Abstract

Piezoelectric micro‐ and nanomaterials can generate local electrical signals when subjected to mechanical stress, a phenomenon that can be exploited to trigger beneficial effects at the cell and tissue level. In recent years, research on biodegradable piezoelectric material has gained momentum, as these materials can degrade after fulfilling their function. Thus, they promise to considerably impact regenerative medicine, targeted therapy, and microrobotics, with better chances to match regulatory requirements with respect to their nondegradable counterparts. This review offers a comprehensive overview of recent advancements in biodegradable piezoelectric micro‐ and nanomaterials, focusing on their piezoelectric mechanisms, material types, and methods to enhance their properties. Current characterization techniques, emphasizing both piezoelectricity and biodegradability at the micro/nano scale, are also discussed. Furthermore, it is discussed how to use these materials in intelligent platforms for regenerative medicine and responsive drug delivery systems. The application of piezoelectric micro‐ and nanomaterials in microrobotics is also examined, particularly their potential for minimally invasive procedures. Finally, challenges and future directions are highlighted, underscoring the importance of biodegradable piezoelectric materials as versatile platforms for advancing biomedical technologies.

Keywords: biodegradation, minimally invasive therapy, nanorobots, organic nanomaterials, piezoelectricity, regenerative medicine

This article outlines the key efforts in the state‐of‐the‐art of biodegradable piezoelectric nanomaterials and their possible impact in the biomedical field. Material types and compositions, fabrication techniques, methods to enhance piezoelectric properties, and characterization approaches are described. Specific applications of these materials in regenerative medicine, targeted therapy, and microrobotics are discussed, highlighting current challenges and future directions.

1. Introduction

Micro‐ and nanomaterials are particularly attractive due to their high surface energy, targeting properties, and cell–material interactions. The dominance of surface forces over volume forces at small scales underscores the relevant role assumed by micro‐ and nanomaterials and their potential in reshaping the landscape of various scientific disciplines, from materials science to medicine and beyond. The last decade has seen, in particular, remarkable advancements in the field of piezoelectric materials.

Piezoelectricity is an intrinsic property of certain materials, which can convert a mechanical response into electrical charges (direct piezoelectricity) and vice versa (converse piezoelectricity).[ 1 ] The unique characteristics of piezoelectric inorganic materials ground on their nonsymmetric crystal structure, which allows the alignment of opposite ions to form an electric dipole moment. Dipoles are uniformly distributed and oriented throughout the crystal regions of the material, forming domain structures. These domains can be aligned in a single direction to uniformize the material polarization, thus increasing the piezoelectric response.

The piezoelectricity depends on the material composition, including the orientation and symmetry of the crystals. The applied stress (T) and the resulting electric polarization (P) in a piezoelectric material are proportionally related as follows:

| (1) |

where d corresponds to the piezoelectric coefficient tensor, which describes the piezoelectric activity of the material. This coefficient can be expressed as a third‐rank tensor with 3 × 6 components indicated as d ij , where the subscript i represents the directions of the generated polarization and j represents the direction of the applied stress. The subscripts from 1 to 3 denote the X, Y, and Z directional axes, whereas the subscripts from 4 to 6 indicate the shear planes that are perpendicular to each of those axes, respectively (Figure 1a). Piezoelectricity is a direction‐dependent property, as each component is defined with a magnitude and a direction, positive or negative, depending on the resulting strain or induced polarization concerning their reference axis.[ 2 ]

Figure 1.

a) Schematic representation of the directions in the Voigt notation, and the piezoelectric tensor describing the coefficient responsible for the normal and shear piezoelectricity. Chemical formulas and crystal structures shown as examples of b) an inorganic (e.g., barium titanate) and c) organic (e.g., collagen) material. Inorganic materials are featured by a higher piezoelectric response in the same direction as the applied stimulus, while organic ones often show a higher shear behavior.

Piezoelectricity is often found in natural structures, including human body tissues. Since the discovery of piezoelectric polarization in wool and hair in 1941,[ 3 ] piezoelectricity has been observed in various human tissues, including bone, tendon, and skin.[ 4 ] At a smaller scale, piezoelectricity has been observed in proteins, amino acids, and polysaccharides, wherein the physical principles of piezoelectricity varied with respect to inorganic materials. Indeed, organic materials possess well‐organized and highly ordered structures that exhibit low symmetry and lack an inversion center. Despite that, the functional groups and the spatial configurations of organic polymers lead to unconventional sources of piezoelectricity.[ 5 ] For instance, the piezoelectric properties of macromolecules such as long‐chain peptides, proteins, polysaccharides, and synthetic polymers are influenced not only by intramolecular dipoles but also by other factors such as hydrogen‐bond networks, spatial folding, and helical and fibrous structures.[ 6 ]

Piezoelectric materials offer several advantages over conventional biomaterials, as they can be used to transmit electricity to living systems in response to processes, such as body movements or external stimulation (e.g., ultrasound).[ 7 ] For instance, piezoelectricity has shown healing potential for hard and soft tissues. Indeed, when a tissue such as bone or cartilage is compressed or, in some other cases, when a tendon, ligament, or skin is stretched, electrical stimuli are generated.[ 8 ] For example, the human tibia can generate up to 300 μV of piezoelectric potential during walking.[ 9 , 10 ] According to Wolff's law, bone is susceptible to remodeling when subjected to stress, and collagen piezoelectricity has been invoked as one of the main potential mechanisms behind this process.[ 11 ] Therefore, mechanically induced electrical energy has the potential to exert a significant regulatory effect at both cellular and molecular levels, for example in the activation of cell pathways (e.g., calcium signaling pathways) and for the regulation of mechanosensitive channels. In the former case, piezoelectric materials can induce localized electric fields that lead to the opening of voltage‐gated calcium channels on the cell membrane that may regulate important activities in eukaryotic cells, as depolarization signals in neurons, and contribute to synaptic activity.[ 10 , 12 ] In the latter case, the PIEZO1 and PIEZO2 protein receptors are among the most extensively studied mechanosensitive transducers in cells and enable the detection of cell membrane deformation due to mechanical stimuli.[ 13 , 14 ] The activation of these channels contributes to the regulation of various cellular activities, including osmoregulation, volume control, and cellular responses to mechanical forces.

Piezoelectricity, like ferroelectricity, concerns the electroresponsive behavior of certain materials, but they have distinct characteristics and underlying mechanisms. Ferroelectricity is a property of certain materials that exhibit a spontaneous electric polarization (a permanent dipole moment) that can be reoriented by applying an external electric field. In other words, the spontaneous polarization in ferroelectric materials naturally leads to a piezoelectric response when the material is mechanically deformed. All ferroelectric materials are piezoelectric; however, not all of them are ferroelectric.

Compared to their bulk counterparts, piezoelectric micro‐ and nanomaterials possess outstanding advantages in eliciting cell‐specific responses. This is attributed to their size, and shape (flakes, wires, rods, fibers, tubes, particles, film), thus in their high surface‐area‐to‐volume ratio, which results in high surface energy, as well as the potential presence of nanotopography and its impact on surface energy.[ 15 ] It is worth remarking that miniaturizing piezoelectric materials to the micro‐ and nanoscale has significant consequences. Indeed, micro‐ and nanoscale piezoelectric structures can exhibit an enhancement or decrease in their piezoelectric coefficients compared to their macroscale counterparts owing to various factors, including the concentration and elimination of crystal surface defects or the contraction or expansion of the crystal lattice.[ 16 ] However, downscaling allows a faster response with a reduced need for the voltage, or mechanical magnitude to impose a deformation, required for performing a specific electromechanical task.[ 17 ] In theory, the driving energy for piezoelectric nanostructures can be substantially less than the one needed to operate macroscale piezoelectric transducers.

Piezoelectric micromaterials are usually used in applications requiring larger forces or displacements, such as in ultrasonic transducers or microactuators. On the contrary, nanomaterials are more suitable for applications requiring high sensitivity, low power, or incorporation into nanoscale devices, such as biomedical sensors, energy harvesters, or wearable electronics. Indeed, piezoelectric nanotransducers, lighter than bulk materials, are also more suitable for integration on flexible substrates, which may better conform to tissues when implanted than more rigid piezoelectric bulk materials. Piezoelectric micro‐ and nanomaterials have been exploited for various applications in the fields of regenerative medicine,[ 18 , 19 ] targeted therapy and controlled drug delivery,[ 20 ] and microrobotics.[ 21 ] In regenerative medicine, the primary tissue targets include bone, skin, nerve, cardiac, and muscle tissues, showing promising outcomes such as improved bone healing and integration, accelerated nerve cell differentiation and neural network formation, support for the regeneration of damaged myocardial tissue, and enhanced myoblast differentiation.[ 22 ]

For targeted therapy and microrobotics, the focus has primarily been on developing responsive drug delivery systems and cancer treatments, enabling precise stimulation and delivery with high spatial accuracy. Piezoelectric nanomaterials can also be easily injected into tissues, inhaled, or released into circulation and used to elicit drug release by applying external ultrasound stimulation,[ 19 ] or in conjunction with other materials such as magnetic, optical, and plasmonic.[ 23 ] Nonetheless, these piezoelectric materials must be biocompatible and possibly biodegradable so they can be safely applied to biological systems and interfaced with biological tissues.[ 24 ]

In all these applications, piezoelectric nanomaterials show clear advantages over competing technologies, such as implanted electrodes for electrical stimulation of deep tissues, as they avoid the need for invasive procedures and allow a specific and targeted action, up to the single cell level.

Several materials have been examined for various uses, such as sensing, harvesting, actuation, and other biomedical devices. Lead zirconate titanate (PZT), potassium sodium niobate (KNN), barium titanate (BTO), and lithium niobate (LiNbO3) have been widely recognized as inorganic materials with excellent piezoelectric properties.[ 25 ] Regardless, their nondegradability and potential leakage of hazardous or toxic constituents pose challenges in their use for biomedical implants today. Since 2014, the Restriction of Hazardous Substances (RoHS) Directive (2011/65/EU, also known as RoHS II) has been applied to medical devices standardizing the use of hazardous materials and, therefore, limiting the presence of toxic elements. In particular, lead‐based materials such as the PZT have raised issues due to the brittleness of these ceramics and the toxicity of Pb released from the implant.[ 26 ] In addition, risks of infection or potential material rejection constitute other possible unsafe consequences of the implantation, which may require a second intervention for material retrieval. Using coatings or encapsulating materials has been suggested to mitigate potential toxic concerns,[ 27 ] although optimal solutions are still under investigation. Apart from the intrinsic toxicity of the material, the accumulation of nondegradable piezoelectric particles may also lead to harmful consequences in the long term, especially when gathered in targeted organs via blood circulation over time. In this case, in vivo fate and biodistribution undoubtedly vary based on the interplay of the size, surface charge, and chemical composition, leading to potential unexpected concerns.[ 28 ]

In terms of dimensions, it has been recognized that large rigid particles with a diameter >2 μm preferentially accumulate within the spleen, liver, and lungs, nanoparticles with a range of 20–150 nm may partially escape filtration by the liver and spleen, while only small‐sized nanoparticles or particle fragments (hydrodynamic diameter < 5.5 nm) are cleared by the kidneys.[ 29 ] Accumulation of inorganic material may lead to chronic inflammation, as the persistent presence of nondegradable particles can cause ongoing inflammation of organs and tissue damage, and the repeated activation of the immune system may lead to hypersensitivity and autoimmune responses. It has been observed that long‐term exposure to nanomaterials is associated with increased levels of inflammatory mediators, such as tumour necrosis factor (TNF‐α) and Cxcl2, as well as an increased risk of fibrosis.[ 30 ]

Monitoring the long‐term safety and efficacy of products involving particles is of primary importance. However, this approach requires a longitudinal study and the use of markers in conjunction with appropriate imaging systems to evaluate the particle fate over time.

Biodegradable piezoelectric materials have attracted a growing interest in recent years. They are capable of safely dissolving in the host environment (e.g., bodily fluids), in a hydrolytic or enzymatic degradation process that does not produce any harmful byproducts, circumventing the need for additional surgical procedures.[ 31 ] According to their nature, biodegradable piezoelectric polymers can be categorized into synthetic polymers (such as poly‐L‐lactic acid), and natural polymers, as proteins (such as collagen and silk), polysaccharides (such as cellulose, chitin, and chitosan), peptides/amino acids, and other compounds (e.g., virus).

Numerous reviews have been devoted to piezoelectric biomaterials with a particular emphasis on different types of biomaterials or specific applications, such as energy harvesting, sensing, and actuation.[ 32 , 33 , 34 ] Several reviews have reported the perspectives of utilizing biological piezoelectric polymers.[ 35 , 36 , 37 , 38 ] Nonetheless, none of these works have explored the potential of degradable piezoelectric micro‐ and nanomaterials, which may hold great potential in targeting therapies at the micro‐ and nanoscale levels.

This review provides a comprehensive overview of the research ongoing in the field of piezoelectric and biodegradable micro‐ and nanomaterials, with a particular emphasis on their applications in regenerative medicine, targeted therapy, and microrobotics. We classify these piezoelectric materials into distinct groups based on their inherent characteristics. We also discuss the strategies for their synthesis, analysis, and improvement of piezoelectric performance. An overview of the biodegradation mechanism of organic piezoelectric materials is provided, with a particular emphasis on the intracellular pathways activated by biodegradable nanomaterials. The application of such piezoelectric biomaterials in regenerative medicine, targeted therapy, and microrobotics is discussed, highlighting possible future perspectives.

2. Synthesis and Characterization of Biodegradable Piezoelectric Nanomaterials

2.1. Materials and Techniques to Improve Piezoelectricity

2.1.1. Materials

In inorganic materials, the crystalline structure determines the piezoelectric properties; materials exhibiting a noncentrosymmetric geometry can produce electrical dipoles upon mechanical perturbation. The direction and magnitude of the generated electric charge are contingent upon the material's crystallographic alignment and the applied mechanical stress (Figure 1b). Although inorganic crystals, such as quartz and Rochelle salt, are the most known piezoelectric materials,[ 2 ] inorganic ceramics like PZT, BTO, KNN, ZnO, boron nitride, and LiNbO3 have been shown to possess good piezoelectric properties (Table 1 ). Despite their notable performance, the application of inorganic piezoelectric materials in medicine may encounter challenges concerning their biocompatibility and biodegradability. For example, lead‐based piezoelectric materials possess an inherent toxicity due to the presence of the lead element.[ 39 ] To this aim, the in vivo biocompatibility of lead‐free piezoelectric materials (BTO, KNN, LiNbO3) has been investigated;[ 40 ] however, their degradation products (e.g., Nb) can cause toxicity, as demonstrated in mice and rat models.[ 41 ]

Table 1.

Comparison of different piezoelectric materials in terms of type, structure, synthesis approach for the fabrication of micro‐ and nanomaterials, and piezoelectric coefficients.

| Type | Material | Structure/mechanism of piezoelectricity | Synthesis | Piezoelectric coefficients | References |

|---|---|---|---|---|---|

| Inorganic | Lead zirconate titanate (PZT) | Perovskite, ferroelectric | Aqueous precipitation method, hydrothermal synthesis |

d 31 = 93.5 to −274 pC N−1 d 33 = 225–590 pC N−1 |

[19, 226] |

| Barium titanate (BaTiO3, BTO) | Perovskite, ferroelectric | Hydrothermal synthesis |

d 31 = −33.4 to −78 pC N−1 d 33 = 90–788 pC N−1 |

[19] | |

| Potassium sodium niobate (KNN) | Perovskite, ferroelectric | Solid‐state process | d 33 = 93–700 pC N−1 | [227] | |

| Lithium niobate (LiNbO3) | Perovskite, ferroelectric | Sol‐gel method, Solid‐state process, hydrothermal synthesis |

d 31 = −1 pC N−1 d 33 = 16–41.5 pC N−1 |

[1, 228] | |

| Boron nitride | Wurtzite, nonferroelectric | Arc discharge method, chemical vapor deposition |

d 11 = 0.5–1.27 pC N−1 d 33 = 0.3 pC N−1 |

[229] | |

| Zinc oxide (ZnO) | Wurtzite, nonferroelectric | Vapor–solid growth process |

d 31 = −5 pC N−1 d 33 = 6–13 pC N−1 |

[19, 230] | |

| Synthetic polymers | PVDF | Orthorhombic β‐phase crystal, ferroelectric | Electrospinning, solvent casting |

d 31 = 23 pC N−1 d 33 = −24–34 pC N−1 |

[44] |

| Polyvinylidene fluoride ‐ trifluoroethylene (PVDF‐TrFE) | β‐crystalline form, ferroelectric | Electrospinning, Solvent casting | d 33 = 30 pC N−1 | [42, 43] | |

| Nylon‐11 | δ′‐phase crystalline structure, ferroelectric | Electrospinning, antisolvent method |

d 31 = 14 pC N−1 d 33 = 3.8–4 pC N−1 |

[19, 231] | |

| Poly‐L‐lactic acid (PLLA) | β‐crystalline form, nonferroelectric |

Melt‐press template wetting method, electrospinning, solvent casting |

d 14 ≈ 3.7–20 pC N−1 d 31 = 1.58 pC N−1 d 33 = 3.1 pC N−1 |

[19, 47, 51, 232] | |

| Polyhydroxybutyrate (PHB) | Orthorhombic crystal, ferroelectric | Electrospinning, dip coating |

d 14 = 1–2 pC N−1 d 31 = 3.25 pC N−1 d 33 = 2.1–4.13 pC N−1 |

[35, 50, 233] | |

| Natural‐derived polymers | γ‐Glycine | Trigonal crystal systems of piezoelectric γ‐phase structure, nonferroelectric | Solvent evaporation |

d 31 = 3.2 pC N−1 d 33 = 4.1–10.4 pC N−1 |

[62, 185, 186] |

| β‐Glycine | Monoclinic crystal systems of piezoelectric β‐phase structure, nonferroelectric | Solvent casting/evaporation |

d 16 = 178 pm V−1 d 22 = −5.7 pm V−1 d 33 = 4.7 pC N−1 |

[61, 212] | |

| Poly‐γ‐methyl‐L‐glutamate (PMLG) | Crystals of piezoelectric β‐phase structure, nonferroelectric | Electrospinning, electrospray | d 14 = −2 pC N−1 | [234, 235] | |

| Poly‐γ‐benzyl‐L‐glutamate (PBLG) | α‐helical peptide, nonferroelectric | Electrospinning, electrospray | d 33 = 15–25 pC N−1 | [53] | |

| Diphenylalanine (FF) | Noncentrosymmetric hexagonal crystal structure, nonferroelectric | Self‐assembly |

d 14 = −10 pC N−1 d 15 = 80 N−1 d 33 = 9.9–17.9 pm V−1 |

[63, 64, 65, 236] | |

| Collagen | α‐helixes wrapped in right‐handed fashion, nonferroelectric | Self‐assembly |

d 14 = −0.2–12 pm V−1 d 15 = 1 pC N−1 d 33 = 4.8 pm V−1 d 35 = 27 pm V−1 |

[54, 73, 75, 237] | |

| Chitin | Polysaccharides founded in three forms in nature (α, β, and γ), nonferroelectric | Self‐assembly |

d 14 = −0.2–1.5 pC N−1 d 33 = 9.49 pC N−1 |

[54, 77] | |

| Chitosan | Noncentrosymmetric orthorhombic structure, nonferroelectric | Postcasting neutralization, solvent casting |

d 31 = 6–10 pC N−1 d 33 = 0.8–18.4 pC N−1 |

[79] | |

| Keratin | α‐helical peptide, nonferroelectric | Self‐assembly | d 14 = −0.1 to 1.8 pC N−1 | [238] | |

| Silk | ‐sheet crystallinity, nonferroelectric | Self‐assembly | d 14 = −1.5 pC N−1 | [83] | |

| Cellulose | Crystalline (cellulose I) and less ordered cellulose domains, nonferroelectric | Pressure filtering |

d 14 = −0.1–0.2 pC N−1 d 33 = 4.7–82.6 pC N−1 |

[69] | |

| M13 bacteriophage | Right‐handed helical structures, nonferroelectric | Enforced infiltration | d 33 = 7.8 pm V−1 | [84] |

Piezoelectric polymers have emerged as an alternative and promising solution to inorganic materials. Among the various options, polyvinylidene fluoride (PVDF) and its copolymer, as the poly (vinylidene fluoride‐co‐trifluoroethylene) (PVDF‐TrFE), stand out as the most frequently exploited piezoelectric polymers.[ 42 ] The reported d 33 for PVDF‐TrFe is around 30 pC N−1,[ 43 ] which is significantly lower than that observed in inorganic materials (e.g., KNN has a d 33 between 93 and 700 pC N−1, depending on the processing conditions[ 19 ]). PVDF has good biocompatibility; however, it is not degradable in biological environments, limiting its applications in the medical field.[ 44 ]

The use of piezoelectric materials featuring both biocompatibility and biodegradability would greatly enlarge the spectrum of applications in biomedicine. Also, one of the peculiar aspects of organic materials is their noticeable shear piezoelectricity generated from the alignment and deformation of molecular dipoles within the material's structure (Figure 1c). In general, the majority of biodegradable piezoelectric materials exhibit a robust shear piezoelectricity, but show weak transverse and longitudinal piezoelectric properties. Despite their generally lower piezoelectric response compared to inorganic counterparts, the advantages conferred by their biocompatible and biodegradable nature may outweigh this limitation.[ 36 ]

Several examples of biodegradable piezoelectric materials derive from various sources, with different structures and degradation pathways. Generally, these materials can be divided into synthetic polymers and natural piezoelectric ones.

The former include poly lactic acid (PLA) and poly‐L‐lactic acid (PLLA, a conformation of PLA containing only the L‐stereoisomer), polyhydroxybutyrate (PHB), poly‐γ‐benzyl‐L‐glutamate (PBLG), or poly‐γ‐methyl‐L‐glutamate (PMLG). PLA is synthesized by polycondensation of lactic acid (LA) monomers, or by ring‐opening polymerization of lactides.[ 45 ] To obtain the pure L‐stereoisomer (PLLA), the synthesis should start from the optically pure L‐LA isomer; this is attained only when LA is synthesized by microbial fermentation. The piezoelectric properties observed in PLA and PLLA derive from their semicrystalline structure, characterized by a chiral conformation and the alignment of electric dipoles in the C=O groups along the polymer backbone. In the thermodynamically stable α‐form of PLA, the C=O groups exhibit random orientation, resulting in negligible piezoelectric effects. Conversely, in the β‐crystalline form, the C=O groups align along the main chain, imparting piezoelectric properties to the material.[ 46 ] Achieving this orientation in PLA and PLLA necessitates specific processing techniques, such as thermal stretching or electrospinning, which promote the rearrangement of molecular chains along the stretching direction. PLLA exhibits piezoelectricity predominantly along the Z‐axis, characterized by a d 14 coefficient typically ranging from 9 to 11 pC N−1,[ 47 ] which is notably lower than inorganic piezoelectric materials. Nevertheless, PLLA continues to be extensively utilized in various biomedical applications owing to its biocompatibility and biodegradability. Furthermore, post‐treatment procedures aimed at enhancing its molecular orientation and crystallinity can potentially increase its piezoelectric performance (d 14 coefficient) up to 20 pC N−1. The piezoelectric properties of PLLA also depend on its optical purity and molecular weight. Tajitsu demonstrated that PLLA with a lower D‐isomer content and high molecular weight might result in films with a higher piezoelectric response.[ 48 ] Similarly, Schönlein et al. showed that by increasing the D‐content from <1% up to 12%, the d 14 decreases from 3.7 ± 0.3 pC N−1 to 0.[ 49 ]

PHB is a biodegradable polyester that belongs to the class of polyhydroxyalkanoates (PHAs), naturally occurring biopolymers synthesized by microorganisms under conditions of nutrient limitation.[ 50 ] The piezoelectric features of PHA‐based materials stem from the presence of an asymmetric carbon atom linked to a polar oxygen group.[ 51 ] In the case of pure PHB electrospun nanofibers, the piezoelectric coefficients are ≈3.25 pC N−1 (d 31) and 4.13 pC N−1 (d 33).[ 50 ] The molecular weight of PHB impacts its piezoelectric properties; in fact, it has been observed that a decrease in the molecular weight from 803 to 102 kDa resulted in a lower number of piezoelectric domains in PHB films, leading to a lower piezoresponse.[ 52 ]

PBLG is a synthetic polypeptide derived from the polymerization of γ‐benzyl‐L‐glutamate. It has a repeating unit of glutamic acid with a benzyl ester side chain. The structure of PBLG allows it to form helical conformations, contributing to its unique piezoelectric properties. Indeed, PBLG exhibits piezoelectric properties primarily due to its ordered helical structure, which lacks inversion symmetry, an essential requirement for piezoelectricity. This material has been studied for its interesting mechanical, structural, and piezoelectric properties. PBLG showed a d 33 coefficient in the form of fibers up to 25 pC N−1.[ 53 ]

PMLG is a synthetic biopolymer obtained by polymerization of γ‐methyl‐L‐glutamate repeating units. Belonging to the broader class of polyamides, PMLG is characterized by the presence of amide bonds (–CONH–) in its polymer backbone. PMLG shows a relatively low shear piezoelectricity (d 14 = −2 pC N−1) with respect to the previous synthetic polymers.[ 54 ]

The exploration of natural piezoelectric materials garnered significant attention due to their implications in vital physiological processes, thereby driving extensive research into their piezoelectric properties and potential medical applications.[ 36 ] For instance, it has been demonstrated that bone tissue displays piezoelectric behavior, and this peculiar activity is responsible for crucial functions such as bone remodeling and healing.[ 22 ] Furthermore, other naturally occurring macro materials, such as spider silk,[ 55 ] fish collagen,[ 56 , 57 ] chicken feathers,[ 58 ] prawn shells,[ 59 ] and porcine skin,[ 60 ] have demonstrated varying degrees of piezoelectricity.

The precise origins of piezoelectricity in polymers remain subject to ongoing investigations; nonetheless, it has been observed that many biological materials adopt helical or spiral conformations, lacking a center of symmetry, thereby endowing them with piezoelectric capabilities.[ 22 ]

Among the natural piezoelectric materials, amino acids and peptides (the fundamental constituents of biological materials) have garnered attention. With 19 out of the 20 natural amino acids exhibiting chirality and thus lacking crystal symmetry,[ 61 ] experimental studies have confirmed their piezoelectricity, except for methionine.[ 2 ] The only nonchiral amino acid, glycine, exhibits crystallization in three distinct polymorphs: α, β, and γ. The α‐form, characterized by an antiparallel molecular arrangement, does not manifest piezoelectric behavior due to the cancellation of net polarization.[ 62 ] Conversely, both the γ and β forms display piezoelectricity owing to their noncentrosymmetric geometries. However, the β‐form is metastable and primarily observed in nanoconfined environments; under typical ambient conditions, it tends to revert to the more stable γ‐form. Measurements reveal that γ‐glycine possesses a longitudinal piezoelectric coefficient d 33 of ≈10 pm V−1,[ 62 ] whereas β‐glycine exhibits a lower longitudinal coefficient d 22 of ≈−5.7 pm V−1, alongside a notably high shear piezoelectric coefficient d 16 of around 178 pm V−1.[ 61 ]

Diphenylalanine (FF), a peptide composed of two phenylalanine units, has also generated attention due to its piezoelectric and mechanical properties. Due to its peculiar structure, FF can self‐assemble into a tubular supramolecular structure through hydrogen bonding and π–π stacking interactions.[ 63 ] FF nanotubes with hexagonal (P6) crystal structure exhibit high shear piezoelectricity (d 15) along the tube axis. Furthermore, studies have revealed that the orthorhombic form of FF nano‐ and microtubes also possesses shear piezoelectricity. Some authors also measured longitudinal coefficients d 33 between 9.9 and 17.9 pm V−1.[ 64 , 65 ] It is worth mentioning that the piezoelectric behavior of FF nanotubes is contingent upon their unidirectional growth and dimensions.

Cellulose, a linear polysaccharide comprised of glucose units, possesses a fibrous crystalline arrangement, imparting mild piezoelectric characteristics.[ 2 ] Cellulose is the primary structural constituent of plant cell walls and thus contributes to plant rigidity, strength, and overall structural integrity.[ 66 ] Cellulose chains have a net dipole; however, in plants, cellulose microfibrils follow an antiparallel alignment, thus resulting in a net cancellation of the dipole moment at the macroscopic scale.[ 2 ] This linear configuration facilitates extensive hydrogen bonding between adjacent cellulose chains, contributing to its remarkable strength and insolubility in water. At the micro‐ and nanoscale, cellulose crystals display piezoelectric properties due to their alignment in both positive and negative orientations along the Z‐direction, while maintaining a random orientation in the X–Y plane.[ 67 ] Cellulose derived from wood exists in two polymorphs: a triclinic crystal structure with no symmetry, (I α) or a monoclinic crystal structure (I β). The presence of hydrogen bonds, particularly prominent in the 2D I β polymorph, significantly contributes to cellulose piezoelectric properties. Various cellulosic materials, including cellulose nanocrystals, cellulose nanofibers, and bacterial nanocellulose sourced from onion skin and bleached birch cellulose, have piezoelectric behavior, albeit with low magnitudes (<1 pC N−1).[ 68 ] Rajala et al. demonstrated that films composed of cellulose nanofibrils with monoclinic symmetry (space group C 2∥x 3) have a piezoelectric sensitivity, which is closely related to the longitudinal piezoelectric coefficient d 33, ranging from 4.7 to 6.4 pC N−1.[ 69 ] Miao et al. investigated the effects of different parameters on the piezoelectric properties of cellulose nanocrystals (CNC).[ 70 ] They demonstrated that the response depends on the surface chemistry of CNC and on the ionic strength of the solution in which CNC are dispersed. CNC films containing sodium sulfate groups showed a very low piezoresponse, in the order of sub‐pC N−1 while films containing hydrogen sulfate groups had a higher d 33 (5.3 pC N−1). The authors were able to significantly increase the d 33 to 82.6 pC N−1 by casting the CNC films from a suspension 3 mM NaCl. Despite its biocompatibility, cellulose resistance to degradation in numerous organisms, including the human body, poses challenges for its use in biomedical applications, given the lack of specific enzymes (e.g., microbial and fungal) capable of breaking down its strong bonds. Indeed, the numerous intra‐/inter‐molecular hydrogen bonds inside/between polymer chains render the crystalline microfibrils highly resistant to hydrolysis.[ 71 ]

Collagen is the most abundant protein in the human body, comprising ≈30% of the total protein mass. It provides structural integrity and robustness to various tissues, encompassing vital components such as skin, bones, muscles, tendons, and ligaments. Collagen‐rich structures, including cartilage, ligaments, hair, and skin, exhibit a fiber‐like structure with intriguing piezoelectric properties.[ 72 ] Although the mechanism underlying collagen piezoelectricity has not been fully elucidated, it appears to primarily stem from the inherent molecular charge distribution and polarity within the molecule itself. Residues within collagen molecules feature dipoles that undergo realignment along the molecule's elongated axis when subjected to mechanical stress. This realignment alters the magnitude of the dipole moment, consequently generating piezoelectricity. The piezoelectric coefficient d 14 of collagen ranges from 0.2 to 2 pC N−1, a value that can be enhanced through various means, such as adjusting the pH from acidic to neutral. Denning et al. reported a coefficient of d 14 = 12 pm V−1 in fibrillary rat tail collagen, indicating the highest piezoelectric response observed among collagen samples.[ 73 ] Denning et al. also studied the difference piezoelectricity of collagen I and collagen II fibrils.[ 74 ] Type I collagen is the key component in skin, tendons, and ligaments and it makes up over 90% of the organic material in bones, while type II is mainly found in cartilage. The authors showed that the d 15 of collagen type II was roughly 28–32% of that of collagen type I, speculating that this different piezoelectricity could be related to the different sources of the polymer, to the different polypeptide composition, and to a higher density of covalent crosslinks in type I, which enhance its mechanical stability and reduce its deformability. Techniques aimed at increasing collagen piezoelectric properties include self‐assembling collagen bundles and their cross‐linking through 1‐ethyl‐3‐[3‐dimethylaminopropyl]carbodiimide hydrochloride (EDC)‐N‐hydroxysuccinimide (NHS), genipin, and tissue transglutaminase. Bera et al. investigated collagen‐mimicked tripeptide structures, achieving a d 33 coefficient of 4.8 pm V−1 and a noteworthy d 35 coefficient (27 pm V−1) thanks to the incorporation of hydroxyl groups.[ 75 ]

Chitin is a polysaccharide composed of β‐(1 → 4) linked N‐acetylglucosamine monomers. Chitin is found in the shells of arthropods, cell walls of fungi, and wings of butterflies. The chitin found in crab shells and butterfly wings was found to show piezoelectricity. It may exist in three forms in nature, such as α, β, and γ. In the early 1970s, Fukada et al. discovered the shear piezoelectricity in α‐chitin.[ 76 ] Hoque et al. utilized biowaste from crab shells to extract chitin nanofibers. The chitin nanofibers used to fabricate a thin film piezoelectric nanogenerator showed a d 33 equal to 9.49 pC N−1.[ 77 ]

Chitosan is a natural polysaccharide, which can be extracted from chitin deacetylation. This linear polysaccharide is composed of β‐1,4‐d‐glucosamine. Chitosan exhibits an orthorhombic structure with a nonsymmetric space group of P212121, which endows it with piezoelectric property.[ 78 ] Chitosan has garnered significant attention in research areas such as biodegradable sensors and energy harvesting systems. The maximum d 33 coefficient reported for chitosan was 18.4 pC N−1.[ 79 ] Amran et al. studied both the d 31 and d 33 of chitosan films, obtained by drying solutions of chitosan in different acids.[ 80 ] In all cases, the d 31 was found to be higher than the d 33 due to low thickness of the films, enhancing the voltage output for d 31, since in this conformation the piezoresponse was measured perpendicularly to the applied force. Among the different acids, formic acid led to the highest d 31 (10 pC N−1) and d 33 (1.1 pC N−1). In contrast, films formed from lactic and acetic acid solutions led to the lowest d 31, probably due to a decreased noncentrosymmetry in chitosan in these conditions.

Silk is a natural polymer produced by certain insects and spider species, composed of two different proteins: sericin and fibroin. Silk fibers are composed of fibroin microfibrils arranged into filaments and enveloped by sericin.[ 81 ] Silk has inherent piezoelectric properties attributed to its intricate α‐helix and β‐sheet substructures.[ 82 ] Comprising a blend of crystalline and amorphous phases, silk material piezoelectricity is notably influenced by factors such as the degree of crystalline orientation, β‐sheet crystallinity, and an increased presence of silk II.[ 83 ] Upon subjecting silk films to a draw ratio of 2.7, a shear piezoelectric constant d 14 of ≈1.5 pC N−1 was observed. Strategies to enhance silk film piezoelectric characteristics include solution drying, draw, and zone drawing, which improve β‐sheet content and crystallinity.[ 1 ] In fact, processing parameters have an impact on the piezoelectric properties of silk. Yucel et al. compared two drawing techniques to obtain uniaxially oriented piezoelectric silk films: zone drawing and water immersion drawing.[ 83 ] Zone drawing at a ratio of 2.7 led to an over twofold increase in the d 14 with respect to untreated films, related to an increase in β‐sheets content and crystal orientation. In contrast, water immersion drawing was less efficient in orienting silk crystals, resulting in a lower piezoelectric response with respect to films obtained by zone drawing. The authors also tried to improve only the β‐sheets content by performing methanol treatment, without aligning the crystals, but this did not result in a piezoelectricity improvement, suggesting that alignment is a key factor in the piezoelectricity of silk.

The filamentous bacteriophage M13 is a single‐stranded DNA virus belonging to the family Inoviridae. It has a long, filamentous shape, with a diameter of about 6–7 nm and a length of ≈880 nm. Each phage is enveloped by 2700 copies of a predominant coat protein known as pVIII, alongside five instances of minor coat proteins (pIII and pIX) positioned at both ends. The pVIII proteins exhibit an α‐helical configuration with a dipole moment oriented from the amino‐ to the carboxy‐terminal direction, thereby providing coverage to the phage with a combination of fivefold rotational and twofold screw symmetries. Since the structured alignment of the M13 protein coat lacks inversion symmetry, M13 has inherent piezoelectric properties. Lee et al. measured the piezoelectricity of a film composed of M13 phages, with a thickness > 100 nm, and found a value of d 33 equal to 7.8 pm V−1.[ 84 ] While exhibiting encouraging piezoelectric properties, the complete piezoelectric response of M13 phage films is still not fully understood. A more thorough investigation is needed to completely clarify the phage piezoelectric traits, thereby uncovering its potential applications. Bacteriophages infect bacterial cells; thus, they are considered safe to be used in humans even if recent studies highlighted that they could interact with the host immune system, inducing cellular immune responses.[ 85 ] This poses some challenges in their direct use in biomedical applications.

2.1.2. Techniques to Improve Piezoelectricity

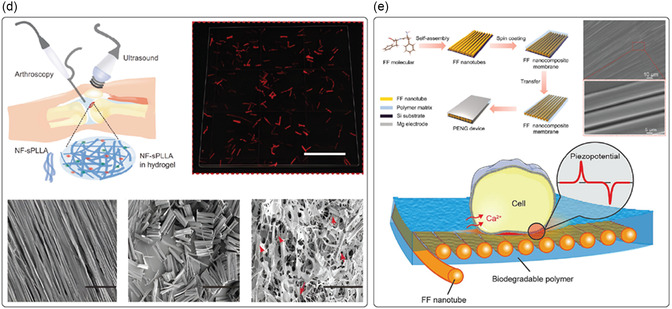

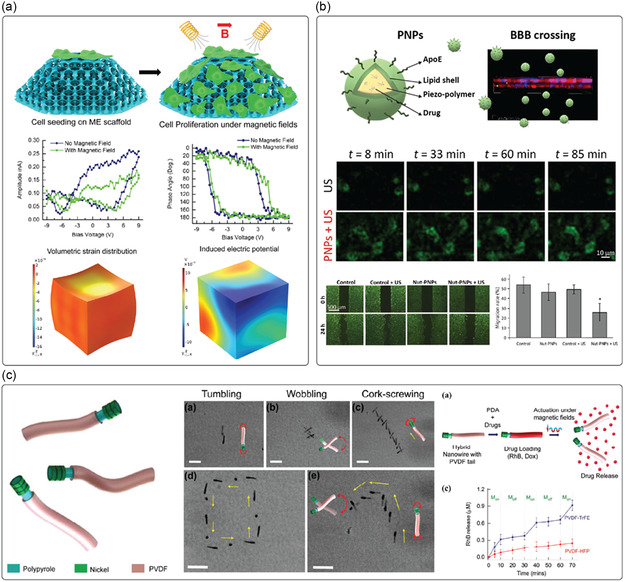

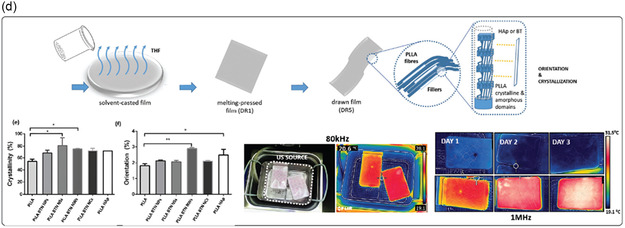

Fabrication techniques for improving piezoelectricity in organic piezoelectric micro and nanomaterials typically involve processes like electrospinning, template wetting, self‐assembly, melt electrowriting (MEW), and electrospray (Figure 2a). Electrospinning is a technique used to fabricate micro‐ and nanofibers by applying a high voltage to a polymer solution or melt.[ 86 ] The electric field causes the material to be drawn into fine fibers, which are collected on a substrate. These fibers exhibit enhanced piezoelectric properties due to their high aspect ratio and alignment of molecular dipoles during the process. The electrospinning processing and solution parameters can be modulated to obtain the desired morphology and piezoelectric properties. For instance, Tai et al. demonstrated that PLLA concentration played a major role in determining the final fiber diameter, with larger diameters obtained at lower PLLA concentrations; this reflected on the piezoelectric properties of the fibers, since as‐spun fibers with lower diameter displayed larger d 33.[ 87 ] Gade et al. explored the impact of the applied voltage on the β‐phase content of PVDF electrospun fibers.[ 88 ] Unexpectedly, the content of β‐phase decreased with increasing applied voltages; the authors concluded that at high applied voltages, the stretching effect provided by the electric field is compensated by the increased jet instability due to the high number of potential ions, leading to a decrease in the electroactive β‐phase. Nevertheless, the effect of the applied voltage on PVDF fiber diameter and β‐phase content is still unclear.[ 89 ] Other authors, in fact, reported a completely opposite behavior, with an increased β‐phase content at higher applied voltages,[ 90 ] while others could not observe any dependence at all.[ 91 ] These differences suggest that the relationship between applied voltage and piezoelectricity is not straightforward, as it also depends on the specific system. Consequently, generalizing a common trend is challenging, and each case must be carefully analyzed under its specific operating conditions. Template wetting involves filling the pores of a template (like anodic aluminum oxide or silicon molds) with a polymer solution.[ 92 ] After the solvent evaporates, the template is removed, leaving behind micro‐ and nanostructures such as rods, tubes, or wires of the piezoelectric material. This method allows for precise control over the size and shape of the materials, which can enhance their piezoelectric performance.[ 93 ] Self‐assembly refers to the spontaneous organization of organic molecules into ordered structures, driven by noncovalent interactions such as hydrogen bonding, van der Waals forces, and π–π interactions. In the context of piezoelectric nanomaterials, self‐assembly can lead to the formation of highly ordered nanostructures, such as micelles, nanorods, or ultra‐thin films, which can exhibit significant piezoelectric properties due to their organized molecular arrangement. Another technique that can be used to fabricate devices based on biodegradable piezoelectric materials together with the self‐assembly approach is the layer‐by‐layer (LbL) deposition. Nanocomposite films can be prepared by LbL to alternately deposit different materials in thin layers, enabling complementary attractive interactions driven by electrostatic forces, hydrogen bonding or covalent bonding.[ 94 ] The deposition technique depends on the material and on the desired final properties. For instance, a conductive layer can be deposited by sputtering or spin coating, while polymeric films are usually deposited by spin and dip coating or casting. Lee et al. prepared a peptide‐based piezoelectric energy harvester through a meniscus‐driven self‐assembly of aligned FF nanotubes.[ 95 ] The authors were able to form unidirectionally aligned FF nanotubes by dip‐coating various substrates in a solution of FF in hexafluoroisopropanol (HFIP) and subsequently pulling them at controlled speed. The spontaneous unipolarization of FF nanotubes was attributed both to the interaction with the charged substrates and to the meniscus‐driven self‐assembly. A similar approach was used to fabricate a bio‐piezoelectric nanogenerator based on FF nanotubes.[ 96 ] FF nanotubes were prepared by dip coating a silicon substrate in a HFIP/FF solution and pulling at a fixed speed. A thin layer of biodegradable polymer (poly lactic‐co‐glycolic acid, polycaprolactone, polyvinylalcohol, PLA or PHBV) was then spin coated on the FF nanotubes, and the composite polymer/FF nanotubes membrane was then separated from the silicon substrate and finally a thick Mg electrode was deposited on both sides by an electron beam evaporator. The presence of a polymer matrix, in particular PLA, imparted a high mechanical stress on the FF nanotubes, enhancing the piezoelectric performance of the nanogenerator.

Figure 2.

a) Depiction of some techniques used to improve the piezoelectric activity of materials (e.g., electrospinning, template wetting, self‐assembly, melt electrowriting, and electrospray), that tend to favor the alignment of the dipoles in the material, thus maximizing piezoelectricity. b) Polymer crystallization can be controlled in terms of crystal organization as a result of different procedures as: annealing, by adapting time and temperature; drawing a polymer sample, which produces a significantly higher degree of orientation; electrical poling, which allows the alignment of dipole moments in (i) un‐poled ferroelectric material, through the application of an electric field, (ii,iii) with surface electrodes; corona poling of a ferroelectric material, which does not require electrodes attached to the material.

Other techniques that can be used to process piezoelectric polymers include MEW and electrospray. Even though they are not used to improve the piezoelectricity of polymers, they can be employed to process the material to obtain well‐aligned crystal and/or induce dipole during fabrication, which is, in turn, related to piezoelectric properties. MEW is a high‐resolution manufacturing technique based on the electrohydrodynamic processing of polymers used to produce fibers in the micro‐ and nanometer range.[ 97 ] In MEW, a polymer is first heated up to its melting point into a syringe and then an electric field is applied between the nozzle and the grounded collector plate to draw the polymer as a continuous filament. The gold standard polymer used in MEW is polycaprolactone (PCL); however, other polymers can be also processed with this technique. Florczak et al. were the first to process PVDF with MEW, working at 170 °C and at voltage of 2.7 kV.[ 98 ] PVDF processed with MEW was found to have an increased β‐phase content up to 79% with respect to the unprocessed polymer (49%), resulting in higher piezoelectric response (d 33 up to 23.7 pm V−1). The same group also processed PVDF‐TrFE with MEW, using a similar set‐up.[ 97 ] Also in this case the content of β‐phase was found to be higher compared to the unprocessed material.

Electrospray is usually used to obtain micro‐ and nanoparticles starting from a solution of the polymer dissolved in a solvent with a certain degree of conductivity.[ 99 ] The polymer solution is fed through a nozzle or capillary and subjected to a high‐voltage electric field, causing the formation of fine charged droplets. As the solvent evaporates, the polymer forms charged particles. Despite the potentiality of this technique to process piezoelectric biodegradable polymers, to the best of our knowledge it has never been applied to this purpose. Correia et al. produced PVDF microparticles by electrospraying and investigated the influence of the formulation parameters (e.g., polymer concentration, electric field, flow rate) on the size of the obtained microparticles.[ 100 ] The authors found that the polymer concentration was the most critical parameter for obtaining microparticles, while all the other parameters had minimal impact on the final output. PVDF microparticles had a β‐phase content between 63% and 74%, and a crystallinity between 45% and 55%, regardless of the processing parameters.

However, the piezoelectric response of any material depends on several factors, including the degree of crystallinity, its specific crystalline structure, its morphology, defects, and impurities. Therefore, different techniques can be used to tailor these features to improve the performance of piezoelectric materials. Thermal annealing, drawing, and electrical and corona poling are primarily used for this purpose (Figure 2b).

Thermal annealing is a standard process used to improve the crystallinity of a material and optimize its mechanical, electrical, and thermal properties. The material is heated up to a specific temperature (the annealing temperature), which is usually set above the recrystallization temperature, and then held at that temperature for a defined time. During the heating phase, the material can rearrange its internal structure more efficiently, reducing or even eliminating defects in its crystalline structure. After this phase, the material is cooled down to induce its recrystallization, resulting in a higher crystallinity degree. Thermal annealing, however, does not necessarily improve or act on the anisotropy necessary to guarantee piezoelectricity. In some cases, amorphous structures are key for allowing a piezoelectric response. For example, in odd‐numbered nylon, the piezoelectricity manifests when it displays a disordered mesophase crystal structure, essential for dipole rotation.[ 101 ] This phase is obtained upon fast quenching of melted nylon. When nylon is annealed, its crystal structure becomes more ordered, thus inhibiting dipole switching, and partially canceling its piezoelectric behavior. In some other cases, annealing can also cause chemical changes, such as the evaporation of constituent elements (i.e., Na, K, Bi), which ultimately lead to the degradation of the piezoelectric properties.[ 102 ]

A technique frequently used to improve the alignment of the dipoles is mechanical stretching (drawing), during which the material, usually a polymer, is subjected to tensile forces to elongate it along the direction of the applied stress. This causes changes in the material's crystalline structure, in the orientation of the polymer chains, and its morphology. The piezoelectric properties of several biodegradable polymers have been enhanced by exploiting this technique. For example, silks and collagens display piezoelectricity because of dipole re‐orientation of their constituent amino acids.[ 103 ] Kaplan et al. showed that by mechanical drawing silk fibers, the content of ß sheets (rich in electric dipoles) is promoted.[ 83 ] Indeed, spider silk fibers display enhanced piezoelectricity owing to the increased crystallinity attained by a strain‐hardening process. Authors have also shown that mechanical stretching of a PLLA film up to stretch ratios of 5–6 induced an increase in the d 14 coefficient.[ 104 ]

Another common technique to align the dipole moments in piezoelectric materials is called electrical poling, in which the material is subjected to high electric fields, at high temperatures (close to its Curie point).[ 36 ] This method is applied to materials that are also ferroelectric, meaning that they possess a spontaneous electrical polarization that can be reversed by the application of an electric field. Electrical poling can be performed in two modalities. In the former, the two opposing surfaces of a piezoelectric material are directly attached to two electrodes. Subsequently, a direct current voltage is incrementally increased until the electric field across the sample aligns with specified saturation polarization values, typically ranging from 5 to 1000 kV cm−1. This voltage is sustained for a predetermined duration. At the end, the sample is gradually cooled to room temperature under a constant electric field, and the high‐voltage source is deactivated.[ 105 ] Recently, Yang et al. demonstrated that by confining the growth of β‐glycine and by in situ poling it during crystallization, films with aligned domains and exceptional piezoelectric performance for this class of biomaterials can be attained.[ 93 ] In the latter (an indirect method), corona poling is performed. An electrode is put into direct contact with the bottom surface of a piezoelectric material. Above the sample, a pin‐point conduction pointer (the corona needle) operates at high voltages (8–20 kV), inducing the ionization of the gas molecules (either air or inert gas) near the needle. Another metallic grid just below the needle operates at a lower voltage (0.2–3 kV), directing the ionized particles toward the surface of the piezoelectric material.[ 105 ] Also, corona poling is performed at high temperatures to facilitate the rearrangements of the internal dipoles.

Processing piezoelectric materials with a porous structure can also lead to an increase in their piezoelectric response. For example, Kim et al. showed that nanoporous arrays of PVDF exhibited up to six times higher piezopotential and piezocurrent than those of bulk counterparts.[ 106 ] It is worth mentioning that an increased porosity can also be detrimental to piezoelectricity. The pore organization can also affect the piezoelectric performance, usually with disordered pores leading to decreased piezoelectricity.[ 107 ] It is also possible to improve the performance of piezoelectric materials by topological design. Recently, Song and co‐workers have shown that stress redistribution within films can lead to a significant increase in piezoelectricity in kirigami structures of PVDF.[ 108 ] The authors showed that the stress redistribution can be attained by two different approaches: 1) using laser‐induced thermal topological depolarization; and 2) by rearranging the stress into a specific direction so that the stress is maximized on the surface of the piezoelectric film.

2.2. Characterization Techniques

2.2.1. Size, Stability, and Morphology

Characterization techniques are illustrated here to define the piezoelectric nanomaterials’ size, morphology, and stability in physiological fluids, as well as their piezoelectric properties.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) are extensively employed to examine the size and morphology of solid micro‐ and nanomaterials or those dispersed in a liquid, following dehydration. SEM is a versatile imaging technique to capture high‐resolution images and detailed surface information from various samples.[ 109 ] It produces images at higher resolution compared to optical microscopy, with a resolution typically of a few nanometers, employing accelerating voltages that range from 5 to 30 keV. Usually, metallization of samples with a thin layer of gold or platinum is needed to reduce charging effects. TEM can manage an accelerating voltage of up to 300 keV, corresponding to a resolution of tens of nanometers.[ 110 ] It is a powerful tool for surface texture analysis, allowing for the visualization of atomic structures and lattice arrangements at the nanoscale, thus providing insights into the arrangement of atoms and defects. Also, diffraction studies can be performed to give details on the surface crystallographic structure, identify crystalline phases, determine grain orientations, and analyze defects like dislocations and grain boundaries.

SEM and TEM can also be coupled with energy‐dispersive X‐ray diffraction (EDX), which can be applied to extract qualitative and quantitative information about the elemental composition of the sample. Despite their utility in visualizing materials and distinguishing surface details, these techniques are constrained by a few limitations, including the necessity to dehydrate and metalize the material under investigation. Such processes may alter the surface of the material under visualization. Above all, these methods do not provide information about the three‐dimensionality of nanomaterials or their behavior in a physiological environment.

Atomic force microscopy (AFM) is a nonoptical imaging technique that allows for high‐resolution measurements of various properties of a sample surface in different environments.[ 111 ] It is particularly handy for the 3D characterization of nanoparticles with sub‐nanometer resolution. To operate AFM, a probe with a sharp tip is scanned over a sample surface using a piezoelectric scanner. As the tip engages the surface, the cantilever bends due to forces between the tip and sample, and this deflection can be utilized for surface topography visualization. This technique can measure the 3D topography (size and shape) and the mechanical properties of nanomaterials, including their elastic moduli.[ 112 ] This technique is often combined with piezoresponse force microscopy (PFM, described in the next section) to couple topography and piezoelectricity.[ 74 ] Unlike SEM and TEM, AFM can also be employed in liquid, thus providing information about the material behavior in a liquid environment. Despite these advantages, the use of AFM is limited as the data acquired from the sample are altered by the choice of the tip size, shape and material, which determine different tip‐sample interactions.

While AFM can measure the thickness of nano‐ and microscale materials, its range is limited to heights below 10 μm. Therefore, it is important to consider other techniques that can measure thickness across a broader range, such as standard profilometry, optical profilometry, and spectroscopic ellipsometry.[ 113 ]

Standard profilometry measures the step height between a material and its substrate using a stylus. This method is versatile and straightforward; however, the stylus may damage very soft materials. Optical profilometry, in contrast, is a nondestructive technique that uses interference patterns of light reflected from the material surface and substrate to measure thickness. The thickness is calculated based on the path length differences that produce constructive or destructive interference. While this technique is well‐suited for thin films, its resolution is limited for ultra‐thin films (thickness lower than 100–200 nm), and it relies on the material's refractive index.

Spectroscopic ellipsometry, in contrast, measures changes in the polarization of light (amplitude and phase) reflected from a surface to determine thickness and optical properties. Like optical profilometry, it is nondestructive. However, spectroscopic ellipsometry offers a higher resolution for ultra‐thin films, and a more detailed material characterization, particularly for determining refractive index, optical constants, or the properties of multilayered structures.

Dynamic light scattering (DLS) is a broadly used technique that measures the size and stability of particles in colloidal suspensions. When particles are suspended in a liquid solution, they undergo Brownian motion that causes light to scatter them off. The particles cause localized changes in the refractive index, which produces intensity variations and helps determine their size.[ 114 ] As a result of DLS, the hydrodynamic size of micro‐ and nanomaterials dispersed in a solution is a measure of their size, while the polydispersity indicates how well they are dispersed (lower values than 0.5 indicate good dispersion[ 115 ]). While DLS is effective in measuring particle size in monomodal samples (e.g., spherical shape), it might not be accurate for anisotropic samples (e.g., nanorods) with a significant difference in the ratio between the diameters of the particles. In such cases, conventional DLS measurements might not be able to measure particle mixtures precisely. In contrast, the DLS technique is often used with electrophoretic light scattering that provide information about the colloidal solution's stability by analyzing the zeta potential, which is related to the surface charge of particles in a colloidal solution. High zeta potential values (positive or negative, absolute value higher than 30 mV) indicate strong electrostatic repulsion between particles. This repulsion helps to prevent particle aggregation, leading to a stable colloidal solution.

Another technique suitable for measuring the size of nanomaterials is the Brunauer–Emmett–Teller (BET).[ 116 ] BET is a technique used to calculate the specific surface area of materials, particularly porous materials. The method is based on the physical adsorption of gas molecules onto the material's surface. The specific surface area measured by BET can give clues about the shape of micro and nanomaterials. For instance, higher surface area values often indicate more complex or irregular shapes, while lower values might suggest smoother or more spherical shapes.

2.2.2. Piezoelectricity

Various techniques have been employed to investigate piezoelectricity in biomaterials. Laser interferometry has been utilized to evaluate the piezoelectric properties of macroscopic samples by considering the voltage‐induced surface displacement generated by the converse piezoelectric effect. This technique can also furnish data regarding the polarization–electric field (P–E) hysteresis loops, enabling the determination of polarization charge density under the application of DC triangular waveforms.

Second harmonic generation (SHG) imaging is a nonlinear optical procedure wherein two photons of identical frequency interact with a nonlinear medium, generating a photon with twice the frequency (half the wavelength) of the incident photons. This technique evaluates nonlinear optical properties resulting from light diffraction, which is exclusively observed in polar crystals and materials with noncentrosymmetric crystal structures.[ 117 ] For example, SHG microscopy is widely used in biomedical imaging to visualize collagen fibers in tissues due to its SHG‐active properties.[ 118 ]

As research has shifted from the analysis of bulk materials to thin films, nanostructures, and 2D materials, obtaining information at smaller scales presents challenges and the use of different techniques. Optical‐based methods are limited to the macro‐ and microscopic scale because of the diffraction limit,[ 119 ] whereas the preparation of electrodes over nanostructures is often unfeasible. Furthermore, natural piezoelectric materials may exhibit weak piezoelectric and ferroelectric properties, which are difficult to identify using macroscopic techniques.

Scanning probe microscopy (SPM) techniques have emerged as one of the most promising approaches to evaluate the piezoelectric and ferroelectric properties at small scales. Among the different SPM methods currently adopted, PFM is the most well‐known technique for elucidating the piezoelectric and ferroelectric properties of micro and nanomaterials.

In PFM, an alternating voltage is applied with a specific frequency to a conductive tip to induce a surface displacement to the material under analysis. The result is an electromechanical response due to the converse piezoelectric effect. From this measurement, the amplitude and phase signals can be deduced, based on the magnitude and polarization direction of the piezoresponse. The estimation of the effective piezoelectric coefficient is based on the linear slope of the plot of amplitude versus Vac amplitude, as piezoelectricity exhibits a linear correlation between mechanical strain and electric field.[ 120 ] Traditionally, the frequency is selected below the initial contact resonance frequency, which is primarily influenced by the mechanical properties of the cantilever and the tip‐sample contact stiffness.[ 121 ]

PFM hysteresis loop measurements are also commonly employed to examine ferroelectric characteristics. The local electric field‐polarization (E–P) hysteresis can be measured by applying a probing alternate voltage while the direct current voltage is either on‐field or off‐field. It is worth mentioning that the PFM signal is typically obtained in the off‐field state to minimize the electrostatic contribution. This hysteresis loop measurement can be further extended to explore spatially varying local switching behaviors, such as switching spectroscopy‐PFM.[ 122 ] As a specific operational mode of PFM, the so‐called general mode PFM, allows the acquisition of the cantilever deflection over a full frequency range.[ 123 ] Multidimensional data can be obtained by simultaneously recording cantilever responses, such as out‐of‐plane and in‐plane deflection, to ascertain the diverse piezoelectric coefficients of the material under analysis. This approach is frequently coupled with nanoindentation modules, which can provide precise control over the force exerted on the material during the stimulation, which is crucial when analyzing biological and soft biomaterials. The peak force tapping allows the probe to intermittently contact the sample to measure instantaneous forces as low as 10−12 N. This modality enables the imaging and analysis of synthetic and biological piezoelectric polymers such as cellulose nanowires,[ 124 ] nylon,[ 125 ] PLLA,[ 126 ] and collagen.[ 127 ]

Another PFM approach is based on the utilization of the direct piezoelectric effect.[ 128 ] Although mechanical stimulation would be more immediate in understanding the piezoelectricity of materials, several drawbacks are still limiting this approach, such as the need for sophisticated electronics to acquire small and reliable electrical signals.

The PFM can provide significant insights into the piezoelectricity at the micro‐ and nanoscale, even if there are drawbacks to approaching similar quantitative values to those measured by macroscopic techniques.[ 129 ] The occurrence of electrostatic effects has the potential to impact the signal reliability, thereby altering the estimation of the piezoelectric coefficient. In this case, a preliminary analysis through Kelvin probe microscopy can be performed to quantify the surface potential of the material before the PFM analysis. In the alternative, strategies to minimize the electrostatic force include increasing the spring constant of the SPM cantilever,[ 130 ] conducting measurements at higher AC frequencies,[ 131 ] and compensating the surface potential by applying an external direct current voltage.[ 132 ] The use of a stiff tip may partially solve the issue of electrostatic phenomena. Still, such an approach might not be helpful in analyzing organic piezoelectric biomaterials, as many of them are less rigid and resistant than ceramics or synthetic polymers. Another potential source of measurement misinterpretation is caused by the intrinsic dependence on the tip properties, such as stiffness and resonance frequency. Other drawbacks of the PFM analysis include the nonuniform electrical field distribution underneath the SPM tip, as well as instrumental background noise.[ 133 , 134 ]

PFM is a valuable tool for studying the piezoelectric properties of micro‐ and nanomaterials, but it is still far from being considered an element of industrial test‐bench equipment for standard evaluation, especially for organic materials.

Alternatively, the piezoelectric behavior of a material can be indirectly estimated using other material characterization techniques that are more related to the chemical structure of the polymers.[ 101 ] Although differential scanning calorimetry (DSC) is not commonly employed to determine the piezoelectricity of polymers directly, it has the potential to provide valuable information about the piezoelectric behavior of polymers indirectly through the analysis of phase transitions and structural changes.[ 87 ] Polymer phase transitions, such as the glass transition, crystallization, and melting transition, are often associated with changes in molecular ordering and alignment, which can influence the piezoelectric properties of the material. The degree of crystallinity can be quantified using DSC. Crystalline regions within polymers are known to exhibit piezoelectric behavior since the arranged molecular structure aids the generation of electric dipoles in response to mechanical stress. Additionally, DSC can provide insights into the molecular orientation of polymers, which is crucial for understanding their piezoelectric properties. DSC is often used to quantify the crystallinity of thermoplastic materials, such as PLLA.

X‐ray diffraction (XRD) can also provide information about the crystallographic structure and molecular arrangement of polymers, which are fundamental factors influencing their piezoelectric behavior.[ 2 , 79 ] By analyzing the diffraction patterns, XRD can determine the presence and nature of crystalline phases within polymer samples, which is responsible for the piezoelectric behavior. XRD can also detect structural changes induced by mechanical deformation or external stimuli, providing information on the improvement of the piezoelectric properties induced on the biomaterial. Indeed, polar group alignment along specific crystallographic directions can enhance the piezoelectric properties of polymers by promoting a preferential orientation of electric dipoles in response to mechanical stress. XRD is usually used to analyze the presence of different phases in organic materials such as glycine.[ 93 ]

A further helpful method for determining the existence of specific crystal phases is the Fourier‐transform infrared (FTIR) spectroscopy. FTIR spectroscopy can identify the functional groups in polymers based on their characteristic absorption bands in the infrared spectrum.[ 135 ] Specific functional groups, such as polar groups (e.g., —OH, —NH2, —COOH), or hydrogen bonding interactions within or between polymer chains are known to contribute to the piezoelectric properties of polymers by facilitating the generation of electric dipoles in response to mechanical stress. This method can also allow to check for polymer chain alignment within the sample by employing a polarizer. FTIR is often used to discriminate the different phases of PVDF. Still, it has also been explored for the analysis of the secondary structures of proteins at the micrometer scale (e.g., formation of β‐sheets in silk). Similarly to FTIR, Raman spectroscopy is another powerful tool for investigating the piezoelectric properties of materials. It may provide detailed information about the vibrational modes of a material, which can be correlated with its piezoelectric behavior. Raman spectroscopy can be used to identify different crystalline phases of a material.

Although DSC, XRD, FTIR, and Raman spectroscopy do not directly measure piezoelectric properties, they can be used with other techniques, such as polarized light microscopy, mechanical testing, and piezoelectric measurements, to provide a comprehensive understanding of the piezoelectric behavior of polymers.

A summary of the techniques discussed is reported in Table 2 .

Table 2.

Summary of the techniques used to characterize piezoelectric biomaterials from the morphological, piezoelectric, and chemical perspective.

| Technique | Sample type and preparation | Instrument parameters | Sample size | Outputs |

|---|---|---|---|---|

| Electron microscopy | Solid and dried sample coated, covered by a thin layer of gold/platinum for nonconductive samples (not needed for environmental Electron microscopy). For TEM of organic nanomaterials, a staining with uranyl acetate might be necessary; for larger samples it is often required the use of the ultramicrotome |

SEM: acceleration voltage (typical range: 5–30 keV), probe current, spot size, working distance, detector type (secondary electron detector or backscattered electron detector), scanning speed and vacuum level (low or high) TEM: acceleration voltage (typical range: 50–300 keV), condenser lens system (size and intensity of the electron beam), objective lens focus and aperture, camera length, detector type, vacuum level, stigmation modulation |

SEM: lateral dimensions of few μm up to 1–2 cm in size; Thickness: lower than few mm TEM: lateral dimension: lower than 3 mm per dimension; Thickness: less than 100 nm |

Size and morphology, elemental composition, atomic structures, lattice arrangements, arrangement of atoms and defects, surface crystallographic structure and crystalline phases, grain orientations |

| Atomic force microscopy (AFM) | Dried or liquid samples in the form of thin films, or micro‐ and nano‐sized materials. No special preparation needed | Tip shape and radius, tip coating, cantilever stiffness, cantilever resonant frequency, scanning speed, tip‐sample interaction mode (contact, noncontact or tapping), force or amplitude setpoint, scan area |

Area: 0.25–0.5 μm up to 100–200 μm; Thickness: sub‐nm to hundreds of μm, with steps lower than 10 μm in the topography |

3D topography (size and shape), mechanical properties of nanomaterials, (e.g., stiffness), and other surface properties (e.g., adhesive, electrical and chemical properties) |

| Dynamic and electrophoretic light scattering | Suspension of solid particles | Laser wavelength, scattering angle, detector sensitivity, temperature, measurement duration, cuvette material, and path length, applied voltage |

Volume: 1–3 mL Particle size: 0.5 nm to 10 μm Concentration: typical range from 10−5 (w/v) up to 10% (w/v), dependent on material optical properties (e.g., absorbance or refractive index) |

Hydrodynamic size, stability (polydispersity index) |

| BET | Dried samples in the form of thin films, or micro‐ and nano‐sized materials | Adsorption gas (e.g., nitrogen, krypton), relative pressure (typical P/P0 range: 0.05–0.35), degassing temperature and time | Sample size: 10–500 mg, depending on the instrument and the surface area | Specific surface area (m2 g−1), pore volume and pore size distribution, adsorption‐desorption isotherms |

| Piezoresponce force microscopy (PFM) | Dried samples in the form of thin films, or micro‐ and nano‐sized materials, over a conductive substrate | Tip shape and radius, tip coating, cantilever stiffness, cantilever resonant frequency, drive amplitude and phase, scanning speed, tip‐sample interaction (applied force), scan area |

Area: 0.25–0.5 μm up to 100–200 μm Thickness: sub‐nm to hundreds of μm, with steps lower than 10 μm in the sample topography |

3D topography (size and shape), and piezoelectricity (amplitude and phase signals) |

| Differential scanning calorimetry (DSC) | Fine powder, film, or small piece of solid materials | Temperature range, heating/coaling rate, sample pan type, purge gas and flow rate, instrument sensitivity, and resolution | Sample size: from 1 to 10 mg | Thermal properties: phase transitions, melting points, crystallization, and specific heat capacity |

| X‐ray diffraction analysis (XRD) | Dehydrated solid samples, powders, thin films, or small bulk pieces, deposited onto a specific sample holder with zero background | X‐ray source, X‐ray tube voltage (10–60 kV), and current (5–100 mA), goniometer settings (e.g., scan range, step size, and scan speed), detector type, slits, temperature |

Area: the area typically scanned is around 1–5 mm2 Thickness: few nm up to 10–50 μm |

Crystallographic structure and molecular arrangement of polymers, elemental composition, surface details |

| Fourier‐transform Infrared Spectroscopy (FTIR) | Dried and liquid samples, powders, thin films, or coatings | Spectral range (typically 100–4000 cm−1) and resolution, detector type, source type, interferometer configuration (e.g., Michelson interferometer), path length, number of scans, beam splitter material | Area/volume: up to 1 cm2 with thickness above 200–300 nm (thin film). A few mg for solid samples, or a few μL liquid solutions | Vibrational modes of molecules, chemical composition, and molecular structure, functional groups in polymers or hydrogen bonding interactions |

| Raman spectroscopy | Dried and liquid sample, powders, thin films, or coatings, and microparticles | Excitation wavelength (commonly 532, 633, or 785 nm), laser power, spectral range (typically 100–4000 cm−1) and resolution, collection mode (backscattering vs transmission), numerical aperture and magnification of objective lens, integration time, scanning speed and accumulation, temperature control, filter and optical components, environment control, detector type, signal averaging, background subtraction | Area: small sample areas (micron‐scale) can be analyzed; no strict size requirement for bulk samples | Vibrational modes of molecules, chemical composition and molecular structure, functional groups in polymers and crystalline information |

2.2.3. Biodegradability

The concept of “degradation” refers to an irreversible alteration in the overall characteristics, structure, and form of the polymer, often induced by the chemical breakdown of its molecular chains.[ 136 ] More generally, degradation is driven by biotic means (biodegradability) or abiotic means (hydrolysis, photolysis, or oxidization). Biodegradation is a multifaceted and naturally occurring phenomenon influenced by the biological activity of living organisms.[ 137 ] By definition, a biodegradable material is a substance that biological processes can naturally decompose into simpler and nontoxic compounds. For the applications addressed in this review, the state‐of‐the‐art report refers to the biodegradation of piezoelectric micro‐ and nanomaterials in the human body. Thus, in this context, biodegradability strictly refers to the material's ability to be processed within the body and divided into nontoxic subunits over the average human lifespan. More specifically, ISO‐10993‐9‐2009 defines “biodegradation” as the “decomposition of a material due to the biological environment”.[ 138 ]