Abstract

Nearly a quarter of a century ago, we wrote a review paper about the very new technology of chemical vapour deposition (CVD) of diamond thin films. We now update this review and bring the story up to date by describing the progress made—or not made—over the intervening years. Back in the 1990s and early 2000s, there was enormous excitement about the plethora of applications that were suddenly possible now that diamonds could be fabricated in the form of thin films. Diamond was hailed as the ultimate semiconductor, and it was believed that the few remaining problems would be quickly solved, leading to a new ‘diamond age’ of electronics. In reality, however, difficulty in making large-area diamond wafers and the elusiveness of a useful n-type dopant slowed progress substantially. Unsurprisingly, over the following decade, the enthusiasm and funding for diamonds faded, while competing materials forged ahead. But in the early 2010s, several new game-changing applications for diamonds were discovered, such as electrochemical electrodes, the nitrogen-vacancy (NV) centre defect that promised room-temperature quantum computers, and methods to grow large single-crystal gemstone-quality diamonds. These led to a resurgence in diamond research and a new hope that diamond might finally live up to its promise.

This article is part of the theme issue ‘Science into the next millennium: 25 years on’.

Keywords: diamond, chemical vapour deposition, review

1. Introduction

In the year 2000, we wrote a review paper entitled ‘Diamond Thin Films: A 21st Century Material’ [1] discussing the relatively new subject of diamond chemical vapour deposition (CVD). The review described what was known at the time about the mechanism of deposition—the limitations of the process—and then speculated about how this technology might develop following a few decades of research. It ended by giving a dozen or so promising applications. Nearly a quarter of a century later, the review has accumulated nearly 1000 citations and has become the ‘go to’ paper for new researchers beginning in this field. So, for this special edition of Phil. Trans. R. Soc. A, it is timely to update the original review and evaluate whether the technology has advanced as predicted. Through the use of advanced plasma diagnostics and computer simulation much of the fundamental science underpinning the diamond CVD process—some of which was only speculation at the time—has now been confirmed. However, arguably the most important development in this field over the past 25 years is the astonishing diversity of applications that have now emerged for this material, including medical implants, quantum computing, solar energy generation, optics, electrochemistry, particle detectors, ‘everlasting’ batteries and, of course, the capability to fabricate very large single-crystal diamond (SCD) gemstones that are now challenging natural diamonds for the larger share of the jewellery market [2].

Interest and associated research funding for CVD diamond boomed during the 1990s, fuelled by media hype and unrealistic expectations that the next ‘ultimate semiconductor’ material was imminent. However, the crash soon followed. For a decade from about 2000, the failure to achieve n-type doping and frustratingly slow progress in the deposition of large-area diamond wafers dampened enthusiasm for the alleged ‘wonder material’. At the same time, competing materials such as SiC and GaN went from strength to strength, and new exciting wonder materials, such as graphene, promised to outshine even diamond in performance. Funding for diamond research dwindled, until around 2010, when scientists and funding agencies began to realize that the competing materials were also having serious problems of their own—graphene, in particular, having been extremely overhyped [3], meaning diamond was back in the game! This was helped by the discovery that the nitrogen-vacancy (NV) centre in diamond (see §9) could act as a single-photon source, which opened up the almost unbelievable prospect of room-temperature quantum computing. Other exciting applications, such as diamond electrochemical electrodes and biosensors, fuelled diamond’s resurgence, and the spectacular success of synthetic diamond gemstones in the worldwide jewellery market [2] drove the long-awaited technological breakthroughs in diamond growth rate, large-area deposition and defect understanding. Diamond has been recently called the ‘Sleeping Beauty’ of semiconductors [4]—showing outstanding properties with respect to other competing materials but never quite matching their performance in actual commercial devices. It may now be the decade that Sleeping Beauty awakens, bringing with it the new hope that diamond may finally live up to its promise.

Currently, there are over 200 research groups studying the growth or applications of CVD diamonds worldwide and as many as 100 commercial companies fabricating diamonds for gemstone or other applications, or utilizing CVD diamonds in novel applications. As a result, the cost of diamonds has fallen rapidly over the past decade. At the time of writing, the typical cost for a freestanding SCD sample (4 × 4 × 0.5 mm) from a company such as Element Six is approximately $2000, while that for a larger (10 × 10 × 0.5 mm) polycrystalline sample is only approximately $50−200 depending on quality, while the number of suppliers has increased accordingly (see electronic supplementary material, table S1).

As one might expect for a ‘follow-on’ paper, to avoid unnecessary duplication of content, it is recommended that the reader first become familiar with the original paper [1] before starting this one. It is also worth pointing out that due to page limitations, only a few of the most important CVD diamond applications are discussed below. However, another recent review covers the vast range of other applications for this material in some detail [5].

2. CVD

To recap very briefly, in the CVD process [1,6], a diamond coating is deposited on to the surface of a suitable substrate, for example, a smaller diamond ‘seed’ in the case of gemstone growth, a Si wafer for electronic devices, a quartz window for optics, or a mechanical component for wear applications. This substrate is positioned on a heated stage inside a vacuum chamber and heated to 700–1000°C while process gases are passed over the substrate at a pressure of 20−300 torr. The gas mixture typically consists of a carbon source, such as methane, diluted to a few per cent input mole fraction in hydrogen, although small amounts of other gases such as O2, N2 or dopants such as B2H6 or PH3 are sometimes added depending on the required product. This gas mixture is energised using either a heated metal (W, Ta or Re) filament placed a few millimetres above the substrate surface or by application of a microwave (MW) discharge in the form of a ‘plasma ball’ that sits above the substrate surface. The thermal or electrical energy deposited into the process gases fragments the molecules to form a chemical ‘soup’ of atoms, radicals, ions and clusters near the substrate surface. Reactive species (mainly H atoms and CH3 radicals) from this hot gas mixture diffuse to the surface, and if the conditions are correct, they adsorb on to the surface, migrate around and eventually form a continuous layer of diamond. The diamond coating can remain on the surface after growth and be utilized in situ, or the substrate can be chemically etched away to leave a freestanding diamond foil or ‘wafer’, or in the case of thick single crystals, undergo further processing (laser cutting and polishing) to produce synthetic diamond gemstones for the jewellery market.

3. Methods for production of diamond CVD

In 2000, when the original review was written, the technology required for diamond CVD was only about 10 years old, and four main deposition techniques were in use: hot filament CVD (HFCVD), MW plasma-enhanced CVD (MWCVD), arc-jets (plasma torches) and oxyacetylene welding torches. In the intervening years, both torch methods have largely fallen out of use in the West. Although extremely high diamond growth rates (approx. 1000 μm h−1) could be achieved with these systems [7], problems with substrate cooling, poor uniformity over areas greater than approximately 5 × 5 mm2 and inadequate run-to-run reproducibility meant that these methods fell out of favour compared to the more reliable plasma systems. Nevertheless, the easily accessible, bright, visible emission from these torch systems permitted important fundamental studies to be performed on the gas chemistry and growth mechanisms, using techniques such as optical emission spectroscopy (OES) and cavity ring-down spectroscopy [8–10]. These studies provided early empirical data that would later be essential in developing models of the CVD process (see §4).

In China, it was a different story. Arc-jet plasma deposition systems continued to be developed, and this technology is now considered fully mature and commercialized [11]. A series of direct current (DC) arc jets with powers up to 100 kW [12] were developed for different applications, which are capable of mass-producing polycrystalline diamond wafers of diameters up to 150 mm and thickness of approximately 3 mm. Using this technique, the Chinese company, Hebei Plasma Diamond Technology Co. Ltd, has become the main supplier of freestanding diamond film products in the world.

(a). HFCVD

This technique remains popular among university research groups, mainly for its low cost, versatility, and especially its ability to deposit diamonds over large areas—something with which most other methods still have difficulty. It is now possible to buy commercial HFCVD reactors that deposit polycrystalline diamond uniformly on to Si wafers of area up to 0.5 m2 [13], although the low deposition rates (approx. 1 μm h−1) mean that thick (greather than 100 μm) large-area diamond films remain rather expensive to manufacture and produce. Smaller HFCVD reactors for sample areas of approximately 100 mm2 can be built in-house from standard vacuum components for as little as $20,000, and nowadays many small research groups have their own bespoke diamond HFCVD reactor to study niche research areas. In China, over the past 10 years, HFCVD reactors have been scaled up and modified by biasing the substrate in a technique known as electron-assisted HFCVD [14], together with adopting closely packed filament multi-arrays and short filament-to-substrate distances. As such, HFCVD has become the most important and dominant technique in China for the mass production of thick freestanding polycrystalline diamond films for mechanical and thermal applications [11].

(b). DC plasmas

These systems were first reported for diamond CVD in 2012 [15], but they remain the ‘poor relation’ among plasma deposition systems, with only a few research groups adopting this as their growth method of choice, mainly at Jilin University in China [16] and in South Korea [17]. DC plasma systems do not require the growth chamber to be a tuned cavity, which is a major drawback with the design of MW plasma systems (see §3d). This greatly simplifies the design of DC reactors and affords the advantage of easier scale-up to larger-area samples. However, the high-power supplies required are expensive, and the growth conditions are not as flexible as those in MWCVD systems, hence their continued relative unpopularity.

(c). Distributed antenna systems

Rather than use one large plasma source, a number of alternative reactor designs have been developed in the past decade that generate several smaller plasmas distributed in an array or grid over a large area. These distributed plasma reactors have two major advantages over other CVD methods. First, it makes possible very large deposition areas, greater than 1 m2. Second, the deposition temperatures (400°C) are typically much lower than those in conventional HFCVD or MWCVD systems, allowing diamond deposition on to substrate materials with low melting points. Indeed, addition of O-containing gases into the feed-gas mixture has been reported to further reduce the growth temperature to 130°C [18]. There are downsides however, the lower deposition temperatures mean that the diamond quality is poor, being mostly nanocrystalline, and growth rates are extremely low (a few 10s of nm h−1). Nevertheless, such systems have enabled thin ( less than 100 nm) nanodiamond films to be deposited on to large sheets of glass or plastic for use as protective layers—which would be impossible by other methods.

(i). Linear antenna plasma deposition

This is the most commonly used of these new distributed plasma growth methods, being first reported by a consortium of research groups based in Prague in 2011 [19]. In a linear antenna plasma deposition (LAPD) system, 2.45 GHz MW power is delivered into the growth chamber via several pairs of linear coaxial antennas enclosed in quartz envelopes. These linear plasma sources are arranged parallel to one another a few cm above the substrate holder (figure 1). The use of high-frequency MW pulses and low pressures (approx. 1 mbar) increases the plasma electron density to 1011 cm−3 [20], while pulsing the plasma power at duty cycles of approximately 30% creates ‘on-off’ cycles that allow the gas dynamics to be altered in a transient manner, while minimising the thermal loads [21].

Figure 1.

Diagram of a LAPD system. Redrawn from [20].

(ii). Distributed antenna array MW

A similar deposition process to LAPD, called a distributed antenna array MW (DAAM) system, uses 16 coaxial plasma sources inserted into a square metallic flange in a process chamber and arranged in a 4 × 4 matrix [22]. A 6 kW MW generator is coupled to the system using antennas located in a rectangular waveguide (figure 2). The MW power is divided between the 16 sources, and a discharge is ignited around each source inside the reactor chamber. When the MW power is increased, the plasmas expand and produce a sheet of uniform plasma. The DAAM system allows substrates with sharp edges to be uniformly coated without disturbing the electric field. However, the growth rates and film quality are similar to those deposited by LAPD systems.

Figure 2.

(a) Schematic diagram of a DAAM system, redrawn from [22]. MW power is coupled into a rectangular waveguide and is divided equally between 16 applicators (180 W each), which transport the power to the sources within the chamber using coaxial cables. One of the applicators is shown in more detail on the left; the power passes through a matched load into a tuned antenna protected by a quartz coating, igniting a plasma around each source protruding inside the low-pressure reactor. (b) View of the 16 coaxial ignited plasma sources plasma sources inside the DAAM reactor arranged in a 4 × 4 matrix. Photo reproduced with permission from [22].

(iii). Surface wave plasma (SWP)

Another new type of system designed for large-area, low-temperature diamond deposition utilizes multi-slot MW antennas and surface wave plasmas (SWPs) [23] (figure 3); SWP reactors use multiple 5 kW, 2.45 GHz MW generators to launch MWs along separate waveguides into which several carefully designed slots have been cut allowing the MWs to access the reactor chamber below. Quartz windows separate the waveguide slots from the vacuum chamber while allowing the MWs to initiate plasmas beneath the slots. Thus, a set of small dense plasmas is formed in a rectangular array allowing substrates of area 600 × 400 mm2 to be coated. The substrate stage is water-cooled, allowing nanocrystalline diamond films to be deposited at temperatures as low as 100–500°C.

Figure 3.

Schematic illustrations of components of a SWP reactor, (a) a slot antenna, (b) a MW launcher with five slots, (c) a large-area MW antenna composed of four launchers and (d) large-area SWP reactor. Figure based upon diagram in [23].

Because LAPD, DAAM and SWP systems cannot deposit high-quality diamonds at reasonable rates, they will probably remain niche techniques for researchers primarily focused on large-area, low-temperature deposition of smooth films with high mechanical strength and low residual stress.

(d). MW plasma reactors

MW plasmas have now become the standard diamond growth technique of choice for most research groups worldwide, despite their high cost. This is due to their compatibility with existing semiconductor fabrication facilities, reproducibility, ability to deposit polycrystalline and SCD with extremely low levels of unwanted impurities (e.g. residual nitrogen concentrations less than a few parts per billion (ppb)) [24,25], ability to use a wide range of process gas mixtures (especially oxygen-containing gases) and the high growth rates that are possible when using high-power reactors. In the past 20 years, driven mainly by the rapid growth in the lab-grown diamond gemstone industry, the technology behind MWCVD has made huge leaps forward [26]. The preferred design of the MW chamber nowadays is the ‘top-hat’ design, formerly known as the ASTEX-style reactor (figure 4), with the older NIRIM-style reactors [1] rarely used nowadays due to issues with Si contamination from the quartz tube. For larger substrates, ‘clam-shell’ reactors are also popular as they provide easier access to the growth chamber. Although most MW systems currently use 5−6 kW power supplies, the commercial requirements for faster growth rates and larger areas have led to greater-volume MW systems being produced with power supplies up to 100 kW [11]. Because MWCVD requires the deposition chamber to be a resonant cavity for efficient transfer of energy from the MWs to the process gases, the chamber size depends inversely on the frequency of MWs used to generate the plasma. To achieve the necessary power densities over larger areas, the MW frequency is often lowered from 2.45 GHz to 915 MHz, allowing the size of the MW resonant cavity to increase accordingly.

Figure 4.

An example of a top-hat MWCVD reactor (Seki model SDS6380). This reactor has power supplies up to 5 kW (at 2.45 GHz) and is capable of depositing polycrystalline diamond films, SCD diamond plates or SCD gemstones at high rates. The chamber is water-cooled, with a substrate platen capable of accommodating samples up to 50 mm in diameter. Photo courtesy of Philippe Bergonzo, Seki Diamond Systems [13].

The next important and imminent development in MWCVD technology will be the use of MW solid-state power supplies (SSPS), which, although being slightly less energy efficient than the current magnetron-tube technology, offer a number of advantages. First, for a cost approximately 50% higher than a standard MW magnetron tube, SSPSs provide higher stability (fewer fluctuations in the plasma means fewer growth defects) and a significantly longer lifetime (20–30 years compared to approx. 5 years for a magnetron). However, their main benefit is seen in factories with multiple MWCVD reactors in close proximity. As well as the main MW frequency, magnetron tubes also generate unwanted harmonics that vary from tube to tube. These harmonics can perturb the operation of other nearby magnetrons, causing plasma instabilities and fluctuations in all the plasmas in a CVD factory. To overcome this problem, large CVD facilities use special MW filters or costly uninterruptible power supply circuitry on every reactor to block the interference. In contrast, SSPSs generate only a single pure MW waveform with no harmonics and so do not require an uninterruptible power supply. SSPCs began to enter the market from several manufacturers (e.g. Sairem, Muegge) in 2023, with higher power (6 kW and above) promised to become available within a few years.

MWCVD is by far the most widely used deposition technique in China for diamond films. It is used for the growth of the highest-quality diamond films required for electronic, thermal, optical and quantum applications. Chinese lab-grown diamond gemstones currently make up approximately 50% of the worldwide market for synthetic diamond jewellery—and although the high-pressure high-temperature (HPHT) method [11] is the technique of choice for the majority of industrial mass production of SCD in China, MWCVD is preferred for the largest and purest gemstones [11]. At first, the thousands of MWCVD reactors required for this huge endeavour were imported into China from companies such as Plassys (France), iPlas (Germany) and Seki (Japan). But cheaper home-made MWCVD diamond deposition systems were quickly developed by Chinese manufacturers such as Uniplasma (Shenzhen), DMT-Diamond (Xian), Three Three Zero (Chengdu), Heuray Microwave (Chengdu) and Tanfangcheng (Carbon Equations, Shanxi), and these now comprise 50% of the MW growth systems in China [11].

4. The chemistry of CVD diamond growth

The ‘standard model’ for diamond growth that was devised in the 1990s [27,28] has stood the test of time and has proven to be an accurate description of the diamond CVD process. This model still underpins our understanding of diamond growth today. The model assumes that because CVD growth temperatures (approx. 1000 K) are below the Debye temperature of diamond (approx. 2240 K), the bulk diamond lattice cannot spontaneously rearrange itself into the more thermodynamically favourable graphite structure. Furthermore, the carbon atoms at each surface are (nearly) all terminated with H, which eliminates any ‘dangling bonds’ that would otherwise cause the surface to restructure into more stable, graphitic structures.

In the growth chamber, the thermal energy from the hot filament or MW energy from the MW power supply dissociates H2 into H atoms, which then react with the hydrocarbons present in the gas mixture to create a complex chemical soup of hydrocarbon species. These include neutral molecules and reactive carbon-containing radicals, in particular CH3. The H atoms also react with the hydrogens in the C–H bonds that terminate the diamond surface carbon atoms, abstracting the H (to reform H2) and in doing so creating surface radical sites. The most likely fate for these surface radicals is that another gas-phase H atom will attach to it, reforming the stable surface. Occasionally, however, a CH3 will attach to the surface radical site instead. If there are other nearby surface radical sites, the adsorbed CH3 can migrate across the surface until it finds a diamond step-edge, to which it attaches, thereby adding one more carbon to the diamond lattice. Any non-diamond sp2 carbon species that adsorb are quickly etched back into the gas phase by the H atoms that continually strike the surface. H atoms etch sp3 carbon approximately 20 times slower than sp2 carbon, so all non-diamond carbons are swept off the surface, while sp3 carbons survive long enough to propagate the diamond structure.

Although the standard model is still fundamentally valid, our understanding of the mechanisms involved in diamond CVD has advanced greatly over the past 20 years, as reviewed in detail by Butler et al. [29]. This is mainly due to the use of sophisticated in situ diagnostics of the growth environment, using various non-invasive spectroscopic techniques such as optical emission [30], cavity ring-down [31] and direct line-of-sight absorption methods [32,33], as well as more intrusive methods such as mass spectrometric sampling from the plasma [34]. Studies such as these provided key quantitative data about the spatial distribution and concentrations of many of the gas-phase species within hot-filament, MW-plasma and DC arc-jet reactors. These values enabled the development of accurate three-dimensional (3D) models of the chemical processes and gas dynamics in the growth chamber under CVD conditions, which, in turn, made it possible to estimate similar data for the species that are less amenable to spectroscopic analysis (such as the key CH3 radical).

In addition, individual gas-phase and gas-surface reactions, particularly for the diamond C(100):H (2 × 1) surface, were simulated at the molecular level by quantum-mechanical codes such as density functional theory (DFT) [35]. These enabled potential reaction pathways to be studied (figure 5), determination of the relative stability of surface adsorbates [36], the role of dopants in the growth process [37–39] and the function of different reactants and mechanisms in growth [40]. The data from these various experimental measurements and computer simulations were then combined into macro-scale computer models of the whole CVD process, enabling processes such as surface migration, nucleation and step-edge growth to be predicted [41]. More recent kinetic Monte Carlo (kMC) models [42,43] (figure 6) have predicted growth rates, crystallite morphology, etch-pits and the role played by an immobile ‘critical nucleus’ in the initiation of a new diamond layer.

Figure 5.

Series of elementary steps by which an incident CH3 radical can insert into a C−C dimer bond on the C(100):H (2 × 1) surface. The respective minima (normal font) and transition state (in italics) energies are in kJ mol−1 relative to that of structure 1. The dots indicate the location of a radical group, i.e. a ‘dangling bond’ with an unbonded electron. Redrawn using data in [29].

Figure 6.

3D projections of the surfaces generated by a 3D kMC model representing the different types of diamond growth resulting from different process conditions. More details of these diamond film varieties can be found in §5. (a) UNCD, with no crystal faces visible as a result of continual random renucleation. (b) Nanocrystalline diamond (NCD), with some small terraces appearing (i.e. nanocrystallites) as a result of a layer-by-layer growth coupled with renucleation. (c) Microcrystalline diamond (MCD), where layer-by-layer growth dominates leading to large micron-sized faceted crystallites. (d) SCD, where growth is now entirely by layer-by-layer growth. The layers have been coloured to make it easy to distinguish individual layers. Reproduced with permission from [42] under the Creative Commons CC BY 3.0 licence.

Although the standard growth model is well accepted, there are still some aspects of the mechanism that remain controversial or unresolved. A detailed discussion of two of these issues is given in the electronic supplementary material, but a summary of the important points is provided in the next two sections.

(a). The C2 controversy

The first controversial issue concerns the importance, or otherwise, of the C2 radical as a growth species. Key to the standard model is the idea that the main growth species are CHx (x = 0–3) and, in particular, the methyl radical, CH3 [28], which is supported by a wide range of direct and indirect evidence. These ideas were challenged, however, in 1994, when a paper reported that diamond films could be grown in a MW plasma using a mixture of Ar and vapourised C60, i.e. with apparently no H present [44]. The new type of diamond film, termed ultrananocrystalline diamond (UNCD), consisted of approximately 4 nm diamond crystallites, and it was suggested that with allegedly no H present, a different growth mechanism must be operating to that for normal CVD diamond. In the absence of CH3, the C2 radical was suggested as the growth species. Indirect evidence was presented for this contentious view in that the plasma was bright green in colour due to emission from the bright Swan bands of the C2 radical [45], in contrast to the lilac colour of traditional CH4/H2 plasmas, while DFT calculations showed that C2 radicals were able to insert directly into surface dimers [46].

However, in the few years following these first reports of ‘H-free diamond growth’, no research groups were able to reproduce the results using the Ar/C60 recipe. In all cases, UNCD films were successfully deposited only when trace amounts of H2 were added to the Ar/C60 gas mixture, or alternatively using Ar/CH4 mixtures that produce H atoms upon fragmentation—otherwise the films were graphitic. This suggested that maybe there were trace amounts of H2 from an unknown source present in the original Ar/C60 experiments. Cavity ring-down spectroscopy was used to measure the absolute concentration of C2 in the plasma during UNCD growth, and this was found not to correlate with the film growth rate [47]. Experimental and modelling results of the gas-phase concentrations during UNCD growth showed that, although the concentration of C2 was high in the centre of the plasma (and gave rise to the bright green emission), its concentration fell by many orders of magnitude close to the cooler diamond surface [48] and was insufficient to account for the observed growth rate.

Nowadays, the C2 growth mechanism has largely been discounted as a viable mechanism for UNCD growth—or for the growth of any form of diamond [49]—although it is still sometimes cited in papers! However, the role of C2 (and the more abundant C2H) in renucleation and defect formation is still very much a possibility.

(b). The nitrogen effect

The second controversial issue regarding diamond growth involves the so-called catalytic role played by nitrogen. Many studies have shown that even trace amounts of N2 in the process gas mixture significantly increase the growth rate from MW-activated CH4/H2 gas mixtures, sometimes by a factor of 10 or more [50,51]. The morphology of the growing diamond surface is also modified by the presence of nitrogen in the gas mixture, which encourages the preferential formation of flat, square {100}-faceted crystals in the case of polycrystalline diamond films. Excess nitrogen in the process gas mixture, however, produces smaller and less well-oriented surface facets. With further increases in gas-phase nitrogen concentration, the films become nanocrystalline or even graphitic [52,53]. For homoepitaxial growth of SCD, nitrogen in the input gas mixture has been shown to promote macroscopic step-bunching (as shown in figure 7) and disrupt growth on all but the {100} face of an SCD seed [54].

Figure 7.

SEM image showing macroscopic step-bunching on the surface of an SCD sample grown using nitrogen-containing gas mixtures. Reprinted with permission from [51].

To avoid these issues, in the interests of process control and reproducibility, diamond researchers are now far more careful to control unwanted N2 (and other) impurities in the gas mixture. It is now common to add high-vacuum turbopumps to CVD reactors to reduce the chamber base pressure to less than 10–6 mbar prior to diamond growth, along with the use of process gases with extremely high purity. Such careful control has allowed electronic-grade SCD films to be fabricated which contain N concentrations of less than 0.1 ppb [24].

This so-called ‘nitrogen effect’—the addition of tiny amounts of N2 to the process gas mixture causing dramatic changes to the growth rate and morphology—is still not fully understood. Indeed, nitrogen has sometimes been described as acting as a ‘catalyst’ in the growth, due to a small concentration causing a large effect, but this term is not strictly correct as the gas-phase nitrogen is not unchanged in the reaction—some small fraction ends up incorporated in the film. So how does the usually inert N2 molecule cause such huge effects?

To answer this, a combination of experimental studies (such as laser absorption and OES) and computer modelling of MW-activated N2/H2 and NH3/H2 plasmas revealed that the hot plasma environment could create excited-state N2 species [55,56]. Some of these excited-state N2 molecules have sufficient energy that their reactions with other gas-phase species or with the diamond surface break the strong N2 triple bond. Thus, unreactive N2 is converted to more reactive N-containing radical species such as N atoms and NH, NH2 and CN radicals, which can now participate in the diamond CVD process.

Theory suggests that these reactive N-containing species should be able to insert into a C−C dimer bond on the C(100):H (2 × 1) surface via a ring-opening/ring-closing reaction mechanism [57] analogous to that shown earlier in figure 5 for the case of CH3 addition. These reactions provide viable routes for N incorporation into substitutional sites in the diamond lattice, but they do not explain the unusually large effect that N has on growth rates and morphology.

Theoretical calculations have been used to investigate a number of possible mechanisms. The first suggests that adsorbed NH species at different step edges on the C(100):H (2 × 1) surface enhance the binding of gas-phase CH3/CH2 groups at these locations [58]. A second suggestion is that the additional electron density provided by a buried near-surface N atom weakens any nearby surface C−H bonds. This enhances the rate of the H-abstraction step that creates the surface radical site necessary for CH3 radical addition [59]. Other mechanisms explain the apparent ‘catalytic’ nitrogen effect as a consequence of a layer-by-layer growth mechanism growth model in which the rate-limiting step is the nucleation of a new layer. Initiation of a new layer requires the creation of a ‘critical nucleus’—an immobile surface feature with a low etch rate, which acts as a starting point for subsequent rapid lateral growth. Indeed, Monte Carlo models using step-flow growth conditions that include such critical nuclei have demonstrated tenfold enhanced growth rates [42,60]. Butler & Oleynik [61] suggested that adsorbed CN might act as just such a critical nucleus because it cannot undergo the β-scission reaction responsible for trimming longer-chained hydrocarbons from the diamond surface (see electronic supplementary material, fig. S1). Hence, it only takes a single CN adsorbate across an entire surface composed of billions of carbon atoms to initiate a new layer, which explains the apparent catalytic effect. A similar mechanism involving the critical nucleus being a lone C–N dimer sitting among the thousands of C–C dimers on the flat (100) surface was recently proposed by Oberg et al. [62]. It remains unclear which of the many proposed mechanisms is responsible for the nitrogen effect, or whether it is a combination of several of them.

(c). Remaining issues in CVD diamond growth

Despite the continued success of the standard model of diamond growth and the updates and improvements made to it over the past 20 years, there are still a number of details about the growth mechanism that remain elusive. Unfortunately, research has almost stopped in this fundamental area, partly as a result of the community and funding agencies believing (incorrectly) that the growth mechanism was essentially ‘solved’, but also because, after 20 years of research, funding agencies are now focusing on applications of diamond technology that can produce demonstrable commercial products, rather than fundamental understanding. However, in many cases, it is the ignorance of the basic science that is inhibiting progress with many applications. Some of the unsolved problems are as follows:

-

—

What is the role in growth (if any) of larger hydrocarbon species, such as C2 or C2H? If their role is detrimental to growth rate or diamond purity, can the plasma conditions be modified to reduce or eliminate these species?

-

—

What causes renucleation? It is clear that as the concentration of C > 1 hydrocarbons in the gas phase increases (e.g. by increasing the CH4:H2 ratio), the rate of renucleation increases, leading to twinning and smaller crystallites. But exactly which species cause renucleation, and by what mechanism, is still not known.

-

—

The reaction rate for a CH3 radical attaching to a surface radical site is limited by a temperature-dependent sticking factor, P. The value of P results from a combination of factors that reduce the reaction probability, such as a geometrical factor (g) due to unfavourable collision orientation and a steric-electronic factor (s), arising from the electron spin selection rules involved in bond formation. Also, only a fraction, F, of the total surface radical sites will be accessible for adsorption, and the value of F will depend upon the surface temperature and local H-atom concentrations. Thus, p = g × s × F, and the three factors can be estimated for different growth conditions [63,64]. For example, electronic-spin statistics show that for CH3, on average, three collisions out of four will be on the triplet surface and will not lead to reaction at the high temperatures of diamond CVD [65], i.e. s ~ 0.25, while typically F ~ 0.5 for CVD conditions [63]. The value for g, however, remains little more than a ‘best guess’. As is clear, the uncertainties in these estimates are large, leading to predicted growth rates from computer simulations that can differ from experiment by an order of magnitude. Molecular-dynamics calculations of the reaction process may provide more accurate, or at least more justifiable values [66,67], but nevertheless, the value of P and its variation with growth conditions and surface orientation remain key inputs to various growth models that urgently need refining.

-

—

Although many macroscopic simulations of diamond CVD confirm the role of surface migration in step-edge growth and surface smoothing [41,42], the exact mechanism by which this happens remains somewhat vague. In particular, the rates with which adsorbed CH2 ‘bridge’ species migrate across adjacent dimer reconstructions, or into vacant trough sites, or down atomic steps, are all unknown and yet are key to the quantitative modelling of diamond CVD.

-

—

Trace amounts of nitrogen in the gas phase are known to significantly increase the growth rate and change the surface morphology. There are many suggested mechanisms for this (see earlier), but none have yet been confirmed experimentally.

-

—

Are there strategies, other than simply increasing MW power, that might be used to improve growth rates or uniformity, such as addition of trace gases (O2, halogens, noble gases, D2), or improved gas injection configurations [68] or tuning the substrate position [69]?

5. The CVD diamond film

When diamond is grown homoepitaxially [24] on to an existing SCD seed crystal (which can be a natural diamond or one grown by CVD or HPHT methods), then the product is an enlarged SCD that can either be cut and polished into a gemstone (which is the basis for the flourishing CVD diamond gemstone market [2]) or laser cut into flat SCD substrates usually a few millimetre in size, suitable for advanced applications or further seeds.

In contrast, heteroepitaxial growth (diamond grown on to a non-diamond substrate) begins from numerous individual isolated nucleation sites, e.g. from microdiamond or nanodiamond seed crystals scattered on the surface, or surface defects such as scratches, impurities or dislocations [6]. The individual diamond nuclei enlarge as gas-phase carbon species adsorb on to them, and new carbon atoms add to the diamond lattice. The nuclei grow in three dimensions until they meet their immediate neighbours, whereupon they fuse together to form a coalesced (or closed) two-dimensional (2D) film that then continues to grow normally to the surface. The resulting material will usually be polycrystalline, composed of almost pure diamond crystallites (or grains) joined together by grain boundaries that contain varying amounts of impurities and non-diamond carbon. The morphology and the average crystallite size, and hence the resulting film properties, can be tuned [70] simply by choosing the appropriate process conditions [71], as shown in figure 8.

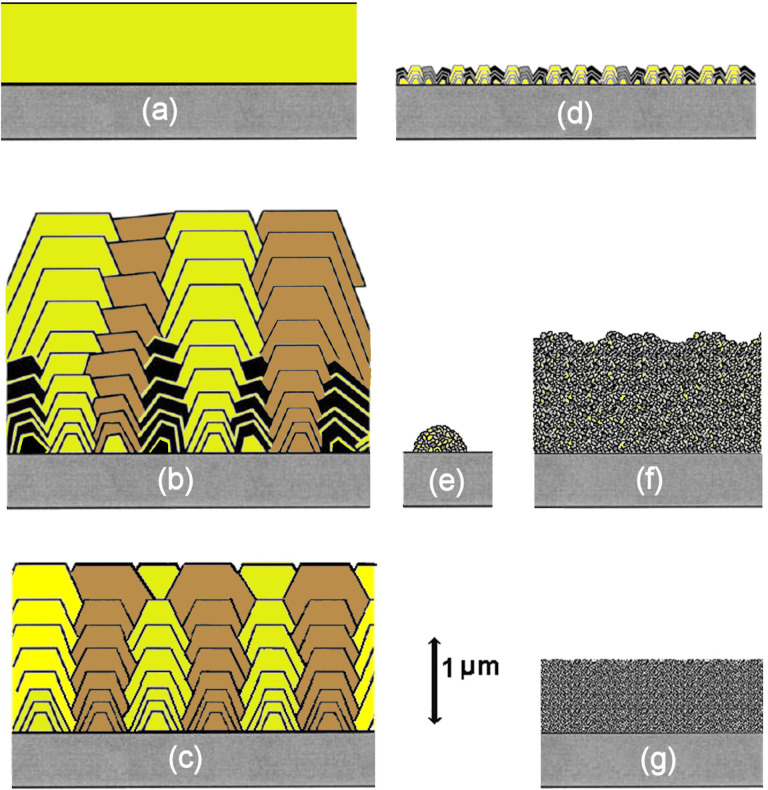

Figure 8.

Schematic representation of various types of CVD diamond film deposited on to a substrate (grey). The colours yellow, brown and black are used to allow the reader to discriminate between different diamond crystallites (grains) and their growth evolution. (a) SCD film grown epitaxially on an SCD substrate. (b) MCD columnar growth from randomly located nuclei, where the slowest growth face determines the overall film texture, in this case (100). (c) Highly oriented textured MCD obtained following special nucleation procedures, such as BEN (see §7). (d) Faceted NCD, which is really just thin MCD with high nucleation density. (e) ‘Cauliflower’ (or ‘ballas’) NCD before it has coalesced into a continuous film. (f) Cauliflower NCD film. (g) UNCD. Computer simulations of some of these diamond-film types were shown previously in figure 6.

Diamond films are usually grouped into categories depending on their crystallite size and morphology.

(a). SCD

Figure 8a is a near-perfect diamond crystal lattice with sizes that can approach several centimetres. It is usually deposited by templating on to an existing SCD seed, which can be later removed by laser cutting. Minimizing any remaining defects in the SCD layer (dislocation density, impurities, vacancies, etc.) is currently the goal for both the gemstone industry and for electronic device applications, as in both cases, ultra-high-purity SCD is the ‘billion-dollar prize’.

(b). Microcrystalline diamond

These films (figure 8b) exhibit faceted crystallites of size 0.5 µm to a few 100 µm, with a columnar growth structure that produces anisotropic properties that vary with film thickness. The grain boundaries between crystallites, which contain non-diamond carbon, are typically only a few angstroms thick. The crystallites in microcrystalline diamond (MCD) films are usually randomly oriented, as a result of the nucleation being from seeds or surface scratches that were themselves randomly located and oriented. As the film grows, the fastest growing surface (110) grows out via the van der Drift competitive growth model [72], leaving only the slowest growing facets, (100) or (111), visible at the film surface. The ratio of square (100) to triangular (111) facets in the film depends upon the growth conditions and is quantified by the α-parameter [73]. So-called ‘textured’ MCD films can be made using seeds that are arranged to be oriented all in the same direction, or by using specialized seeding nucleation strategies such as BEN [74] (see §7). These films grow preferentially in the (100) orientation, and as the growth islands merge, the resulting continuous film can appear as near single-crystal over large areas (figure 8c).

(c). Nanocrystalline diamond

These films [75] contain crystallites ranging in size from approximately 10 to 100 nm. Unfortunately, there are two types of diamond film that are often labelled ‘NCD’ (nanocrystalline diamond) in the literature. Diamond films grown with high nucleation density but for short periods of time, such that the films are less than 1 μm thick, have a facetted morphology and grain boundaries, just like MCD, except the crystallites are 10−100 times smaller. These NCD films have almost identical properties to MCD, except their ratio of grain boundaries to crystallites is larger due to their smaller size (figure 8d). Alternatively, NCD films can also be made by increasing the hydrocarbon concentration in the CVD gas mixture. This changes the growth chemistry, increasing the rate at which renucleation occurs and promoting the growth of secondary crystallites as ‘off shoots’ of the original nucleus. The greater the C:H ratio in the gas mixture, the higher the rate of secondary nucleation, resulting in a larger number of smaller crystals. This type of diamond growth leads to more rounded crystallites, which form into hemispherical agglomerates (figure 8e), sometimes referred to as ‘cauliflower’ or ‘ballas’ diamond (figure 8f). The grain boundaries in cauliflower diamond films can be several nanometres thick and contain sp, sp2 and sp3 hybridised carbon bonded in variety of configurations, along with impurities such as H and N. Although NCD films have properties that are generally inferior to MCD, their nanometre-scale surface roughness often makes them useful as wear-resistant protecting coatings in mechanical applications [76].

(d). UNCD

UNCD films [77,78] have crystallite sizes less than 10 nm embedded in an sp2-carbon matrix, and although their properties are less extreme compared to MCD and NCD, they have the advantage of being smooth on the nanometre scale (figure 8g) so that they can be used as vacuum pump seals [79] or medical applications [80]. UNCD is deposited using gas chemistries that have a much lower hydrogen concentration than for standard CVD conditions, for example, 1% CH4 in Ar, where the H:C ratio is only 4 compared to greater than 200 in standard 1% CH4/H2 mixtures. The grain boundaries in these films can be several nanometres wide, making them almost the same size as the diamond crystallites. These boundaries (especially when doped with N [81]) can form electrically conducting pathways through the film, allowing them to be used in electronic device applications [82].

6. The substrate material

A major goal in the field of diamond CVD is the lowering of substrate temperatures required for growth, as this would permit the use of a much wider range of substrate materials of industrial importance. Das & Singh recently published a comprehensive review [83] of the many attempts to deposit CVD diamonds at lower temperatures. These included methods such as varying the composition of the gas mixture (in particular by addition of O-containing gases or halogens) or by alteration of the processing conditions, such as by coating the substrate with another material, pulse modulation of the MW plasma or cyclic modulation of the CH4 flowrate. Many of these techniques succeeded in lowering the deposition temperature by 100–200°C, but usually at the cost of greatly reduced growth rates, poorer quality diamonds and/or significantly added complexity to the CVD process. Most researchers now grudgingly acknowledge that for high-quality diamonds, there is no option but to deposit at temperatures greater than 700°C and accept the substrate limitations this entails.

The major problem associated with such high-temperature growth is that many common industrial materials, such as plastics, glass, semiconductors (GaAs, CdS and CdSe) and metals (Al, Zn, Sn, Pb, Mg and many of their alloys) have melting points lower than the diamond deposition temperature and so cannot be used as substrates. Many remaining materials (e.g. Ti, Fe (including steels [84]), Ni, Co and Cr) either have a solid-state solubility for carbon that is too high at standard CVD process temperatures, such that most of the deposited carbon reacts to form a metal carbide rather than a diamond film, or are unreactive towards carbon (Cu and Ge), such that the deposited diamond film grows but does not adhere to the substrate. Moreover, some materials when heated to CVD diamond temperatures ( greater than 600°C), notably Fe, Co and Ni, catalyse the conversion of sp3 carbon into sp2 phases, promoting graphitization over diamond deposition.

Of the remaining materials, thermal expansion mismatch is then often the major problem. The substrate expands at the high growth temperature, and the diamond film then grows upon this expanded substrate. The sample is then cooled back to room temperature, whereupon the substrate contracts back to its normal size while the attached diamond film—with a much lower linear coefficient of thermal expansion (CTE)—contracts significantly less. The stresses cause the sample to bow with the diamond side outermost, the diamond film to crack or delaminate or the entire sample to fracture into pieces, depending on the strength of the adhesion between the substrate and the diamond layer.

These problems highlight another of the ongoing problems with diamond CVD technology, which has been around since the 1990s—there remain only a few materials upon which high-quality diamond films can be deposited. Apart from the diamond itself, silicon remains the substrate of choice due to its high melting point, low cost, availability as flat, polished wafers, low(ish) CTE (only about three times higher than that of diamond compared to those for most metals which are typically 10−20 times higher) and propensity to form a thin (a few nanometres) carbide to enable the diamond layer to adhere. Other ‘diamond-friendly’ materials are given below.

(a). Oxides and nitrides

It is possible to grow thin layers (a few micrometres) of diamond on to thin (a few micrometres) layers of SiO2 and Si3N4 on a Si substrate. But if the diamond layer or the oxide/nitride layer becomes too thick (e.g. for bulk Si3N4 or SiO2, or quartz), the CTE mismatch often causes the diamond film to delaminate. The same problem occurs with other oxides and nitrides, such as Al2O3 [85], sapphire [86], Ga2O3 [87], MgO [88] and TiO2 [89], which in some cases can be minimized by optimizing the growth conditions. In contrast, many metal oxides can be deposited on to diamonds for use as gate oxides [90], heterojunctions [91] or as surface transfer doping layers [92] (see §12b(ii)).

Diamond can be successfully deposited on to hexagonal [93] and cubic boron nitride [94], although, as for oxides, more work has been reported for the flipped approach—deposition of boron nitride on to diamond [95]. GaN has been of particular interest as a substrate for diamond growth due to its use in high-power electronic devices [96], such as base stations for transmitters used in 5G mobile phone networks [97]. A diamond heat-spreader thermally bonded to a hot GaN device would rapidly dissipate the heat to a remote heat sink or cooling system, enabling the GaN device to operate at higher power loads with a longer lifetime [98]. The room-temperature CTE of GaN is 28% larger than that of diamond [99]; however, the bigger problem is the diamond growth chemistry. Although its normal melting point is approximately 2500°C, GaN reacts with hydrogen at temperatures around only 800°C, decomposing to volatile NH3, N2 and GaH3 resulting in etching of the GaN [100]. Moreover, the interface between GaN and diamond is rather weak because Ga does not readily form a carbide. Thus, the as-grown diamond adheres to the GaN mainly via weak non-covalent interactions, rather than strong covalent bonds, making it prone to delamination. Reasonable quality diamond films have been deposited on to GaN at lower temperatures or using a thin SiC or SiN barrier layer [101], but these tend to have poor adhesion and poor thermal conduction across the GaN/diamond interface—which is a crucial failure for heat spreading applications [102]. Recent work has shown that thick diamond layers can be grown on to AlN [103], which can also be used as a relatively high-thermal-conductivity barrier layer on GaN.

(b). Metals

For pure metals, diamond grows well on Mo, W, Re and Ir, with the latter being used for growth of heteroepitaxial SCD layers (see §7). Beryllium has also been reported to be a suitable metallic substrate for diamond growth for films less than 30 μm thick, so long as the growth temperatures exceed approximately 750°C required to convert the native oxide (BeO) into carbide (Be2C) [104]. For Cu, its inability to form a carbide combined with its very high CTE has meant that diamond films that grow on its surface delaminate upon cooling. This has led to it being used to fabricate freestanding diamond plates [105].

(c). Carbides

Diamond also grows well on many carbides, in particular, WC [106] and SiC [107], due to the fact they are already saturated with C. This means none of the depositing carbon is lost by dissolving into the substrate or reaction to form a carbide. Their low CTE values also help prevent delamination.

(d). Silicides

Very little work has been reported about deposition on to these materials, but some silicides have been shown to meet the criteria for diamond growth, such as Ni3Si [108] and CoSi2 [109], but less so on FexSi (x = 0.5, 1, 3) [110].

(e). Graphite

Diamond growth on to graphitic or sp2-carbon-rich materials is tricky because the CVD conditions are designed to etch sp2 carbon. Diamond has been deposited on to bulk graphite [111,112], but this usually requires careful control of the CVD conditions to reduce the possibility of etching. The trick here, at the start of the deposition process, is to use a very high seeding density—almost a continuous monolayer—together with low deposition temperatures and high CH4/H2 ratios. These conditions aim to make the initial growth rate exceed the graphitic etching rate, thereby rapidly creating a protective continuous layer of diamond over the whole surface, which protects the graphitic substrate from the hydrogen atmosphere before it has a chance to etch. Once this protective coating is continuous, the CVD conditions can revert to normal, to grow higher-quality diamonds at higher rates. More recently, similar growth techniques have been used to diamond coat carbon fibres [113], carbon-fibre composites [114] and carbon nanotubes [115].

Depositing diamonds at much lower temperatures (200°C) has recently become possible using LAPD, DAAM or SWP systems (see §3). These systems have very low deposition rates, but the films they deposit have high sp2 carbon content and are best described as NCD or even UNCD. Nevertheless, they are hard, smooth diamond coatings that can be deposited as thin (less than 10 nm) layers on many substrates that are impossible to coat with conventional high-temperature CVD. These substrates include glass [23,116], fibre optics [117], plastic [118] and infrared optics [119].

7. Nucleation

For heteroepitaxial growth of diamond on to non-diamond substrates, the long initial induction period before which diamond starts to grow can be significantly reduced using a suitable pre-treatment prior to deposition (see the excellent review of nucleation by Mandal [120]). Many different types of pre-treatments have been reported to realize high uniform nucleation density leading to good quality diamond film growth. The list includes mechanical abrasion/scratching, seeding, electrical biasing, covering/coating with Fe or amorphous C, ion implantation, pulsed laser irradiation and carburization, all reviewed in detail in [83]. Mechanical abrasion and seeding were well-known in the 1990s [1]. But many of the other techniques in that list are used rarely, or only for specialized substrates. Perhaps the most important advance relevant for diamond nucleation in the last 20 years has been the discovery and commercial production of detonation nanodiamond (DND) [121].

DND particles typically have sizes 2−10 nm [122], and their most common production method is via detonation of explosives (such as trinitrotoluene and hexogen) in an inert atmosphere or in water/ice, inside a steel chamber [123]. The detonation produces a supersonic shockwave within which the prevailing high pressures and temperatures are sufficient to crystallize carbon into diamond. However, after the transient shockwave passes, the conditions revert to less extreme pressures and temperatures, favouring other forms of carbon. Thus, the explosion produces a mixture of nanodiamond particles, soot and other sp2 carbon material.

The powdery mixture of detonation products is cleaned with various acids and reagents to remove unwanted metallic impurities and soot, and the diamond component is extracted. The resulting DND material is now commercially available from many suppliers worldwide (see electronic supplementary material, table S1) as a powder or as a suspension in water and is currently produced at a rate of several tons per year and sold for as little as $100/kg. Unfortunately, the DND particles tend to fuse into aggregates approximately 100 nm in size, and thus the as-supplied material usually requires de-aggregation before subsequent processing. This can be achieved in many ways, including ball milling, pulverization, high-power sonication, acid treatments, controlled heating in O2 or H2 or combinations of these methods [124]. The DND particles that are finally obtained are often described as having a diamond core surrounded by a (partially) graphitic or fullerene-like shell—and are sometimes called ‘bucky-diamonds’ [125].

Following the various cleaning processes, the surfaces of DND particles are usually terminated with oxygen-containing groups, which makes them hydrophilic and helps their stability in aqueous suspensions (see §1c in the electronic supplementary material). This oxygenated surface can be modified by standard chemical methods, replacing the O-containing functional groups with H (producing a mildly hydrophobic surface), with F (which is superhydrophobic) or with NH2 (which permits further chemical functionalization) or with a host of organic molecules [126].

Functionalized DND particles are currently of great scientific interest in their own right for a range of applications, e.g. as carriers for targeted drug delivery [126] and as luminescence biomarkers [127,128]. However, in terms of diamond CVD, their main utility is in seeding. Due to their small size, an aqueous or ethanolic suspension of DND particles can be drop-cast on to a substrate surface; after drying, a near monolayer of seeds is formed with extremely high density (1012−1013 cm−2), which is close to the theoretical maximum [120]. Alternative DND seeding methods are also popular—the substrate can be dipped into the DND suspension (with or without sonication), spin-coated or submerged, and the DND particles are left to settle on to the surface. A DND suspension can also be electrostatically sprayed on to a surface enabling complex 3D microstructures to be conformally coated in a layer of seeds [129]. More details about the application of DND seeding can be found in the electronic supplementary material.

Bias-enhanced nucleation (BEN) was considered rather a niche method for nucleation in 2000. However, in the last few years, BEN has come to prominence due to it being used to make freestanding SCD wafers that are 92 mm in diameter [74]. BEN works by applying a negative bias of approximately −100 V to the substrate plate during MWCVD for a short nucleation step. The bias accelerates positive hydrocarbon ions from the plasma bulk, which then strike the single-crystal substrate with energies around 100 eV sufficient to implant C just beneath the surface (a process called subplantation). As time goes on, the concentration of sub-planted C reaches saturation, and the C atoms precipitate out of the surface as diamond—but crucially the diamond islands that form are aligned with that of the underlying substrate lattice. After a few minutes, this nucleation step is complete, the bias is turned off and conditions revert to those for standard CVD growth. The diamond islands continue to grow and then coalesce with very little mismatch at the boundaries, eventually producing a near SCD film across the whole substrate.

The original BEN work used Si (100) substrates, and the diamond films produced were called textured diamonds as they were composed of large SCD (100) plates all closely aligned with the substrate lattice [130]. This work was pioneered, among others, by Matthias Schreck from the University of Augsburg, and the big breakthrough was the realization that the nucleation density afforded by BEN was far denser and the crystal orientation distribution much narrower on single-crystal iridium metal substrates. This was partly due to the close lattice match of Ir to diamond [131], but also due to a unique mechanism in which buried lateral growth occurs within an approximately 1 nm-thick carbon matrix induced by the intense ion bombardment, described in detail in [74]. Unfortunately, using freestanding single-crystal Ir substrates is not practicable due to their astronomical cost. However, thin single-crystal Ir layers can be deposited on to various oxides, such as Al2O3, SrTiO3 and MgO [132], with the best being yttria-stabilized zirconia (YSZ). YSZ substrates are available and reasonably inexpensive, but in its bulk form, the CTE mismatch between YSZ and diamond is still rather high. The method of choice, therefore, is to use a triple-sandwich structure by depositing thin layers of YSZ on to a standard cheap Si (001) wafer, followed by a layer of single-crystal Ir, to produce Si/YSZ/Ir substrates. The diamond films grown on these sandwich substrates using BEN followed by MWCVD are near-perfect, transparent single-crystal layers up to 92 mm in diameter by 1.6 mm thick [74] (figure 9).

Figure 9.

Freestanding unpolished large-area SCD wafer synthesised by heteroepitaxy on Ir/YSZ/Si(001). The thickness of the disc is 1.6 ± 0.25 mm and its weight is 155 carat. Reproduced from [74] under the Creative Commons Attribution 4.0 License.

Large-area freestanding diamond films fabricated by this method are now available commercially from the German company Audiatec [133]. Such heteroepitaxially grown SCD films currently suffer from higher defect densities than their homoepitaxially grown counterparts, as well as significant bowing from the remaining CTE mismatch, but the hope is that SCD wafers with substantially larger diameters and fewer defects can be routinely fabricated by this method in the near future.

8. Doping

Undoped CVD diamonds of any grain size are highly electrically insulating. However, doping by incorporation of a suitable impurity atom, usually from Group 3 or 5, can increase the conductivity of the film in a controllable manner. The dopant atoms are usually added to the input gas mixture in gaseous form, e.g. B2H6 for boron, NH3 or N2 for nitrogen, SiH4 for Si and PH3 for phosphorus, or by exposing a solid compound containing the intended dopant (e.g. rods of solid Si or B) to the plasma during deposition. Alternating layers of doped and undoped diamond can be fabricated by switching the doping gas on and off. Dopants in the form of solid rods can be retracted and inserted into the plasma extremely rapidly, allowing very thin (less than 1 nm) dopant layers to be made for so-called ‘delta-doping’ applications (see §12b(ii)).

Adding boron to diamond changes the conductivity in a reproducible and reliable manner (figure 10) [134]. At low-to-medium concentrations, B doping creates a p-type semiconductor [135], while at high concentrations (greater than 1 × 1020 cm−3), the conductivity becomes near-metallic, and for B concentrations above approximately 3 × 1021 cm−3, the films become superconducting at temperatures less than 10 K [136,137]. The p-type conductivity in B-doped diamond (BDD) results from hole carriers, and SCD exhibits the highest hole mobility at room temperature of any wide-bandgap semiconductor [138]. A higher-mobility material has a higher frequency response because the carriers can travel through the device faster. Also, materials with higher mobility transport more carriers per second, which means they can operate at higher currents and therefore higher powers. Although this high hole mobility in BDD drops considerably with increasing temperature and B concentration, it nevertheless remains high enough for BDD to be used in a variety of simple electronic devices (especially those operating at high frequencies and high powers), sensors and electrochemical electrodes [139].

Figure 10.

Conductivity (σ) at 300 K as a function of boron content measured by secondary ion mass spectrometry (SIMS) for various boron-doped diamond samples. Different conductivity mechanisms operate at different B concentrations, as shown by the labelled regions on the plot. The curve predicted by the Seto model of conductivity is plotted as a solid line. Figure reproduced from [134] with permission and colourised. For [B] > 1 × 1021 cm−3 and temperatures less than 10 K (not shown) the conduction mechanism switches to superconductivity via Cooper pairs.

In contrast, n-type semiconductivity—with electrons now acting as carriers—is much harder to achieve, because most potential n-type dopants (P, As and Sb) are too large to easily substitute for a small C atom in the rigid diamond lattice and thus have a low solid-state solubility in diamond [140]. Despite diamond exhibiting high values for electron mobilities similar to the hole mobilities seen in BDD, the low dopant concentration leads to low electrical conductivity and limited device performance. The exception is nitrogen for which atoms are small enough to substitute for carbon [50], but unfortunately, the energy levels of the N donor in diamond are too deep [141] (figure 11) and so are electrically useless for most room-temperature applications. Over the past 20 years, some degree of success has been achieved with phosphorus doping [142], but device performance is still poor compared to competing semiconductor materials such as Si, GaAs, GaN and SiC. Experiments with more unusual candidate dopants, such as Sb [143], Li [144], Na [145], S [146,147] and Se [148], have all proven disappointing.

Figure 11.

The three most common dopant types (e.g. phosphorus, nitrogen and boron) in diamond with the associated energies within the band gap; VB and CB stand for the valence band and conduction band, respectively. The B acceptor level is measured from the top of the VB, while the P and N donor levels are measured from the bottom of the CB.

Co-doping—addition of both p-type and n-type dopants simultaneously—has been attempted—again with little success. B + Li doping failed due to the Li migrating through the diamond (especially when grain boundaries were present), possibly forming Li clusters [149]. Calculations for N + Li co-doping suggested that a LiN4 defect, with substitutional Li, is likely to behave as a shallow n-type donor [150]—if it could somehow be realized experimentally. Similarly, computational predictions for B + N [151], B + P [152] and Se + B [148] look promising, but none have yet been proven experimentally to be useful n-type doping schemes.

Despite all this effort, the continued lack of a reliable n-type dopant with useful electronic properties at room temperature has hindered the use of diamonds in electronic applications more than any other issue. To date, n-doping unfortunately remains the ‘holy grail’ of diamond semiconductor research.

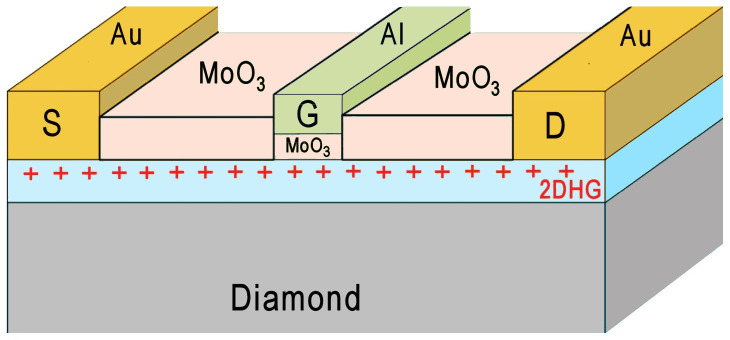

Another type of conductivity can occur in diamonds, as a result of an unusual property of the diamond surface, called ‘surface transfer doping’ [153,154]. Hydrogen-terminated diamond exhibits a surface dipole due to the difference in electronegativity between the carbon atoms in the bulk and the H atoms on the surface. Electron-accepting molecules from the ambient air adsorb on to this polar surface, and electrons are transferred from the bulk diamond to the adsorbates. As a result, the adsorbates become negatively charged. Similarly, the diamond becomes positively charged, and this takes the form of a stable two-dimensional hole-gas (2DHG) layer a few nanometres thick, which forms just below the surface [155]. This layer is electrically conducting, with both a high hole mobility (100−200 cm2 V−1 s−1) and a high hole concentration (1012−1013 cm−2). Unfortunately, the conductivity can be altered or even destroyed by simply changing the atmosphere (pressure, humidity, etc.) above the surface, as this affects the concentration and nature of the adsorbates. To stabilize this fragile conductive layer, the diamond surface can be capped with a protective layer of an electron-accepting oxide, such as V2O3, Al2O3 or MoO3 [156]. This capping layer hermetically seals the surface as well as providing additional surface acceptors helping to generate and stabilize the 2DHG layer. Several groups have recently exploited this process to fabricate novel types of electronic devices (see §12b(ii)).

9. The NV centre

Although its usefulness as a dopant is doubtful, N in diamond, when situated next to a vacancy, forms the so-called ‘NV centre’ [157], as shown in figure 12. The negatively charged version of this defect (NV−) is causing a great deal of excitement in the scientific community because these defects behave as isolated ‘pseudo-atoms’, with a set of energy levels distinct from those of the surrounding diamond. NV centres act as excellent single-photon sources [158], underpinning a host of novel applications involving quantum computing and quantum information processing [159,160] (§12c), as well as quantum sensing and magnetometry [161] (§12c(iii)). When excited by green laser light, the NV centres fluoresce in red, and this gives rise to another set of applications for the study of biological cells [162] (§12c(iii)).

Figure 12.

Schematic diagram of the NV defect centre in the diamond unit cell.

There are a variety of methods to fabricate NV− centres in diamond. The most popular is to implant diamond with N ions, followed by high-temperature annealing. The implantation process adds N to the diamond, with many of the N atoms displacing C atoms from the lattice and taking their place as substitutional atoms. The implantation process also creates damage, such as vacancies and interstitial C atoms. The subsequent anneal then allows the defects to relax into a stable structure, and because the formation energy of an NV− centre is exothermic, these form readily. The difficulty is in not flooding the diamond with too many N atoms such that the density of N atoms is so great they start to cluster. As such, simultaneous implantation of only a few N atoms (less than 5) within a volume of approximately 1 μm3 is required—which is pushing the limits of current implantation technology. Furthermore, the NV centres need to be within a few nanometres of the surface for them to be affected by the presence of any adsorbates (e.g. for sensing purposes) and for any emitted photons to be able to escape the surface [163]. The NVs also need to be separated from any neighbouring NVs by more than 30 nm to prevent dephasing (signal interference between the two centres) [164]. The substrate must be ‘electronic grade’ or ‘quantum grade’—extremely high-quality SCD, which is transparent at the wavelength of the emitted photon with no optical defects (such as birefringence), contain extremely low N concentrations ( less than 1 ppb) and polished to a smoothness of a few nanometres or better. Along with gemstones, these exacting requirements for electronic-grade diamonds for quantum applications remain one of the key driving forces for improvements in diamond growth technology.

As well as the NV− centre, several other diamond ‘colour centres’ have been investigated for quantum applications, including NV0 (neutral NV) [165], SiV− [166], SiV0 [167], GeV− [168], SnV− [169] and PbV− [170], and many more candidate defects are being discovered on a regular basis [171].

10. SCD growth

One of the most remarkable success stories in diamond technology over the past 20 years is the development of methods to grow SCD gemstones of sufficient size and clarity so that they can compete directly with natural diamonds in the jewellery market. The market for CVD lab-grown diamonds was valued at $11.3 billion (USD) in 2022 and is projected to reach $15.9 billion by 2027, growing at an extraordinary rate of approximately 7% a year [172]. This burgeoning demand for SCD gemstones has been the driving force behind significant improvements to both the growth technology (see §3) and the quality and size of high purity diamonds available as substrates for scientific use (see §11). The three crucial considerations for both the gemstone market and scientific applications of SCD are high growth rate, high throughput (either large surface area or more diamond gemstones per growth run) and high purity.

(a). High growth rate and throughput

For gemstones, SCDs up to 1 cm in thickness can now be deposited by MWCVD at growth rates up to 100 μm h−1 [173], although more typical routine industrial growth rates are approximately 20 μm h−1. For SCD growth, the growth chemistry is modified only slightly from that used for polycrystalline films. CH4/H2 is still the preferred gas mixture, except that for high growth rates the carbon concentration in the gas phase is often increased from 1% to approximately 15% CH4 in H2, while process pressures are also increased to over 200 torr. To prevent build-up of longer-chained carbon radicals in the gas phase, which might cause unwanted renucleation, the plasma density is increased to typically 70−300 W cm−3 by using higher-power MW systems. Such high-power (up to 75 kW) 915 MHz reactors can accommodate large substrate platens capable of holding as many as 24 diamond seeds at a time, substantially increasing throughput. Often, small amounts of O2 are added to the gas chemistry to further improve the diamond quality, while additions of small quantities of N2 improve growth rates significantly (see §4b), leading to diamond with a yellowish or light brown colour. These unwanted colours can be partially or wholly removed using a post-growth treatment to produce a clear colourless gemstone [174]. Indeed, most CVD material sold as jewellery has undergone at least one round of post-growth treatment, such as HPHT annealing or a combination of irradiation and annealing.

After decades of studying colour centres in natural diamonds, it is now possible to engineer the correct impurities into CVD diamonds during growth or in post-growth processing, to produce diamond gemstones with specific colours [175]. These so-called ‘fancy’ diamonds can sell for many times the price of their colourless counterparts, and so some manufacturers concentrate on producing these diamonds exclusively. Fancy diamond colours include brown (attributed to non-diamond carbon inclusions and/or internal extended defects such as dislocations), yellow (due to incorporation of nitrogen), red (from post-growth irradiation), blue (due to boron incorporation) and grey (boron again, plus sometimes carbonaceous inclusions; figure 13) [176]. The most famous natural blue diamond is, of course, the 46-carat Hope Diamond, which is permanently on display in the Smithsonian Museum in Washington DC [177]. If the rapid rate of progress in CVD gemstone growth technology continues, a very large, blue, lab-grown diamond should be possible within a few more years [178] (hence a possible secondary meaning for the title of this paper—a new Hope?).

Figure 13.

Examples of fancy-coloured CVD diamond gemstones. Photo reproduced with permission of Infi Advanced Materials Co., Ltd [176].

(b). High purity

This is achieved in various ways. Ensuring that high-quality vacuum components are used throughout the MWCVD process prevents air leaks. The use of ultra-high purity process gases (99.9999%) and hydrogen generators—which generate extremely clean H2 gas (99.99999%, i.e. an impurity content less than 100 ppb) by electrochemically splitting high-purity water—ensure that unwanted impurities in the diamond, especially nitrogen, can be reduced to levels below 0.1 ppb [24]. Extremely stable noise-free MW power supplies and control electronics ensure that growth conditions (pressure, gas flows, power and temperature) remain constant to within fractions of a per cent during the many hours or days required to produce thick films or large gemstones.

However, extended defects, such as dislocations, grain boundaries, twins and cracks, remain a significant problem in SCD growth [179], as these can substantially reduce the diamond quality and cause a variety of problems, such as birefringence [180], unwanted luminescence or carrier leakage in diodes [181]. SCD is usually deposited epitaxially on to mechanical-grade HPHT type-Ib seeds due to their low-cost and availability. Unfortunately, these substrates contain large numbers of point defects (impurities such as N and metal atoms) and extended defects, especially dislocations, that significantly affect the CVD films grown upon them. The dislocations in the substrate are a problem because they transfer to the growing CVD film [182] and ‘thread’ through the layer along the (001) growth direction.

The dislocations at an HPHT seed surface can be revealed and their density determined by a short dry-etch process using an H2/O2 plasma. This process preferentially etches the dislocations projecting from the surface and creates micron-sized inverted-pyramidal square-sided etch-pits visible via optical microscopy [183]. Typical dislocation densities in HPHT seeds are 102−104 cm−2, increasing to 105−107 cm−2 for CVD homoepitaxial SCD, and further to 108−1010 cm−2 for heteroepitaxial SCD [182,184]. However, not all defects have the same detrimental effect. Defects that fatally disrupt the operation of the application in question are termed ‘killer’ defects [185]. The exact nature of what constitutes a killer defect differs depending upon whether the application is optical or electronic, as well as between different types of electronic devices. The typical density of killer defects is 104−105 cm−2 for Schottky junction devices fabricated on a Ib type HPHT substrate [186], i.e. killer defects constitute approximately 1–10% of all dislocations in the sample. For comparison, the lowest killer defect density reported in a device to date is approximately 600 cm−2 [187]. For a particular application, identifying which of the various defects present in the diamond are the killer defects that must be eliminated (or at least minimized) and which are less harmful is currently a major endeavour if SCD devices are to live up to their promise [188].

There are two methods commonly used to significantly reduce the generation of dislocations at the interface between the seed/substrate and the CVD diamond layer. The first involves polishing or etching the seed/substrate prior to deposition to reduce the number and severity of surface defects [189]. The second method involves selecting much higher-quality type-IIa HPHT diamonds with low dislocation density for use as seeds [190]. Other reported methods, which have also been used for heteroepitaxial CVD on Si/YSZ/Ir substrates, include blocking the threading dislocations using thin Au stripes [191], deliberate incorporation of W impurities [192] or a grid of laser-cut holes [193] or Ni etching [182] followed by lateral overgrowth of more diamond. Sometimes the easiest solution is to simply grow the diamond film thick enough that most of the dislocations grow out and disappear [184].

With suitable seed selection combined with substrate pre-treatment and the use of clever growth technology, reports are starting to emerge of CVD SCD films with very low dislocation density (400 cm−2) [194]. Despite such impressive improvements in defect reduction, current state-of-the-art values are still a long way from those required for realistic commercial SCD devices [188], and this will become one of the major challenges for diamond device fabrication in the coming years.