systematic overview of 4D printing polymeric biomaterials for tissue regeneration and provides an in-depth discussion of the principles of these materials, including various smart properties, unique deformation mechanisms under stimulation conditions, and so on. A series of typical polymeric biomaterials and their composites are introduced from structural design and preparation methods, and their applications in tissue regeneration are discussed. Finally, the development prospect of 4D printing polymeric biomaterials is envisioned, aiming to provide innovative ideas and new perspectives for their more efficient and convenient application in tissue regeneration.

Keywords: 4D printing, Polymeric biomaterials, Tissue regeneration

Graphical abstract

Highlights

-

•

The core elements of4D printing polymeric biomaterials are summarized and elaborated.

-

•

The research advances of 4D printing polymeric biomaterials in structure, design, and application are analyzed.

-

•

The latest achievements and breakthroughs of 4D printing polymeric biomaterials in tissue regeneration are introduced.

1. Introduction

4D printing is an advanced manufacturing technology developed based on traditional 3D printing, which adds a time dimension to the 3D structure created by 3D printing, enabling the printed object to automatically undergo shape or morphological changes when subjected to external stimuli as shown in Fig. 1. 4D printing polymeric biomaterials, as a typical class of 4D printing materials, are widely used in tissue regeneration [[1], [2], [3]]. These materials are often characterized by shape memory, responsiveness, or self-assembly, showing great potential for applications in smart structures, soft robots, and biomedical devices [[4], [5], [6], [7], [8]]. For example, shape-memory polymers are capable of transforming from a temporary shape to a permanent one at a specific temperature [6,9], while environmentally responsive polymers can adjust their structure in response to changes in the environment, such as changes in humidity or pH [7,10]. The smart behavior of these materials provides unprecedented creative scope for developing new products that can adapt to environmental changes, repair themselves, or perform complex tasks.

Fig. 1.

Basic elements of 4D printing polymeric biomaterials. Some image elements are referenced.[5] Licensed under a Creative Commons CC BY license. [11] Copyright 2019, Springer Nature. [12] Copyright 2011, Royal Society of Chemistry

In recent years, research has been proliferation into 4D printing polymeric biomaterials for tissue regeneration [[13], [14], [15]]. On one hand, these materials have unique properties, such as processability, biocompatibility, degradability, and bioactivity, which are necessary for medical implants [16,17]. On the other hand, the ability of 4D printing polymeric biomaterials to dynamically adapt their shape and function in response to changes in time or external stimuli (e.g., temperature, humidity, light, etc.) is just enough to mimic the unique properties of natural tissues effectively. Biomaterials for natural tissue regeneration involve complex three-dimensional structures, microstructures, and extracellular matrix (ECM) compositions, as well as dynamic changes to adapt tissues with unique functions [18]. Most of these dynamic functional conformational changes are caused by intrinsic mechanisms in response to internal or external stimuli, which are unable to be mimicked by traditional 3D printing static structures [18]. Therefore, 4D printing polymeric biomaterials demonstrate great potential for repairing, supporting, replicating, or enhancing the function of human tissues and organs [[19], [20], [21], [22]].

This review aims to comprehensively summarize the principles and research progress of 4D printing polymeric biomaterials for adaptive tissue regeneration. Moreover, it delves into the challenges faced in current research, offering insights and inspiration for the innovative application of biomedical implants in the era of personalized medicine.

2. Basic elements of 4D printing polymeric biomaterials

2.1. General elements

2.1.1. Printability

The basic structures of 4D printing materials are constructed through 3D printing technology [[23], [24], [25]], so the printability of these polymers is crucial for the construction of their 3D structures. It is important to choose a printing method that matches the properties of the materials. For inkjet printing methods, the viscosity of the ink is very important. The molecular weight and concentration of polymers are usually important factors affecting the viscosity of the ink. In general, high molecular weights and concentrations lead to an increase in the entanglement of the polymer chains in the system, increasing the viscosity of the ink. When the viscosity is too high, the nozzle will be blocked and when the viscosity is too low, the ink droplets passing through the nozzle will flow on the printing platform, hindering the accumulation of 3D structures. Therefore, the viscosity should be controlled within an appropriate range [26]. For the inks used in SLA and DLP methods, in addition to the requirements just mentioned above, the ink also needs the ability of photocuring, and the type and concentration of the photocuring material also influence the printing process. For this printing method of FDM achieved by extruding filament, the ink is required to be thermoplastic. It can be processed into fine filament and has a certain mechanical strength after cooling. At the same time, the rheological properties of the ink, including shear stress, shear thinning, and thixotropic, are crucial to the printing results [14,[27], [28], [29], [30], [31], [32]]. Nanoparticles such as nanosilicates [26,33], nanocellulose [34], and nanoclay [35] have been used to impart shear thinning behavior to the inks and significantly suppress the shrinkage and expansion of printed structures during crosslinking, thereby improving printing fidelity [36].

As mentioned above, the printability of materials is related to the viscosity, rheological properties, and physical and chemical properties of the materials themselves [37]. From this perspective, the evaluation of material printability is an extremely complex process, so far, there is no comprehensive evaluation theory and parameters. It is difficult for us to evaluate whether a material has printability based on the results of a certain experiment. Some scholars have made attempts in this regard, attempting to obtain a universal empirical conclusion to quickly evaluate the printability of materials. Lee et al. studied rheological parameters including G′, G″, and tan δ. Through the research on the printing process of alginate/gelatin-based gel, it was found that G′ and G″ were more related to the printing pressure, while tan δ was more related to the shape fidelity and extrusion uniformity [38]. Through model prediction and statistical analysis, it was found that materials could be printed when they exhibit high yield viscosity and low plasticity before flowing. When high-elastic materials have greater elasticity in lower frequency ranges and high viscosity in higher frequency ranges, they are often easier to print [39].

2.1.2. Biocompatibility

Biocompatibility includes not only biological inertness, but also biostability and biological function, which depends on the properties of materials (such as crystallinity, charge, wettability, and hardness), and the interactions with the biological environment of the target tissue (protein adsorption, inflammatory processes, contacting with blood). When biomaterials are implanted into the body, they will have an impact and effect on specific biological tissue environments, and the biological tissue will also influence the biomaterials. This interaction persists until an equilibrium is reached or the implant disappears. These materials not only need to coexist safely with biological tissues without causing any damage reactions but also possess functional properties that positively affect the targeted tissues, such as promoting cell differentiation and combating inflammation, etc. [14,40]. It is also essential to identify the potential changes that biomaterials may undergo within the body, such as interactions with the internal environment or their degradation, and to ensure that the resulting products do not adversely affect biological tissues.

The strong dependence of biocompatibility on polymer materials is mainly reflected in the following aspects. First, the chemical composition and structural characteristics of the material are the foundation, which directly determines the interaction mode between the material and the organism. Second, the surface properties of materials, such as hydrophilicity, hydrophobicity, charge distribution, roughness, etc., also significantly affect cell adhesion, cell proliferation, cell differentiation, and other behaviors. Furthermore, the immune response, metabolic processes, and long-term physiological adaptability of organisms to materials are essential factors in evaluating biocompatibility. Usually, a single untreated material is difficult to meet the requirements of multiple indicators. Therefore, researchers often composite different types of materials. For example, natural polymers are biocompatible but have poor mechanical properties, so they are often compounded with synthetic polymers to obtain better mechanical properties. Alternatively, biologically active components can be combined with polymers to develop new materials with good biocompatibility [41].

2.1.3. Biodegradability

The biodegradability of biomaterials in vivo refers to the ability of materials to gradually break down and decompose under specific biological activities or environmental conditions when implanted or introduced into the body, ultimately to be absorbed or metabolized by the organism, or eliminated from the body [42]. It is necessary to understand the degradation mechanism of materials. Polymer materials may interact with microorganisms, enzymes, water, and free radicals, causing molecular chain breakage or cross-linking, resulting in changes in the structure and properties [43]. Polymer materials vary in molecular weight, polydispersity, crystallinity, thermal transitions, and degradation rates, significantly affecting the performance of polymer scaffolds. Given the abundance of cells and the variety of enzymes in body fluids compared to in vitro conditions, this distinct solution environment can result in varied degradation behaviors for the same polymer [44]. The biodegradation of polymers is a complex process, so the dissolution method is commonly used to study the degradation process of materials.

2.2. Unique elements

2.2.1. Stimulation

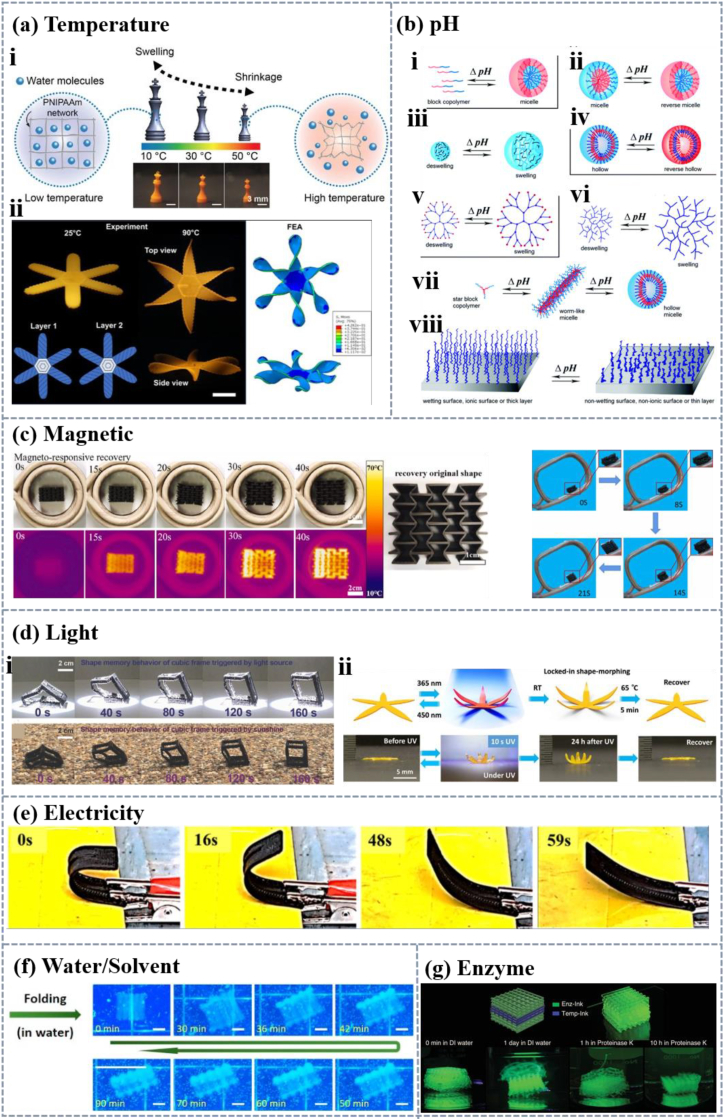

4D printing materials spontaneously change their shape structure over time in response to external stimuli as shown in Fig. 2 [2,[45], [46], [47], [48], [49], [50], [51]]. So stimulus conditions play a crucial role in the dynamic changes of 4D printing polymeric biomaterials. The emergence of this approach provides a potential method to create smart materials of self-regulation.

Fig. 2.

Stimulus-response of 4D printing polymeric biomaterials. (a) Temperature response: i) temperature-responsive swelling of 3D printed PNIPAAm hydrogel structures [52]. Licensed under a Creative Commons CC BY license. ii) petals twisted when bilayer printed structures prepared with different print paths are immersed in hot water at 90 °C [53]. Licensed under a Creative Commons CC BY license. (b) pH-responsive polymers of different architectures: i) unimer–micelle, ii) micelle–reverse micelle, iii) nanogels or microgels, iv) hollow– reverse hollow, v) dendrimer, vi) hyper-branched, vii) micelle morphology changes (from worm-like to hollow), and viii) brushes [54]. Copyright 2017, Royal Society of Chemistry. (c) Magnetic responsive shape memory processes of two kinds of polymeric materials [55,56]. Copyright 2023, Elsevier, and Copyright 2022, IOP Publishing, Ltd. (d) Light response: i) shape recovery process of the cubic frame under a light source of 87 mW cm−2 and insolation of 76 mW cm−2 [57]. Copyright 2017, John Wiley and Sons. ii) deformation process of the flower-like shape printed by polymer material under light conditions [58]. Copyright 2021, John Wiley and Sons. (e) Shape recovery process of U-structured electroactive materials at 35 V [59]. Copyright 2022, Elsevier. (f) Reversible shape change of tracheal hydrogels between pure water and brine [60]. Copyright 2020, Elsevier. (g) Three-dimensional structures were constructed using enzyme-responsive material as the top and bottom thirds and temperature-responsive material as the middle third. The structure was transferred to deionized water and the structure swelled. It was then transferred to proteinase K solution and the material deformed in response to the enzyme [61]. Copyright 2021, John Wiley and Sons.

2.2.1.1. Temperature

Thermal-stimulus response is the most common and extensively studied stimulus in 4D printing as shown in Fig. 2a, and the mechanisms of thermal stimulus response vary greatly among different polymers [62] including glass transition, melting transition, crystallization transition, low critical solution temperature (LCST) and high critical solution temperature (UCST). The ability of materials to accept stimuli and undergo changes in shape or properties is related to their molecular structure and physical and chemical properties. The core of the temperature stimulus-response of shape memory polymers (SMPs) is the phase transition behavior, including glass transition, melting transition, and crystallization transition, which are accompanied by molecular chain movement as the driving force of shape memory [7]. The principle of glass transition is based on the generation and release of stresses in the molecular cross-linking network induced by the transition between the glassy and rubbery states above and below the glass phase transition temperature [63]. Polyurethane (PU) is usually constructed as SMPs through the glass transition temperature. For example, Staszczak et al. prepared PU materials with a glass transition temperature of 45 °C. The material has good shape memory ability, with a shape fixation ratio of about 98 % in three heat engine cycles and little change in subsequent cycles [64]. The principle of the melt transition, which is mainly based on a change in the crystalline structure of the polymer, is another important phase transition process in SMPs. At low temperatures, the polymer molecular chains are well-aligned and form a crystalline structure. When the temperature rises above the transition temperature (melt temperature) the thermal movement of the polymer molecular chains increases, the crystalline structure is disrupted and the material is in the amorphous state. For both transformation modes, the molecular weight and structure of the soft and hard sections of the material will affect the transformation temperature [6], for example, the more rigid groups, the higher the degree of crosslinking, the greater the molecular weight will lead to an increase in the transformation temperature. The crystalline transition is the process by which a polymer is transformed from an amorphous to a crystalline state and is the third important phase transition process in polymers. The principle of crystalline transition is mainly based on the regular arrangement of polymer molecular chains. For this type of transformation, the rate of crystallization transition and crystallinity are important parameters, they determine the speed and degree of shape recovery of the material. Ma et al. fused the two effects to prepare ethylene-vinyl acetate copolymer/poly(propylene carbonate) (EVA/PPC) blends with a triple shape memory effect, which is realized by its unique phase structure and the different transition temperatures of the two polymers. EVA and PPC are incompatible and thus form a distinct phase separation during melt blending, including an island structure (EVA as the continuous phase and PPC as the dispersed phase) and an interconnected structure (PPC as the continuous phase and EVA as the dispersed phase), which provides the necessary phase structure basis for the shape memory effect. During the deformation recovery process, PPC undergoes a glass transition at lower temperatures, and the material returns to its temporary shape, while EVA undergoes a melting/crystallization transition, and the material returns to its initial shape. Reversible phase transitions of EVA and PPC provide reversible deformation and recovery mechanisms for shape memory effects [65]. The temperature response mechanism of hydrogels is mainly based on LCST or UCST [66]. When the temperature is below the LCST, the polymer molecular chains are miscible with water due to the formation of hydrogen bonding with water molecules and the gel swells. Once the temperature is heated up to the LCST, the increase in the activity of H2O molecules results in the breakage of the hydrogen bonds, then the water molecules are released and the gel volume shrinks [67].

2.2.1.2. pH value

pH-responsive polymers are usually formed by cross-linked polyelectrolytes with weakly acidic or weakly alkaline groups, and may also be composed of amphoteric polyelectrolytes with both groups simultaneously. These weak acid or weak base groups accept or release protons in response to changes in the pH of the environment. pH response mechanism is commonly used in gel materials (Fig. 2b). For example, the polymer polyacrylic acid (PAA) with a carboxyl group is pH-sensitive [68]. When the pH of the dispersing medium is larger than the ionization constant (pK), the weak acid groups on the molecular chain ionize to form anion groups with negative charges, and the molecular chain stretches due to electrostatic repulsive forces, thus generating a large osmotic pressure inside the hydrogel causing it to swell [69]. And protonation at lower pH values causes the molecular chain to shrink [70]. In addition to this, weakly acid groups that are pH responsive also include sulfonic acid, phosphoric acid, and boronic acid [54].

As for basic polymers, polymers with amine groups are typical of weakly basic pH-responsive polymers such as poly[(2-diisopropylamino)ethyl methacrylate], and nylon [71]. When the pH of the dispersion medium is less than the pK of the weakly basic polyelectrolyte, the weakly basic group on the molecular chain receives protons to form a positively charged cationic group causing swells due to the increase of the internal osmotic pressure of the hydrogel [72]. Therefore, the ionization degree of the molecular chains of pH-responsive hydrogels will change greatly due to the small change in the environmental pH, resulting in changes in their internal osmotic pressure, leading to swelling or shrinking of hydrogels. The hydrophilicity of hydrogels in water can be adjusted by ion transformation, resulting in an increase or decrease in the solubility of polymer segments or swelling and de-swelling of hydrogels [54].

2.2.1.3. Magnetic field

Compared to other stimulus response methods, magnetic field induced heating can be applied to the positions that are difficult to be heated directly, such as the interior of the human body [73]. Therefore, magnetic response SMP has potential application prospects in the field of intelligent medical devices, and the magnetic response studies are listed in Fig. 2c. For polymers, which are not inherently magnetically responsive, it is usually prepared by compounding magnetic nanoparticles with SMP matrix through blending or covalent bonding. There are two commonly used magnetic induction methods [74,75]. The first way is to directly add magnetic particles to the material and the material can generate heat after being stimulated in the alternating magnetic field to achieve deformation behavior [76,55]. Wang et al. combined iron carbide nanoparticles with hydrogels, where the magnetic particles can generate heat in the presence of an applied magnetic field (the magnetothermal effect), leading to an increase in the temperature of the polymer matrix causing it to undergo a huge volume contraction at high temperatures [77]. In another work, Fe3O4 magnetic particles were precipitated into a polymer network of Poly(N-isopropyl acrylamide) (PNIPAAm) hydrogels by in-situ precipitation method, and the PNIPAAm composite gel and elastomer were designed into a double-layer structure, due to the selective heating of the double-layer gel under the action of an alternating magnetic field, the corresponding layer shrinkage caused the structure to bend achieving self-folding [78].

The second way is to use magnetic particles as an active filler in polymers [55], where the material induces a magnetic moment to change in physicochemical properties, and ultimately a change in shape or properties. Common magnetic particles include iron [79,80], magnetic Fe3O4 nanoparticles [55,[80], [81], [82]], and NdFeB [83]. Inorganic nanoparticles tend to aggregate due to their incompatibility with polymers [84]. To improve the compatibility and dispersion of Fe3O4 with the matrix, the magnetic nanoparticles are coated, modified [85], or functionalized [86] by oleic acid. Although there are advantages to directly inducing changes in magnetic response materials through magnetic fields, there are still some points to note, such as adjusting the frequency of the external magnetic field to a safe range to prevent any potential harm to living tissues.

2.2.1.4. Light

Light-driven polymers introduce photoresponsive functional groups into the polymer network [87]. When the material is irradiated with light of a specific wavelength, molecules undergo optical isomerization reactions, thereby changing the form of the chain segments and achieving light-induced deformation (Fig. 2d) [57,58]. There are many photoresponsive materials which can be mainly divided into two categories. One is based on the photochemical conversion of functional groups to achieve light stimulation response, mainly including azobenzene groups, benzopyran groups, triphenylmethane groups, cinnamic acid groups, etc [46,50,88]. These active groups change their configuration or form charged groups after exposure to light, leading to changes in the conformation or hydrophobicity of the polymer molecular chain, resulting in a shape change of the SMPs or swelling/unswelling of the hydrogel [46]. For example, the azobenzene group is a photoactive group with two isomers, cis and trans. When exposed to specific wavelengths of ultraviolet light, the trans structure of the azobenzene group will transform into a cis structure and when exposed to blue light, the cis structure will transform into a trans structure [58,[89], [90], [91]]. Another kind is based on the principle of photothermal effect, which requires materials to have the ability to convert light energy into heat, raise the temperature of the material above its transition temperature, and thus achieve light stimulus responsiveness [92]. Usually, materials with photothermal effects such as carbon black [57], graphene [93,94], and carbon nanotubes [95] are combined or covalently connected with thermally responsive polymers to achieve photoresponsiveness [96]. For example, graphene has a high photothermal conversion efficiency in the near-infrared region. Near-infrared light or photons strongly interact with graphene or oxidized graphene through resonance vibration, further converting kinetic energy vibration into thermal energy.

2.2.1.5. Electricity

Similar to magnetic-responsive polymers, electric field responsive polymers can also be constructed by loading conductive elements and changing their shape or function in the presence of the electric field. The response of electrical stimulation in 4D printing has been widely studied (Fig. 2e), and the response can be achieved by constructing intrinsic conductive materials and conductive composite materials. The commonly used conductive materials include carbon black [97], carbon nanofiber [98], carbon nanotube [99], polyaniline, polypyrrole, and polythiophen [47,49]. These conductive fillers are usually mixed with printing resins through melting or solution for printing. The response modes of electrical stimulation-responsive materials also usually include two kinds. One is the transfer of heat caused by electrical signals. Dong et al. mixed polylactic acid (PLA) and carbon nanotubes (CNTs) by melting. CNTs have good electrical conductivity, and form a continuous conductive network when added to the PLA matrix, which endows the composite with electrical conductivity. The composite was locally warmed by the Joule heat generated by the CNTs when a voltage was applied, and the PLA molecular chains were oriented and rearranged to deform [59]. Another kind is that when the external electric field is applied, the ions migrate in the hydrogel resulting in changes in osmotic pressure which causes the hydrogel to swell or contract [100]. The extent of the hydrogel expansion/contraction deformation depends on the internal properties of the gel (such as the stiffness and charge density of the gel) and the external properties (such as the strength of the applied voltage) [46]. Sarmad et al. synthesized chitosan-based polymer films in which the cations (Na+) in the solution migrated toward the cathode and the anions (Cl−) and the mobile anions (Ac−) from the chitosan migrated toward the anode when the films were immersed in a sodium chloride solution and a direct current electric field was applied. Since the -NH3+ ions on the chitosan backbone are fixed and cannot migrate, the chitosan film is bent by the electrostatic attraction from the cathode. The ionic migration caused by the electric field results in an osmotic pressure difference, which further pushes the polymer film to bend toward the cathode [101].

2.2.1.6. Water/solvent

Solvent stimulation is usually used for hydrogel materials including various solvents, such as water or other liquids, to change the shape and characteristics of the 4D printing structure as shown in Fig. 2f, [51,102]. There are two kinds of response mechanisms of solvent-responsive polymers. One of them is that solvent molecules enter the material and cause plasticization, greatly reducing the transition temperature of the polymer matrix. The stretched molecular chains return to the most stable state, leading to the recovery of temporary shapes. A work investigated the water response behavior of PU. PU absorbs water when soaked in water, and the hydrogen bond between water and polymer chains weakens that between molecular chains, thereby reducing the glass transition temperature, so that the shape recovery is achieved by absorbing water at room temperature. By controlling the amount of water absorbed by different parts of the polymer, different glass transition temperatures can be generated, thus achieving sequential control of shape recovery [103]. Another response mechanism is using functional groups that respond to solvent stimuli. For example, hydrogen bonding or network structure serves as reversible phases for shape memory, such as the reversible network of cellulose nanowhiskers [104]. When composite materials containing cellulose nanowhiskers absorb water, the network structure of the material is disrupted due to the formation of competitive hydrogen bonds, resulting in a significant decrease in modulus and a change in shape. The network structure can be reformed then the shape can be fixed after drying.

2.2.1.7. Others

In addition to the stimulus factors discussed above, there are other stimulus factors in the 4D printing process, such as enzyme (Fig. 2g) [61], mechanical stress, microwave [105], etc., which can activate changes in supramolecular structure and surface properties [106]. With the development of stimulus diversity, the research direction of stimulus-responsive materials is moving towards multi-stimulus responses like magnetic field/temperature, temperature/solvent, etc [88]. More multi-responsive materials can be created with different structures and superior performance and are widely used in various industries [[107], [108], [109]].

2.2.2. Smart performance

2.2.2.1. Shape memory

The shape memory is one of the most common and widely used properties of 4D printing materials. The deformation behaviors considered in 4D printing include twisting, folding, curling, bending, linear or nonlinear expansion/contraction, etc. [110,111], and the shape changes can be made from 1D to 2D, 2D to 2D, 1D to 3D, 2D to 3D, and so on [110,[112], [113], [114], [115]]. The shape memory capability of SMPs is related to the molecular structure, which usually consists of a fixed phase that defines the initial shape of the material and a reversible phase that controls the temporary shape [7]. The reversible phase is usually the portion of the polymer that undergoes phase transitions including glass transition, crystallization transition, and melt transition, which is discussed in more detail in the section on polymer materials and temperature response. SMPs can be divided into two main categories including unidirectional shape memory and bidirectional shape memory [116]. Unidirectional shape memory materials include two kinds, the first is shape-altering materials, which change shape under stimulus conditions (Fig. 3a–i), and the second type is a material that can be programmed to one or more temporary shapes, and can gradually recover to a permanent shape through multiple temporary shapes under external stimuli. Hydrogels with swelling properties are the representative materials of this type. In the thermosensitive hydrogel, the PNIPAAm layer began to lose water and shrink when the temperature was raised, and after the shape was bent and cooled, the PNIPAM layer absorbed water and expanded again, and the structure returned to the initial plane state [117]. The deformation process is irreversible, and after recovering to a permanent shape, a reprogramming step is required to rebuild the temporary shape (Fig. 3a–ii) [9]. The bidirectional shape memory property is characterized by its reversibility, whereby the polymer is capable of changing the shape in response to a certain stimulus, and then recovering when the stimulus is removed (Fig. 3a–iii). Anthamatten prepared a PCL shape memory material by introducing cross-linking of molecular chains followed by stretching. The resulting network has built-in stress and anisotropy along the stretching direction, conferring a bidirectional shape memory effect in the absence of external loading. The molecular chains can switch between nearly isotropic coils and oriented crystals during thermal cycling. When cooled, the material elongates as crystallization further aligns the PCL chains along the tensile direction, and when heated, the material shrinks back to its relaxed state [101].

Fig. 3.

Smart performance of 4D printing polymeric biomaterials. (a) Different ways of shape memory. (b) Shape memory processes in thermoplastic and thermoset SMPs [118]. Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license (https://creativecommons.org/licenses/by/4.0). (c–d) Self-healing process of polymeric materials [119,120]. Licensed under a Creative Commons CC BY license and Copyright 2024, John Wiley and Sons. (e) Various reversible chemical covalent and noncovalent bonding interactions behind dynamic self-healing materials [121]. Licensed under a Creative Commons CC BY license. (f) Transformation of polymeric materials from free molecules to micelles and macroaggregates in response to changes in pH and temperature [122]. Licensed under a Creative Commons CC BY license. (g) Self-assembly of GEL-CUR hybrid hydrogels [4]. Reprinted with permission from [4]. Copyright 2024, American Chemical Society.

From the properties of the material, SMPs can be divided into thermoset SMPs and thermoplastic SMPs. As shown in Fig. 3b, the molecules of thermosetting polymers consist of a three-dimensional network, and because of the crosslinked network structure, these molecules do not melt and have a well-defined fixed original shape. When the temperature is higher than the transition temperature, the molecular chains of the reversible phase move and deform under the action of external forces, and are frozen upon cooling down so a temporary shape is defined. When the temperature is raised above the transition temperature again, the reversible phase moves under the action of the intramolecular stresses, and the shape of the material is restored to its original shape. The process of shape memory process of thermoplastic SMPs is similar to that of thermoset molecules (Fig. 3b) [118]. However, the molecular structure of these two SMPs is different. Thermoplastic SMPs are usually composed of linear molecules, the molecular chains are broken and free to slide after heating, so the material changes into the melting state, thus their permanent shape could be defined many times [63].

2.2.2.2. Self-healing

Self-healing properties refer to the ability of smart materials to restore or approach their original properties by automatically repairing the damage through internal mechanisms or external stimuli after damage (Fig. 3c and d) [123]. The determining factor for the rationalized design of biomedical self-healing hydrogels is the cross-linking mechanism that includes reversible chemical covalent bonding cross-linking and physical noncovalent interactions [[121], [124], [125]]. Common reversible covalent bonding includes the Schiff reaction [126,127], Diels-Alder reaction [128,129], borate bond [130], and disulfide bond (Fig. 3e) [131,132] and these chemical bonds have dynamic and reversible characteristics. The dynamic covalent bonding in the molecular network of the material is constantly changing dynamically, and there are always uncrosslinked polymer chains with reactive groups in the network, which can be crosslinked at the damaged place many times in a repetitive reaction, and ultimately, the material will recover to the original structure and function. In addition to these chemical bonds, several non-covalent physical interactions can also provide biomedical hydrogels with self-healing properties, such as hydrophobic interactions [124,133], hydrogen bonding [8], ionic interactions [11], and host-guest interactions (Fig. 3e) [134].

These methods are often applied to material matrices to improve their mechanical properties [125]. For example, in the hydrogel material composed of polyvinyl alcohol (PVA)/borax and carboxymethyl chitosan, borax and PVA molecules combine to form a borate ester crosslinked network, which can be reversibly broken and re-formed when damaged by external forces, to achieve self-healing. At the same time, the network structure caused by crosslinking enhances the strength and flexibility of the hydrogel [135]. In addition, self-healing properties are used to give shape memory polymers the ability to be reprogrammed and reconstructed. Currently, most SMPs only have one permanent shape. Ge's team introduced covalent adaptability networks (CANs) into SMPs and successfully prepared MRC-SMPs with high deformability, high glass transition temperature, and high modulus. By processing at higher temperatures, the initial shape can be reconstructed multiple times [119].

The self-healing properties of the materials are closely related to the 3D-printed structures. For example, some complex structures may rupture during the printing process, leading to a decrease in the self-healing ability [136]. Moreover, there may be some microcracks in the 3D printed structure, which are difficult to detect and localize, thus affecting the self-healing effect. In addition, when combining 3D printing and the self-healing properties of materials, it is also important to fully consider the physical and chemical properties of the materials themselves to ensure that they can be adapted to the printing method [136].

2.2.2.3. Self-assembly

Self-assembly refers to the spontaneous organization of macromolecules into ordered structures through non-covalent bonding interactions [137,138]. The self-assembly process does not require external guidance or templates, and the molecules form a stable structure relying on their chemical properties and external conditions [139]. The key to the self-assembly properties lies in the molecular recognition ability including the spatial complementarity of the molecular shape of the molecular shape or non-covalent interaction, which determines the unique orientation of the molecules [5]. Under externally stimulated conditions, the non-covalent interactions of the molecules will change, leading to a change of properties in some molecular chains, such as different crystallization ability or different hydrophilicity between different molecular chain segments, which can be used as a directional assembly condition for self-assembly, thus changing the nature or hydrophilicity of the whole system [5]. Li et al. synthesized peptide-like double-block copolymers by introducing carboxyl groups on the side chains, and the materials exhibit temperature and pH responsiveness in acidic solutions. As the pH decreases or the temperature increases, the hydrophilicity of the material decreases and aggregation occurs to form micelles (Fig. 3f). The formation and disappearance of micelles are reversible, which gives them potential applications in the field of drug carriers [122]. The nanofibers and high helix hydrogels (GEL-CUR) prepared by Wang et al. were able to induce the formation of nanofiber networks within the gel network by the denaturing/renaturing and solvent exchange process (Fig. 3g), and by controlling the drying and swelling conditions, the density and orientation of the CUR nanofibers can be regulated, thus affecting the mechanical properties and cytocompatibility of the hydrogels. The gels supported the adhesion and growth of neural cells, which has great potential for use in neural tissue engineering [4].

Meanwhile, the self-assembly process can provide a basis for the design of shape memory materials. Through the interactions mentioned above, molecules self-assemble to form ordered structures that can be used as the blocks of shape memory materials, enabling shape change and recovery ability under specific conditions. Bao et al. combined a pH-responsive peptide (MA-FIID) with a hydrogel material. Under acidic conditions (such as pH 2.0), the MA-FIID peptide molecules self-assemble to form a fiber with a β-folded structure, and the three-dimensional network structure increases the internal resistance of the hydrogel, thereby limiting the entry of water molecules, resulting in the volume contraction of the hydrogel. By changing the pH of the solution, the process of self-assembly and depolymerization can be controlled, thus regulating the volume expansion and contraction of the hydrogel [140]. Overall, self-assembly is a process of multiple driving forces interacting and combining, and molecular guidance effects are crucial for the formation of highly ordered assembly structures [5].

3. Polymers for 4D printing biomaterials

With the development of the industry and the continuous growth of medical demand, exploring 4D printing polymeric materials with excellent performance has become the focus of current research. Polymers can be categorized into synthetic and natural polymers. In this section, we list some common 4D printing biopolymers and discuss their structures and applications. The properties of different polymers are listed in Table 1.

Table 1.

Properties of different 4D printing polymers.

| Polymers | Physicochemical properties | Stimulation | Advantages | Disadvantages | Ref. |

|---|---|---|---|---|---|

| PNIPAAm | Temperature-sensitive | Temperature | The response temperature is close to the body temperature | Low mechanical strength | [141] |

| PVA | Water-soluble polymer with good adhesion and film-forming properties | Temperature, Water |

Good water solubility; easy to process; good biocompatibility | Low mechanical strength; poor stability | [[142], [143], [144],145] |

| PCL | Semi-crystalline polymer with low melting point and glass transition temperature | Temperature, pH | Good biocompatibility, biodegradability, and flexibility; slow degradation rate; suitable for long-term application | Low mechanical strength; general thermal stability; printing accuracy may be limited | [146,147,148] |

| PLA | High crystallinity | Temperature, pH | Good biocompatibility and degradability; good mechanical properties | Great brittleness and insufficient toughness; degradation products may result in a locally acidic environment | [149,150,151,152] |

| PU | Good mechanical properties, flexibility, and wear resistance | Temperature | Adjustable properties by changing the molecular structure and composition | Relatively poor biodegradability | [153,154,155] |

| Alginate | Natural polymer with good biocompatibility and gel formation ability | Ion, pH |

Rich source; low cost; good biocompatibility and gel properties. | Limited mechanical strength; the rate of degradation is difficult to control precisely | [156,157,158] |

| Chitosan | Natural polysaccharide with good biocompatibility and biodegradability | Enzyme, pH | Good biocompatibility and bioactivity; antibiosis | Poor mechanical properties; difficult to process | [159,160,161] |

3.1. Synthetic polymers

Synthetic polymers are prepared by chemical synthesis methods, such as poly(ε-caprolactone) (PCL), PLA, etc. They have excellent physical and chemical properties and can be customized and modified to meet different biomedical needs.

3.1.1. PNIPAAm

PNIPAAm is a typical thermo-responsive polymer with biocompatibility, and the hydrophilicity of PNIPAAm changes at a LCST of 32 °C, leading to hydration and dehydration phenomena [162,163], thus exhibiting temperature-regulated stretching and shrinkage of the material [164]. Since the PNIPAAm consists of hydrophilic amide groups and hydrophobic isopropyl groups, and when the temperature falls below the LCST, the hydrophilicity of PNIPAAm is enhanced because of the formation of hydrogen bonds between amide groups on the PNIPAAm chains and the water molecules, so the polymer chains are stretched (Fig. 4a and b) [165,166]. When the temperature is warmed up to the LCST, the hydrogen bonding between water molecules and PNIPAAm is weakened, so the water molecules are released, resulting in a globular conformation of the polymer chains (Fig. 4a and b). This kind of thermo-responsive polymer is widely used in biomedical applications due to its relatively low LCST (close to physiological temperature) [166]. Zhao et al. [167] prepared temperature-triggered PNIPAAm hydrogels, which were able to efficiently adhere to biological tissues and actively contract at body temperature to promote wound healing in the absence of any drug as shown in Fig. 4c. Siadati [168] prepared a temperature-sensitive hydrogel drug scaffold by PNIPAAm and niosomal. Encapsulation of rosuvastatin in niosomal allows targeted delivery and controlled release of the drug, thereby promoting the repair of myocardial tissue. By adjusting the composition and structure of the hydrogel and niosomal, the release rate and duration of the drug can be controlled to achieve the therapeutic purpose. Since the drug is encapsulated inside the hydrogel, the degradation rate of the hydrogel affects the rate of drug release. When the hydrogel begins to degrade, the drug is gradually released as the hydrogel network structure is destroyed. Therefore, by adjusting the cross-linking density of the hydrogel, the degradation rate of the hydrogel can be controlled, thus indirectly controlling the release rate of the drug. In addition to this method, LCST modulation is another way to control the drug release rate [165]. Lowering the LCST of PNIPAAm can keep the hydrogel in a sol-gel state at body temperature, thus slowing down the drug release rate. This is suitable for situations where a slow release of drugs is required, such as long-term administration. Elevating the LCST of PNIPAAm allows the hydrogel to remain in a gel state at body temperature, thereby accelerating the rate of drug release. In general, both the molecular weight and the component polymerized affect its LCST [165,169]. It has been reported that high molecular weights enhanced polymer-polymer interactions, which reduced LCST [169]. The LCST of PNIPAM can be modulated by copolymerization with other monomers, which is achieved by adjusting the hydrophilicity. For example, the introduction of hydrophobic monomers may increase the LCST, whereas the introduction of hydrophilic monomers may decrease the LCST. Staubitz et al. [170] found that the LCST of PNIPAAM decreased to about 20 °C by modified with an azobenzene-containing blend illustrated in Fig. 4d.

Fig. 4.

(a) Bonding changes of the amide group of HA-PNIPAAm hydrogen above and below LCSTs[171]. Copyright 2018, John Wiley and Sons. (b) Molecular chain changes in PNIPAAm in response to temperature [164]. Licensed under a Creative Commons CC BY license. (c) Schematic diagram of the synthesis, mechanical activity, and biological applications of SIS-PNIPAm hydrogels [167]. Copyright 2022, Royal Society of Chemistry. (d) DSC plot showing a decrease in LCST of PNIPAAm copolymer after copolymerization with azo [170]. Licensed under a Creative Commons CC BY license. (e) Preparation strategy of DNA-PNIPAAm hydrogel [172]. Copyright 2023, Springer Nature.

PNIPAAm hydrogel has sensitive temperature responsiveness, but its mechanical properties and tunability are limited [173]. To compensate for these shortcomings, many methods were applied. Jiang et al. [172] formed an interpenetrating network structure by combining PNIPAAm with polyacryloyl-modified Y-type DNA, and a crosslinking network was formed between DNA and PNIPAAM via a crosslinking agent (Fig. 4e), which increased the structural stability of the material. The modulus of elasticity (G′) of DNA-PNIPAAm hydrogels is about 25 times higher than that of PNIPAAm hydrogels, and the DNA-PNIPAAm hydrogels have higher elasticity and deformation resistance. In addition, the non-biodegradability of PNIPAAm hydrogels is another limitation for use in biomedical applications [174,175] It could be improved by introducing different biodegradable monomers or natural polymers [176]. Pal et al. [177] utilized the advantages of synthetic and natural biopolymers to synthesize covalently crosslinked hydrogels with stimulating properties based on dextrin (DXT) and PNIPAAm. The hydrogels showed good degradation in lysozyme/phosphate buffered saline (PBS) medium, losing 80 % of their mass in only 21 days.

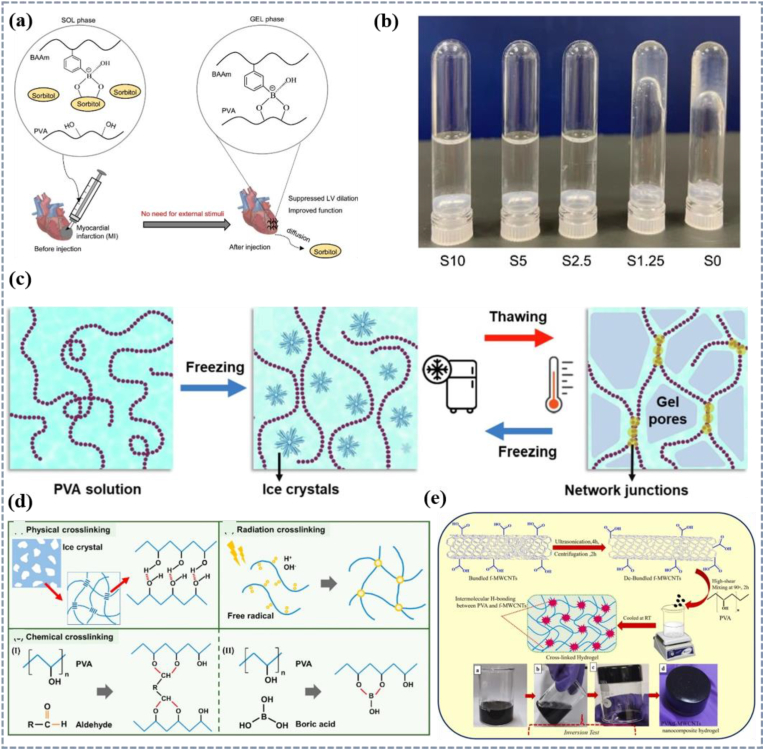

3.1.2. PVA

PVA is a semi-crystalline, water-soluble linear synthetic polymer polymerized from vinyl acetate, with a molecular weight ranging from 20000 to 400000 g/mol depending on the degree of hydrolysis [[142], [143], [144], [178]]. PVA molecules contain a large number of hydroxyl groups, which can form intramolecular and intermolecular hydrogen bonds. Due to these hydrogen bonds, PVA has lower water vapor and gas permeability [[142], [143], [144]]. PVA has good mechanical properties, hydrophilicity, good biocompatibility and biodegradability, and low protein adsorption tendency, so it is often used as a hydrogel in the biomedical field [143,178]. PVA can change shape in response to temperature and water and is therefore often used in drug delivery systems. Its shape memory behavior is mainly dependent on the crystalline behavior of the molecular chains, with the crystalline and cross-linked portions of the molecular chains acting as stationary phases and the amorphous portions of the molecular chains acting as active phases that are capable of moving when the temperature reaches Tg. When PVA is in contact with water molecules, swelling behavior occurs due to hydrogen bonding [179]. Yamaoka [180] studied an injectable composite solution for the treatment of myocardial infarction. This material is composed of poly(3-acrylamidophenylboronic acidco-acrylamide) (BAAm), PVA, and sorbitol (S) (Fig. 5a). The high concentration of sorbitol in the system blocks the cross-linking between BAAm and PVA, keeping it in a solution state (Fig. 5b). After injection into the heart, the sorbitol in the solution can diffuse out spontaneously, resulting in a decrease in the content of the sorbitol and decrease in the viscoelasticity of the system. Under physiological conditions, the groups between BAAm and PVA are cross-linked to achieve gelation.

Fig. 5.

(a) Schematic representation of the composition, delivery, and in situ gelling mechanisms and (b) sol-gel state of PVA injectable materials [180]. Copyright 2024, Elsevier. (c) Preparation of PVA hydrogels by the F-T method [178]. Copyright 2022, Elsevier. (d) Different crosslinking methods of PVA [181]. Licensed under a Creative Commons CC BY license. (e) Schematic diagram of PVA/f-MWCNTs nanocomposite hydrogels prepared by natural cooling at room temperature [182]. Copyright 2024, Elsevier.

The shape memory behavior of PVA can be modulated by cross-linking and crosslinking methods including physical crosslinking (Fig. 5c), chemical crosslinking, and radiation crosslinking and the molecular chain changes are as shown in Fig. 5d, [144]. Vieira et al. [183] prepared PVA hydrogel film by physical crosslinking and chemical crosslinking. It was found that the swelling degree of PVA film prepared by chemical method was lower and it decreased with the increase of crosslinking time. The thermosensitive PNPAAm micro-gel and superparamagnetic iron oxide nanoparticles were confined in the PVA nanofiber membrane. Both crosslinking methods can ensure the thermal and magnetic response properties of the film. Sharma [182] prepared PVA/f-MWCNTs high-strength nanocomposite hydrogels at room temperature by physical crosslinking and natural cooling. PVA/f-MWCNTs nanoparticles can be evenly dispersed in the PVA matrix and the intermolecular hydrogen bonds are formed between the hydroxyl group in the PVA molecule and the carboxyl group in PVA/f-MWCNT to build a hydrogel network (Fig. 5e). The hardness of the composite hydrogel was significantly improved compared with PVA hydrogel and due to the interface interaction and hydrogen bonding, the introduction of f-MWCNTs into PVA matrix can also effectively improve the thermal, mechanical and dielectric properties of the hydrogel.

3.1.3. Polyesters

PLA, and PCL are the typical polyesters for 4D printing biomaterials with excellent biocompatibility and biodegradability, which lays the foundation for its application in biomedical fields [[146], [147], [184], [185], [186], [187]]. They can be completely degraded to carbon dioxide and water in a complex body fluid environment and the degradation rate can be modulated by molecular weight, crystallinity, and degradation conditions [188], ranging from a few months to a few years [146].

Linear PCL does not have a shape memory function, but cross-linked PCL can be used as a shape memory material. The cross-linked structure therein acts as the stationary phase of polycaprolactone, which can produce crystallization with temperature and the molten crystalline phase becomes a reversible phase. However, many of the reported PCL-based shape memory blends have encountered the challenge of inadequate shape recovery, and the stability of shape memory properties remains largely unexplored.

As a semi-crystalline polymer, PLA has a certain shape memory ability, with its crystalline and amorphous regions serving as the stationary phase and reversible phase, respectively [[149], [150], [189]]. Due to the different molecular configurations, including poly D-lactic acid (PDLA), poly L-lactic acid (PLLA), and a randomly arranged structural isomer called poly DL-lactic acid (PDLLA) (Fig. 6a), there may also be some differences in their physical and chemical properties, for example, the regularity of PDLLA molecular chains is poor, so they do not have crystallization ability, while PLLA and PDLA are both semi-crystalline polymers. The melting point of PLA can be controlled by adjusting the ratio of PLLA and PDLA in the material. Through this method, SMPs with practical application potential can also be constructed with higher fineness [190]. Due to the relatively high modulus of glassy and elastic states, PLA has a high shape fixation ratio. However, the inherent brittleness greatly limits the performance of the shape memory characteristics. It is prone to brittle fracture under tensile stress at room temperature, and the deformation and recovery can only occur when the temperature rises to or above Tg (60 °C) which is prone to cause cell damage when used in the human body. In addition, due to the high rigidity of PLA molecular chains, the crystallization rate and crystallinity are low, and the rigidity of the molecular chain and the weak ability of amorphous zone movement lead to a low shape recovery rate.

Fig. 6.

(a) Two configurations of PLA [190]. Licensed under a Creative Commons CC BY license. (b) Preparation process of PCL-PLA nanofiber-based smart nanoporous scaffolds [191]. Copyright 2024, Elsevier. (c) i: Preparation of mCS and mCS/PLA/PCL blends, ii: 4D printing of mCS/PLA/PCL [192]. Licensed under a Creative Commons CC BY license.

Given the flexibility of PCL and the rigidity of PLA, the two are often combined to improve their shape memory capabilities and mechanical properties [185,193,194]. The different phase transition temperatures of PLA and PCL provide a shape memory capability for their composite system [148]. PLA nanofibers between PCL polymer matrices were constructed to introduce intelligent performance and prepared a variable new nanoporous intelligent scaffold (Fig. 6b) [191]. However, some researchers discovered that the composite system still had difficulty in supporting multiple repeated deformations which was due to the weak interfacial force between PCL and PLA and the low internal stress of deformation [195]. So another work introduced chitosan into the PCL/PLA system to improve the compatibility [192]. The modified chitosan was obtained by grafting low molecular weight PLA and PCL onto the side chains of chitosan (Fig. 6c–i). PCL and PLA on the side chains were well compatible with the matrix of the composite system, and the modified chitosan acted as a connecting bridge between amorphous regions of PLA and PCL, which improved the interfacial force of the blends. The compounds did not break during the shape memory process, while the compatibility also improved and a co-continuous structure was formed, which significantly enhanced the shape memory properties of the material (Fig. 6c–ii) [196]. In addition, high-toughness polymers such as PU [197], or inorganic particles such as calcium phosphate, hydroxyapatite (HA), alumina, zirconia, etc [[198], [199], [200], [201]] are usually used to construct PLA-based shape memory systems to improve the mechanical strength and shape recovery ability.

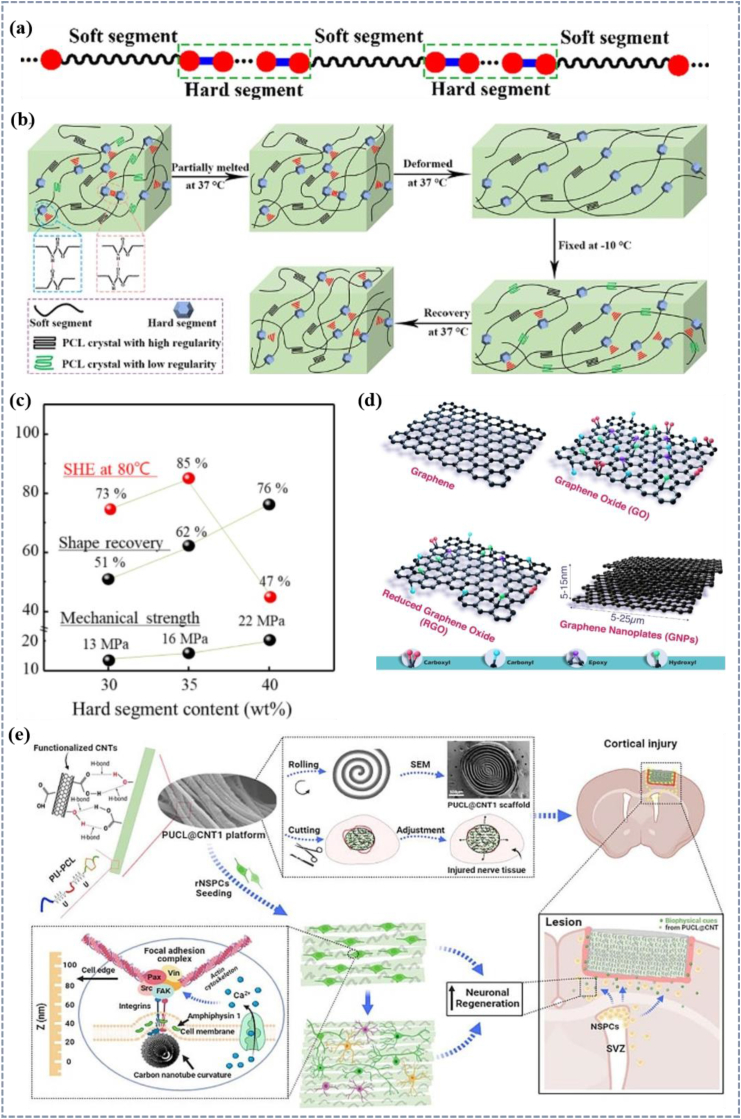

3.1.4. PU

PU is a thermo-responsive synthetic polymer consisting of urethane-linked organic units that have been widely used in biomedical applications because of their excellent physical properties and biostability [195]. PU is composed of two parts, soft and hard segments (Fig. 7a), the soft segments are generally polyether, polyester or polyolefin, etc., and the hard segments consist of isocyanate and chain extender. The structure of PUs with separated soft and hard segments gives them shape memory capability (Fig. 7b), with the hard segments forming a network structure through cross-linking, which serves as a permanent shape for the process of shape memory, and the soft segments acting as molecular switches [202,203]. The selection of the hard and soft segments is critical to the structure and properties of PU materials, and factors such as the ratio and type of the two affect the degree of phase separation and hydrogen bonding [204], leading to differences in shape memory and mechanical properties between different PUs [203]. For example, Zhang et al. found that the addition of rosin chain extenders to PU systems increased the degree of phase separation between the soft and hard segments, and the thermodynamic incompatibility between them became more pronounced [205]. The addition of tetrahydrofuran solvent to PU also modifies the phase separation behavior of the system. The solvent leads to an increase in the fluidity, which makes it easier to form purely soft and hard regions, and with the increase in ordered hydrogen bonding and cross-linking of the hard segments, the size of the phase region increases, the degree of phase separation is increased, and the shape memory capability is enhanced [203]. The final PU properties can be customized based on the properties, structure, and molar mass of the polyols and the diisocyanate involved in the synthesis [206,153].

Fig. 7.

(a) Soft and hard segment structures and (b) shape memory mechanism of PU [207]. Copyright 2022, Elsevier.(c) Relationship between self-healing efficiency, shape recovery, mechanical strength, and hard segment content [154]. Copyright 2019, Springer Nature. (d) Schematic diagram of Graphene, Graphene Oxide, Reduced Graphene Oxide, and Graphene nanoplatelets used as a nanofiller for nanocomposite fabrication [208]. Copyright 2023, John Wiley and Sons. (e) Diagram of preparation, deformation, and the mechanism of promoting neural tissue regeneration of PUCL@CNT [209]. Copyright 2023, Elsevier.

The molecular structure of the soft and hard segments has an impact on the properties of PUs, e.g., the position of the amine groups in the side chains has a significant effect on the properties of PUs. Amino groups in the soft segments enhance the interaction between the hard and soft segments, improve mechanical properties, and reduce surface hydrophobicity, while amino groups in the hard segments disrupt the crystallization of the hard segments, enhance microphase separation, reduce mechanical properties, but increase surface hydrophilicity [210]. Within a certain range, the shape recovery properties of PUs increase as the concentration of hard segments in the PU matrix increases, due to the physical cross-linking between the hard segments that improves the shape recovery and mechanical properties of the PU (Fig. 7c) [154,207]. However, when the content of the hard segments is too high or too low, the shape memory capability decreases [153]. An increase in the length of the soft segments increases the crystallization behavior of the soft segments, which increases the glassy and rubbery modulus. A higher glassy state modulus results in greater shape fixation after deformation, while a higher rubbery state modulus enhances shape recovery after deformation. By adjusting the molecular weight of the soft segments, the recovery temperature of the shape memory behavior can be adjusted to be close to the body temperature, which meets the basic requirements for medical implantation. Karasu et al. prepared PUs using poly(ethylene sebacate) (PES) with different molecular weights and found that the transition temperature of the PUs increased with increasing molecular weight of polyester [211].

Although PU has many advantages and has great potential for application in the field of shape memory materials. However, PU still has some drawbacks, such as poor electrical and thermal conductivity. So in recent years the research on PU mainly focuses on PU composites, expecting to improve the performance by compositing with other materials that are easy to conduct electricity and heat [208,212] including carbon nanotubes, graphene, and so on (Fig. 7d) [208,213]. Li et al. prepared a PU-PCL (PUCL) and CNTs composite scaffolds (PUCL@CNT). CNT-modified materials have good shape memory properties as well as electrical conductivity, and the composites induced a large number of endogenous neural stem cells (NSCs) including neurons near the injury area in a rat corticotomy model, illustrating the potential for the regeneration of neural tissues as shown in Fig. 7e, [209]. Dispersion of conductive materials from the PU matrix is still an important issue, and many approaches including melt blending, situ polymerization, and ultrasonically dispersed solution mixing have been attempted to promote dispersion [214].

3.2. Natural polymers

Natural polymers such as proteins (e.g. collagen, fibronectin), polysaccharides (e.g. chitosan, sodium alginate, hyaluronic acid), etc. are derived from nature and can be obtained from a wide variety of sources such as plants, animals, and microorganisms. Natural polymers have better compatibility with human tissues, reducing the risk of rejection reactions, and can be degraded within the living organisms, and ultimately be absorbed or metabolized by the body without the need for surgical removal. In addition, natural polymers have a structure similar to that of the human ECM, thus providing a suitable microenvironment for cell adhesion, growth, and differentiation. Although most natural polymers do not have the capability of 4D printing by themselves, they can still be used as a class of high-performance matrix materials that can be modified or post-treated to obtain stimulus-responsive capabilities for application in the field of tissue regeneration.

3.2.1. Alginate

Alginate is an anionic natural polysaccharide extracted from brown algae, composed of mannuronic acid (MA) and glucuronic acid (GA) [155]. It has low cytotoxicity and good biocompatibility and can be rapidly biodegraded and cross-linked. Meanwhile, due to its ability to rapidly gel under mild physiological conditions without producing harmful by-products, it is widely used as a bio-printing material [156]. When exposed to divalent cations such as calcium, barium, strontium, etc., the material can chelate with carboxyl groups in the molecular chain, inducing ion crosslinking to form a stable structure shown in Fig. 8a [157]. Different cations exhibit varying affinities for alginate, and the concentration of ions can affect the stability of cross-linking. Research has shown that at low concentrations, Ca2+ binds temporarily to alginate chains, and higher concentrations of Ca2+ promote relatively permanent binding [215]. The properties of alginate can be improved by crosslinking [158], which is achieved by the carboxyl and hydroxyl groups in the molecular chains. By combining functional groups with carboxyl and hydroxyl groups, alginate can be modified to adjust the physical and chemical properties [216]. Cao et al. [157] prepared a 4D printing methacrylate alginate (SA-MA) hydrogel capable of stimulating response. The degree of crosslinking increases when SA-MA hydrogel is immersed in Ca2+ and chitosan solution successively. The double-layer SA-MA hydrogels have different degrees of crosslinking density, resulting in different degrees of shrinkage and self-folding behavior (Fig. 8b). Xu [217] diffused high molecular weight chitosan into polyvinyl alcohol/sodium alginate/chitosan (PSCS) hydrogel, and successfully prepared PSCS double web hydrogel through physical crosslinking. The gel has good PH sensitivity, when the hydrogel is immersed in different PH solutions, the swelling ratio of buffer solution with pH = 2 is lower than that with pH = 12 (Fig. 8c). The reason showing the behavior is that the pKa of SA is 3.2 and in the solution with PH = 2, most COO− groups are converted into -COOH groups, resulting in the increased intermolecular hydrogen bonds, more compact hydrogel structure and low swelling ratio. Based on the different swelling degrees of hydrogels under different PH, a double-layer hydrogel structure was constructed using two hydrogels with large swelling differences, and the double-layer hydrogel can bend spontaneously due to swelling deformation.

Fig. 8.

(a) Deformation mechanism of photocrosslinked methacrylated alginate [157]. (b) Deformation schemes and images of SA-MA bilayer films under the action of Ca2+ solution. The scale bars are 5 mm and 10 mm [157]. Reprinted with permission from [157]. Copyright 2021, American Chemical Society. (c) Deformation of hydrogels in different pH media [217]. Copyright 2024, Elsevier. (d) Intermolecular hydrogen bonds between chitosan and PVA polymeric chains [218]. Licensed under a Creative Commons CC BY license. (e) Schematic diagram of the self-healing mechanism of emulsion gel [219]. Copyright 2024, Elsevier. (f) Adhesion, self-healing properties and (g) self-healing mechanism of CPT hydrogels [220]. Copyright 2024, Elsevier.

3.2.2. Chitosan

Chitosan is obtained by deacetylation of chitin, which is widely present in nature. This natural polymer has unique biological characteristics including antibacterial properties, mucous adhesion, and excellent properties such as compatibility and microbial degradation. Chitosan can be absorbed by the human body system and processed into porous structures that are highly suitable for cell transplantation and tissue regeneration applications. Therefore, it has been widely used in biomedical fields such as wound healing, drug release, and tissue engineering [221]. Pure chitosan-based hydrogel has poor mechanical stability and slow gel speed, so it is often compounded with other materials to improve its performance. For example, when PVA is added to the chitosan matrix, the hydrogen bonds between the hydroxyl group in PVA and the carboxyl group in chitosan help to improve the stability, tensile strength, and toughness of the material (Fig. 8d) [218].In recent years, a series of chitosan derivatives have been developed, including carboxymethyl chitosan (CMC), chitosan methacrylate, ethylene glycol chitosan, maleic anhydride modified chitosan, hydroxybutyl chitosan, etc., which are widely used in drug delivery systems and tissue repair [159]. Chitosan-based materials are commonly used to build self-healing hydrogel systems [[160], [222], [223]], so physical or chemical cross-linking of chitosan is needed to build a dynamic polymer three-dimensional network. The abundant hydroxyl and amine groups in the molecular chains of chitosan provide the structural basis for the realization of the cross-linking structures [161]. A dynamic three-dimensional network structure is constructed through non-covalent interactions, including hydrogen bonds [224], hydrophobic interaction [225], electrostatic interaction [226], etc., and dynamic covalent bonds such as disulfide bonds [227] and imine bonds [228], endowing hydrogels the characteristics with self-healing properties. Zhou et al. [219] cross-linked CMC stabilized lotion with dialdehyde cellulose nanocrystals (DACNC) to prepare self-healing emulsion gel (Fig. 8e). In the absence of any external stimulation, the two independent emulsion gels can be reassembled, which is due to the reversible imine bond between the amino group of CMC and the aldehyde group of DACNC, giving the emulsion gels good self-healing ability [229]. Xiong et al. [220] prepared a series of pH-responsive CPT multifunctional hydrogel dressings by embedding natural plant extract Tannins (TA) as a non-antibiotic crosslinking agent in CMC and TA with different concentrations of TA. The synthesized CPT hydrogel is pH-responsive, which can accelerate dissolution under the pH value of infected wounds, release TA faster, and effectively enhance the antioxidant and antibacterial effects of the hydrogel. CPT hydrogel shows excellent self-healing, adaptive, and adhesive properties (Fig. 8f) due to the hydrogen bonding interaction (Fig. 8g).

4. Applications of 4D polymeric biomaterials in tissue regeneration

The uniqueness of 4D printing biomaterials lies in their ability to accurately simulate complex dynamic processes within living organisms, demonstrating a high degree of intelligent responsiveness and tissue structure matching and providing unprecedented flexibility and controllability for tissue regeneration [230]. This technology solves the difficult problems that traditional methods cannot overcome and brings new hope for the development of tissue regeneration.

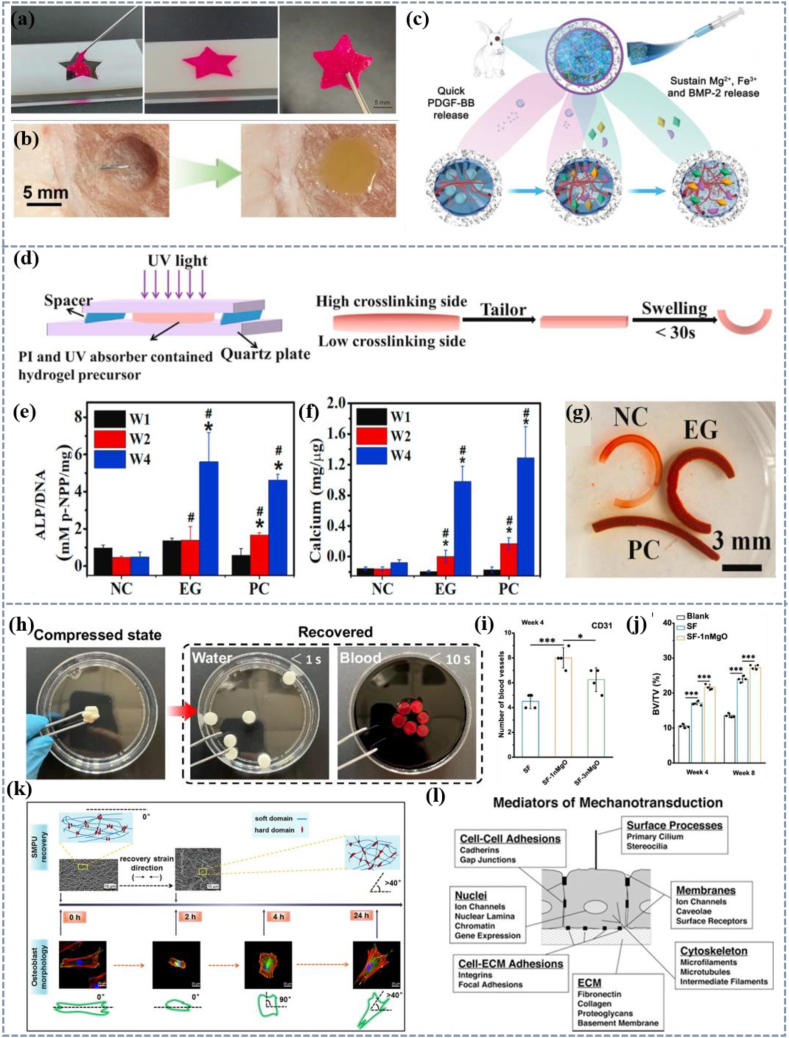

4.1. Bone

Autologous or allogeneic bone transplantation is the traditional way to solve bone defects. However, autologous bone transplantation inevitably leads to damage to the donor site, while allogeneic transplantation carries the risk of immune rejection. 4D printing polymeric materials provide an effective means for bone tissue regeneration therapy with their unique characteristics, especially demonstrating extraordinary potential in handling complex bone repair problems [14]. The materials can customize and design bone tissue scaffolds that highly match the defect site of the patient based on their individualized pathological condition and rehabilitation trajectory [[231], [232], [233]]. The scaffold dynamically adjusts its shape according to the rehabilitation process to support and guide the growth of new bone tissue in the optimal way [234,235], thereby improving the bone tissue repair process and promoting bone regeneration [235].

At present, the commonly used materials for bone tissue regeneration include stimulus-responsive hydrogel [[236], [237], [238], [239], [240]] and shape memory scaffold. Injectable stimulus-responsive hydrogel is an important way to treat bone defects by injecting hydrogel-containing cells into the bone defect site. The hydrogel responds to temperature stimulation to achieve a gel state and dynamically adjusts its shape to fully match the bone defect (Fig. 9a) [237]. Lv et al. added MgFe layered double hydroxides (LDH) nanosheets functionalized by bone morphogenetic protein 2 (BMP-2) to the chitosan/silk fibroin (CS) hydrogel loaded with platelet-derived growth factor bb (PDGF-BB) to construct an intelligent injectable thermal response hydrogel (CSP-LB). The hydrogel solution accurately fits pig tissue defects and quickly solidifies under the condition of a 37 °C water bath (Fig. 9b). Hydrogel realizes the explosive release of PDGF-BB (platelet-derived growth factor BB), the continuous release of BMP-2, bioactive Mg2+and Fe3+ ions (Fig. 9c), with good angiogenesis and osteogenesis performance. Compared with CS hydrogel, its bone volume density increases by 4.5 times and 3.6 times, respectively [241].

Fig. 9.

Applications of 4D printing of polymer biomaterials for bone tissue. (a) The injectable hydrogel is irradiated by blue light to form a stable scaffold [237]. Copyright 2024, Elsevier. (b) Image of injection performance of CS-L hydrogel on pig tissue mode [241]. (c) Biological properties of CSP-LB hydrogel [241]. Copyright 2022, John Wiley and Sons. (d) The diagram of the preparation device and deformation process of crosslinked gradient hydrogel [242]. (e) ALP activity normalized to DNA content [242]. (f) Calcium content normalized to DNA content in the cell-laden hydrogels at varying time points [242]. NC (negative control): cell-laden hydrogels obtained in the presence of a UV absorber and cultured in cell growth medium, EG (experimental group): cell-laden hydrogels obtained in the presence of a UV absorber and cultured in osteogenic medium, PC (positive control): cell-laden hydrogels obtained in the absence of a UV absorber and cultured in osteogenic medium (g) Alizarin red stained scaffolds after 4-week in vitro culture. [242].Licensed under a Creative Commons CC BY license. (h) Photographs of the shape recovery process of silk fibroin/magnesium composite scaffold scaffolds in water and blood [243]. (i) Statistical analysis of stent vessels at 4 weeks after operation [243]. (j) Bone volume changes (BV/BT) in a blank group, fibroin group, and silk fibroin/magnesium group observed at 4 and 8 weeks [243]. Licensed under a Creative Commons CC BY license. (k) The shape restoration process of SMPU affects the morphology of the Osteoblast [244]. Copyright 2019, Elsevier. (l) The mediators of cellular mechanical transduction include ECM, cell-ECM and cell-cell adhesion, membrane components, special surface processes, cytoskeletal filaments, and nuclear structures [245]. Copyright 2006, John Wiley and Sons.

The preparation of hydrogel materials with a cross-linking gradient is a design strategy to realize the deformation function and apply it to bone repair [246]. The mixed solution of polymer, photoinitiator, and UV absorber is spun between two quartz plates. The hydrogel is crosslinked under the irradiation of UV light and the degree of crosslinking of the hydrogel decreases with the increase of the distance from the light source, to obtain the hydrogel with cross-linking gradient and realize the deformation function (Fig. 9d). By adjusting the light irradiation time, intensity, type, and concentration of photoinitiator and polymer system, the gradient of hydrogel can be precisely controlled. Human mesenchymal stem cells (hMSCs) showed strong osteogenic differentiation in gradient hydrogel scaffolds when cultured in an osteoblastic culture medium, indicating the potential for bone tissue regeneration (Fig. 9e–g) [242]. Meanwhile, SMP-based bone repair scaffolds can also effectively cooperate with osteoblasts, promoting cell adhesion and proliferation, and constructing an ideal micro ecosystem for natural regeneration of bone tissue [247]. The stent can be compressed and implanted into the body, fully restoring its original shape upon contact with water or blood (Fig. 9h). Then, the close contact with surrounding tissues promotes the proliferation and adhesion of bone cells, as well as the osteogenic differentiation of bone marrow mesenchymal stem cells in vitro, thereby promoting the growth of vascular and new bone (Fig. 9i and j) [243].

Compared to 3D-printed static scaffolds, the dynamic characteristics of SMP scaffolds also have an impact on tissue regeneration [248]. Luo's team investigated the key role of recovery strain and phase separation nanostructures of shape memory polyurethane (SMPU) in regulating cell morphology and found that the deformation caused by recovery strain in osteoblasts leads the orientation perpendicular to the strain direction. The nanostructures on the surface of the responding SMPUs direct the orientation of the osteoblasts so that they tend to align along the nanostructures (Fig. 9k) [244]. Moreover, the deformation process of the material is accompanied by mechanical forces, which have an influence on cell proliferation, growth, and tissue formation (Fig. 9l) [249,245]. Therefore, the mechanism of 4D printing materials in promoting bone tissue is complex, with factors such as the microenvironment and dynamic properties of the materials acting synergistically to promote bone tissue regeneration through multiple channels.

4.2. Cartilage

Cartilage, as a crucial bridge connecting different bones, plays an indispensable role in maintaining joint stability and reducing friction [250]. It usually cannot return to the original state through self-repair when damaged but will be replaced by scar tissue of which the function and structure are not as good as the original cartilage, greatly affecting the load-bearing capacity of the joint [14].

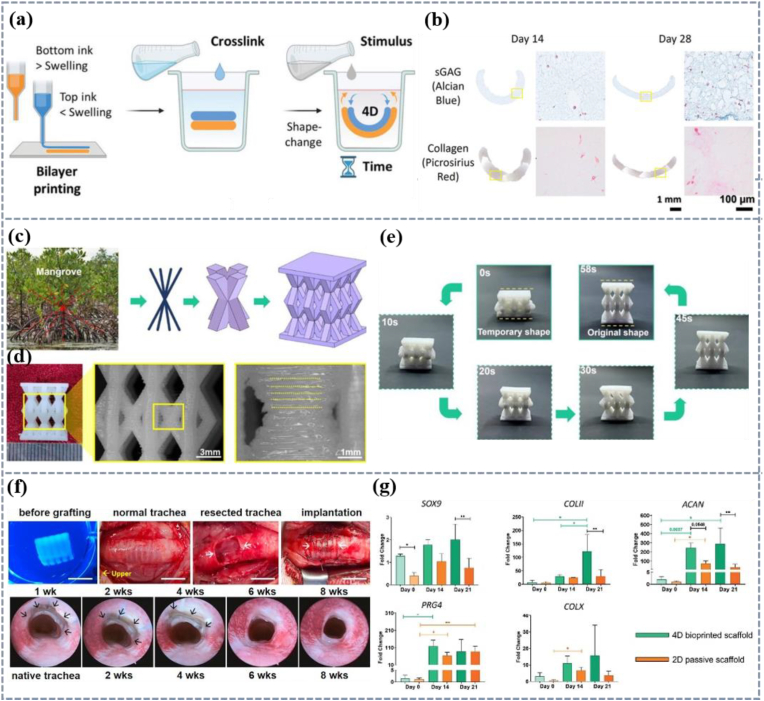

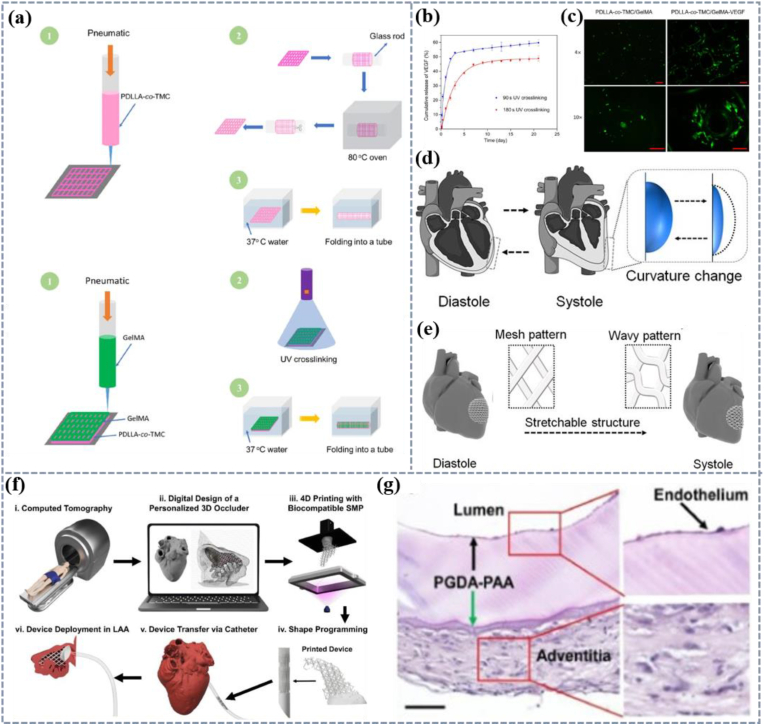

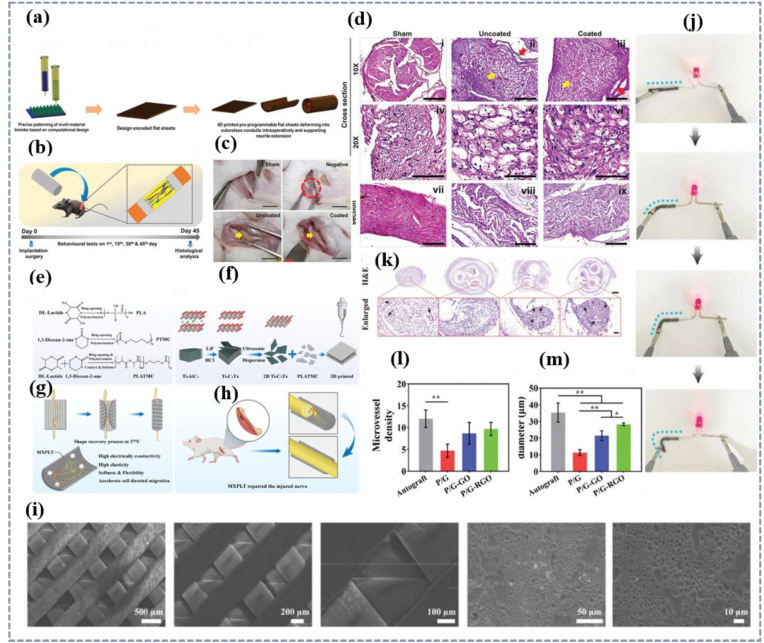

Natural polymers are widely used as cartilage tissue repair materials due to their excellent biocompatibility and biodegradability [251,252]. Hyaluronic acid with a high swelling capacity and alginate with a low swelling capacity were used to prepare double-layer intelligent structure hydrogel. Due to the different swelling degrees, the material has the characteristic of self-bending (Fig. 10a). After culturing the scaffold loaded with cells in a cartilage culture medium for 28 days, the formation of cartilage-like matrix can be observed (Fig. 10b) [253]. However, natural polymers usually have a certain disadvantage in strength, and synthetic polymers can compensate for this disadvantage and provide better mechanical support for materials. A shape memory composite material for cartilage defects was prepared by adding nano HA to the PU matrix. Due to the hydrogen bonding between HA and PU, good mechanical properties and biocompatibility are obtained. Based on the structural characteristics of mangrove forests, a biomimetic 4D printing cartilage scaffold has been designed (Fig. 10c and d), which can recover from a temporary shape to a permanent shape within 60 s at the temperature close to human physiological environment (Fig. 10e). The strength of the composite material increased by 200 %, while the shape recovery ratio and fixation ratio remained above 90 % with application prospects in minimally invasive and cartilage defects [254]. Trachea, as a key cartilage tube connecting the throat and lungs, has a unique structure consisting of 16–20 C-shaped transparent cartilage rings tightly connected by tracheal muscles, ensuring smooth breathing [230]. Kim and his colleagues prepared Sil-MA composite double-layer hydrogel. The TBSCs of the respiratory mucosa and chondrocytes of the tracheal cartilage were loaded on different layers and placed in a culture solution, and the water-induced material curled into a shape similar to the tracheal. The structure loaded with cells was implanted into the injured trachea of rabbits (Fig. 10f). After 8 weeks, it was found that the 4D printing trachea naturally fused with the host trachea to form epithelium and cartilage indicating the potential of this material in the field of tracheal tissue regeneration therapy (Fig. 10f) [60]. Given the complexity of the trachea structure, 4D printing of the trachea can not only accurately reproduce its unique C-ring structure, but also promote the proliferation and differentiation of cells through its dynamic stimulation. Chiesa et al. compared the ability of ear cartilage progenitor cells to differentiate into mature chondrocytes on 4D printing and 2D static scaffolds (Fig. 10g) and found that the cells on the 4D scaffold formed mature cartilage after 21 days of culture which means that the 4D bio-printing self-folding scaffold can promote cartilage formation, indicating that the self-folding scaffold may mimic the role of smooth muscle cell progenitor cells to regulate the shape of tracheal and promote the formation of cartilage [255].

Fig. 10.