Abstract

The continuous evolution of textile technologies has led to innovative functional coatings that enhance protective textiles by integrating flame retardancy, antimicrobial efficacy, and self-cleaning properties. These multifunctional coatings address the growing demand for high-performance materials in healthcare, military, and industrial applications. This study reviews advancements in coating techniques, including dip-coating, spray-coating, sol–gel processes, and layer-by-layer assembly, highlighting their effectiveness in imparting durability, thermal stability, and biological activity to textile substrates. The incorporation of bioactive materials such as chitosan, silver nanoparticles, and plant-derived antimicrobials has demonstrated enhanced pathogen resistance and prolonged fabric functionality. Furthermore, recent developments in phosphorus-based flame retardants and photocatalytic self-cleaning agents, including titanium dioxide and silica nanoparticles, have contributed to the sustainability of functional textiles by reducing environmental impact. Challenges remain in achieving compatibility among diverse functional components while maintaining mechanical integrity and user comfort. Scalability and cost-efficiency also present barriers to commercialization, necessitating cross-disciplinary collaboration among material scientists, engineers, and regulatory experts. Future research should focus on biodegradable alternatives, smart-responsive coatings, and advanced nanomaterial integration to enhance the longevity and eco-friendliness of protective textiles. As industry standards shift towards sustainability, functional coatings are poised to redefine textile applications, offering tailored solutions that balance safety, performance, and environmental responsibility. This review underscores the transformative potential of multifunctional textile coatings and their role in advancing next-generation protective fabrics.

A new generation of functional coatings offers flame retardancy, antimicrobial efficacy, and self-cleaning properties, making them valuable additions to healthcare, the military, and industrial applications.

1. Introduction

Innovative functional coatings that improve flame retardancy, antibacterial qualities, and self-cleaning capabilities are revolutionizing protective textiles. By enhancing performance, safety, and durability, these developments satisfy the rising need for high-efficiency materials. This review focuses on the latest developments and new directions in functional coatings.

Natural fibers such as cotton, silk, and wool, as well as synthetic fibers like regenerated cellulose, nylon, and polyester, each have their own set of qualities. These materials are chemically and physically modified to improve functions such as antibacterial, water-repellent, and flame-retardant qualities for advanced textile applications.1 Synthetic and natural fibers are utilized in coatings and composites, influencing the materials' performance, strength, and flexibility. Increasingly, bio-based elements are being included into textile reinforcements and coatings to improve functionality and sustainability.2 Wool is a natural protein-based textile substrate that is fire retardant, stain resistant, and warm, making it suitable for clothing and flooring. Various treatments, including enzymatic, polymeric coatings, and plasma treatments, are used to improve shrink resistance and durability while being sustainable.3 Cotton, polyethylene terephthalate (PET), and nonwoven textile substrates are frequently utilized in antimicrobial applications; therefore, they need to be modified to improve their durability, antibacterial qualities, and filtering effectiveness. For technological and medical applications, a variety of surface functionalization processes are used to enhance their performance and protective qualities.4 Polyethylene terephthalate (PET) is a popular synthetic textile substrate noted for its durability but lacks perspiration absorption and antistatic qualities. Modifications such as saponification and biopolymer treatments improve its hydrophilicity, UV protection, and comfort while maintaining mechanical integrity.5

Due to the increasing exposure to infectious diseases by healthcare workers during the COVID-19 pandemic, there has been a major increase in demand for protective textiles in the healthcare industry. A vital line of defense against infections is personal protective equipment (PPE), which includes gloves, masks, and gowns. The circumstance calls for advancements in material science and production techniques while highlighting the critical role protective apparel plays in preserving the health of healthcare personnel.6 The need for high-performance protective fabrics that successfully stop liquid and microbiological transmission is highlighted by the rise in newly developing infectious illnesses.7 To defend soldiers from ballistic, biological, and chemical threats, the military employs cutting-edge technologies. These materials protect industrial workers from dangerous conditions like flames and toxins. There will likely be a greater need for protective fabrics as people become more conscious of safety and protection, which will encourage innovation in this crucial area.8 Protective fabrics are crucial for industries, the military, and healthcare because they keep people safe and comfortable in dangerous settings. They ensure sterile conditions in healthcare by guarding against chemicals and biological pollutants. To prevent thermo-physiological strain, they assist employees in avoiding chemical and physical risks while preserving their comfort in industrial environments. Because of stricter safety regulations and increased awareness of the health hazards associated with different jobs, there is a growing need for sophisticated protective fabrics.9 In the healthcare, military, and industrial sectors—where usefulness and safety are critical—protective fabrics are indispensable. They offer medical staff barriers against infections in the healthcare industry. These materials are used by the military to make clothing and equipment that provide chemical and ballistic protection. Wearing protective gear in industrial environments ensures that safety rules are followed while protecting workers from chemicals and mechanical risks. The development of protective textiles has been fueled by growing workplace safety awareness, leading to developments that blend utility, comfort, and durability to satisfy the various demands of different industries.10

Specialized finishes called functional coatings are applied to textiles to provide qualities that improve their functionality and performance. These coatings improve textile items' comfort, safety, and durability, among other things.11 Coatings change the fabric's surface properties without affecting its inherent attributes. Their goal is to turn traditional fabrics into materials with multiple uses that can react to environmental cues or offer defensive advantages. For example, functional coatings can make textiles fire-resistant, water-repellent, or antibacterial, expanding their utility in everyday, medicinal, and technological applications. Click or tap here to enter text. When altering important textile characteristics to satisfy performance standards, functional coatings are essential. For example, hydrophobic treatments that stop water absorption give fabrics water repellency, which makes them appropriate for outdoor and weather-resistant uses. Another crucial change is fire resistance, which involves applying coatings to textiles to lessen their flammability and boost safety in areas where fire threats are a problem. Particularly in medical and athletic clothing, antimicrobial coatings prevent the growth of bacteria and fungi on textiles, enhancing longevity and hygiene. UV protection treatments protect textiles from damaging UV radiation, protecting the material's integrity and the wearer. Furthermore, sophisticated coatings that make it simple for dirt and stains to be removed can be used to add self-cleaning properties, which lowers maintenance requirements and improves the usefulness of the fabrics.11 By altering these characteristics, functional coatings increase the usefulness and durability of textiles while enabling them to satisfy the requirements of contemporary applications in various industries, such as clothing, outdoor equipment, and medical textiles.12 Furthermore, antimicrobial coatings promote hygiene in sporting and medical fabrics by preventing the growth of bacteria and fungi. UV protection coatings prolong the life of textiles exposed to sunshine by shielding the fabric from damaging UV rays. To preserve the beauty of fabric and lower maintenance requirements, self-cleaning properties are provided through coatings that help dirt and stains break down when exposed to light or moisture. Textiles can function in various settings through these changes, extending their useful life.13

A methodical criterion for including research on functional coatings for protective textiles was developed during the review process. Scientific rigor, publication recentness (within the previous five years),14 and relevance to the main functionalities of interest—flame retardancy, antimicrobial qualities, and self-cleaning mechanisms—were the criteria used to choose the examined studies. To reduce any bias and improve the dependability of the insights offered in this review, this methodology was used. The objectives of this review are multifaceted and aim to provide a comprehensive understanding of the advancements in functional coatings for protective textiles. First, it seeks to assess new developments within the field, highlighting recent innovations that enhance textile performance. Additionally, the review will determine the main obstacles that hinder further progress, such as technical challenges or regulatory barriers. Another key objective is to evaluate real-world applications of these coatings across various sectors, showcasing their practical utility and effectiveness in everyday scenarios. The review will also examine coating methods in applying these functionalities to textiles, providing insights into their efficacy and scalability. Furthermore, an essential aspect of this investigation involves exploring how multifunctional coatings can be effectively integrated to achieve synergistic benefits without compromising performance. As sustainability becomes increasingly important, considering safety and environmental considerations is paramount; thus, this review will delve into eco-friendly practices associated with functional coatings. Lastly, the review aims to offer suggestions for additional research avenues that could further contribute to advancing knowledge and innovation in this dynamic area. Through these objectives, the review aspires to illuminate current trends and foster future growth within the protective textile industry.

In this study, functional coatings designed specifically for protective fabrics are thoroughly examined. Included in the scope is an overview of the various methods for applying functional coatings, including dip-coating, spray-coating, plasma treatment, sol–gel processes, and layer-by-layer assembly. Functional coatings offers a comprehensive analysis of flame-retardant, antimicrobial, and self-cleaning coatings, covering their fundamental components, performance evaluation, and recent advancements. Investigate the potential and challenges of combining several uses into a single coating system, analyze the effects of these coatings on people's health and the environment, follow rules, and search for sustainable alternatives.

2. Coating techniques for functional textiles

2.1. Overview of coating techniques

Functional coatings are essential for improving textile performance by providing attributes like flame retardancy, antimicrobial properties, and self-cleaning features. A range of coating techniques has been established to attain these functionalities, each possessing distinct characteristics, benefits, and constraints.

The primer layer functions as a binder, ensuring a strong bond between the textile substrate and the polymer coating. It promotes consistent pigment distribution, increases durability, and preserves oil and water repellent qualities. An excellent primer maintains coating integrity in functional textiles using the squeegee process, ensuring long-term stability.15 Furthermore, the primer improves adhesion efficiency, allowing the coating to adhere firmly to the textile substrate while reducing cracking and peeling. It also serves as a barrier layer, increasing the bonding strength between the textile and the polymer coating, resulting in uniform coverage and long-lasting durability.16 The primer layer also acts as a binding agent between the textile or polymer substrate for the flame-retardant coating, ensuring good adhesion and durability. Primers improve coating uniformity, stability, and fire-resistant performance in surface finishing procedures such as layer-by-layer assembly, dip coating, and spray coating while preserving the material's fundamental qualities.17 Additionally, primers improve adhesion strength and coating penetration for better performance by optimizing the substrate-coating interaction. Additionally, they promote layer cohesiveness, which lowers the possibility of peeling or cracking and guarantees the flame-retardant coating's long-term stability and efficacy.18

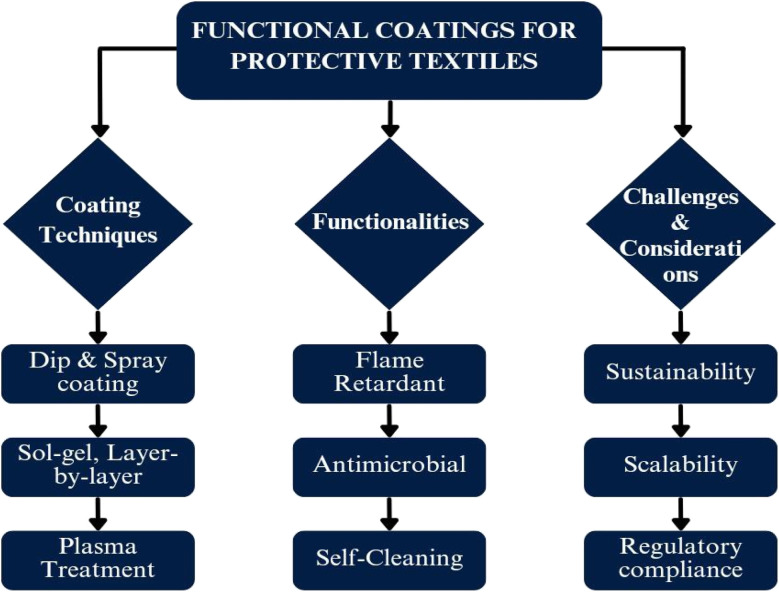

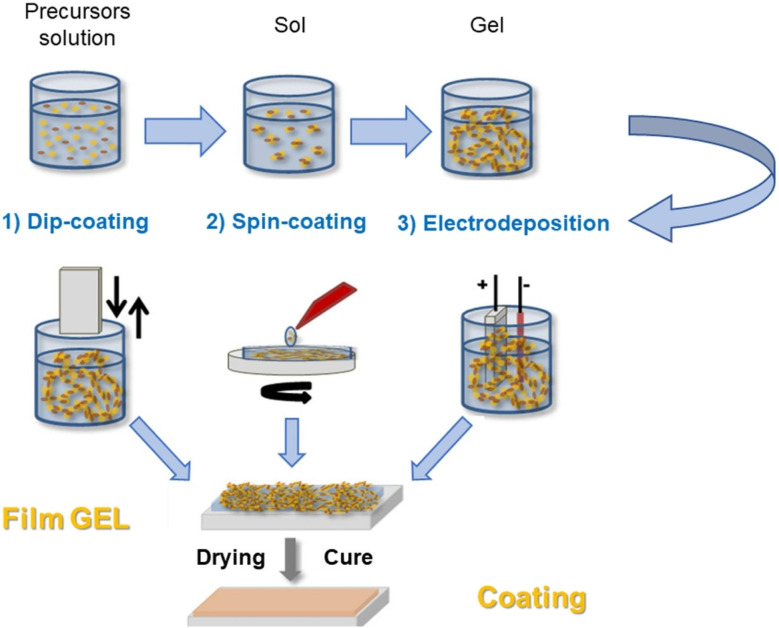

Fig. 1 depicts various coating techniques that can be classified according to their application methods and coating characteristics. Common techniques encompass dip-coating, spray-coating, plasma treatment, sol–gel processes, and layer-by-layer assembly.

Fig. 1. Functional coatings for protective textiles.

To ensure uniform coating deposition and enhanced performance in functional applications, surface modification is required to change the textiles' surface energy, roughness, and chemical reactivity. Textile surfaces can be made more useful without changing their basic characteristics by using surface treatment and modification processes as sol–gel processing, electrospinning, and plasma treatment. Water repellency, flame retardancy, and antibacterial performance are all improved by these techniques, guaranteeing sophisticated multipurpose textiles with increased sustainability and longevity.19 Surface modification and treatment methods based on plasma improve textile qualities by changing the chemistry of the surface without changing the properties of the bulk material. Advanced textile applications like antimicrobial, water-repellent, and dyeable materials can benefit from these treatments because they increase adhesion, wettability, and functional performance.20 Graphene oxide (GO) and reduced graphene oxide (RGO) surface modification improves the electrical conductivity, water resistance, and UV protection of silk textiles. By creating a thin, continuous film through layer-by-layer deposition, surface qualities are enhanced, and durability is preserved even after several washing cycles.21

Chemical techniques like grafting, enzymatic modification, and nano-treatments and sophisticated physical procedures like plasma, UV, and ozone treatment are the most current advancements in surface therapy and modification. In addition to providing functional coatings and increased fiber strength for high-performance textile applications, these innovative techniques improve the wettability, shrink resistance, and bacterial resistance of fibers.22

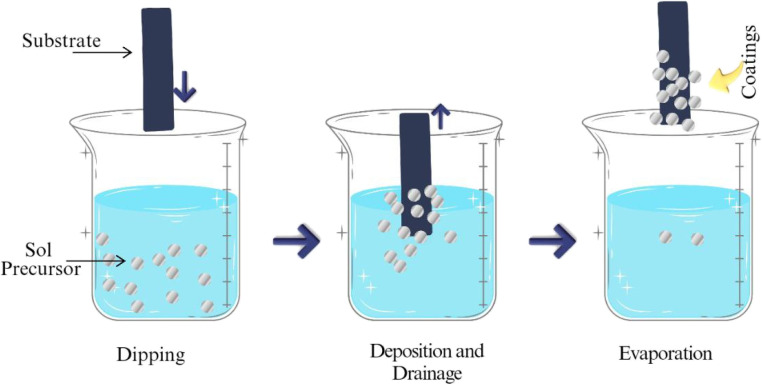

2.2. Dip-coating

The process of dip-coating entails submerging the textile substrate in a solution that holds the intended coating material. Upon the withdrawal of the textile, the liquid coating bonds to the surface, resulting in a consistent layer.23,24Fig. 2 depicts the dip-coating process, showcasing the immersion of a substrate in a coating solution followed by its withdrawal. The quality of the coating is influenced by several parameters, as extended immersion can result in thicker coatings.25 Higher temperatures may enhance the interaction between the coating material and textile fibers. Increased concentrations can produce thicker coating layers; however, they might result in inconsistent application. It presents advantages and disadvantages. Effortless configuration, economical, and ideal for extensive manufacturing. Limited to thin coatings, which presents challenges in achieving uniform thickness for complex geometries.26

Fig. 2. Dip-coating mechanism.

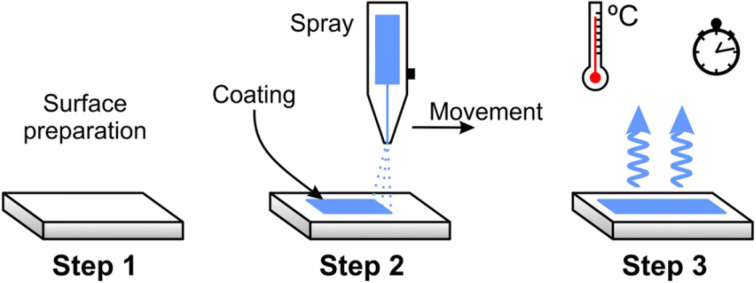

2.3. Spray-coating

Spray-coating involves atomizing the coating material and applying it to the textile surface using a spray gun. This method is compatible with various materials and allows for adjustable application rates.27Fig. 3 shows a spray used to apply a coating to a textile surface. There are many application considerations, including adjusting the distance from the substrate or the spray pressure can control coating thickness; achieving a uniform coating can be challenging, especially on textured fabrics, and uneven surfaces may lead to varied coating properties.29

Fig. 3. Spray-coating setup. Reproduced with permission from ref. 28 Copyright 2020, Springer-Verlag GmbH Germany, part of Springer Nature.

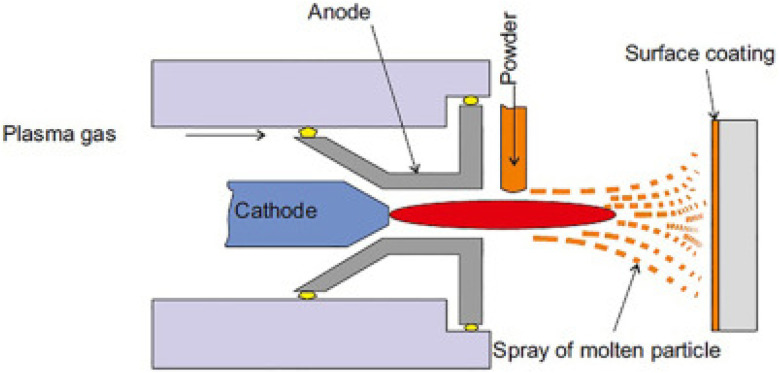

2.4. Plasma treatment

Plasma treatment modifies the surface chemistry of textiles, enhancing adhesion for subsequent coating applications. This technique involves ionizing gas to create plasma, which interacts with the textile surface.30Fig. 4 represents a plasma chamber showing the transition of gas to plasma and its interaction with the textile surface. Usually, plasma has been used to enhance the effectiveness of antimicrobial agents, improve the bonding and performance of flame-retardant coatings, and so on.32

Fig. 4. Plasma treatment mechanism. Reproduced with permission from ref. 31 Copyright 2021, Elsevier Ltd.

2.5. Sol–gel process

The sol–gel process involves the transition of a solution (sol) into a solid (gel) network. This method can create durable, multifunctional coatings on textiles through controlled hydrolysis and condensation reactions33,34Fig. 5 illustrates the sol–gel transition from solution to gel and then to a solid coating on textiles. It produces highly durable coatings with multi-functionality (e.g., hydrophobicity, flame retardancy). However, the process requires many stages to complete individually and takes a long time as well, so the cost and complexity of achieving uniform coatings on large-scale textiles make this process difficult to consider viable.36,37

Fig. 5. Sol–Gel process overview. Reproduced with permission from ref. 35 Copyright 2022, Elsevier Ltd.

2.6. Layer-by-layer assembly

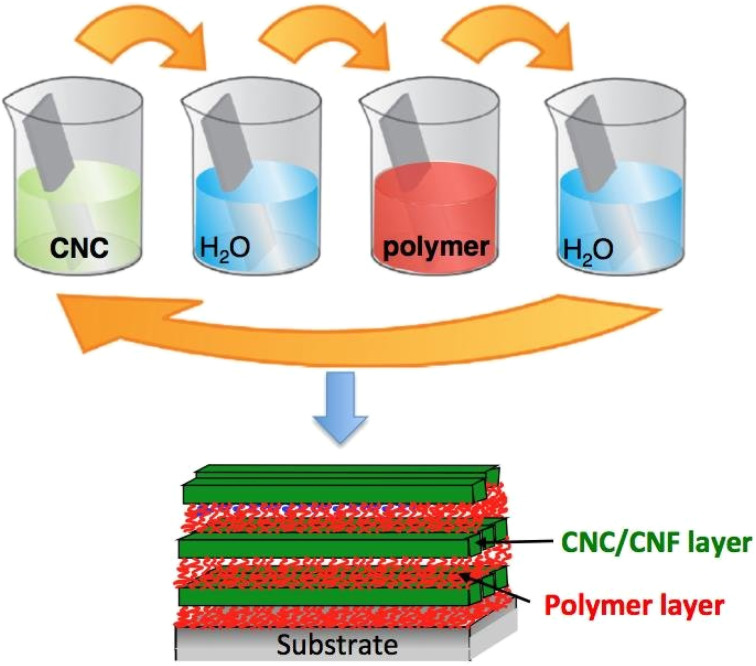

The layer-by-layer assembly technique involves sequentially depositing alternating layers of different materials onto the textile surface, allowing for customizable properties and thicknesses.38Fig. 6 shows the sequential application of layers onto a textile substrate, highlighting the control over thickness and functionality. Allows for precise control over the functionality and thickness of coatings; potential for creating highly customized textiles. While complexity in scaling production and ensuring uniformity over large surfaces.38,40

Fig. 6. Layer-by-Layer assembly. Reproduced with permission from ref. 39 Copyright 2018, De Gruyter.

3. Flame retardant coatings

3.1. Mechanisms of flame retardancy

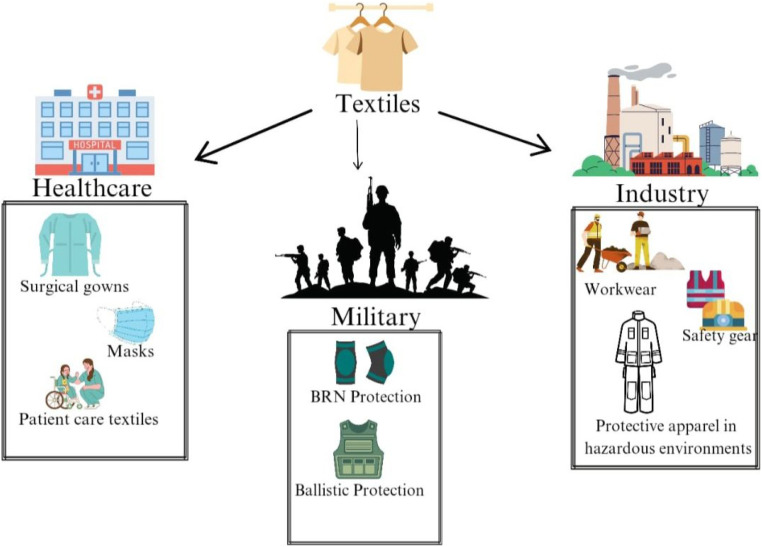

Fig. 7 shows the significant role of textiles in healthcare, the military, and industry by adjusting to requirements for safety and functionality. Textiles in healthcare are used in surgical gowns, masks, and patient care fabrics, promoting hygiene, infection prevention, and comfort. Specialized textiles for the military offer protection via equipment such as bulletproof vests for ballistic safety and materials engineered to defend against biological and radioactive hazards. In industrial environments, textiles are crucial for worker safety, providing robust workwear, helmets, reflective vests, and protective suits for hazardous conditions. This underscores that textiles are not merely fabrics; they are essential for ensuring safety and fulfilling the requirements of many vocations.

Fig. 7. Various uses of textiles in the protective sector.

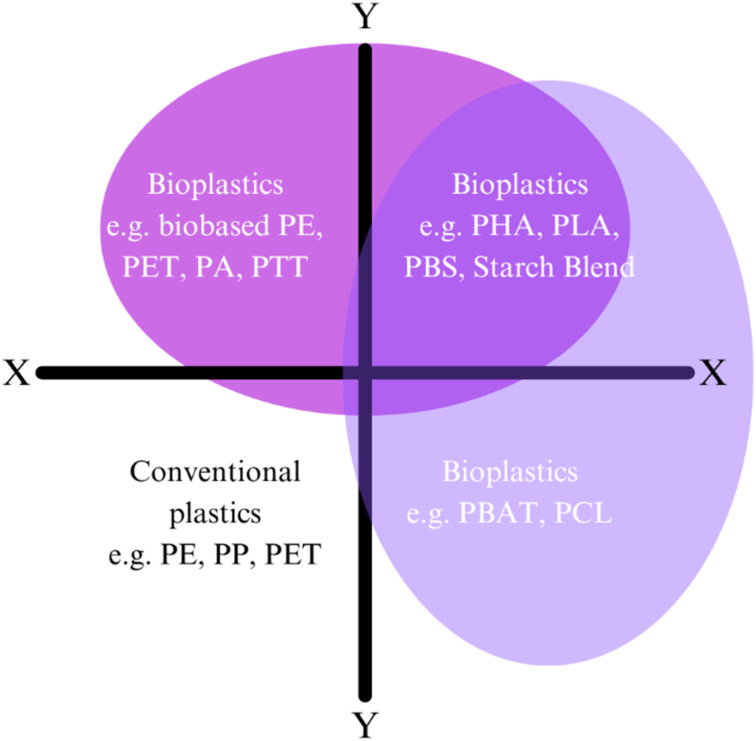

Flame retardants are chemical agents formulated to diminish the flammability of materials and impede the propagation of fire. They function by disrupting the combustion process, either by postponing ignition, reducing the rate of heat release, or inhibiting the generation of flammable gases. These effects are accomplished via chemical processes that interfere with one or more components of the fire triangle: heat, fuel, and oxygen. Flame retardants significantly enhance fire safety in several industries by modifying thermal deterioration or creating protective barriers. Two major classes of flame retardants are based on halogen or phosphorus. Bromine compounds are usually the most effective among the halogen-containing compounds. The flame-retardant efficacy of halogen compounds is often significantly enhanced when used with antimony compounds, typically Sb2O3. Phosphorus-based flame retardants are of at least similar significance. Proposals for various materials and end-use applications have been made for members of nearly all classes of organophosphorus compounds. Inorganic phosphorus flame retardants form ammonium phosphates and elemental red phosphorus. The flame-retardant properties of elemental phosphorus may seem unexpected, as its significantly negative oxidation enthalpy underpins the chemiluminescence of the white phosphorus allotrope, which ultimately inspired the term “phosphorus”.41 Halogenated flame retardants, previously used extensively, have faced heightened scrutiny, leading to intensified research on halogen-free and phosphorus-based flame retardants specifically. This advancement is additionally ascribed to laws and significant changes in market expectations, as greater emphasis has been placed on developing more sustainable flame retardants.42 Phosphorus-based flame retardants have appeared as a significant alternative to halogenated variants. Phosphorus is essential for halogen-free flame-retardancy due to its chemical diversity, several flame-retardant processes, and great efficacy at low concentrations. Phosphorus chemistry is among the oldest branches of chemistry, encompassing the ongoing advancement of novel techniques to enhance the safety and sustainability of chemical processes. Phosphorus-based flame retardants show versatility due to their structural variability, which ranges from inorganic to organic forms, the differing phosphorus content within these molecules, and the presence of phosphorus in various oxidation states, from 0 to +5, leading to distinct flame-retardant mechanisms in both gas and condensed phases. This architectural change makes phosphorus distinctive for the construction of flame retardants with customized property profiles, such as density or glass transition temperatures (Tg), by altering the binding pattern (e.g., from alkyl to phenyl groups).43

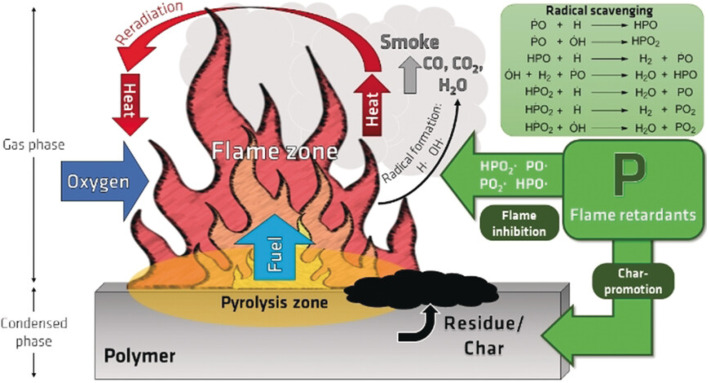

Flame retardants impede combustion via dual-phase mechanisms. In the gaseous state (see Fig. 8), they emit active phosphorus-containing species, which function as radical scavengers, neutralizing highly reactive radicals such as H˙ and OH˙ in the combustion zone. This interrupts the chain processes essential for supporting combustion. Concurrently, in the condensed phase, flame retardants help the development of a protective char layer on the polymer surface. This character functions as a physical barrier, diminishing the emission of combustible gases (from pyrolysis) and insulating the substrate from heat. Flame retardants efficiently decelerate or inhibit flame propagation by diminishing heat feedback, restricting oxygen availability, and curtailing fuel supply, resulting in the production of less flammable gases (e.g., CO, CO2, and H2O) and smoke.44

Fig. 8. Flaming combustion of polymeric material and the role of phosphorus-based flame retardants. Published under CC-BY-NC License43 Copyright 2018, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

3.2. Types of flame-retardant materials

Inorganic additives, such as aluminum or magnesium hydroxyl, serve as the primary flame-retardant part in the coating system while also functioning as synergistic co-additives that enhance flame-retardant efficacy. Nonetheless, inorganic fillers often need elevated loadings, which may negatively affect the physical qualities of the coatings. Furthermore, such additives may show incompatibility with the binder system (e.g., UV curable coating), resulting in blooming and other analogous adverse effects. The inorganic metal compounds mostly consisted of titanium, zirconium, and aluminum, which were integrated into the cotton using the sol–gel process. Adding metal compounds enhanced the thermal characteristics of coatings, except the aluminum compound. In comparison to pure cotton, all sol–gel coated fabrics showed an increase in water content of at least 24% upon curing. In the vertical flame tests, the burning rates fell by about 50%, while the char residues rose by around 100–200%. Metal alkoxide coating techniques are regarded as effective in providing fabrics with enhanced flame retardancy. A formulation for a flame-retardant coating consisting of a cross-linked thermosetting polymer based on polyurethane and magnesium hydroxide as a metal hydroxide. This invention delineates the formulation of a coating precursor and a method for applying a flame-retardant layer to a plastic composite plank. The metal hydroxide content of coating matrix (approximately 30%) is said to impart self-extinguishing properties to the substrate.45 The layer-by-layer assembly of nanoparticle-based coatings concentrated on the deposition of hybrid organic–inorganic structures composed of anionic clay (montmorillonite or LAPONITE®) combined with a cationic polymer (branched polyethyleneimine). The findings, derived from cotton as a substrate, showed enhanced thermal stability and superior flame-retardant characteristics. In pursuit of this research direction, the coating structure has been changed by cutting the organic components to ease the application of a wholly inorganic coating. From a layer-by-layer perspective, the deposition of all-nanoparticle coatings introduces added constraints, rendering it more challenging compared to polyelectrolyte/nanoparticle alternatives. Nanoparticle coatings, consisting of alumina-coated silica (10 nm) and silica nanoparticles (10 or 40 nm), show notable flame-retardant effects on cotton and polyester (PET) materials. These coatings significantly mitigated the melt-dripping phenomenon in PET and prolonged the ignition time during flammability assessments. Excessive stacking, however, reduced the resilience of the covering, hence diminishing overall performance. Horizontal spray deposition appeared as the most effective approach for optimizing the application, guaranteeing uniform coating, and improving thermal barrier qualities during combustion. Furthermore, 50 nm alumina nanoparticles, characterized by their amphoteric properties and pH-adjusted surface charge, were employed to develop multifunctional coatings on cotton. These coatings not only augmented flame retardancy but also bolstered tensile strength and UV resistance, underscoring their multifaceted applicability.46 Modified chitosan-based flame retardants offer great potential due to their sustainability, biodegradability, and strong charring properties. Researchers developed two novel bio-based flame retardants by modifying chitosan through phosphorylation and phosphorization reactions. These flame retardants significantly improved the fire resistance of polylactic acid composites. With just 3% of these additives, the materials achieved higher oxygen index values (29% and 27%) and a V-0 rating in vertical combustion tests, demonstrating excellent flame retardancy. However, increasing one type of flame retardant reduced the material's strength. In contrast, the second type maintained better mechanical performance due to improved compatibility with the polymer matrix, balancing fire resistance and structural integrity.47

Epoxy resin (EP) is extensively used yet constrained by its flammability, causing the development of environmentally sustainable flame retardants. Chitosan, a prevalent bio-based substance, often employs solvent-intensive, low-yield synthesis techniques that undermine sustainability goals. This work introduces a solvent-free, environmentally friendly method for manufacturing chitosan-based ammonium phytate (PUCS) as a flame retardant for EP. The use of 7.5 wt% PUCS elevated the limiting oxygen index from 22.2% to 32.2% and enhanced the vertical burning rating. Cone calorimeter experiments proven diminished heat release rates, showing superior flame retardancy. The mechanical properties of EP/PUCS composites remained right for engineering applications, providing a sustainable and efficient possibility for flame-retardant EP.48

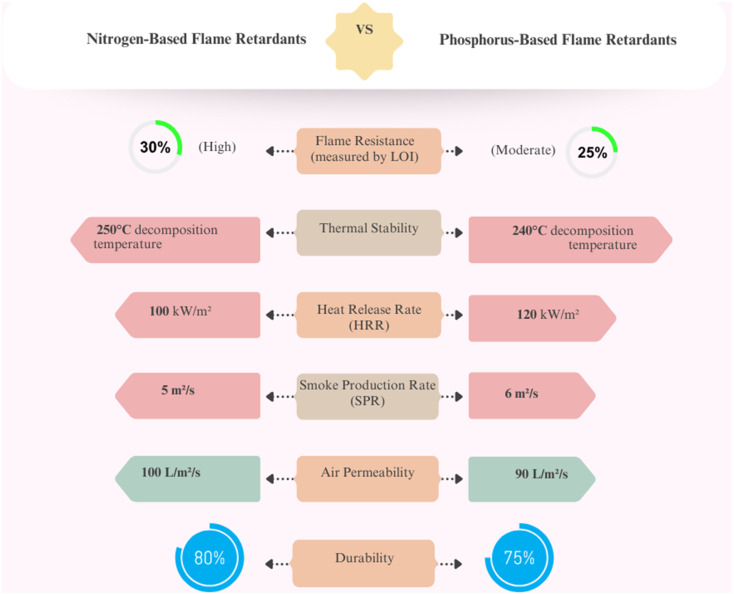

3.3. Performance evaluation

One often-used method to evaluate flammability of fabric numerically is the limiting oxygen index (LOI). It provides a straightforward method to assess the efficiency of flame-retardant treatments over a spectrum of chemical uses since it gauges the lowest concentration of oxygen needed to support combustion. Many traditional flame-retardant treatments for cellulosic fabrics show a linear relationship between LOI values and phosphorus content when nitrogen and phosphorus ratios are kept constant. Tris (aziridinyl) phosphine oxide (APO) deviates from this pattern, however, suggesting special characteristics. Investigating the contribution of nitrogen to improving flame-retardant performance benefits, especially from this method. By exact measurements, one may quantify and investigate the synergistic interplay between nitrogen and phosphorus. Extensive investigations of two chemical systems showed that LOI values may be said as straightforward functions of their nitrogen and phosphorus concentrations. Fascinatingly, the combined effect of nitrogen and phosphorus did not peak at a given ratio, suggesting a more complicated link between the two elements. In vertical flame testing for several materials, an LOI of about 0.26 has been linked to a 5 inch char length; exceptions, including sateen fabric, were noted. Even more than fabric weight, air permeability was found to be a major determinant of the chemical requirements for obtaining efficient flame retardancy. This emphasizes how crucial fabric structure is to decide how effective flame-retardant treatments are49 the phenomenon of flame extinction is examined by the LOI test, a prevalent technique in the industry for assessing flame retardancy. The LOI quantifies the minimal oxygen concentration necessary to keep combustion, providing a dependable metric for evaluating a material's resistance to burning. The LOI enables the determination of essential features, including the minimum mass release rate required to extinguish flames and its variation with oxygen levels.50 Extinction properties are defined by computing parameters, such as activation energy and reaction rates, based on a simplified single-step chemical reaction during burning. The LOI has been proven to correlate with many flammability characteristics, including heat release and breakdown behavior, as assessed using methods such as thermal analysis and calorimetry. The extinguishment of flames on a solid surface is affected by thermal conduction to the material and the aerodynamics surrounding the flame. Heat transfer is represented by a heat transfer coefficient, as flame radiation near the surface is negligible at the extinction point. The dynamics of airflow, which influence flame stability, are characterized by the ratio of the duration of airflow surrounding the material to the time necessary for chemical reactions. This ratio assesses the rate at which a flame can be extinguished under certain conditions. The critical mass flux for flame extinction is determined using these factors, along with their influence on flow conditions and oxygen concentrations. This method emphasizes the significance of material characteristics, including thermal absorption and chemical reaction velocities, in attaining flame resistance, elucidating the behavior of materials under various fire conditions. Fig. 9 depicts flame retardancy evaluation based on different contributions, including nitrogen and phosphorus relationships versus flammability characteristics.

Fig. 9. Comparison of flame retardancy performance indicators.

3.4. Challenges and trends

The increasing focus on sustainability has underscored the significance of eco-friendly flame retardants (FRs) as substitutes for conventional, non-renewable, and often hazardous alternatives. These eco-friendly flame retardants, sourced from natural materials such as cellulose, lignin, and chitosan, are essential for improving the fire safety of biobased composites used in vital sectors including automotive, construction, and marine. In contrast to traditional flame retardants, environmentally friendly alternatives are biodegradable, renewable, and show a diminished ecological imprint, consistent with worldwide initiatives to mitigate carbon emissions. In Fig. 10 the graphic illustrates that these flame retardants run via mechanisms such as gas-phase dilution and condensed-phase char development to effectively suppress flames. Furthermore, sophisticated testing methodologies of various sizes are essential to assess their efficacy and change them for practical applications. The creation of sustainable flame retardants guarantees fire safety while easing the transition to renewable materials, giving them essential for ecologically responsible advancements in materials science.51

Fig. 10. Overview of eco-friendly flame retardants, testing methods, and applications in sustainable materials. Reproduced with permission from ref. 51 Copyright 2024, Sage Publications.

Innovations in sustainable and bio-based flame retardants emphasize the development of effective, eco-friendly solutions sourced from natural components such as lignin, chitosan, and phytic acid. This includes the application of nanotechnology to improve fire resistance, specialized coatings for uses, and the incorporation of flame-retardant characteristics into biopolymers and composites. Researchers are investigating plasma treatments and surface modification methods to enhance compatibility and durability. These innovations look to diminish toxicity, improve performance, and bolster global sustainability initiatives across several sectors.

4. Antimicrobial coatings

4.1. Mechanisms of antimicrobial action

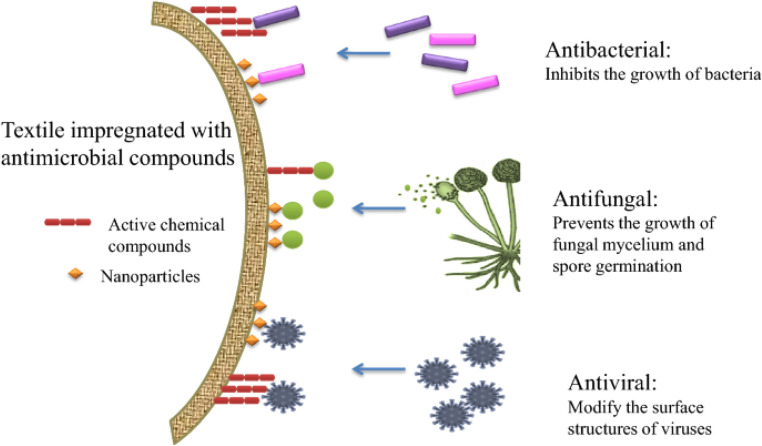

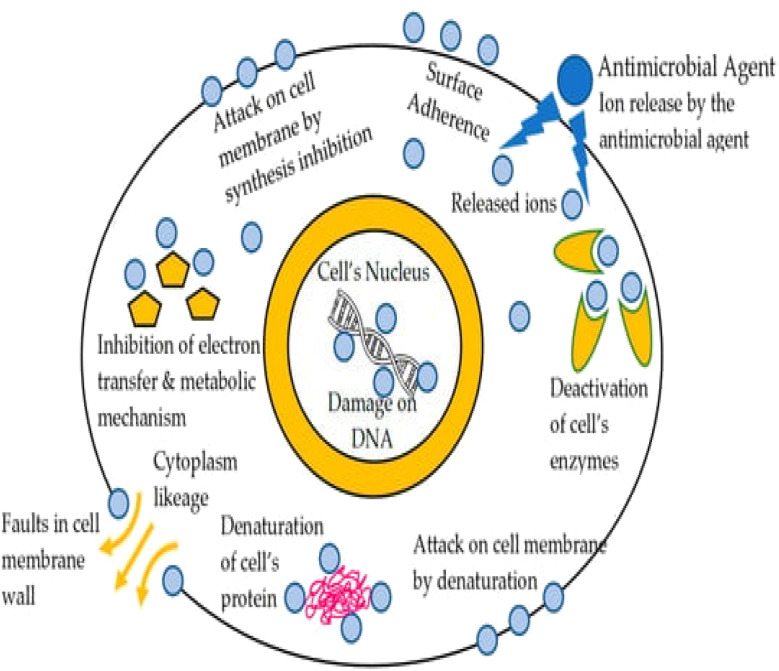

The large surface area and moisture-retaining qualities of textile constructions create a perfect habitat for microorganisms to flourish, which has bad consequences for the fabric and the user. Antimicrobial coatings have been created to solve this by stopping bacterial development, thus improving cleanliness and lowering health hazards.24 These coatings use both chemical and physical techniques to include antimicrobial compounds either chemically into textiles or physically onto surfaces.52 From healthcare to hygiene items, sportswear, food packaging, air filtration, and water purification systems, antimicrobial textiles have grown indispensable in many different uses. These fabrics are made to either destroy germs or stop their growth, so guaranteeing increased cleanliness and safety. Apart from their antibacterial characteristics, durability is also more important since it guarantees that the functional characteristics resist several washes and extended use without losing efficacy. Moreover, design, color retention, patterns, and other aspects are being combined to satisfy the needs of stylish and multifarious apparel. Reflecting increasing consumer awareness and market demand, many commercial brands today include these elements in their products. Further creativity is driven by developments in synthetic and natural antimicrobial compounds and diagnostic methods to evaluate activity against viruses, fungi, and bacteria. These innovations guarantee that antimicrobial fabrics not only meet practical requirements but also provide modern applications with sustainable, elegant, and high-performance solutions.53Fig. 11 shows how fabrics coated with antimicrobial agents, including nanoparticles and active chemical agents, fight different microbes. Antibacterial textiles stop bacterial development; antifungal textiles stop fungal mycelium development and spore germination; and antiviral textiles change the surface structure of viruses to lower their activity. These features provide better safety and cleanliness in many different uses.

Fig. 11. Mechanisms of antimicrobial textiles with active compounds and nanoparticles. Reproduced with permission from ref. 53 Copyright 2021, Springer-Verlag GmbH Germany, part of Springer Nature.

Incorporating environmentally safe antimicrobial chemicals as well as metal-based nanoparticles like silver, copper, and zinc oxide has shown amazing advancement in antimicrobial textiles in medical applications. By use of sustainable finishing methods, these materials improve the ability of the fabrics to minimize microbial development, lessen infection rates, and encourage wound healing. The developments underline the important part antimicrobial fabrics play in enhancing healthcare efficiency and safety.54

4.2. Types of antimicrobial coatings

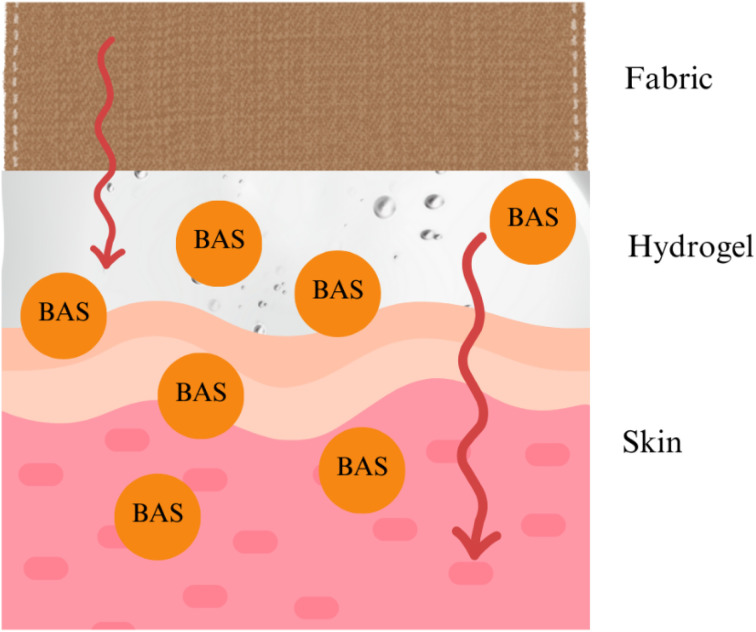

Antimicrobial coatings are classified into natural agents and metal-based agents. Natural agents, such as chitosan and essential oils, originate from sustainable sources and offer environmentally beneficial antibacterial protection.55,56 Metal-based treatments, like silver nanoparticles and zinc oxide, show significant efficacy against bacteria and are extensively used for their potent antimicrobial capabilities. Intimate clothing fabrics must have both comfort and antimicrobial qualities. Chitosan-silver finishing on cotton fabric investigates good antibacterial properties against S. aureus and E. coli.24,57 While water vapor transfer, surface friction, and flexibility stayed the same, the final fabric proved enhanced air permeability and hydrophilicity in comparison to the untreated fabric. Within reasonable bounds, chitosan attachment resulted in a slightly increased bending rigidity. Chitosan-silver dual compounding is a potential solution for intimate apparel because it maximizes comfort without sacrificing fabric quality and improves antibacterial efficiency.58 Safe and natural linear polysaccharides, chitosan is extensively applied for the multifunctional finishing of textiles. Using core–shell nanoparticles, it has been employed to generate antibacterial cotton fabric with a 99% reduction rate against S. aureus where poly(poly(n-butyl acrylate)) forms the core and chitosan forms the shell. About 300 nm in size, the nanoparticles were described using FT-IR and 1H NMR and then pad-dry-cure covered into cotton fabrics to show outstanding antibacterial efficacy.59 Compared to conventional finishes, microencapsulation of essential oils in textiles provides enhanced durability and controlled release. Applied to cotton and polyester cloth, concentrated on microencapsulating citronella oil using gelatin and gum Arabic as shell materials. Fiber type affected the release mechanism; cotton displayed a non-Fickian kinetic model, while polyester displayed Fickian diffusion. These results emphasize the possibilities of essential oil microencapsulation in producing textiles with longer-lasting functional effects.60 The processes by which encapsulated substances, such as essential oils, are liberated from microcapsules are depicted in Fig. 12. The release rate, which is triggered by a variety of events, is crucially controlled by the polymeric shell. Mechanical stimulation includes friction or physical pressure that causes the shell to burst, allowing the core material to be released. When external factors like pH shifts, enzymatic activity, or solvents weaken the shell and permit the core to escape, chemical stimulation takes place. While diffusion enables the core material to seep through the shell as external liquids, such as solvents, penetrate the structure, thermal stimuli use heat to melt the shell material, resulting in the core release. Active agents are delivered efficiently and gradually thanks to this controlled release method, which is adapted to applications and environmental circumstances.61

Fig. 12. Release mechanisms of essential oils from the micro/nanocapsules. Reproduced with permission from ref. 61 Copyright 2016, Taylor & Francis.

Metal-based nanoparticles, especially silver and zinc oxide nanoparticles, show significant potential as antibacterial agents owing to their broad-spectrum efficacy against both Gram-positive and Gram-negative bacteria. Silver nanoparticles are proficient at eradicating germs by compromising their cell membranes, altering metabolic processes, and interfering with DNA, giving them a favored choice for medicinal applications despite ongoing worries about their toxicity. Zinc oxide nanoparticles are successful in eradicating bacteria by comparable methods, offering the advantage of greater safety than silver, albeit with less potency. Both categories of nanoparticles present interesting substitutes for conventional antibiotics, particularly in combating antibiotic-resistant bacteria; yet, their safety, especially with prolonged exposure, continues to be a critical focus of continuing study.62

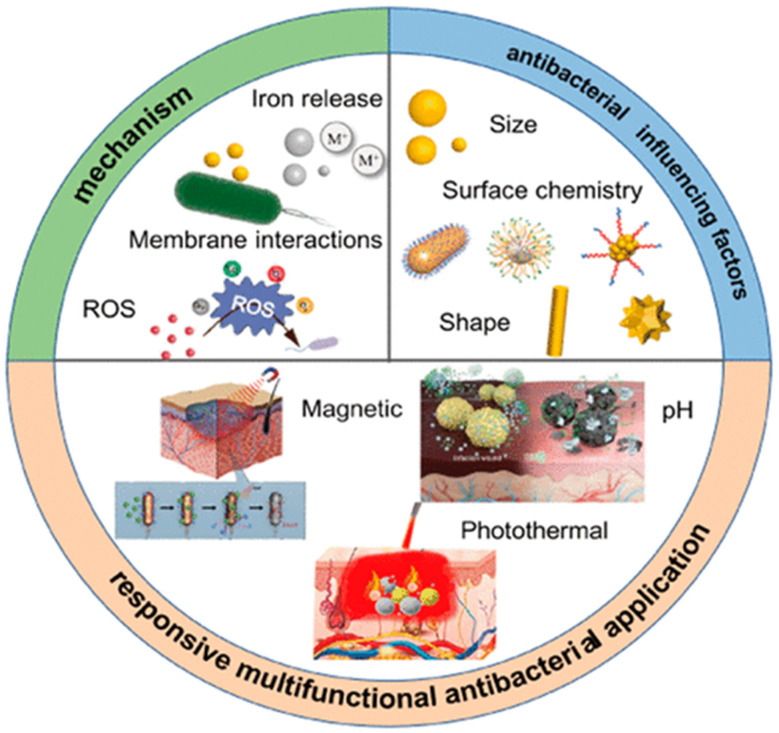

While treating infections is more challenging due to multidrug-resistant bacteria and biofilm formation, noble metal nanoparticles (NMNPs) such as gold, silver, and platinum present a good substitute for conventional antibiotics. By upsetting their cell membranes, attaching to DNA or enzymes, and even producing reactive oxygen species or heat under light, these nanoparticles can kill bacteria. Although they show tremendous promise in combating infections, their toxicity requires careful thought in medical use; hence, it is crucial to make sure their antibacterial force does not compromise safety.63 Antibiotic abuses has led to the rise of drug-resistant bacteria, making it harder to treat infections with traditional antibiotics. Metal-based nanoparticles (MNPs), like copper, titanium, and zinc oxide, are being looked at as promising alternatives because they are less likely to cause bacterial resistance and tend to be safer for human cells. This review highlights the antimicrobial potential of gold and silver nanoparticles, which have shown great promise in killing bacteria. It also covers new research on MNPs that can be triggered by light, magnetic fields, or pH changes, making them even more effective. As technology advances, MNPs are expected to be key in overcoming antibiotic resistance and improving treatments for bacterial infections.64

Fig. 13 shows the processes, influencing elements, and uses of multifarious antibacterial materials. It emphasizes systems such as iron release, ROS formation, and membrane interactions in addition to elements including size, shape, and surface chemistry influencing antibacterial efficacy. Applications include photothermal antibacterial systems, magnetic, pH-responsive, and photochemical systems.

Fig. 13. Multifunctional antibacterial mechanisms and applications. Reproduced with permission from ref. 64 Copyright 2024, American Chemical Society.

Since quaternary ammonium compounds (QACs) (see Fig. 14) are cationic surfactants that efficiently target bacteria, fungi, and certain viruses, they are often used as antimicrobial agents in textiles. To interrupt vital processes and kill microorganisms, their antibacterial effect involves electrostatic interactions between the positively charged nitrogen atom and the negatively charged microbial cell membrane. Although QACs work well, their lack of reactive functional groups prevents them from creating strong chemical connections with fibers, which causes gradual separation and decreased endurance. New developments include sol–gel technology and polymerizable QACs improve durability and wash fastness by forming networks of polymers or covalent connections on textile surfaces. Furthermore, to give dyes their color and antibacterial qualities, QACs have been added, making them suitable for use on both natural and synthetic fabrics, including cotton, wool, polyester, and polyamide.65

Fig. 14. General chemical structure of quaternary ammonium compounds (QACs). Published under CC-BY License65 Copyright 2023, MDPI.

4.3. Durability and wash fastness

Different methods aiming at increasing the durability and adherence of antimicrobial coatings to stop bacterial adhesion and biofilm development are covered in this review. It emphasizes recent developments in surface modifications to improve the long-term performance of antimicrobial surfaces by including hydrophobic, superhydrophobic, and self-cleaning characteristics. To guarantee continuous antibacterial efficacy, the review also covers techniques for strengthening the binding strength of coatings to substrates, like surface functionalization and the use of hybrid materials. It also underlines the need to strike a compromise for useful industrial uses between increasing durability and preserving antibacterial action.66 Several techniques are used to increase the durability and adherence of antimicrobial coatings: surfactants, binders, and post-treatment treatments. These methods ensure long-lasting antibacterial activity by helping to improve the stability of the coating and lower leachability. Furthermore, hybrid material compositions and surface functionalization are investigated to increase coating adherence to substrates while preserving their photocatalytic activity. These methods look to solve problems about the endurance and efficiency of photocatalytic antimicrobial coatings in practical settings.67 Ensuring the long-term effectiveness and performance in practical uses of antimicrobial fabrics depends critically on standards and methods for evaluating their wash fastness. Usually using ISO 6330 or AATCC 135, these criteria entail assessing the preservation of antimicrobial qualities following several washing cycles. Monitoring bacterial development on the cloth after several washes helps one to evaluate the lifetime of the antimicrobial effect and, hence, its protective qualities. Such testing is crucial to guarantee that antimicrobial textiles keep their safety and utility over time and stay effective.68

4.4. Biocompatibility and safety

Although medical textiles have great advantages for hospital usage, end users' possible hazards must be carefully evaluated. These hazards include skin irritation or allergic reactions brought on by chemical treatments or finishing chemicals applied in the fabrics, therefore generating negative health consequences. Furthermore, compromising their safety and efficacy could be the deterioration of antibacterial qualities or the release of toxic compounds from textile materials over time. New materials, including those used in implants or medication delivery systems, also need careful study to make sure they do not harm patients over time. Their biocompatibility and durability help to figure out this.69 Particularly in recycling and reuse situations, end users of medical textiles run possible hazards, including exposure to dangerous chemicals, germs, or pathogens that could linger on textiles following incorrect treatment or insufficient sterilization. If not properly controlled, the recycling process may undermine the integrity and safety of materials, therefore causing problems including lower mechanical strength, loss of biocompatibility, or the release of harmful compounds from broken-down polymers. Furthermore, the difficulty of preserving the antibacterial qualities and adaptability of medical textiles following recycling could lead to insufficient protection for patients, therefore raising their risk of infections or negative responses. These issues draw attention to the requirement for strict safety procedures and cutting-edge technologies in medical textile reuse and recycling.70 One less spoken-about concern of antimicrobial medical textiles is the possibility of inducing antimicrobial resistance. Should these fabrics be worn extensively or their antibacterial qualities fade over time, they could help resistant bacteria proliferate, therefore aggravating future treatments of diseases. The discharge of nanoparticles or chemicals from these materials raises further difficulties as, should they reach out and come into touch with internal tissues or skin, they could be harmful. Although these fabrics can be rather useful, their environmental impact should not be disregarded; if not disposed of correctly, they could leak dangerous chemicals into the surroundings, therefore influencing aquatic life or ecosystems. As we keep developing and using these cutting-edge materials, these are crucial problems that demand more focus.71 Although safety and biocompatibility rules for antimicrobial textiles vary depending on the market, their main goals are usually to guarantee that antimicrobial treatments are safe and efficient for human usage. Antimicrobial textiles must follow the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) rule in the European Union to guarantee that the chemicals used in textiles are non-toxic and do not endanger the environment. The FDA supervises the safety of textiles used in medical applications in the United States, so antimicrobial treatments must satisfy biocompatibility criteria for devices that come into direct touch with the skin or mucous membranes. Globally, regulations like ISO 10993 for biocompatibility and ASTM F2897 for antimicrobial testing guarantee that these fabrics are safe, durable, and do not negatively affect human health or the environment.52 Recent regulatory changes for antimicrobial textiles reflect increased concerns about public health, safety, and environmental effects. Regulations today place a high value on ensuring that antimicrobial agents used in textiles have been properly studied for toxicity and environmental safety, especially as novel materials such as natural polymers and metal-based agents are introduced. The goal is to ensure that these medicines defend against microorganisms without harming people or the environment. Antimicrobial resistance (AMR) is also gaining attention, forcing producers to create effective and long-term treatments. Along with this, there is a drive for more environmentally friendly choices, such as plant-based antimicrobials and smart fabrics, which provide long-term protection without jeopardizing safety. These developing requirements reflect a broader trend of ensuring that antimicrobial textiles are not only functional but also safe, sustainable, and responsible.

5. Self-cleaning coatings

5.1. Mechanisms of self-cleaning

5.1.1. Photocatalytic cleaning

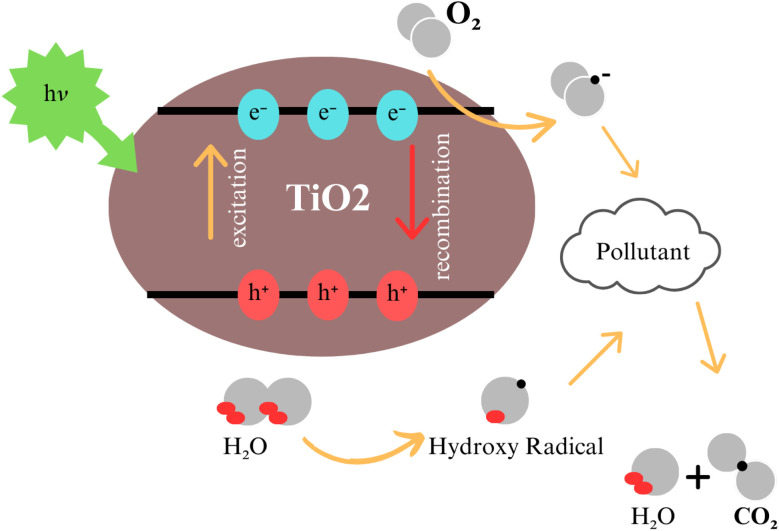

Titanium dioxide (TiO2) nanoparticles have revolutionized photocatalysis by providing effective solutions for breaking down organic matter and enabling self-cleaning surfaces (see Fig. 15).73 These nanoparticles are highly valued for their chemical stability, non-toxicity, and strong oxidative potential under ultraviolet (UV) light.74,75 Upon exposure to UV light with energy equal to or greater than its bandgap (∼3.2 eV for anatase), TiO2 generates electron–hole pairs:73–75TiO2 + hν → e− + h+

Fig. 15. Generation of hydroxyl radicals and reactive oxygen species under light irradiation for pollutant breakdown. Reproduced with permission from ref. 72 Copyright 2021, Springer-Verlag GmbH Germany, part of Springer Nature.

The photogenerated holes (h+) oxidize water (H2O) or hydroxide ions (OH−) to produce hydroxyl radicals (˙OH):76,77h+ + H2O → ˙OH + H+

These radicals are highly reactive and degrade organic pollutants into benign compounds like carbon dioxide (CO2) and water (H2O). Simultaneously, the electrons (e−) reduce molecular oxygen to superoxide radicals:78,79e− + O2 → O2−

These radicals further take part in breaking down pollutants.

Recent advancements have enhanced the photocatalytic activity of TiO2, expanding its utility beyond UV light to the visible spectrum (∼45% of sunlight) through doping with elements like nitrogen, carbon, and metals such as iron and copper.80–82 Nanostructuring, including the creation of nanotubes, nanowires, and hierarchical architectures, has further increased the surface area and active sites for photocatalysis.83,84 In wastewater treatment, TiO2 achieves over 90% degradation of harmful compounds like methylene blue and phenol within an hour of UV exposure.85,86 In self-cleaning applications, TiO2 coatings decompose organic residues while shifting surface properties from hydrophobic to super hydrophilic (contact angle <5°), ensuring dirt and water removal. TiO2-based air purifiers effectively reduce volatile organic compounds (VOCs) like formaldehyde by up to 80%, while their antibacterial properties destroy bacterial membranes and biofilms through ROS generation.87–89

5.1.2. Hydrophobic and hydrophilic mechanisms

The self-cleaning capabilities of surfaces have gained significant attention due to their potential applications in environmental sustainability, healthcare, and advanced materials.90 These effects are primarily driven by two mechanisms based on surface properties: hydrophobicity (water-repelling) and hydrophilicity (water-attracting). Hydrophobic surfaces show high water contact angles (θ > 90°), where water droplets bead up and roll off, carrying away dirt and contaminants.91,92 Superhydrophobicity, with contact angles exceeding 150°, is achieved through hierarchical surface structures and low surface energy materials, such as fluorinated silanes or polytetrafluoroethylene (PTFE).93,94 The “lotus effect”, inspired by lotus leaves, exemplifies this mechanism, where micro- and nanoscale roughness traps air, minimizing water-surface contact.95 This principle is used in self-cleaning glass, reducing maintenance costs by up to 40%, and in treated textiles, enhancing durability and stain resistance.96

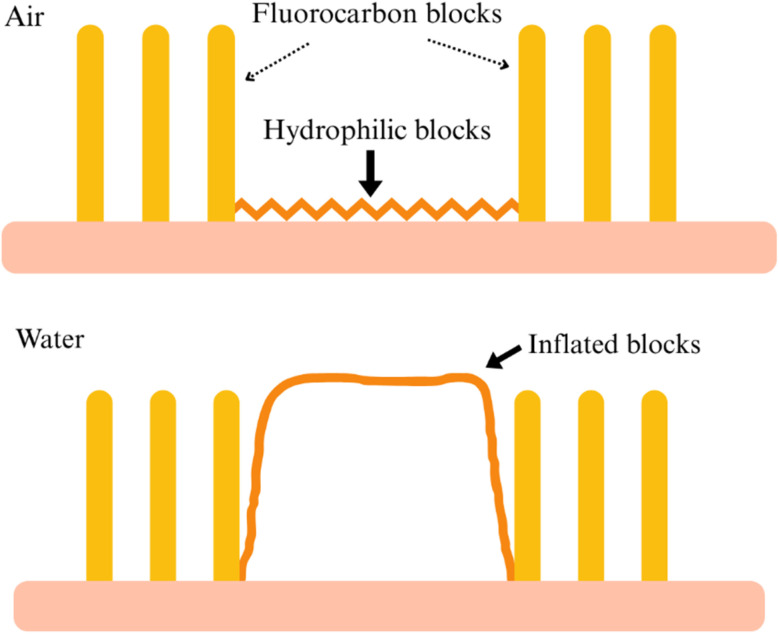

As shown in Fig. 16, the interplay between hydrophobic and hydrophilic mechanisms in textile finishing is being controlled by the dynamic behavior of fluorocarbon and hydrophilic blocks. In the top diagram, where the fabric is exposed to air, the fluorocarbon blocks dominate the surface, which are basically hydrophobic in nature. Fluorocarbon chains have low surface energy, which prevents water droplets from spreading or adhering to the fabric. This property is essential for applications like water-repellent clothing, rainwear, or stain-resistant textiles. By orienting outward, these fluorocarbon blocks form a protective layer that resists liquid penetration, ensuring the fabric is still dry and clean even in harsh conditions. The bottom diagram illustrates the fabric's behavior in a water-rich environment, where the hydrophilic blocks come into play. Hydrophilic blocks, which are water-attracting, absorb and interact with water molecules. In this case, they allow the fabric to wick away moisture, enabling it to manage sweat or water effectively. This property is highly desirable in activewear, undergarments, and technical textiles, where moisture transport and breathability are critical for user comfort. When the hydrophilic mechanism is active, the fluorocarbon blocks become less dominant, allowing the fabric to perform optimally in wet conditions.97

Fig. 16. Dynamic surface behavior of textile finishes. Published under CC-BY License97 Copyright 2023, MDPI.

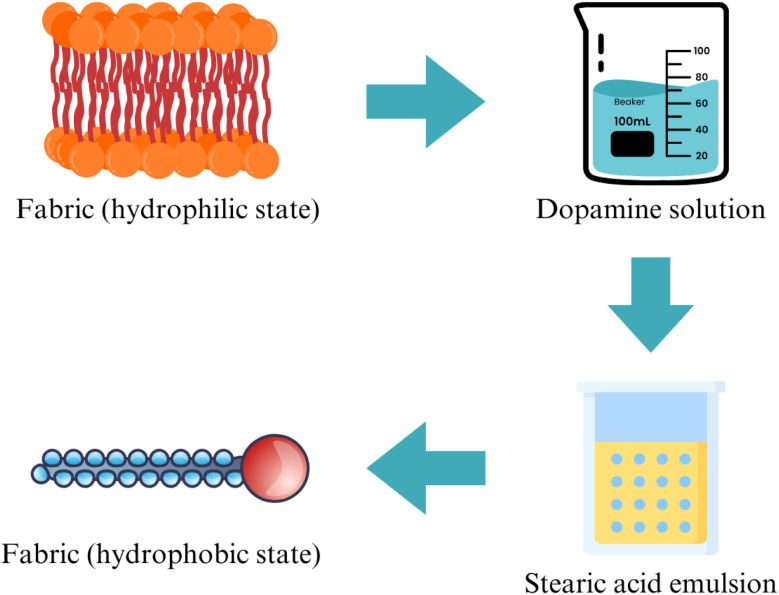

This dual-functionality approach is made possible by advanced textile finishing techniques, often involving block copolymers of fluorocarbon blocks. On the other hand, in a different study, a process for transforming textiles from a hydrophilic to a hydrophobic state is achieved through a two-step coating procedure (see Fig. 17). This approach uses the adhesive properties of dopamine and the hydrophobic nature of stearic acid to change the textile surface, creating a durable water-repellent finish. The resulting fabric shows a robust hydrophobic surface, transforming its wetting behavior from hydrophilic to hydrophobic.

Fig. 17. Achieving hydrophobicity through coating by dopamine and stearic acid. Reproduced with permission from ref. 98 Copyright 2019, Royal Society of Chemistry.

5.2. Common self-cleaning materials

5.2.1. Photocatalytic agents

Recent advancements have enhanced the photocatalytic efficiency of TiO2, addressing its limitation to UV light (∼5% of the solar spectrum). Doping with elements like nitrogen, carbon, or transition metals (e.g., iron and silver) has extended its activity into the visible spectrum, making it more effective under natural sunlight. For instance, nitrogen-doped TiO2 can achieve degradation rates comparable to UV-activated TiO2 under visible light conditions. Additionally, the development of TiO2-based nanostructures such as nanotubes, nanowires, and hierarchical frameworks has increased surface area and light absorption, further boosting efficiency.83

Applications of TiO2 span diverse fields. In air purification, TiO2-coated filters reduce VOCs and harmful gases like formaldehyde by up to 80%. In antimicrobial coatings, TiO2 effectively destroys bacterial cell walls through ROS, making it invaluable for hospital sanitation and public health. TiO2 is also widely used in self-cleaning surfaces, where it eases the decomposition of organic residues and shifts surface properties to super hydrophilic, enabling easy dirt removal.99

Emerging research explores combining TiO2 with other advanced oxidation processes (AOPs) like ozonation and UV-C irradiation, which can enhance pollutant degradation. Furthermore, hybrid photocatalysts, such as graphene-TiO2 composites, have shown improved charge separation and electron transfer efficiency, resulting in faster and more complete contaminant breakdown. Green synthesis methods for TiO2 nanoparticles, using plant extracts or waste products, are also gaining traction to reduce environmental impact. With its versatile applications and ongoing innovations, TiO2 continues to lead as a powerful photocatalytic agent, offering scalable and sustainable solutions for addressing global environmental challenges.100,101

5.2.2. Superhydrophobic materials

Superhydrophobic materials, inspired by natural phenomena like the lotus leaf effect, show exceptional water-repelling properties with contact angles exceeding 150° (see Fig. 18) and low sliding angles that allow water droplets to roll off effortlessly. Two key strategies for achieving this effect involve the use of silica nanocoatings and fluorinated compounds.103,104 Silica nanocoatings play a crucial role in creating the dual roughness required for superhydrophobicity. These coatings, fabricated through methods such as sol–gel synthesis and chemical vapor deposition, introduce micro- and nanostructures that trap air, minimizing contact between water droplets and the surface. Recent advancements include doped silica nanoparticles, such as silica-titanium dioxide composites, which enhance durability and introduce photocatalytic self-cleaning properties and precise lithographic techniques that enable tunable wetting properties.105 Surfaces treated with silica nanoparticles often achieve water contact angles up to 170° and sliding angles as low as 2°, with particle sizes in the range of 10–100 nm providing superior performance.

Fig. 18. Diagrammatic representation of the “self-cleaning” idea. A drop of water rolling over the surface of a lotus leaf (A) and a smooth, solid surface (B). Reproduced with permission from ref. 102 Copyright 2022, Springer Nature Switzerland AG.

Fluorinated compounds complement silica coatings by reducing surface energy, a fundamental requirement for water repellency. Fluorinated alkyl silanes, such as perfluorooctyltriethoxysilane (PFOTES), chemically bond to silica structures, forming low-energy monolayers that repel water.106 Recent research has advanced fluoropolymer-silica hybrids for enhanced durability, developed plasma-assisted fluorination methods to reduce environmental impact, and explored alternatives to traditional perfluorinated compounds due to toxicity concerns. Superhydrophobic surfaces created using fluorinated silanes show water contact angles between 160° and 175°, with modified PFOTES coatings staying effective after over 1000 cycles of abrasion.

The constructive collaboration of silica nanocoatings and fluorinated compounds maximizes superhydrophobicity by integrating structural roughness with low surface energy. These coatings show high thermal and mechanical durability, withstanding temperatures up to 300 °C and keeping performance after repeated stress.107 For instance, silica-fluorinated composites achieve water contact angles of 172° and support self-cleaning properties even in corrosive environments. Chemicals like tetraethyl orthosilicate (TEOS) and methyltriethoxysilane (MTES) are commonly used as silica precursors, while perfluorooctyltriethoxysilane (PFOTES) and hexafluorobutyl acrylate serve as fluorinated agents.108

5.3. Limitations and performance

5.3.1. Durability challenges

Maintaining the self-cleaning properties of materials after repeated washing is a significant challenge, particularly for superhydrophobic and superhydrophobic surfaces. These surfaces rely on delicate hierarchical structures and low-surface-energy coatings to repel water and contaminants, but their performance often degrades due to physical abrasion, chemical interactions, or loss of surface functionality during washing processes.95 Abrasion and mechanical wear erode the micro- and nanostructures essential for trapping air and minimizing water adhesion, while detergents and cleaning agents can chemically degrade hydrophobic polymers or fluorinated compounds. Additionally, repeated washing can strip away low-energy coatings, exposing the substrate and reducing water repellency. For super hydrophilic surfaces, contamination by oils or organic residues during washing can interfere with water spreading, diminishing self-cleaning efficiency.

Recent advancements aim to address these challenges by improving coating durability. Nanoengineered coatings with enhanced adhesion, such as silica nanoparticles functionalized with silane coupling agents like (3-aminopropyl) triethoxysilane (APTES), show stronger substrate bonding and keep water contact angles above 150° even after 50 washing cycles.109,110 Self-healing coatings, incorporating microcapsules or polymer matrices that release repair agents, restore water-repellent properties after mechanical abrasion or washing, achieving contact angle recovery rates exceeding 90%. Fluorine-free hydrophobic alternatives, such as long-chain alkyl silanes and silicone-based polymers, have been developed to address environmental concerns associated with perfluorinated compounds. These alternatives, combined with nano-patterned structures, resist chemical degradation while keeping contact angles above 160°. Durable micro- and nanostructures, such as titanium dioxide nanowires and graphene oxide composites, show excellent abrasion resistance, keeping self-cleaning properties after prolonged washing cycles.85

Hybrid coatings that combine inorganic nanoparticles, such as silica or zinc oxide, with organic polymers like polydimethylsiloxane (PDMS) further enhance durability by using the flexibility of polymers and the wear resistance of inorganic materials.111 For instance, silica-PDMS hybrid coatings have kept water contact angles of 165° after 100 washing cycles. Similarly, layered graphene coatings keep self-cleaning properties even after 50 cycles of ultrasonic washing due to their hydrophobic nature and mechanical robustness. Plasma-treated surfaces functionalized with hydrophobic silanes have also shown improved resistance to mechanical and chemical degradation during washing.

5.3.2. Environmental safety

The use of self-cleaning agents, particularly in superhydrophobic and photocatalytic materials, has transformed industries by offering surfaces that repel water, dirt, and pollutants, but their environmental impact is a growing concern.112,113 Many self-cleaning agents rely on nanomaterials, fluorinated compounds, and photocatalysts like titanium dioxide (TiO2), which pose risks to ecosystems if released into the environment.114,115 Nanoparticles such as TiO2, zinc oxide (ZnO), and silica (SiO2) are crucial for creating micro- and nanostructures or enabling photocatalytic activity (see Fig. 19). Still, their release during manufacturing, use, or degradation can harm aquatic organisms through oxidative stress or bioaccumulation. For instance, TiO2 nanoparticles at concentrations as low as 1–10 mg L−1 have been linked to reduced growth in algae and crustaceans, while ZnO nanoparticles show potential for bioaccumulation in aquatic food chains. In soil, silica nanoparticles can disrupt microbial activity, affecting nutrient cycles. Fluorinated compounds, such as per- and polyfluoroalkyl substances (PFAS), are another concern due to their persistence, bioaccumulation, and toxicity.116 Often called “forever chemicals,” PFAS resist degradation and have been detected in water bodies and soil, sometimes exceeding safe thresholds. Their accumulation in wildlife and humans has been associated with endocrine disruption and reduced fertility. Additionally, photocatalytic agents like TiO2 can produce secondary pollutants such as formaldehyde and volatile organic compounds (VOCs) through reactive oxygen species (ROS) generation, while prolonged use can lead to metal ion leaching, further contributing to environmental toxicity.79

Fig. 19. Methodologies that are usually followed to produce nanoparticles. Published under CC-BY License97 Copyright 2023, MDPI.

Recent advancements aim to address these environmental safety concerns. Green nanotechnology has introduced biodegradable alternatives, such as cellulose nanocrystals (CNCs) derived from plant biomass and biopolymer-coated nanoparticles that reduce toxicity while supporting functionality. Non-fluorinated hydrophobic coatings, including silicone-based materials and alkyl ketene dimers (AKDs), are being developed as sustainable replacements for PFAS. Hybrid coatings combining silica nanoparticles with plant-derived hydrophobic agents provide eco-friendly solutions without compromising performance.117 Photocatalytic materials are also being improved through doping with metals like silver or gold to enhance efficiency under visible light while reducing harmful by-products. Encapsulation of photocatalysts in protective layers, such as graphene oxide or zeolites, minimizes the release of reactive species and metal ions. Lifecycle assessments (LCAs) are increasingly used to evaluate the environmental footprint of self-cleaning agents, while recycling strategies, such as recovering TiO2 nanoparticles from wastewater through filtration, help mitigate environmental release.118,119

Studies underscore the importance of these advancements. For example, PFAS-free coatings like those based on AKDs achieve water contact angles of 150°, comparable to traditional fluorinated coatings. Silver-doped TiO2 has shown a 30% increase in pollutant degradation efficiency under visible light with 25% fewer ROS by-products, while graphene oxide-encapsulated TiO2 reduced metal ion leaching by 70% compared to unmodified materials. Despite these developments, challenges are still in ensuring scalability, cost-effectiveness, and regulatory compliance. Future research is focused on biodegradable nanomaterials, non-toxic hydrophobic agents, and advanced photocatalysts to balance functionality with safety. By integrating lifecycle assessments and robust regulatory frameworks, self-cleaning technologies can evolve to deliver high efficiency with a minimal ecological footprint.120

5.4. Applications and use cases

5.4.1. Industry applications

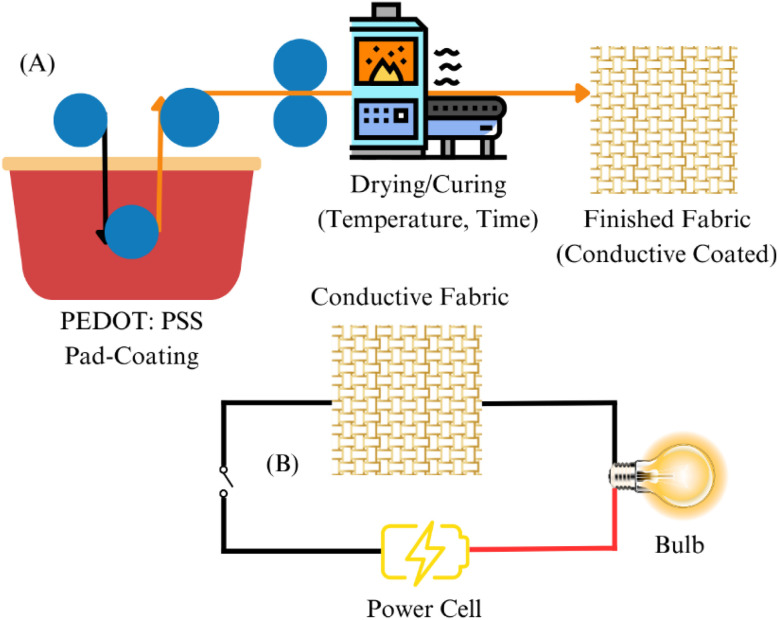

Textiles for healthcare and outdoor applications have advanced significantly, using innovations in materials science, nanotechnology, and functional finishes (see Fig. 21) to meet specific performance demands such as antimicrobial protection, moisture management, UV resistance, and durability. In healthcare, antimicrobial fabrics play a critical role in preventing infections, using agents like silver nanoparticles, zinc oxide (ZnO), and quaternary ammonium compounds (QACs). For instance, silver nanoparticles at concentrations of 10–20 ppm have been shown to reduce bacterial presence by over 99.9% within hours, while ZnO offers long-lasting antibacterial properties with environmental benefits. Barrier textiles, often coated with materials like polytetrafluoroethylene (PTFE) or polyurethane (PU), are used in surgical gowns and masks, with multi-layered nonwoven structures like spunbond-meltblown-spunbond (SMS) composites achieving filtration efficiencies exceeding 95% for particles as small as 0.3 microns. Additionally, smart healthcare textiles incorporating graphene or conductive polymers check health metrics like body temperature and heart rate in real time, while electrospun nanofiber membranes enable controlled drug delivery (see Fig. 20).122

Fig. 21. Diagrammatic representation of: (A) poly-3,4-ethylenedioxythiphene:polystyrene sulfonate (PEDOD:PSS) continuous coating process; (B) electrical conductivity testing of pretreated fabric. Published under CC-BY License123 Copy 2022, MDPI.

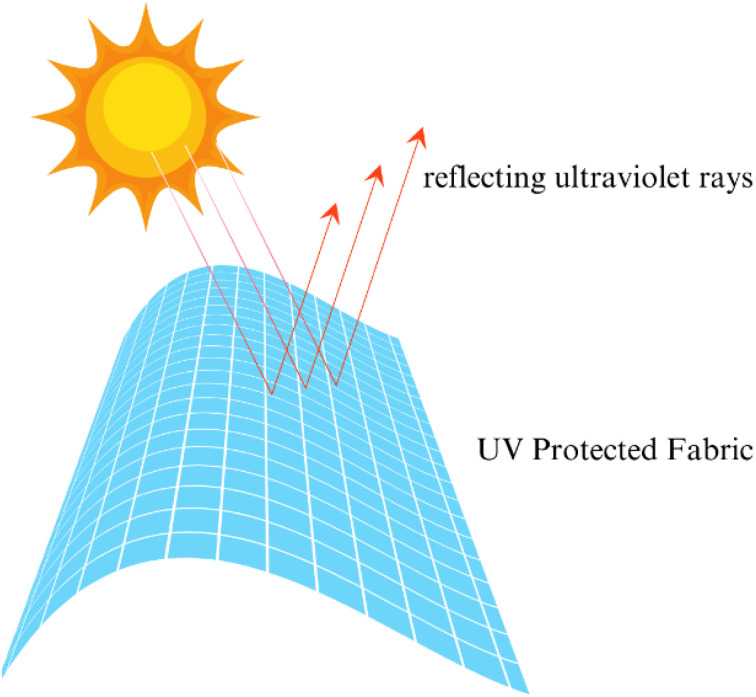

Fig. 20. Hydrogel immobilized on a modified cloth releases BAS (biologically active substances). Published under CC-BY License121 Copy 2021, MDPI.

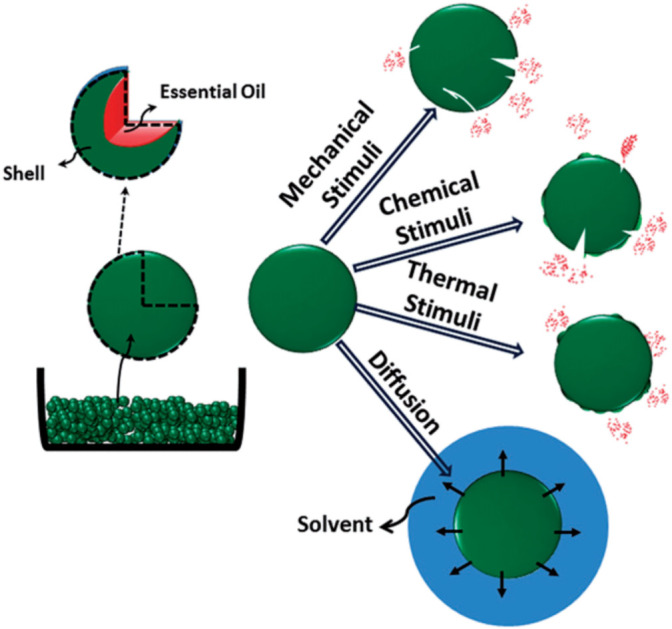

Outdoor textiles are designed for durability and comfort in extreme conditions, with advancements including weather resistance, UV protection, and self-cleaning properties. Water-resistant and breathable fabrics treated with durable water repellents (DWR) are widely used, with eco-friendly alternatives like silicone-based finishes and wax emulsions gaining traction. High-performance laminates such as Gore-Tex combine waterproofing, windproofing, and breathability, offering ratings exceeding 20 000 g per m2 per day. For UV resistance, agents like titanium dioxide (TiO2) and ZnO are incorporated to block harmful radiation, achieving ultraviolet protection factor (UPF) values above 50. Also, achieving conductivity using functional compounds like poly-3,4-ethylenedioxythiphene:polystyrene sulfonate (PEDOD:PSS), thus smart textile functionality (see Fig. 21) can be achieved. Self-cleaning coatings using silica nanoparticles or fluorinated silanes keep cleanliness by repelling water and dirt, while titanium dioxide-based photocatalytic finishes degrade organic stains under sunlight.124

Industrially, healthcare textiles are used in antimicrobial scrubs, hospital bed linens, and wound dressings, with nonwoven materials dominating disposable products in a global market exceeding $30 billion in 2023. In outdoor applications, high-performance fabrics are integrated into sportswear, tents, and sleeping bags, using lightweight, breathable materials like Thinsulate and UV-protective clothing with UPF ratings exceeding 50. Military and protective gear use advanced textiles such as Kevlar and Nomex for fire resistance and ballistic protection, while smart textiles with embedded sensors check soldier health and environmental conditions. Supporting data highlights the durability of these innovations, such as antimicrobial fabrics keeping efficacy after 50 washing cycles and self-cleaning coatings maintaining water contact angles above 150° even after extensive washing. Future research focuses on sustainable materials like bio-based polymers and plant-derived nanofibers, along with multi-functional textiles integrating antimicrobial, UV-resistant, and smart features, addressing both performance and environmental demands. These advancements ensure that healthcare and outdoor textiles continue to evolve, meeting industry needs while aligning with sustainability goals.125Table 1 depicts certain types of coating performances and other relatable issues.

Table 1. Performance metrics for each coating type, including key materials, mechanisms, applications, and measurable performance indicators.

| Coating type | Key materials | Mechanism and features | Performance metrics | Reference |

|---|---|---|---|---|

| Flame-retardant (FR) | - Phosphorus-based compounds (ammonium polyphosphate, intumescent coatings) | - Forms a protective char layer, reducing flammability | - Limiting oxygen index (LOI): >25% | Yang et al.126 |

| - Metal hydroxides (Mg(OH)2, Al(OH)3) | - Gas-phase and condensed-phase flame inhibition | - Heat release rate (HRR): reduced by 30–60% | ||

| - Halogen-free FRs | - Prevents heat and oxygen supply, delaying combustion | - Char residue formation: 2–3× increase | ||

| - Nanoparticles (TiO2, SiO2) | ||||

| - Bio-based FRs (chitosan, lignin, DNA-based FRs) | ||||

| Antimicrobial (AM) | - Metal-based agents (silver (Ag) nanoparticles, zinc oxide (ZnO), copper (Cu)) | - Kills or inhibits bacterial growth | - Bacterial reduction: >99% (ISO 20743) | Bolaños-Cardet et al.127 |

| - Natural agents (chitosan, essential oils, tannins) | - Disrupts microbial cell membranes | - Wash durability: effective up to 50 washes | ||

| - Synthetic agents (quaternary ammonium compounds (QACs), polyhexamethylene biguanide (PHMB)) | - Prevents biofilm formation | - Zone of inhibition: ≥2 mm | ||

| Self-cleaning (SC) | - Photocatalytic agents (TiO2, ZnO, SiO2) | - Photocatalysis: breaks down organic stains and bacteria using light | - Contact angle (superhydrophobicity): >150° | Nomeir B. et al.128 |

| - Hydrophobic coatings (silica nanoparticles, fluorinated silanes) | - Superhydrophobicity: water droplets roll off, carrying away dirt | - Dirt removal efficiency: >90% | ||

| - Graphene oxide & carbon-based nanocoatings | - Superhydrophilicity: water spreads evenly, washing away contaminants | - Photocatalytic degradation: ∼80% pollutant removal in 6 hours | ||

| Multi-functional coatings | - Hybrid nanocomposites (Ag–TiO2, SiO2–TiO2) | - Combines flame-retardant, antimicrobial, and self-cleaning properties | - Retention of functionalities: >80% after 30 washes | |

| - Layer-by-layer (LbL) coatings | - Balances durability, sustainability, and performance | - Flame retardancy (LOI): >28% | ||

| - Bio-based & biodegradable functional coatings | - Optimized for real-world applications | - Bacterial reduction: ∼99% after 50 cycles | ||

| - Graphene oxide-based multifunctional coatings | He et al.129 | |||

| Liang et al.130 |

6. Synergistic multi-functional coatings

6.1. Integration of multiple functionalities

6.1.1. Combining flame retardant, antimicrobial, and self-cleaning properties

Developing multi-functional coatings that combine flame retardant, antimicrobial, and self-cleaning properties presents a range of challenges despite their immense potential for safety, hygiene, and durability. A key hurdle is the compatibility and stability of diverse chemical components. For example, flame retardants like ammonium polyphosphate (APP) are hydrophilic, while self-cleaning agents such as silica-based hydrophobic coatings require a non-polar environment, leading to phase separation or reduced adhesion. Performance trade-offs further complicate the process, as high loading levels of flame retardants can compromise transparency and flexibility, while antimicrobial agents like zinc oxide (ZnO) nanoparticles can degrade coating material through photocatalytic activity.131,132 Scalability also stays a critical challenge, as techniques like layer-by-layer (LbL) assembly, though effective at the laboratory scale, are difficult to implement uniformly in industrial applications.

Environmental and health concerns are increasingly driving the need for sustainable alternatives.133 Halogenated flame retardants and silver nanoparticles (AgNPs), while effective, pose risks due to toxicity and bioaccumulation.134 Researchers are exploring bio-based solutions like lignin and chitosan to address these issues. Long-term durability is another obstacle, as functionalities like superhydrophobicity in self-cleaning coatings can degrade with wear, while flame retardants and antimicrobial agents may lose effectiveness due to UV exposure or leaching. For instance, coatings with 5 wt% graphene oxide (GO) show a 50% reduction in peak heat release rate (PHRR) but experience a 20% decline in antimicrobial efficacy due to altered surface properties. Similarly, TiO2-based coatings with ZnO nanoparticles achieve 90% bacterial reduction but lose 30% of their water-repellent properties after 200 abrasion cycles. To address these challenges, advancing hybrid nanocomposites can be integrated, such components as GO, TiO2, and AgNPs for synergistic effects.134,135

6.1.2. Materials supporting multi-functionality

Silver-doped titanium dioxide (Ag–TiO2) is a versatile agent with significant potential for combining antimicrobial, self-cleaning, and flame-retardant properties, making it ideal for multi-functional material applications in healthcare, construction, and environmental remediation. Its antimicrobial efficacy arises from the synergistic effects of silver ions (Ag+), which disrupt microbial cell membranes and inhibit enzymatic functions, and TiO2, which generates reactive oxygen species (ROS) under UV or visible light to further damage pathogens. Coatings with Ag–TiO2 nanoparticles achieve over 99% bacterial reduction within hours, effectively targeting even antibiotic-resistant strains. Additionally, the photocatalytic properties of TiO2, enhanced by silver doping, allow for the breakdown of organic contaminants and enable self-cleaning in low-light conditions.136 Ag–TiO2 coatings create super hydrophilic surfaces with water contact angles below 5°, ensuring dirt and debris are easily washed away.137