Abstract

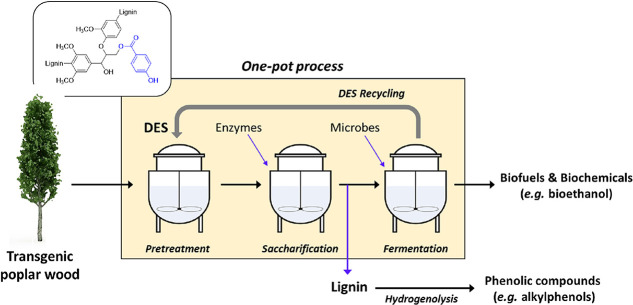

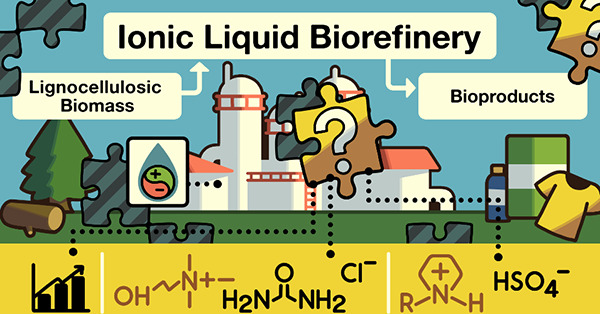

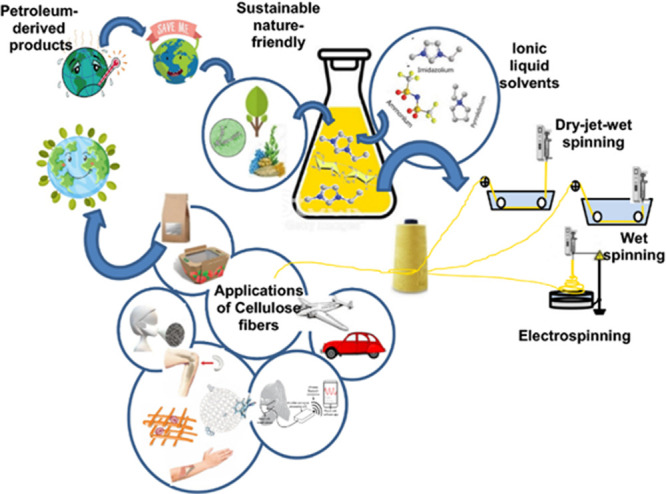

Biorefineries, which process biomass feedstocks into valuable (bio)products, aim to replace fossil fuel-based refineries to produce energy and chemicals, reducing environmental and health hazards, including climate change, and supporting a sustainable economy. In particular, lignocellulose-based biorefineries, utilizing the most abundant renewable feedstock on Earth, have significant potential to supply sustainable energy, chemicals and materials. Ionic liquids (ILs, organic salts with low melting temperatures) and deep eutectic solvents (DESs, mixtures with eutectic points lower than the ideal mixture) are capable of dissolving some of the key lignocellulose polymers, and even the whole biomass. Furthermore, they have intrinsic advantages over molecular solvents, including safer usage profiles and high tunability, which allow tailored physicochemical properties. Such properties provide unique opportunities for the development of new processes that could unlock the full potential of future biorefineries. Here, we review the current state of lignocellulosic biomass processing with ILs and DESs, with a specific focus on the pretreatment chemistry, process flow and products from each component; followed by discussions on sustainability assessments and technological challenges. We aim to inform the research community about the opportunities, challenges and perspectives in developing truly sustainable lignocellulose-based biorefineries.

1. Introduction

1.1. Importance of Biorefining in the Global Context

The reliance of current industries on fossil feedstocks to produce energy, chemicals, and materials is a major driving force behind increasing pollution and environmental hazards, including those affecting human and environmental health and ecosystem stability. ,

Furthermore, fossil feedstocks face constant issues related to price instability and are deemed to be long-term depleted. Public awareness of these issues is driving consumer pressures and policy changes to set new standards for industrial production, demanding the development of more sustainable and less hazardous processes based on the use of renewable feedstocks. Therefore, the foundations of an economy with long-term sustainability must transition to affordable and renewable supplies of raw materials. This will lead to additional benefits in different areas, including more widespread and equal access to energy that is more resilient and less dependent of geopolitics; the generation of new and safer employment opportunities; the development of new technology innovations; etc. −

The achievement of such a sustainable economy will require biorefineries to replace the current production of energy and chemicals from fossil carbon sources. Biorefineries use plant biomass as a feedstock to produce different biobased products, including biofuels and platform chemicals.

1.2. Biorefinery Concept

Plant biomass (aka lignocellulosic biomass) is a sustainable and renewable carbon resource for bioenergy generation and the manufacturing of bio-based products. It has a range of advantages, including very low carbon footprint, since plants use atmospheric CO2 for their growth, abundant availability, and price stability. It has been estimated that the substitution of fossil feedstock for biomass derived feedstocks to produce chemicals can lead to a decrease of up to 86% in the emissions of greenhouse gas emissions and carbon footprint.

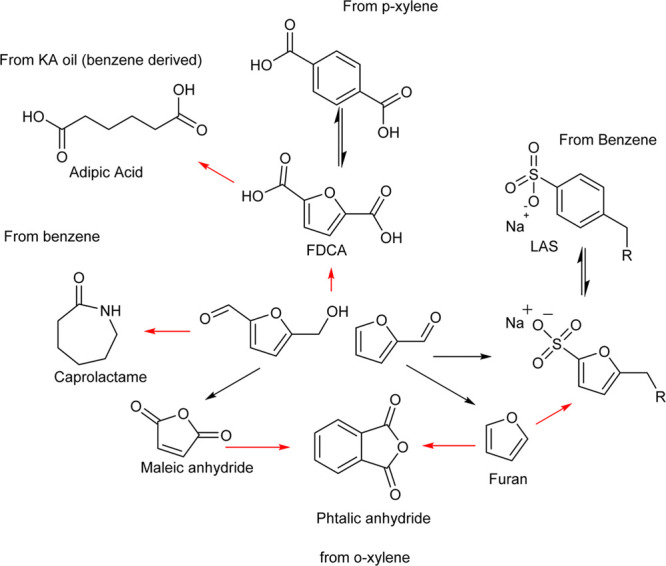

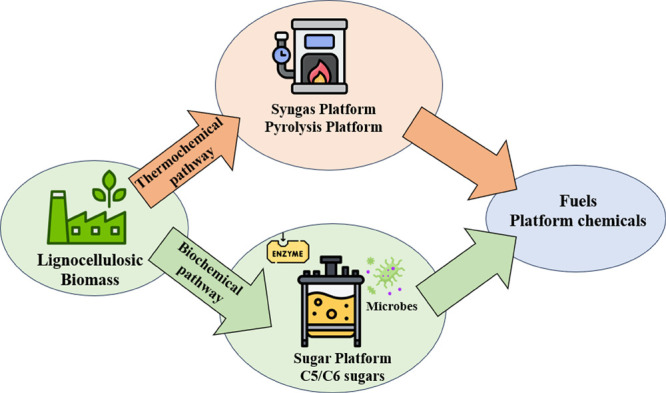

The potential for utilizing biomass as an energy source is still limited by the efficiency of conversion processes, and a comparatively lower calorific value. Nevertheless, the integrated biorefinery is a viable approach for optimizing the utilization of biomass, including the byproducts generated from several conversion processes, and transforming them into lucrative bio-based product streams. The concept was born as an effort to highlight the necessity to achieve not only economic viability but also technical and product flexibility, with production sites capable of producing fuels, platform chemicals, materials, and polymers.

A biorefinery refers to a facility that combines different deconstruction and conversion technologies, including thermochemical, biochemical, combustion, and microorganism growth platforms, to effectively generate a range of sustainable bio-based product streams. These product streams encompass biofuels, biochemicals, bioenergy, and other bio-products of significant value. The biorefinery concept has been developed over decades and employed for the purpose of processing a range of biomass feedstocks, including lignocelluloses, algae, and different forms of waste materials. The US Department of Energy (DOE) provided the first precise definition of a biorefinery in 2004: “A biorefinery is an all-encompassing term for a processing facility where biomass feedstocks are converted and extracted into a variety of valuable products.”

Biorefineries are typically classified into four distinct categories based on the type of substrate utilized: first-generation (1G) biorefineries employ starch and sugar feedstocks; second-generation (2G) biorefineries utilize lignocellulosic biomass feedstocks; third-generation (3G) biorefineries rely on algal feedstocks; and fourth generation (4G) biorefineries use genetically modified microorganisms to create a carbon-sink. Since lignocellulosic biomass is the most abundant renewable source of materials on earth, with 180 billion tons produced per year by plants, second-generation biorefineries have the potential to be a major supplier for sustainable energy, chemical products and materials. Nevertheless, lignocellulosic biomass has a very recalcitrant structure that needs to be deconstructed to access the valuable biopolymers before they can be further processed. Traditional lignocellulose deconstruction technologies have important environmental and safety concerns. Nowadays, the Kraft process, a process developed in the XIX century, based on the use of highly alkaline solutions containing sodium sulfite, represents 90% of the pulping industry. This process presents serious environmental concerns. It has been estimated that, per ton of processed dry pulp, it consumes 45 tons of water and produces 3 kg of sulfur containing gases, 15 kg of other volatile organic compounds and 150 kg of fine particulate matter. The aqueous effluents from this process contain more than 250 different compounds, including halogenates and heavy metals, and current treatment methods can not completely decontaminate them. Furthermore, it is the fourth largest industrial energy user, accounting for 6% of global industrial energy consumption.

Therefore, the development of new, cleaner and more sustainable processes is highly needed. The discovery in the early 2000s that a novel class of nonmolecular solvents called ionic liquids (ILs) could dissolve some of the key lignocellulose polymers, and even the whole biomass, opened a big opportunity for the development of new processes that could satisfy the needs of future biorefineries.

1.3. ILs and DESs: Introduction and History

ILs are salts that can be found in the liquid state before their decomposition temperature. They present relatively low melting points due to having molecular structures that present some degree of asymmetry, charge delocalization, and weak intramolecular interactions. As salts, ILs have negligible vapor pressure at normal conditions, high thermal stability, and high resistance to flammability, reducing drastically safety and environmental concerns associated with solvent volatility (toxicity by inhalation, solvent release to the atmosphere, explosion hazards, etc.). Furthermore, the high number of possible combinations of different cations and anions makes possible to adjust their chemical-physical properties designing ILs best suited for a given application (stability, melting point, viscosity, hydrophilicity). −

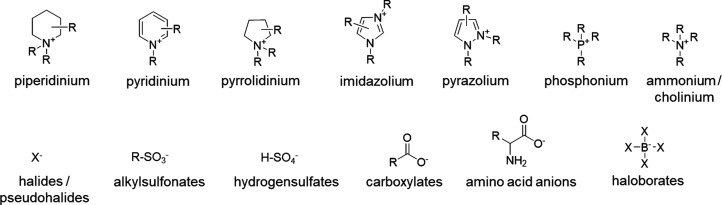

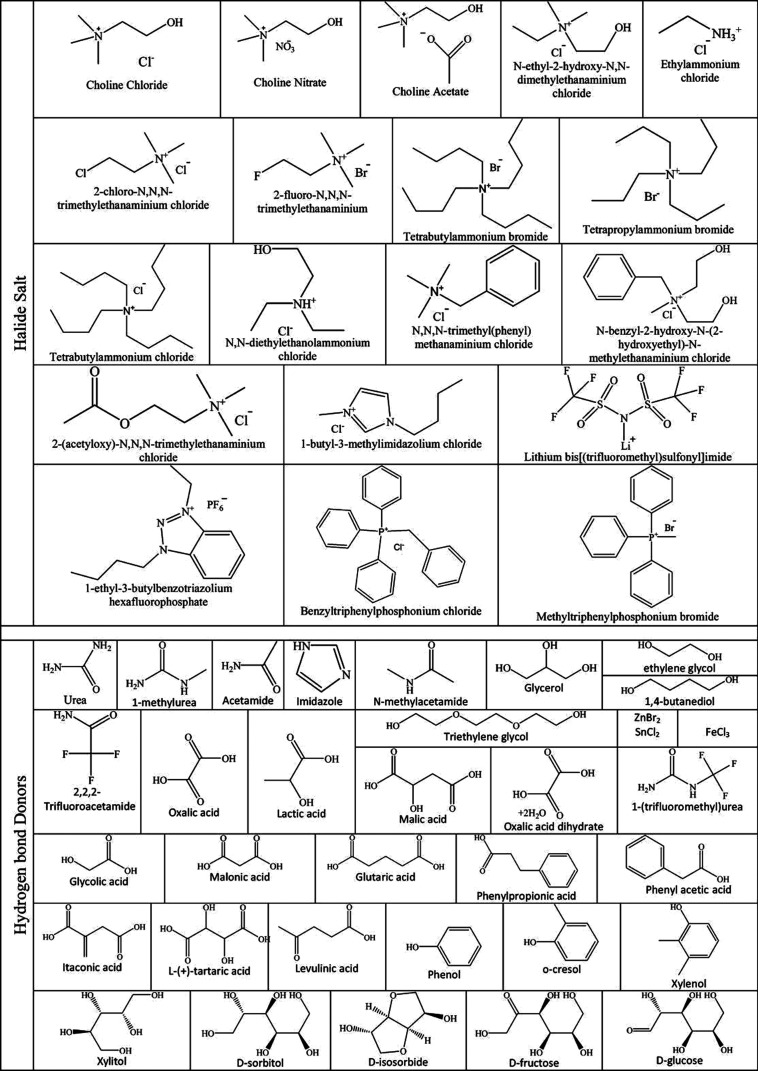

Due to the nonsystematic approach that characterizes the literature regarding abbreviation conventions for naming ILs, which leads to a variety of ambiguous forms, here we will follow the guidelines proposed by Hallett and Welton in 2011, where possible. It establishes an alphanumeric system for the alkyl chains, where the alkyl chains are indicated by a capital C with the number of carbon atoms indicated as a subscript number. Branching of the alkyl chains is indicated by the corresponding superscript before the “C” (e.g., with this system a tert-butyl chain will be indicated as t C4). Similarly, the presence of functional groups will be indicated by the type of functional group, followed a subscript number before the “C” indicating its position in the chain (e.g., a butyl chain functionalized with an alcohol group at the terminal carbon will be indicated as (HO)4C4). The charged centers are indicated with the most common alphabetical abbreviations (“im” for imidazolium, “py” for pyridinium, “pyrr” for pyrrolidinium, “N” for ammonium, “P” for phosphonium, etc). The most common anions and cations studied today are reported in Figure .

1.

Common cations and anions used for synthesis of ILs.

Eutectic solvents (ESs) have been traditionally defined as mixtures of a hydrogen bond accepting (HBA) salt and a hydrogen bond donor (HBD) molecule with lower melting points than their precursors. In 2003, Abbott et al. coined the term “deep eutectic solvents” to describe the decrease in melting point of the liquid obtained by mixing two solid components, choline chloride ([Ch]Cl, 302 °C) and urea (133 °C), in stoichiometric proportions, which resulted in the formation of a eutectic solution with a remarkably low melting point (12 °C). Since then, the definition of Deep Eutectic Solvents (DESs) has been revised as mixtures of pure compounds that have an eutectic point temperature that is significantly lower than that of the ideal mixture, including mixtures of both Brønsted and Lewis acids and bases. As with ILs, DESs offer high design flexibility with tunable properties and are also considered as designer solvents.

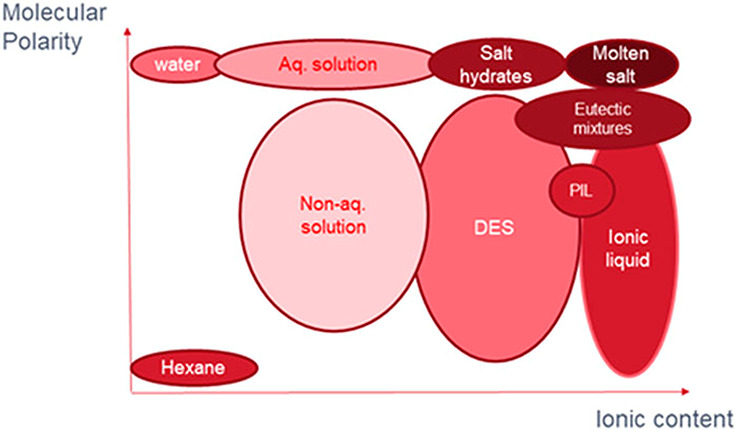

The close relationship between ILs and DESs has led the scientific community to often treat DESs as an extension of ILs research; with both types of compounds being investigated for the same applications, most notably for the dissolution, fractionation and purification of biopolymers, and their performances compared. In fact, in many cases, a wide range of DESs employed in the literature are prepared using ILs as one of the starting materials, normally as the HBA. Moreover, there is some overlap between DESs with protic ionic liquids (PILs) and even certain mixtures of ILs and solvents as water (Figure ).

2.

Representation of the chemical space, in terms of ionic content and polarity of their molecular component, occupied by the types of solvents under review in that document, DESs and ILs, compared to other related solvent systems as depicted by Abbot et al. Adapted with permission from ref . Copyright 2021 American Institute of Physics.

1.4. Scope of This Review

This review provides an overview of IL and DES-based biorefinery scenarios (e.g., lignin-first, lignin-last, simultaneous conversion) with a specific focus on the pretreatment chemistry, process flow and products from each component (including cellulose, hemicellulose, lignin, lipids and extractive products); followed by discussions on sustainability assessment and technological challenges (scaling, IL/DES recycle and recovery, potential product recovery and integration of upstream and downstream processes) around each specific scenario. Since the technological challenges around solvent cost and recovery in biorefineries are an active research frontier, key to ensure their success, it is our aim to provide a critical report about the opportunities, challenges and perspectives related to the use of ILs and DESs in biorefining. The intent is to inform the research community working in this field, to keep making progress towards a truly sustainable lignocellulose-based biorefinery.

2. Discussion

2.1. Biorefinery Types and Generations

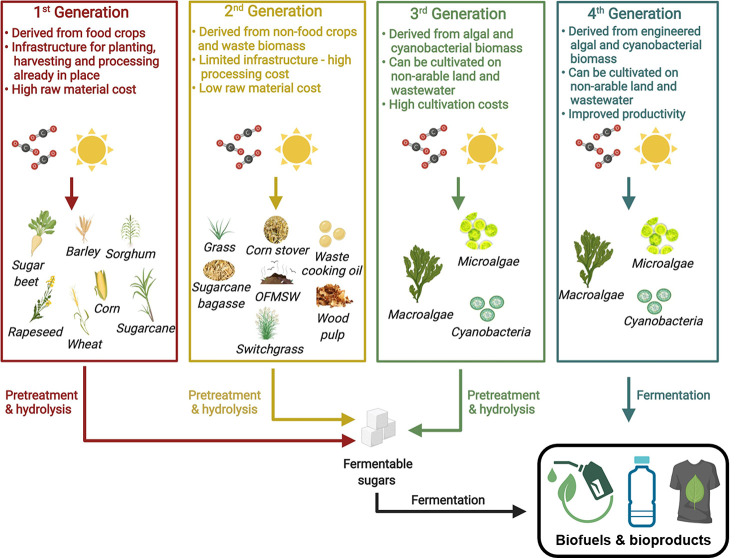

The next section provides a more comprehensive discussion of different types of biorefineries, along with a corresponding list of examples and their associated products, as seen in Figure . The four generations of biorefineries will certainly play a considerable role in the global society to achieve the goals of sustainable development and implementing a circular economy. Nevertheless, generations 1, 3, and 4 still present issues related to land use, feedstock availability, and technology development. Due to its feasibility and inherent potential to help mitigate GHG emissions, we will focus on the application of ILs for the development of 2G biorefineries, based on the conversion of lignocellulose.

3.

Illustrations of possible feedstocks are depicted alongside the advantages and disadvantages associated with each generation of biofuel. Adapted with permission from ref . We also want to highlight that the 2G feedstock is an abundant feedstock in contrast to the note by authors on limited availability. , Adapted with permission from ref . Copyright 2023 the Public Library of Science under CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/).

2.1.1. First-Generation Biorefineries

1G biorefineries, also known as conventional biorefineries, utilize feedstocks derived from glucose, sugar and vegetable oil-containing crops. Corn, wheat and sugarcane are used to produce bioethanol, while soybeans and rapeseed are used to produce biodiesel. , In 2012, approximately 40% of the maize crop in the United States was used to produce ethanol, making corn the primary source of first-generation bioethanol. Sugarcane is the second most important feedstock for first-generation biofuel production, such as ethanol. Unlike corn, sugarcane provides sugar that can be readily converted to ethanol through fermentation. Corn, on the other hand, provides starch that must be heated prior to fermentation. The feedstock is first subjected to enzymatic hydrolysis (for starch) and fermentation, followed by distillation to separate the biofuel from the byproducts. Other resources, such as wheat, rapeseed, sugar beets and peanuts, could be used as well.

Although first-generation biofuels have been extensively commercialized, they have a number of drawbacks. The crops used to produce first-generation biofuels are the same used to feed humans and animals, a sensitive topic with potential ethical implications. Moreover, large-scale monocultured feedstocks further endanger food chains, while cultivation of these resources outside of conventional agricultural regions imperil biodiversity by occupying more land and invading natural ecosystems. However, the effect of the production of first-generation biofuels on food prices is far from being clear, with many factors playing a role. There is an intense debate around this issue, with no consensus so far among researchers.

2.1.2. Second-Generation Biorefineries

The contentious relationship between 1G feedstocks and food security and the potential of the conversion of agricultural and forestry residues into valuable products has led to the transition to 2G lignocellulosic feedstocks as an alternative source for biofuels and chemicals production. 2G biorefineries use non-edible lignocellulosic biomass, including non-food crops, agricultural and forestry byproducts and waste materials from different manufacturing processes. Hence, these largely avoid the competition for land of agricultural value. Reduced needs of fertilizer also help mitigate the carbon footprint. Another key advantage is its availability: lignocellulosic biomass is the most abundant renewable material on the planet. Globally, approximately 180 billion tons of lignocellulosic biomass are produced annually, primarily by perennial herbaceous and woody plant species, of which only about 4.4% are utilized for producing biochemicals, bioenergy and non-food bioproducts. Thanks to the diversity of plant options and high availability in tropical and temperate regions, lignocellulosic materials are a practical source of biomass feedstock for biorefineries.

2G biomass feedstocks can be divided into three categories according to their origin. Plants harvested for cellulose production are considered primary cellulose sources. For example, cotton is grown as a feedstock for the textile industry, while tree species like pine, spruce, and Eucalyptus are used to feed pulp and paper mills. Similarly, some fast-growing crops such as Miscanthus, willow, and poplar can be harvested for energy production. Even though these materials are non-edible, and some of them can be grown on land not suitable for food production and of low ecological value, in some cases their production might compete for arable land with food crops or require the clearing of forest for new land, prompting a new “forest versus fuel” debate. By-products of forestry and agricultural production are considered secondary cellulose sources. Maize stover, rice or wheat straw and oil palm empty fruit bunches fit in this category. Finally, tertiary cellulose sources include cellulose-containing by-products and waste materials from different manufacturing processes, such as construction and demolition (C&D), breweries, textile industry, etc. These waste streams have low or even negative value, due to the costs associated with their disposal. While some of them are incinerated to produce electricity, landfilling is the main means of disposal for these streams. As a result, waste is released to the environment, producers are economically penalized and a stream of potentially valuable feedstocks is lost. Their potential valorization would open the door for a cheap raw material that is available locally even in areas, where access to primary and secondary cellulose is limited while reducing the costs associated with waste disposal. On the other hand, tertiary cellulose is usually found in complex mixtures with other components, such as other biopolymers and biomolecules and different types of contaminants including preservatives, resins and paints, plastic, sand and glass, etc., which can make their valorization challenging. , There have been several studies that have presented techno-economic analyses of second-generation biorefineries that use ILs and DESs. −

2.1.3. Third-Generation Biorefineries

Typically, 3G biorefineries use algae and seaweed as feedstocks for bio-renewables production. , Microalgae are aquatic unicellular biomass mainly formed by proteins, carbohydrates and lipids. The primary advantages of microalgal biomass for biodiesel production are their rapid growth rate, high photosynthetic efficiency and low cultivation costs since they can be grown in sewage and wastewater. Nevertheless, their growth and lipid content are highly dependent on cultivation conditions: temperature, light intensity, CO2 concentration, pH value and nutrient composition of the culture medium. Algal crops are well-known commercial producers of nutraceuticals, animal feed and feed supplements and numerous other goods. The objective of third-generation biorefineries is to use microbial cell factories to utilize atmospheric CO2, sunlight, inorganic compounds from waste streams, and electricity generated by sustainable sources (e.g., photovoltaic cells and wind power) for bioproduction. , Third-generation biorefineries reduce the cost of processing feedstock and pose fewer security risks to food and water supplies. On the other hand, the availability of sunlight and the maintenance of inorganic ions’ pH pose the greatest difficulty in microalgal cultivation. Sunlight availability can be increased by constructing the system from low-cost acrylic-type material. The lack of sunlight during the night can be compensated for by providing artificial illumination, which will ultimately increase the cultivation system's overall yield. However, the efficient capture of renewable energy for bioproduction is a crucial challenge. Another key challenge is the efficient fixation of atmospheric CO2. Furthermore, the optimal development of industrially viable products requires the selection of robust algal strains, reasonable capital and operating costs for cultivation, pretreatment and extraction and the desired process sustainability. In this regard, achieving an initial fractionation of algal biomass with minimally tunable parameters is the most important step toward the production of sustainable products.

Significant progress has been made to date, including the validation of eight natural and synthetic CO2 fixation pathways, the development of synthetic energy capture techniques and the commercialization of several CO2-based plants. Despite recent progress, the fractionation of algal biomass into industrial products is still in its infancy. Issues around cell concentration, dewatering, affordability and efficient deconstruction of algae at scale remain extremely challenging. Considering future food/feed demand, shifting environmental conditions, and political instability in major oil-producing countries, more research into third-generation algae-based biorefineries is inevitable.

2.1.4. Fourth-Generation Biorefineries

Fourth-generation biorefineries are derived from genetically modified microorganisms, such as microalgae and cyanobacteria, to enhance biofuel-producing organisms as feedstocks. , The capacity of microorganisms to convert CO2 into fuel via photosynthesis is exploited and maximized by genetic modifications, thereby creating an artificial “carbon sink”. Several types of microalgae have been successfully produced by introducing genes into the nucleus, chloroplasts and mitochondria of cells.

4G biorefineries require a minimum number of stages to convert energy, reducing processing needs. The main environmental benefits are CO2 assimilation, wastewater purification, and reduced greenhouse gas emissions. On the other hand, the environmental impact of the gene modification process requires further investigation.

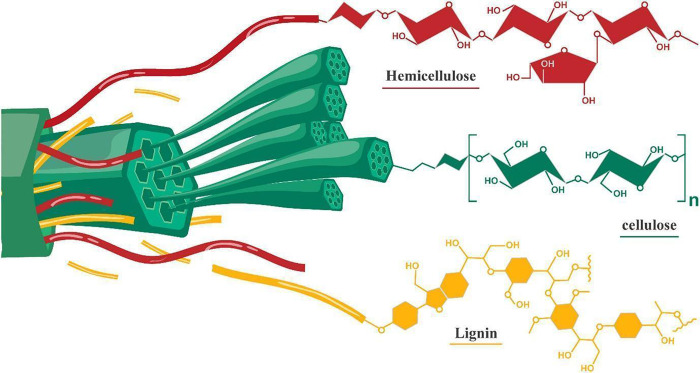

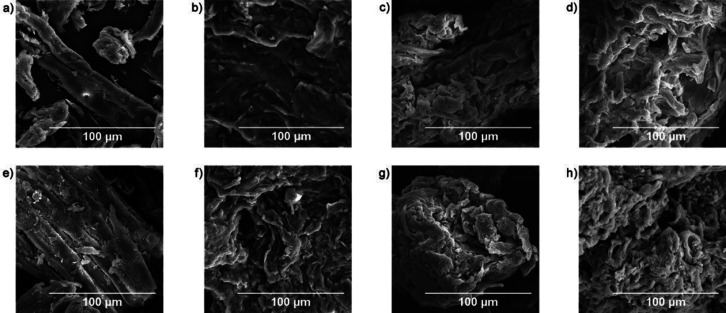

2.2. Lignocellulose Structure

Lignocellulosic biomass is a composite material synthesized by plant cells. It consists primarily of a mix of polymeric carbohydrates, cellulose and hemicellulose, and aromatic polymer–lignin intertwined together in a complex structure (Figure ). It also contains smaller amounts of structural proteins, lipids and ashes. The arrangement of polymers in lignocellulosic biomass results in a highly recalcitrant structure, which must be decomposed to use it as feedstock for chemicals or energy.

4.

Schematic representation of the plant cell wall of a lignocellulosic biomass consisting of cellulose, lignin, and hemicellulose. Adapted with permission from ref . Copyright 2023 Wiley-VCH.

Its appearance and properties vary greatly depending on the type of plant (Figure ). Cellulose (C6 sugar) accounts for 30–50% of total lignocellulosic dry matter, whereas hemicellulose (a mixture of C5 and C6 sugars) and lignin (provides structure rigidity) account for 20–40% and 15–25% of total feedstock dry matter, respectively. Cellulose is composed of glucopyranosyl monomeric units connected by 1,4-glycosidic bonds, resulting in a sheet-like structure that enables the packaging of multiple cellulose strands into crystalline fibrils. The main forces between the flat sheets of cellulose are Van der Waals (VdW) interactions. Hemicelluloses are bound noncovalently to the surface of cellulose fibrils to function as an amorphous matrix material. Hemicellulose is a branched polymer with greater functional and compositional diversity than cellulose. Functional compounds such as acetyl, methyl, cinnamic, and glucuronic acids are also in its structure. ,, Lignin, an aromatic-containing polymer, produced when plant growth terminates, provides structural reinforcement and resilience to plant tissue. It is formed by the combination of three main monomeric units guaiacyl (G units), syringyl (S units) and p-hydroxyphenyl (H units). Lignin of different types of species (softwoods, hardwoods, and grasses) differ in the relative amounts of these 3 monomeric units. These disparities in composition have a substantial effect on delignification and biomass destruction. ,

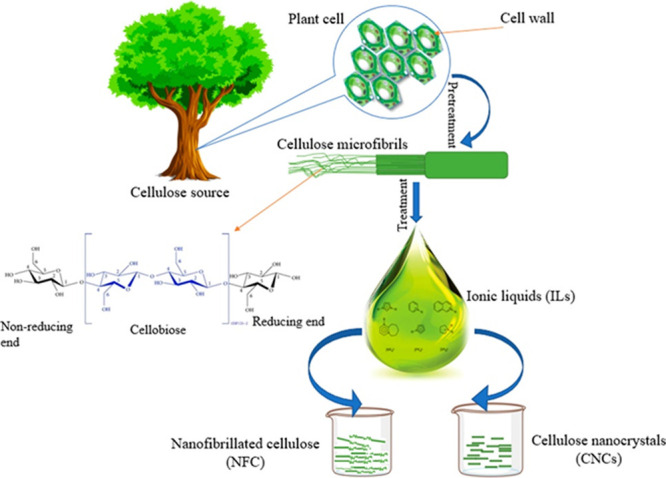

2.2.1. Cellulose

Cellulose is the largest single component of lignocellulosic biomass whose composition on a dry weight basis is typically in the range of 35–50 wt%. It is a homopolysaccharide composed of glucopyranosyl monomers linked by β-1,4-glycosidic bonds. The configuration at the anomeric carbons results in a stretched chain shape, with hydrogen bonds connecting these chains to form flat sheets. Cellobiose is defined as the minimum conformational unit of cellulose, whereas glucose represents the fundamental unit of the homopolymer chains.

In cellulose, glucose chains are bound by dispersion forces and hydrogen bonds in the crystalline structure, in approximately 40 glucan chains known as elementary fibrils. Such elementary fibrils, which essentially have a very long length and a width of approximately 250 Å, bundle into microfibrils. Microfibrils contain highly ordered, crystalline regions and less organized, amorphous regions. Both regions occur in characteristic proportions in different celluloses. The number of glucopyranose units per cellulose chain is defined as the degree of polymerization (DP), and it can vary depending on the source and extraction method. In nature, cellulose chains have a degree of polymerization of 10,000 glucopyranose units in wood cellulose and 15,000 in native cotton cellulose.

The supramolecular organization of cellulose chains with numerous recognized polymorphs and amorphous domains in the solid state is determined by the complex hydrogen bonding network formed by the hydroxyl groups. Cellulose polymorphs are divided into four categories: cellulose I, which is found in native cellulose, and celluloses II, III and IV, which can be obtained irreversibly under specific circumstances and are thermodynamically more favorable. The most significant cellulose allomorph for materials science is cellulose II. It develops from cellulose I following mercerization (treatment with aqueous NaOH) or after native cellulose has been dissolved and then precipitated in an antisolvent, a procedure that is frequently referred to as regeneration. Cellulose dissolving ILs such as dialkyl imidazolium acetates can form the cellulose II structure by dissolution followed by regeneration, typically achieved by “crashing out” the cellulose through the addition of an antisolvent.

2.2.2. Hemicellulose

Hemicelluloses are branched heteropolysaccharides with shorter chains than cellulose. Sugar moieties in hemicelluloses may be subdivided into pentoses, hexoses, hexuronic acids, and deoxyhexoses. Hydroxyl groups from β-d-xylopyranosyl units may be partially substituted by acetyl groups at O-2 or O-3. Small quantities of other sugars, such α-l-rhamnose and α-l-fucose, might also make up hemicelluloses, and acetyl groups can partially replace the hydroxyl groups in the sugar moieties. Only seaweeds, red and green algae, contain homopolymers of xylose, also known as homoxylans. The degree of acetylation varies according to the type of biomass and the amount of acetyl groups is between 1–6 wt% of total biomass on a dry basis. The main composition of the various hemicelluloses was depicted in Table .

1. Main Types of Hemicelluloses Found in Diverse Feedstocks (Adapted from Girio et al. 2010) .

| units |

|||||

|---|---|---|---|---|---|

| type of hemicellulose sugar | feedstock type | content | degree of polymerization | backbone | side chain |

| arabinogalactan (AG) | softwoods | up to 35 wt% | 100–600 | β-d-Galp | β-d-Galp |

| α-l-Araf | |||||

| β-l-Arap | |||||

| xyloglucan (XG) | hardwoods, grasses | 2–25 wt% | β-d-Glcp | β-d-Xylp | |

| β-d-Xylo | β-d-Galp | ||||

| α-l-Araf | |||||

| α-l-Fucp | |||||

| acetyl | |||||

| galactoglucomannan (GGM) | softwoods | 10–25 wt% | 40–100 | β-d-Manp | β-d-Galp |

| β-d-Glcp | acetyl | ||||

| glucomannan (GM) | softwoods and hardwoods | 2–5 wt% | 40–70 | β-d-Manp | |

| β-d-Glcp | |||||

| glucuronoxylan (GX) | hardwoods | 15–30 wt% | 100–200 | β-d-Xylp | 4-O-Me-α-d-GlcpA |

| acetyl | |||||

| arabinoglucuronoxylan (AGX) | grasses, cereals and softwoods | 5–10 wt% | 50–185 | β-d-Xylp | 4-O-Me-α-d-GlcpAβ-l-Araf |

| arabinoxylans (AX) | cereals | 0.15–30.0 wt% | α-l-Araf Feruloy | α-l-Araf | |

| 4-O-Me-α-d-GlcpA | |||||

| acetyl | |||||

| glucuronoarabinoxylans (GAX) | grasses and cereals | 15–30 wt% | α-l-Araf | ||

| 4-O-Me-α-d-GlcpA | |||||

| acetyl | |||||

| homoxylans (X) | algae | β-d-Xylp | |||

Xylans and glucomannans are the two hemicelluloses that are most significant regarding abundance. The primary hemicellulose found in secondary cell walls, xylans make up 20–30% of the biomass found in herbaceous and woody plants. Additionally, xylans can make up as much as 50% of the tissues found in certain grasses and grains. The primary hemicellulosic elements in the secondary wall of softwoods are manan-type hemicelluloses, such as glucomannans and galactoglucomannans, while they are found in smaller quantities in hardwoods.

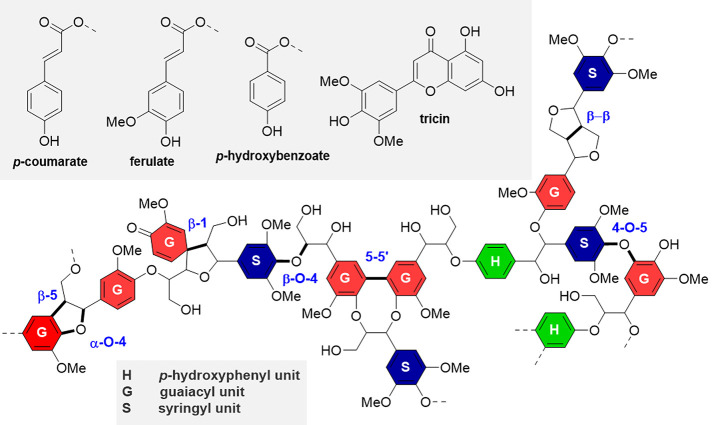

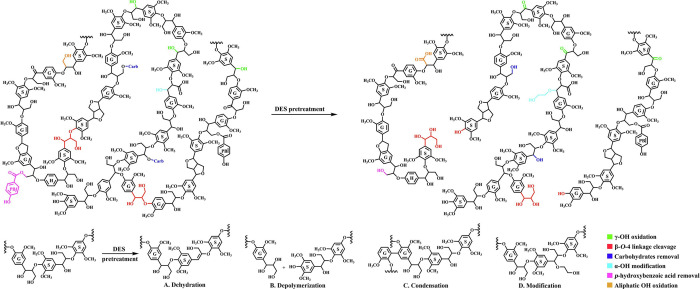

2.2.3. Lignin

Lignin is a complex amorphous macromolecule made up of aromatic monomers. It is the most abundant natural source of aromatic structures. It evolved to give vascular plants rigidity and stiffness, allowing their tissue to resist the negative pressure created by the transport of water within the plants. Furthermore, it provides water impermeability and a physical and chemical barrier that protects plants from microbial and animal attacks.

The fact that native lignin cannot be recovered unaltered, together with the natural variability depending on species, genetic variability and growing conditions, means that its native structure has not been completely elucidated. However, a lot about its structure and biosynthesis is known. Lignin is a complex and amorphous biopolymer formed of phenylpropane based sub-units linked by ether and C–C bonds, and has a molecular weight of between 2,500 to 10,000 g/mol.

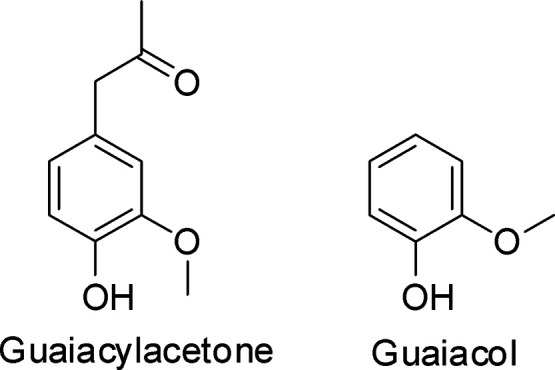

Lignin is biosynthesized mainly from the radical polymerization of three hydroxycinnamyl alcohols (monolignols), namely guaiacyl, p-coumaryl and sinapyl alcohols, derived from the enzymatic conversion of l-phenylalanine. Their polymerization yields guaiacyl (G), p-hydroxyphenyl (H) and syringyl (S) units, respectively, which vary in the degree of methoxylation presented on the aromatic ring (Figure ). , Other less common subunits found in lignin are ferulates (which connect lignin with hemicellulose), coniferaldehyde, sinapaldehyde and 5-hydroxyconiferyl.

5.

Representative structure of lignin to include various known units and interunit linkages in a range of grassy and woody lignocellulosic biomass. Adapted with permission from ref . Copyright 2024 Wiley-VCH.

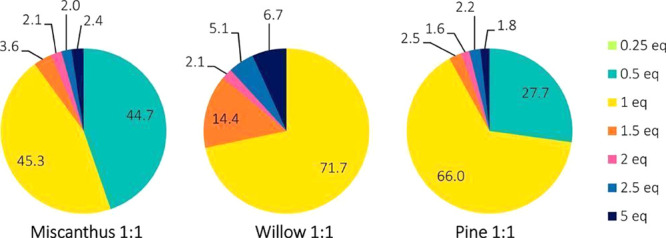

The proportion of each of these units varies in different types of biomass. Lignocellulosic biomass employed for biorefining can be divided into 3 main groups according to species: softwoods, hardwood and grasses. Softwood is wood from gymnosperm trees (e.g., pine or spruce) and has the highest lignin content (25–35%). Lignin from gymnosperms is very homogeneous, mostly made of coniferyl alcohol (G units, up to 95%) and lacking S units (syringyl alcohol) and is generally more branched than angiosperm lignin. , Hardwoods are angiosperm trees and have lower lignin content than softwoods (15–30%). Hardwood lignin contains a mixture of about 60% of S-units and 40% of G-units. It contains abundance of β-O-aryl ether linkages, and it is crosslinked to polysaccharides by lignin carbohydrate linkages. Grasses contain less lignin than both soft- and hardwoods (9–20%), being a mixture of S, G, and H units (p-coumaryl alcohol, ranging from 20% to 50%). Grasses also contain high proportions of coumarates and ferulates. Furthermore, a different type of lignin, formed only by catechyl alcohol units (C-units), can be found in the seed coating of many plant species, including members of the Cactaceae, Orchidaceae, Euphorbiaceae, and Cleomaceae families. , C units are nonmethylated; hence, C-lignin is a linear homopolymer. C-Lignin can coexist together with the more common G/S lignin, but it is not attached to it.

Lignin monomers are linked by different types of ether bonds, such as β-O-4′ (β-aryl ether), 4-O-5′, α-O-4′, 4-O-5, and C–C bonds as β-5′ (phenylcoumaran), β–β′ (resinol), 5–5′, and β-1′ linkages. β-O-4′ is the most abundant linkage found in lignin, typically representing around half of the total amount of lignin interunit linkages, but ranges between 20% for some softwoods up to 80% for some hardwood species have been reported. Next in abundance are β–β′ and β-5′ linkages, which allow lignin chains to grow linearly forming long strains. ,,

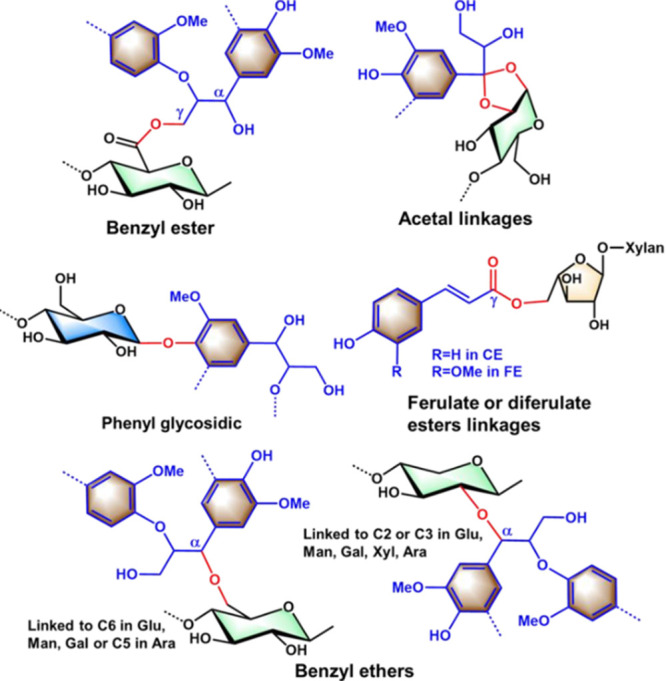

Furthermore, lignin can be crosslinked to carbohydrates (mainly hemicellulose, but also to some extent to cellulose) via covalent bonds, forming what is known as lignin–carbohydrate complexes (LCCs). It has been suggested that the level of cross linking via LCCs is directly related to the cell wall rigidity and resistance to enzymatic attack of biomass. In softwoods, all lignin fragments are linked to carbohydrates, up to 50% being linked to cellulose. In hardwoods between 47% to 66% of lignin fragments are linked to carbohydrates, with up to 17% linked to cellulose. Eight different types of lignin–carbohydrate bonds have been found: benzyl ether, benzyl ester, glycosidic or phenyl glycosidic, hemiacetal or acetal linkages, and ferulate or di-ferulate esters (Figure ). Efficient biomass pretreatment processes must be able to cleave and/or hydrolyze these linkages. LCCs of grasses contain ferulic acid (FA) bonded to hemicellulose (feruloylated arabinoxylan) by ester bonds, LCCs involving glucan and xylan have been reported as well. LCCs of grasses show prevalence of phenyl glycosidic bonds. , LCCs of hardwood involve xylan and glucan moieties, and phenyl-glycosidic linkages are predominant. For softwoods, benzyl ether linkages are prevalent and different LCC structures have been proposed, a branched structure involving glucomannan and a linear structure involving xylan.

6.

Some of the main types of LCC bonds found in lignocellulosic biomass. Adapted with permission from ref . Copyright 2023 Elsevier Ltd.

It should be noted that lignin biosynthesis, and consequently its structure, is very adaptable and admits different variations on the aromatic ring and the side chain. Gene editing has been used to produce genetically modified strains with tailored lignin content and characteristics (e.g., reduced recalcitrance). This allows for milder pretreatment conditions for cellulose fractionation and further conversion or the development of specific lignin products. In this regard, it has been proposed that engineering of the lignin in the pith tissue of certain species, where is more easily accessible, is a potential avenue to produce lignins for targeted applications.

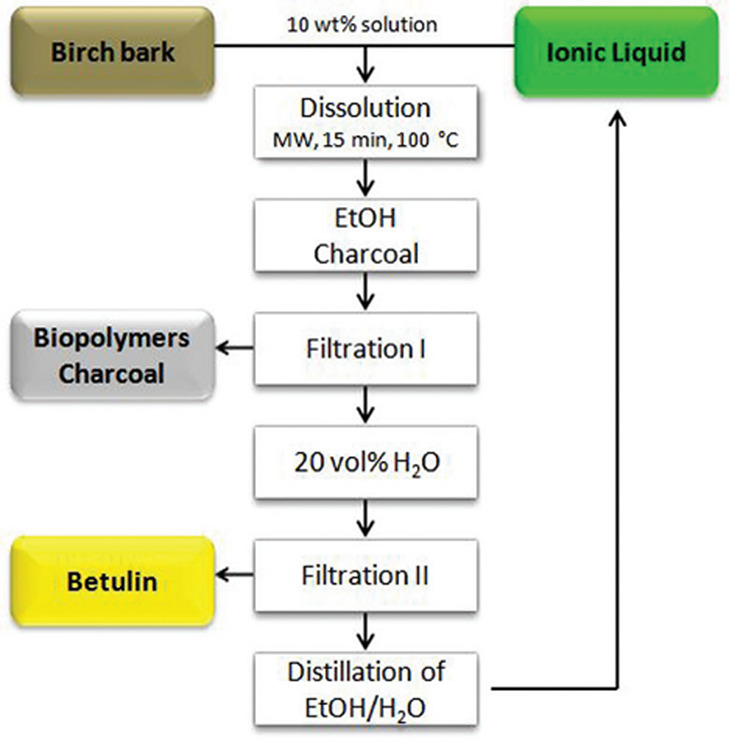

2.2.4. Lipids and Extractives

Although cellulose, hemicellulose, and lignin are the main structural components of lignocellulosic biomass, different amounts of other compounds such as proteins, lipids and inorganic material can be also found. These families of compounds are referred to as extractives. Extractives are usually secondary metabolites produced by plants not for structural purposes, but to perform different biological activities. These include plant defense against pathogens and herbivores and adaptations to environmental conditions. The term extractive covers thousands of different molecules, which are classified in families depending on their molecule structure and biosynthetic pathway. The main families of compounds are alkaloids, phenolic compounds, or polyphenols and terpenoids. Other classes that have been reported include saponins, lactones, ginsenosides, tocopherols, sterols and carotenoids. Extractives can be recovered from different plant parts, most commonly from leaves, roots and barks, for their use in a wide range of applications. For example, extracts rich in the terpenoids carnosic acid and carnosol produced from rosemary leaves are currently authorized as antioxidants in foods and cosmetics; extracts rich in the polyphenols hydroxytyrosol produced from olive tree leaves are used in foods and as bleaching in cosmetic products; extracts rich on triterpenic saponins from the wood and/or bark of Quillaja saponaria tree are currently approved as foaming agents and emulsifiers in foods and dietary supplements; phytosterol derived from tall oil, a by-product from the Kraft process, are used as nutraceuticals to reduce cholesterol; and tropane alkaloids are recovered from roots of several plants to be used in pharmaceutical products because of their anticholinergic activity. ,

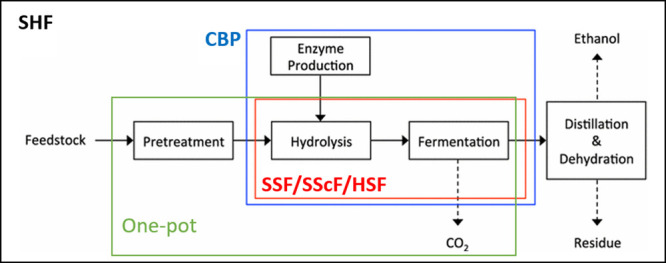

2.3. Lignocellulosic Biomass Utilization Strategies

The words pretreatment and fractionation have been inadvertently used as interchangeable terms in the literature. However, they present different meanings in the field of biomass utilization. Pretreatment methods change the structure and composition of biomass, making it more suitable for subsequent processes. Fractionation methods, on the other hand, aim to separate the structural components of biomass for separate valorization. A pretreatment method that can be considered good may not efficiently fractionate lignocellulosic biomass and vice versa. There is not a single pretreatment or fractionation method that gives the best results for all cases due to differences in the structure of different biomasses and different end-use requirements. The selection of the most suitable method for a given process depends on several factors, including productive factors such as yields and recovery and economic and technological aspects that must be considered for implementation at an industrial scale. Further valorization of the streams must be also considered, i.e., processes that break down lignin could be useful to produce ethanol but may not be suitable for lignin recovery. Therefore, several pretreatment and fractionation methods have been developed and studied using different biomass sources. Biomass pretreatment and fractionation processes can be classified into physical, chemical, physicochemical, thermochemical and biochemical methods, depending on how the changes in the biomass are achieved. Although, many times they are combined to improve their overall efficiency.

Physical processes, including milling/crushing, − extrusion, − microwave, − and ultrasound, − modify the lignocellulosic biomass structure without the need of chemical or biochemical reactions. They are, in general, more environmentally friendly and prevent chemical degradation of biomass, avoiding loss of sugars and other compounds. On the other hand, they suffer from high energy consumption and insufficient biomass deconstruction. To overcome these disadvantages, they are usually performed followed by chemical, physicochemical, or biological methods.

Chemical processes are among the most employed. These methods use acids, − alkalis, ,− oxidants − and organic solvents ,− to perform biomass degradation, usually breaking the linkages between the different biopolymers. They lead to extensive chemical changes in the biomass and are usually more efficient than physical and biological methods, but these chemical changes can also produce undesirable by-products. Other disadvantages of chemical methods are the large amount of chemicals consumed and the need to remove them from the biomass. , Most of the chemical methods employ reagents and pH-dependent conditions that are noncompatible with downstream bioconversion processes involving enzymes and microbial strains. To enable downstream processes, separation of these reagents is mostly achieved by (water)-washing. However, this adds on to the process complexity, operational cost, and carbon loss. ,, This has led to the foundation of biocompatible deconstruction technologies to overcome the above-mentioned shortcomings and explore the benefits of process integration. − Combinations between chemical and physical methods have been largely studied to achieve better results, indeed physicochemical have been evaluated for biomass deconstruction to take advantage of physical and chemical changes at the same time. Physicochemical methods used to pretreat biomass include liquid hot water, − steam explosion (SE), ,− ammonia fiber explosion (AFEX), − and CO2 explosion. − These methods exert physical and chemical changes over the biomass to reach the biomass deconstruction, particularly in SE and AFEX, in which the swift release of pressure promotes the biomass deconstruction while organic acids derived from the biomass in SE or the ammonia in AFEX promote chemical changes in the biomass. Sometimes chemicals such as acid in SE or hydrogen peroxide in AFEX are added to further improve the chemical deconstruction.

Biochemical methods are considered eco-friendly and safe as they do not require chemicals or high temperature/pressure conditions. However, they are usually expensive and slow in comparison to other methods due to the high cost of enzymes and the slow hydrolysis rates. Microbial pretreatments can be divided into two different processes: biodelignification, which aims to remove lignin from the biomass, and saccharification which aims to hydrolyze cellulose and hemicellulose in sugars. , Enzymes and microorganisms have been evaluated to perform biomass delignification, while saccharification is normally performed using enzymes.

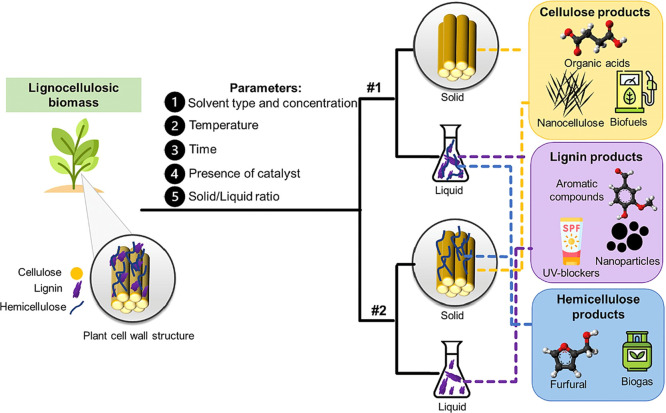

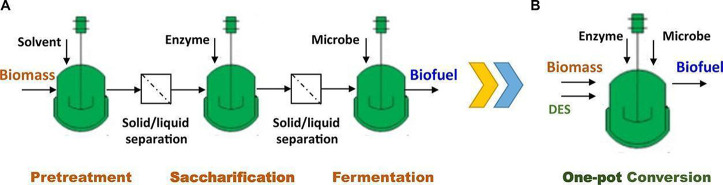

When not physical, the pretreatment and fractionation strategies can be summarized in Figure . Basically, they aim to remove the lignin from the lignocellulosic biomass, therefore they are delignifying. Hemicelluloses are more sensitive to changes in process parameters such as temperature, time and pH and they can be greatly removed (strategy 1) or they can be preserved (or partially preserved as it will be seen later on the IL categories) in the treated material (strategy 2). If fractionation is efficient, lignin and hemicellulose products can be valorized into different chemicals and/or materials. Otherwise, the pretreated material can be biochemically converted into biofuels such as bio-ethanol, bio-butanol, or bio-succinic acid.

7.

Pretreatment and fractionation strategies for the utilization of lignocellulosic biomass. Adapted with permission from ref . Copyright 2023 Elsevier Ltd.

2.4. ILs and DESs as a Solution for Biorefining

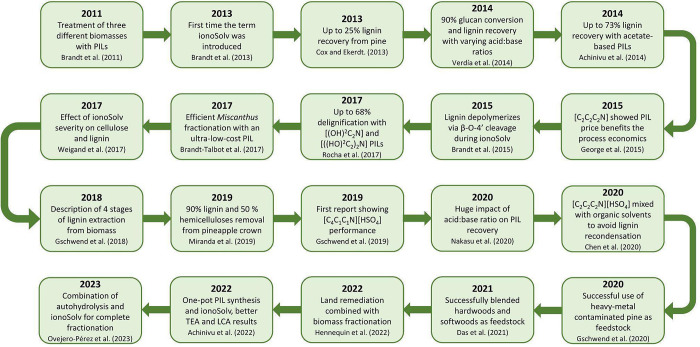

Among the chemical biomass processing methods, the use of ILs and DESs for the pretreatment and fractionation of lignocellulosic biomass has shown to be very effective, being one of the more promising areas for their application at the industrial level. The finding of the dissolution of cellulose in ILs in the early 2000s became the stepping stone of the use of ILs (and DESs) in biorefinery. , From the decade of the 2010s onwards, the biomass pretreatment field has been focusing on: (1) expanding the feedstock portfolio to different types of biomasses, − (2) optimization of pretreatment parameters for each feedstock, , (3) understanding the relationship between IL/DES structure and pretreatment performance, − (4) looking into the fate of the hemicellulose and lignin fraction upon pretreatment, − (5) evaluating the reuse and recycling of the IL/DES, ,− (6) studying the scale-up of the pretreatment − and (7) evaluating the feasibility of IL/DES pretreatment by techno-economic analysis. ,,− ,,, From all of the literature on the topic, it can be concluded that ILs/DESs are efficient pretreatment agents and, depending on the cation and anion, they can be used to create an economically viable process.

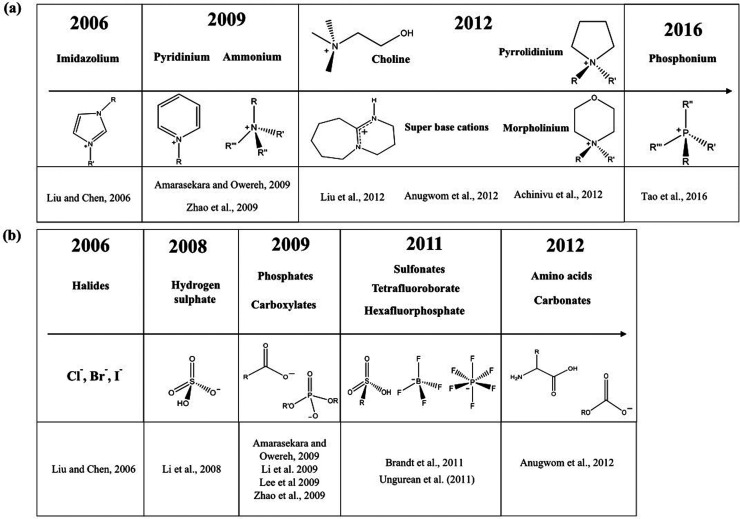

The main types of anions and cations employed on the pretreatment of lignocellulosic biomass are shown in a timeline in Figure . The main cations range from nitrogen-containing heteroaromatic compounds such as imidazolium and pyridinium to aliphatic and cyclic ammonium (Figure ). More exotic phosphonium cations have been also employed, but to a lesser extent. Compared to the variation of anions, cations are less diverse because anions play a bigger role in the interaction between ILs/DESs and lignocellulosic biomass. The most employed anions are halides, carboxylates, hydrogen sulphate, and amino acid (AA) derived anions. It is important to note that the work mentioned in Figure is related to biomass pretreatment and not to the solubilization of lignocellulosic fractions. Therefore, they employ enzymatic hydrolysis as a means of evaluating the pretreatment.

8.

Timeline of the main types of (a) cations and (b) anions introduced as pretreatment agents of lignocellulosic biomass. These studies performed pretreatment and enzymatic saccharification as a means of evaluation pretreatment performance. R and R′ denote either −H or −alkyl substituents. References from this figure are: Liu and Chen, 2006; Amarasekara and Owereh, 2009; Zhao et al., 2009; Liu et al., 2012; Anugwom et al., 2012; Achinivu et al., 2012; Tao et al., 2016; Li et al., 2009; Lee et al., 2009; Brandt et al., 2011; Ungurean et al., 2011.

In the following sections we will be reviewing and assessing all the relevant aspects of lignocellulosic biomass pretreatment and deconstruction with ILs and DESs, from the properties of these novel types of solvents and their mechanisms of interaction with lignocellulose, to the implications and challenges of their integration in commercial scale biorefineries (>25 MMtons/year production capacity).

2.4.1. Properties, Toxicity, Degradability, and Biocompatibility of ILs and DESs

The uses and applications of ILs and DESs have evolved in the last decade linked to the development in the understanding of their properties. In general, ILs and DESs as a class of materials have some widely accepted generic physicochemical characteristics (e.g., high viscosities and densities, ultra-low vapor pressure at ambient conditions, etc.). Nevertheless, considering the ability to tune the structural and functional properties of ILs and DESs as a function of their constituents, a wide range of ILs/DESs are available (the total number of possible ILs/DESs has been estimated to be >1020). Hence, it is very difficult to generalize and summarize all of their properties. ,,− The evolution of the understanding of the physicochemical properties of ILs and DESs, thanks to the improvement of characterization and quantification methods, is putting under question some of the previously generalized properties, including electrochemical window, long term thermal stability, polarity, and volatility. ,,

When designing ILs for targeted applications, traditionally, the choice of anion was used as the constituent with the largest impact on the values of the key physicochemical properties of the final ILs, while the choice of cation charged group and side chains was used to fine tune such properties. Another factor that has a significant effect on the design of ILs and DESs are their hydrophobic/hydrophilic properties, which are responsible for their solvation performance. In this review article, a detailed description will not be provided. Rather, only essential observations are given below:

Melting points of ILs and/or DESs can be unpredictable in nature as they can undergo supercooling and may contain different amounts of impurities.

The ultra-low vapor pressure and resistance to flammability of ILs at ambient conditions, make the handling of ILs/DESs safer than that of common molecular solvents.

ILs and DESs are denser than molecular organic solvents, with typical density values ranging from 1 to 1.6 g·cm‑3. ,

The viscosity of a solvent plays a big role in catalytic, mixing, and pumping applications. The viscosity of the majority of ILs/DESs is one to three orders of magnitude higher than conventional solvents. ,

The unique physical and chemical properties of ILs and DESs can be exploited for addressing many of the drawbacks associated with the use of organic solvents in industrial processes, such as flammability and volatility. In a common petrochemical plant, the use of an organic solvent requires the addition of flares and catalytic burners to ensure that emissions are below the threshold established by legislation. On the other hand, the majority of ILs and DESs are generally highly resistant to flammability and thanks to their negligible vapor pressure that do not require the addition of any extra unit operations to manage vapors safely in terms of personnel exposure. The negligible vapor pressure also implies that the chance of dispersing ILs and DESs in the environment is much lower compared to organic solvents and facilitates their recovery and recycling. An efficient separation of the products is needed to guarantee high recovery and minimize the washing steps.

The idea that ILs (or/and DESs) could replace conventional solvents has created a lot of interest in the academic and industrial communities. This substitution is enforced by the EU REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations that are designed to improve safety and protect the environment and their restricted substances list, which phases out hazardous chemicals and provides further opportunities for safer, ILs and DESs-based processes. − However, due to the relative higher cost and concerns about the potential toxicity of some ILs/DESs, their use in large scale applications needs to be justified. , The implementation of ILs/DESs at industrial scale is feasible in processes where the benefits of employing an IL/DES overcome the associated costs of its use (as in some electrochemical applications) or where the cost is not a key factor (pharmaceutical and medical applications); those where they are used in a scale that is relatively small in the overall process (as catalysts, in coatings and thin films, as lubricants, surfactants, or additives, etc.); and those that can be performed with low-cost ILs (such as certain protic ILs). Currently, several examples of ILs/DESs applications established at the industrial scale, either already commercialized or at pilot plant stage, can be found and have been summarized in literature. ,

2.4.1.1. Toxicity

Solvent toxicity represents a danger for humans and the environment since potential accidents due to release can arise. Legislation regulating the handling of chemical compounds usually sets limits on the volume of flammable and toxic chemicals in a chemical plant including storage and process flow streams. This, together with experience gained from past incidents, has been pushing the chemical industry to keep raising the safety standards, aiming to create effective health and safety measures. In this regard, toxicity and biodegradability have been major challenges for ILs/DESs as the first generation of ILs were not biodegradable and the assessments of their toxicities were not well established. However, taking these considerations into account, in recent years a lot of effort has been made in exploring alternative, less toxic and more environmentally friendly ILs. Thanks to this, the perceptions of high toxicity and low biodegradability are being diminished. In fact, a significant range of bio-derived and biocompatible ILs have been established in the literature. − It is important to note that each IL or DES needs to meet certain minimum requirements to qualify as a biocompatible ILs as far as toxicity is concerned. Nevertheless, the large-scale production of sustainable, environmentally friendly, and cost competitive ILs remains challenging. Finally, it should be highlighted that very often the organic solvents that the ILs/DESs are replacing have higher toxicity and environmental impacts, so their substitution is still advantageous even when the replacement is not completely innocuous.

It is well known that the head group of the cation in an IL plays a significant role in toxicity, − with longer side chains having a greater impact on living organisms. It has been demonstrated that the inclusion of an ester group in the alkyl chains of an IL increases the susceptibility of such side chain to be biodegraded. However, the assessment of the (bio)degradability of the IL needs to take into account the bioavailability and the fate of the resulting fragments and, hence, all the other present functional groups.

The effect of the anions on the toxicity of ILs seem to be more difficult to predict but, as a broad generalization, seem to be related with their hydrophobicity/lipophilicity. Other effects, such as their stability towards hydrolysis also play a role in some cases (e.g., anions that can release HF show higher cytotoxicity than that predicted according to their lipophilicity). ,

2.4.2. Integration of ILs and DESs with Industry

Although the substitution of the solvents employed in the chemical industry for safer and more environmentally friendly alternatives can lead to significant improvements in the safety levels of industrial processes, including health and environmental benefits, it can also lead to a drastic impact on the commercial viability of the process. A change in the solvent employed in a process can have a deep impact in the way such processes are performed: from operational parameters to the selection of materials for most plant components. Moreover, the choice of one specific solvent can favor one step by penalizing other steps. For example, in the Difasol process the application of ILs in a large-scale process is still hindered by the capital cost of the equipment. , For new solvents such as ILs or DESs to be economically sustainable, they should be supplied at competitive prices and industry-scale volumes. Economic considerations can therefore help shape technical aspects of solvent design. Nevertheless, as mentioned in the previous section, several applications of ILs/DESs at scale have been already established, highlighting the potential of ILs/DESs to help shape the future of the chemical industry. ,,

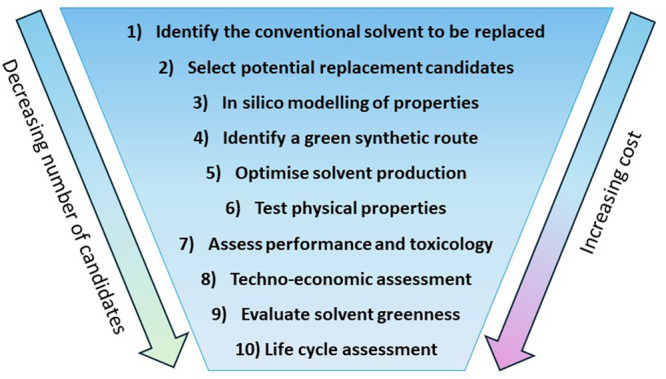

2.4.2.1. Methods for Solvent Selection

Jin et al. proposed a useful 10-step methodology to evaluate the choice of solvent for any given process (Figure ). The selection of potential viable replacements for a solvent that needs to be abandoned is based on the comparison of the Kamlet–Taft (K−T) parameters as a tool to compare solvent properties. Solvents with similar values for these parameters are considered the most promising candidates to substitute the problematic solvent. Further studies to evaluate the viability of the potential candidates have to be performed. These include the evaluation of their physical properties, synthetic routes, toxicology and final implementation through Life Cycle Assessment (LCA).

9.

Method for the selection of a solvent for a defined application proposed by Jin et al. Adapted with permission from ref . Copyright 2017 Royal Society of Chemistry.

A simple criterion to quickly assess the most promising IL/DES for a given process should focus on the role that the IL/DES will play in the process and its potential performance. After the identification of suitable candidates, production cost assessments should be made. The number of synthetic steps required for solvent synthesis can offer guidance for both potential cost and sustainability. As a rough estimation, the cost of a solvent could be assumed to double with each step away from a precursor. In the case of ILs, those employing aprotic (fully alkylated) cations normally require an extra step (ion metathesis) and will therefore be much more expensive than their protic counterparts.

2.4.2.2. Industrial Processes Based on the Use of ILs/DESs

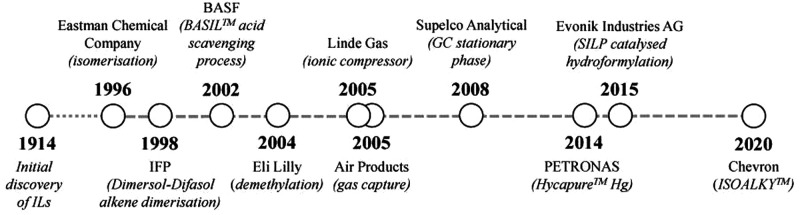

ILs have been already successfully established in at least 57 industrial processes at scale, starting in 1996 with their application in the isomerization of 3,4-epoxybut-1-one to 2,5-dihydrofuran, an intermediate for the production of tetrahydrofuran, by the Eastman Chemical Company. In 2002, BASF demonstrated the large-scale application and recycling of ILs in their BASIL (biphasic acid scavenging with ILs) process. By 2019, 57 processes based on ILs had been either already commercialized or were in the pilot development stage. A timeline of the introduction of industrial processes based on ILs is shown in Figure .

10.

Timeline of industrial processes based on the use of ILs. From Greer et al. 2020. Adapted with permission from ref . Copyright 2020 MDPI under CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/).

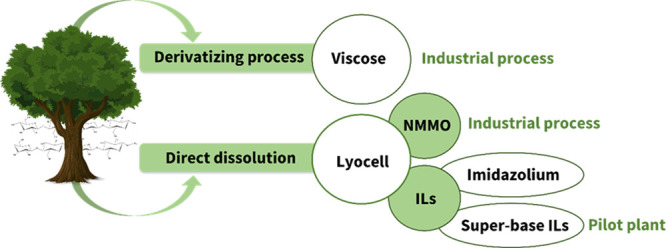

Of special interest for this review is the integration of ILs in industrial pulping processes. In this regard, there are a few applications that are already at the pilot stage of development. These include the Ioncell process, an alternative to Lyocell processes developed at the Aalto University in Finland. It uses superbase ILs, such as 1,5-diazabicyclo[4.3.0]non-5-ene acetate ([DBNH][C1CO2]), to dissolve cellulose-pulp for dry-jet wet spinning production of high performance cellulose fibers with application in fabrication of textiles. Metsä Spring is also developing a fiber-production technology based on cellulose pulp dissolution with ILs. Lixea, a start-up company from Imperial College London, is commercializing biomass fractionation with ILs via their registered Dendronic process. Their pilot plant, located in Bäckhammar, Sweden, started operating in May 2022. Erg Bio Inc. is a startup located in Dublin, CA that is commercializing the ASPIRE IL technology for biomass conversion into biofuels and bioproducts. In contrary to the IL-based development, there are limited examples of DES-based startup. Bioeutectics, an Argentinian biotech, develops and provides natural and high-performance solvents for sustainable industrial products and processes.

2.4.2.3. Industrial Production of ILs and DESs

The implementation of ILs/DESs in industry demands their production at the relevant scale. This can be a challenging task, considering the high costs of some ILs/DESs and some of their properties, such as high viscosities, which can make them hard to handle. The availability of certain starting materials can also limit the scaling up of the production of some ILs/DESs.

Many companies now commercialize ILs/DESs as part of their portfolio, including Merck, Acros Organics, BASF, Evonik, etc., and there are a few companies that are primarily IL producers (with either a few or no DES product line), e.g., Iolitec, Proionic, Scionix and Solvionic. More than 500 ILs can be purchased from those companies. Moreover, at least 10 ILs are available in quantities over 1 tonne. Proionic has developed the carbonate-based IL synthesis process (CBILS), a low impact technology that allows to produce a variety of ILs in multi-tonne scale using a continuous flow process. Iolitec are also capable of producing ILs in the tonne scale. As a consequence of the increasing production capabilities, the prices of several ILs are being reduced. , DESs, on the other hand, owing to their limited industrial applications and simple preparation (requiring only heating and stirring or two or more components) have not been a top rated product portfolio for most of the chemical companies.

2.5. Types and Classification of ILs and DESs for Biorefining

For ILs, in terms of their synthetic mechanism and proton availability, two main categories can be considered, protic (PILs) and aprotic ILs (AILs). This distinction is important since both classes of ILs work differently when applied for lignocellulosic biomass pretreatment. The main structural difference between PILs and AILs is that while AILs have fully alkylated cations, PILs have an acidic proton, a proton that can dissociate in aqueous medium and decrease the medium’s pH. Some AILs with halide and alkyl sulfate anions can dissolve cellulose and establish chemical pathways to valorize it to further chemical compounds. On the other hand, Brønsted acidic PILs can fractionate biomass by dissolving lignin, obtaining a high purity cellulose which can be used for further processing.

Furthermore, other categories can be considered in terms of their origin −biobased ILs, BILs, which are ILs that can be obtained from renewable sources, chemical behavior and alkaline ILs, a category that includes ILs that can be either AILs of PILs, with anions with high β, such as acetates or derived from AAs, or DESs, a class of solvents that share many characteristics with ILs and even show some overlap between both classes of solvents, as already discussed.

Regarding DESs, a novel class of innovative solvents that have acquired significant scientific and technological significance, are typically considered as cost-effective alternatives to conventional organic solvents and ILs. Synthesized by combining Brønsted or Lewis acids and bases in precise molar ratios, DESs have significantly lower eutectic points than the optimal liquid mixture. , The resulting liquid always has a lower freezing point than the components used to synthesize DESs. The majority of commonly reported DESs are HBAs such as quaternary ammonium, phosphonium salts with amides, carboxylic acids, or other HBDs, such as urea, thiourea, glycerol, and oxalic acids. Based on the chemical nature and type of these HBDs and HBAs, DESs are classified into several types (types I, II, III, IV, and V) as discussed below.

2.5.1. Aprotic ILs

AILs are the most common type of ILs found in the literature. They have fully alkylated cations and their synthesis usually involves at least an amine or phosphine quaternization reaction followed by an ion metathesis stage. Other synthetic stages might be needed depending on the target structure. These preparations are lengthier and more complicated than those of PILs and they usually employ more expensive starting materials compared with PILs. The need of ion metathesis for the preparation of many AILs implies low atom economies and the production of salt-containing waste streams, necessitating costly waste disposal. Often, the preparation of AILs present problems associated with halide contamination in the final product, requiring appropriate analysis and purification or specialized synthetic procedures.

When applied to biomass processing, alkaline AILs follow a different mechanism than neutral AILs, as will be explained with detail in section . It has been reported that, under certain conditions, some AILs with basic anions and imidazolium or phosphonium cations, such as 1-ethyl-3-methylimidazolium acetate ([C2C1im][C1CO2]) and tetradecyltrihexylphosphonium acetate ([C14C6C6C6P][C1CO2]), can act as PILs, displaying acid–base equilibrium behavior, via carbenes or ylide formation, respectively.

2.5.2. Protic ILs

The synthesis of protic ionic liquids (PILs) is a simple neutralization reaction via transfer of a proton (H+) between an acid and a Brønsted base. Often, PIL synthesis can be performed solvent-free. , However, if strong Brønsted acids such as sulfuric or nitric are employed the reaction is exothermic. To minimize hazards, dropwise addition of aqueous diluted acid to the Brønsted base or appropriate cooling should be employed. PILs possess remarkably different physicochemical properties compared to conventional AILs, including in some cases an ability to distill due to high volatility, although this can be related to a low-ionicity IL and the fact that distillation takes place via the neutral acid and base. , By having an exchangeable proton, PILs exhibit Brønsted acidity, which allows them to be used as solvents for a number of acid catalyzed reactions including Diels–Alder, Beckmann rearrangement and condensation reactions such as aldol or Baeyer. Since most PILs are synthesized from simple acids and bases, they usually present short life cycle trees and tend to be more environmentally friendly due to reduction in by-product generation, solvent losses, energy use and carbon dioxide generation. This also makes PILs manufacture cheaper (up to 40 times) when compared to the most common AILs studied in the literature for applications in biomass pretreatment. ,,

In either case, for both AILs and PILs, the choice of the precursor is reflected in the final cost of the IL. For example, longer alkyl chain ILs and functionalization or the presence of heteroatoms such as phosphorus or fluorine increase production costs. Techno-economic analysis of the bulk-scale synthesis of ILs showed that while aqueous mixtures of alkylimidazolium hydrogen sulfate ILs can be produced in the price range of $2.96–5.88 kg–1; replacing the cation precursor for simpler and cheaper trialkylamines can reduce the cost to bulk scale for as little as $0.78 kg–1, which is comparable to the cost of common organic solvents like acetone and toluene. , For reference, estimates of bulk prices of frequently investigated AILs are in the range of $40–81 kg–1, or 5–20 times of the price of organic solvents. This finding addressed one of the main concerns raised about using ILs in large quantities: their alleged high cost. Furthermore, in the long term, it is expected that synthesis of biobased PILs from the lignocellulosic biomass itself, in a strategy similar to Socha and co-workers, will be possible further reducing the environmental impacts associated with the production of ILs. ,

One potential issue of certain PILs is that, if the difference in pK a between the two-precursor species is not large enough, the proton transfer might not be complete, leaving behind some proportion of the molecular species. , Additionally, the drying step can push the reaction equilibrium towards the molecular precursors, favoring the removal of one of them from the mixture, creating a nonstoichiometric mixture that is concentrated in the less volatile precursor species. Comprehensive discussions on PILs proton transfer, ionicity, and their impact on the physicochemical properties of the ILs can be found elsewhere. ,−

2.5.3. Biobased ILs and DESs

Biobased ionic liquids (BILs) are defined as the ILs obtained from natural products, their analogues, or bioactive molecules. Typically, this class of ILs is considered as green, renewable, biocompatible and/or biodegradable. Similarly, natural DESs (or NADESs) are also biobased DESs prepared from components that could be obtained from natural sources such as [Ch] and carbohydrates, among others. ,, Such class of solvents are interesting due to their origin and have potential to sustain a closed-loop biorefinery for continuous production of biochemicals and bio-based materials. ,

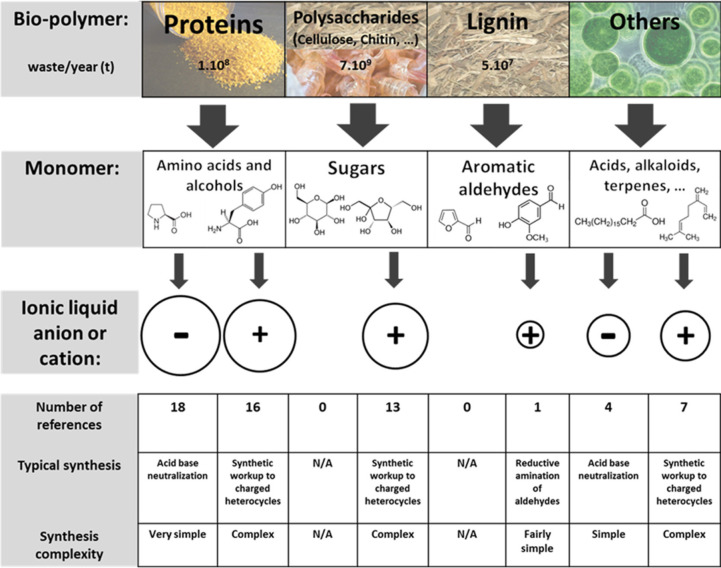

Although several components, including AAs, sugars, aromatic aldehydes, alkaloids, terpenes and fatty acids, have been employed as precursors to the components of BILs or NADES, [Ch]- and AA-based ILs/DESs have dominated the literature mostly owing to their simple synthetic protocol (Figure ). , It is worth remarking that, despite being labeled as bio-based, many of the DESs and ILs reported in literature are being obtained from [Ch] and glycine, which are produced from petrochemicals. These could, indeed, be obtained from biological sources, but at significantly higher prices (up to six-fold). This is reflected in the prices of AAs produced from fermentation (lysine) or protein hydrolysis, which are considerably higher. In a similar fashion, other amines usually produced from fossil sources, and therefore not labeled as “bio”, could be also obtained from renewable and low-carbon footprint feedstocks and processes, but again still at higher prices than their petro-based counterparts. ,

11.

Precursors to bio-based ILs. Adapted with permission from ref . Copyright 2016 American Chemical Society.

Since the first synthetic report of AA-based [Ch] ILs by Ohno et al., several newer synthetic protocols have been developed and studied for their physicochemical, toxicity and biodegradability properties. Liu et al. first explored the application of these [Ch][AA] ILs in the biomass processing demonstrating about 30 times higher lignin solubility compared to polysaccharides. Thermal stability and viscosity are important parameters for successful application of these ILs in biorefinery. Most of these ILs were found to be thermally stable in the temperature range of 150–200 °C, while the viscosity depends on the size and complexity of the anions. The toxicity studies on the [Ch][AA] ILs have classified these as practically non-toxic to most bacterial cultures paving the path to integrate the bioconversion processes without separation of ILs unlike traditional imidazolium-based ILs. ,

2.5.4. Deep Eutectic Solvents (DESs)

The majority of commonly reported DESs contain HBAs such as quaternary ammonium and phosphonium salts with HBDs such as amides, carboxylic and oxalic acids, urea, thiourea, glycerol, etc. By their own nature, DESs are non-stoichiometric and can be defined by the general formula: Cat + X – zY where Cat+ represents ammonium, sulfonium, or phosphonium cation, while X is a Lewis base, usually a halide anion, and z is the total number of Y molecules which interact with anion.

2.5.4.1. Type I DES

This category of eutectic mixtures is comprised of quaternary ammonium, phosphonium, sulfonium salts and non-hydrated metal halides, including FeCl3, ZnCl2, LaCl3, and SnCl2. , However, the high cost and limited availability of anhydrous metal halides appropriate for DESs synthesis limit their application.

2.5.4.2. Type II DES

This type of DESs are characterized by the utilization of hydrated metal halides and quaternary ammonium salts. Due to the low cost of hydrated metal halides and their insensitivity to moisture, type II DESs compounds are used in numerous industrial applications.

2.5.4.3. Type III DES

This class of DESs is the most researched and well-liked in the scientific community, as it is derived from inexpensive, non-toxic, and biodegradable starting compounds. In particular, quaternary ammonium salts are combined with HBDs such as alcohols, amides, and carboxylic acids to create these eutectic compositions. [Ch]Cl is a frequently employed quaternary ammonium salt (HBA) for type III DESs that is derived from biomass and classified as a vitamin source. ,,

2.5.4.4. Type IV DES

Abbott et al. reported the development of type IV DESs by combining transition metal halides with appropriate HBDs such as ethylene glycol, acetamide, and 1,6-hexanediol. This category of DESs is still in its infancy in terms of research. ,

2.5.4.5. Type V DES

Non-ionic compounds are also utilized in the preparation of eutectic mixtures with low melting points for DES of type V. Recently, Coutinho et al. found that the thymol–menthol system exhibits type V non-ionic deep eutectic mixtures with extraordinarily strong interactions.

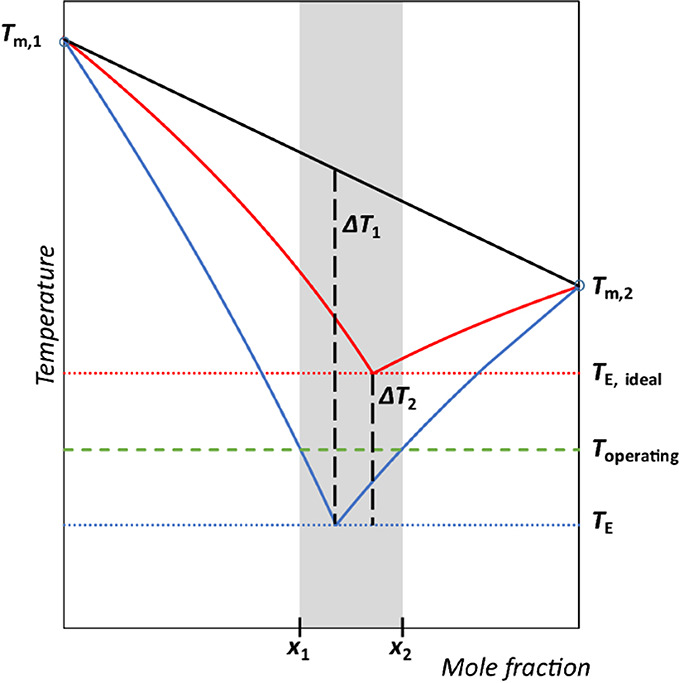

Figure summarizes the principal characteristics of the solid–liquid phase diagrams for these binary DESs. Note that the eutectic composition is a single value corresponding to the minimal melting temperature in the phase diagram, as shown in Figure . The formation of these low-melting eutectic composites is driven by hydrogen bonding interactions between the components. It is hypothesized that the interaction of the HBD with the quaternary salt reduces the anion–cation electrostatic force responsible for the formation of hydrogen bonds, thereby significantly lowering the freezing point of the mixture. DESs share the advantageous solvent properties of ILs, such as minimal volatility, a broad liquid range and biocompatibility. , Nonetheless, several hypotheses, such as charge delocalization, cluster formation, and a decrease in lattice energies due to the use of asymmetrical cations in DESs, have been proposed to explain the lowering of the eutectic solutions' melting point.

12.

Schematic representation of the comparison of the SLE of a simple ideal eutectic mixture (red line) and a deep eutectic mixture (blue line). Adapted with permission from ref . Copyright 2018 Springer Nature.

Figure depicts the HBAs and HBDs used to prepare a variety of popular DESs. As it shows, it is possible to obtain neoteric DESs with specific physical and chemical properties by modulating the HBAs and HBDs. Due to the wide availability of HBAs and HBDs, a variety of structural modifications are conceivable; therefore, as with ILs, DESs are also known as “designer solvents”. − Choi et al. reported the production of highly viscous natural deep eutectic solvents (NADES) by combining [Ch]Cl with various HBDs such as AAs, organic acids, and carbohydrates. In a similar fashion, Silva et al. prepared and termed as “therapeutic deep eutectic solvents (THEDES)” by combining an active pharmaceutical ingredient (API) with a previously prepared eutectic mixture. While the majority of the innovated DESs till date are hydrophilic and water-miscible, Osch et al. reported the formation of water-immiscible hydrophobic DESs. −

13.

The most prevalent structures of hydrogen-bond donors and halide compounds employed in the synthesis of DESs. Adapted with permission from ref . 2015 American Chemical Society.

Due to the versatility and uniqueness of DESs, they have acquired significant scientific and technological significance as alternatives to conventional organic solvents and ILs and have been studied in applications including biomass processing and lignin chemistry. , The potential for designing suitable DESs with high applicability for the dissolution of various biomass is significant, as the properties of DESs may be readily adjusted by modifying the HBDs and HBAs. , As such, effective utilization of DESs for the treatment of biomass can be possible only with a thorough understanding of their physicochemical properties. DESs still have the challenges associated with ILs for their use at scale, most notably costs associated with efficient recovery and recycling and biocompatibility.

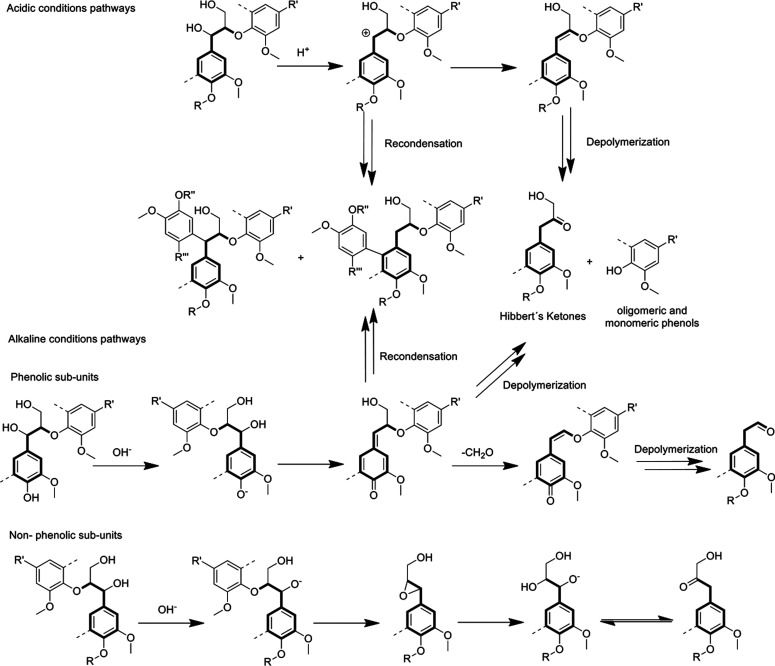

2.6. Mechanisms of Biomass Pretreatment with the Different Types of ILs and DESs

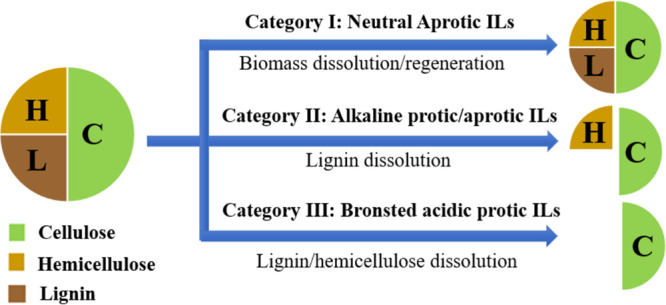

Biomass delignification with four different types of IL-based solvent systems, that follow different mechanisms, has been very successful: (I) neutral AILs, usually based on chloride or alkylsufate anions, (II) alkaline ILs (which can be either aprotic or protic ILs and include most BILs), , typically based on acetate or AA derived anions, and (III) Brønsted acidic PILs, in particular those with hydrogen sulfate and chloride anions; and (IV) DESs. ,,

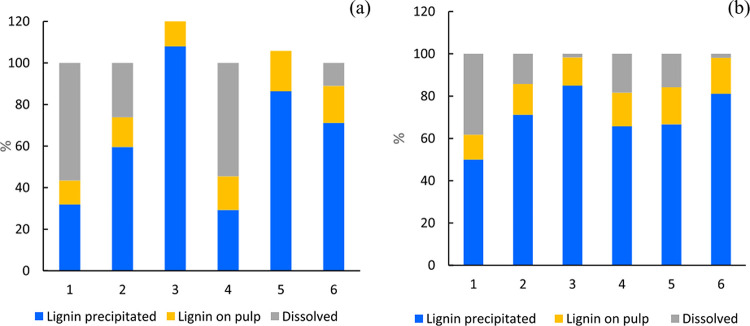

The type of IL and the water content employed during the pretreatment determine which mechanism comes into play. Each of these types of systems offer different advantages, disadvantages, and working mechanisms and will be discussed in this review. Neutral AILs are capable of dissolving the lignocellulosic biomass, but usually they are not very selective towards specific macrocomponent like lignin or cellulose. Alkaline ILs (either protic or aprotic) are capable of solubilizing lignin but, depending on the severity, have limited ability to solubilize hemicelluloses. Brønsted acidic PILs that solubilize most of the hemicelluloses and lignin, producing a cellulose-rich pulp (Figure ). These categories are mainly based on the type of anion that constitutes the IL, as it determines the main interaction with lignocellulosic biomass. DESs typically dissolve both lignin and hemicellulose, in a similar fashion to Brønsted acidic PILs.

14.

The three main categories of ILs used in the pretreatment of lignocellulosic biomass.

Since most IL-based pretreatment technologies typically have low water content during biomass pretreatment, acidity rules from the pH scale are not applicable. Therefore, other types of acidity scales have been developed, such as the Hammett acidity function which uses a range of closely related UV–vis probes to generate the Hammett acidity, H 0. ,

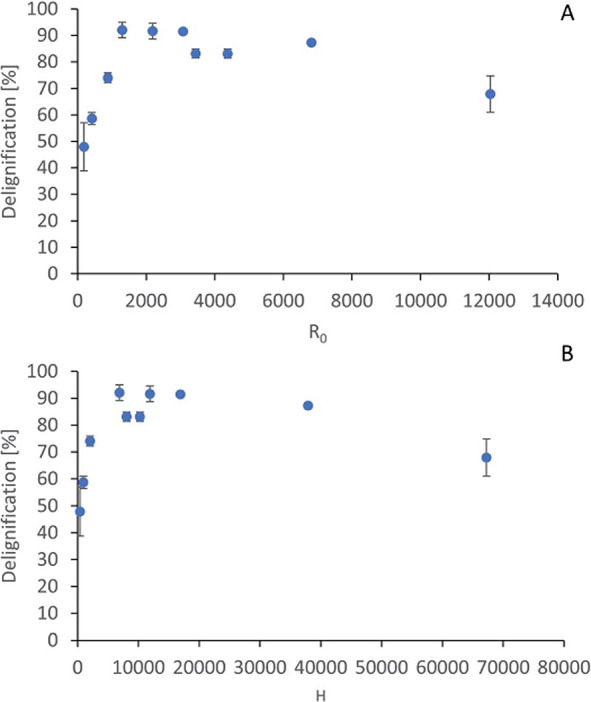

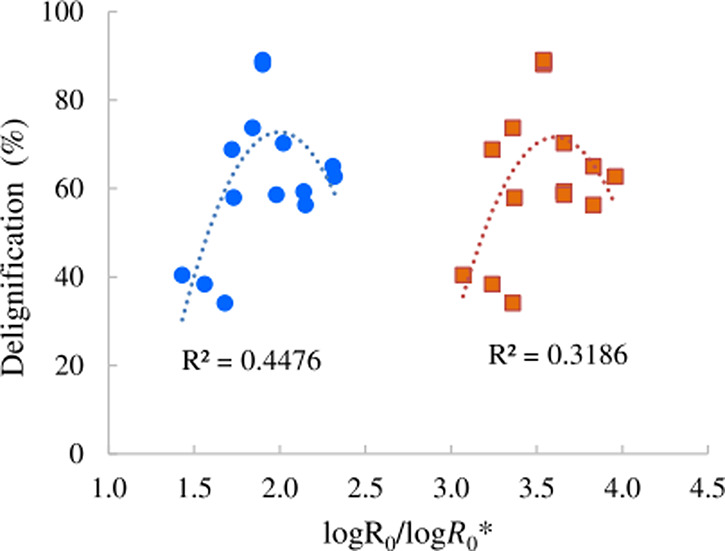

Abouelela et al. (2023) introduced the H 0 values of the IL butyl-N,N-dimethylammonium hydrogensulfate ([C4C1C1N][HSO4]) to the pretreatment severity factor, R 0, commonly used for hydrothermal and dilute acid pretreatments, on the pretreatment of pine and observed that the new R • 0 presented better correlation between severity and pretreatment parameters such as mass loss, glucan and lignin recovery. This will be discussed in further detail in section .

Other methods to measure the acidity of ILs include the one developed by Fărcaşiu to estimate the acidity of organic solvents by using the 13C NMR spectrum of mesityl oxide as a probe, that was later adapted by Grasvik et al. for [HSO4]-based ILs. They were able to correlate the Δδ of mesityl oxide with the H 0 of the ILs within the range of −1 < H 0 < −9, outside such range, large changes in H0 correspond to small changes in Δδ. In depth studies about the structure, proton dissociation, and acidity of protic ILs based on hydrogen sulfate anions and their interactions with water have been recently published. ,

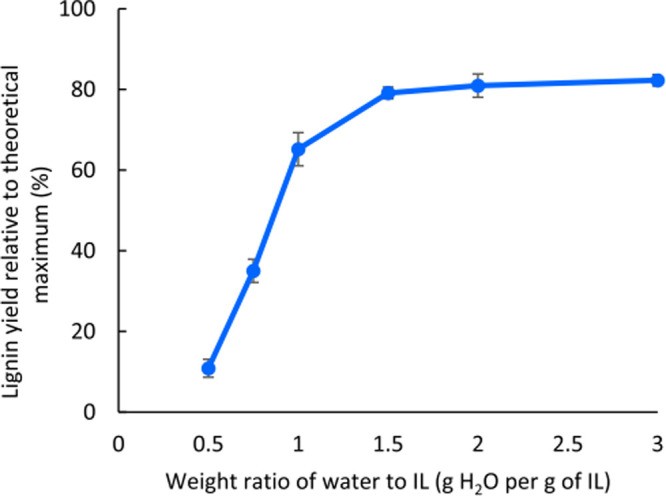

It should be noted that the delignification ability of a solvent is not necessarily reflected in the recovered lignin yields. Delignification quantifies the proportion of lignin in the biomass that gets dissolved into the pretreatment solvent, independently of how much of it is recovered from the liquor. Lignin yield quantifies the amount of lignin precipitated from the pretreatment and washing liquor upon the addition of an antisolvent. Antisolvents are added to the pretreatment liquor to reduce the solvation power of the IL, allowing precipitation of the lignin from the IL (and also of the cellulose if the process follows the dissolution mechanism). Appropriate selection of antisolvent is key to maximize lignin recovery and minimize further reactivity of lignin.

2.6.1. Pretreatment with Neutral AILs

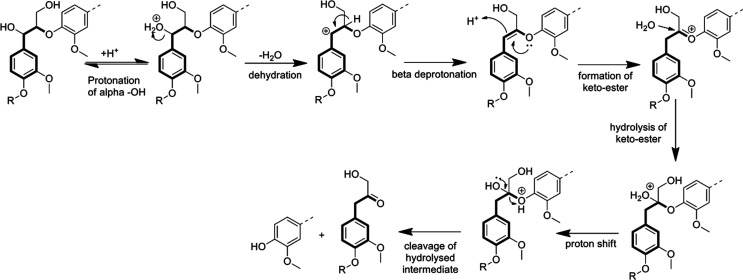

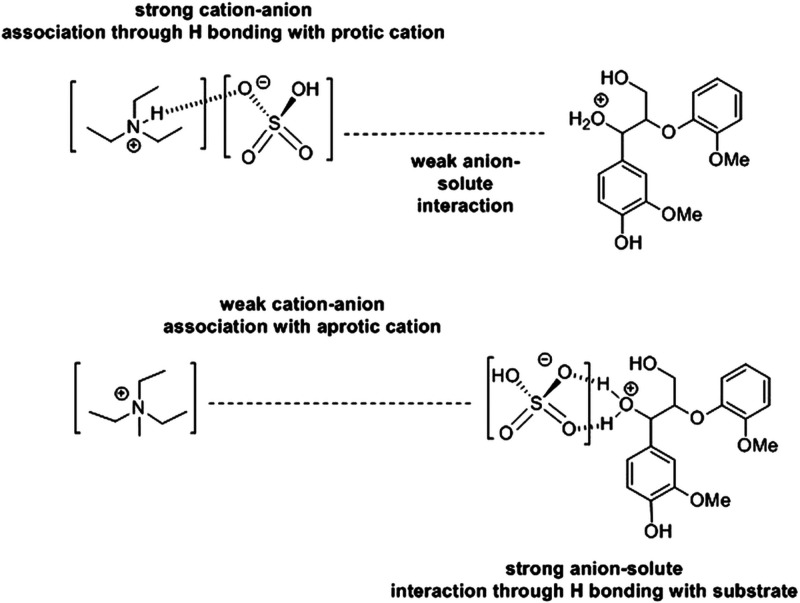

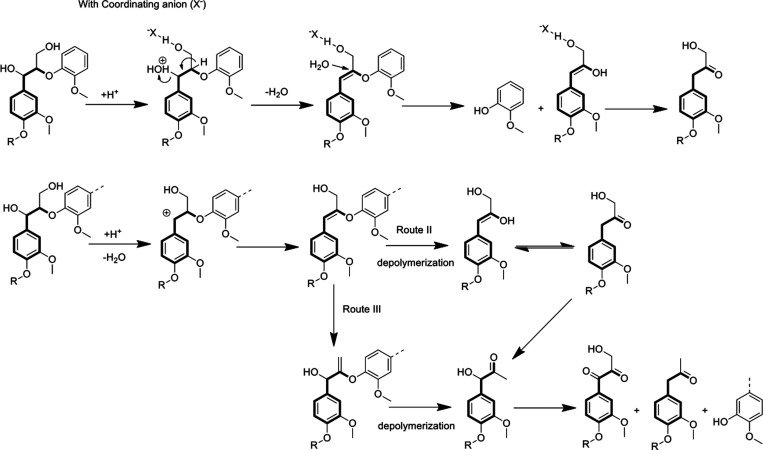

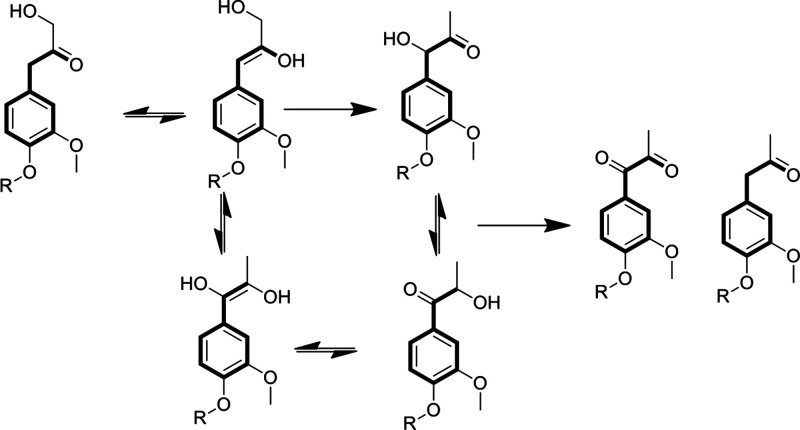

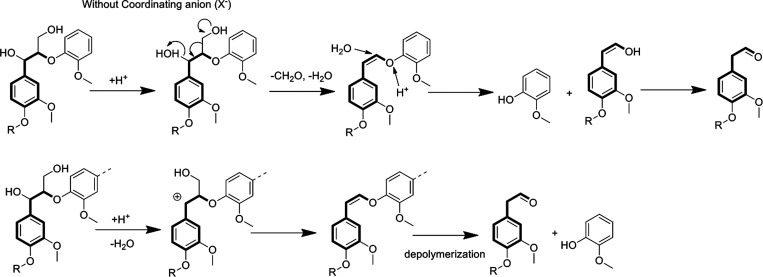

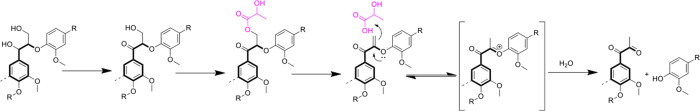

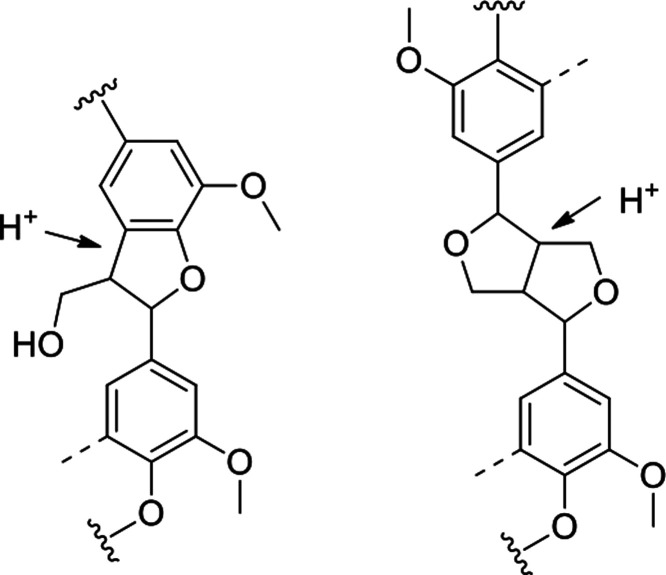

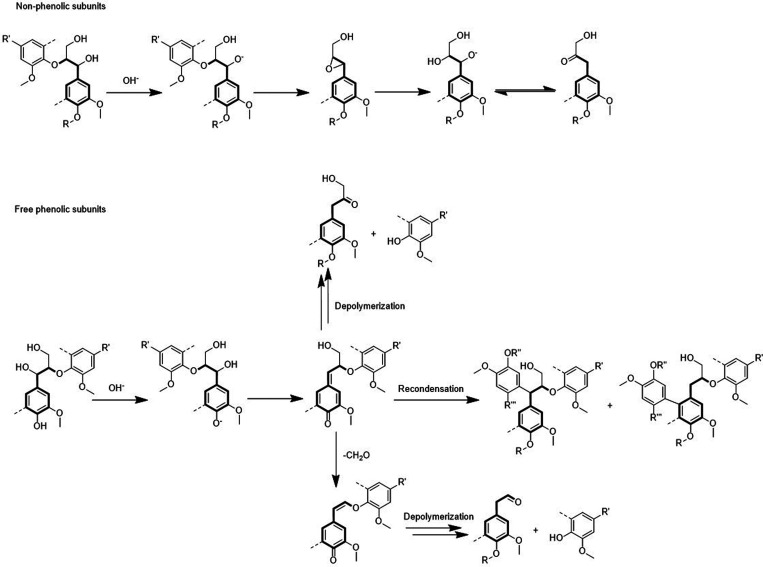

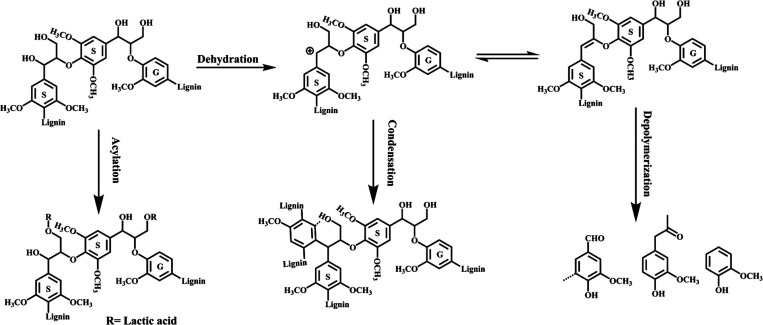

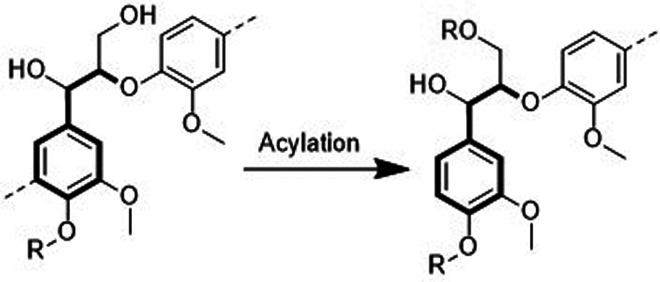

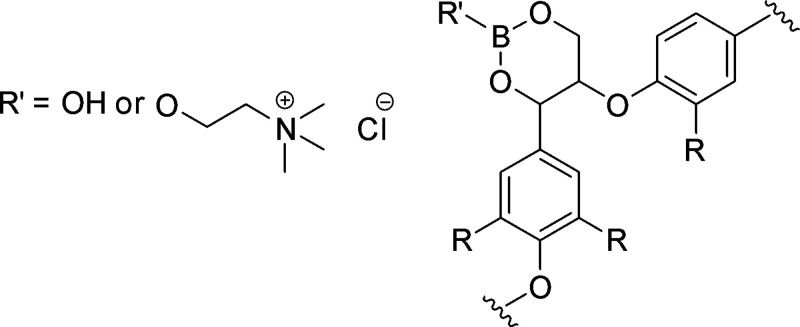

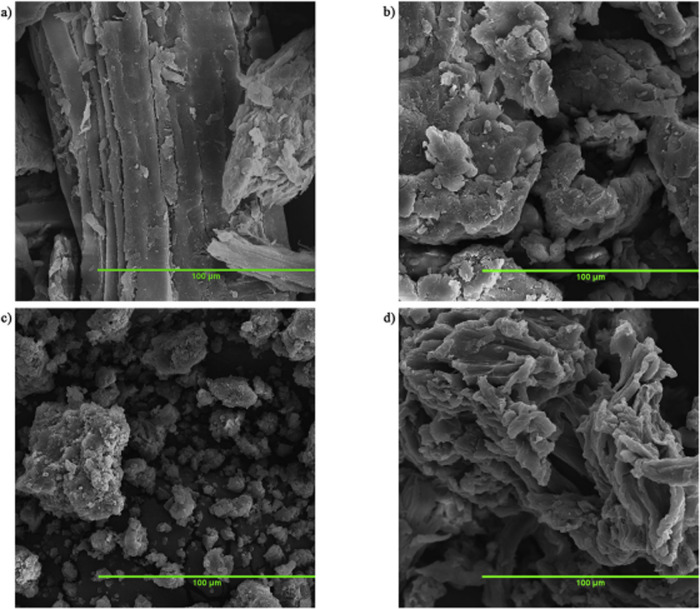

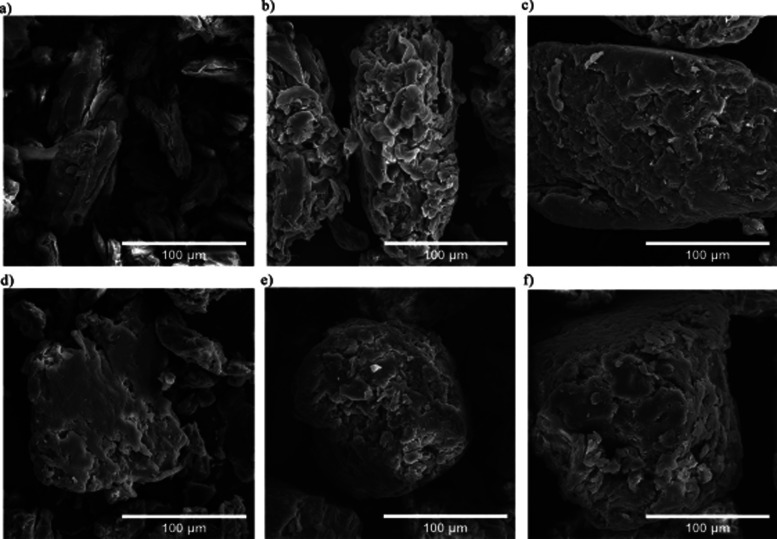

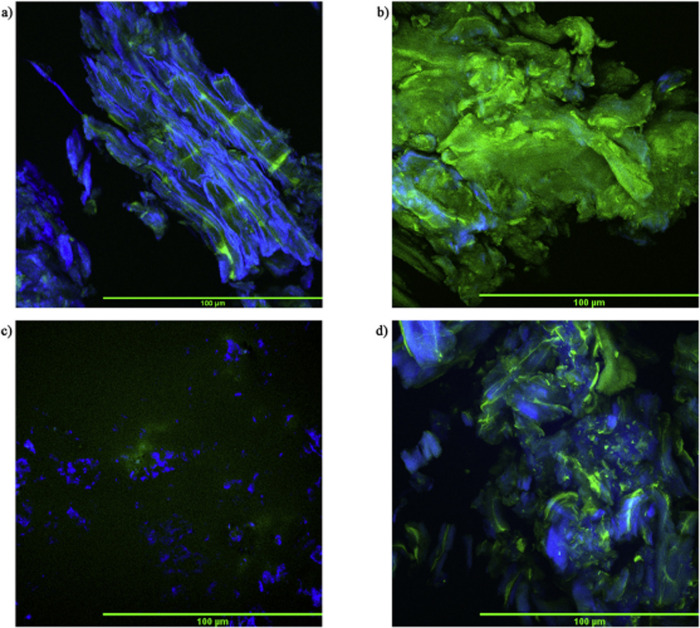

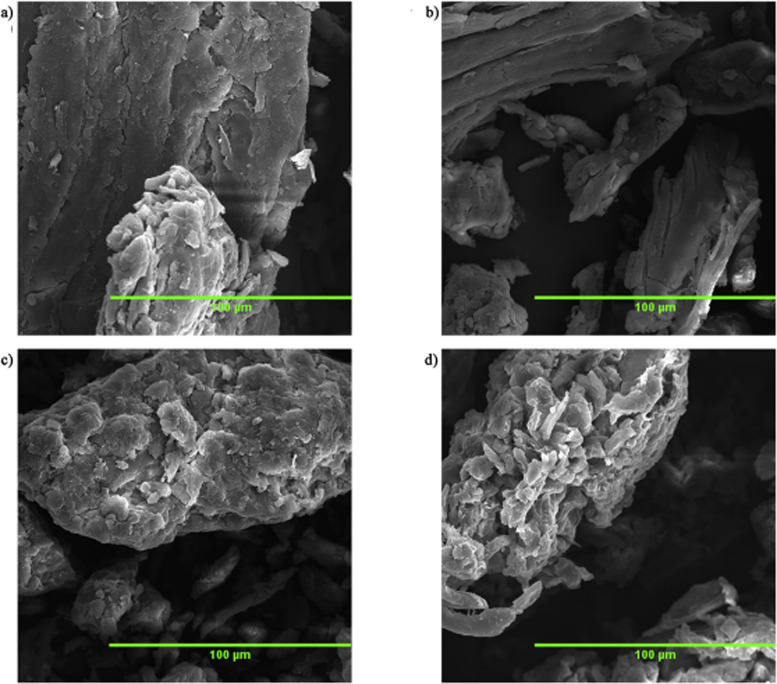

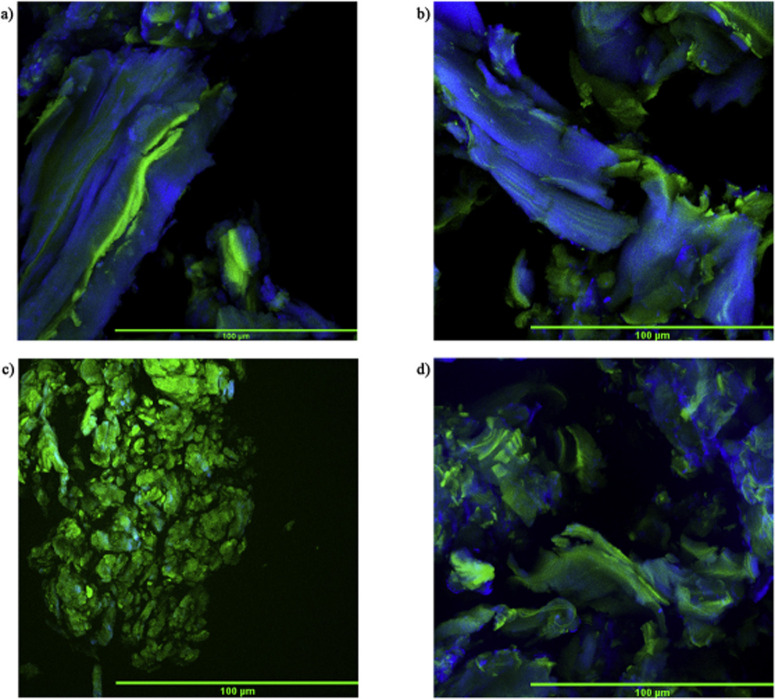

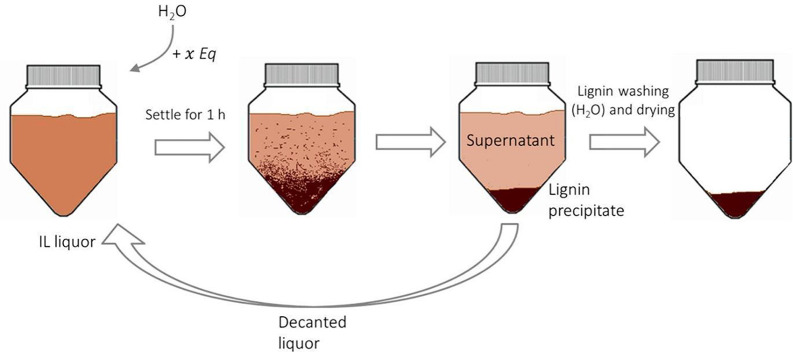

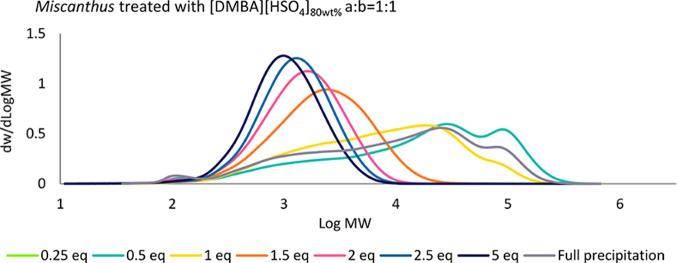

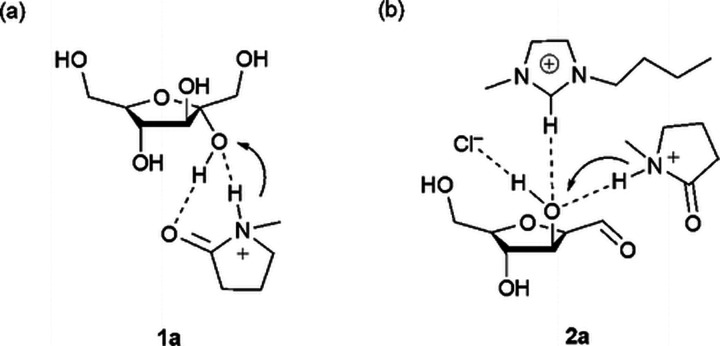

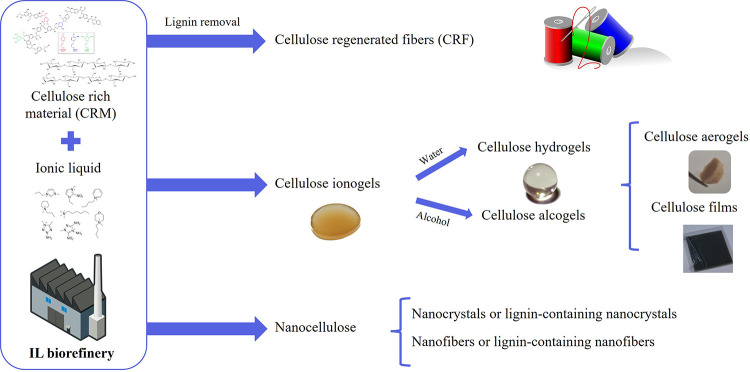

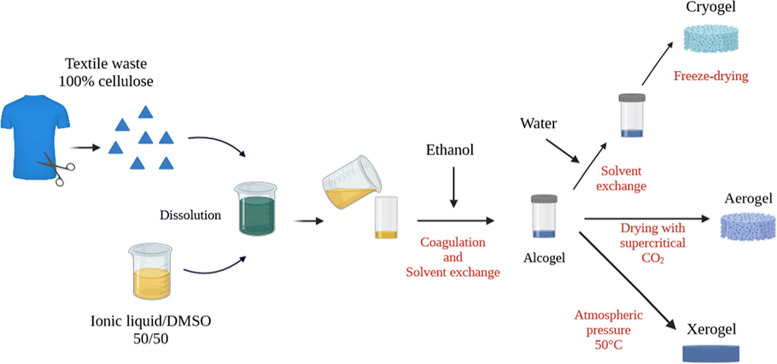

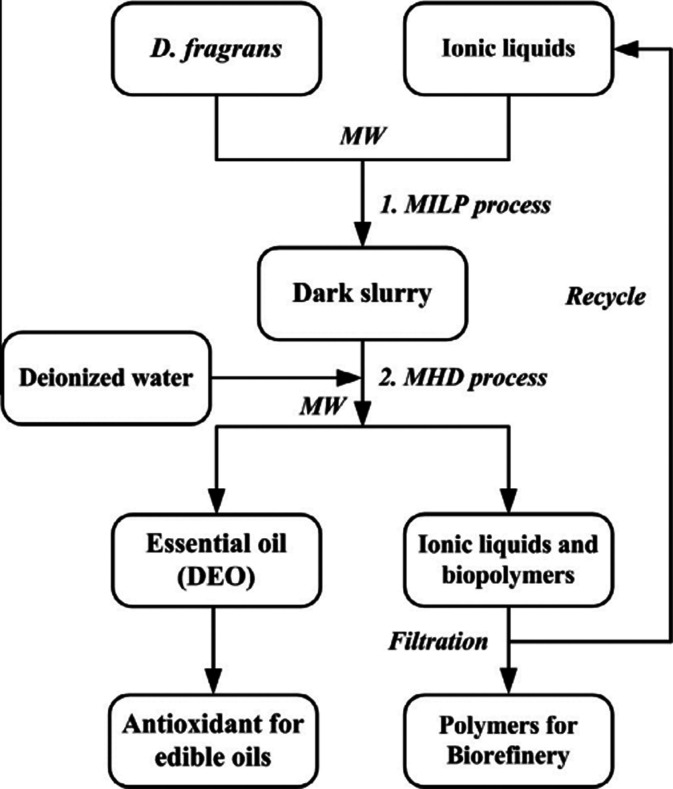

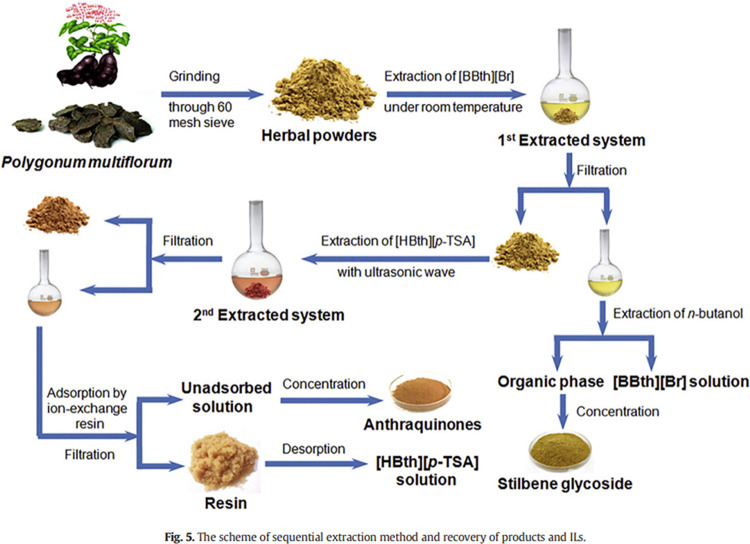

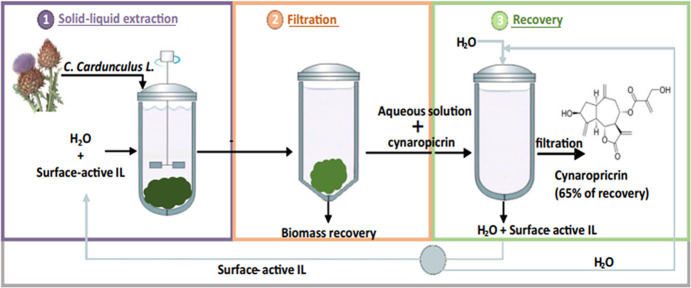

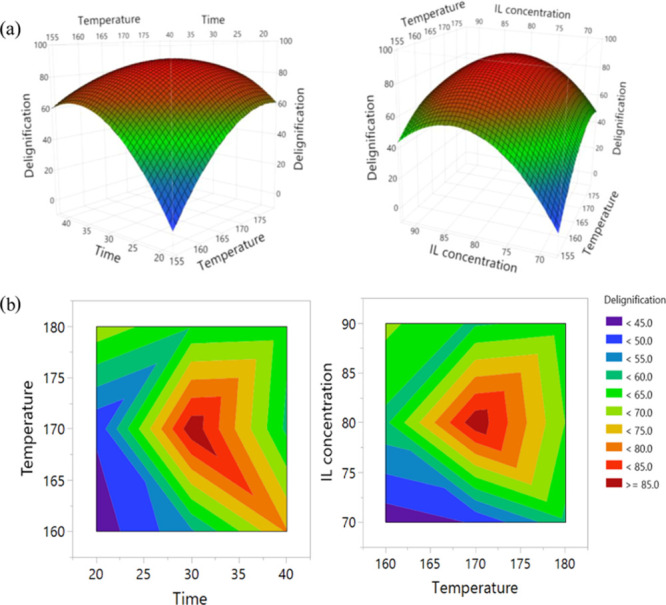

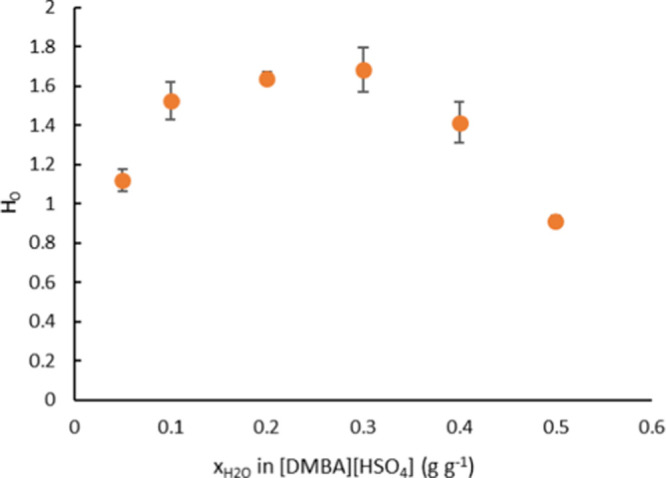

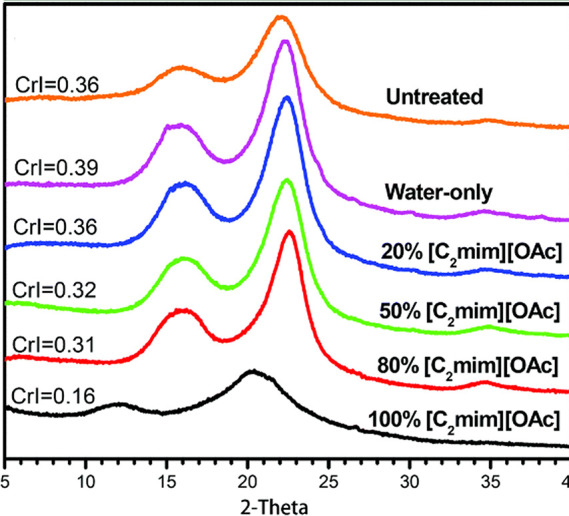

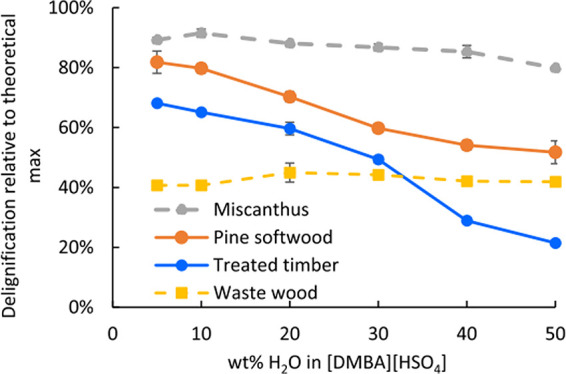

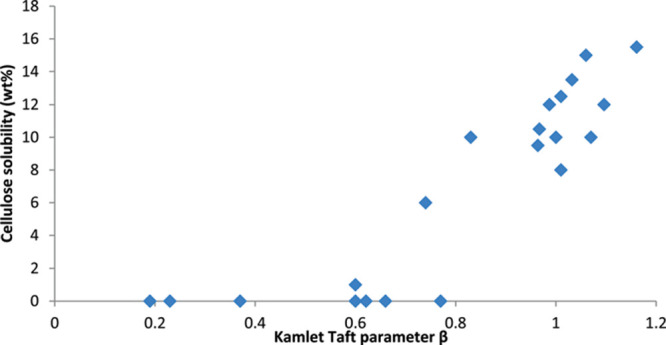

Neutral or slightly acidic AILs containing anions with low Brønsted basicity (such as halides, alkylsulfates, etc) but relatively high β can dissolve lignocellulosic biomass, but they usually are not very selective towards specific macrocomponent like lignin or cellulose (Figure ). Typical aprotic cations include dialkylimidazolium-derived structures like [C2C1im] or [C4C1im]. − The most used and classic example is [C4C1im][Cl], one of the first aprotic ILs employed in cellulose and biomass dissolution studies. Several studies were dedicated to understand the effect of this IL on lignocellulosic biomasses such as corn stover, palm oil fronds, rice straw and husk , and sunn hemp fibre. Additionally, a few review papers have been dedicated to explore the use of such ILs such as the works by Cao et al. (2017), Halder et al. (2019) and Colussi et al. (2023). ,,