Abstract

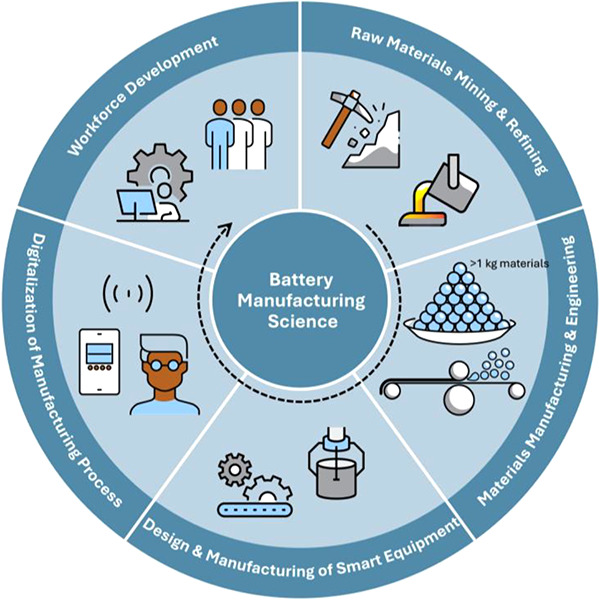

This Review explores the status and progress made over the past decade in the areas of raw material mining, battery materials and components scale-up, processing, and manufacturing. While substantial advancements have been achieved in understanding battery materials, the transition to large-scale manufacturing introduces scientific challenges that must be addressed from multiple perspectives. Rather than focusing on new material discoveries or incremental performance improvements, this Review focuses on the critical issues that arise in battery manufacturing and highlights the importance of cost-oriented fundamental research to bridge the knowledge gap between fundamental research and industrial production. Challenges and opportunities in integrating machine learning (ML) and artificial intelligence (AI) to digitalize the manufacturing process and eventually realize fully autonomous production are discussed. The review also emphasizes the pressing need for workforce development to meet the growing demands of the battery industry. Potential strategies are suggested for accelerating the manufacturing of current and future battery technologies, ensuring that the workforce is equipped with the necessary skills to support research, development, and large-scale production.

1. Introduction

In light of the escalating importance of batteries for broad applications in modern societies, it is crucial to establish a sustainable strategy that pinpoints and addresses the scientific challenges in battery manufacturing. For academic researchers, manufacturing seems a little far from their daily research, as they are not familiar with the manufacturing process which is usually taken care of by industry. It is not clear what kind of roles researchers can play in supporting battery manufacturing. Meanwhile, for industry, most of the published research is valuable in deepening scientific understanding, but there is still uncertainty whether those new materials or ideas are suitable for large-scale production, because the first criterion to assess the feasibility of any new material, component, or battery technology is the cost, which includes both materials and processing.

The cost of Li-ion batteries (LIBs) has dropped significantly from a few thousand dollars per kWh in the 1990s to around $100/kWh today. However, to further accelerate electric vehicle (EV) market penetration and enable large-scale deployment of grid energy storage, the cost must be reduced below $100/kWh. Achieving this requires cost-efficient materials and processing technologies along with increased cell-level energy density, because the cost of a battery is defined as $$/kWh. In addition to the cell-level energy from each building block of the pack, battery lifetimethat is, the total deliverable energy during the lifespan of the batteryalso plays a key role in determining the cost in the long term, which needs more fundamental understanding about stabilizing the structures of cathodes and their interfaces, which is not the focus of this Review. CO2 emission from battery manufacturing has been covered by quite a few review papers − and thus will not be discussed herein.

Fundamental research related to battery manufacturing needs to be cost oriented. For conventional LIBs, graphite production is quite mature. To further reduce the cost of graphite production, natural graphite is of great importance, but its electrochemical performance still needs further improvement without introducing an additional cost. The manufacturing of high-performance graphite also relies on equipment such as specialized furnaces to precisely tune the temperatures and heating environments to control the electrochemical properties of carbon. Hard carbon is also proposed for LIBs and, so far, is the best anode material for Na-ion batteries. Synthesis of hard carbon from sustainable resources is one of the promising directions from a manufacturing cost and scalability point of view.

For the conventional LiNi0.6Mn0.2Co0.2O2 (NMC622) cathode, the manufacturing costs fluctuate with raw material prices, including lithium salts and transition metal sulfates. Additionally, various synthesis approaches also impact the production cost of NMC materials. New approaches are needed to increase the tolerance level of raw materials while simplifying the manufacturing process of NMC cathode materials and reducing the carbon footprint during production. As more nickel is packed into NMCs, e.g., LiNi0.8Mn0.1Co0.1O2 (NMC811) or LiNi0.9Mn0.05Co0.05O2(NMC90), different challenges arise, delaying their large-scale adoption for use in commercial EV batteries. For high-nickel NMCs, the moisture sensitivity, gassing, and cracking issues are still not well addressed; however, they might be overcome through cost-effective synthesis innovations. Similarities can be found in other cathode materials, such as LiFePO4, LiMnPO4, and LiFe1–x Mn x PO4, which still need to be downsized to nanoparticles for sufficient ionic conductivity, but that raises problems in making dense and thick electrodes for high-energy applications. All of these issues are new opportunities to integrate materials science and engineering to tackle the pressing challenges in reducing manufacturing cost for battery materials with enhanced properties and performances.

To manufacture next-generation high-energy batteries such as lithium metal (solid or liquid) or lithium–sulfur batteries, processing costs need to be further lowered through innovations. For example, ideally, if coupled with an NMC cathode, no lithium metal is needed on the anode side, assuming the Li+ stored in the NMC cathode can be 100% reversibly utilized back and forth. However, due to the aggressive side reactions between Li and electrolytes, Li stored in an NMC cathode is quickly consumed, leading to very fast cell degradation. Before an “anode-free” cell is realized, an appropriate amount of Li metal is still necessary on the anode side to compensate for the continuous loss of Li+ ions upon each cycle. The thinner the lithium metal foil, the lower the material cost, but processing ultrathin lithium metal foil below 20 μm could be quite expensive. Another good example is the sulfur cathode. Sulfur is almost “free” compared to NMCs because it is the byproduct of crude oil processing. But sulfur/carbon-based composites still have challenges before their successful implementation in Li-S batteries. For example, the highly porous S/C electrode absorbs at least twice the amount of electrolyte as in conventional NMC cathodes, thus sacrificing cell-level energy. Reducing the porosity and tortuosity of the S/C composite electrode is not easy because of the nature of their nanostructures. Solid-state electrolytes have already achieved high ionic conductivity at room temperature, comparable to that of liquid electrolyte. But processing the particles into solid membranes will result in some loss in conductivity due to the presence of grain boundaries, which may become limiting at practical conditions. In addition, large-format processing of solid-state membranes without any defects is a prerequisite for commercializing solid-state batteries, although most of the demonstrated cells still have limited dimensions. ,

To directly support battery manufacturing, different mindsets are needed in performing fundamental research. It is critical for us to understand the true challenges in lowering the cost of battery materials and processing through a comprehensive survey from the raw materials supply chain to production. Advanced in-line characterization and smart manufacturing will further increase the yields and reduce the cost of “waste”. Scrapes from the production line as well as the spent batteries can be directly recycled and fed back into the manufacturing line as “raw” materials. If the cost to recycle spent batteries becomes comparable to that of the freshly mined materials, then those recycled batteries would also be good “feedstock” to make fresh batteries, reducing the supply chain risks. To ensure sustainable manufacturing, workforce developmentfrom operators to researchersneeds to happen in parallel with tailored courses for various industries, and they need to reach the best practical impacts.

2. Raw Materials Mining and Refining

2.1. Lithium Salts

2.1.1. Lithium Extraction

Raw lithium salts are the building blocks of LIBs from cathode synthesis to electrolyte production and anode prelithiation. Lithium is mainly extracted from natural resources such as rocks, spodumene LiAl(SiO3)2, or brines. There is more lithium stored in continental brines than in hard rock ores. The former is the primary mining method for lithium production.

Extraction of lithium from brines relies on evaporitic technology, which pumps the saltwater from underground aquifers to the surface and relies on open-air evaporation to concentrate the brine. This process takes up to two years, which is very slow and cannot respond resiliently to the market need. The brine solution is then processed by adding chemicals to precipitate and refine lithium salts. , The locations of brines suitable for lithium extraction are geographically restricted. Brine sources with diluted lithium such as geothermal brines cannot adopt the conventional evaporation method for lithium extraction due to their different chemistry and much longer time for processing. However, new extraction methods such as direct lithium extraction, e.g., ion exchange, electrochemical methods, etc. are being investigated which may accelerate the process of concentrating lithium salts in all brines with different lithium concentrations, if scalability can be demonstrated.

In hard rock deposits, lithium is present in the form of Li2O in spodumene, the content of which varies from 2.9 to 7.6 wt%. The mainstream approach to extract lithium from spodumene is through acid roasting (phase transition and sulfuric acid digestion) (Figure ). A high-temperature calcination step is required to first convert the α-type monoclinic structure of spodumene to the β-type tetragonal form, with a selective sieving process to increase Li2O concentration. Then the converted spodumene is mixed with an excessive amount of sulfuric acid, reacting at 250 °C. The related chemical reactions for acid roasting are shown in Figure . Li2O will dissolve in sulfuric acid, forming Li2SO4, which will eventually be converted to insoluble Li2CO3 by using a Na2CO3 solution. It has been found that the leaching rate of the impurities in the spodumene is slow. Adding additional amounts of sulfuric acid does not increase the extraction yield of lithium, indicating that not all the impurities in spodumene are accessible by acid, depending on their specific locations or environment in the hard rock. To further improve the extraction yield, more fundamental research is necessary to quickly understand the distribution of different impurities before and after acid roasting. Energy involved in the extraction of lithium is also intensive. Reducing the temperature needed for phase transition of spodumene, shortening the time used for high-temperature calcination by energy-efficient use of fluidized-bed systems, or decreasing the amount of strong acid used are all important research areas to improve lithium extraction from rocks.

1.

A simplified process diagram for lithium carbonate production with lithium brine extraction and hard rock mining. Modified and reproduced from ref under the terms of the CC-BY 4.0 license.

Concentrated lithium, extracted from either brines or hard rocks, will undergo a series of refining process to meet battery-grade purity (Figure ), removing major impurities such as Mg and Ca by using chemical agents such as Ca(OH)2 and Na2CO3, respectively, which counts for 30–40% of the total cost of lithium production and is accompanied by CO2 emission. In the refinery process, Mg removal is still much more challenging than Ca removal because of Mg’s size being almost identical with that of Li. The presence of Mg impurity considerably impacts the extraction efficiency of Li from brines, making it challenging to separate them. An increased Mg/Li mass ratio dramatically decreases the feasibility of extracting Li from the corresponding brines, most of which, unfortunately, have a high Mg/Li ratio. In addition, Mg precipitates into smaller particles compared to their calcium counterpart, not to mention that the concentration of Mg is higher than that of Ca, especially from those brines with high Mg/Li ratios. All of these factors add to the increased cost of eliminating Mg during the refining process. Therefore, new but cost-efficient approaches are urgently needed to expand available brine sources for lithium extraction.

A recent interesting work found that up to 1% Mg impurity in raw lithium salt materials in fact improves the electrochemical performances of cathode materials synthesized using Li2CO3, with this “high” impurity of Mg presumably assigned to the doping effects of Mg. Indeed, Mg is a common dopant used to tune the lattice structure and thus the rate and/or cycling stability of battery materials. , If some of the impurities in the raw lithium salts can be utilized as dopants to positively impact the later-formed functional materials, it will greatly ease and accelerate the production of raw lithium salts and, therefore, reduce the cost of lithium extraction.

The extracted salts are either further utilized to prepare lithium metal ingots through electrolysis, which will be discussed in a later section, or processed to battery-grade-purity salts for battery materials synthesis or electrolyte use.

2.1.2. Salts as Precursors for Battery Materials Synthesis

Li2CO3, LiOH·H2O, and LiOH, extracted and refined from brines or rocks, are the commonly used salts for battery materials production. The synthesis of commercial Ni-rich cathodes such as polycrystal NMC811 often utilizes LiOH or LiOH·H2O as a lithium salt precursor, while low-cost Li2CO3 is used for manufacturing NMC622, NMC532, and LiNi1/3Mn1/3Co1/3O2 (NMC111), which have reduced nickel content.

Li2CO3, LiOH·H2O, and LiOH along with LiNO3 and Li3PO4 are also used for synthesis of phosphate cathodes such as LiFePO4 or LiMnPO4, depending on the specific route used. From a cost point of view, Li2CO3 is still the preferred raw salt for mass production of phosphates cathode materials because, as discussed earlier, Li2CO3 is the most common form of lithium salt after being extracted and processed from rocks or brines. An interesting work took advantage of a lithium salt such as Li1–x Mg y V2–z N z O5 as an additive mixed with preheated LiFePO4 precursors, followed by milling and sintering to form a composite-phase material. The salt additive has both good ionic and electronic conductivities which “glue” nanosized LiFePO4 into micron-sized particles (D50: 2 μm), which not only increases the tap density of as-prepared LiFePO4 but suppresses the particle growth of LiFePO4 during high-temperature calcination, leading to excellent rate capabilities for both charge and discharge.

Current wisdom believes that lithium salts need to be downsized homogeneously to be mixed with different precursors for a uniform chemical reaction to happen during high-temperature calcination. This leads to the necessity of premilling and/or sieving lithium salts, which adds on the cost. If chemical lithiation can happen without the need to control the particle size of lithium salts, the materials manufacturing efficiency will be improved. Impurities such as iron and sodium in the lithium salts need to be cautiously controlled and monitored because they not only impact the structural stability of the as-prepared cathode materials or electrolytes but also may contaminate the anode or damage the solid–electrolyte interphase (SEI) upon cycling.

2.1.3. Salts for Electrolyte

Liquid electrolytes used for batteries are made by dissolving salts in solvents. Dissociated salts in the electrolyte solution provide ionic conductivity, which is dominated by lithium hexafluorophosphate (LiPF6) for LIBs. Some other salts, such as lithium hexafluoroarsenate (LiAsF6), lithium borohydride (LiBH4), and so on, are also used but mainly as additives. Lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) and lithium bis(fluoromethanesulfonyl)imide (LiFSI) have corrosion issues at elevated voltages, − but the discovery of concentrated electrolytes enabled their broad application in not only Li-ion but also Li metal batteries.

LiPF6 is manufactured by reacting phosphorus pentafluoride (PF5) with lithium fluoride (LiF) by following the overall reaction below.

From the above reactions, the key raw materials used for LiPF6 production are hydrogen fluoride (HF), LiCl, and phosphorus pentachloride (PCl5). The PCl5 is mixed with HF to prepare PF5 (Reaction 1). Then PF5 reacts with LiCl in liquid HF to form LiPF6 (Reaction 2). Anhydrous HF, obtained by treating liquid HF with high-purity fluorine (F2) gas (from electrolysis), is needed for reactions. High-purity F2 gas is from an electrolysis process.

The whole process is illustrated in Figure . Hazardous HF is always needed for LiPF6 production, raising the manufacturing cost due to safety and control measures. But for now, there is no alternative solvent that works better than HF for LiPF6 production to give the high yield and purity needed in LiPF6 manufacturing.

2.

Process flow for LiPF6 production. Reproduced with permission from ref . Copyright 2019 American Chemical Society.

LiFSI is emerging as a next-generation lithium salt for electrolytes, complementing LiPF6. Following its initial industrialization by Nippon Shokubai, major manufacturers within the lithium battery supply chain in China, Japan, and Korea have commenced the large-scale production of LiFSI and are progressively expanding their production capacities.

The synthesis of LiFSI typically consists of three

primary steps:

(1) preparation of dichlorosulfonimide (Reaction

1 below), (2) fluorination of dichlorosulfonimide (Reaction 2), and (3) lithium ion exchange (Reaction 3). Although

the overall synthesis route for LiFSI is fixed, the raw materials

and process conditions utilized in each step can vary depending on

the specific route employed. The mainstream

synthesis pathway for LiFSI is illustrated in the reactions below.

−

Recent market trends suggest a steady increase in market penetration of LiFSI, with continued growth expected in the foreseeable future. In comparison to LiPF6, LiFSI exhibits substantially enhanced thermal and chemical stability with higher resistance to hydrolysis. Electrolytes based on LiFSI demonstrate improved performance across both high- and low-temperature regimes, as well as superior rate capability, attributed to the higher ionic conductivity and reduced SEI resistance. The development of high-concentration electrolytes (HCEs) based on LiFSI has opened a brand new direction for studying electrode–electrolyte interphases, which has a potential to be applied in certain battery technologies. This enhancement brough by HCEs is primarily attributed to the solvation structure, wherein the Li+ cation exhibits a strong association with FSI– anions as well as the solvent, facilitating the formation of an anion-derived SEI. The resulting SEI is more stable and robust than the conventional solvent-derived SEI, as it is predominantly composed of inorganic components, which exhibit resistance to dissolution and mitigate continuous formation in subsequent cycles.

However, a notable limitation of HCEs is the high concentration of salts, which leads to increased viscosity and higher costs. To mitigate these issues, localized high-concentration electrolytes (LHCEs) have been proposed. LHCEs utilize weak or nonsolvating solvents as diluents, thereby retaining the beneficial properties of HCEs while reducing the overall salt concentration and viscosity to levels akin to those of conventional electrolytes. This strategy helps reduce the cost of LHCEs relative to HCEs by decreasing the salt concentration in the electrolyte. It also improves the cycling stability, calendar life, and operational temperature range of the batteries. −

Yet, the production cost of LiFSI still remains higher than that of LiPF6, primarily due to the more complex synthesis route and the lower yield of LiFSI, whereas LiPF6 has been in production for a longer period and is well-established in the market, benefiting from a more standardized synthesis process. , However, ongoing advancements in the production processes of LiFSI, coupled with potential breakthroughs in industrial-scale manufacturing and accelerated market demands, could lead to cost reductions, positioning LiFSI as a promising candidate for future applications, particularly due to its reduced fluorination compared to LiPF6.

Impurity Impacts

Impurities in electrolytes critically influence the performance and safety of LIBs. LiPF6 commonly contains impurities such as water, hydrofluoric acid (HF), metal contaminants (such as Na, K, Ca, Mg, Fe, Cu), anion contaminants (including Cl– and SO4 2–), and insoluble particulates. Similar impurities are observed in other commercial electrolyte salts, such as LiBF4, LiAsF6, and LiFSI, although additional impurities may exist as well. Besides, impurities also come from electrolyte solvents, usually including water and organic contaminants. These impurities arise from various sources and adversely affect battery performance in different ways. For example, a trace amount of water can infiltrate the electrolyte due to inadequate handling, insufficient drying, or exposure to humid conditions. Water reacts with salts like LiPF6 to generate HF, a highly corrosive byproduct that exacerbates electrolyte degradation over time. −

Metal contaminants in the form of metal particulates or metal ions, commonly originating from contaminated raw materials or equipment, negatively impact the anode performance by inducing metallic deposition. These contaminants also poison the SEI layers and accelerate the degradation of the electrolyte. Cl– and SO4 2– usually stem from contaminated materials and the LiPF6 synthesis processes. These anions accelerate the corrosion of the aluminum current collectors. Additionally, they may react with other components to form insoluble precipitates, thereby increasing the internal resistance of the battery. Organic impurities, such as acids, alcohols, and aldehydes, are mainly residual reactants or byproducts from solvent production processes. They can engage in undesired oxidation/reduction reactions at the electrode surfaces, diminishing battery efficiency. In lithium metal batteries, impurities containing active protons can undergo severe chemical reactions with the lithium metal anode due to the highly reactive nature of metallic lithium. Of note, there is also a report on the water-derived HF “guiding” lithium metal growth into columns, smoothing dendrite growth.

Rigorous monitoring and control of electrolyte impurities are essential to maintain the high quality of the electrolyte and ensure optimal battery performance, reproducibility, and safety. China has established a comprehensive set of chemical industrial standards governing the production and application of common electrolyte materials, including salts, solvents, and additives. − These standards outline requirements for product quality, test methods, and inspection procedures, as well as guidelines for marking, labeling, packaging, transportation, and storage. For instance, the standards stipulate that LiPF6 must meet a minimum purity of 99.95%, whereas commonly utilized carbonate solvents are mandated to achieve a minimum purity of 99.99% for battery application. In academic research, when developing innovative electrolytes that incorporate chemicals beyond conventional salts and solvents, it is crucial for researchers to exercise rigorous quality control during electrolyte preparation. Additionally, detailed information about chemical purity and impurities may need to be disclosed in publications to ensure the reliability and reproducibility of the electrolyte for practical applications.

Electrolyte Recycling

Considering the amount of electrolyte (15–20 wt%) used in batteries and the cost of battery-grade salts, electrolyte recycling is underemphasized in battery recycling research. Early literature on LIB recycling proposed liquid extraction methods for electrolyte recycling, while subsequent studies of battery recycling often overlooked electrolyte recovery. , Considering the high volatility, flammability, and toxicity associated with contemporary battery electrolytes, improper management of these materials in spent batteries poses substantial environmental and health risks. − In addition to the economic benefits of recovering valuable electrolyte components, it is imperative to address these hazards effectively to mitigate potential adverse effects.

However, the electrolyte in spent LIBs is predominantly absorbed within the porous electrode materials, making electrolyte recycling more challenging. To overcome these difficulties and improve the efficiency of the electrolyte recycling process, several approaches have been proposed. The first approach is to recover the electrolyte through a liquid extraction method. Because of the high cost associated with liquid solvent extraction, researchers have explored the use of liquid and supercritical CO2-assisted methods to improve electrolyte recovery rates. − In contrast to traditional liquid solvent extraction techniques, the supercritical CO2-assisted approach facilitates the efficient removal and recovery of the electrolyte through pressure relaxation. High effectiveness in supercritical fluid extraction can be achieved by optimizing operational parameters such as pressure, temperature, and extraction duration. For example, a recovery rate of 89.1 ± 3.4 wt% of the electrolyte from Panasonic 18650 batteries was attained using supercritical CO2 and an acetonitrile/propylene carbonate mixture in a 3:1 ratio. Given that spent electrolytes are composed of a complex mixture of salts, solvents, additives, and their decomposition products, and considering the wide variety of battery types and electrolyte formulations on the market, the optimal strategy for electrolyte reuse involves selectively extracting individual components from the electrolyte mixture. This selective extraction represents a potential area for future research in the field of electrolyte recycling, with cost analysis being conducted in parallel.

2.2. Nickel, Manganese, and Cobalt Salts for Li-Ion Cathodes

Nickel, manganese, and cobalt are constituent elements of many cathode chemistries for rechargeable batteries. All of these relevant elements must ultimately be extracted from the earth via the mining of ore. The concentration and quality of ore are determined by geological history, as deposits are unevenly distributed around the world in varying degrees of quality and concentration. At the outset, the two most important chemical characteristics of any ore are (1) the concentration of the relevant element in the ore and (2) the presence of unwanted impurities in the ore. Besides concentration, the financial and environmental costs for refining the ore are direct functions of the quantity and type of impurities present in the ore. Some impurities may be in high concentration but relatively easy to remove, while other impurities may be in low concentration but difficult or even impossible to remove. Impurities can include but are not limited to cations such as sodium, potassium, or calcium or heavy metals such as molybdenum or chromium, just to name a few.

In the example of manganese processing, the concentration of the raw ore is critical. Because the raw manganese ore must be roasted to make the manganese soluble in acid for leaching, the amount of energy required to synthesize a specific quantity of battery-grade manganese is ultimately a direct function of the concentration of manganese in the raw ore. Low-concentration ore still requires the same amount of roasting on a per-weight basis as high-concentration ore while producing significantly less manganese via leaching. The problem of low-concentration ore bedevils the processing of nickel, cobalt, and other materials. At a sufficiently low concentration, the processing of the ore becomes economically unviable.

For manganese processing, the concentration of calcium in the ore is problematic. Because manganese is extracted via a leaching process, high quantities of calcium will lead to significant blockages in the plant’s pipes and equipment, costing time, energy, and money to clean and maintain them. Other impurities are added as part of the extractive or refining process. For example, in manganese processing, manganese sulfate (MnSO4) is created as an intermediate product. If the process is not carefully controlled, then the final product will contain sulfate in varying concentrations.

Nickel is more expensive than manganese and still dominates high-energy Ni-rich cathode materials. Only high-content Nickel I is used by battery manufacturers to make nickel sulfate (NiSO4), a precursor for NMC811 synthesis. Nickel II, with lower nickel content, is mainly utilized in stainless-steel production. Innovations to convert Nickel II, such as nickel pig iron, to nickel matte and eventually NiSO4 for cathode manufacturing with cost-efficient approaches will be of great importance from the point of view of relieving the challenge of the battery-grade nickel shortage.

Cobalt is still used, although its use is continuously decreasing, in cathode materials. Two-thirds of the global Co supply is mined in Africa, where there are concerns about child labor and harm to workers’ health. Recycle and reuse of those valuable metals in spent car batteries will help. But we also need to understand that, for now, mining those metals is still less expensive than recycling them from used EV battery packs. So the key is to develop cheaper ways to recycle LIBs and make them competitive with freshly mined ones. In addition, scale will help reduce the recycling cost, especially if environmental concerns can also be resolved.

It is not well understood whether some of the common impurities in nickel, cobalt, and manganese can be used as dopants, which should be determined by the type and concentrations of those impurity “dopants”. Ores from different geographical locations may contain various contents of the same element impurity, so fast analysis and quantification of impurities is needed.

2.3. Iron and Phosphorus Materials as Precursors for Polyanion-Based Cathodes

Olivine cathodes, especially LiFePO4 (LFP), have been widely commercialized for EVs in Asian countries and have been deployed for grid applications. The majority of industrial methods for the production of LiFePO4 utilize solid-state processes, which require the selection of appropriate raw materials of iron, lithium, and phosphorus sources for calcination. Based on the iron source, the process can be categorized into iron phosphate (FePO4), ferrous oxalate (FeC2O4), and ferric oxide (Fe2O3) routes.

For the preparation of iron sources, iron ore, such as hematite (Fe2O3) and magnetite (Fe3O4), is typically used as a raw material to extract elemental iron. Compared to other non-ferrous metals such as Ni and Co, the metallurgy of iron is more large-scale and the resources are more abundant. In the subsequent manufacturing processes, the metallic iron reacts with different acids to form iron salts, such as FeCl2, FeSO4, and so on. The ferrous oxalate-based sintering process is currently the most widely used industrial route due to its simplicity and scalability. The preparation of ferrous oxalate can be achieved by adding oxalic acid to an iron salt solution.

Other precursors for LFP production include lithium carbonate (Li2CO3), lithium hydroxide (LiOH), and lithium acetate (CH3COOLi), which are commonly used as lithium sources. Ammonium phosphates serve as phosphorus sources, including ammonium dihydrogen phosphate (NH4H2PO4) and diammonium hydrogen phosphate ((NH4)2HPO4). H3PO4 is also directly used as a phosphorus source for LFP synthesis, but impurities easily dissolve in H3PO4, so strict quality control is required. The production of ammonium phosphates is usually driven by the neutralization reaction of phosphoric acid (H3PO4) with ammonia in the reaction tower. Phosphoric acid is a critical industrial raw material for the production of phosphorus sources for polyanion-based cathodes, which can be produced by treating phosphate rock (commonly apatite) with sulfuric acid.

For the route in which iron phosphate is chosen as iron source, FePO4 precursor is first synthesized by the reaction of ferrous sulfate with purified phosphoric acid or phosphates, e.g., NH4H2PO4. Then the iron phosphate precursor is subsequently calcinated with lithium salt such as Li2CO3, carbon black, and/or organic additives (glucose, sucrose, or starch) to coat carbon on as-produced LFP to enhance its electronic conductivity. For the processes that use ferric oxide as the iron source, lithium dihydrogen phosphate (LiH2PO4) is used as both the lithium and phosphorus source. Ferric oxide is manufactured from the purification of hematite ore materials, for which purity is critical. The production of lithium dihydrogen phosphate also involves phosphoric acid (H3PO4) as the reactant, which reacts with lithium hydroxide (LiOH) to form LiH2PO4. ,,

Compared to LiFePO4, LiMnPO4 offers a higher operating voltage (∼4.1 V), which increases the theoretical energy density (21% higher than LiFePO4), but it is limited by poorer ionic and electronic conductivity compared to its LiFePO4 countpart. LiMn x Fe1–x PO4 combines the characteristics of both LiFePO4 and LiMnPO4 by the substitution of Mn2+ at the transition metal Fe2+ site, providing a balance between energy density and cycling stability. The synthesis of lithium manganese phosphate (LiMnPO4) and lithium manganese iron phosphate (LiMn x Fe1–x PO4) can also be industrialized with the further introduction of manganese sources using solid-state methods. Common manganese sources include Mn(H2PO4)2, MnCO3, and Mn(CH3COO)2. Manganese ores, such as pyrolusite, rhodochrosite, and manganite, can served as the primary raw materials for obtaining these compounds, which has been discussed in an earlier session. Iron sources still include iron phosphate, ferrous oxalate, and ferric oxide, with corresponding manufacturing routes. ,

A key advantage of olivine cathodes is the abundance of precursor materials needed to manufacture these cathodes. The precursor raw materials are better distributed globally than Ni and Co raw materials. A shortage of phosphorus for battery applications is unlikely to happen on a global scale. However, supply chain security may call for more distributed phosphate processing facilities. Meanwhile, the supply of phosphate for battery manufacturing should not impact fertilizer production, which is the primary consumer of phosphorus. Fe and Mn are both abundant and well distributed globally. Fe/Mn precursors used to produce olivine cathodes can come in different chemical forms, including metal, metal phosphates, metal sulfates, and metal oxides. The wide selection space of Mn and Fe precursors opens possibilities for manufacturing innovations. Different manufacturing technologies could use different precursors, allowing for a new process design that could reduce manufacturing cost, liquid and gaseous waste, and energy consumption.

2.4. Artificial and Natural Graphite

Natural and synthetic graphite are indispensable materials in the construction of LIBs, albeit with distinct characteristics and production methodologies. Usually, many energy-intensive process steps are involved in the production of graphite (Figure ), which is also carbon intensive.

3.

Flowchart illustrating the manufacturing process for graphite anode materials.

Natural graphite, sourced from naturally occurring deposits, primarily consists of carbon and is extracted through mining operations worldwide. Conversely, synthetic graphite is meticulously produced via the carbonization of organic precursors such as petroleum coke or coal tar pitch. , This process yields graphite with highly controlled atomic structures and purities, ensuring consistency in its electrochemical properties. While natural graphite may exhibit varying compositions and structures due to its geological origins, synthetic graphite offers a more uniform structure and purity, enhancing its suitability for the most demanding battery applications. Despite its typically lower cost stemming from mining processes, natural graphite often suffers from higher impurities and inconsistent performance, whereas synthetic graphite’s engineered properties deliver superior electrochemical performancemost notably longer cycle life, less swelling during charge/discharge cycles, and less gas generation and therefore less pressure buildup in the cell. The choice between natural and synthetic graphite hinges on factors such as performance requirements, cost considerations, and application-specific needs within the lithium-ion battery industry. Approaches that can efficiently remove the unwanted impurities and enhance the electrochemical properties of natural graphite without increasing the total cost will be attractive to industry processing.

2.5. Hard Carbons

In addition to natural and synthetic graphite, hard carbon has been extensively studied as an alternative material for LIB anodes. Hard carbon is a type of noncrystalline carbon material distinguished by its inability to graphitize or form ordered structures, even at temperatures exceeding 2800 °C. Hard carbon is typically derived from biomass or petroleum residues through controlled pyrolysis processes, resulting in a disordered carbon structure with a high capacity for lithium storage.

The interlayer spacing and porosity of hard carbon and, therefore, its capacity can be adjusted by changing the processing temperature, which enables customization based on the desired application. The structure, being more amorphous than that of graphite, can provide advantages with respect to rate performance and capacity. However, challenges such as lower initial Coulombic efficiency and limited understanding of its structural evolution during cycling, leading to faster degradation, warrant further research and optimization efforts to fully exploit the potential of hard carbon in LIBs. The exploration of hard carbon alongside natural and synthetic graphite represents a significant avenue for advancing battery technology and addressing the growing demand for energy storage solutions.

Furthermore, the investigation into natural graphite, synthetic graphite, and hard carbon transcends LIBs, encompassing sodium-ion battery systems. Despite LIBs dominating the energy storage landscape, sodium-ion batteries have garnered increasing attention due to the abundance and cost-effectiveness of sodium resources that diversify the supply chain of battery technologies. However, although sodium is cheaper and more abundant than lithium, the necessity of utilizing hard carbon as the anode material in Na-ion batteries sacrifices the cost reduction brought by using sodium because hard carbon is much more expensive than graphite, which is a common anode in LIBs. More basic research is necessary to reduce the manufacturing cost of hard carbon for Na-ion batteries. Recent studies − also show promising results from graphite when used in optimized Na-ion batteries. If graphite can be directly utilized as the anode for Na-ion at large scale, the cost of Na-ion battery systems will be considerably reduced.

The fundamental operating principle of sodium-ion batteries mirrors that of lithium-ion batteries, with sodium ions shuttling between the cathode and anode via the electrolyte during charge and discharge cycles. Analogous to their lithium counterparts, sodium-ion batteries necessitate suitable anode materials for effective energy storage. However, in sodium-ion batteries, the movement of sodium ions within the stack of graphene sheets constituting graphite is impeded.

While a few different cathode materials can be utilized for sodium-ion batteries, hard carbon is currently the only viable anode active material to realize the commercial viability of sodium-ion batteries. Due to its large spacing between the graphene sheets compared to graphitic carbon, hard carbon possesses a higher sodium-ion storage capacity, reaching up to 300 mAh/g. The storage mechanism of Na+ in hard carbon remains a subject of ongoing debate, with several models proposed, including the “intercalation–filling”, “adsorption–intercalation”, “adsorption–filling”, and “three-stage” models. These models suggest various ways in which Na+ ions interact with hard carbon electrodes during charge and discharge cyclessome propose intercalation into graphitic layers during specific phases, while others suggest adsorption at surface or defect sites. Each model provides valuable insights into the complex behavior of Na+ storage in hard carbon electrodes, underscoring the need for further research in this area. −

The carbonization process plays a key role in tuning the microstructures of hard carbon anode materials. The heat treatment usually happens from a few hundred Celsius degrees to about 2000 °C. For comparison, the temperature used to prepare competitive synthetic graphite is usually greater than 3000 °C, , half the temperature of the surface of the sun. Specialized furnaces are needed to tune precisely the temperatures and heating environments to precisely control the electrochemical properties of carbon. The temperature needed for hard carbon production also depends on the precursors, which contain various impurities. , Sucrose, glucose, polymer resin, and natural biomass have all been used to synthesize hard carbon. From the manufacturing cost aspect, it may be worthy of study to find the lowest temperature needed for each different precursor to produce hard carbons with balanced performance. Alternatively, a low-temperature hydrogen reduction method or Joule heating to shorten the heating time also may help to further reduce the manufacturing cost by saving energy.

While hard carbons derived from biomass provide opportunities for cost reduction, the attainable purity, tap density, and surface area vary depending on the different biomass precursors. A stable massive supply of biomass raw materials with consistent quality and controlled impurities remains a challenge for hard carbon manufacturing. Nevertheless, the abundance of carbonaceous materials and deepening understanding of the nanostructures available ensure that the technology will continue to advance as new precursors and processing technologies are developed to continue to provide a high-energy, long-lasting, environmentally friendly, and sustainable anode material for years to come.

2.6. Silicon-Based Anodes

Silicon-based anodes are at the forefront of research and development for next-generation LIBs with a targeted cell level energy density of about 350 Wh/kg. However, the practical implementation of silicon anodes is hindered by challenges such as volume expansion, structural disintegration, , and the instability of the SEI. , Novel synthesis and manufacturing technologies have been developed and can address these issues to a certain extent. There are a few key production pathways for Si-based anodes, involving silane gas deposition, silicon oxide reduction, and recycling silicon from solar panels.

Silane (SiH4) is an important gas-phase precursor in producing high-purity silicon for battery anode applications. The global production of silane is dominated by a few major chemical companies, such as Air Liquide, Dow Chemical, REC Silicon, and Wacker Chemie, through the operation of large-scale facilities capable of producing high-purity silane gas. Key production facilities are in regions with a strong presence in the semiconductor and photovoltaic industries, including the United States, Europe, and East Asia. The process of using silane to create a silicon anode often involves chemical vapor deposition (CVD) to deposit silicon onto a substrate. This method is advantageous due to its ability to produce uniform, high-purity silicon coatings with controlled texture. Applying this method to a porous carbon substrate has also been demonstrated to be effective for manufacturing C/Si composites with controlled composition and morphology. The production and supply of silane gas, however, can be limiting factors. Specifically, silane’s properties as a highly flammable, reactive, and toxic gas make it essential to handle it with extreme caution. Co-locating a Si anode manufacturing facility with a silane plant(s) is probably the most practical approach to address these challenges, but it adds obvious constraints.

While silicon, at about 28%, is the second most abundant element in the Earth’s crust, it is mainly found in the silica (SiO2) or silicate (SiO4) forms. The use of silicon oxides as precursors for manufacturing silicon-based anode materials has gained significant attention. SiO x (silicon suboxide, x < 2) anodes represent a hybrid approach, balancing the high capacity of silicon with the stability of oxides. The reduction process can be done through various chemical and thermal processes, incorporating carbon to improve conductivity and buffer volumetric changes. It often results in a composite material, where silicon is dispersed within an oxide matrix. This structural hierarchy can be carefully tailored to optimum structural robustness. Despite improved cycle stability and moderate capacity, SiO x anodes typically have lower initial Coulombic efficiency and complex synthesis requirements which complicate manufacturing process and cost.

Recycling silicon from end-of-life solar panels is an interesting approach to produce silicon-based anodes, addressing both the supply chain sustainability and environmental impact of silicon production. As of 2024, many of the first-generation solar panels installed in the early 2000s are reaching the end of their typical 25-to-30-year lifespan. This initial wave of decommissioning creates a substantial volume of retired solar cells. The recycling process involves collecting and mechanically processing silicon wafers from decommissioned solar panels, followed by chemical and thermal treatments to remove impurities. The purified silicon is then processed into fine particles or composites, enhancing its electrochemical performance and stability. Recycling silicon from solar panels reduces waste and the need for raw material extraction, contributing to a circular economy. However, the variability in the quality and composition of silicon from solar panels necessitates rigorous purification and standardization processes. Overcoming challenges related to cost, safety, and processing complexity is crucial for the commercial viability of these technologies.

2.7. Lithium Metal Processing

Lithium metal has become an important anode for next-generation rechargeable lithium metal batteries that potentially can double the cell-level energy of state-of-the-art LIBs. The foil format of Li metal is processed by extrusion or a vapor-based technique. Before that, lithium ingots are obtained from the electrowinning process in a molten salt electrochemical cell. , Because of the different processing technologies, surface roughness, impurities, the type and amount of metal alloys, and the corresponding tensile stress of lithium metal foils vary.

Metallic lithium is typically produced through the electrolysis of lithium chloride (LiCl), which is derived from Li-containing minerals or lithium-rich brines. The electrowinning process takes place in a LiCl–KCl eutectic molten salt (400–450 °C), with a graphite anode and stainless-steel cathode (Figure a). ,, The lighter lithium metal floats to the surface of the molten salt and is collected, while chlorine gas is processed or vented on the anode. After being collected and cooled, the lithium ingot will be stored in an inert environment to prevent oxidation before further processing.

4.

(a) Illustration of molten salt electrolysis to produce Li metal ingots. Reproduced with permission from ref . Copyright 2020 Nature Publishing Group. (b) Different processing methods to produce lithium metal foils from lithium ingots or similar. Reproduced with permission from ref . Copyright 2023 Nature Publishing Group.

In Li metal battery applications, the methods for processing Li foil are crucial for both performance and cost. Currently the widely applied methods can be divided into mechanical processing, evaporation/sputtering deposition (Figure b), ,, and electrochemical plating. The calendaring process can reduce the Li foil thickness effectively from about 500 to 50 μm. Further reducing the thickness of the Li foil to below 50 μm will need different approaches such as sputtering, physical vapor deposition, and thermal evaporation. However, challenges exist in reducing the deposition time and cost while producing lithium foil on a large scale, all of which are rooted in lithium’s low melting point of 181 °C and high vapor pressure at low temperatures (10–4 Torr at 407 °C). Besides these three methods, Livent’s LIOVIX or SLMP offers a flowable, stabilized lithium composition mixed with binders and solvents. This enables the direct printing of lithium layers onto current collectors with precise, controlled loading. Another recently reported method, tape casting of molten lithium, involves spreading molten lithium onto a substrate using a doctor blade system, forming thin films (5–50 μm) as the metal cools. Under a processing temperature of 275 °C, the formation of the lithiophilic Li alloys layer enables the self-wettability toward the molten Li, allowing for the fabrication of ultrathin Li films.

2.8. Sulfur and Sulfides for Next-Generation Lithium Batteries

Sulfur materials, in the form of elemental S8, small-molecule S x (x < 4), or sulfurized polyacrylonitrile (SPAN), are promising candidates for transition-metal-free cathodes. − When coupled with a lithium metal anode to form a Li-S battery, this technology can theoretically deliver a gravimetric energy density of 2500 Wh kg–1 at the material level, with demonstrated practical cell-level energy exceeding 500 Wh kg–1. Additionally, sulfur is an earth-abundant element and is readily available as a massive byproduct of the petroleum/natural gas industries. Another advantage of sulfur compared to transition-metal-oxide cathodes is its ease of recycling via direct sublimation, which is both energy efficient and cost efficient.

Despite these advantages, manufacturing Li-S batteries that meet performance metrics for practical use still faces significant obstacles, including limited cycle life, low rate-capability, severe self-discharge, and potential safety concerns. A significant gap still exists between materials discovery and cell performance improvement. Nanosized and highly porous host materials have been widely adopted to enhance sulfur utilization in sulfur cathodes. Some of the host materials are very expensive, sacrificing the cost advantages of sulfur itself. More importantly, those highly porous hosts bring additional practical challenges for manufacturing high areal capacity electrodes (>5 mAh cm–2), as they need a large excess of inactive binders to “glue” the nanoparticles. A detailed cost analysis of Li-S battery technology including the processing cost will be very helpful.

All-solid-state batteries (ASSLBs) employing high-energy cathodes and metallic Li anodes have a good potential to enable high-energy Li metal batteries with enhanced safety attributes. Some inorganic solid-state electrolytes (SSEs) possess high Li+ transference number (∼1.0), low activation energy (<0.3 eV), and conductivities even higher than those of conventional organic liquid electrolytes. Although oxides are intrinsically more stable than sulfides, sulfide-based SSEs (S-SSEs) are arguably more viable for bulk-type ASSLBs. This stems from sulfides’ low material density, low elastic modulus, and high ionic conductivity, which allow its intimate contact with active materials and practical processability through slurry or dry processing. , Following the work on Li10GeP2S12 (LGPS), a series of sulfide-based compounds displaying extremely high ionic conductivities (>10–2 S/cm) have been developed. , By using surface-coated cathodes, stable cycling of LiCoO2 cells, high-power NMC cells, and high-energy NMC cells have been demonstrated in pouch cells, proving the viability of S-SSEs for high-performance ASSLBs. S-SSEs are also compatible with sulfur both chemically and electrochemically, making them feasible for S cathode fabrication without additional cathode coating. ,

Despite the advancement in SSEs, significant manufacturing challenges, including materials’ mositure sensitivity, Li/SSE interfacial stability, and scalable procesing of SSE films and electrodes, need to be addressed before the large-scale deployment of SSEs. , To reach a cell level energy of 500 Wh kg–1 in a 2 Ah pouch cell, the areal capacity of S cathodes needs to be greater than 8 mAh cm–2. Although S-SSEs allow Li metal cycling at certain current densities and areal capacities, stable Li cycling at capacities matching those of high-areal-capacity S cathodes is still beyond reach. This is why long cycling of high-areal-capacity cathodes usually requires the use of indium as the interface for Li metal anodes to mitigate the interfacial problems, which unfortunately sacrifices cell energy due to the heavy material (In: 7.3 g/cm3) and its high working voltage (0.6 V vs Li). Comprehensive strategies built on innovations in material development, interfacial engineering, chemo-mechanical management, and applicable processing are essential to overcome the barriers with Li faced by manufacturing practical ASSLBs.

Another significant challenge in manufacturing ASSLBs is developing feasible processing technologies for the scalable and efficient fabrication of ultrathin SSE separators, high-energy electrodes, and full cells. , Currently, most ASSBs are evaluated at lab scale using binder-free electrolyte pellets, which are very thick (>100 μm) to ensure appropriate mechanical strength. This method is impractical due to poor processability and a significant sacrifice in cell level energy, in addition to the cost concern. Employing innovative manufacturing techniques to fabricate thinner, yet robust, SSE membranes will help address this challenge. The wet slurry coating process, a well-established scalable approach in LIB manufacturing, requires a small amount of polymeric binder and sufficient solvents to form a uniform slurry. However, a chemically compatible solvent and polymeric binder are necessary to minimize the side effects from processing SSEs. Considering sulfides’ moisture sensitivity and chemical instability, dry processing is usually preferred. This method has been adopted in commercial supercapacitors but is not widely used in the fabrication of ASSBs, particularly with S-SSEs. Without solvent, homogenizing the distribution of SSE powders and polymeric binder particles is very challenging when aiming to achieve a high-quality freestanding film with a very lean amount of binder (<1 wt%). Through fibrillation of polytetrafluoroethylene (PTFE), sufficient binding for high-mass-loading electrode fabrication can be achieved with a very small amount of binder. However, the PTFE fibers in the processed SSE separator easily react with Li metal chemically, propagate through the separator, and short the cell. Therefore, compatible binder materials, feasible processing technologies, and dedicated equipment are required to enable the scalable manufacturing of ASSLBs.

2.9. Copper and Aluminum Processing: From Electrowinning to Recycling

Current collectors are pathways for conducting electrons but are inactive components, which means their weight needs to be reduced as much as possible without sacrificing their mechanical and electric properties in order to improve cell-level energy. Today’s lithium batteries use copper and aluminum as the current collectors for anodes and cathode, respectivelysodium batteries can use aluminum for both electrodes because aluminum does not form an alloy with sodium at the same electrochemical potentials driving Na+ ions to go into or come out of hard carbon structures. Because copper (density of 8.94 g cm–3) is much heavier than aluminum (density of 2.7 g cm–3), decreasing the thickness/weight of copper current collectors is very effective for improving cell energy. In addition, copper is more expensive than aluminum; thus, the following discussion will focus on copper mining and processing.

Mining of copper is complicated because the ore usually contains less than 1% of copper. Depending on the types of ore, copper oxides or copper sulfides, different extraction methods are utilized to yield 99.99% pure copper. Copper oxides are more abundant in the ore, but they have a lower concentration of copper. Copper sulfide ores contain more copper but are less abundant. Copper processing operations consume a huge amount of water and are very energy-intensive in the mining industry.

A hydrometallurgical leaching process is usually used to extract copper from copper oxide ores. Water-based solutions are used to extract and purify copper from oxide ores at ordinary temperatures. As shown in Figure , the process goes through three steps: heap leaching, solvent extraction, and electrowinning. Heap leaching is generally used for low-grade ores like copper oxide by utilizing percolating chemicals such as sulfuric acid to leach out metals. Sulfuric acid is sprayed through sprinklers on top of a heap pile built by crushed ores on a slight slope. The acid diffuses through the heap and dissolves the copper from the ore. The resulting solution consists of sulfuric acid and copper sulfate. The copper in the leaching solution is further concentrated by solvent extraction. Two immiscible liquids (leaching solution and another solvent) are mixed vigorously and allowed to separate, with different minerals left in each liquid. The copper sulfate moves from one liquid to the other solvent due to different solubilities, leaving impurities in the original leaching solution, which will be further recycled to extract more copper out. Electrowinning is then applied to electrochemically plate copper metal out of copper sulfate solutions. An inert electrode is usually used as the counter electrode in the electrowinning process. Common materials include lead alloy and titanium plates coated with RuO2, IrO2, or PbO2. Oxygen is generated on the inert electrode side during the electrowinning process. , The presence of iron impurities such as Fe2+ will be oxidized on the anode side, forming Fe3+, which then goes back to the cathode and gets reduced back to Fe2+, forming a shuttle and thus lowering the efficiency of cooper plating. Pb/Sb alloy is therefore used to retard the reoxidation process from Fe2+ to Fe3+. ,

5.

Manufacturing processes to convert different copper ores into pure copper.

Sulfide ores are usually processed using the pyrometallurgy method. Heat and intense energy are used to extract and purify copper from the sulfide ores. Four steps are involved, as presented in Figure : froth flotation, thickening, smelting, and electrolysis. Sulfide ores are processed repeatedly into fine sands before liquid is added to form slurries. Copper minerals are separated from rocks through a froth flotation process. Chemical reagents are then added to the slurry, which bind to the copper particles, making them hydrophobic. Copper-rich particles, created by blowing air into the slurry, rise to the top. The froth is skimmed off for thickening, which allows the solids from bubbles to sink to the bottom of a large tank called a thickener. After filtering, the concentrated copper is ready for smelting at up to 2300 °F, leading to the formation of molten liquids. The heated liquid goes through a slag-settling process. This step separates the matte and slag from the molten liquids. The matte is a mixture of copper, sulfur, and iron, while the slag is a dense and glassy material composed of iron, silica, and other impurities. About 0.3–6% copper is also trapped in the slag. The flotation method is usually applied to recover metallic copper resources from the copper slag in industrial use. Iron and sulfur in the molten matte then burn off, concentrating the copper content to 98%. After further smelting to burn off oxygen, the molten copper now has 99% purity and is next refined through electrorefining to electrochemically dissolve copper from a less pure copper anode (99% copper purity) and redeposit it on the cathode side, which has 99.99% purity of copper.

When copper or aluminum foils are too thin, it becomes challenging to handle and coat active materials, because of mechanical issues. So, the challenge is to manufacture ultrathin metal foil (a few microns) that is still sufficiently durable for battery use. The tabbing areas of those ultrathin current collectors also raise challenges of increased resistance and heat generation. Copper foils used for Li batteries are often manufactured by rolling or electrodeposition. Rolled Cu foils provide a double-sided smooth surface but may be too expensive for batteries. Electroplated Cu is much cheaper, and more importantly, it has higher surface roughness, which benefits electrode coating. Besides making copper/aluminum foil thinner and thinner, other approaches include metal mesh current collectors, perforated current collectors, and composite current collectors. An additional advantage of perforated current collectors is that spikes are left on both sides of the perforated metal foils to help integrate electrodes on the two sides together. The integrated structures enabled by perforated metal current collectors also provide the benefit of extending the electron conduction “highway” inside the entire electrode. Composite current collectors are prepared by coating super thin Cu layers (a few hundreds of nm) on both sides of a thin polymer film, e.g., polyimide. As the current collectors become thinner and thinner, the tabbing area needs appropriate design not only for proper welding of thin tabs together but also for managing heat due to resistance increases of each thin tab.

The production of aluminum and copper metals is highly carbon-intensive: about 12 tonnes of CO2 equivalents (CO2e) per tonne of aluminum and 6 tonnes of CO2e per tonne of copper. A more sustainable way to obtain such metals is urgently needed. Today’s aluminum production involves high-temperature electrolysis, also known as the Hall–Héroult process, which consumes a significant amount of electricity (over 14 MWh per tonne of aluminum)using renewable electricity can reduce a large portion of CO2 emission. The high-temperature electrolysis process itself is very emission-intensive because the carbon anode used in the electrolysis cells reacts with oxygen and electrolytes to form CO2 and perfluorocarbons which have global warming potential (GWP) a few thousand times as strong as CO2the amount of CO2e released annually during the high-temperature electrolysis process for global aluminum production is more than the total combined annual CO2e release from all the four states in the U.S. Pacific Northwest region (WA, OR, ID, MT). Research to replace consumable carbon anodes with inert oxygen evolution electrodes is ongoing, but significant effort is still needed to move the technology into the market.

Aluminum and copper can be recycled repeatedly without losing performance; they have an infinite recyclable life, and their common recycling is much less carbon intensive. Recycling copper and aluminum from batteries is still at an early stage before commercialization but is attracting significant attention. Copper and aluminum recycled from other sources are often coated with insulation or mixed-metal alloy scraps. For battery current collector applications, upcycling of these mixed-metal alloy scraps to pure metal is needed but challenging. For example, only two industrialized technologies in use are capable of refining aluminum: the Hoopes process and the segregation method, which are limited by either purity, long upcycling duration, or waste of aluminum recourse. New processes capable of upcycling aluminum and copper for battery current collector applications are needed.

3. Science and Engineering in Battery Materials Manufacturing

3.1. Cost-Oriented Fundamental Research

Not only is understanding cost components important for battery manufacturing, but it also provides new insights for scientists and engineers to identify the key directions to support industry in lowering production costs. In general, materials costs account for 60–80% of the total cost, while manufacturing costs are about 20–40% that of conventional LIBs. To reduce the manufacturing cost of batteries, both materials and processing need to be cost efficient. A completely different mindset is necessary to revisit science and engineering solutions behind the pressing challenges that industry faces, which are all related to cost reduction.

3.1.1. Processing Lithium Metal for Rechargeable Lithium Metal Batteries

Lithium metal has been used in primary batteries such as lithium carbon fluoride (Li/CF x ) and lithium thionyl chloride (Li/SOCl2) batteries, which have been commercialized for years. For example, Li/CF x batteries have high energy density and long storage life, making them good for military, sensor, and space applications. For Li/SOCl2 batteries, the electrolyte is based on sulfonated thionyl, which also serves as the cathode. Li/SOCl2 batteries work at both very low and high temperatures with excellent durability, making their usage broad, especially for industrial applications and defense.

In recent years, rechargeable lithium metal batteries have also received much attention. Good progress has been demonstrated in both energy density and cycling stability. The safety of rechargeable lithium metal batteries has not been fully investigated yet, but one of the major root causes of lithium metal battery safety is the pulverization of lithium metal after extensive cycling, which also impacts the cycle stability. This means that if lithium pulverization can be mitigated or eventually eliminated in rechargeable lithium metal batteries, safety and cycling will both be improved. Although challenging, it is worthy of more effort to fully understand the stripping and electroplating process through dedicated fundamental research which needs to be conducted at testing conditions relevant to practical cells.

In lithium metal batteries, the lithium anode mainly exists in the form of a foil. Lithium metal foils are derived from lithium ingots through either an extrusion process or vapor-based deposition. Depending on the technology used, lithium foils with different thicknesses can be processed either for prelithiation of the silicon anode or as a lithium metal anode directly. As discussed earlier, lithium metal thicker than 50 μm is relatively convenient to produce and has been used in rechargeable lithium metal batteries. Lithium metal thinner than 50 μm is more challenging to manufacture, considering thickness homogeneity at an enlarged scale, control of defective sites, and surface roughness. Innovations are needed to develop cost-efficient processing technologies to produce thin lithium metal foils.

For free-standing lithium foils, a special substrate is needed to support sticky lithium metal which needs to be detached conveniently to release it. For lithium foil attached to copper current collectors, a protective film is still needed to cover the surface of the lithium metal. If the protective film can directly serve as the separator or even the solid-state membrane to be used in solid-state batteries, the add-on value brought by this functional protective layer will be nontrivial compared to the use of pure lithium metal foil itself. Lithium metal alloys have been investigated and compared with pure lithium metal in terms of their reversibility and dendrite formation. Because the solid-state electrolyte interphase layers still form and are being accumulated within the alloys, the cycling improvement by using different alloys is limited, if any. A different look at lithium metal alloys from the tensile stress and surface stickiness points of view may bring some new insights toward reducing the manufacturing cost of thin lithium metal or alloy foils.

Lithium ingots are derived from a lithium salt such as lithium chloride (LiCl) through molten salt electrolysis (Figure a), which is still the only commercialized production approach for lithium metal. LiCl is usually converted from Li2CO3 by using a chlorinating agent such as hydrogen chloride. Thus, lithium metal is intrinsically extracted from hard rocks or brines, which are the sources for producing Li2CO3, as we discussed earlier. The electrolysis process to produce lithium metal is quite straightforward. The cathode used is a steel on which liquid lithium will be electroplated (Figure a). A graphite electrode is employed as the anode on which the chlorine gas evolves. The overall electrochemical reaction is shown in Figure a. The electrolyte used in the electrolysis is a mixture of LiCl and KCl. The former participates in the electrochemical reactions on both electrodes, while the latter is a supporting electrolyte. One can imagine that this process is energy and capital intensive. The generation of chlorine gas also poses environmental concerns. A concept of carbonate-to-metal lithium has been proposed to convert lithium directly from lithium carbonate, thus removing the harmful chlorine gas in the process. Directly reprocessing lithium metal scraps into ingots has seen some success, although it may still need some time to understand whether lithium scraps from different suppliers will produce the consistent quality and purity needed for battery applications. The manufacturing cost of those new innovative technologies needs to be compared to that of the state-of-the-art electrowinning process.

3.1.2. Low-Cost Processing of Phosphate Cathode (LiFePO4/LiFe x Mn y PO4/LiMnPO4)

Solid-state synthesis of LiFePO4, LiMnPO4, or their mixed solutions is still the mainstream approach. However, the solid-state method usually lacks good control over particle morphology, especially at the primary particle scale. Therefore, the solid-state method, when used in practical production, usually requires repeated mechanical grinding and high-temperature processing. These tedious processes improve the final product quality but also increase energy consumption during production. There is ample room for new innovations in solid-state manufacturing. Technologies that can decrease the manufacturing temperature and duration will further decrease the cost of these materials and improve the environmental friendliness of the production. Solution-based methods, such as sol–gel, coprecipitation, and hydro-/solvothermal techniques, may seem appealing, as they could offer better morphological control. However, liquid waste management could be a challenge and often does not meet the “green chemistry” principles.

Further, during LFP synthesis, many impurities readily form, such as Li3PO4 and Li4P2O. FeP, Fe2P, and Fe3P are also found as impurities which develop under the reducing environment and high temperatures. In addition, oxygen leakage during high-temperature synthesis also leads to the formation of Fe2O3, while Li deficiency promotes the impurity of Li3Fe2(PO4)3. The roles of some impurities are still arguable. For example, Fe2P is reported to improve the electronic conductivity, while others believe that Fe2P formation needs to be suppressed as an impurity in the LFP product. Similarly, Li3PO4 and Li4P2O7 are also claimed to improve the rate capabilities of LFP, although they will impact the stoichiometry and thus usable capacity of LFP. These inconsistent observations highlight the importance of reassessing cathode materials in a battery system by designing specific full-cell protocols to ensure the electrochemical performance of the entire electrochemical cell is dominantly controlled by the cathode and cathode–electrolyte interphase (CEI) instead of the SEI or other limiting steps. Innovations are needed to realize impurity control of LFP with reproducible performance without increasing the manufacturing cost.

The chemical space of olivine cathodes has been well established. The design principles for olivine cathode active materials and electrode formulations have been well developed. Olivine cathodes are compatible with different cell formats, including prismatic, blade, and cylindrical battery types. BYD’s balde battery also provides a new direction for enhancing the utilization of cell space through structural design at the module level to increase the energy density of LFP-based chemistry. Due to the competition and significant lithium salts dropping, the cost of olivine cathode-based batteries has approached a new low in the past year, falling below $100/kWh in 2023. Although the prediction for the market share of different cathode materials could fluctuate, the use of olivine cathodes is likely going to increase, especially when high energy density is not a priority, such as electric buses and commuter vehicles. Reports have suggested that the overall carbon footprint of olivine-based batteries is lower than that of NMC-based ones. Further advancements in low-carbon manufacturing technologies, coupled with the adoption of renewable energy in production regions, could amplify the environmental benefits of these batteries. In the next decade, olivine-based lithium-ion batteries are likely to face some competition from sodium-ion batteries, although it is not clear which chemistry is safer due to the lack of “apples-to-apples” comparisons for safety testing. Continued innovation in olivine technologies from materials to electrode and cell levels remains crucial for maintaining their competitive edge.

3.1.3. NMC Synthesis and Scaleup

The dominant approach for NMC synthesis is the coprecipitation method, during which transition metal cations such as Ni2+, Mn2+, and Co2+ in their sulfate solutions are precipitated out into transition metal hydroxide precursors, followed by multiple steps of heating, washing, and annealing to obtain the final products. The coprecipitation method has been successfully adopted by industry in producing tons of NMC cathodes such as LiNi1/3Mn1/3Co1/3O2 (NMC111), LiNi0.4Mn0.4Co0.2O2 (NMC442), LiNi0.5Mn0.3Co0.2O2 (NMC532), and LiNi0.6Mn0.4Co0.4O2 (NMC622).

Although the coprecipitation method is a mature manufacturing process for NMC synthesis, there are still spots for scientists and engineers to work on to further reduce the production cost and impact on the environment. For example, a huge amount of wastewater is generated during the coprecipitation step. Although the wastewater can be recycled and reused, the ideal situation would be to minimize or eventually eliminate wastewater generation. In addition, LiOH·H2O and LiOH are usually preferred as the salt precursors due to their low melting points compared to Li2CO3, especially for high-nickel NMC synthesis. However, a huge amount of corrosive water is generated during large-scale production, which becomes a key challenge in cathode manufacturing.

In addition to conventional polycrystal NMCs, single-crystal NMCs have been broadly investigated in the past few years. Especially for nickel-rich NMCs, challenges such as cracking, moisture sensitivity, and gassing plague their large-scale use in batteries, but all originate from phase boundaries. Single crystals without any grain boundaries are believed to at least mitigate those problems associated with nickel-rich NMCs. However, single-crystal synthesis is more expensive than that of polycrystals, considering the reaction media and calcination time at high temperatures needed for single-crystal growth. A recent work utilizing Li2O instead of conventional LiOH as the salt precursor provides a new direction for single-crystal NMC synthesis by taking advantage of an interesting sublimation phenomenon of Li2O. The self-generated Li2O vapor from sublimation quickly diffuses and comes in contact with the surfaces of all other precursor particles, which leads to the rapid sintering of single-crystal NMCs. More innovations are needed for lithium salts to address manufacturing challenges and eventually reduce the cost of NMC production.

For the reasons discussed above, all-dry synthesis of NMCs , is now being revisited with an intention to simplify the manufacturing process. Transition metal oxides are directly mixed with Li2CO3 followed by calcination. All-dry synthesis is not new and has been used for LiCoO2 production and high-voltage spinel. However, LiCoO2 has only one transition metal, Co, in the structure, while NMCs have three transition metals that need to be mixed homogeneously at the atomic level to ensure the structure stability and capacity from the mixed layered oxides, which is why coprecipitation is employed to prepare NMC precursors. In addition, all-dry synthesis may pose a challenge for impurity control due to contamination from milling media, and it can damage the material structure or its interface upon cycling. Nevertheless, if the milling energy and media can be well controlled, the direct solid-state synthesis will provide a new direction for scaling up NMCs; a detailed cost analysis is still necessary because transition metal oxides used in all-dry synthesis are also derived from sulfates by heating or other processes that introduce additional steps in the entire manufacturing process. Alternatively, NMC622, with medium Ni, content is also being revisited to enhance its stability at high voltages (>4.2 V vs graphite) to extract high energy similar to that of NMC811 but without all the problems that NMC811 currently has, which will need a deep understanding of both lattice structure stability and CEI properties at elevated voltages.

3.1.4. Impurity Control