Abstract

In the era of biodegradable packaging, protein-based biopolymers have emerged as a sustainable alternative to petroleum-based polymers due to their unique properties. Despite significant advances in this field, a comprehensive analysis of recent technological innovations with commercial viability assessments remains lacking. This review addressed this gap by systematically examining recent lab development in plant protein-based packaging, including sources, fabrication methods, real-time applications, commercial challenges, and their relationship to food packaging applications. Through analysis of recent studies, 2020–2025, we identify recent research trends that have focused on enhancing the properties of biodegradable polymers by incorporating antimicrobial, insecticidal, and antifungal agents, thereby creating active systems to prolong the shelf life of foods. Furthermore, our critical evaluation of advancements in fabrication techniques such as 3D printing, electrospinning, co-polymerization, casting, molding, extrusion, and coating has enabled the production of protein-based packaging with diverse shapes and properties. This review uniquely bridges the gap between laboratory innovations and commercial applications by examining current trends in sources, functions, applications, and future commercial challenges associated with plant protein-based packaging. By understanding the potential of these biopolymers, we can contribute to the development of sustainable and innovative packaging solutions within the food industries, offering a roadmap for both researchers and industry stakeholders.

Keywords: Plant proteins, Food packaging, Sustainability, Commercial challenges, Biopolymer

Graphical abstract

Highlights

-

•

Sustainable plant protein as alternatives to petroleum-based packaging.

-

•

Enhancements in properties through chemical and physical modifications.

-

•

Relationship between properties, fabrication methods, and real-world applications.

-

•

Challenges, commercialization prospects, and future trends.

1. Introduction

Before the Industrial Revolution, food packaging relied on natural materials like leaves, shells, and animal skins. With evolving human needs, packaging systems have advanced to include materials like wood, grass, and animal organs (Byrd and Dunn, 2020). The rise of industrial food production significantly increased demand for durable packaging materials, leading to petroleum-based plastics that dominate the market due to their versatility, durability, and cost-effectiveness (Brody et al., 2008). Major commercial packaging material include polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET or PETE), polystyrene (PS), polyvinyl chloride (PVC), polyamide (Nylon), ethylene vinyl alcohol (EVOH), polylactic acid (PLA), polycarbonate (PC), and combinations thereof (Ebnesajjad, 2012; Shaikh et al., 2021).

However, the environmental consequences of this plastic dominance have become increasingly severe. Approximately 350 million tons of plastic garbage are generated worldwide annually, with only 9 % recycled and roughly 22 % improperly managed according to Organization for Economic Co-operation and Development (OECD) figures (Annex). This inadequate waste management has led to significant ecological damage and human health concerns, particularly through microplastic migration into food systems (Katsara et al., 2022; Shruti and Kutralam-Muniasamy, 2024). Firstly, in 2004, Thompson et al. revealed in their research publication that "microplastics" are threatening the environment (Thompson et al., 2004). Additionally, Oceanographers' reports found that approximately 65 million microplastic particles are released into the water daily after being treated by the sewage treatment plant (Li et al., 2023).

In response to these mounting concerns, regulatory frameworks have emerged globally, with several countries implementing bans on plastics below 60 μm in thickness (Behuria, 2021). Simultaneously, brands and consumer preferences have shifted toward environmentally conscious purchasing decisions, driving demand for sustainable packaging alternatives, especially when more countries implement laws prohibiting single-use, conventional plastics. (Davis and Song, 2006). This convergence of regulatory pressure and consumer demand has created unprecedented opportunities for biodegradable packaging materials, with the global market projected to reach $140.6 billion by 2029 at a CAGR of 5.97 % (Verma et al., 2024). Driven by these global regulations and sustainability targets, there is a pressing need to explore eco-friendly packaging alternatives. This review focuses on evaluating protein-based biodegradable packaging materials as a sustainable replacement for conventional plastics.

Among various biopolymers, plant protein-based materials have emerged as particularly promising due to their superior barrier and mechanical properties compared to other polysaccharides (Athanasopoulou et al., 2024; D'Almeida and de Albuquerque, 2024; Sabato et al., 2001). The crosslinking capability of proteins enhances film strength by linking molecules together, while their compatibility with plasticizers and additional polymers enables property customization for specific applications (Wittaya, 2012). Key protein sources, including soy, zein, gluten, pea, and sunflower, offer abundant, commercially viable raw materials (Kumar et al., 2022). Furthermore, these materials can be incorporated with active agents to develop active packaging systems that prolong the shelf life of foods (Infante-Neta et al., 2024; Pawde et al., 2024). From the regulatory perspective, biodegradable packaging materials must comply with standards such as ASTM D6400, EN 13432, or ISO 17088, which ensure that these materials degrade efficiently without leaving toxic residues (ASTM, 2012; Standardization, 2012). For food packaging applications, materials must adhere to stringent food safety regulations, including FDA 21 CFR (U.S.) or EU Regulation 10/2011, to prevent the migration of harmful substances into food products (Avellanet, 2009).

Despite significant advances in protein-based packaging development, including various fabrication techniques such as extrusion blowing (Mangaraj et al., 2019), solution casting (YousefniaPasha et al., 2021), coating (Ramos et al., 2016), co-polymerization (Chalermthai et al., 2020), electrostatic spinning (Mehta et al., 2023) printing and advanced methods like 3D printing (Dey et al., 2022) a critical knowledge gap persists. Current literature lacks a comprehensive analysis of how protein source selection, fabrication method choice, and commercial feasibility interconnect to determine successful food packaging applications.

Therefore, this review addresses the following research question: How do different plant protein sources and fabrication methods interact to influence the commercial viability and application success of biodegradable food packaging materials? To answer this question, we systematically examine: (1) the relationship between protein source characteristics and packaging performance, (2) how fabrication methods affect scalability and cost-effectiveness, and (3) commercial barriers and opportunities in food packaging applications. By bridging this knowledge gap, this review provides a strategic framework for researchers and industry stakeholders to develop scalable, cost-effective protein-based packaging solutions for commercial food industry implementation.

2. Sources of plant-based protein for packaging

Proteins are naturally occurring macromolecules composed of long chains of 20 amino acids, primarily made up of carbon, hydrogen, oxygen, nitrogen, and sometimes sulfur (Belitz et al., 2004; Rawdkuen, 2019). Their diverse structures determine specific functions, which can be altered (denatured) by treatments such as heat, pH changes, or chemical exposure for targeted application (Senthilkumaran et al., 2022). By harnessing the power of nature, researchers have been developing innovative and environmentally sustainable packaging solutions to minimize the ecological footprint of packaging materials (Patel, 2023). In the search for alternatives to petroleum-based plastics, plant-based proteins have drawn growing industrial attention due to their multifunctionality and health benefits (Kaewprachu et al., 2016). In this section, we explored various sources of plant proteins, their properties, manufacturing capacities, and potential to replace petroleum-based plastics. The exploration focuses on their functional characteristics and scalability for sustainable packaging development.

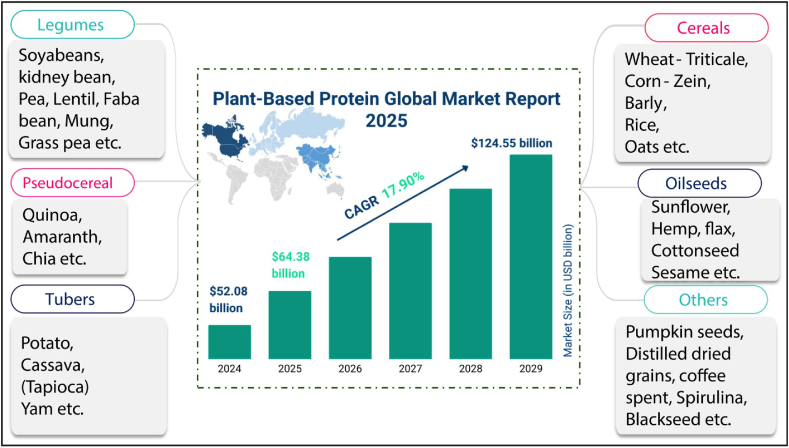

Global protein demand presents both dietary and industrial challenges, creating opportunities for sustainable packaging. Addressing this demand with environmental sustainability is a growing focus for industries and start-ups (Aschemann-Witzel et al., 2021). Plant protein as a packaging material is a rising research and business interest. According to the FAO, 2.01 billion tons of municipal solid waste (MSW) is generated annually, including agricultural waste, a rich source of proteins (Piercy et al., 2023). Several agro-industrial waste streams have been identified as promising protein sources (Prandi et al., 2019). The plant-based protein market is expanding rapidly, expected to reach USD 64.38 billion by 2025 with a CAGR of 23.6 %, as depicted in Fig. 1 (Plant-Based Global Market Report 2025). This growth reflects increasing consumer demand for plant protein-based materials. Among them, 38–40 million tons annually from the brewing industry, Brewer's Spent Grain (BSG), which contains 14–30 % protein (Chetrariu and Dabija, 2020). Various protein sources and market forecasts are shown in Fig. 1. Recent research advancements from the past five years are summarized in Table 1, providing an overview of advancement in plant protein-based packaging. In the commercial sector, notable innovations include the partnership between startup Xampla and the UK retailer Gousto, developing a sustainable film pea protein derived from legumes and agricultural waste. This breakthrough led to the creation of the world's first vegan, edible stock cube wrapper, offering an eco-friendly alternative to conventional packaging.

Fig. 1.

Illustration of global market overview and primary sources of plant-based proteins (Becze et al., 2024; Biswas et al., 2023; Hadidi et al., 2022; Mirpoor et al., 2022).

Table 1.

Summary of principal studies utilizing plant protein as base material for packaging material development from 2021 to 2025.

| Sl. No. | Base Material | Fabrication Technique | Study objective | Results | Reference |

|---|---|---|---|---|---|

| 1. | Soy & Pea protein | Solution casting after the Protein fibrillization process | To develop soy and pea protein-based fibrils for biodegradable film | Film resulted in enhancements in the structural, mechanical, and functional properties | Karabulut (2025) |

| 2. | Kidney bean protein & grape pomace | Solution casting | Develop an active biodegradable packaging film with Antioxidant and antibacterial properties | Results reflected that a 50/50 ratio improved hydration, barrier, structural, mechanical and thermal properties | Samani et al. (2025) |

| 3. | Soybean lipophilic protein & thyme oil | solution casting | Develop emulsion films with enhanced thyme oil retention to prolong the shelf life of salmon | Film demonstrated strong biocompatibility, water resistance, thermal stability, antioxidant and antimicrobial activity, sustained release capabilities, and efficient biodegradability | Sun et al. (2025) |

| 4. | Grass pea protein, apple pomase pectin & propolis extract | Dipping solution | To assess the effect of propolis extract concentrations in edible coatings on black mulberry shelf life | A 12 % propolis extract coating was most effective, maintaining postharvest quality of black mulberries and extending their shelf life to 18 days at 4 °C | Salimi et al. (2025) |

| 5. | Blackseed protein combined with furcellaran & chitosan | Layer by layer solution casting | Designing multi-layer biodegradable film | The tested films exhibited enhanced water behavior, improved UV–Vis barrier properties, and increased antioxidant activity (DPPH >70 %) compared to the control film | Kasprzak et al. (2024) |

| 6. | Zein- & soy protein isolate | Injection molding | To check impact of recycling on biodegradable bio-based materials | It is confirmed that protein-based bioplastics derived from two different renewable sources can be reprocessed while preserving their mechanical properties | Alsadat-Seyedbokaei et al. (2024) |

| 7. | Wheat, zein protein & carrot pomase | Compression molding | Design natural polymeric materials by compression molding | These biocomposites exhibiting mechanical strength (elastic modulus of 244 MPa and tensile strength of 10 MPa), elongation at break of 24 %, high transparency and optical clarity, effective UV blocking, excellent antioxidant activity, and strong barrier properties against water | Merino et al. (2024) |

| 8. | Spent coffee grounds (SCGs) protein | Mycelium-based pellets (produced by pellet mill) | Valorization of SCGs through protein extraction for use in mycelium-based packaging and pellets | These findings emphasize the potential of SCGs as a versatile resource, offering sustainable solutions across multiple industries | Becze et al. (2024) |

| 9. | Soya protein, grape seed & green tea extracts | Film formation by 3D printing with accuracy (>98 %), pressure of 0.062 MPa and nozzle diameter of 0.25 mm | Design and fabricate edible active packaging materials using 3D printing technology | Grape seed and green tea extracts modified the structural, mechanical, and antioxidant properties of films by affecting protein-protein interactions and altered the rheological behavior | Ahmadzadeh et al. (2023) |

| 10. | Cottonseed protein & PLA | Solvent casting method | Reduces cost while enhancing the opacity and stretchability of the film to some extent | The combination offers complementary benefits, making these films suitable for food packaging applications | Biswas et al. (2023) |

| 11. | Zein | Injection molding | The aim of this work was to develop bioplastics using zein | The absence of significant crosslinking facilitated melting, thereby confirming the recyclability of zein-based materials while preserving their properties | Alsadat-Seyedbokaei et al. (2023) |

| 12. | Soybean, wheat, Zein protein & cellulose nanocrystals | Solution casting | To enhance physicochemical properties of plant protein packaging film through integration with biodegradable materials | The study demonstrated that cellulose nanocrystals significantly improved the physicochemical properties | Fu et al. (2022) |

| 13. | Hemp seed protein | Solution casting | Develop biodegradable packaging using hemp protein and different glycerol concentrations and at different pH level | Films prepared at pH 12 with 50 % glycerol (w/w protein) as a plasticizer demonstrated improved resistance, maintained flexibility, and found higher in heat-sealing strength | Mirpoor et al. (2022) |

| 14. | Sunflower protein isolates & bacterial nanocellulose | Solution casting | Application of sunflower-based biorefinery to biodegradable biofilms for food packaging applications | The biofilms were tested for fresh strawberry packaging, demonstrating effective preservation at 10 °C by inhibiting microbial growth and maintaining the quality | Efthymiou et al. (2022) |

| 15. | Soy Protein | Extrusion and injection molding | To develop soy protein-based bioplastics by incorporating zinc sulfate through extrusion, utilizing different plasticizers and processing temperatures | The results highlight the significant potential of extrusion for bioplastic development, offering the possibility of reducing operating costs during industrial processing | (Jiménez‐Rosado et al., 2022) |

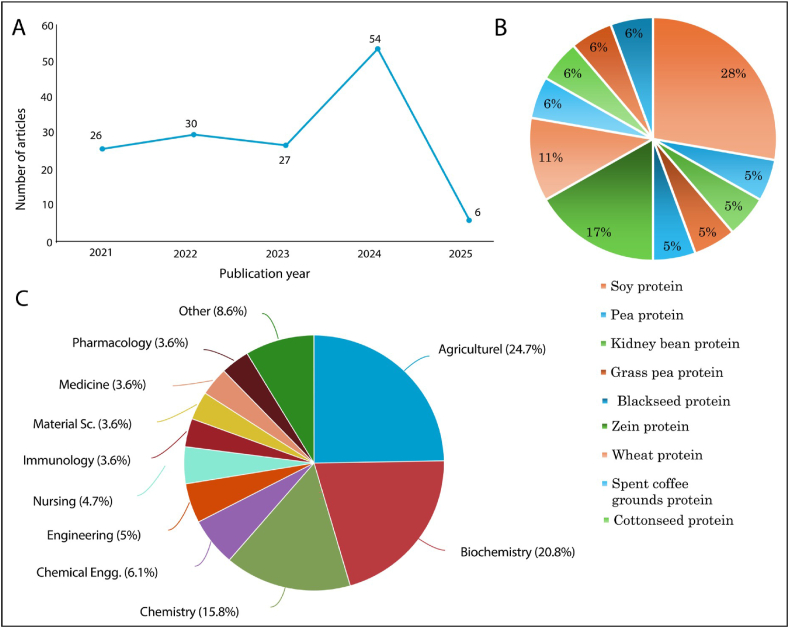

To analyze the research trends and identify plant sources used in food packaging, a literature search was conducted using the Scopus database with a systematic review methodology (Scopus.com). The search followed PRISMA guidelines to ensure transparency and reproducibility. The query included: KEY (plant AND protein AND packaging) AND PUBYEAR >2020 AND PUBYEAR <2026, filtered to English-language research articles. Furthermore, subject-specific filters were applied to include only articles categorized under "Food Packaging" or "Proteins" as exact keywords. Inclusion criteria specified peer-reviewed research articles published between 2021 and 2025, studies with an explicit focus on plant proteins for food packaging applications, and articles in full text. Exclusion criteria removed conference papers, book chapters, reviews, animal protein studies, purely synthetic polymer work, and inaccessible full texts. This ensured comprehensive, high-quality analysis. These criteria yielded 143 research articles (shown year-wise in Fig. 2A), indicating a steady increase in publications and growing academic interest. Of these, 15 explicitly examined plant proteins in food packaging applications. Fig. 2B shows the percentage-wise distribution of plant protein sources used in packaging, revealing that soy, wheat, and pea proteins are the most used plant sources, reflecting their availability and functional properties. Fig. 2C categorizes the dataset by subject area, demonstrating the interdisciplinary nature of the research, with contributions from food science, materials science, and environmental disciplines. These trends underscore the expanding focus on sustainable, plant-based alternatives in packaging technology.

Fig. 2.

Overall illustration of plant protein-based packaging research articles published from 2021 to 2025: (A) Number of articles published per year, (B) Percentage distribution of different plant-based sources used, and (C) Articles categorized by subject area (Source:Scopus.com for A & C).

2.1. Legumes based protein for packaging

Legumes are a vital source of plant-based proteins, typically ranging from 17 to 40 %. Among them, soybeans are the most widely cultivated and considered the leading source of plant-protein (Adilah et al., 2023; Murdayanti and Rawdkuen, 2016). Other legumes, including chickpeas, lentils, peas, faba beans, cowpeas, and peanuts, also exhibit high protein content. In addition to their protein content, legumes are rich in starch and lipids, making them a promising resource for developing biodegradable packaging. Starch serves as a natural polymer, while lipids function as plasticizers (Thamarsha et al., 2024). However, lipid-protein interactions can influence the mechanical and barrier properties of films, depending on their hydrophobic or protein lipid structure (Enujiugha and Oyinloye, 2019). The global legume protein market is projected to reach USD 14.86 billion by 2025, with a CAGR of 5.6 % from 2025 to 2032 (Singh et al., 2025). Legumes offer superior commercial viability due to established supply chains, proven extraction technologies, and feedstock costs of USD 0.30–0.50/kg. Their inherent plasticizer content reduces the need for additives. However, high humidity can impair water barrier performance due to protein lipid interactions, requiring formulation optimization. Legumes support industrial-scale production with existing infrastructure, making them suitable for large-volume applications where cost efficiency is prioritized.

2.2. Cereals based protein for packaging

Cereals contain proteins such as albumin, globulin, prolamin, glutelin, zein, and gluten. Key sources include corn-derived zein, wheat gluten, and rice proteins, often obtained as byproducts from oil extraction and grain milling. Their balanced hydrophobic and hydrophilic amino acid content enhances film forming properties (Linares-Castañeda et al., 2023). FAO estimates global cereal protein production at 2.5 billion tonnes annually, highlighting their potential in eco-friendly packaging solutions. Brewer's spent grain (BSG), primarily from barley malt husks, is rich in protein and traditionally used as animal feed. US Patent 2022162529A1 outlines systems for processing BSG into materials for sustainable packaging (Mcknight Darin et al., 2022). Bio composites from wheat gluten and zein exhibit an elastic modulus of 244 MPa, tensile strength of 10 MPa, and 24 % elongation at break, proving their potential as plastic alternatives (Merino et al., 2024). Cereals offer scalability advantages due to high production volumes and low feedstock costs (USD 0.10–0.25/kg). However, lower protein content (8–15 % in wheat, 9–12 % in corn) demands higher processing volumes. Variability in protein quality and the need for additives complicate processing. Despite these challenges, cereals are optimal for cost-sensitive applications requiring moderate performance.

2.3. Pseudocereals based protein for packaging

Pseudocereals such as quinoa, chia, and amaranth primarily yield globulin proteins with excellent film-forming and bioactive properties. Amaranth protein films, enhanced with betanin via coacervation and ultrasound treatment, offer active and sustainable packaging (Constantino and Garcia-Rojas, 2022). Quinoa protein based edible packaging films, enhance stability of active compounds under environmental conditions (K. Chen et al., 2023). Enzymatic hydrolysis with pancreatin improves emulsifying, foaming, and antioxidant properties in quinoa protein (Daliri et al., 2021; Karaca, 2022) Similarly, Chia seeds have also produced fully biodegradable, water-soluble films (Fernandes et al., 2020). Pseudocereals possess complete amino acid profiles and natural antimicrobial properties, positioning them as premium alternatives. However, commercial adoption is limited by high feedstock costs (USD 3–8/kg), small production volumes (typically <1000 tons/year), and complex extraction processes. Supply volatility and processing challenges restrict their use to high-value, niche markets.

2.4. Oilseed based protein for packaging

Oil cakes, the residual meal from oil extraction, offer protein (15–50) suitable for packaging materials (Vinayashree and Vasu, 2021). These by-products are rich in proteins and polysaccharides. Optimizing processing conditions, particularly pH, enhances the usability of these proteins in packaging applications (R. Zhang et al., 2024). The global oilseed market is expected to reach USD 432.26 billion by 2031, growing at a CAGR of 5.1 % (Coherent Market Insights). Films from defatted peanut flour show good water vapor barriers but low tensile strength compared to other protein-based films (Riveros et al., 2018), while sesame protein films with nanoclay demonstrate increased tensile strength but reduced elongation and permeability (Lee et al., 2014). Film properties vary by source, indicating that optimized formulations can enhance performance. The use of waste streams reduces feedstock costs. However, variability due to residual oil content, inconsistent protein extraction, and non-standardized processing limits reproducibility. Despite these challenges, oilseeds hold commercial promise due to their processing infrastructure and growing demand, especially in applications matched to specific source properties.

2.5. Tubers based protein for packaging

Starch from tubers like cassava, potatoes, yams, and cubioe is a biodegradable, renewable material with a global production of 60 million tons annually (Ai and Jane, 2024). Starch is a heterogeneous polymer composed of two key components: amylose, a linear polymer of α-1,4-linked glucose units, and amylopectin, a highly branched polymer with short α-1,4 chains linked by α-1,6 bonds (P. Chen et al., 2006). Starch comprises amylose and amylopectin, with amylose offering properties similar to synthetic polymers (Liu et al., 2009). Heat processing causes gelatinization, altering its structure, but starch decomposes before melting, making it unsuitable for conventional plastic processing (Lan et al., 2010; Tongdeesoontorn and Rawdkuen, 2019). Additives like PLA are used to overcome this, enhancing mechanical and thermal properties (Jiang et al., 2022). Tubers benefit from established agricultural infrastructure and low-cost feedstock. However, thermal decomposition and amylose/amylopectin variability require hybrid processing with compatible polymers. Despite limitations, tuber-based materials are viable for cost-efficient packaging in regions with strong starch processing capacity.

2.6. Others plant proteins for packaging

Additional sources include pumpkin seed (Lalnunthari et al., 2019), spent coffee grounds (SCG) (Becze et al., 2024), spirulina (Benelhadj et al., 2016), and black seeds (Kasprzak et al., 2024). Protein content varies in pumpkin seeds (24 %), spirulina (45 %), SCG (12–17 %), and black seeds (20–22 %). Spirulina, a microalga, offers antimicrobial, antioxidant, and immunomodulatory properties (Khan et al., 2005). Films from algae commonly use GRAS-certified alginate and carrageenan (Benelhadj et al., 2016). Spirulina's market is projected to grow from USD 0.7 billion in 2024 to USD 1.57 billion by 2032 (Market data forecast). It offers high protein content and antimicrobial function, but costs USD 15–25/kg, limiting use to premium products. SCG provides a low-cost (USD 0.05–0.10/kg) waste valorization option but requires large volumes due to lower protein content. Pumpkin and black seeds offer moderate protein levels but face supply and functional variability. Commercial viability varies, with spirulina suited for high value uses, SCG for low-cost projects, and others for specific functional requirements.

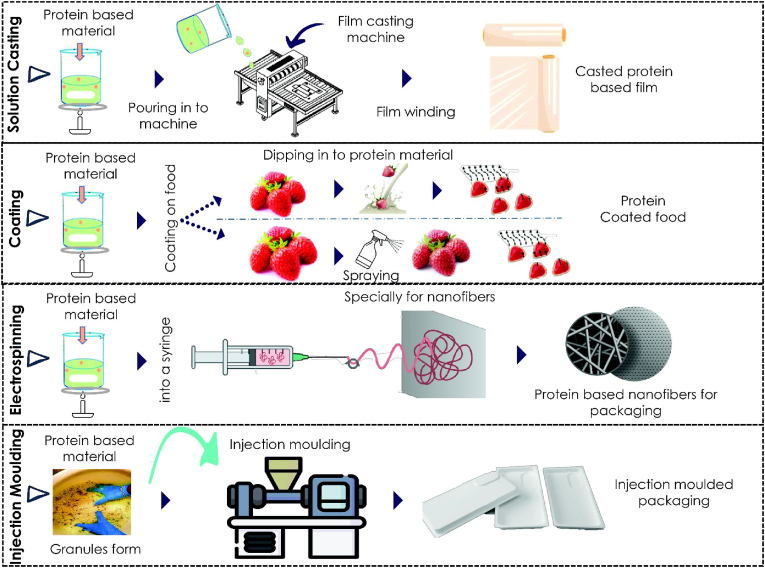

3. Types of food packaging from plant-based proteins

Various techniques have been employed to fabricate plant protein-based packaging materials, as illustrated in Fig. 5. The selection of an appropriate processing technique depends on the desired packaging type, which, in turn, is dictated by its intended application in food systems (Marsh and Bugusu, 2007). Similarly, selecting a suitable packaging type is critical for maintaining food quality, safety, and extending shelf life see Table 2. Therefore, ensuring compatibility between the product and the selected packaging material is essential to optimize preservation and functional performance (Verghese, 2008). The selection of a specific packaging material for a specific food product is primarily determined by the food product's requirements, including mechanical protection, barrier properties, and environmental considerations (Verghese, 2008).

Fig. 5.

Schematic illustration solution and granules based packaging material formation from plant protein-based materials, with each column representing a different fabrication method: Column 1- solution casting (Samani et al., 2025), Column 2- coating (Patil et al., 2023), Column 3- electrospinning, and Column 4- injection molding (Alonso-González et al., 2021). (Image source: Google).

Table 2.

Comparative overview of plant protein-based packaging types: applications, market trends, and environmental benefits.

| Packaging type | Description & applications | Market insight | Environmental benefits |

|---|---|---|---|

| Films & Coatings | Thin layers applied directly to food to enhance shelf life, protect from moisture, oxygen, and microbial contamination | Market for protein-based films: USD 132.5M in 2024, projected to USD 234M by 2034 | Edible, biodegradable, safe (GRAS status), reduces synthetic packaging use |

| Disposable cutlery | Includes spoons, forks, straws made from plant protein composites as eco-friendly alternatives to plastic cutlery. | Global market: USD 10.66B (2024), projected to USD 14.87B by 2030 with 5.61 % CAGR. | Replaces petroleum-based cutlery, reduces waste from food delivery and takeout services |

| Capsules & Pods | Encapsulate food powders or liquids (e.g., condiments, nutrients); convenient for single serve portions | Emerging market with increasing interest in convenience and eco-packaging | Reduces excess packaging, offers biodegradable and recyclable options |

| Wraps & pouches | Used as standalone packaging (e.g., snack wraps, pouch liners) with specific barrier properties | Applied in flexible food packaging and evolving to replace multilayer plastics | Biodegradable, recyclable, potentially edible reduces synthetic primary packaging material |

| Edible packaging | Entire packaging can be consumed along with food; primarily based on safe plant proteins | Gaining attention due to FDA GRAS classification and consumer shift to natural products | Zero-waste potential, eliminates disposal issues, ideal for sustainability conscious consumers |

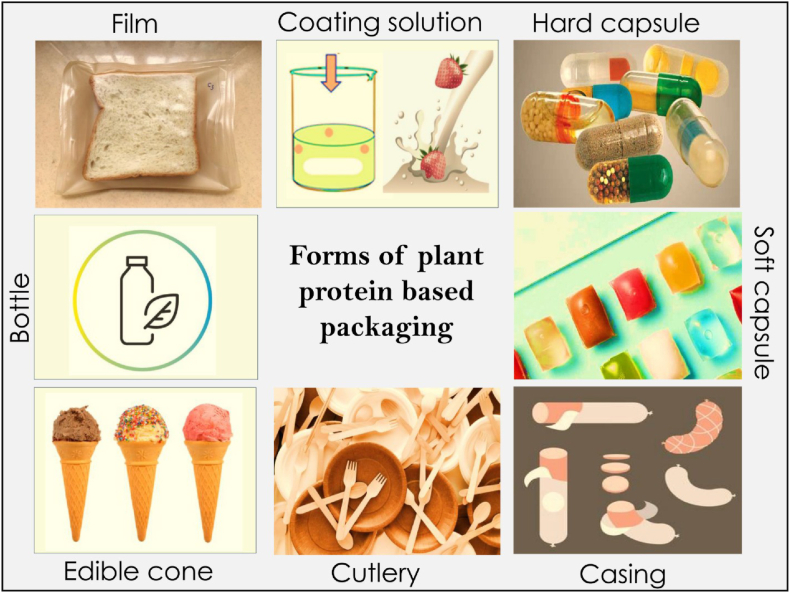

Plant protein-based packaging can be classified into various forms based on functionality and application, as shown in Fig. 3. Among these, films and coating solutions have the highest demand and market potential due to their compatibility with various foods. Notably, the global market for protein-based films alone is valued at USD 132.5 million in 2024 and is predicted to reach USD 234 million up to 2034 (Future Market Insights). Additionally, these plant protein-based materials are non-toxic and safe for direct contact with food, making them ideal for food coatings and wrappings. Furthermore, the growing demand for sustainable packaging, driven by increasing environmental concerns and stringent regulatory policies in various countries, has accelerated their adoption in the food industry (Nordin and Selke, 2010).

Fig. 3.

Illustration of various forms of plant-based protein packaging materials for different food applications (source: freepic & packagingguruji.com).

Moreover, proteins consist of monomers that contribute to their unique functional characteristics, making them more desirable for coating applications than other materials due to their strong capacity for intermolecular interactions. Protein-based coatings have been widely applied within the food industry, particularly for fruits, vegetables, seafood, meat, and dried fruits (Hassan et al., 2018; Khin et al., 2024; Tongdeesoontorn and Rawdkuen, 2019; Zhen et al., 2022). Moreover, consumer concerns regarding synthetic and chemically derived coating solutions have led to a growing preference for natural, protein-based sustainable coatings. These coatings have gained significant attention, particularly because they are classified as GRAS by the FDA (Shahidi and Hossain, 2022).

The third-largest demand within the edible and protein-based packaging sector is for cutlery. After petroleum-based conventional films, plastic cutlery significantly contributes to plastic pollution. The increasing consumer preference for on-the-go dining and the rapid expansion of the food delivery sector further drives the demand for disposable cutlery (Acquavia et al., 2021). The global disposable cutlery market reflects this trend, growing from USD 10.14 billion in 2023 to USD 10.66 billion in 2024, with a projected CAGR of 5.61 % and reaching USD 14.87 billion by 2030 (researchandmarkets.com). In the US alone, approximately 500 million single-use plastic straws are used daily, while in Europe, annual consumption is estimated at 25.3 billion, posing a significant environmental threat (Dybka-Stepien et al., 2021). To address this issue, global strategies are focusing on reducing plastic cutlery, cups, and packaging consumption. A key approach involves replacing these with biodegradable and eco-friendly alternatives to mitigate plastic waste and contribute to global pollution reduction efforts.

On the other hand, capsules form packaging are becoming an emerging solution for encapsulating liquids or powder food, enabling easy storage, transport, and consumption (Khin et al., 2024). They eliminate extra packaging, reduce waste, and allow novel formulations, such as encapsulating flavors, nutrients, or supplements. Ideal for single-serving condiments, beverages, and nutrient delivery, they offer a customizable, eco-friendly solution (Đorđević et al., 2015). Protein based films, wraps, pouches, and coatings protect food from environmental factors, reducing reliance on non-edible packaging and improving recyclability. For example, an oxygen-barrier coating for roasted peanuts could replace an oxygen-barrier layer in flexible pouches, enabling simpler, recyclable packaging. Even after opening, edible coatings maintain product protection, enhancing shelf life (specright.com).

4. Characteristics and properties of plant protein-based food packaging

The effectiveness of food packaging is largely determined by its mechanical, barrier, and thermal properties, which are essential for protecting food quality and safety (Kaewprachu and Rawdkuen, 2014). From an environmental perspective, biodegradability is a key attribute, ensuring sustainable waste management. Currently, petroleum-based packaging materials offer superior mechanical strength, barrier efficiency, and thermal stability; however, their environmental impact remains a significant concern due to their non-biodegradable nature (Wu et al., 2021). To address this, natural biodegradable materials, particularly plant protein-based polymers, have emerged as promising alternatives capable of competing with conventional plastics since proteins have a unique structure (based on 20 different monomers) which provides a broader range of functional properties (Kaewprachu et al., 2016). This section highlights recent advancements in the mechanical, barrier, thermal, and biodegradable properties of plant protein-based packaging materials.

4.1. General properties and functions of plant protein based packaging

4.1.1. Mechanical properties

The mechanical, barrier, and thermal properties of protein-based packaging can be enhanced by incorporating plasticizers, additives, surfactants, cross-linking agents, blending with biopolymers, and employing nanotechnology (Mostafa et al., 2023; Shah et al., 2023). When evaluating edible films, key mechanical parameters such as Young's modulus, Elongation at Break (EAB), Puncture strength, and Tensile Strength (TS) are crucial for determining their performance. Incorporation of protein-based polymers with other biopolymers is an effective approach to improve the mechanical and functional properties films (Calva-Estrada et al., 2019). For instance, the reinforcement of soy protein with cellulose nanofibers resulted in a remarkable increase in TS (by 300 %) and Young's modulus (by 666.6 %) (Milani and Tirgarian, 2020). Previous studies have reported that soy protein films exhibit poor mechanical properties, rendering them brittle and difficult to handle. However, the incorporation of gelatin into protein films significantly improved TS and EAB, enhancing both strength and flexibility (Cao et al., 2007). This enhancement is credited to the formation of a hydrogen bond network between polar groups, improving the mechanical and barrier properties of protein films (Dehghani et al., 2018).

4.1.2. Barrier properties

Among all the corn-zein proteins, those that exhibit excellent barrier properties are promising materials for food packaging. Their unique protein structure provides a high intermolecular binding potential, improving their functional performance (Tihminlioglu et al., 2010). However, despite their superior barrier characteristics, zein films are limited in packaging applications because of poor mechanical properties (L. Zhang et al., 2020). Zein and wheat gluten films have shown strong resistance to oxygen permeability, with OTR (oxygen transmission rate) values as low as 0.1–0.4 cm3 m−2·day−1 atm−1, making them suitable for oxygen sensitive food products. However, high water vapor permeability (WVP), often in the range of 4–8 g mm/m2·day·kPa, limits their use for moist food items unless properly modified. Currently, ethylene vinyl alcohol (EVOH) is widely used as a coating substance to improve the barrier properties of low-barrier polymers. However, zein-based coatings have the potential to replace EVOH in the future, offering a more sustainable alternative. Incorporating additives can improve zein-based edible films' desirable properties (Escamilla-Garcia et al., 2013; Vieira et al., 2011). Similarly, wheat gluten serves as an effective coating material for films because of its high barrier properties, such as a barrier for water and oxygen diffusion, which contribute to food deterioration. The cohesiveness and elasticity of gluten also facilitate film formation (Rocca-Smith et al., 2016). Among protein-based films, wheat gluten-based films exhibit the highest elasticity along with excellent oxygen barrier properties, hydrophobicity, and thermal stability. However, they are limited by high water vapor permeability (WVP) and low mechanical strength, necessitating further optimization (Fabra et al., 2015; Mojumdar et al., 2011). In food contact applications, such films have demonstrated shelf-life extension of up to 5–7 days for perishable fruits and vegetables by significantly slowing oxygen ingress and microbial growth. Studies have shown that incorporating glycerol as a plasticizer enhances the mechanical properties of gluten-based films by increasing TS while decreasing EAB (Sharma et al., 2017).

4.1.3. Thermal properties

Thermal properties play a crucial role in determining the stability of packaging under varying heat conditions during processing, transportation, and storage. Polymers with high crystallinity exhibit superior mechanical and thermal properties, whereas low molecular weight polymers often demonstrate reduced strength due to their highly crystalline nature (Balani et al., 2015). Among protein-based films, those derived from myofibrillar proteins exhibit excellent thermal stability, high transparency, and superior water vapor resistance, outperforming many other protein-derived films. Myofibrillar proteins are generally water-insoluble but can dissolve in concentrated saline solutions, making them a promising material for packaging applications (Milani and Tirgarian, 2020). The polypeptide sequence of plant proteins, the continuity of protein strands, and the makeup of amino acid residues all play a significant role in determining their structural and functional characteristics (Hadidi et al., 2022). Since proteins are inherently susceptible to thermal denaturation, recent studies have explored innovative strategies to enhance their thermal stability. For instance, the application of cold plasma technology has been shown the thermal degradation temperature of protein-based films from 264 °C to 323.57 °C, significantly improving their thermal resistance (G. Chen et al., 2019). Additionally, the addition of pea protein with tapioca starch using blown film extrusion technology has been reported to enhance the physical, thermal, and barrier properties of the developed films, rendering them highly appropriate for oil packaging applications (Huntrakul et al., 2020).

4.1.4. Biodegradability and composability

Commercial biodegradable plastics require certification to validate sustainability claims, as their degradation profiles vary based on composition, thickness, and additives. Each product needs separate certification, tested by third-party laboratories, methodology set by the International Organization for Standardization (ISO), the American Society for Testing and Materials (ASTM), the European Committee for Standardization (CEN), and others. These certifications assess biodegradability, compostability, disintegration, and ecotoxicity, ensuring compliance with environmental standards (Ghosh and Jones, 2021). Among polysaccharides, proteins, and lipids, proteins exhibit superior food packaging material due to their nutrient and biodegradability. Their limited solubility in water can be enhanced by adjusting the pH above or below their isoelectric point (Nadendla and Friedman, 2017). Proteins are naturally susceptible to degradation due to their peptide bonds, which microbial enzymes efficiently hydrolyze into smaller peptides and amino acids, eventually mineralizing into carbon dioxide, water, and biomass (Colla et al., 2015). Each protein source contributes uniquely to biodegradability. Soy proteins, for instance, offer significant advantages due to their gelation, emulsification, and water- and oil-holding capacities. Their high solubility is attributed to the interaction between β-conglycinin and the basic polypeptide of glycinin, making them suitable for sustainable packaging applications (Ma, 2020). However, plant-protein-based films must also comply with food safety regulations such as FDA 21 CFR and EU Regulation No. 10/2011, which limit migration of chemicals into food, restrict non-GRAS additives, and require toxicological data for novel substances. These regulations present formulation and scalability challenges in commercial applications. Future research should focus on improving barrier properties while maintaining biodegradability through biopolymer blends, enzymatic modifications, and nanotechnology approaches. Developing standardized assessment protocols for biodegradation under real-world conditions will further enhance the commercial viability of protein-based packaging.

4.2. Advanced plant-based protein packaging: active system

Active packaging plays a vital role in preserving food by actively interacting with the packaged food to maintain quality and freshness (Pawde et al., 2024). Using plant-based proteins as base materials for active packaging has emerged as a promising strategy. This approach involves the incorporation of active compounds into the plant protein matrix during packaging fabrication. Plant proteins offer significant advantages over conventional plastic-based materials in active packaging applications. Their inherent functional properties allow them to serve as effective carriers for active compounds, facilitating controlled release and prolonged activity (Said and Sarbon, 2019). The interaction between the protein matrix and active agents enhances the efficacy and longevity of the active packaging system, making plant-based protein films a sustainable and functional alternative to synthetic polymers.

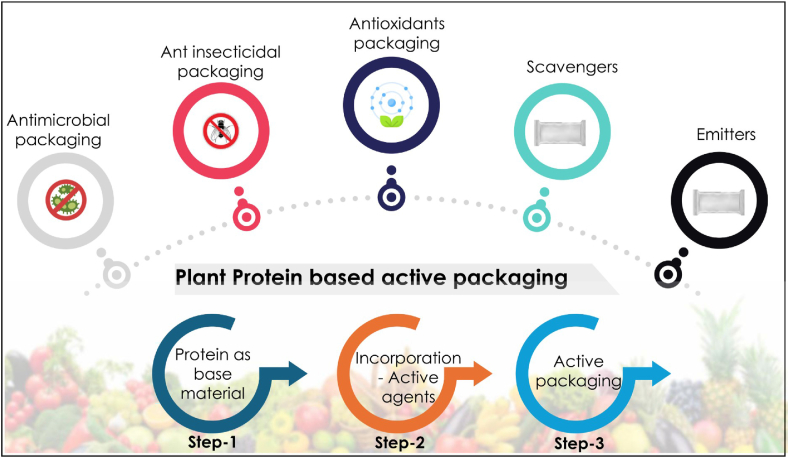

Active packaging systems can be categorized based on the form of packaging and the type of active agents incorporated, as illustrated in Fig. 4. These systems encompass a wide range of technologies designed to enhance food preservation, including oxygen scavengers, moisture absorbers, antimicrobial agents, ethylene absorbers, humidity controllers, carbon dioxide absorbers/emitters, anti-insecticidal packaging, flavor and aroma absorbers, UV blocking, and pH regulators (Ozdemir and Floros, 2004). In addition to direct incorporation into packaging materials, active compounds can also be integrated into coating formulations, which are considered a subset of active packaging. These coatings act as functional barriers, providing additional protection while interacting with the food surface. Regulatory guidelines currently permit only GRAS compounds for coating applications, ensuring food safety and compliance with legal standards (Blancas-Benitez et al., 2022). With growing interest in sustainable alternatives, plant-based protein films have emerged as effective carriers for active agents, driving innovation in next-generation active packaging. The global active packaging market, valued at USD 29.94 billion in 2024, is projected to reach USD 78.36 billion by 2034, growing at a CAGR of 10.10 % (Precedence research).

Fig. 4.

Overview of active packaging systems made using plant protein as a base material.

5. Fabrication method possibilities

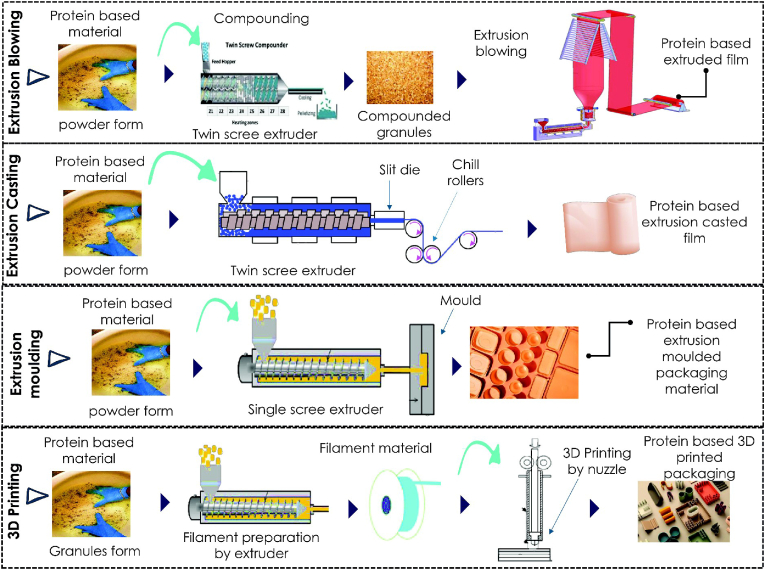

The selection of fabrication methods for producing packaging material depending on the intended application and the based material used. The selection of fabrication method and process parameters can influence the properties of the resulting material (Calva-Estrada et al., 2019; Mudgal et al., 2024). Different packaging systems can be produced using various techniques like extrusion blowing, casting, coating, electrospinning, injection molding, and 3D printing, as illustrated in Fig. 5, Fig. 6. For example, films can be produced using several methods, including solution casting, electrospinning, extrusion, and printing. From these techniques, melt extrusion is the most commonly used commercially for film making, owing to its scalability and efficiency for film (Calva-Estrada et al., 2019). Furthermore, casting-based methods are primarily limited to laboratory-scale research. Val Siqueira et al. observed a higher number of publications on casting compared to other methods, with its usage increasing by 100 %, while extrusion and molding grew by 22 % and 40 %, respectively. This trend suggests that starch based plastic research is still in its early stages, with casting serving as a fundamental step for formulation verification (do Val Siqueira et al., 2021). In this section, we explore techniques for protein based packaging production, focusing mainly on the challenges and possibilities of each and the comparison between all the methods discussed in Table 3.

Fig. 6.

Schematic illustration extrusion based packaging material formation from plant protein-based materials, with each column representing a different fabrication method: Column 1- extrusion blowing (Jiménez‐Rosado et al., 2022), Column 2- extrusion casting, Column 3- extrusion molding and, Column 4- 3D printing (Ahmadzadeh et al., 2023).

Table 3.

Comparison of fabrication methods for plant protein-based packaging materials.

| Fabrication method | Key features | Advantages | Challenges/Limitations | Application |

|---|---|---|---|---|

| Solution Casting | Solution preparation, casting, thickness, drying | Simple setup, good for additive incorporation, uniform films and applicable for batch process | Not scalable, batch process, long drying times, limited dimensions | Research films, formulation optimization |

| Extrusion | Heat, shear, pressure processing via screw extruders | High scalability, continuous process, versatile film formation (blowing, molding, etc.) | Requires precise control over process parameters; high setup cost | Films, trays, containers |

| Coating | Dipping, spraying, layer-by-layer, fluidized bed | Direct food contact, enhances shelf life, low material usage (spraying) | Poor water barrier, limited to surface layer applications | Edible coatings, perishable food wrapping |

| 3D Printing | Additive manufacturing using bio inks, layer by layer formation | Customizable designs, accurate control, automated | High moisture sensitivity, protein plasticizer compatibility, low material diversity | Functional films, smart packaging system |

| Electrospinning | High voltage electric field creates ultrafine protein fibers | High surface area, tunable properties, nanostructured films | Poor spinnability of many plant proteins, often requires polymer blending | Bioactive films, smart/active packaging |

| Injection Molding | High pressure injection of molten material into molds | Mass production, precise shaping, reusable molds | Process optimization needed, limited to rigid packaging | Cups, trays, cutlery |

| Compression Molding | Sheets pressed between heated molds under pressure | Suitable for water insoluble proteins, uniform thickness | Less detailed than injection molding, energy intensive | Plates, trays, containers |

5.1. Solution casting

This method is primarily used on the laboratory scale, particularly for developing protein-based films. Albumin proteins, being water-soluble, coagulate upon heating, whereas globulin fractions, classified as globular proteins, are insoluble in water but soluble in dilute saline solutions (Hadidi et al., 2022). However, the high processing cost, limited production capacity, and challenges in scaling up restrict its widespread commercial application (Madhumitha et al., 2018). This method involves several key steps: solution preparation, casting, drying, and winding, as illustrated in Fig. 5, Column 1. At the laboratory level, casting is typically performed on Teflon plates or Petri dishes, whereas commercial production utilizes casting machines equipped with drying and winding systems. Precise control over film thickness and drying temperature is crucial, as these parameters depend on the formulation materials used (Siemann, 2005). Solvent casting enables better incorporation of additives into biopolymer films, enhancing their functional properties. However, it operates as a batch process, making it unsuitable for large-scale production (Cheng et al., 2024). Despite its advantages in research and formulation optimization, solution casting has several limitations, including long drying times and restricted film dimensions, typically ranging between 25 and 30 cm in width or length (de Moraes et al., 2013). Given these constraints, efforts should be directed toward exploring alternative fabrication methods that offer better scalability and industrial feasibility.

5.2. Extrusion methods

Extrusion is a conventional and widely used film and bag formation technique, encompassing various methods such as extrusion blowing, extrusion casting, extrusion compression molding, and extrusion injection molding. This process involves the application of heat, shear, and pressure, which significantly influence the molecular dynamics and structural properties of proteins (Alibekov et al., 2024). Typically, the extrusion process begins with feeding of base materials into a screw extruder via a hopper as illustrated in Fig. 6 column 1. Inside the extruder, heat and shear forces elevate the temperature of the film-forming materials to their melting point. The molten material is then pushed through a die head, shaping it into granules, which may subsequently be processed in a blowing extruder for film formation. The screw speed, temperature, and other process parameters are adjusted based on the specific properties of the raw material (Pawde et al., 2023). Different extrusion techniques produce various packaging materials. Extrusion blowing forms thin films through blowing, pressing, and cooling, while extrusion compression molding uses hot pressing and cooling for uniform films with improved mechanical properties. Extrusion injection molding, a cost-effective method, injects molten material into molds to create complex plastic structures, making it widely used in polymer processing (do Val Siqueira et al., 2021).

5.3. Coating

Coating is a primary packaging layer, directly touching the food surface to enhance its protection and extend shelf life. Various coating techniques, including dipping, spraying, fluidized bed coating, panning, layer-by-layer deposition, and cross-linking, have been extensively studied in the literature (Kupervaser et al., 2023). Among these, dipping and spraying have achieved commercial success. The dipping method consists of three key steps: (i) immersion of the food product in the coating solution for a specified duration, (ii) adherence of the coating material to the food surface, and (iii) solvent evaporation, as illustrated in Fig. 5, Column 2 (Gupta et al., 2024). Uniformity in coating thickness depends on key material parameters such as density, viscosity, and surface tension. Spraying, another widely used commercial technique, offers higher efficiency compared to dipping by providing a more uniform coating while minimizing material usage. This is achieved through the use of fine nozzles, with sizes ranging from micrometers to nanometers, ensuring precise application and reduced wastage (Ahuja and Rastogi, 2023). Protein coatings show better gas barrier properties compared to other polysaccharides. However, the hydrophilic nature of proteins compromises their water barrier efficiency. The ability to form effective protein-based coatings is largely influenced by the composition, distribution, and polarity of amino acids, which determine the formation of intermolecular bonds such as hydrogen, amino, and disulfide linkages (Paidari et al., 2024). Addressing these limitations through novel cross-linking strategies and material modifications remains a key focus in advancing protein-based coating technologies.

5.4. D printing and electrospinning

3D printing has emerged as a rapid and scalable alternative to conventional packaging fabrication methods such as extrusion and solution casting. This technology offers accurate accumulation, controlled structures, and customizable properties, significantly reducing variability in the characteristics of the produced films due to its automated process control (Leontiou et al., 2023). As an innovative packaging fabrication method, 3D printing enables the development of functional materials with tailored properties (Ahmadzadeh et al., 2023). Protein-based materials are extensively utilized as bio-inks for 3D food printing due to their excellent structure-forming abilities, as well as their functional and nutritional benefits (Aghababaei et al., 2025). However, challenges associated with using plant proteins for extrusion-based 3D printing include their high moisture absorption, processing conditions, and the selection of suitable plasticizers to ensure optimal printability (Rowat et al., 2021). The success of 3D and emerging 4D printing technologies depends on critical material properties such as printability, stability, and time-dependent behavior.

Electrospinning is another promising technique for fabricating protein-based packaging materials. In this method, a high-voltage electric field is applied to a protein solution, causing the formation of ultrafine fibers that are deposited onto a collector (Wang et al., 2021). This process allows for the production of nanofibers with diameters ranging from nanometers to micrometers, offering enhanced surface area and tunable functional properties (Topuz and Uyar, 2020). Due to their inherent spinnability limitations, plant proteins are often blended with synthetic polymers to improve their processability. Among plant proteins, zein is the most widely used for electrospun nanofiber formation, given its excellent film-forming properties (F. Aghababaei et al., 2024). Both 3D printing and electrospinning provide unique opportunities for the development of next-generation sustainable packaging materials, enabling the fabrication of tailored, functional, and biodegradable films for food packaging applications.

5.5. Injection molding

Injection molding and compression molding are utilized for fabricating rigid biopolymer-based packaging materials such as cutlery, cups, containers, and trays (Cheng et al., 2024). In compression molding, biopolymer sheets are placed between heated molds and subjected to pressure, making it particularly suitable for hydrophobic materials with limited water solubility, as illustrated in Fig. 5, Column 4. The properties of the final molded products are influenced by key processing parameters, including temperature and molding duration (Kupervaser et al., 2023). Injection molding involves injecting molten polymer under high pressure into temperature-controlled molds, allowing the production of complex and detailed structures. This method consists of two main stages: a mixing stage and an injection molding stage, where crucial factors such as molding time and injection pressure play a significant role in determining product quality (Perez-Puyana et al., 2016). Due to its efficiency, repeatability, and capability to create intricate designs, injection molding is highly suitable for large-scale production. By optimizing material composition and processing conditions, this technique offers a promising approach to developing sustainable biopolymer-based packaging solutions.

Each fabrication method for plant protein-based packaging has unique advantages and challenges. Solution casting is typical in research but lacks scalability. Extrusion is commercially viable but requires precise control. Coating methods are well-established but have water barrier limitations. 3D printing and electrospinning offer precision but face material challenges. Injection and compression molding enable rigid packaging but need process optimization. Advancing scalability and formulation is key to commercial success.

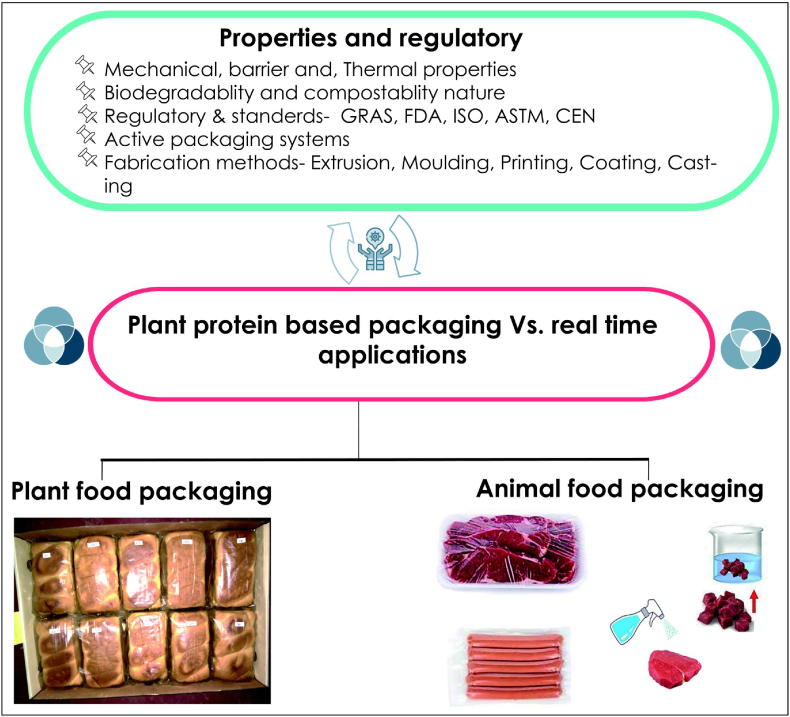

6. Real-time applications on food packaging

Protein based packaging is targeted to replace traditional plastics in food packaging while maintaining quality, safety, and shelf life. Extensive research has been conducted on protein-based packaging materials; however, their transition from laboratory studies to real-time food packaging applications remains limited. There are numerous factors to consider when applying the developed protein-based packaging material for real-time food packaging applications. This relationship is presented in Fig. 7. Challenges such as insufficient mechanical strength and functional properties hinder their commercial viability. Despite these obstacles, certain protein-based materials have successfully been applied in real-world scenarios, with a few achieving commercial success. Protein-based packaging materials hold great promise for food packaging due to their GRAS status by the FDA, eliminating regulatory challenges (FDA, 2006).

Fig. 7.

Relationship between properties, regulations, and real-time applications of protein-based biodegradable packaging materials (Packed meat image source: (Hashemi et al., 2023).

Additionally, their inherent nutritional benefits and consumer acceptance further support their feasibility for commercialization (Assad et al., 2020). Regulatory compliance says that newly developed packaging materials must be composed of non-toxic, food-grade components. Over time, protein-based packaging has found diverse applications, including edible coatings for fruits and confectionery, collagen-based casings for sausages, and protective coatings for delicate food products such as nuts and bakery items to prevent oxidation and physical damage (Iversen et al., 2022).

While the prime role of packaging is to protect foods, protein-based packaging integrated with active compounds can further extend shelf life by enhancing barrier properties and providing antimicrobial benefits (Assad et al., 2020). The selection of suitable packaging material depends on several factors, including the nature of the food product, intended shelf life, and functional requirements of the packaging system (Bhaskar et al., 2023). In this section, we will understand the need and challenges of protein-based packaging for plant and animal-based food products.

6.1. Plant-based applications

Post-harvest losses remain a major challenge for exporters, with nearly 40–50 % of fresh produce in developing countries failing to reach consumers, as reported by the FAO. These losses stem from inadequate harvesting practices, poor post-harvest handling, and improper packaging, ultimately impacting food security and efforts to reduce global hunger. Fruits and vegetables are highly perishable, with short shelf lives and high sensitivity to environmental exposure (Pawde et al., 2024). Proper packaging plays a crucial role in minimizing these losses. Protein based biodegradable packaging has the advantage of in-package atmosphere modification to match produce respiration while reducing condensation for fruits and vegetables (Cheng et al., 2024). Edible coatings can control respiration rates, extending fresh produce's shelf life. Protein-based materials offer superior performance compared to conventional wax coatings, making them a promising solution for enhancing the preservation of fruits and vegetables (Tongdeesoontorn and Rawdkuen, 2019). Numerous studies have been shown the protein based packaging application for fruits and vegetables (J. Chen et al., 2025; K. Chen et al., 2025; Larrea et al., 2023; Mohamed et al., 2020; Pan et al., 2025).

6.2. Animal-based application

Animal based products are particularly susceptible to spoilage due to microbial growth and oxidative processes, which are exacerbated by high oxygen concentrations and light exposure. Cheese, for instance, presents unique challenges in preservation because of its diverse characteristics. Edible coatings and films have been extensively studied and applied to cheese to extend its shelf life (Hadidi et al., 2022). Meat and meat products are highly perishable, with a notably short shelf life. Particularly in online delivery, packaging plays a crucial role in maintaining meat quality. However, elevated oxygen levels can promote the rapid proliferation of Gram-negative bacteria on meat (Kodal Coşkun et al., 2014). While numerous studies have focused on packaging for fresh meat and fish, the direct contact of biodegradable materials with high-moisture foods may render them less suitable compared to their application with dried food products. Further research is necessary to transition from laboratory-based studies to industrial applications. The feasibility and affordability of large-scale production, interactions between the food matrix and packaging materials, and film-forming and mechanical qualities are essential topics that need further research. The effective commercialization of novel protein-based packaging materials made from plant leftovers depends on addressing these factors.

7. Commercial prospective

Replacing synthetic polymers is essential to mitigate environmental harm. Biodegradable packaging offers an eco-friendly alternative. The global plastic packaging market was valued at approximately USD 384.35 billion in 2023 and is predicted to grow at a CAGR of 3.5 % from 2024 to 2030 (Market analysis report). This growth presents a significant opportunity for stakeholders to adopt biodegradable solutions. The global bioplastics market, which includes protein-based materials, was valued at USD 12.7 billion in 2023 and is projected to reach USD 32.9 billion by 2032, growing at a CAGR of 11.2 %. Protein-based packaging represents a niche within this market but is gaining traction due to its renewable origin and functional properties (Global Bioplastics Market Report, 2024).

Developing protein-based biodegradable materials involves balancing performance with degradability. Notably, studies indicate that 67 % of bioplastics, including starch- and cellulose-based types, exhibit toxicity levels comparable to conventional plastics due to additives and manufacturing processes (Ali et al., 2023) Addressing these issues is crucial for advancing safe biodegradable packaging. Commercial case studies, such as NatureWorks using plant proteins in composite materials and Notpla's seaweed- and protein-based edible films used for takeaway packaging, highlight growing industrial interest in sustainable alternatives. However, large-scale adoption is still limited by cost, scalability, and regulatory approval timelines.

Utilizing by-products for biodegradable packaging can enhance national economies by adding value to agricultural outputs and reducing waste. For example, soy protein extracted from soybean processing waste and gluten from wheat milling by-products have been successfully integrated into film production processes, demonstrating a circular economy approach. Further, all possible recycling techniques should be investigated to optimize the environmental advantages of these materials. Regulatory compliance is vital for edible packaging materials. Components must be GRAS for their intended use or approved by authorities like the U.S. FDA. Additionally, all components must be listed on product labels to inform consumers, especially those with allergies or intolerances.

7.1. Challenges associated with protein-based packaging

A significant concern arises from the common incorporation of materials like polylactic acid (PLA) into these packaging solutions. While intended to enhance performance, this combination often necessitates specialized industrial composting facilities for complete biodegradation, a resource that remains limited in many regions. Consequently, biodegradation rates can vary considerably depending on the specific polymer blend. Furthermore, ecotoxicity concerns have been raised regarding the potential release of nanoparticles during the fragmentation of these materials. The sensitivity of protein-based films to moisture also presents a significant drawback, rendering them unsuitable for packaging high-moisture foods. Additionally, these films frequently exhibit brittleness and low elasticity, which complicates handling and diminishes durability during packaging processes. These physical limitations restrict their direct application in high-demand sectors such as meat, dairy, or frozen foods unless adequately modified through plasticizers or blending. Finally, scaling up laboratory-developed methods for protein-based packaging to industrial production poses a substantial challenge. The costs associated with raw material sourcing and manufacturing can be considerably higher than those associated with conventional plastics, further impeding commercial viability. For instance, while whey protein-based films show excellent barrier properties, their industrial production is hindered by high purification costs. Current pilot-scale systems for protein film production remain limited, and only a few companies globally have invested in full-scale biopolymer manufacturing using protein matrices. Future progress depends on cost-effective extraction techniques, improved supply chain logistics, and policy incentives.

8. Conclusion

This comprehensive review has explored various plant protein sources, including legumes, cereals, oilseeds, spent grains, and tubers, as viable options for packaging production. These proteins exhibit favorable film-forming properties, making them suitable for food applications. However, water sensitivity and limited mechanical strength persist, necessitating further research and development. Advancements in blending plant proteins with biodegradable additives have shown potential in enhancing the functional properties of these bioplastics. Such approaches aim to improve water resistance and mechanical performance, addressing some of the limitations of pure plant protein-based materials. Overcoming these challenges requires interdisciplinary research on material science innovations, such as blending proteins with other biopolymers or incorporating cross-linking agents to enhance their properties. Additionally, developing efficient and scalable production methods is crucial for successfully commercializing protein-based packaging solutions. Despite these advancements, the scalability and economic feasibility of plant protein-based packaging remain key concerns. Production costs and processing techniques require optimization to compete effectively with conventional plastics. Moreover, consumer acceptance and regulatory approvals play a critical role in the widespread adoption of these sustainable materials. While plant protein-based food packaging offers a viable and eco-friendly alternative to petroleum-based polymers, continued research is essential to overcome existing challenges. Future studies should focus on improving material properties, cost-effectiveness, and processing methods. Collaborative efforts among scientists, industry stakeholders, and policymakers are essential to facilitate the transition toward sustainable packaging solutions that align with environmental conservation goals.

CRediT authorship contribution statement

Subhash V. Pawde: Writing – original draft, Validation, Data curation, Investigation, Conceptualization. Pimonpan Kaewprachu: Writing – review & editing. Passakorn Kingwascharapong: Writing – review & editing. Samart Sai-Ut: Writing – review & editing. Thomas Karbowiak: Writing – review & editing. Young Hoon Jung: Writing – review & editing. Saroat Rawdkuen: Writing – review & editing, Supervision, Conceptualization, Project administration.

Declaration of competing interest

The authors declare no known financial interests or personal relationships that could have influenced the work reported in this paper.

Acknowledgements

This research was also supported by the Postdoctoral Fellowship from Mae Fah Luang University with Post-Doctoral Researcher Grants, (No.06/2025). Also gratefully acknowledge the additional financial support via the Reinventing University Program Fund [F01-683R-04-045], The Office of the Permanent Secretary of the Ministry of Higher Education, Science, Research and Innovation.

Data availability

Data will be made available on request.

References

- Acquavia M.A., Pascale R., Martelli G., Bondoni M., Bianco G. Natural polymeric materials: a solution to plastic pollution from the agro-food sector. Polymers (Basel) 2021;13(1):158. doi: 10.3390/polym13010158. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Adilah Z.M., Jamilah B., Hanani Z.N. Storage stability of mayonnaise packaged in soy protein isolate films incorporated with mango kernel extract. Food Packag. Shelf Life. 2023;40 doi: 10.1016/j.fpsl.2023.101216. [DOI] [Google Scholar]

- Aghababaei F., McClements D.J., Martinez M.M., Hadidi M. Electrospun plant protein-based nanofibers in food packaging. Food Chem. 2024;432 doi: 10.1016/j.foodchem.2023.137236. [DOI] [PubMed] [Google Scholar]

- Aghababaei F., McClements D.J., Pignitter M., Hadidi M. Plant protein edible inks: upgrading from 3D to 4D food printing. Food Chem. 2025;X doi: 10.1016/j.fochx.2025.102280. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ahmadzadeh S., Hettiarachchy N., Luthra K., Chen J., Seo H.-S., Atungulu G.G., Ubeyitogullari A. Effects of polyphenol-rich grape seed and green tea extracts on the physicochemical properties of 3D-printed edible soy protein films. Food Packag. Shelf Life. 2023;40 doi: 10.1016/j.fpsl.2023.101184. [DOI] [Google Scholar]

- Ahuja A., Rastogi V.K. Spray coating of edible insect waxes for liquid food packaging. Appl. Surf. Sci. 2023;624 doi: 10.1016/j.apsusc.2023.157150. [DOI] [Google Scholar]

- Ai Y., Jane J.-l. Starch in Food. Elsevier; 2024. Understanding starch structure and functionality; pp. 55–77. [DOI] [Google Scholar]

- Ali S., Isha, Chang Y.-C. Ecotoxicological impact of bioplastics biodegradation: a comprehensive review. Processes. 2023;11(12):3445. doi: 10.3390/pr11123445. [DOI] [Google Scholar]

- Alibekov R.S., Urazbayeva K.U., Azimov A.M., Rozman A.S., Hashim N., Maringgal B. Advances in biodegradable food packaging using wheat-based materials: fabrications and innovations, applications, potentials, and challenges. Foods. 2024;13(18):2964. doi: 10.3390/foods13182964. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alonso-González M., Felix M., Guerrero A., Romero A. Effects of mould temperature on rice bran-based bioplastics obtained by injection moulding. Polymers (Basel) 2021;13(3):398. doi: 10.3390/polym13030398. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alsadat-Seyedbokaei F., Felix M., Bengoechea C. Zein as a basis of recyclable injection moulded materials: effect of formulation and processing conditions. Polymers (Basel) 2023;15(18):3841. doi: 10.3390/polym15183841. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alsadat-Seyedbokaei F., Felix M., Bengoechea C. Effect of recycling on thermomechanical properties of zein and soy protein isolate bioplastics. Processes. 2024;12(2):302. doi: 10.3390/pr12020302. [DOI] [Google Scholar]

- Annex, A. Compose the OECD Global Plastics Outlook Database.

- Aschemann-Witzel J., Gantriis R.F., Fraga P., Perez-Cueto F.J.A. Plant-based food and protein trend from a business perspective: markets, consumers, and the challenges and opportunities in the future. Crit. Rev. Food Sci. Nutr. 2021;61(18):3119–3128. doi: 10.1080/10408398.2020.1793730. [DOI] [PubMed] [Google Scholar]

- Assad I., Bhat S.U., Gani A., Shah A. Protein based packaging of plant origin: fabrication, properties, recent advances and future perspectives. Int. J. Biol. Macromol. 2020;164:707–716. doi: 10.1016/j.ijbiomac.2020.07.140. [DOI] [PubMed] [Google Scholar]

- ASTM S. ASTM International West Conshohocken; USA: 2012. D6866–12, Standard Test Methods for Determining the Biobased Content of Solid, Liquid, and Gaseous Samples Using Radiocarbon Analysis. [Google Scholar]

- Athanasopoulou E., Bigi F., Maurizzi E., Karellou E.I.E., Pappas C.S., Quartieri A., Tsironi T. Synthesis and characterization of polysaccharide-and protein-based edible films and application as packaging materials for fresh fish fillets. Sci. Rep. 2024;14(1):517. doi: 10.1038/s41598-024-51163-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Avellanet J. BioProcess International; 2009. FDA 21 CFR Part 11 Revisited. [Google Scholar]

- Balani K., Verma V., Agarwal A., Narayan R. Physical, thermal, and mechanical properties of polymers. Biosurfaces: a materials science and engineering perspective. 2015;329 doi: 10.1002/9781118950623.app1. [DOI] [Google Scholar]

- Becze A., Simedru D., Barta D.-G., Senila L., Varaticeanu C., Blaga T. Sustainable valorisation of coffee waste as a protein source, mycelium-based packaging material and renewable energy pellet. Molecules (Basel) 2024;29(21):4983. doi: 10.3390/molecules29214983. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Behuria P. Ban the (plastic) bag? Explaining variation in the implementation of plastic bag bans in Rwanda, Kenya and Uganda. Environ. Plan. C Politics Space. 2021;39(8):1791–1808. doi: 10.1177/239965442199483. [DOI] [Google Scholar]

- Belitz H.-D., Grosch W., Schieberle P., Belitz H.-D., Grosch W., Schieberle P. Amino acids, peptides, proteins. Food Chem. 2004:8–91. doi: 10.1016/B978-0-12-816061-9.00013-8. [DOI] [Google Scholar]

- Benelhadj S., Fejji N., Degraeve P., Attia H., Ghorbel D., Gharsallaoui A. Properties of lysozyme/Arthrospira platensis (Spirulina) protein complexes for antimicrobial edible food packaging. Algal Res. 2016;15:43–49. doi: 10.1016/j.algal.2016.02.003. [DOI] [Google Scholar]

- Bhaskar R., Zo S.M., Narayanan K.B., Purohit S.D., Gupta M.K., Han S.S. Recent development of protein-based biopolymers in food packaging applications: a review. Polym. Test. 2023;124 doi: 10.1016/j.polymertesting.2023.108097. [DOI] [Google Scholar]

- Biswas A., Cheng H.N., Kuzniar G., He Z., Kim S., Furtado R.F.…Sharma B.K. Bilayer films of poly(lactic acid) and cottonseed protein for packaging applications. Polymers (Basel) 2023;15(6):1425. doi: 10.3390/polym15061425. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Blancas-Benitez F.J., Montaño-Leyva B., Aguirre-Güitrón L., Moreno-Hernández C.L., Fonseca-Cantabrana Á., del Carmen Romero-Islas L., González-Estrada R.R. Impact of edible coatings on quality of fruits: a review. Food Control. 2022;139 doi: 10.22271/phyto.2022.v11.i1c.14342. [DOI] [Google Scholar]

- Brody A.L., Bugusu B., Han J.H., Sand C.K., McHugh T.H. Scientific status summary. Innovative food packaging solutions. J. Food Sci. 2008;73(8):R107–R116. doi: 10.1111/j.1750-3841.2008.00933.x. [DOI] [PubMed] [Google Scholar]

- Byrd M., Dunn J.P. Bloomsbury Publishing USA; 2020. Cooking through History: A Worldwide Encyclopedia of Food with Menus and Recipes [2 Volumes] [Google Scholar]

- Calva-Estrada S.J., Jiménez-Fernández M., Lugo-Cervantes E. Protein-based films: advances in the development of biomaterials applicable to food packaging. Food Eng. Rev. 2019;11:78–92. doi: 10.1007/s12393-019-09189-w. [DOI] [Google Scholar]

- Cao N., Fu Y., He J. Preparation and physical properties of soy protein isolate and gelatin composite films. Food Hydrocoll. 2007;21(7):1153–1162. doi: 10.1016/j.foodhyd.2006.09.001. [DOI] [Google Scholar]

- Chalermthai B., Ashraf M.T., Bastidas-Oyanedel J.R., Olsen B.D., Schmidt J.E., Taher H. Techno-economic assessment of whey protein-based plastic production from a Co-polymerization process. Polymers (Basel) 2020;12(4):847. doi: 10.3390/polym12040847. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen G., Dong S., Zhao S., Li S., Chen Y. Improving functional properties of zein film via compositing with chitosan and cold plasma treatment. Ind. Crops Prod. 2019;129:318–326. doi: 10.1016/j.indcrop.2018.11.072. [DOI] [Google Scholar]

- Chen J., Zhang Y., Liu H., Lu H., Xu X., Shen M. Sodium alginate-camellia seed cake protein active packaging film cross-linked by electrostatic interactions for fruit preservation. Int. J. Biol. Macromol. 2025;288 doi: 10.1016/j.ijbiomac.2024.138627. [DOI] [PubMed] [Google Scholar]

- Chen K., Jiang J., Tian Y., Guo Y., He T., Xie Y.…Jiang F. Improved konjac glucomannan/curdlan-based emulsion coating by mung bean protein addition for cherry tomato preservation. Int. J. Biol. Macromol. 2025;291 doi: 10.1016/j.ijbiomac.2024.139080. [DOI] [PubMed] [Google Scholar]

- Chen K., Zhang M., Mujumdar A.S., Wang M. Encapsulation of different spice essential oils in quinoa protein isolate-gum Arabic coacervates for improved stability. Carbohydr. Polym. 2023;300 doi: 10.1016/j.carbpol.2022.120250. [DOI] [PubMed] [Google Scholar]

- Chen P., Yu L., Chen L., Li X. Morphology and microstructure of maize starches with different amylose/amylopectin content. Starch Staerke. 2006;58(12):611–615. doi: 10.1002/star.200500529. [DOI] [Google Scholar]

- Cheng J., Gao R., Zhu Y., Lin Q. Applications of biodegradable materials in food packaging: a review. Alex. Eng. J. 2024;91:70–83. doi: 10.1016/j.aej.2024.01.080. [DOI] [Google Scholar]

- Chetrariu A., Dabija A. Brewer's spent grains: possibilities of valorization, a review. Appl. Sci. 2020;10(16):5619. doi: 10.3390/app10165619. [DOI] [Google Scholar]

- Colla G., Nardi S., Cardarelli M., Ertani A., Lucini L., Canaguier R., Rouphael Y. Protein hydrolysates as biostimulants in horticulture. Sci. Hortic. 2015;196:28–38. doi: 10.1016/j.scienta.2015.08.037. [DOI] [Google Scholar]

- Constantino A.B.T., Garcia-Rojas E.E. Microencapsulation of betanin by complex coacervation of carboxymethylcellulose and amaranth protein isolate for application in edible gelatin films. Food Hydrocoll. 2022;133 doi: 10.1016/j.foodhyd.2022.107956. [DOI] [Google Scholar]

- D'Almeida A.P., de Albuquerque T.L. Innovations in food packaging: from bio-based materials to smart packaging systems. Processes. 2024;12(10):2085. doi: 10.3390/pr12102085. [DOI] [Google Scholar]

- Daliri H., Ahmadi R., Pezeshki A., Hamishehkar H., Mohammadi M., Beyrami H.…Ghorbani M. Quinoa bioactive protein hydrolysate produced by pancreatin enzyme-functional and antioxidant properties. Lwt. 2021;150 doi: 10.1016/j.lwt.2021.111853. [DOI] [Google Scholar]

- Davis G., Song J. Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind. Crops Prod. 2006;23(2):147–161. doi: 10.1016/j.indcrop.2005.05.004. [DOI] [Google Scholar]