ABSTRACT

The shoulder joint is one of the functionally and anatomically most sophisticated articular systems in the human body. Both complex movement patterns and the stabilization of the highly mobile joint rely on intricate three‐dimensional interactions among various components. Continuum‐based finite element models can capture such complexity and are thus particularly relevant in shoulder biomechanics. Considering their role as active joint stabilizers and force generators, skeletal muscles require special attention regarding their constitutive description. In this contribution, we propose a constitutive description to model active skeletal muscle within complex musculoskeletal systems, focusing on a novel continuum shoulder model. Based on a thorough review of existing material models, we select an active stress, an active strain, and a generalized active strain approach and combine the most promising and relevant features in a novel material model. We discuss the four models considering physiological, mathematical, and computational aspects, including the applied activation concepts, biophysical principles of force generation, and arising numerical challenges. To establish a basis for numerical comparison, we identify the material parameters based on experimental stress–strain data obtained under multiple active and passive loading conditions. Using the example of a fusiform muscle, we investigate force generation, deformation, and kinematics during active isometric and free contractions. Eventually, we demonstrate the applicability of the proposed material model in a novel continuum mechanical model of the human shoulder, exploring the role of rotator cuff contraction in joint stabilization.

Keywords: active skeletal muscle, continuum mechanical shoulder model, finite element method, muscle material model, musculoskeletal modeling, parameter identification

We propose a constitutive model for active skeletal muscle designed for complex musculoskeletal systems based on a thorough review and comparison of existing approaches. We demonstrate its applicability in various numerical examples, including a large‐scale simulation of a novel continuum shoulder model.

1. Introduction

As one of the functionally and anatomically most complex articular systems in the human body, the shoulder joint combines mobility and stability in a unique musculoskeletal system. The anatomical structure of the involved glenohumeral joint allows for an extensive range of motion [1], while passive and active soft tissues ensure the joint's integrity through static and dynamic mechanisms [2]. Muscles, especially the rotator cuff and the deltoid, perform multiple essential functions. First, muscles actively stabilize the glenohumeral joint's bony structures through concavity compression [2, 3] and scapulohumeral balance [4, 5]. Second, muscles act as torque generators and enable complex movement patterns through their sophisticated interplay [6, 7]. Maintaining this delicate balance between mobility and stability is essential for proper shoulder function, yet it is easily disrupted by injury or pathological conditions [8, 9]. Despite the high incidence of shoulder disorders in clinical practice [10, 11], understanding of the underlying biomechanics remains limited. Developing objective, reliable diagnostic procedures and effective, monitorable treatments thus presents a major challenge for medical professionals and biomedical engineers.

Computational musculoskeletal models offer great potential to study the shoulder's biomechanics and physiology, investigate pathological conditions and (patient‐specific) treatments, and accelerate developments of medical devices such as surgical tools, implants, or rehabilitation equipment for physical therapy. While numerous reduced‐dimensional multi‐body models exist [12], research on comprehensive three‐dimensional continuum mechanical models remains limited. Especially in a joint as complex as the shoulder, three‐dimensional interactions between the geometrically complex components, sophisticated muscle fiber architectures [13], and directional material properties [14] are central to the shoulder's physiology. Here, continuum mechanical models can offer critical insights beyond those offered by reduced‐dimensional approaches and help to further improve these highly efficient and desirable reduced‐dimensional models.

Considering their role as active joint stabilizers and force generators, skeletal muscles deserve special attention regarding their constitutive description. Current shoulder models either apply purely passive material models neglecting the muscle's active properties or use active stress material models [15, 16] that generate internal forces and contractile deformations in response to a prescribed external stimulation.

Research on the constitutive modeling of active skeletal muscle is though fairly advanced. There exist various active constitutive models differing in the applied mathematical concept, rheological properties, modeled scales, and considered active force generation mechanisms.

Whether the active stress muscle material models [15, 16] used in existing shoulder models are the most suitable approach has not yet been investigated. The question of which material model best characterizes the shoulder's skeletal muscles at an appropriate level of detail while being computationally efficient and robust for such a large‐scale application remains open.

In this article, we aim to identify a suitable material model for modeling the active skeletal muscle components in a full three‐dimensional continuum mechanical model of the human shoulder. To achieve this, we comprehensively review existing approaches, conduct a detailed study of three selected material models, and ultimately integrate the most promising and relevant properties into a modified material model suitable for our application scenario.

In Section 2, we provide an overview of current musculoskeletal models for the human shoulder and conduct a thorough review of existing constitutive descriptions for active skeletal muscle. We place particular focus on constitutive descriptions applicable to continuum mechanical musculoskeletal simulations, although our research extends beyond this scope. From the reviewed material models, we select three hyperelastic material models for further investigation in Section 3: the active stress approach by Blemker et al. [15], which has already been applied to models of the human shoulder and knee; the microstructurally inspired generalized active strain approach by Weickenmeier et al. [17]; and the mathematically well‐posed active strain approach by Giantesio et al. [18]. Aiming to combine these models' most promising and relevant properties, we suggest a modified constitutive model tailored for application in complex musculoskeletal systems. We compare the four introduced skeletal muscle models considering physiological, mathematical, and computational aspects. We discuss the concepts of modeling active material behavior from a mathematical and physiological perspective, address analytical and numerical problems arising from the mathematical formulations, and analyze the included biophysical principles of force generation in terms of physiological correctness and relevance considering the modeling of the human shoulder. To establish a basis for a numerical comparison, we fit the material parameters to a common set of experimentally obtained stress–strain data from the literature in Section 4. Contrary to the original publications, we consider multiple active and passive loading conditions, as a single load case is generally insufficient to uniquely determine the material response. In Section 5.1, we investigate force generation, deformation, and kinematics during active isometric and free contractions using a fusiform muscle geometry as a simple example. Eventually, we demonstrate the applicability of the suggested material model in simulations of two complex problems. By the example of a two‐component muscle–bone model, we introduce an approach for incorporating complex activation patterns within the material model in Section 5.2. In Section 5.3, we present a full continuum mechanical model of the human shoulder, utilizing the proposed material model for the muscular components. We employ the model to simulate the concavity compression effect, a crucial stabilizing mechanism in the shoulder, where the active rotator cuff muscles pull the humeral head toward the glenoid fossa. Section 6 summarizes our key findings and discusses future perspectives.

2. Literature Review

2.1. Musculoskeletal Models of the Human Shoulder

Computational models of the human shoulder can be primarily categorized into multi‐body and continuum mechanical finite element models.

Reduced‐dimensional multi‐body models are based on rigid body dynamics and assume the body segments, that is, the bones, as non‐deforming rigid bodies. Muscles connect those rigid segments and are modeled as one‐dimensional line actuators. For muscles with a broad attachment area, multiple actuators can be defined. Often, these approaches apply wrapping methods to geometrically constrain the muscle force path and prevent penetration between muscle and bone [19, 20].

Because muscles are assumed to be simplified one‐dimensional objects that deform independently of each other, multi‐body models fail to capture a wide range of phenomena, such as contact or sliding interactions between the joint components, three‐dimensional (non‐uniform) deformations and stress distributions, or complex fiber arrangements and tendon morphologies. Despite these disadvantages, multi‐body models have been successfully applied in research and technology. Areas of application include investigations of movement actuation [21], muscle force and moment arm estimations [22, 23], and the simulation of neuromuscular control of prostheses [24] and surgical procedures [25]. A comprehensive overview of multi‐body models of the shoulder and upper extremity can be found in [12, 26, 27, 28].

In contrast, continuum mechanical models discretize muscles and other deformable structures in a full three‐dimensional fashion. These models can thus resolve internal stress and strain distributions and can account for contact and three‐dimensional interactions between geometrically complex parts. Further, implementations involving sophisticated muscle fiber arrangements [29, 30, 31] and tendon morphologies [16, 32], complex (nonhomogeneous) constitutive behavior [15, 16, 33], and spatially varying muscle activation can be realized [34, 35]. Of course, such models come with additional challenges that, for example, include an increased computational cost and a higher complexity regarding the geometric design, discretization, methods of contact modeling, and solution techniques.

While reduced‐dimensional multi‐body human shoulder models are common in the literature, only a few continuum‐based models of the entire human shoulder exist. We conducted a thorough review of existing continuum mechanical shoulder models and in the following briefly summarize our findings.

To provide an overview, Table 1 lists the reviewed models along with their distinctive features. The number of incorporated anatomical components varies, ranging from basic models incorporating only the most fundamental joint muscles to comprehensive models encompassing the entire upper limb musculature. Bones are commonly considered rigid bodies or, in some cases, integrated into the finite element (FE) discretization and assigned a comparably high material stiffness. Muscles are typically discretized using three‐dimensional tetrahedral or hexahedral elements, except for the surface‐based two‐dimensional modeling approach in [36].

TABLE 1.

Continuum mechanical models of the human shoulder in literature. Only models featuring at least one muscle actuating the glenohumeral (GH) joint are considered in this summary.

| Model description and objective | Model components | Discretization | Muscle material | Contact | |

|---|---|---|---|---|---|

| Büchler et al. [37] | FE model to quantify the impact of the humeral head shape on the stress distribution in the scapula | Humerus, scapula, subscapularis, supraspinatus, infraspinatus, cartilage in GH joint |

Bones: linear hexes, rigid surface elements Muscles, cartilage: linear hexes |

Passive exponential hyperelastic | Bone–muscle, GH joint |

| Terrier et al. [38] | FE model to investigate the biomechanical influence of a supraspinatus deficiency | Humerus, scapula, rotator cuff, deltoid, cartilage in GH joint |

Bones: rigid Muscles: linear hexes with truss elements for fibers, cables Cartilage: linear hexes |

Passive fiber reinforced hyperelastic Neo‐Hooke | Bone–muscle, GH joint |

| Metan et al. [39] | FE model to investigate stresses during adduction and abduction shoulder exercises | Humerus, scapula, clavicula, infraspinatus, subscapularis, deltoid, triceps, ligaments |

Bones: rigid, tets Muscles, ligaments: hexes, pents |

Passive linear elastic | GH joint |

| Duprey et al. [40] | FE model to predict injuries in impact scenarios based on the HUMOS full‐body model | Humerus, scapula, clavicula, several muscles, ligaments, skin |

Bones: shells, hexes Muscles: springs, shells, hexes |

Passive elastoplastic | Not defined |

| Inoue et al. [41] | FE model to investigate stress distribution in the rotator cuff tendons | Humerus, scapula, subscapularis, supraspinatus, infraspinatus, acrom. del‐toid, cartilage in GH joint | Hexes | Passive nonlinear elastic | GH joint, subacromial space |

| Zheng et al. [42] | FE model to investigate glenohumeral motion and contact mechanics of the GH joint | Humerus, scapula, clavicula, rotator cuff muscles, cartilage in GH joint, four GH joint ligaments | Tets | Passive linear elastic | GH joint |

| Teran et al. [43] | Finite volume model to simulate dynamic deformation, inversely compute muscular activation | Bones and 30 muscles of the upper limb |

Bones: rigid Muscles: tets |

Active stress material [15] | Muscle–muscle |

| Webb et al. [23] | FE model to examine muscle fiber paths and moment arms | Humerus, scapula, clavicula, rotator cuff muscles (incl. tendons), deltoid |

Bones: rigid surface elements Muscles, tendons: linear hexes |

Active stress material [15] | Muscle–muscle, muscle–tendon, bone–muscle |

| Pean et al. [22] | Comprehensive three‐dimensional FE model to investigate shoulder biomechanics | Humerus, scapula, clavicula, rotator cuff, deltoid, eight additional shoulder muscles |

Bones: rigid surface elements Muscles: linear hexes |

Active stress material [15] | Bone–muscle |

| Pean et al. [36] | FE model with surface‐based muscles to investigate shoulder biomechanics | Humerus, scapula, clavicula, rotator cuff, deltoid, eight additional shoulder muscles |

Bones: rigid surface elements Muscles: membrane elements |

Active stress material [15] | Bone–muscle |

| Assila et al. [16] | FE model to investigate pathomechanisms of the rotator cuff associated to wheelchair propulsion | Humerus, scapula, clavicula, rotator cuff and deltoid muscles (including tendons and epimysia) |

Bones: rigid shells Muscles, tendons: tets Epimysia: shells |

Presumably an active stress material combining [45, 46, 47] | Between all model components |

The majority of reviewed models neglect the active contractile behavior of muscle tissue [37, 38, 39, 40, 41]. Instead, they solely account for the passive response and prescribe external forces or displacements to generate movement. Typically, those models employ hyperelastic, transversely isotropic, nonlinear material models to account for the passive muscle characteristics. The work in [42] employs a linear elastic passive material model and defines one‐dimensional tensile stress states in the initial condition to simulate muscle contraction. More recent publications assign active constitutive laws to the muscular components such that the prescribed activation controls the motion. The most common approach is the active stress material model from [15], which has been applied in [22, 23, 43, 44]. Although it is not explicitly detailed in the text how active and passive contributions are combined, we presume that the model in [16] employs an active stress approach by adding an active stress contribution from [45] to a passive material model based on [46] and [47]. To the best of our knowledge, these two are so far the only active muscle material models applied in the context of continuum mechanical modeling of the human shoulder.

2.2. Constitutive Modeling of Active Skeletal Muscle

Research regarding the three‐dimensional constitutive modeling of skeletal muscle tissue is fairly advanced, and there exists a variety of elaborate material models for both the passive characteristics and the active contractile behavior. Typically, skeletal muscle is modeled with nonlinear, hyperelastic constitutive laws, for example, [15, 18, 48, 49]. Some authors, such as [50, 51, 52, 53, 54], choose viscoelastic approaches to incorporate rate‐dependent properties. Hypervisco‐poroelastic constitutive approaches are presented, for example, in [55, 56]. Due to the high water content, the tissue is mostly assumed to behave as a (nearly) incompressible material. Depending on the information incorporated, the constitutive models can be classified as purely phenomenological or multi‐scale. A common approach is to first consider the passive material behavior and then include the active characteristics.

2.2.1. Passive Constitutive Models

2.2.1.1. Fiber and Matrix Contributions

From a histological point of view, the muscle's passive behavior is governed by the extracellular matrix (ECM) and the passive contribution of the embedded muscle fibers. As the fibers are arranged in parallel bundles, most material laws assume a transversely isotropic fiber orientation in an isotropic tissue matrix.

Purely phenomenological models fit the constitutive behavior through mathematical formulations reflecting the experimentally observed behavior. Typically, the modeling of hyperelastic behavior starts with the definition of a strain‐energy function . In accordance with the histological composition of muscle tissue, a common approach is to additively split the strain‐energy function (where the index points to the passive contribution) into the two respective parts, and .

The most popular choice for is an isotropic Mooney–Rivlin constitutive law, as in [34, 43, 56, 57, 58, 59, 60, 61, 62, 63, 64, 65]. Other approaches apply Ogden‐type material models [16, 66], exponential Humphrey‐type constitutive laws [67, 68, 69, 70, 71, 72], quadratic polynomial functions [73, 74, 75], or simpler Neo‐Hooke [49, 76, 77, 78] and Saint‐Venant–Kirchhoff relations [79]. In [80, 81], the extracellular matrix material is modeled by a rubber‐like nonlinear stress–strain relation based on measurable physical muscle parameters. The work of Blemker et al. [15, 32, 82, 83] proposes a transversely isotropic model, accounting explicitly for the extracellular matrix resistance to a long‐fiber shear and cross‐fiber shear by two strain‐energy components. Building on prior work [78], a sophisticated model for the extracellular matrix featuring two preferred fiber directions for the included collagen fibers is presented in [84].

The passive muscle fiber stress contribution usually depends non‐linearly on the current fiber stretch. Common choices include exponential functions, for example, in [16, 49, 64, 76, 78, 85, 86] or polynomial functions, for example, in [33, 87]. Another popular option is a piecewise‐defined, experimentally‐based function [88] as seen in [15, 57]. The authors in [65] assume fibers are oriented in an ellipsoidal distribution, which allows for a direction‐dependent modulation of fiber stiffness.

Ehret et al. [48], and others in succession [17, 18, 89], circumvent an additive split into the matrix and fiber contributions by introducing a coupled exponential‐type model. A similar concept is applied in [90].

In contrast to what is called here purely phenomenological models, multi‐scale models exploit the hierarchical structure of skeletal muscle and incorporate micromechanical features. A common approach is to create representative volume elements for, for example, the fiber muscle cells and the extracellular matrix. Through homogenization techniques, the microstructural information is projected to the macro scale and incorporated into a constitutive law on the continuum level. Such approaches are found, for example, in [91, 92, 93, 94, 95].

A special concept is presented in [96], where skeletal muscle is modeled as an elastically linked system of two independently meshed domains for the fiber and matrix constituents.

2.2.2. Active Constitutive Models

2.2.2.1. Active Stress, Active Strain, Generalized Active Strain, and Mixed Approaches

To include the fibers' active contractile properties, two concepts—the active stress and the active strain approach—are commonly applied. Next to that, there exist so‐called generalized active strain approaches and mixed approaches combining the two concepts. For a detailed explanation, see [97, 98, 99, 100].

The active stress approach adds an active stress term to the passive stress component such that the stress tensor (here given as the second Piola–Kirchhoff stress tensor) reads . Often, the active fiber stress depends on an activation parameter that scales the maximal isometric active muscle force. In a rheological model, the active stress approach is represented by a parallel arrangement of a passive, elastic spring and an active element, see Figure 1a. Examples of such hyperelastic, viscoelastic and poro‐visco‐hyperelastic material models are [15, 34, 35, 61, 62, 76, 80, 86, 87, 101, 102], [53, 54, 77, 103, 104] and [55, 56], respectively. The main advantage of this concept is due to experimental practice and a straightforward interpretation of the active stress contribution [17, 48, 105]. In classical experiments on muscle tissue, both the muscle's force response in the passive resting state and the activated contractile state is tested. The characteristics of the resting state can then be attributed to the passive stress component, while the difference between the passive and the total activated stress–strain curve governs the active stress term [105]. Generally, the active stress tensor is considered a non‐conservative contribution as it is not derived from the potential energy [99]. The active stress approach may thus violate the principle of energy conservation, possibly leading to numerical instabilities or non‐physical predictions.

FIGURE 1.

Rheological models illustrating the different concepts of muscular activation as in [97].

Opposed to that, the concept of active strain relies on a multiplicative decomposition of the deformation gradient into . While the active contribution maps the reference configuration onto a stress‐free intermediate configuration, the elastic contribution maps from the intermediate configuration onto the current configuration. Since elastic energy is stored solely through , the strain‐energy function is expressed in terms of rather than . Active contractile characteristics are commonly incorporated through an activation parameter in the formulation of . A representative rheological model consists of a passive, elastic spring in series with an active element, as shown in Figure 1b. Hyperelastic and viscoelastic constitutive laws following the active strain approach can be found in [18, 77, 105] and [50, 51], respectively. Due to the mathematical construction of the active strain approach, the strain‐energy function inherits its mathematical properties from the underlying passive strain‐energy function [99]. This includes properties such as frame invariance and rank‐one ellipticity, which ensure that there is a guaranteed solution to the associated equilibrium equations [99]. These considerations do not apply for the active stress approach. In contrast to the active stress approach, the active contribution is not an experimentally observable quantity but rather more complex in its interpretation.

A generalized active strain concept was originally presented in [48] and later adapted in [17] and [89]. Active properties are included by increasing the invariant accounting for the passive longitudinal fiber characteristics by an active contribution , such that the combined invariant is . According to [97], this is equal to applying the multiplicative decomposition of the deformation gradient to a part of the strain‐energy function. A rheological representation is shown in Figure 1c. Advantage lies in the more physiological representation of the muscle tissue. On the cellular level, a sarcomere includes both an active component (actin–myosin complex) and a passive component (titin filaments) arranged in series [106]. Modeling muscle as a parallel arrangement of the serially arranged sarcomere components and an elastic component representing the passive connective tissue provides a more accurate representation of tissue characteristics than a pure active stress or active strain approach [48, 97].

Mixed approaches combine the principles of active stress and active strain approaches. These models include three components: a passive stress component , represented by the parallel spring in Figure 1d, an active stress component , represented by the parallel active element, and an active‐strain‐based component that depends exclusively on the partial deformation gradient and is represented by the serial arrangement of the spring and active element. As for the active strain approach, is derived from the multiplicative decomposition of the deformation gradient . Examples of such mixed approaches are [107, 108]. Mixed approaches are motivated by the commonly accepted physiological hypothesis that skeletal muscle tissue employs redundant pathways for stress transmission. The active stress approach assumes there is no elastic coupling between muscle fibers and the extracellular matrix, and the active stresses are directly transmitted by the muscle fibers. In contrast, the active strain approach assumes that stresses are transmitted through the extracellular matrix. By combining both approaches, mixed models thus aim to more accurately reflect the dual mechanisms of active stress transmission in skeletal muscle.

The approaches in [67, 68, 85] and similarly in [69, 70, 71, 72] are expansions of the classic so‐called Hill‐type model to three dimensions. In this case, the total muscle force is—equivalently to the generalized active strain approach—estimated by adding the forces from a passive spring and the serial arrangement of a passive spring and a contractile active element.

2.2.3. Activation Characteristics

2.2.3.1. Influences on Muscular Activation and Force Generation

A muscle's potential for force production is governed by various factors, such as its geometry, histological composition, neural activity, its current state of motion and deformation, and its contraction history. While geometric factors, such as size and fiber architecture, are considered in the geometric representation of the finite element model, histology‐, activity‐, and motion‐related factors are commonly included in the material description. In any of the concepts presented above, the active contribution, be it , or , involves the computation of an activation quantity accounting for a varying number of those effects.

Experimentally observable force‐stretch, force‐velocity, and force‐stimulation‐frequency dependencies are commonly included in a phenomenological fashion.

Thereof, the force‐stretch dependency is considered in most publications. Popular choices for its mathematical description include (piecewise‐defined) exponential [16, 33, 73], linear [61, 87], or parabolic [15, 34, 57, 75, 79] formulations. Besides that, sigmoid functions [77, 86, 101] and a normalized Weibull distribution [48, 70] were proposed in the literature. A detailed review and assessment of existing mathematical models describing the force‐stretch dependency is provided in [109].

Less common is the additional inclusion of a force‐velocity dependency. Often, a hyperbolic relation based on the work in [110] and [111] is chosen [48, 61, 64, 80, 101, 112]. Other authors present exponential and arcus‐tangent functions; see [63, 70, 72, 73] and [85].

The simplest approach to account for the neural activity (or, in other words, the stimulation frequency) is to linearly scale the active contribution with an activation factor; see, for example, [15, 62, 74, 75, 79]. To simulate temporal variations of muscular activation, for example, the successive build‐up of a fused tetanic contraction state, some authors include a time‐dependent activation function [64, 68, 69, 70, 71, 72, 73, 85]. More sophisticated formulations such as [61, 77, 80, 101, 112] resolve the time‐dependent activation level on the scale of milliseconds by a superposition of single muscle twitches. An additional composition into different fiber types, as proposed by Ehret et al. [48], featuring different twitch force amplitudes and frequencies, is accounted for by a weighted sum of the contributions. The work of [16] employs a model that describes active muscle tension in terms of relative calcium ion concentration. Since calcium concentration and neural excitation intensity are correlated, the authors prescribe normalized activation directly as model input.

Despite experimental evidence (see [89] for a summary), history‐dependent effects such as force depression and force enhancement are less commonly included in the constitutive description. To include these effects, the authors in [89] propose an extension of the constitutive law in [48] by a so‐called dynamic function. This function accounts for a dynamic force–velocity dependency and the effects of force depression and force enhancement by evaluating a differential equation. Opposed to this phenomenological approach, the work in [87] accounts for force enhancement effects on the micro‐scale. At the sarcomere level, force enhancement is primarily governed by actin–titin interactions. To incorporate these interactions, they combine their multi‐scale chemo‐electro‐mechanical model with a “sticky‐spring” mechanism for actin–titin interactions [113].

Other multi‐scale approaches link the macroscopic constitutive model to detailed mathematical descriptions of electrical, biophysical, and chemical processes at the microscopic level (see [114] for a comprehensive review).

Monodomain or bidomain equations are frequently used to model the action potential propagation along a muscle fiber, as seen in, for example, [34, 35, 66, 115, 116] and [117, 118], respectively. An approach integrating the mechanism of electromechanical delay, that is, the time difference between the muscle's stimulation and a measurable produced force, is further proposed in [66]. The authors of [119] incorporate an electric field that triggers mechanical activation once the electric potential exceeds a certain threshold. A phenomenological model of motor‐unit recruitment driven by neural activity is coupled to the continuum level in [58, 118].

Chemical processes such as calcium‐concentration‐driven muscle activation and calcium activation dynamics, that is, the release of calcium from the sarcoplasmic reticulum, are added, for example, in [34, 35, 76, 115] and [34, 35, 76]. To describe the de‐ and attachment of cross‐bridges during muscle contraction on a molecular level, partial differential equations based on the Huxley sliding filament theory are applied in [76, 120]. One of the most detailed descriptions of the electrophysiological behavior of a half‐sarcomere on the cellular level is presented in [121], and is coupled to continuum mechanical constitutive laws in [34, 35, 58, 118]. It models the entire pathway from electrical excitation to muscle cell contraction through differential equations, thereby including electrochemical models of the membrane electrophysiology, calcium (activation) dynamics, cross‐bridge dynamics, and fatigue.

Besides the basic modeling of physiologically realistic behavior of healthy skeletal muscle, the study of specific (pathological) biological processes is an ongoing research topic. Examples include models for damage [122], fatigue [34, 35], and age‐related loss of activation [123].

3. Material Models for Active Skeletal Muscle

The choice of an appropriate material model is essential to obtain physiologically realistic kinematics and stress results. Based on the literature review in the previous section, we select three material models for a detailed investigation. In addition, we propose a fourth modified material model that combines the most promising features of the three models from the literature into a skeletal muscle material model specifically tailored for application to human shoulder modeling.

Following a very brief introduction to the basic continuum mechanical quantities in Section 3.1, Section 3.2 summarizes the four investigated models and highlights the modifications made in our work. In Section 3.3, we compare the approaches and critically analyze the respective advantages and disadvantages before providing an interim discussion in Section 3.4.

3.1. Continuum Mechanical Basics

In nonlinear continuum mechanics, the deformation gradient , with the Jacobi determinant , serves as the primary measure of deformation. and denote the coordinates of a material point in current and reference configuration, respectively. The right Cauchy–Green tensor is an important quantity to calculate the strains with regard to the reference configuration and is defined as

| (1) |

Following a multiplicative decomposition of the deformation gradient into isochoric and volumetric parts, the modified right Cauchy–Green tensor , which describes the isochoric contribution, is introduced. All modified, that is, isochoric, quantities are indicated by in this work.

Hyperelastic material laws postulate the existence of a strain‐energy function . To account for the fiber direction in a transversely isotropic material model, a structural tensor can be incorporated into the strain‐energy function, such that . Assuming the fiber direction in reference configuration as the unit vector , the structural tensor is computed to . The stretch in fiber direction is

| (2) |

The second Piola–Kirchhoff stress tensor is derived from the strain‐energy function as

| (3) |

while the first Piola–Kirchhoff stress tensor results from the push‐forward operation

| (4) |

Solving a continuum mechanical problem with the finite element method, usually requires the linearization of the constitutive equation. Therefore, the forth‐order elasticity tensor is computed to

| (5) |

3.2. Selected Material Models

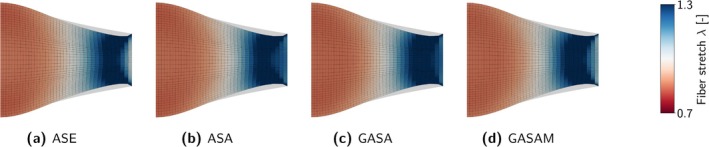

We evaluate three hyperelastic and nearly incompressible material models from the literature based on either the active strain, active stress, or the generalized active strain approach. In accordance with the anatomical predominant unidirectional fiber alignment on the local scale, all of the selected material models assume a transversely isotropic fiber distribution with respect to this preferred fiber direction. Blemker et al.'s active stress model [15], here named ASE, is chosen due to its successful application to several single muscles [32, 82, 124, 125] and muscle tissue parts [83] but also comprehensive models of the human shoulder [22, 23] and the human knee [126]. Weickenmeier et al.'s model [17], termed GASA, is selected because it incorporates muscle activation through a novel generalized active strain approach and allows for seamless integration of micromechanical data. Giantesio et al.'s model [18], abbreviated ASA, is a variant of the aforementioned GASA‐model but uses an active strain approach to include activation in a mathematically well‐posed manner.

In addition to these three models, we introduce a fourth material model, the GASAM‐model, which combines the optimal features of the previously mentioned models for our application to complex musculoskeletal systems.

Figure 2 provides a schematic overview of the constitutive laws. Table 2 summarizes material parameters and abbreviations used in the following.

FIGURE 2.

Schematic overview of the investigated constitutive laws for active skeletal muscle tissue.

TABLE 2.

Overview of the material parameters for the ASE‐, ASA‐, and GASA‐models in Blemker et al. [15] (used in this work in a variant, i.e., in combination with the Neo‐Hooke material model [127]), Giantesio et al. [18] and Weickenmeier et al. [17], respectively. Additionally, the table includes the material parameters for the herein‐proposed GASAM‐model.

| Passive material parameters | |||||

|---|---|---|---|---|---|

| ASE | ASA, GASA, and GASAM | ||||

|

|

Along fiber shear modulus |

|

Parameter related to along fiber properties | ||

|

|

Transverse fiber shear modulus |

|

Parameter related to transverse fiber properties | ||

|

|

Magnitude of passive along fiber tension |

|

Stiffness parameter | ||

|

|

Exponential growth rate of passive along fiber tension |

|

Weighting factor for isotropic tissue constituent | ||

|

|

Bulk modulus |

|

Incompressibility parameter | ||

|

|

Neo‐Hookean shear modulus | ||||

| Active material parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| ASE | ASA and GASA | GASAM | ||||||

|

|

Optimal fiber stretch |

|

Optimal fiber stretch |

|

Optimal fiber stretch | |||

|

|

Minimum linear fiber stretch |

|

Minimum fiber stretch |

|

Minimum fiber stretch | |||

|

|

Maximum isometric stress |

|

Number of activated MUs per reference cross‐section area |

|

Maximum active nominal stress | |||

|

|

Amplitude of time‐dependent activation |

|

Twitch force of MU

|

|||||

|

|

Frequency of time‐dependent activation |

|

Twitch contraction time of MU

|

|

Frequency of time‐dependent activation | |||

|

|

Interstimulus interval of MU

|

|||||||

|

|

Fraction of MU

|

|||||||

Note: For brevity, motor units are abbreviated as MU. A MU of type is denoted MU .

.

3.2.1. Active Stress Approach (ASE)

Blemker et al. [15] present a purely phenomenological material model with a fiber‐stretch‐dependent activation, named ASE in this work. Following the concept of active stress, activation is modeled by adding an active stress contribution to the passive stress. Near‐incompressibility is achieved through a decoupled strain‐energy function involving a purely isochoric part and a purely volumetric part .

The isochoric part is formulated with respect to the modified invariants

| (6) |

and the strain invariants

| (7) |

Considering the bulk modulus , the along fiber shear modulus , and the transverse fiber shear modulus , the proposed strain‐energy function reads

| (8) |

It involves the contributions and accounting distinctively for shear along and transverse to the fiber direction. The term can be attributed to active and passive tension and compression along the fiber direction ( and , respectively). With the total Cauchy fiber stress , is implicitly given by the equation

| (9) |

Accounting for the active stress, comprises an active part and a passive part . Considering the maximal isometric fiber stress , we compute to

| (10) |

The amplitude scales the active contribution. In contrast to the original formulation in [15], we introduce an additional time‐dependent function . By this integration, we can establish a time‐dependent activation profile comparable to one in the GASA‐model introduced in the upcoming Section 3.2.2. To mimic the successive build‐up of twitch forces up to a fused tetanized level, we choose the tanh‐function

| (11) |

with the frequency and activation start time . Setting results in the original material model in [15]. The functions and in Equation (10) account for the experimentally observed active and passive force‐stretch‐dependencies, respectively. Assuming the maximal isometric fiber stress occurs at the optimal fiber stretch , the active stretch‐dependency is given as in the original publication as

| (12) |

Different from the original formulation, we assume that passive fibers solely produce a stress response in all tensile states, that is, when and not as originally when . Considering the minimum linear fiber stretch and the parameters and , the passive stretch‐dependency reads

| (13) |

with

| (14) |

Since is now only involved in the computation of , the active and passive behavior is decoupled and the material parameters can be fitted to the two scenarios independently.

We provide the derivation of the second Piola–Kirchhoff stress tensor in Section A.1.1 of Appendix A for the reader's convenience, as these equations have not been published so far. The presented equations reflect the additive composition of a passive and an active stress component, as it is characteristic of the active stress concept. Details about the elasticity tensor derivation are given in Section S1.1 of the supporting information.

Remark 1

For passive compression along the fiber direction (that is, ), and in succession become zero. If shear contributions vanish as well, the entire stress response is zero (see also the remark in [90]). From a modeling perspective, this can be attributed to the fact that the material neglects the compressive stiffness of the fiber surrounding tissue. Instead, it solely incorporates components directly associated with the muscle fibers. To account for the influence of the fiber surrounding tissue and circumvent numerical difficulties arising from the lack of stiffness in plain compressive states, this work pairs the material model with the isometric Neo‐Hookean material model in [127] with the strain‐energy function .

Remark 2

The stress computation exhibits singularities in case the argument of in the invariant in Equation (7) becomes . To calculate the stress, the derivative of with respect to is formed and accounted for in the auxiliary variable (see Equation (A4)). The zero in the denominator thus leads to a singularity for the case that . In an analytical setting, we can compute the limit, such that . In a numerical evaluation, the singularity can be circumvented by adding a very small contribution to such that . This behavior can be attributed to the chosen invariants, initially published by Criscione et al. [128]. As previously noted by Bleiler et al. [93], the derivative of the invariant becomes singular in case of vanishing shears.

3.2.2. Generalized Active Strain Approach (GASA)

The generalized active strain approach by Weickenmeier et al. [17], here named GASA, is based on the fully incompressible model for passive and active muscle presented by Ehret et al. in [48, 80]. On this basis, Weickenmeier et al. [17] propose two compressible constitutive descriptions that model the muscle tissue as nearly incompressible. The so‐called coupled approach circumvents the commonly applied additive volumetric‐isochoric split of the strain‐energy function. Since it has been proven to be advantageous in maintaining incompressible behavior, we employ this coupled approach in our forthcoming studies. In contrast to the active stress and active strain concept, activation is achieved through the modification of an invariant.

The proposed strain‐energy function incorporates the material parameters , , and , and the incompressibility parameter . The weighting parameters and , related by , describe the percentage contribution of the extracellular matrix and the muscle fibers, respectively. While the structural tensor accounts for the muscle fiber alignment, the isotropic matrix contribution is included in the structural tensor . Considering the activation parameter , the two general invariants (with its passive and active parts and , respectively) and are introduced as

|

(15) |

Based on those quantities, the strain‐energy function is defined as

| (16) |

For the computation of the activation parameter , two assumptions are made: first, the model nominal stress response to a uniaxial deformation along the fiber direction matches the experimentally measured total nominal stress, and second, this measured total nominal stress can be additively decomposed into passive and active contributions. Based on these considerations, can be explicitly expressed in terms of the active nominal stress . Assuming is the principal branch of the Lambert function, given as the solution of the inverse function , the activation parameter is obtained as

| (17) |

(and its derivative with respect to , ), denotes the passive part of the first generalized invariant for uniaxial tension and are given in Equation (A5).

The active nominal stress accounts for the force‐stretch‐dependency through and for the force‐velocity‐dependency through . It further incorporates the term in which is the peak level of the active nominal stress, and is a dimensionless, normalized, time‐dependent function, such that

| (18) |

The total active force created by muscle motor units of type is calculated as the sum of the force responses at time weighted by the corresponding fraction in the muscle . then results from multiplication with the number of activated muscle units per unit reference cross‐section area according to

| (19) |

results from superposition of single twitches characterized by the experimentally observed microstructural quantities , , and . The twitch contraction time defines the time until the peak twitch force in the ascending phase of a single twitch response is reached [129, 130]. denotes the interstimulus interval. For a detailed explanation of the computation of , we refer to the original publication [48].

The stretch‐dependency is chosen as a function representing experimentally observed behavior. It depends on , the minimal fiber stretch at which myofilaments still overlap and , the fiber stretch associated to the maximal twitch force. Its mathematical description reads

| (20) |

For comparative reasons, the velocity‐dependency is neglected in this work and set to .

The derivation of the second Piola–Kirchhoff stress tensor has been published in [17]. For the reader's convenience, we provide the equation using our notation in Section A.1.2 of Appendix A. Similarly, the equations for the elasticity tensor are presented in Section S1.2 of the supporting information.

3.2.3. Active Strain Approach (ASA)

Based on the same incompressible model [48] as the compressible GASA‐approach [17] introduced in the previous section, Giantesio et al. [18] propose an active strain approach, here termed ASA. A common approach to enforce the incompressibility condition, that is, , is to add an additional contribution to the strain energy function that penalizes deviations from . To this end, we incorporate a volumetric penalty term similar to the coupled formulation in [17].

The active strain approach relies on a multiplicative decomposition of the deformation gradient into an elastic part , associated with the elastic deformation and an active part , resulting from an internal active deformation, such that . Considering the activation parameter , the active deformation gradient is defined as

| (21) |

The strain‐energy function is expressed in terms of the elastic Cauchy‐Green strain tensor instead of . With the elastic general invariants

| (22) |

the strain energy function thus reads

| (23) |

The computation of the activation parameter relies on the same two assumptions as mentioned for the GASA‐model. Consequently, is implicitly given as the solution of the equation

| (24) |

The generalized elastic invariants for uniaxial tension, and , are provided in Equation (A7), while their passive counterparts, and , are given in Equation (A5). The stretch‐ and time‐dependencies included in the above equation are formulated in the same fashion as for the GASA‐model, and are given in Equation (20) and (19), respectively. We apply a standard Newton–Raphson algorithm to determine from Equation (24).

Again, as a service to the reader, we present the derivation of the second Piola–Kirchhoff stress tensor in Section A.1.3 of Appendix A. Further, the derivation of the elasticity tensor is provided in Section S1.3 of the supporting information.

Since in the passive case , and thus and , the GASA‐ and ASA‐model coincide in absence of any activation. In the active case, the nominal stress in the fiber direction due to uniaxial loading along the fibers is identical. We recall, that both models determine the activation parameter such that the equation is fulfilled. Since and coincide, must also be equivalent.

3.2.4. A Modified Constitutive Description of Active Muscle Designed for Complex Musculoskeletal Models (GASAM)

Aiming to combine the optimal properties of the three material models proposed in the literature for our application, we introduce a fourth material model, referred to as the GASAM‐model. While the advantages of our modified model will be discussed in much detail in Section 3.3, we here present the constitutive equations. The GASA‐model from [17] serves as a basis. We perform two modifications:

We add the additional term , which takes into account the derivative , to in Equation (A6). A positive side effect of this modification is that can now be given by an explicit and computationally less expensive equation. For a detailed explanation, we refer to [18].

Instead of the elaborate calculation of via the superposition of the twitch forces, we use the smooth function . is now prescribed as a material parameter and specifies the amplitude of the tanh‐function.

The term is computed from the strain‐energy function in Equation (16) to

| (25) |

With the explicit formulation of the activation level in [18],

| (26) |

the derivative reads

| (27) |

The additional contribution to the elasticity tensor is provided in Section S1.4 of the supporting information. For a visual comparison between our modified model and the three models selected from the literature, we refer to Figure 2.

3.3. Comparison of the Selected Approaches

In the following, we analyze the presented material models and compare them considering the models' ability to represent physiological reality, their mathematical properties, resulting numerical challenges, and aspects of computational efficiency. Our goal is to assess the strengths and weaknesses of each model and, based on these theoretical aspects, provide a rationale for our preference for the modified material model.

3.3.1. Activation Concept

3.3.1.1. Physiological Representation and Mathematical Properties

In Section 2.2, we discussed the different activation concepts and assessed how well the models reflect physiological reality (consider the rheological representations in Figure 1). Comparing the four models against this background, the generalized active strain models (GASA and GASAM) stand out as the physiologically most plausible. They comprehensively represent the tissue structure and its mechanical properties, incorporating both serial elastic properties of the sarcomeres (titin filaments [106]) and the parallel elastic properties of the connective tissue [48, 97, 131]. The active stress model (ASE) accounts for the connective tissue's elasticity but neglects the sarcomeres' serial elasticity, while the active strain approach (ASA) captures the sarcomeres' active and passive elastic characteristics but disregards the connective tissues parallel contribution.

We have further outlined the mathematical properties associated with the different activation concepts in Section 2.2. As typical for the active strain approach, the ASA‐model's active strain‐energy function, preserves the elliptic properties of the underlying passive strain‐energy function, thereby ensuring well‐posedness of the associated balance equations (see [18] for a full discussion). For the ASE‐model, the active stress is not derived from a potential, as it becomes evident through the implicit definition of . Although we did not examine the model's elliptic properties in detail, we emphasize that the well‐posedness of the equilibrium problem is not given by construction, but depends on the specific active stress tensor.

3.3.1.2. Passive Material Model

Examining the passive material models, we find differences in the construction of the model equations and the parametric control of model properties. The ASE‐model separates the contributions for different loading modes, with the parameters , , and distinctively addressing along fiber shear, transverse fiber shear and along fiber tension. In our variant, the Neo‐Hookean contribution accounts for the isotropic ECM stiffness through the parameter . Conversely, the GASA‐, ASA‐, and GASAM‐model exhibit a more convoluted structure, where the parameters , , and describe the combined properties of anisotropic fibers and isotropic ECM. For the GASA‐, ASA‐, and GASAM‐model, the degree of anisotropy can be easily controlled through . The ASE‐model links the anisotropic invariant with several parameters, making it more challenging to control the level of anisotropy.

It could be argued that splitting the stress response into components associated with distinct loading modes (ASE‐model) simplifies fitting the model stress to experimental measurements. However, as further discussed in Section 4, fitting the combined stress response (GASA‐, ASA‐, and GASAM‐model) has also proven to be straightforward. Against this background, we do not prefer one material model over the other.

3.3.2. Activation Level

3.3.2.1. Implicit or Explicit Computation

In the ASA‐model, computing the activation parameter involves solving an implicit equation, introducing additional numerical challenges associated with the iterative solver, including the selection of step size and initial guess, as well as possible convergence problems. While we have not conducted specific tests to precisely determine its impact on the computation effort, we expect and experienced this to perform worse than an explicit computation. As is implicitly defined, its derivatives are approximated using central differences. Selecting an appropriate step size for the central differences scheme thus presents a manageable yet additional challenge.

For the GASA‐model, the activation parameter is explicitly given. However, its computation involves the principal branch of the Lambert W function, , which is defined implicitly. Here, the same considerations as above apply.

The GASAM‐model includes the additional stress contribution , which leads to a fully explicit expression for . This explicit computation of the activation level avoids potential difficulties associated with the application of iterative solvers and is computationally more efficient. Similarly, the ASE‐model formulae contain no additional implicit equations, and the same advantages are applicable.

3.3.2.2. Force‐Stretch‐Dependencies

A closer look at the active force‐stretch‐dependencies and in Figure 3 reveals some numerically problematic and physiologically unrealistic features. Due to the non‐smooth definition of the GASA‐, ASA‐, and GASAM‐model's stretch‐dependency in Equation (20), and, in conclusion, also the stress response is not continuously differentiable at . While this could potentially lead to numerical difficulties, such as convergence problems of the implicit solver when transitioning the critical point , we did not experience such issues. In contrast, the ASE‐model's stretch‐dependency in Equation (12) is continuously differentiable in the entire stretch regime. For values and , the stretch‐dependency , however, shows an unphysiological rise. The convergence to zero values for large fiber stretches and the absence of an active contribution for values below a certain minimal stretch is thus better captured by the GASA‐, ASA‐, and GASAM‐model's . We further note that is symmetric with respect to , whereas can represent non‐symmetric force‐stretch relations.

FIGURE 3.

Active force‐stretch dependencies in Equation (20) and in Equation (12).

For both and , the parameter represents the fiber stretch related to the maximal isometric active stress. In , the parameter describes the minimal fiber stretch at which muscle activity is observed—an experimentally measurable and interpretable quantity. In contrast, with , this value is preset to , which limits the options for adjusting the minimal actively contracting fiber length.

Apart from the active stretch‐dependency , the ASE‐model considers the passive stretch‐dependency (see Equation (13)) depicted in Figure 4. Similarly, this function is not continuously differentiable at . We further note that the parameter is a pure phenomenological quantity with no physiological meaning.

FIGURE 4.

Adapted passive force‐stretch‐dependency in Equation (13). The original in [32] is zero for .

3.3.2.3. Time‐Dependent Activation Functions

Figure 5 compares the time‐dependent activation functions and . While the superposition of individual twitch forces in the computation of for the ASA‐ and GASA‐model is crucial for observing the time‐dependent evolution of active forces at a millisecond scale, it can be disregarded for our application. Still, we acknowledge the use of physical, experimentally measurable, and well‐interpretable microstructural parameters in . Due to its lower computational expense, we opt for the time‐dependency proposed for the ASE‐model and adopted in the GASAM‐model for this application.

FIGURE 5.

Time‐dependent activation functions in Equation (19) and in Equation (11).

3.3.2.4. Consistency of Stress Tensor Derivation

Comparing the stress terms of the ASA‐ and GASA‐model in Equations (A9) and (A6), we notice that the ASA‐model's stress response considers the dependence of the activation parameter on the stretch in the stress derivation through the term . As already pointed out in [18, 108], the GASA‐model neglects this dependency. Our GASAM‐model explicitly accounts for this dependency through the term defined in Equation (25). Whether these terms should be included will be discussed below, considering mathematical and physiological aspects.

All four models are based on the assumption that muscle tissue behaves as a hyperelastic material. Within the mathematical framework of hyperelasticity, stresses are derived from an underlying strain energy potential (expressed through the strain energy density function). Given this fundamental assumption, it is mathematically consistent to include the additional stress term and . Neglecting these terms compromises the hyperelastic model's internal consistency and its inherent mathematical properties.

From a physiological perspective, the interpretation of and is less clear. and account for the dependence of the activation parameter on the stretch , or more generally speaking, the dependence of the active muscle force on the deformation. Active muscle force is generated by cross‐bridge formation between actin and myosin filaments. Modeling muscle as purely hyperelastic implies that these cross‐bridges store elastic energy. As long as the cross‐bridges remain intact, this assumption can be considered valid (see [132] for details on the elastic properties of the myosin head). Once actin and myosin filaments detach and slide past each other, elastic energy storage is no longer possible. Maintaining the cross‐bridge linkage requires metabolic energy (ATP), which a purely mechanical hyperelastic model cannot account for.

Neglecting the terms and means that in the strain energy density function, the activation parameter is regarded as constant and, as such, deformation‐independent. As a result, the active muscle contribution is treated as not storing elastic energy. Physiologically, this would imply that the intact cross‐bridges are considered inelastic. Even though the cross‐bridge elasticity and the metabolic energy required to sustain the linkage could balance each other out, we do not have enough certainty to conclude that.

Consequently, we opt to incorporate the terms and (as done for the GASAM‐model) such that the model remains mathematically consistent within the assumption of hyperelasticity. Still, neglecting the metabolic energy contributions remains a limitation that a purely hyperelastic model cannot overcome.

3.3.2.5. Numerical Treatment of Singularities

Circumventing the singularities in the computation of the ASE‐model invariant's derivative, mentioned in Section 3.2.1, involves adding a small numerical contribution. While this is considered to not affect the solution to a considerable extent, it is not particularly elegant.

3.4. Discussion

In the following, we provide an interim summary outlining our rationale for favoring the GASAM‐model based on the theoretical aspects discussed and address the remaining limitations.

We believe the GASAM‐model strikes a balanced trade‐off between physiological plausibility, mathematical consistency, and computational efficiency. We consider the employed generalized active strain approach physiologically more plausible than the active stress and active strain approaches used by the ASE‐ and ASA‐models. Unlike the GASA‐model, the GASAM‐model explicitly includes the term , ensuring the deviation is consistent with the underlying assumption of hyperelasticity. Further, the GASAM‐model offers an explicit expression for the activation parameter, which is computationally less costly and avoids the challenges associated with the implicit computations seen in the GASA‐ and ASA‐models. Compared with the GASA‐model, the GASAM‐model uses the computationally cheaper yet sufficiently accurate time‐dependency . Additionally, the force‐stretch dependency correctly captures the decay of active force at large stretches and its absence below a minimal stretch (unlike the function used by the ASE‐model). Finally, minor numerical issues, such as the singularities observed in the ASE‐model, are not a concern.

Despite the advantages of the proposed GASAM‐model, some limitations remain. As we focused on purely hyperelastic approaches, we neglected viscous phenomena and history‐dependent activation properties, such as force enhancement and depression. Depending on the particular problem, these effects can be of significant influence and may need to be incorporated into the model (see, e.g., [89]). Additionally, metabolic processes associated with muscular activation are not captured by a purely hyperelastic modeling approach. Mixed active‐stress active‐strain approaches were not investigated, though they may offer a more physiological description of the dual mechanisms of active stress transmission in skeletal muscle.

4. Material Parameter Identification

The material parameters provided in the original publications were determined based on experimental data that differed across the publications. To establish a basis for comparison between the four materials, we fit their parameters to a common set of experimental stress–strain data. One load case is generally not enough to uniquely determine the material response. Unlike the original publications, we thus consider multiple active and passive load conditions to determine a unique set of parameters representing the experimentally observed data. To this end, we compute the analytical stress as a function of a given deformation and use this function to fit the material parameters to the experimental stress–strain curves. The material models are implemented into the solid finite element framework of the comprehensive and well‐tested open‐source research simulation code 4C (implemented in C++) [133]. For verification purposes, we compare the numerically calculated stress responses with the analytical solutions.

4.1. Experimental Data and Associated Load Cases

The experimental data serving as a basis for the subsequent fitting of the material parameters was selected according to the following criteria. If available, we preferably chose human specimen data. Since we are interested in the continuum mechanical characteristics rather than the behavior of isolated fibers, we only consider muscle tissue sample data for the fitting. To ensure the comparability of experimental results across different load cases, we use data obtained at comparable quasi‐static strain rates ().

In total, data corresponding to six different load cases is incorporated into the fitting. Table 3 gives an overview of the load cases and their abbreviations, the respective literature reference, and whether the data was obtained in the active or passive muscle state. While the passive muscle material behavior is fitted to data representing all six load cases, the active response is fitted solely to data obtained from uniaxial tension along the fiber direction. To the best of our knowledge, unfortunately, there is no published data testing the active muscle response in load cases different from uniaxial tension.

TABLE 3.

Experimental data used in the parameter fitting: Load case, muscle state, abbreviation, and reference.

| Abbreviation | Load case | State | Reference |

|---|---|---|---|

| UTCAF | Uniaxial tension and compression along fiber direction | Active | [134] |

| Passive | [135], mean of supraspinatus and deltoid measurements | ||

| UTCTF | Uniaxial tension and compression transversal to fiber direction | Passive | [14] |

| SAF | Simple shear along fiber direction | ||

| PSAF | Pure shear along fiber direction | Passive | [136], mean of measurements of differently sized samples |

| PSTF | Pure shear transversal to fiber direction | ||

| PSTIF | Pure shear transversal to isometrically constrained fibers |

With the muscle fibers aligned in the e 3‐direction, the deformation gradients corresponding to the aforementioned load cases are listed in Table 4.

TABLE 4.

Load cases and associated deformation gradients for which the stress response is computed analytically and numerically during the material parameter fitting.

| UTCAF | UTCTF | SAF | PSAF | PSTF | PSTIF | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

Note: The cubes' dimensions are with , and the geometry is discretized using one linear hexahedral element. Muscle fibers are aligned in e 3‐direction and indicated in red. The deformation is expressed in terms of the stretch and the shear (only for SAF). The Dirichlet boundary conditions enforcing the respective deformation in the simulation are detailed in Table A1 in Appendix A.

The experimental data used in this study originates from different publications with variations in, for example, the experimental test setup, the tested species, or the specimen size and constitution (intact muscle [134] vs. tissue samples [14, 135, 136]). Although we have made efforts to select comparable data, the experimental data may exhibit inconsistencies compared with a dataset where all load scenarios were investigated under a unified experimental setup. While such a dataset would offer greater consistency, to the best of our knowledge, it is unfortunately unavailable. Given these variations, we are cautious about drawing overly strong conclusions considering the alignment of the model responses with the experimental data and focus on comparing the model responses to one another.

4.2. Analytical Stress–Strain Responses

As noted in [17] and [15], the compressible and incompressible formulation of the material models described in Section 3 coincide for the case that the incompressibility parameters and , respectively, approach infinity. In contrast to the nearly incompressible formulations presented in Section 3, for an analytical interpretation, we consider the fully incompressible formulations as also given in [18] for the ASA‐model and in [48] for the GASA‐model. The fully incompressible formulation of the ASE‐model is obtained as the isochoric contribution with the unmodified strain measures and invariants. In the simulation, we then apply appropriate incompressibility parameters and to recover the close‐to incompressible state.

With the deformation gradients for the six load cases in Table 4, we derive the first Piola–Kirchhoff stress in the respective load direction. The analytical expressions are provided in Table A2 in Appendix A. Analyzing the equations highlights the importance of using multiple load modes for the fitting of the passive material parameters. As an example, fitting the ASE‐model to experimental data solely obtained from UTCAF would result in arbitrary values of the parameters and , as those do not appear in the corresponding equation in Table A2.

4.3. Parameter Identification Through a Least‐Squares Fit

We fit the material parameters of these analytical stress–strain responses to the experimental data in Table 3 by solving a least‐squares minimization problem. For this purpose, we employ the Trust Region Reflective algorithm [137] implemented in the scipy.optimize.least_squares method from the Python SciPy library (version 1.7.2) [138]. For the interested reader, bounds and initial guesses for the optimization parameters are provided in Section S2 of the supporting information.

Since the experimental data for the active load case UTCAFact was obtained under isometric conditions at a tetanic activation level [134], the time‐dependent activation functions and are set to . This also means that the parameters involved in the computation of and cannot be determined from the experimentally determined stress–strain curves. Still, the active parameters , , , and in are physically measurable micromechanical quantities whose values we adopt from [48]. To create a comparable time‐dependent activation function , its parameter , governing the time‐dependent rise of the activation, is set to match the slope of . Figure 5 shows the two normalized functions.

4.4. Results

Table 5 lists the parameter values obtained from the fitting and the literature. The experimental data and the analytical and computational results are shown in Figures 6 and 7 for the passive and active load cases, respectively. Table A3 in Appendix A lists the computed error measures.

TABLE 5.

Material model parameters fitted to the experimental data listed in Table 3.

| ASE | GASA and ASA | GASAM | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

0.1000 | kPa |

|

2.3796 | — |

|

2.3796 | — | |||

|

|

0.0500 | kPa |

|

0.5161 | — |

|

0.5161 | — | |||

|

|

3.6055 | — |

|

27.1072 | kPa |

|

27.1072 | kPa | |||

|

|

4.4883 | — |

|

0.6388 | — |

|

0.6388 | — | |||

|

|

10,000 | kPa |

|

1000 | — |

|

1000 | — | |||

|

|

1.2264 | — |

|

1.1806 | — |

|

1.1806 | — | |||

|

|

1.4000 | — |

|

0.5680 | — |

|

0.5680 | — | |||

|

|

1.1450 | kPa |

|

0.4619 | mm−2 |

|

64.6809 | kPa | |||

|

|

69.5471 | — |

|

2.5, 4.4, 76.8 | 0.001 N |

|

34.4017 | — | |||

|

|

34.4017 | — |

|

0.02, 0.011, 0.011 | s | ||||||

|

|

10 | kPa |

|

0.004, 0.004, 0.004 | s | ||||||

|

|

0.05, 0.29, 0.66 | — | |||||||||

Note: , , , and are considered fixed and adopted from [48]. is set to match the slope of .

FIGURE 6.

Passive stress‐stretch responses with fitted parameters for six different load cases alongside the experimental data listed in Table 3. Results of the analytical equations are plotted alongside the numerical results. The obtained curves overlap because the results are nearly identical.

FIGURE 7.

Active stress‐stretch responses with fitted parameters for six different load cases. For the sake of a better visibility, the plotting resolution is chosen such that only the twitch maxima are depicted for the ASA‐ and GASA‐model. Since in the active case only experimental data from uniaxial tension in the fiber direction was used for the parameter identification, the remaining load cases show solely the numerically obtained stress–strain response.

As expected, the nearly incompressible formulations used in the simulation coincide with the analytical incompressible responses for the chosen incompressibility parameters. Further, as designed, the passive responses for the GASA‐, ASA‐, and GASAM‐model coincide.

4.4.1. Goodness of Fit

As mentioned, we keep the evaluation of the goodness of fit concise and refer to Section A2.2 of Appendix A for a full quantitative analysis of the models' alignment with experimental data.

Qualitatively, all material models approximate the experimental data reasonably well. An exception is the UTCTF load case in tension. Contrary to the experimental data, which suggests a stiffness increase for rising stretches, the fitted stress responses flatten. Quantitatively, the accuracy of different models in representing the experimental data varies depending on the specific load scenario and stress–strain range.

4.4.2. Differences Between the Model Stress Responses

Where no experimental data was available, the stress responses of the different material models are—to no surprise—different. Although qualitatively, the model responses are comparable, quantitatively there are major differences.

First, we evaluate the results for passive muscle. For compressive states of UTCTF and tensile states of PSTIF, the ASE‐model behaves slightly stiffer than the other models. The opposite is true for compressive states of UTCAF. Differences between the material models for tensile states of PSAF and PSTF are minor.

Considering the active muscle behavior, we observe significant differences between the computational material model responses for PSTIF, SAF, and compressive states of UTCTF. In all three cases, the ASE‐model behaves the least stiff, followed by the ASA‐model. Contrarily, deviations between the material model responses are comparably small for UTCTF in tension, PSAF, and PSTF.

4.5. Discussion

Recalling that the experimental data originate from multiple publications with potential variations in the experimental conditions, we consider all models to provide reasonable quantitative approximations. While all models fail to capture the increase in stiffness with rising stretches for the passive UTCTF load case in tension reported by [14], it is worth noting that other experimental sources report a decrease in stiffness with increasing stretches [139, 140], which would align more closely with the model predictions.

Differences between the ASE‐model response and the other three are partly explained by the non‐matching passive material model responses. Deviations between the GASAM‐ and GASA‐model are caused by the additional stress term . Since all active material parameters can be uniquely fitted through the UTCAF load case, we rule out the possibility that the differences are due to random, undetermined parameters. Instead, the remaining differences are attributed to the use of different activation concepts. Specifically for the active SAF load case, the results presented in [98] support our hypothesis. The authors report that active stress and active strain concepts yield different results in shear, even when both fit uniaxial tension data. Consistent with our findings, they observe that the active stress model predicts lower stresses than the active strain model.

Considering the ability to represent the experimental data, we rate no single material model universally superior to the others. Further experimental evidence is necessary to determine which model more accurately represents reality. The verification of the passive material response could be extended by experimental data from additional load cases, such as planar biaxial loading [141]. While multiple load cases for the passive muscle were considered, only uniaxial compression/tension tests were used for the active muscle. Experimental measurements of transverse and shear stress‐stretch responses for active muscle tissue would provide further insights into which material model yields the physiologically most accurate predictions.

5. Numerical Examples

To demonstrate the applicability of the material models to biomechanically relevant scenarios—in particular human shoulder biomechanics—and investigate the material behavior using the fitted parameters, we consider three numerical examples: A simple fusiform muscle, a two‐component model consisting of one bone and one muscle, and a full human shoulder model. Simulations are again conducted using 4C [133].

5.1. Fusiform Muscle Contraction

5.1.1. Geometry and Mesh

In the first step, we consider the geometry of a fusiform muscle with length in the e 3‐direction and a circular cross‐section with varying radius as depicted in Figure 8a. The outer contour along the e 3‐axis is described by spline curves through the points , , and such that the muscle's radius increases from at the ends to at its center. We choose , , and . With reported mean cross‐section areas of [142], [143], and [144], and lengths of [145], those measures approximately represent an average‐sized teres minor muscle.

FIGURE 8.

Fusiform muscle geometry, mesh, and fibers.

We use Cubit 13.2 [146] to create linear hexahedral element meshes with three different refinement levels as specified in Table 6 and shown in Figure 8c. To prevent the occurrence of locking phenomena, we apply the F‐bar element technology [147].

TABLE 6.

Mesh quantities of the fusiform muscle geometry for different refinement levels.

| Refinement level | Number of elements | Number of nodes | ||

|---|---|---|---|---|