Abstract

Expanding the diversity of substrate materials for the growth of single-crystalline films enables the heterointegration of electronic and optoelectronic devices in modern semiconductor industry. However, the substrate materials are restricted to those having matched single-crystalline lattices with the epilayers, thereby making the use of non-single-crystalline substrates infeasible. Here, we report an epitaxy strategy for the wafer-scale growth of high-quality single-crystalline gallium nitride (GaN) on an amorphous silicon dioxide (SiO2) substrate. We achieve this result through a chemical bond transition, converting multilayer molybdenum disulfide (MoS2) to molybdenum nitride (MoN), which serves as a buffer layer to engineer a preferred orientation for the epitaxy of the overlying GaN film. Using this method, we also demonstrate the growth of an AlGaN/AlN/GaN heterostructure with high electron mobility exceeding 2000 square centimeters per volt per second. The resultant high-electron-mobility transistors exhibit subthreshold swing, on/off ratio, and threshold voltage comparable to those commercial devices.

Wafer-scale epitaxy of single-crystalline III-nitride semiconductors on amorphous SiO2/Si(100) substrates.

INTRODUCTION

Epitaxy has long been recognized as a key technique in the development of advanced semiconductor devices over the past several decades (1–3). The fundamental principle of epitaxy requires substrates to establish a specific single-crystalline epitaxial relationship, thus limiting the selection of substrates. Homoepitaxy, which involves growing films on a substrate of the same material, marked the beginning of epitaxy technology and laid the foundation for the Si industry. In contrast, heteroepitaxy enables the growth of single-crystalline films on substrates of dissimilar materials, paving the way for the significant achievements of compound semiconductors (such as GaAs and GaN) in optoelectronic and high-power/high-frequency applications (4–7). The evolution from homoepitaxy to heteroepitaxy effectively expands the categories of substrate materials that are conducive to the growth of high-quality single-crystal films.

To further overcome the substrate limitations, two emerging epitaxy techniques, termed as remote epitaxy and van der Waals (vdW) epitaxy, have been recently proposed. These techniques use two-dimensional (2D) materials as a unique buffer layer (8–10). Remote epitaxy can grow single-crystalline films seeded by the underlying host substrate through 2D materials (usually one to two layers of graphene) (5, 11–13). It allows the epitaxial films to be easily released from the substrate, benefiting the reuse of the expensive single-crystalline substrates and facilitating the heterointegration with other materials via layer transfer. However, similar to conventional homo- or heteroepitaxy, remote epitaxy still requires the use of single-crystalline substrates.

In contrast, vdW epitaxy redefines the epitaxial relationship through the use of a 2D material buffer layer, which, in principle, enables the growth of single-crystalline films on arbitrary substrates. A variety of 2D materials, such as graphene (14–16), hexagonal boron nitride (h-BN) (17, 18), or transition-metal dichalcogenides (19, 20), have been explored for vdW epitaxy of III-V compound semiconductors, providing aligned orientations for both out-of-plane and in-plane directions. However, the vdW force is insufficient to ensure consistent alignment of epitaxial orientations across all nucleation grains, leading to the formation of numerous grain boundaries and a high density of defects (13). Thus far, achieving high-quality epitaxial films that are suitable for practical devices on non-single-crystalline substrates remains a critical challenge.

RESULTS AND DISCUSSION

Epitaxial strategy for engineering the in-plane orientation

In this work, we propose to convert multilayer MoS2 to ultrathin MoN layer as a 2D buffer for the epitaxy of GaN on an amorphous substrate (Fig. 1, A and B). The conversion process is accompanied by a transition of chemical bonds, specifically from vdW bonds to covalent bonds. This transition can form strong dangling bonds on the surface, similar to those found on traditional single-crystalline substrates (21). As a result, the nucleation grains on the MoN buffer in Fig. 1B exhibit a well-aligned in-plane orientation, which contributes to the subsequent epitaxial growth of high-quality single-crystalline GaN on the amorphous substrate.

Fig. 1. Comparison of MoN and other buffers for the epitaxial growth of AlN.

(A and B) Schematic diagram of the nucleation and epitaxy of III-nitrides on an amorphous SiO2 with MoS2 (A) and MoN (B) buffers. The blue dashed arrows with arbitrary orientations and the solid arrows with consistent orientation represent the random and unidirectional in-plane orientation of the nuclei, respectively. (C) Binding energies of N-polar AlN on MoN, MoS2, graphene (Gra), and h-BN under a fixed number of AlN units. (D and E) Distributions of charge density difference in AlN/MoS2 and AlN/MoN heterostructures (red, positive; green, negative). The isosurface level is 0.006 e bohr−3. (F) Total energy difference versus in-plane orientation angles from 0° to 120° with 15° increments for the AlN cluster on MoS2 and MoN buffers. The AlN cluster at an in-plane orientation of 0° is used as a reference. (G and H) Out-of-plane (top) and in-plane (bottom) EBSD IPF maps of GaN grown on MoS2 (G) and MoN (H) buffers.

Here, we choose sputtered AlN as the initial nucleation layer on the MoN buffer. We performed density functional theory (DFT) calculations to study the interaction between the deposited atoms (Al atoms and N atoms) and the buffer layers (see Methods for details; fig. S1). Our DFT calculations point out that Al atoms are initially absorbed on the surface of the buffer layer. Then, two potential absorption sites were taken into consideration for the subsequently deposited N atoms: the hollow site or the top site of Al sublattice (fig. S1). The two sites are associated with the two distinct polarities in the hexagonal crystal structure, namely, N-polar and Al-polar configurations. For the N-polar configuration (N atoms at the hollow sites of Al sublattice), the calculated total energy is −90.37 eV, whereas for the Al-polar configuration (N atoms at the top sites of Al sublattice), the calculated total energy is −87.38 eV. The larger absolute total energy of the N-polar configuration compared to the Al-polar configuration indicates that the AlN nucleation prefers to form a N-polar hexagonal lattice structure on the MoN buffer layer. Therefore, the N-polar hexagonal lattice structure was used for the DFT calculations concerning AlN nucleation on the other 2D vdW buffers (MoS2, graphene, and h-BN).

First, we considered the MoS2 buffer layer to evaluate the impact of our proposed buffer conversion process on AlN nucleation. We calculated the binding energy of N-polar AlN on both the MoN and MoS2 buffers, along with other typical 2D vdW buffers such as graphene and h-BN for comparison (Fig. 1C). Significantly, the epitaxy of N-polar AlN on the MoN buffer exhibits much higher binding energy than those on the 2D vdW buffers of MoS2, h-BN, and graphene. In addition, the interface distance between N-polar AlN and MoN is estimated to be 1.86 Å, less than those in the other buffer cases (fig. S2A). The higher binding energy together with the shorter interface distance indicates that a stronger interfacial interaction is formed between AlN and MoN, which is clarified as the covalent bonding, as we expect in Fig. 1B.

Furthermore, the interfacial interactions between N-polar AlN nucleation and both the MoS2 and MoN buffer layer are visualized by means of the 3D distributions of charge density difference (Fig. 1, D and E). Obviously, the charge density redistribution mainly occurs around the interface of AlN/MoS2 heterostructure. Little variation in charge density is observed on the topmost surface of S atoms and Mo atoms. Bader charge analysis of Fig. 1D reveals that the interfacial Al atom has an additional charge of 0.041 e more than that of bulk Al atoms (fig. S2B). Thus, charge accumulation occurs on the bottom of the Al atoms, implying an electrostatic interaction between AlN and MoS2. This situation is identical for other 2D material buffer layers, such as graphene and h-BN (fig. S2, C and D). In the AlN/MoN heterostructure, the charge density redistribution occurs not only at the interfacial region but also at the Mo atomic layer beneath the surface. The Bader charge analysis applied to Fig. 1E reveals that the interfacial Al atom loses only 0.003 e compared to the charge of bulk Al atoms, which is an order of magnitude smaller than the charge difference observed in the AlN/MoS2 interface. The smaller charge difference in electrons of Al atoms in Fig. 1E suggests that a covalent bond as strong as bulk AlN is formed between AlN and MoN, consistent with the results of the binding energy discussed above.

To verify the engineering of the in-plane epitaxial orientation, we conducted DFT calculations to determine the total energy of N-polar AlN on MoN or MoS2 at different in-plane rotation angles from 0° to 120° (Fig. 1F and fig. S3). On MoS2, the configurations at 0° (or equivalently 120° due to the rotational symmetry inherent in the hexagonal lattice structure), 15°, and 105° exhibit similar minimal total energy values (energy difference is less than 4 meV/unit cell). This implies that the AlN nuclei are possibly formed within the range of these specific in-plane orientation angles on the MoS2 buffer. Thus, we inferred that the epitaxial N-polar AlN on MoS2 is very likely to present an in-plane misorientation. In the case of N-polar AlN on MoN, we observed a single minimum energy at the 0° (or equivalently 120°) configuration. The energy barrier, which is defined as the maximum total energy difference at all rotational angles, is calculated as 169 meV/unit cell, almost 2.7 times higher than that of N-polar AlN on MoS2. These findings suggest that the MoN buffer layer has the potential to facilitate a well-aligned in-plane orientation for the epitaxial growth of N-polar AlN.

To examine the above epitaxial strategy, we used MoN or MoS2 as a buffer layer to grow GaN films on the amorphous SiO2 substrate. The AlN thin layer was initially deposited as the nucleation layer on the buffer (see Methods for details). The electron backscatter diffraction (EBSD) inverse pole figure (IPF) map was used to identify domains with unique crystalline orientations in the GaN epilayer. When using the MoS2 buffer, we found that most GaN domains exhibit a [0001] out-of-plane orientation, as indicated by the red color in the IPF color triangle (Fig. 1G). However, the in-plane orientations were diverse in these GaN domains, distinguished by a range of colors from blue to green in the EBSD IPF map. The in-plane misorientation suggests the polycrystalline nature of the GaN epilayer grown on MoS2, as predicted by the DFT calculation above. In contrast, a single color was observed in the out-of-plane (c-axis) and in-plane EBSD IPF maps of the GaN epilayer grown on the MoN buffer layer (Fig. 1H). This observation indicates the single crystallinity of the GaN film with no azimuthal intermixing in both the out-of-plane and in-plane orientations. Consequently, our epitaxial strategy involving the conversion of MoS2 to MoN as the buffer layer could work well for the epitaxy of single-crystalline GaN on an amorphous substrate.

Nucleation of AlN on the MoN buffer

Because MoN outperforms MoS2 in the epitaxy of single-crystalline GaN, we prepared a MoN buffer on the 2-inch amorphous SiO2 substrate (fig. S4A). Generally, directly growing single-crystalline MoN on an amorphous substrate is challenging. Thus, we chose to transfer multilayer MoS2 onto an amorphous substrate and converted them to MoN by nitridation (see Methods for details). The surface morphology was inspected after each fabrication step. The transferred MoS2 and converted MoN exhibited a uniform and flat surface without obvious wrinkling or cracks over the entire 2-inch wafer scale (fig. S4, B and C). The macroscopic crystalline orientations of the MoS2 and MoN films were determined by x-ray diffraction (XRD) measurements. The 2-theta/omega scans in Fig. 2 (A and B) confirm that the MoS2 and MoN films have an out-of-plane crystalline orientation only along the [0001] direction; and the inset phi-scan figures, showing six diffraction peaks, confirm the sixfold rotation symmetry of the in-plane crystalline orientation for the MoS2 and MoN films. Thus, we demonstrated that the MoN buffer inherits the hexagonal lattice architecture of the MoS2 layers (Fig. 2, A and B) (22). In addition, the thickness of the MoN buffer was measured as 6.6 nm, which is approximately half the thickness of the MoS2 films (fig. S5). The reduction in thickness confirms the conversion from vdW bonds in MoS2 to covalent bonds in MoN, a process we term “chemical bond transition.”

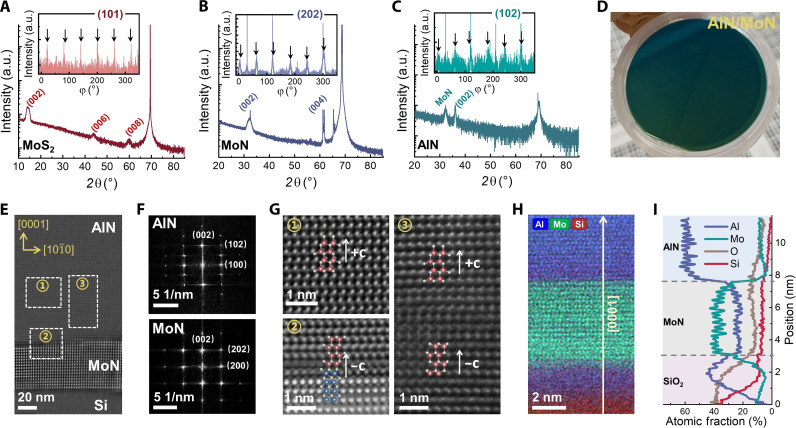

Fig. 2. Epitaxial relationships between the MoN buffer and AlN nucleation layer.

(A to C) 2-Theta/omega scans of the MoS2 (A), MoN (B), and AlN (C). Insets show the corresponding in-plane XRD phi scans at MoS2 (101), MoN (202), and AlN (102) planes. a.u., arbitrary units. (D) Photograph of the AlN/MoN template on a 2-inch SiO2 substrate. (E) Cross-sectional HAADF-STEM image of the AlN/MoN interface. (F) FFT images of AlN and MoN obtained from (E). (G) iDPC-STEM images of the regions marked by dashed boxes in (E). (H) Atomically resolved EDX elemental map for Al, Mo, and Si at the AlN/MoN/SiO2 heterointerfaces. (I) Atomically resolved EDX spectra for Al, Mo, O, and Si along the [0001] direction marked in (H).

Then, we deposited a 30-nm–thick AlN film as a nucleation layer on the MoN buffer by reactive sputtering, which is a common process to assist the uniform nucleation when growing GaN on traditional sapphire or Si(111) substrates (23). Similarly, we performed XRD to characterize the crystalline orientation of the AlN nuclei. A single (002) diffraction peak in the 2-theta/omega scan and six (102) diffraction peaks in the phi scan were observed in Fig. 2C, demonstrating the dominant hexagonal lattice feature of the AlN nuclei. Furthermore, when referenced against the diffraction peaks from the Si(100) substrate, the relative locations of the six diffraction peaks in the phi scans of both MoN and AlN were found to be identical (Fig. 2, B and C). Therefore, we concluded that the in-plane hexagonal lattice of the AlN nucleation layer exhibits no rotation relative to that of the MoN buffer. Figure 2D shows a photo of the 2-inch AlN/MoN template with uniform surface. However, we could observe small grains on the surface of the as-deposited AlN due to insufficient binding energy during the sputtering (fig. S6A). These grains could grow larger and become uniformly distributed across the entire thin film after a high-temperature (HT) annealing process in the metal-organic vapor phase epitaxy (MOVPE) chamber (fig. S6B), providing a better surface morphology for the subsequent epitaxial growth.

The atomic structure of the AlN nuclei and MoN buffer and their heteroepitaxial interface were further investigated by cross-sectional high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM). The STEM image in Fig. 2E shows an ordered atomic arrangement in the (110) plane of the AlN, with a sharp and uniform interface between AlN and MoN. The fast Fourier transform (FFT) images in Fig. 2F illustrate that the AlN (002) and (100) planes are parallel to the MoN (002) and (200) plane, respectively. These alignments match well with the relationships of the macroscopy crystalline orientations between AlN and MoN measured by XRD. Besides, we observed the coincidence of some diffraction spots in the FFT image from the AlN/MoN interface (fig. S7A), such as AlN (002) with MoN (002), AlN (102) with MoN (202), and AlN (100) with MoN (200). This coincidence suggests that these corresponding planes in AlN and MoN have a similar interplanar distance. We measured the Al and Mo atomic spacing along the [10 0] axis as 2.7 and 2.5 Å, respectively (fig. S7B). These values agree well with the theoretical values ( a/2 = 2.693 Å for AlN and a/4 = 2.505 Å for MoN). As a result, the in-plane lattice mismatch between AlN and MoN was calculated to be ~8%, smaller than that between AlN and sapphire or Si(111) substrates (24). The smaller lattice mismatch is an extra advantage of the 2D MoN buffer for the epitaxy of AlN and other III-nitride semiconductors.

Furthermore, we observed polarity inversion near the AlN/MoN interface from the integrated differential phase contrast (iDPC) STEM images (Fig. 2G). The overlying epitaxial atomic layers of AlN nuclei marked as Region 1 in Fig. 2E are identified as an Al-polar structure, whereas the initial epitaxial atomic layers of AlN nuclei marked as Region 2 in Fig. 2E are identified as a N-polar structure. This N-polar AlN structure initially grown on MoN matches well with the prediction by the prior DFT calculations. The polarity inversion was observed to have occurred in Region 3 of Fig. 2E, within a range of six atomic layers as shown in Fig. 2G. We attributed this polarity inversion to the presence of oxygen atoms, which might be diffused from the beneath SiO2 layer. Thus, we performed atomically resolved energy-dispersive x-ray spectroscopy (EDX) elemental mapping and spectra of the AlN/MoN/SiO2 heterostructure along the [0001] direction (Fig. 2, H and I). Approximately 15% of the oxygen fraction was measured at the MoN/AlN interface. These oxygen atoms are likely diffused to the AlN nuclei at HTs, leading to the polarity inversion during the growth of the AlN atomic layers (25, 26). Similarly, the Al atoms diffused through the MoN buffer in an opposite direction and accumulated at the MoN/SiO2 interface (Fig. 2H).

Epitaxy of single-crystalline GaN on the AlN/MoN template

After preparing the AlN/MoN template, we grew GaN films on this template by MOVPE and realized high-quality single-crystalline GaN on the 2-inch wafer (Fig. 3A). The epitaxial growth includes multistep growth procedures (see Methods for details). First, a thin layer of AlN was grown at HTs. This epitaxial AlN layer could further improve the crystal quality of the prior AlN nuclei. Then, we introduced a 3D island formation layer of GaN at an HT in Stranski-Krastanov growth mode. The sharp reduction of the in situ reflectivity reveals that the surface roughness of the epilayer was increased, indicating that 3D islands were formed during the growth (fig. S8A). Notably, the thickness of the GaN 3D island layer should be carefully controlled because it is crucial for the coalescence of GaN islands into a continuous film. Last, a 2D growth mode was used for the epitaxy of the overlying GaN film, in which most of the dislocations and defects could be eliminated. The recovered in situ reflectivity and its periodic fluctuation in fig. S8A suggest a transition of the growth mode from 3D to 2D and the formation of a flat GaN film, respectively.

Fig. 3. Characteristics of single-crystalline GaN on the amorphous SiO2 substrate.

(A) Photograph of the 2-inch GaN on the SiO2 substrate. (B) SEM image of GaN islands. The edges of GaN islands are outlined by the yellow hexagons. (C) In-plane EBSD map of GaN after 3D island growth. (D and E) SEM and AFM images of GaN by 2D growth mode. (F) XRD phi scan of the GaN (102) plane. The four peaks with higher intensity originate from the signals of the Si(100) substrate. (G) XRCs of the (002) and (102) peaks of the as-grown GaN. (H) Statistical bar graph of XRC (002) and (102) FWHM values across 15 experimental repetitions. (I) Benchmark of the FWMH values obtained in our GaN against those grown on polycrystalline or amorphous substrates reported in the literature. The hollow and solid symbols represent the XRC FWHM values of (002) and (102) plane, respectively. Poly, polycrystalline substrate. (J and K) Cross-sectional dark-field TEM images of the as-grown GaN with g = [0002] and g = [11 0] conditions, respectively.

To understand the evolution of the surface morphology, we interrupted the above epitaxial growth at each stage and took out the samples for examination (fig. S8, B to F). Hexagonal GaN islands in diverse sizes were clearly observed after the second step in 3D growth mode. The edges of these hexagonal islands were well aligned as we plotted in Fig. 3B, and a single color was observed in the in-plane EBSD IPF map of the GaN islands (Fig. 3C). These findings imply that the GaN islands distributed at different locations can maintain the same in-plane orientation, benefiting from the single-crystalline nature of the AlN/MoN templates. In addition, the continuous GaN film after the merging of islands exhibits a highly uniform and atomically flat surface with clear atomic step terraces (Fig. 3, D and E). The root mean square (RMS) roughness is measured as around 0.168 nm, comparable to GaN films grown on traditional substrates (27).

The XRD phi scan of the as-grown GaN film shows six (102) diffraction peaks with an interval of 60°, demonstrating its sixfold rotation symmetry and hexagonal lattice feature (Fig. 3F). To evaluate the crystal quality, the full width at half maximum (FWHM) of the (002) and (102) x-ray rocking curves (XRCs) was measured as 0.19° and 0.32°, respectively (Fig. 3G). These values are almost as low as those of GaN grown on traditional Si(111) substrates (28), suggesting high crystal quality of the GaN epilayer grown on our AlN/MoN template on the amorphous SiO2 substrate. Notably, we repeated 15 MOVPE runs of the same epitaxial growth procedure and achieved an average XRC (002) and (102) FWHM values of 0.23° and 0.38°, respectively (Fig. 3H). The similar values from run to run illustrate that such results are highly reproducible. We also benchmarked our FWHM values against previous results for nitride semiconductors grown on polycrystalline or amorphous substrates (Fig. 3I) (14–17, 19, 29–36). Obviously, we obtained the lowest values for both the XRC (002) and (102) FWHM. The (102) FWHM of our GaN films is even lower than the (002) FWHMs of other reported GaN films, illustrating super high quality compared to previous results.

The predominant threading dislocations (TDs) in our as-grown GaN epilayer are edge and mixed types, according to the dark-field cross-sectional TEM observation (Fig. 3, J and K). We noticed that most TDs are initially filtered by the AlN and 3D GaN island layers, subsequently being annihilated within the overlying GaN films. Therefore, we focused on dislocations within the top 3-μm GaN region (marked by the yellow square in Fig. 3K), which has an area of ~21.5 μm2. As a result, we obtained a total dislocation density of 2.2 × 108 cm−2. This comparable low TD density to that of traditional GaN films (37) demonstrates the high crystal quality of our GaN epilayers grown on the amorphous SiO2 substrate. Our AlN/MoN template was also capable of facilitating the epitaxy of single-crystalline GaN film on quartz, confirming the scalability of our strategy in the heteroepitaxy of nitrides on other non-single-crystalline substrates (fig. S9).

Demonstration of AlGaN/AlN/GaN HEMTs

The success of growing high-quality single-crystalline GaN films on amorphous SiO2 substrates motivated us to explore its potential for electronic devices, which has not yet been realized by direct epitaxial growth on these substrates. Before device fabrication, we first grew the AlGaN/AlN/GaN heterostructure on an amorphous SiO2 substrate (Fig. 4A). A 1-nm-thick layer of AlN was inserted between AlGaN and GaN to enhance the polarization field at the interface for the formation of high-density 2D electron gas (2DEG). The AlGaN/AlN/GaN heterostructure exhibits very sharp and clear interfaces with highly ordered atomic lattice arrangement. A standard temperature-dependent Hall measurement was used to evaluate the mobility and density of the 2DEG formed at the interface of the heterostructure (fig. S10). The electron density slightly increases from 7.7 × 1012 to 7.9 × 1012 cm−2 when the stage temperature decreased from 300 K [room temperature (RT)] to 5 K (Fig. 4B), due to the large strain in the AlGaN/AlN/GaN heterostructure (38). The same order of magnitude for the electron density at different temperatures also confirms the existence of the 2DEG in the heterostructure. Furthermore, we obtained a super high electron Hall mobility from 2240 to 13,355 cm2 V−1 s−1 when the stage temperature decreased from RT to 5 K. This significant increase in Hall mobility is attributed to the suppression of the phonon scattering at low temperatures. The super high mobility value of 2240 cm2 V−1 s−1 observed at RT surpasses that of most reported AlGaN/AlN/GaN heterostructures grown on traditional substrates (Fig. 4C) (28, 37, 39–48). The exceptionally high electron mobility arises from the low 2DEG density and the insertion of AlN in our heterostructure, which suppresses interface roughness scattering and alloy disorder scattering (49, 50). This marks the successful demonstration of such a high mobility of 2DEG in high-electron-mobility transistor (HEMT) heterostructures grown on an amorphous substrate.

Fig. 4. Performance of HEMTs on the amorphous SiO2 substrate.

(A) Cross-sectional HAADF-STEM images of the epitaxial HEMT structure on the amorphous SiO2. (B) Temperature-dependent electron density (n2d) and Hall mobility (μH) of the 2DEG in the AlGaN/AlN/GaN heterostructure. (C) Benchmark of 2DEG mobility. (D) Optical microscope image and the cross-sectional SEM image of the fabricated HEMT devices on the amorphous SiO2. (E) Transfer characteristics of a typical HEMT device under VDS = 0.1 and 10 V. (F) Output characteristics of the same device in (E). (G) Transfer curves of 200 HEMT devices at VDS = 10 V. (H to J) Statistics of SS, on-off ratio, and Vth of the corresponding devices in (G). VGS, gate-source voltage; IDS, drain-source current.

Last, we fabricated HEMT devices on this heterostructure to investigate its electrical properties (see Methods for details; Fig. 4D). The device channel length (L) and width (W) is designed as 16 and 50 μm, respectively. The cross-sectional scanning electron microscopy (SEM) image reveal the device structure at the source, drain, and gate region (Fig. 4D). Figure 4E shows the transfer characteristic of a typical HEMT device at the drain-source voltage (VDS) of 0.1 and 10 V. The threshold voltage (Vth) of the device is around −2.8 V (@IDS = 1 μA mm−1), presenting a typical behavior of the D-mode HEMTs. The subthreshold swing (SS) is calculated as 83 mV/dec, and the on/off ratio is obtained to be greater than 109. The output characteristic of the device exhibits a saturated on-state current (ION) (@VGS = 5 V) of ~182 mA mm−1 (Fig. 4F). These values have already approached the performance of standard D-mode HEMTs on traditional substrates (51). In addition, we measured the transfer curves of 200 HEMT devices to evaluate the uniformity of the fabricated HEMTs on the amorphous SiO2 substrate (Fig. 4G). The statistical plots of SS, on/off ratio, and Vth, derived from the transfer curves, are presented in Fig. 4 (H to J). The SS values range from 70 to 116 mV/dec with a coefficient of variation of 10.6% (defined as the ratio of the SD to the mean); the on/off ratios are primarily within the range of 108 to 1011, and the Vth values span from −3.7 to −2.7 V with a coefficient of variation of 8.8%. These results demonstrate the excellent consistency and reproducibility of the HEMT device performance on the amorphous SiO2 substrate.

In conclusion, we report the wafer-scale growth of unprecedentedly high-quality single-crystalline GaN films on amorphous SiO2 substrates by using a MoN 2D buffer, derived from a multilayer MoS2 vdW buffer through a chemical bond transition. The crystal quality of the epitaxial GaN films on amorphous substrates is comparable to that of GaN grown on conventional single-crystalline substrates. We also demonstrate the GaN-based HEMT device grown on such amorphous substrates, approaching the performance of commercially available devices. Our work provides a general strategy toward the epitaxial growth of single-crystalline III-nitride semiconductors on non-single-crystalline substrates, thereby breaking the long-standing limitation of using only crystalline substrates. We predict that this direct growth method will open up possibilities for the industrialization of 2D material buffers and for the heterointegration of III-V compound semiconductors on diverse platforms for integrated electronics and photonics.

MATERIALS AND METHODS

Formation of the MoN buffer layer on the amorphous SiO2 substrate

The precursor MoO2 was first grown on a precleaned c-plane sapphire substrate by pulsed laser deposition (PLD) (Neocera180) process using a 248-nm KrF laser with a repetition rate of 5 Hz. The high-quality epitaxial MoO2 film deposition process was conducted in O2 ambient at a pressure of 10 mtorr and a temperature of 400°C. A 50-nm Si3N4 capping layer was first deposited on the surface of MoO2 precursor film, and then annealing was performed at 900°C for 1 hour in high vacuum to further improve the MoO2 crystalline quality. After cooling down to RT naturally, the Si3N4 capping layer was removed through buffered oxide etch (BOE) (20:1) solution, leaving the MoO2 ready for converting into high-quality MoS2 film. The sulfurization process was carried out in a three-zone chemical vapor deposition (CVD) system with argon (Ar) as the carrier gas, keeping a flow rate of 100 standard cubic centimeter per minute (SCCM) and a pressure of about 9 torr at 900°C for 1 hour. A similar process has been described in previous works (52, 53). A single-crystalline 2D MoS2 film with uniform in-plane and out-of-plane mono-orientation was obtained successfully on the sapphire substrate.

Subsequently, the transfer of MoS2 from the sapphire to the SiO2 substrate was conducted using the polydimethylsiloxane (PDMS)–based transfer method. A purchased PDMS (Gel-Pak) film was attached carefully on the surface of the MoS2 film without air bubbles at the interface. Then, the sample was submerged in deionized water for 10 min to separate the PDMS/MoS2 stack from the sapphire substrate. After detaching, the PDMS/MoS2 stack was transferred onto the SiO2 substrate and baked at 80°C for 60 min to reduce the stickiness between the PDMS and MoS2 film. After releasing PDMS, the MoS2 layer was successfully transferred to the SiO2 substrate.

Then, a nitridation process on the MoS2 film was carried out in the same three-zone CVD system. The whole reaction process was conducted in NH3 atmosphere with a flow rate of 100 SCCM and a pressure of 10 torr at 800°C for 1 hour. The wafer-scale MoN film can successfully inherit the mono-orientation feature from the MoS2 films. More details could be approached in a previous work (22).

Sputtering of AlN and epitaxy of single-crystalline GaN

The deposition of AlN was performed in an iTops A230 magnetic control sputtering system. The sputtering chamber was pumped to a base pressure of 4 × 10−7 torr. During the sputtering process, 99.9999% pure Ar and N2 gases were introduced into the chamber with a mixed ratio of 1:1 at a pressure of 4 × 10−3 torr after the substrate temperature stabilized at 450°C. A 99.999% pure aluminum target, as the source of atoms, was bombarded by plasma. After 7 min of deposition, a 30-nm AlN film was grown on the MoN buffer layer.

Before the epitaxy of nitrides, the AlN/MoN template was patterned into a rectangle with 50 μm in length and 100 μm in width by photolithography and inductively coupled plasma (ICP) etching. Then, the patterned AlN/MoN template was loaded into the Veeco K465I MOVPE chamber, and we conducted an NH3 in situ annealing at 900°C for 15 min. Trimethylgallium (TMGa), trimethylaluminum (TMAl), and NH3 were used as Ga, Al, and N precursors. An HT-AlN with a thickness of around 40 nm was grown on the surface of sputtered AlN at a temperature of 1020°C for 10 min at a pressure of 60 torr. Then, a 3D growth mode for the epitaxy of GaN islands was conducted at a temperature of 1020°C and a pressure of 400 torr for 5 min. Subsequently, the GaN film was grown at a pressure of 75 torr at 1060°C for 2 hours. The thickness of the as-grown GaN epilayer is around 5 μm. To obtain an HEMT structure, the epitaxial growth of AlN (1 nm), AlGaN (20 nm), and GaN (1 nm) was further performed layer by layer on the GaN epilayer.

TD distribution in the GaN film

Figure 3 (J and K) presents the dark-field cross-sectional TEM images taken near the [10 0] zone axis with g = [0002] and g = [110], respectively. According to the invisibility criterion (gb = 0), the dislocations viable in the image with g = [0002] (Fig. 3J) should be either pure screw or mixed dislocations, whereas those viable in image with g = [11 0] (Fig. 3K) are of edge or mixed types (54). We observe that most dislocations presented in Fig. 3J are also viable in Fig. 3K. This indicates that the TDs in our GaN epilayer grown on the amorphous SiO2 are predominantly edge and mixed types. After counting dislocations in Fig. 3 (J and K), we determined that the total dislocation density is around 2.2 × 108 cm−2 for the as-grown GaN epilayer on the amorphous SiO2 substrate. This value of the TD density are comparable to those observed in GaN films grown on the Si(111) substrate (7).

Hall measurement of the AlGaN/AlN/GaN heterostructure

We first fabricated a six-probe Hall bar pattern on the AlGaN/AlN/GaN heterostructure using photolithography and ICP etching to obtain a Hall bar device. Ti (30 nm)/Al (120 nm)/Ni (50 nm)/Au (100 nm) metal electrode pads were then deposited onto the patterned devices by e-beam evaporation. Rapid thermal annealing was performed at 850°C for 30 s to form ohmic contacts on the AlGaN layer. Before the hall measurements, the electrodes on the Hall bar device were bonded to a small printed circuit board with aluminum wires using an ultrasonic wire bonder. The sample was subsequently connected to the measurement stage and loaded into a 12T Cryogenic cryogen-free measurement system (CFMS-12). Keithley 6221 and 2182 nanovoltmeters were used for current source and voltage source detection, respectively.

Fabrication of HEMT devices

The HEMT devices were fabricated on the same epistructure as the Hall bar device. The drain and source ohmic electrodes were formed following the same procedure as described for the Hall bar device. Then, 50 μm–by–50 μm mesas were defined by photolithography and ICP etching. After depositing a 20-nm Al2O3 gate dielectric layer by atomic layer deposition, the gate contacts were defined by photolithography, followed by e-beam evaporation of Ni (50 nm)/Au (100 nm) and a lift-off process. Last, the source and drain windows were opened using reactive ion etching. All electrical measurements were performed using a Keithley 4200 semiconductor parameter analyzer.

Characterizations

The cross-sectional HAADF-STEM, EDX mapping, iDPC, and dark-field TEM images were obtained by Titan Themis-Z TEM with a probe corrector at an accelerating voltage of 300 kV. The 2-theta/omega scans, phi scans, and XRCs of films were obtained using an x-ray diffractometer (Bruker, D8 DA Vinci) with Cu Kα (λ = 1.5418 Å). The surface morphology of samples was characterized by atomic force microscopy (AFM) (Dimension Icon) and SEM (Zeiss Crossbeam 350; operating at 3 kV). The EBSD plots were obtained from a SIGMA500 electron microscope equipped with an Oxford Nordlys Max detector. The out-of-plane orientation of the GaN epilayer was determined through EBSD measurements conducted on the sample in the normal direction, whereas the in-plane orientation was obtained from EBSD measurements in the transverse direction.

DFT calculations

All density functional calculations were performed using the Vienna ab initio simulation package (VASP) (55, 56). Visualizations of structures were conducted in the VESTA software (57). Perdew-Burke-Ernzerhof (PBE) exchange-correlation functionals and projector augmented-wave (PAW) potentials were used (58). The cutoff energy of 500 eV and the self-consistent convergence criteria of 10−5 eV were set to ensure sufficient accuracy. The Brillouin zone was sampled with the Monkhorst-Pack grid, with a k-point density of 20 points/Å−1 for geometry relaxations and 40 points/Å−1 for self-consistent energies calculations. All systems were relaxed until the Hellman-Feynman forces acting on each atom were smaller than 0.01 eV/Å. A 12-Å–thick vacuum was added to avoid the image interaction due to the periodic boundary condition. vdW correction with Grimme’s DFT-D3 approach (59) was adopted for MoS2, graphene, and h-BN systems. For AlN slabs, pseudo-H atoms with a charge of 0.75 e passivate the N-terminated face.

Acknowledgments

Funding: Z.Z. acknowledges the National Key Research and Development Program of China (no. 2023YFB3610300), the National Nature Science Foundation of China (no. 62274083), the Natural Science Foundation of Jiangsu Province (no. BK20232042), and the Fundamental Research Funds for the Central Universities (no. XJ2024005803. K.X. acknowledges the National Nature Science Foundation of China (no. 62204073), the Fundamental Research Funds for the Central Universities (no. JZ2023HGTB0273), and National Nature Science Foundation of Anhui Province (no. 2208085QF210). X.W. acknowledges the National Key Research and Development Program of China (no. 2022YFA1402404) and the National Nature Science Foundation of China (no. 62274085). X.W. and B.L. acknowledge the National Nature Science Foundation of China (no. T2221003). R.Z and B.L. acknowledge the Collaborative Innovation Center of Solid-State Lighting and Energy-Saving Electronics. K.O. and H.N.A. acknowledge the King Abdullah University of Science and Technology (KAUST).

Author contributions: Z.Z. and X.X. conceived the idea of the epitaxy of GaN on the amorphous substrate. Z.Z., R.Z., and B.L. supervised the project. Y.S. performed data collection and analysis. X.X. prepared the MoS2 and MoN buffer layers and performed XRD and AFM of these films. K.X., Z.Z., and Z.J. conducted the epitaxial growth of III-nitrides using MOVPE. G.F. and K.X. performed the AFM and XRD measurements of the epitaxial nitrides. Y.W. and S.D. performed DFT calculation and data analysis. Y.S. performed TEM characterization and was responsible for the fabrication and characterization of HEMT device and Hall bar device. F.Z. grew the gate dielectric layer. H.G. and D.C. helped with data analysis of the fabricated HEMT. X.Z. and X.F.W. performed the Hall measurement at different temperatures and data analysis. T.T., K.O., X.R.W., and H.N.A. provided resources for the experiments and commented on the manuscript. Z.Z. and Y.S. cowrote the manuscript. All authors contributed to the discussion of the results.

Competing interests: The authors declare that they have no competing interests.

Data and materials availability: All data needed to evaluate the conclusions in the paper are present in the paper and/or the Supplementary Materials.

Supplementary Materials

This PDF file includes:

Figs. S1 to S10

REFERENCES AND NOTES

- 1.Liu C., Liu T., Zhang Z., Sun Z., Zhang G., Wang E., Liu K., Understanding epitaxial growth of two-dimensional materials and their homostructures. Nat. Nanotechnol. 19, 907–918 (2024). [DOI] [PubMed] [Google Scholar]

- 2.Liu B., Chen D., Lu H., Tao T., Zhuang Z., Shao Z., Xu W., Ge H., Zhi T., Ren F., Ye J., Xie Z., Zhang R., Hybrid light emitters and UV solar-blind avalanche photodiodes based on III-nitride semiconductors. Adv. Mater. 32, e1904354 (2020). [DOI] [PubMed] [Google Scholar]

- 3.van Deurzen L., Kim E., Pieczulewski N., Zhang Z., Feduniewicz-Zmuda A., Chlipala M., Siekacz M., Muller D., Xing H. G., Jena D., Turski H., Using both faces of polar semiconductor wafers for functional devices. Nature 634, 334–340 (2024). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Kum H., Lee D., Kong W., Kim H., Park Y., Kim Y., Baek Y., Bae S. H., Lee K., Kim J., Epitaxial growth and layer-transfer techniques for heterogeneous integration of materials for electronic and photonic devices. Nat. Electron. 2, 439–450 (2019). [Google Scholar]

- 5.Park M., Maekawa T., Hwang K., Cable J., Noriyuki W., Choi K., Noh Y. K., Oh Y., Baek Y., Lee K., Remote epitaxy and freestanding wide bandgap semiconductor membrane technology. Nat. Rev. Electr. Eng. 1, 680–689 (2024). [Google Scholar]

- 6.Wen P., Tiwari P., Mauthe S., Schmid H., Sousa M., Scherrer M., Baumann M., Bitachon B. I., Leuthold J., Gotsmann B., Moselund K. E., Waveguide coupled III-V photodiodes monolithically integrated on Si. Nat. Commun. 13, 909 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Sun Y., Zhou K., Sun Q., Liu J., Feng M., Li Z., Zhou Y., Zhang L., Li D., Zhang S., Ikeda M., Liu S., Yang H., Room-temperature continuous-wave electrically injected InGaN-based laser directly grown on Si. Nat. Photonics 10, 595–599 (2016). [Google Scholar]

- 8.Bae S.-H., Kum H., Kong W., Kim Y., Choi C., Lee B., Lin P., Park Y., Kim J., Integration of bulk materials with two-dimensional materials for physical coupling and applications. Nat. Mater. 18, 550–560 (2019). [DOI] [PubMed] [Google Scholar]

- 9.Kobayashi Y., Kumakura K., Akasaka T., Makimoto T., Layered boron nitride as a release layer for mechanical transfer of GaN-based devices. Nature 484, 223–227 (2012). [DOI] [PubMed] [Google Scholar]

- 10.Chung K., Lee C. H., Yi G. C., Transferable GaN layers grown on ZnO-coated graphene layers for optoelectronic devices. Science 330, 655–657 (2010). [DOI] [PubMed] [Google Scholar]

- 11.Kim H., Liu Y., Lu K., Chang C. S., Sung D., Akl M., Qiao K., Kim K. S., Park B. I., Zhu M., Suh J. M., Kim J., Jeong J., Baek Y., Ji Y. J., Kang S., Lee S., Han N. M., Kim C., Choi C., Zhang X., Choi H. K., Zhang Y., Wang H., Kong L., Afeefah N. N., Ansari M. N. M., Park J., Lee K., Yeom G. Y., Kim S., Hwang J., Kong J., Bae S. H., Shi Y., Hong S., Kong W., Kim J., High-throughput manufacturing of epitaxial membranes from a single wafer by 2D materials-based layer transfer process. Nat. Nanotechnol. 18, 464–470 (2023). [DOI] [PubMed] [Google Scholar]

- 12.Kim Y., Cruz S. S., Lee K., Alawode B. O., Choi C., Song Y., Johnson J. M., Heidelberger C., Kong W., Choi S., Qiao K., Almansouri I., Fitzgerald E. A., Kong J., Kolpak A. M., Hwang J., Kim J., Remote epitaxy through graphene enables two-dimensional material-based layer transfer. Nature 544, 340–343 (2017). [DOI] [PubMed] [Google Scholar]

- 13.Kong W., Li H., Qiao K., Kim Y., Lee K., Nie Y., Lee D., Osadchy T., Molnar R. J., Gaskill D. K., Myers-Ward R. L., Daniels K. M., Zhang Y., Sundram S., Yu Y., Bae S. H., Rajan S., Shao-Horn Y., Cho K., Ougazzaden A., Grossman J. C., Kim J., Polarity governs atomic interaction through two-dimensional materials. Nat. Mater. 17, 999–1004 (2018). [DOI] [PubMed] [Google Scholar]

- 14.Liang D., Jiang B., Liu Z., Chen Z., Gao Y., Yang S., He R., Wang L., Ran J., Wang J., Gao P., Li J., Liu Z., Sun J., Wei T., Quasi van der Waals epitaxy of single crystalline GaN on amorphous SiO2/Si(100) for monolithic optoelectronic integration. Adv. Sci. 11, 2305576 (2024). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Singh A. K., Ahn K., Yoo D., Lee S., Ali A., Yi G. C., Chung K., van der Waals integration of GaN light-emitting diode arrays on foreign graphene films using semiconductor/graphene heterostructures. NPG Asia Mater. 14, 57 (2022). [Google Scholar]

- 16.Ren F., Liu B., Chen Z., Yin Y., Sun J., Zhang S., Jiang B., Liu B., Liu Z., Wang J., Liang M., Yuan G., Yan J., Wei T., Yi X., Wang J., Zhang Y., Li J., Gao P., Liu Z., Liu Z., Van der Waals epitaxy of nearly single-crystalline nitride films on amorphous graphene-glass wafer. Sci. Adv. 7, eabf5011 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Xu W., Xu S., Tao H., Gao Y., Fan X., du J., Ai L., Peng L., Zhang J., Zhang J., Hao Y., High quality GaN grown on polycrystalline diamond substrates with h-BN insertion layers by MOCVD. Mater. Lett. 305, 130806 (2021). [Google Scholar]

- 18.Chung K., Oh H., Jo J., Lee K., Kim M., Yi G. C., Transferable single-crystal GaN thin films grown on chemical vapor-deposited hexagonal BN sheets. NPG Asia Mater. 9, –e410 (2017). [Google Scholar]

- 19.Yin Y., Liu B., Chen Q., Chen Z., Ren F., Zhang S., Liu Z., Wang R., Liang M., Yan J., Sun J., Yi X., Wei T., Wang J., Li J., Liu Z., Gao P., Liu Z., Continuous single-crystalline GaN film grown on WS2-glass wafer. Small 18, e2202529 (2022). [DOI] [PubMed] [Google Scholar]

- 20.Zheng Z., Zhang L., Song W., Feng S., Xu H., Sun J., Yang S., Chen T., Wei J., Chen K. J., Gallium nitride-based complementary logic integrated circuits. Nat. Electron. 4, 595–603 (2021). [Google Scholar]

- 21.Sasaki T., Zembutsu S., Substrate-orientation dependence of GaN single-crystal films grown by metalorganic vapor-phase epitaxy. J. Appl. Phys. 61, 2533–2540 (1987). [Google Scholar]

- 22.Xu X., Smajic J., Li K. H., Min J. W., Lei Y., Davaasuren B., He X., Zhang X., Ooi B. S., Costa P. M. F. J., Alshareef H. N., Lattice orientation heredity in the transformation of 2D epitaxial films. Adv. Mater. 34, e2105190 (2022). [DOI] [PubMed] [Google Scholar]

- 23.Amano H., Sawaki N., Akasaki I., Toyoda Y., Metalorganic vapor phase epitaxial growth of a high quality GaN film using an AlN buffer layer. Appl. Phys. Lett. 48, 353–355 (1986). [Google Scholar]

- 24.Zhao D. G., Xu S. J., Xie M. H., Tong S. Y., Yang H., Stress and its effect on optical properties of GaN epilayers grown on Si(111), 6H-SiC(0001), and c-plane sapphire. Appl. Phys. Lett. 83, 677–679 (2003). [Google Scholar]

- 25.Mohn S., Stolyarchuk N., Markurt T., Kirste R., Hoffmann M. P., Collazo R., Courville A., di Felice R., Sitar Z., Vennéguès P., Albrecht M., Polarity control in group-III nitrides beyond pragmatism. Phys. Rev. Appl. 5, 054004 (2016). [Google Scholar]

- 26.Liu F., Wang T., Zhang Z., Shen T., Rong X., Sheng B., Yang L., Li D., Wei J., Sheng S., Li X., Chen Z., Tao R., Yuan Y., Yang X., Xu F., Zhang J., Liu K., Li X. Z., Shen B., Wang X., Lattice polarity manipulation of quasi-vdW epitaxial GaN films on graphene through interface atomic configuration. Adv. Mater. 34, e2106814 (2022). [DOI] [PubMed] [Google Scholar]

- 27.Sang Y. M., Zhuang Z., Xing K., Jiang Z., Li C., Xu F., Zhang D., Yu J., Zhao J., Zhi T., Tao T., Li C., Huang K., Ohkawa K., Zhang R., Liu B., Optimizing Al composition in barriers for InGaN amber Micro-LEDs with high wall-plug efficiency. IEEE Electron Device Lett. 45, 76–79 (2024). [Google Scholar]

- 28.Christy D., Egawa T., Yano Y., Tokunaga H., Shimamura H., Yamaoka Y., Ubukata A., Tabuchi T., Matsumoto K., Uniform growth of AlGaN/GaN high electron mobility transistors on 200 mm silicon (111) substrate. Appl. Phys. Express 6, 026501 (2013). [Google Scholar]

- 29.Chen Y., Zang H., Zhang S., Shi Z., Ben J., Jiang K., Jia Y., Liu M., Li D., Sun X., Van der waals epitaxy of c-oriented wurtzite AlGaN on polycrystalline Mo substrates for enhanced heat dissipation. ACS Appl. Mater. Interfaces 14, 37947–37957 (2022). [DOI] [PubMed] [Google Scholar]

- 30.Choi J. H., Zoulkarneev A., Kim S. I., Baik C. W., Yang M. H., Park S. S., Suh H., Kim U. J., Bin Son H., Lee J. S., Kim M., Kim J. M., Kim K., Nearly single-crystalline GaN light-emitting diodes on amorphous glass substrates. Nat. Photon. 5, 763–769 (2011). [Google Scholar]

- 31.Yu J., Wang J., Yu W., Wu C., Lu B., Deng J., Zhang Z., Li X., Hao Z., Wang L., Han Y., Luo Y., Sun C., Xiong B., Li H., Low-temperature and global epitaxy of GaN on amorphous glass substrates by molecular beam epitaxy via a compound buffer layer. Thin Solid Films 662, 174–179 (2018). [Google Scholar]

- 32.Chen Q., Yang K., Shi B., Yi X., Wang J., Li J., Liu Z., Principles for 2D material assisted nitrides epitaxial growth. Adv. Mater. 35, e2211075 (2023). [DOI] [PubMed] [Google Scholar]

- 33.Liu D., Hu L., Yang X., Zhang Z., Yu H., Zheng F., Feng Y., Wei J., Cai Z., Chen Z., Ma C., Xu F., Wang X., Ge W., Liu K., Huang B., Shen B., Polarization-driven-orientation selective growth of single-crystalline III-nitride semiconductors on arbitrary substrates. Adv. Funct. Mater. 32, 2113211 (2022). [Google Scholar]

- 34.Kumaresan V., Largeau L., Madouri A., Glas F., Zhang H., Oehler F., Cavanna A., Babichev A., Travers L., Gogneau N., Tchernycheva M., Harmand J. C., Epitaxy of GaN nanowires on graphene. Nano Lett. 16, 4895–4902 (2016). [DOI] [PubMed] [Google Scholar]

- 35.Chung K., Beak H., Tchoe Y., Oh H., Yoo H., Kim M., Yi G. C., Growth and characterizations of GaN micro-rods on graphene films for flexible light emitting diodes. APL Mater. 2, 092512 (2014). [Google Scholar]

- 36.Song W., Ren F., Wang Y., Yin Y., Zhang S., Shi B., Feng T., Wang J., Liang M., Zhang Y., Wei T., Yan J., Wang J., Li J., Yi X., Liu Z., GaN-based LEDs grown on graphene-covered SiO2/Si (100) substrate. Crystals 10, 787 (2020). [Google Scholar]

- 37.Hospodková A., Hájek F., Hubáček T., Gedeonová Z., Hubík P., Hývl M., Pangrác J., Dominec F., Košutová T., Electron transport properties in high electron mobility transistor structures improved by V-pit formation on the AlGaN/GaN interface. ACS Appl. Mater. Interfaces 15, 19646–19652 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Tokuda H., Yamazaki J., Kuzuhara M., High temperature electron transport properties in AlGaN/GaN heterostructures. J. Appl. Phys. 108, 104509 (2010). [Google Scholar]

- 39.Wilson M., Marinskiy D., Lagowski J., Almeida C., Savtchouk A., Nguyen D., Benjamin M., Method for noncontact measurement of 2DEG mobility and carrier density in AlGaN/GaN on semi-insulating wafers. Jpn. J. Appl. Phys. 61, 020903 (2022). [Google Scholar]

- 40.Wang X., Wang C., Hu G., Xiao H., Fang C., Wang J., Ran J., Li J., Li J., Wang Z., MOCVD-grown high-mobility Al0.3Ga0.7N/AlN/GaN HEMT structure on sapphire substrate. J. Cryst. Growth 298, 791–793 (2007). [Google Scholar]

- 41.Miyoshi M., Egawa T., Ishikawa H., Study on mobility enhancement in MOVPE-grown AlGaN/AlN/GaN HEMT structures using a thin AlN interfacial layer. Solid State Electron. 50, 1515–1521 (2006). [Google Scholar]

- 42.Lin S., Wang M., Sang F., Tao M., Wen C. P., Xie B., Yu M., Wang J., Hao Y., Wu W., Xu J., Cheng K., Shen B., A GaN HEMT structure allowing self-terminated, plasma-free etching for high-uniformity, high-mobility enhancement-mode devices. IEEE Electron Device Lett. 37, 377–380 (2016). [Google Scholar]

- 43.Cordier Y., Hugues M., Lorenzini P., Semond F., Natali F., Massies J., Electron mobility and transfer characteristics in AlGaN/GaN HEMTs. Phys. Status Solidi C 2, 2720–2723 (2005). [Google Scholar]

- 44.Liu H. F., Dolmanan S. B., Zhang L., Chua S. J., Chi D. Z., Heuken M., Tripathy S., Influence of stress on structural properties of AlGaN/GaN high electron mobility transistor layers grown on 150 mm diameter Si (111) substrate. J. Appl. Phys. 113, 023510 (2013). [Google Scholar]

- 45.Wang X., Hu G., Ma Z., Ran J., Wang C., Xiao H., Tang J., Li J., Wang J., Zeng Y., Li J., Wang Z., AlGaN/AlN/GaN/SiC HEMT structure with high mobility GaN thin layer as channel grown by MOCVD. J. Cryst. Growth 298, 835–839 (2007). [Google Scholar]

- 46.Bajaj S., Shoron O. F., Park P. S., Krishnamoorthy S., Akyol F., Hung T. H., Reza S., Chumbes E. M., Khurgin J., Rajan S., Density-dependent electron transport and precise modeling of GaN high electron mobility transistors. Appl. Phys. Lett. 107, 153504 (2015). [Google Scholar]

- 47.Palacios T., Suh C. S., Chakraborty A., Keller S., DenBaars S. P., Mishra U. K., High-performance E-mode AlGaN/GaN HEMTs. IEEE Electron Device Lett. 27, 428–430 (2006). [Google Scholar]

- 48.Su C.-W., Wang T. W., Wu M. C., Ko C. J., Huang J. B., Fabrication and characterization of GaN HEMTs grown on SiC substrates with different orientations. Solid State Electron. 179, 107980 (2021). [Google Scholar]

- 49.Jena D., Smorchkova I., Gossard A. C., Mishra U. K., Electron transport in III–V nitride two-dimensional electron gases. Phys. Status Solidi B 228, 617–619 (2001). [Google Scholar]

- 50.Li H., Keller S., Chan S. H., Lu J., DenBaars S. P., Mishra U. K., Unintentional gallium incorporation in AlN and its impact on the electrical properties of GaN/AlN and GaN/AlN/AlGaN heterostructures. Semicond. Sci. Technol. 30, 055015 (2015). [Google Scholar]

- 51.Guo H., Shao P., Zeng C., Bai H., Wang R., Pan D., Chen P., Chen D., Lu H., Zhang R., Zheng Y., Improved LPCVD-SiNx/AlGaN/GaN MIS-HEMTs by using in-situ MOCVD-SiNx as an interface sacrificial layer. Appl. Surf. Sci. 590, 153086 (2022). [Google Scholar]

- 52.Xu X., Zhang C., Hota M. K., Liu Z., Zhang X., Alshareef H. N., Enhanced quality of wafer-scale MoS2 films by a capping layer annealing process. Adv. Funct. Mater. 30, 1908040 (2020). [Google Scholar]

- 53.Xu X., Wang Z., Lopatin S., Quevedo-Lopez M. A., Alshareef H. N., Wafer scale quasi single crystalline MoS2 realized by epitaxial phase conversion. 2D Mater. 6, 015030 (2019). [Google Scholar]

- 54.Bai J., Wang T., Parbrook P. J., Lee K. B., Cullis A. G., A study of dislocations in AlN and GaN films grown on sapphire substrates. J. Cryst. Growth 282, 290–296 (2005). [Google Scholar]

- 55.Hohenberg P., Kohn W., Inhomogeneous electron gas. Phys. Rev. 136, B864–B871 (1964). [Google Scholar]

- 56.Kohn W., Sham L. J., Self-consistent equations including exchange and correlation effects. Phys. Rev. 140, A1133–A1138 (1965). [Google Scholar]

- 57.Momma K., Izumi F., VESTA: A three-dimensional visualization system for electronic and structural analysis. J. Appl. Cryst. 41, 653–658 (2008). [Google Scholar]

- 58.Blöchl P. E., Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994). [DOI] [PubMed] [Google Scholar]

- 59.Grimme S., Antony J., Ehrlich S., Krieg H., A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010). [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Figs. S1 to S10