Abstract

Beef tallow is an important raw material in Chongqing hotpot seasoning but raises great concern on health due to the cholesterol issue. Herein, palm oil was expected to replace beef tallow at weight ratios of 2:1, 1:1, and 1:2 without reducing hotpot flavor. The blending of palm oil to beef tallow effectively decreased cholesterol content to 33.20 mg 100 g−1, as well as the level of saturated fatty acids to 50 % in hotpot oil. The fading in brightness and yellowness of oil models occurred owing to heat treatment. The blending oil at 2:1 showed similar hardness, melting and crystallization behaviors to beef tallow, probably due to the similar fat crystal network. The volatile compounds of hotpot seasoning made from the oil were closer to that from neat beef tallow. These findings may provide a new strategy to develop healthier and tastier base oil for the production of Chongqing hotpot seasoning.

Keywords: Beef tallow, Palm oil, Chongqing hotpot oil, Key volatile compounds

Highlights

-

•

The blending of palm oil to beef tallow effectively decreased cholesterol content.

-

•

The blending oil at 2:1 showed similar fat crystal network to beef tallow.

-

•

Volatiles in hotpot seasoning significantly varied with rising the ratio of palm oil.

1. Introduction

Chinese hotpot is a traditional cuisine with a history of more than 2000 years, and has gained popularity worldwide for its appealing taste. Chongqing hotpot is a typical hotpot in China, especially in the southwestern regions, which is characterized by a hot, spicy, and flavorful soup. It is made from beef tallow (BT), Pixian pea sauce, chilis, pepper, ginger, garlic, and other spices as raw materials through a complex process of frying or cooking (Zhang et al., 2021). As reported by Pang et al. (2023), Chongqing hotpot has been a signature local food regularly consumed by a population of almost 110 million, and more than 150,000 Chongqing hotpot restaurants have been opened across China. In addition, the further growth of the consumption of hotpot seasoning is expected, which is estimated to increase globally with a total production of 668.9 billion yuan by 2025 (Liu et al., 2023).

As a carrier of flavor substances, beef tallow has been commonly used in Chongqing hotpot seasoning, accounting for about 40–50 % of the total components, which plays an essential role in the formation of the hotpot flavor (Guo et al., 2023). Beef tallow is a type of edible animal fat made from beef adipose tissue through high temperature processing. It contains a variety of fatty acids, vitamins, minerals, and other nutrients, and also has desirable physical properties including good heat stability, strong antioxidant, and unique flavor (Li et al., 2024). There has been a growing body of studies into volatile compositions and sensory properties of beef tallow in hotpot. Ye et al. (2022) found that beef tallow was a vital precursor for odor development in hotpot, and could be involved in fat oxidation and Maillard reaction, resulting in the formation of specific volatile compounds that provided characteristic hot flavors. Sun et al. (2021) identified characteristic aroma components of beef tallow from Chinese hotpot seasoning, and found that 2-furfurylthiol, 2-acetylthiazole, anethole, (E)-2-decenal, and 1,8-cineole were the key odorants for the overall aroma of beef tallow. However, beef tallow contains approximately 50 % saturated fatty acids, as well as 50–300 mg cholesterol/100 g fat, which could cause diet-related diseases (e.g., hypertension and obesity) (Yavari et al., 2009). Shifting towards healthier hotpot seasoning, especially by reducing the consumption of beef tallow without reducing the flavor, is urgently needed for the long-term sustainability of the hotpot industry.

Vegetable oil with low cholesterol content is expected to replace beef tallow partially and produce healthier hotpot oil. Palm oil (PO) is the most consumed vegetable oil in the world and usually extracted from the oil palm's fruit flesh. Currently, few scientific findings suggested palm oil as a risk factor for cardiovascular disease, and it was then regarded as a viable alternative for the use of solid fat formulation by virtue of its fatty acid composition (Fattore & Fanelli, 2013). Li et al. (2018) produced a low trans margarine fat analog with the blend of palm oil and soybean oil at a mass ratio of 4:3, and the resulting oil showed the potential in formulating healthier margarine as a healthy alternative to beef tallow. However, when the blend of palm oil and beef tallow was used to produce hotpot seasoning, different types of hotpot oils could contribute to flavor differences. That may be associated with the type and content of volatile compounds, the mutual synergistic or inhibitory effects between volatiles (Zou et al., 2023). Therefore, it is of significance to compare the changes of volatile compounds in Chongqing hotpot seasoning made from different oils, which may provide a more general and applicable reference to the selection of hotpot oils from a flavor perspective.

In this study, the differences of oil models in physicochemical properties (such as oxidation status, color, hardness, melting and crystallization behaviors, etc.) were compared in detail. The characteristic flavors of hotpot seasoning made from different oils were used to evaluate the potency of beef tallow/palm oil blend as the base oil for the production of Chongqing hotpot seasoning. More specifically, the fatty acid composition of oil models was determined by a gas chromatography, and the melting and crystallization behavior were evaluated using differential scanning calorimetry (DSC). Polarized light microscopy was used to study the crystal morphology of oil samples. Additionally, the overall aroma characteristics of different oil models were analyzed by electronic nose (E-nose), and principal component analysis (PCA) was performed to clarify the odor variations among samples with various weight ratios. The key volatile compounds in five kinds of hotpot oil were finally identified and quantified by SPME/GC–MS.

2. Materials and methods

2.1. Materials

Beef tallow was purchased from Shuai Ke Food Co., Ltd. (Chongqing, China). Palm oil and mixed seasonings packet were purchased from a local supermarket. Isopropanol, chloroform, thiobarbituric acid (TBA), and 1,1,3,3-tetraethoxypropane were obtained from Maclin Biochemical Technology Co., Ltd. (Shanghai, China). All other chemicals were analytical-grade purity and were used without any further processing.

2.2. Sample preparation

Preparation of Chongqing hotpot oil samples was performed according to the method of Zou et al. (2022) with modifications. The oil models were prepared by mixing beef tallow and palm oil. Weight ratios of beef tallow to palm oil were 2:1, 1:1, and 1:2 to match textural and sensory properties of traditional hotpot. 400 g of hot water was added to the mixed oil. Then, the mixtures were stirred and simmered at 100 °C for 15 min. When standing for 5 min, the oil models were obtained from the upper oil layer.

2.3. Measurement of acid value (AV), peroxide value (PV), malondialdehyde (MDA), and cholesterol

The quality parameters of different oil models were determined according to the method reported by Zhang et al. (2022) with modifications. 15 g of oil samples were heated at 100 °C for 18 h using an HCJ-6E numerical show constant temperature oil.

bath (Changzhou Enpei Instrument Co., Ltd., China). The changes of oil models in AV, PV, MDA, and cholesterol contents were detected at 3 h intervals.

2.4. Determination of color

The color changes of oil models during heat treatment were determined using a NH310 portable colorimeter (Shenzhen, China). The values of L*, a*, and b* were recorded for each sample, which represented that the color ranged from luminosity (−) to brightness (+), from greenness (−) to redness (+), and from blueness (−) to yellowness (+), respectively. The total color change (ΔE) of the oils was calculated according to the following equation (Shao et al., 2015):

where L0*, a0*, and b0* are the initial color values of samples, and Li*, ai*, and bi* denote the final color values of samples.

2.5. Assay of fatty acids composition

Fatty acid methyl esters (FAMEs) derived from oil models were analyzed by a 7890 A gas chromatography (Agilent Technologies, Palo Alto, USA) equipped with a flame ionization detector and a DB-WAX capillary column. The oven temperature was held at 150 °C for 3 min and then increased to 240 °C at a heating rate of 10 °C min−1. The temperature of the injector and detector was 250 °C.

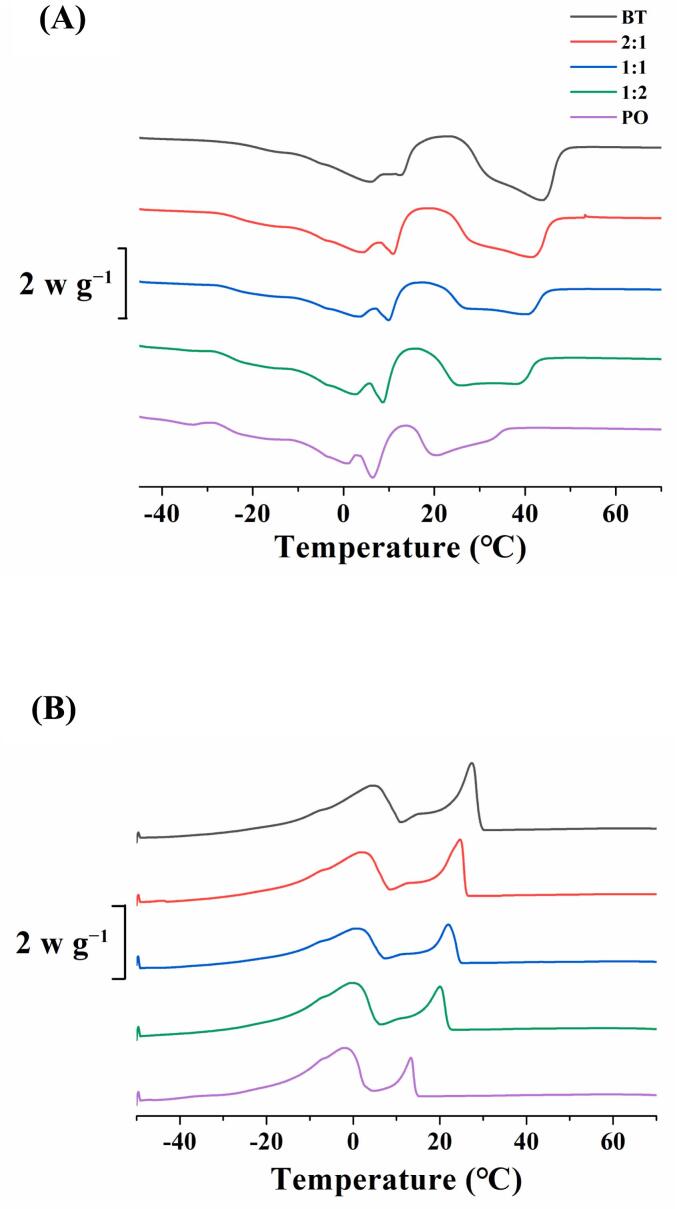

2.6. DSC measurement

The thermal properties of oil models were evaluated on a DSC (DSC-1, Mettler-Toledo corp., Switzerland) under a nitrogen atmosphere at a flow rate of 50 mL min−1. Approximately 5 mg of samples in 40 mL aluminum pans were heated to 70 °C until the complete melting of oil crystal structure and then cooled to −50 °C with a ramp rate of 10 °C min−1.

2.7. Morphology observation

An aliquot of sample deposited on a microscope slide was observed under an ECLIPSE E600W POL polarized light microscopy (Nikon, Tokyo, Japan) with a hot stage (Linkam ED600, UK) at 10 °C. A built-in camera was used to photograph crystal morphology of oil models with a 100× magnification.

2.8. Hardness test

Oil samples were compressed twice to 60 % of the original height at a time interval of 5 s, and the hardness was recorded on a Rapid TA texture analyzer (Tengba Technology Co., Ltd., Shanghai, China) with a cylindrical probe (P/50) under a trigger force of 5 g. The pre-test speed, test speed, and after-test speed were set at 2.0, 1.0, and 2.0 mm s−1, respectively (Huang et al., 2019).

2.9. E-nose measurement

An E-nose device (C-Nose, BosinTech Co. Ltd., Shanghai, China) was employed to assess the flavor of oil models at room temperature. 5.0 g of each oil sample in a 20 mL sealed vial was equilibrated at 40 °C in a water bath for 10 min. Clean and dry air was used as carrier gas at a flow rate of 1.0 L min−1 (Han et al., 2022).

2.10. Determination of volatile compounds by SPME/GC–MS

Before the experiments, oil models were heated to 80 °C and were added to make hotpot seasonings, respectively. Then, volatile compounds in hotpot seasoning with the oil samples were extracted using a solid phase micro-extraction (SPME) fiber (50/30 μm DVB/CAR/PDMS, Supelco Co., USA), and were further analyzed by a QP2010 SE GC–MS system (Shimadzu, Kyoto, Japan) equipped with a Rtx-Wax column of 30 m × 0.25 mm I.D. and 0.25 μm film thickness (Restek Corp., Bellefonte, PA, USA). The initial oven temperature was kept at 40 °C for 2 min, and was then increased to 100 °C at a rate of 3 °C min−1. When standing for 2 min, the temperature was finally increased to 280 °C at a rate of 5 °C min−1 and was held for 5 min. The flow rate of carry gas (helium) was fixed at 1.0 mL min−1. Mass spectra was set in the electron impact mode with an energy voltage of 70 eV and an ion source temperature of 250 °C, and was operated in the 35–400 m/z range (Zhou et al., 2025).

2.11. Statistical analysis

All the samples were freshly prepared and measured in triplicate. Experimental data was expressed as means ± standard deviations and was further analyzed by One-way analysis of variance (ANOVA). Statistical significance was confirmed when the p-value was <0.05. In addition, PCA was conducted to interpret the signal responses of the sensors in E-nose to the odor variations among oil models at different weight ratios using Origin 2018. A heat map was generated using TBtools software (version 2.110) to show similarities and differences in the concentration and composition of volatile compounds among hotpot oils.

3. Results and discussion

3.1. Changes of oil models in oxidation status and cholesterol content

As shown in Fig. 1A, beef tallow had the highest AV of 2.25 mg g−1. The addition of palm oil decreased the AV of the blending oil, and the corresponding values were 1.68 (2:1), 1.42 (1:1), and 1.21 (1:2) mg g−1, respectively. No obvious change of different oil models in AV was observed during 18 h of heating process, indicating that no rancidity occurred in oil samples as a result of triglyceride hydrolysis during heat treatment. Similar results were reported by the previous literature, in which no significant change in oil sample AV was observed under any of the heating treatment conditions (Zhang et al., 2021). The PV of the blending oil was also decreased by the addition of palm oil. The PV of oil samples remained unchanged and then showed a rising trend when heated more than 9 h (Fig. 1B), suggesting that the formation rate of primary oxidation products of oil models might be increased with heating time increasing over 9 h (Suri et al., 2020). However, the MDA content of different oil samples was significantly increased by heating treatment, but the MDA content was still much lower than 0.25 mg in 100 g sample according to the National Standard of China (GB 10146–2015). In addition, the cholesterol content of beef tallow was decreased by mixing palm oil, which may be very positive to reduce the incidence of cardiovascular disease (Xu et al., 2021). A decreased trend of cholesterol content in all oil models was observed during a heating period of 18 h. That might be associated with the formation of cholesterol derivative, resulting from the oil oxidation (Nourbehesht et al., 2018). Zou et al. (2022) mixed beef tallow with palm stearin to make Sichuan hotpot oil and also found that the addition of palm stearin could significantly reduce the cholesterol content.

Fig. 1.

Changes of different oil models in (A) acid value (AV), (B) peroxide value (PV), (C) malondialdehyde (MDA) content, and (D) cholesterol content during the heat treatment.

3.2. Changes in color during heat treatment

Color was considered as a direct indicator to evaluate the quality of hotpot oil. As shown in Fig. 2, the blending of palm oil to beef tallow at various weight ratios greatly influenced color values. The a* and b* values of beef tallow were decreased by the addition of palm oil, while the L* values did not change significantly until the weight ratio reached up to 2:1. When oil models were heated for 18 h, the a* values showed a declining trend. That might be associated with the generation of oxidation products, which might be degraded to volatile compounds with low molecular weight (Zepka et al., 2009). However, a similar trend was observed for b* and L* values. The b* and L* values of oil models increased during 9 h of heating process but decreased with heating time ranging from 9 to 18 h, indicating the fading in brightness and yellowness of oil models caused by heat treatment. Similar results have been reported by Zheng et al. (2018), who found that the deepening in the color of oil with an increase in heating temperature or time. Moreover, the ΔE values of oil models were increased rapidly at the beginning of heating, and then the growth rate decreased gradually with the increasing heating time. The blending of palm oil to beef tallow decreased the ΔE values of samples to less than 3, indicating that total color differences could not be easily distinguished (Obón et al., 2009).

Fig. 2.

Changes of oil models at various ratios in color values: (A) L*, (B) a*, (C) b*, and (D) ∆E.

3.3. Fatty acid composition

As expected, there were eight fatty acids detected in oil samples, including myristic acid, palmitic acid, palmitoleic acid, heptadecanoic acid, stearic acid, oleic acid, linoleic acid, α-linolenic acid (Table 1). The levels of saturated fatty acids in beef tallow and palm oil were 58.2 % and 46.0 %, in agreement with the previous findings by Li et al. (2018). The predominant saturated fatty acids in beef tallow were palmitic acid and stearic acid with the contents of 25.51 % and 26.82 %, respectively, while palm oil mainly consisted of palmitic acid (40.32 %) and oleic acid (43.03 %). The level of unsaturated fatty acid in palm oil was significantly higher than that in beef tallow. Thus, the levels of saturated fatty acids in blending oil were decreased to 54.3 % (2:1), 51.5 % (1:1), and 50.0 % (1:2), respectively, largely because of the addition of palm oil with a high content of oleic acid. Similarly, Mba et al. (2017) investigated the fatty acid composition of canola oil, palm oil, and their blend, and found that the blending oil showed an intermediate level between canola oil and palm oil. Mao et al. (2022) found that the saturated and unsaturated fatty acid ratio of palm oil was well balanced, and the blending of palm oil to beef tallow could provide the ability to meet the plasticity requirements of shortening products.

Table 1.

Fatty acid composition of oil models at various weight ratios.

| Fatty acids content (%) | BT | 2:1 | 1:1 | 1:2 | PO |

|---|---|---|---|---|---|

| Myristic acid (C14:0) | 2.93 ± 0.01a | 2.14 ± 0.09b | 1.73 ± 0.13c | 1.43 ± 0.03d | 0.79 ± 0.18e |

| Palmitic acid (C16:0) | 25.51 ± 0.17d | 30.41 ± 1.35c | 33.41 ± 0.04b | 35.73 ± 0.01b | 40.32 ± 1.47a |

| Palmitoleic acid (C16:1) | 1.29 ± 0.01a | 1.34 ± 0.09a | 0.96 ± 0.21b | 0.70 ± 0.87c | 0.12 ± 0.03d |

| Heptadecanoic acid (C17:0) | 1.70 ± 0.01a | 1.23 ± 0.67b | 0.85 ± 0.09c | 0.62 ± 0.25d | nd |

| Stearic acid (C18:0) | 26.82 ± 0.66a | 19.82 ± 2.37b | 14.81 ± 0.01c | 11.73 ± 0.57d | 4.51 ± 1.03e |

| Oleic acid (C18:1) | 4.98 ± 1.34d | 34.61 ± 0.76c | 37.41 ± 0.23b | 39.02 ± 0.79b | 43.03 ± 0.02a |

| Linoleic acid (C18:2) | 2.94 ± 0.54d | 5.44 ± 0.88c | 7.06 ± 1.62b | 7.99 ± 0.01b | 10.44 ± 0.05a |

| α-Linole nic acid (C18:3) | 0.26 ± 0.01a | 0.19 ± 0.01b | 0.17 ± 0.08b | 0.16 ± 0.04b | 0.13 ± 0.09b |

| Saturated fatty acid | 58.2 ± 0.12a | 54.3 ± 2.34b | 51.5 ± 0.89c | 50.0 ± 0.03c | 46.0 ± 2.11d |

| Unsaturated fatty acid | 41.8 ± 0.28d | 45.7 ± 1.01c | 48.5 ± 0.02b | 50.0 ± 0.05b | 54.0 ± 1.60a |

Results are expressed as mean values ± standard deviation of three replicates. Different letters in each row indicate significant difference (p < 0.05).

nd, not detected.

3.4. Thermal analysis

As shown in Fig. 3A, three broad endothermic peaks were observed in the melting process of beef tallow, and the corresponding temperatures (Tm) to melting peaks were 4.97, 13.08, and 43.41 °C, respectively. However, the melting curve of palm oil showed one sharp endothermic peak and two broad endothermic peaks centered at the temperature of 0.34, 6.60, and 20.38 °C, respectively. When beef tallow was mixed with palm oil, the three melting peaks of the blending oil occurred at the temperature ranging from 1.80 to 40.77 °C. In particular, the endothermic peaks of the beef tallow/palm oil blend at the weight ratio of 2:1 were similar to that of beef tallow, in accordance with the previous finding of Zou et al. (2022). Moreover, the endothermic enthalpy (ΔHm) of beef tallow were 4.69, 1.44, and 57.35 J/g, and the values of palm oil were 5.64, 8.66, and 25.17 J/g, while the ΔHm values of blending oil varied from 1.63 to 48.04 J/g due to the mixing of palm oil to beef tallow (Table 2). Fig. 3B presents the crystallization behavior of oil samples at various weight ratios. All the oil samples showed two crystallization peaks at the phase transition temperature of −1.90 - 4.69 and 13.33–27.38 °C, showing a slight hysteresis in the process of phase transformation between the peak temperature of crystallization peak and melting peak (Mao et al., 2023). With the increasing ratio of palm oil in the samples, two crystalline peaks of the blending oil shifted to the left, and the corresponding ΔHc values were 28.50–39.38 and 7.59–12.01 J/g, suggesting that fatty acid composition in the blends had a great impact on the melting and crystallization behavior (Meng et al., 2010).

Fig. 3.

(A) The melting and (B) crystallization curves of oil models at various ratios.

Table 2.

Melting and crystallization characteristics of different oil models.

| Fats | Melting property |

Crystallization property |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Peak 1 |

Peak 2 |

Peak 3 |

Peak 1 |

Peak 2 |

||||||

| Tm (°C) | ΔHm (J/g) | Tm (°C) | ΔHm (J/g) | Tm (°C) | ΔHm (J/g) | Tc (°C) | ΔHc (J/g) | Tc (°C) | ΔHc (J/g) | |

| BT | 4.97 ± 0.02a | 4.69 ± 0.67b | 13.08 ± 0.06a | 1.44 ± 0.71d | 43.41 ± 0.13a | 57.35 ± 0.22a | 4.69 ± 0.04a | 31.41 ± 1.71c | 27.38 ± 0.29a | 14.49 ± 0.09a |

| 2:1 | 4.25 ± 0.01a | 3.59 ± 0.66c | 10.89 ± 0.02b | 1.63 ± 0.63d | 40.68 ± 0.03b | 48.04 ± 0.96b | 2.12 ± 0.01b | 35.09 ± 2.35b | 24.65 ± 0.56b | 12.01 ± 0.77b |

| 1:1 | 3.61 ± 0.05b | 2.80 ± 1.16d | 10.14 ± 0.09b | 4.02 ± 0.12c | 40.77 ± 0.01b | 11.74 ± 1.00e | 0.66 ± 0.01c | 28.50 ± 2.84d | 21.96 ± 0.32c | 7.59 ± 1.29c |

| 1:2 | 1.80 ± 0.05c | 2.70 ± 1.48d | 8.78 ± 0.09c | 6.27 ± 1.64b | 25.61 ± 0.03c | 40.90 ± 0.28c | −0.19 ± 0.01d | 39.38 ± 1.41a | 20.07 ± 0.40c | 8.42 ± 0.78c |

| PO | 0.34 ± 0.26d | 5.64 ± 0.98a | 6.60 ± 0.61d | 8.66 ± 0.11a | 20.38 ± 0.18d | 25.17 ± 1.07d | −1.90 ± 0.01e | 38.00 ± 0.25a | 13.33 ± 0.19d | 6.88 ± 0.88c |

Results are expressed as mean values ± standard deviation of three replicates. Different letters in each column indicate significant difference (p < 0.05).

3.5. Crystal microstructure and hardness

The binary blends of beef tallow and palm oil were crystallized at 10 °C, and the crystal microstructures were observed under polarized light microscopy (Fig. 4A - E). Neat beef tallow showed a dense network formed from both clustered globular crystals and small needle-like crystals, while neat palm oil presented the morphology of fine feathery spherulites. When beef tallow was mixed with palm oil, the change of the blending oil in the microstructure occurred. The crystals aggregated to form larger clusters and higher density at the weight ratio of 2:1. That might be associated with a eutectic growth behavior, i.e., the 2-position of triacylglycerols component of palm oil grew on the peripheral of beef tallow seed crystals (Mahisanunt et al., 2020). As the weight ratio was changed to 1:1, the increased content of palm oil induced the formation of crystal nucleus with larger size, which could affect the texture and plasticity of oil samples (Nguyen et al., 2021). However, with the increasing ratio of palm oil content to 1:2, little change of crystals in the shape and size was observed, and the small crystal particles almost disappeared. Moreover, beef tallow and pail oil had the hardness of 252.03 and 7.47 g, respectively. The addition of palm oil into beef tallow decreased the hardness as the weight ratio of palm oil in the blends increased. However, the blending oil at the weight ratio of 2:1 showed no significant change in the hardness of beef tallow, probably due to the similar fat crystal network, which might be considered more desirable for Chongqing hotpot oil (Liu et al., 2010).

Fig. 4.

Crystal morphology of different oil models at 10 °C (scale bar: 25 μm).

3.6. Aroma attribute analysis of oil models

Fig. 5A shows the response signal intensity of each sensor in the E-nose to the aroma compounds of oil models. All the five samples showed similar signals in the profile of the radar map from 6 sensors including sn-07, sn-17, sn-18, and sn-19. However, each sensor responded differently to the samples. Sensors sn-07 and sn-17 had the highest response values, followed by the sensors sn-18 and sn-19, indicating that the odor intensity of corresponding volatile compounds to sensors sn-07 and sn-17 was higher (Chen et al., 2023; Jin et al., 2023). As the weight ratio of palm oil in models increased, the response value of sensor sn-07 and sn-17 increased, and a slight change of sensors sn-18 and sn-19 in the response intensity was observed, suggesting that the mixing of palm oil with beef tallow increased the content of short-chain alkanes and hydrogen-containing compound, and had a certain impact on the level of some aroma compounds such as aromatic hydrocarbon, esters, alcohols, aldehydes, and ketones (Shen et al., 2023).

Fig. 5.

(A) The radar chart and (B) PCA biplot of the electronic nose test for different oil models.

To further clarify the odor variations among oil samples with various mixing ratios, PCA was performed on the E-nose response values of samples. The results displayed that the cumulative variance contribution rate of the two principal components was 97.6 % (Fig. 5B), indicating that the majority of odor information in all samples could be elucidated by the first two principal components (Sun et al., 2024). The score plot showed a clear distribution of the oils according to the mixing weight ratio. Beef tallow had a negative value for PC1 and partly overlapped the x-axis. Palm oil showed negative PC1 and PC2 values, and was thus located in the third quadrant of the score plot. For the beef tallow/palm oil blend, the oil at the weight ratio of 2:1 partially overlapped on the y-axis and was closest to the distribution of beef tallow, indicating the typical similar characteristics to beef tallow (Yuan et al., 2023). However, the blending oil at 1:1 had positive and negative contributions to PC1 and PC2, respectively, which were located in the second quadrant of the plane. The oil at 1:2 had positive PC1 and PC2 values and was placed in the first quadrant of the plane, showing the distinctive behavior among all oils (Suri et al., 2020). Moreover, the oils at 1:1 and 1:2 were located on the right side of the biplot, indicating that the samples were positively correlated with the six sensors. The oil at 1:2 was positively correlated with sensors sn-07 and sn-17, while the oil at 1:1 was positively correlated with the other four sensors (Shao et al., 2023).

3.7. Volatile compounds identified by SPME/GC–MS

The volatiles were extracted from five hotpot oil samples by SPME and were identified by GC–MS. As shown in Fig. 6A, the identified volatiles in hotpot with beef tallow, blending oil at various weight ratios, and palm oil were grouped as alcohols, aldehydes, acids, esters, ketones, hydrocarbons, and others. In total, 58 volatile compounds were identified and quantitated in hotpot oil with beef tallow, of which aldehydes and hydrocarbons were the main volatile compounds, accounting for 27.08 % and 48.03 % of the total volatiles, respectively. The volatile compounds with high concentration from the two classes were trans-2-decenal (103.20 μg kg−1), 2,3-dihydro-1H-indene-4-formaldehyde (84.85 μg kg−1), nonanal (47.61 μg kg−1), (−)-isocaryophyllene (85.13 μg kg−1), octamethyl cyclotetrasiloxane (75.14 μg kg−1), and 2,2,4,4,6,6-hexamethylcyclotrisilazane (71.80 μg kg−1) (Table 1S). A total of 39 volatile compounds were detected in hotpot with palm oil. The major compounds in the volatiles were alcohols, aldehydes, and hydrocarbons, among which linalool (64.83 μg kg−1), (−)-4-terpenol (25.42 μg kg−1), citral (29.75 μg kg−1), trans-2-decenal (25.83 μg kg−1), myrcene (101.70 μg kg−1), (−)-isocaryophyllene (88.72 μg kg−1), dodecamethylcyclohexasiloxane (93.30 μg kg−1) had higher composition. Compared to palm oil, beef tallow showed the higher composition of aldehydes and the lower composition of ketones. These aldehydes had the odor descriptions like nutty, tallow, burning, and fruit (Song et al., 2014).

Fig. 6.

(A) The proportion and (B) heat map of volatile flavor compounds in different oil samples. Red color represents a high content, and green color indicates a low content. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

When the blending oils were used as hotpot oil, the alterations of five hotpot oils in the concentration and composition of volatile compounds were exhibited in a heat map. The oil samples from the five models were well distinguished by hierarchical cluster (Fig. 6B), and beef tallow and the blending oil at 2:1 were always grouped as closely, in agreement with those in the PCA (Dong et al., 2021). There were altogether 56 volatiles identified in the blending oil at 2:1, which mainly covered 5 alcohols, 12 aldehydes, 2 acids, 3 esters, 3 ketones, and 27 hydrocarbons. The main volatiles of the blending oil at 2:1 were similar to that of beef tallow, but the concentration of some volatile compounds such as nonanal (41.74 μg kg−1), (−)-isocaryophyllene (90.06 μg kg−1), and 2,2,4,4,6,6-hexamethylcyclotrisilazane (59.58 μg kg−1) changed. In addition, some specific ketones like piperitone (8.22 μg kg−1) and 2-hydroxy-4,6-dimethoxyacetophenone (6.58 μg kg−1) only appeared in the blending oil, which might provide the aroma properties of mint and Chinese pepper to the flavor of hotpot seasoning (Zhang et al., 2024). That could be associated with the types and composition of numerous volatiles in oil samples, which could participate in further thermal reactions as flavor precursors and produce a variety of volatile compounds that contributed to the flavor of overall sensory system (Song et al., 2017). As the weight ratio of palm oil to beef tallow was further increased, the types and related amount of flavor compounds in hotpot varied significantly among samples, in accordance with the result of E-nose measurement, indicating that oil models greatly influenced the flavor of hotpot oil, and the blending oil at 2:1 might be a potential replacer of neat beef tallow in Chongqing hotpot seasoning without reducing the flavor.

4. Conclusions

In this work, the impact of palm oil on the quality characteristics of Chongqing hotpot seasoning was investigated. The mixing of palm oil with beef tallow decreased the contents of cholesterol and saturated fatty acids in beef tallow, and increased the content of short-chain alkanes and hydrogen-containing compounds. The differences between the flavor of five oil models were completely distinguished by E-nose. The major volatile compounds in hotpot oil were hydrocarbons, followed by aldehydes, alcohols, esters, ketones, and acids. The concentration and composition of volatile compounds in hotpot seasoning significantly varied depending on the weight ratio of palm oil to beef tallow. The blending oil at 2:1 had similar melting and crystallization behaviors, hardness, crystal microstructure, as well as main volatiles to beef tallow compared with other oil models, which might be expected to develop as a resource for producing healthier and tastier Chongqing hotpot oil.

CRediT authorship contribution statement

Cen Zhang: Writing – review & editing, Writing – original draft, Methodology. Wenjing Lu: Formal analysis. Di Chen: Software. Yuhao Zhang: Formal analysis. Jie Li: Formal analysis. Zhongjun Gou: Formal analysis. Chaogeng Xiao: Validation, Supervision.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This study was financially supported by the Key Research and Development Program of Zhejiang Province (Grant No. 2022C04033).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.fochx.2025.102371.

Appendix A. Supplementary data

Supplementary material

Data availability

The authors do not have permission to share data.

References

- Chen L., Ning F., Zhao L., Ming H., Zhang J., Yu W.…Luo L. Quality assessment of royal jelly based on physicochemical properties and flavor profiles using HS-SPME-GC/MS combined with electronic nose and electronic tongue analyses. Food Chemistry. 2023;403 doi: 10.1016/j.foodchem.2022.134392. [DOI] [PubMed] [Google Scholar]

- Dong W., Chen Q., Wei C., Hu R., Long Y., Zong Y., Chu Z. Comparison of the effect of extraction methods on the quality of green coffee oil from Arabica coffee beans: Lipid yield, fatty acid composition, bioactive components, and antioxidant activity. Ultrasonics Sonochemistry. 2021;74 doi: 10.1016/j.ultsonch.2021.105578. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fattore E., Fanelli R. Palm oil and palmitic acid: A review on cardiovascular effects and carcinogenicity. International Journal of Food Sciences and Nutrition. 2013;64(5):648–659. doi: 10.3109/09637486.2013.768213. [DOI] [PubMed] [Google Scholar]

- Guo K., Wang Q., Xia T., Wang L., Song H., Yang L. Effect of smelting temperatures on the odor compounds of beef tallow through instrumental and sensory techniques. Journal of Food Composition and Analysis. 2023;119 doi: 10.1016/j.jfca.2023.105280. [DOI] [Google Scholar]

- Han L., Chen M., Li Y., Wu S., Zhang L., Tu K., Pan L., Wu J., Song L. Discrimination of different oil types and adulterated safflower seed oil based on electronic nose combined with gas chromatography-ion mobility spectrometry. Journal of Food Composition and Analysis. 2022;114 doi: 10.1016/j.jfca.2022.104804. [DOI] [Google Scholar]

- Huang X., Li J., Chang C., Gu L., Su Y., Yang Y. Effects of NaOH/NaCl pickling on heat-induced gelation behaviour of egg white. Food Chemistry. 2019;297 doi: 10.1016/j.foodchem.2019.06.006. [DOI] [PubMed] [Google Scholar]

- Jin G., Zhu Z., Wu Z., Wang F., Li J., Raghavan V., Li B., Song C. Characterization of volatile components of microwave dried perilla leaves using GC–MS and E-nose. Food Bioscience. 2023;56 doi: 10.1016/j.fbio.2023.103083. [DOI] [Google Scholar]

- Li K., Zhang L., Yi D., Luo Y., Zheng C., Wu Y. Insights into the volatile flavor profiles of two types of beef tallow via electronic nose and gas chromatography–ion mobility spectrometry analysis. Foods. 2024;13(10):1489. doi: 10.3390/foods13101489. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li Y., Zhao J., Xie X., Zhang Z., Zhang N., Wang Y. A low trans margarine fat analog to beef tallow for healthier formulations: Optimization of enzymatic interesterification using soybean oil and fully hydrogenated palm oil. Food Chemistry. 2018;255:405–413. doi: 10.1016/j.foodchem.2018.02.086. [DOI] [PubMed] [Google Scholar]

- Liu Y., Gao P., Wang S., Liu H., Yin J., Zhong W., Hu C., He D., Wang X. Investigation of hotpot oil based on beef tallow and flavored rapeseed oil in commercial hotpot seasoning. European Journal of Lipid Science and Technology. 2023;125(8):1–11. doi: 10.1002/ejlt.202300051. [DOI] [Google Scholar]

- Liu Y., Meng Z., Zhang F., Shan L., Wang X. Influence of lipid composition, crystallization behavior and microstructure on hardness of palm oil-based margarines. European Food Research and Technology. 2010;230:759–767. doi: 10.1007/s00217-010-1217-7. [DOI] [Google Scholar]

- Mahisanunt B., Hondoh H., Ueno S. Coconut oil crystallization on Tripalmitin and Tristearin seed crystals with different polymorphs. Crystal Growth & Design. 2020;20(8):4980–4990. doi: 10.1021/acs.cgd.0c00064. [DOI] [Google Scholar]

- Mao J., Gao Y., Meng Z. Crystallization behavior and compatibility analysis of beef tallow-based binary/ternary fat mixture systems. Food Research International. 2022;161 doi: 10.1016/j.foodres.2022.111814. [DOI] [PubMed] [Google Scholar]

- Mao J., Gao Y., Meng Z. Crystallization and phase behavior in mixture systems of anhydrous milk fat, palm stearin, and palm oil: Formation of eutectic crystals. Food Chemistry. 2023;399 doi: 10.1016/j.foodchem.2022.133877. [DOI] [PubMed] [Google Scholar]

- Mba O., Dumont M., Ngadi M. Thermostability and degradation kinetics of tocochromanols and carotenoids in palm oil, canola oil and their blends during deep-fat frying. LWT- Food Science and Technology. 2017;82:131–138. doi: 10.1016/j.lwt.2017.04.027. [DOI] [Google Scholar]

- Meng Z., Liu Y., Jin Q., Huang J., Song Z., Wang F., Wang X. Characterization of graininess formed in all beef tallow-based shortening. Journal of Agricultural and Food Chemistry. 2010;58(21):11463–11470. doi: 10.1021/jf102496p. [DOI] [PubMed] [Google Scholar]

- Nguyen V., Rimaux T., Truong V., Danthine S., Dewettinck K., Van Bockstaele F. Effect of milk fat concentration on fat crystallization of palm oil-based shortenings. Journal of the American Oil Chemists Society. 2021;98(1):115–125. doi: 10.1002/aocs.12426. [DOI] [Google Scholar]

- Nourbehesht N., Shekarchizadeh H., Soltanizadeh N. Investigation of stability, consistency, and oil oxidation of emulsion filled gel prepared by inulin and rice bran oil using ultrasonic radiation. Ultrasonics Sonochemistry. 2018;42:585–593. doi: 10.1016/j.ultsonch.2017.12.029. [DOI] [PubMed] [Google Scholar]

- Obón J., Castellar M., Alacid M., Fernández-López J. Production of a red–purple food colorant from Opuntia stricta fruits by spray drying and its application in food model systems. Journal of Food Engineering. 2009;90(4):471–479. doi: 10.1016/j.jfoodeng.2008.07.013. [DOI] [Google Scholar]

- Pang M., Zhang Q., Zhou J., Yin Q., Tan Q., Zhong X., Zhang Y., Zhao L., Yang Y., Hao Y., Wang C., Zhang P., Zhang L., Yang Y. Dietary patterns and environmental impacts of Chongqing hotpot in China. Resources, Conservation and Recycling. 2023;198 doi: 10.1016/j.resconrec.2023.107118. [DOI] [Google Scholar]

- Shao D., Venkitasamy C., Li X., Pan Z., Shi J., Wang B., Teh H., McHugh T. Thermal and storage characteristics of tomato seed oil. LWT- Food Science and Technology. 2015;63(1):191–197. doi: 10.1016/j.lwt.2015.03.010. [DOI] [Google Scholar]

- Shao Y., Liu X., Zhang Z., Wang P., Li K., Li C. Comparison and discrimination of the terpenoids in 48 species of huajiao according to variety and geographical origin by E-nose coupled with HS-SPME-GC-MS. Food Research International. 2023;167 doi: 10.1016/j.foodres.2023.112629. [DOI] [PubMed] [Google Scholar]

- Shen C., Cai Y., Wu X., Gai S., Wang B., Liu D. Characterization of selected commercially available grilled lamb shashliks based on flavor profiles using GC-MS, GC × GC-TOF-MS, GC-IMS, E-nose and E-tongue combined with chemometrics. Food Chemistry. 2023;423 doi: 10.1016/j.foodchem.2023.136257. [DOI] [PubMed] [Google Scholar]

- Song S., Tang Q., Fan L., Xu X., Song Z., Hayat K., Feng T., Wang Y. Identification of pork flavour precursors from enzyme-treated lard using Maillard model system assessed by GC-MS and partial least squares regression. Meat Science. 2017;124:15–24. doi: 10.1016/j.meatsci.2016.10.009. [DOI] [PubMed] [Google Scholar]

- Song S., Tang Q., Hayat K., Karangwa E., Zhang X., Xiao Z. Effect of enzymatic hydrolysis with subsequent mild thermal oxidation of tallow on precursor formation and sensory profiles of beef flavours assessed by partial least squares regression. Meat Science. 2014;96(3):1191–1200. doi: 10.1016/j.meatsci.2013.11.008. [DOI] [PubMed] [Google Scholar]

- Sun J., Ma M., Sun B., Ren F., Chen H., Zhang N., Zhang Y. Identification of characteristic aroma components of butter from Chinese butter hotpot seasoning. Food Chemistry. 2021;338 doi: 10.1016/j.foodchem.2020.127838. [DOI] [PubMed] [Google Scholar]

- Sun X., Yu Y., Wang Z., Akhtar K., Saleh A., Li W., Zhang D. Insights into flavor formation of braised chicken: Based on E-nose, GC-MS, GC-IMS, and UPLC-Q-Exactive-MS/MS. Food Chemistry. 2024;448 doi: 10.1016/j.foodchem.2024.138972. [DOI] [PubMed] [Google Scholar]

- Suri K., Singh B., Kaur A., Yadav M.P., Singh N. Influence of microwave roasting on chemical composition, oxidative stability and fatty acid composition of flaxseed (Linum usitatissimum L.) oil. Food Chemistry. 2020;326 doi: 10.1016/j.foodchem.2020.126974. [DOI] [PubMed] [Google Scholar]

- Xu C., Weng Z., Zhang L., Xu J., Dahal M., Basnet T.B., Gu A. HDL cholesterol: A potential mediator of the association between urinary cadmium concentration and cardiovascular disease risk. Ecotoxicology and Environmental Safety. 2021;208 doi: 10.1016/j.ecoenv.2020.111433. [DOI] [PubMed] [Google Scholar]

- Yavari A., Heshmati A., Hamedi M., Haghbin S. Effects of bleaching and deodorization processes of beef tallow on cholesterol removal by lecithin treatment. Journal of the American Oil Chemists' Society. 2009;87:109–114. doi: 10.1007/s11746-009-1477-1. [DOI] [Google Scholar]

- Ye Y., Ye S., Wanyan Z., Ping H., Xu Z., He S., Cao X., Chen X., Hu W., Wei Z. Producing beef flavors in hydrolyzed soybean meal-based Maillard reaction products participated with beef tallow hydrolysates. Food Chemistry. 2022;378 doi: 10.1016/j.foodchem.2022.132119. [DOI] [PubMed] [Google Scholar]

- Yuan N., Chi X., Ye Q., Liu H., Zheng N. Analysis of volatile organic compounds in milk during heat treatment based on E-nose, E-tongue and HS-SPME-GC-MS. Foods. 2023;12(5):1071. doi: 10.3390/foods12051071. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zepka L.Q., Borsarelli C.D., da Silva M.A.A.P., Mercadante A.Z. Thermal degradation kinetics of carotenoids in a cashew apple juice model and its impact on the system color. Journal of Agricultural and Food Chemistry. 2009;57(17):7841–7845. doi: 10.1021/jf900558a. [DOI] [PubMed] [Google Scholar]

- Zhang R., Chen K., Chen X., Yang B., Kan J. Thermostability and kinetics analysis of oil color, carotenoids and capsaicinoids in hotpot oil models (butter, rapeseed oil, and their blends) LWT- Food Science and Technology. 2021;152 doi: 10.1016/j.lwt.2021.112216. [DOI] [Google Scholar]

- Zhang W., Chen C., Li Y., Guo F., Liu W., Liu S., Sun Y., Wang X., Shen Y., Wang P. Analysis of composition and source of the key aroma compounds in stir-fried pepper tallow. Food Chemistry. 2024;441 doi: 10.1016/j.foodchem.2023.138321. [DOI] [PubMed] [Google Scholar]

- Zhang Z., He S., Zhang L., Li X., Jin R., Liu Q., Chen S., Wang J., Sun H. The potential application of vegetable oils in the D-xylose and L-cysteine Maillard reaction system for meaty aroma production. Food Research International. 2022;155 doi: 10.1016/j.foodres.2022.111081. [DOI] [PubMed] [Google Scholar]

- Zheng L., Jin J., Huang J., Wang Y., Korma S.A., Wang X., Jin Q. Effects of heat pretreatment of wet-milled corn germ on the physicochemical properties of oil. Journal of Food Science and Technology. 2018;55:3154–3162. doi: 10.1007/s13197-018-3243-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhou L., Zheng M., Zhang T., Wang S., Jiang X., Li B., Hu Z., Tse T., Reaney M., Nie Q., He D., Hu C., Zheng J., Lei F., Zhang Q. Chemical property, bioactive constituent and volatile compound changes of beef tallow during an improved flavor-retaining refining approach. Food Chemistry. 2025;477 doi: 10.1016/j.foodchem.2025.143491. [DOI] [PubMed] [Google Scholar]

- Zou S., Zhang Y., Wang Q., Yang L., Karrar E., Jin Q., Zhang H., Wu G., Wang X. Effect of palm stearin on the physicochemical characterization and capsaicinoid digestion of Sichuan hotpot oil. Food Chemistry. 2022;371 doi: 10.1016/j.foodchem.2021.131167. [DOI] [PubMed] [Google Scholar]

- Zou S., Zho U.J., Du Y., Cheng J., Wang Y., Zhang Z. Texture and volatile profiles of beef tallow substitute produced by a pilot-scale continuous enzymatic interesterification. Food Chemistry. 2023;429 doi: 10.1016/j.foodchem.2023.136980. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material

Data Availability Statement

The authors do not have permission to share data.