Abstract

Colloidal nanoparticle self‐assembly is a key area in nanomaterials science, renowned for its ability to design metamaterials with tailored functionalities through a bottom‐up approach. Over the past three decades, advancements in nanoparticle synthesis and assembly control methods have propelled the transition from single‐component to binary assemblies. While binary assembly has been recognized as a significant concept in materials design, its potential for intelligent and customized assembly has often been overlooked. It is argued that the future trend in the assembly of binary nanocrystalline superlattices (BNLSs) can be analogous to the ‘0s’ and ‘1s’ in computer programming, and customizing their assembly through precise control of these basic units could significantly expand their application scope. This review briefly recaps the developmental trajectory of nanoparticle assembly, tracing its evolution from simple single‐component assemblies to complex binary co‐assemblies and the unique property changes they induce. Of particular significance, this review explores the future prospects of binary co‐assembly, viewed through the lens of ‘AI‐guided programmable assembly’. Such an approach has the potential to shift the paradigm from passive assembly to active, intelligent design, leading to the creation of new materials with disruptive properties and functionalities and driving profound changes across multiple high‐tech fields.

Keywords: artificial intelligence, binary co‐assembly, colloidal nanoparticles, intelligent novel materials, self‐assembly, superstructural materials

Colloidal nanoparticles self‐assembly advances towards intelligent, customized assembly through precise control of binary co‐assemblies. This review explores the evolution from monolithic to binary assemblies, highlighting how the AI‐guided programmable assembly approach has the potential to shift from passive assembly to active intelligent design. It paves the way for the development of disruptive new materials and profound changes in various high‐tech fields.

1. Introduction

Colloidal nanoparticles, defined as particles dispersed in a medium with at least one dimension at the nanometer scale, which can be either crystalline or amorphous in nature, are renowned for their exceptional optical, electrical, and magnetic properties. Typically, these particles consist of an inorganic core surrounded by a layer of material with specific functional groups serving as surface ligands. This coating can include, but is not limited to, long‐chain alkanes, polymers, or other organic and inorganic materials depending on the application requirements and design purposes.[ 1 ] Advances in nanosynthesis technologies have enabled researchers to precisely control the size, chirality,[ 2 ] and morphology[ 3 ] of nanoparticles by fine‐tuning synthesis parameters, such as precursor selection, type of surface ligands, reaction temperature, and duration.[ 1 , 4 ] These control techniques not only facilitate the development of nanomaterials with unique properties but also lay the groundwork for designing novel composite materials and manufacturing functional devices. If a nanoparticle is likened to an ‘artificial atom’, then the monolithic assembly of nanoparticles can be analogously viewed as an “atom‐like assembly”, where each nanoparticle serves as an “atom‐like” unit.[ 5 ] Arranging these units into a superstructure imitates the atomic arrangement in a crystal, resulting in well‐organized 1D, 2D, and 3D structures.[ 6 ] Nano‐assembled structures not only inherit the fundamental properties of nanoparticles, such as the quantum confinement effect, size effect, and surface effect but also exhibit emergent phenomena arising from their unique configurations, such as quantum coupling and synergistic effects,[ 7 ] opening a new pathway for synthesizing functional materials with desired collective properties by leveraging the weak interactions that exist at the nanoscale.[ 8 ]

As the understanding of nanoparticle self‐assembly mechanisms deepens and new materials are discovered, the field of colloidal nanoparticle self‐assembly continues to make significant breakthroughs.[ 9 ] Research has shifted from the monocomponent assembly of single‐type nanoparticles to the binary assembly of different types of nanoparticles, leading to more complex functionalities and structures.[ 6 , 9 , 10 ] Binary assembly typically involves combining nanoparticles with complementary properties, such as one providing stability and the other providing functionality.[ 11 ] By precisely controlling the interactions between nanoparticles, researchers can design composite materials with specific optical, electrical, or bioactive properties.[ 9 , 10 , 12 ] However, most current research efforts remain focused on synthesis methods,[ 4 , 10 , 13 ] morphological characteristics,[ 12 , 13 , 14 ] and basic properties[ 4 , 10 , 13 , 15 ] of BNLSs, and a variety of colloidal nanocrystalline self‐assembled materials have been designed and reported,[ 1b,g 5 , 6 , 8 , 16 ] whereas the special properties and practical applications of these superstructures have been less explored. Moreover, the kinetic control of the traditional nanoparticle assembly process appears to be particularly insufficient. Due to the multitude of variables affecting the assembly process, including, but not limited to, temperature, concentration, solvent properties, types of surface modifiers and their coverage, etc., the complexity of these factors is intertwined, making the optimization of the assembly conditions extremely difficult. Against this background, researchers often need to spend a lot of time and effort on repeated experiments to find the best combination of parameters to achieve the desired assembly structure and function.

Recent advances in AI‐guided assembly strategies now offer powerful tools to address these limitations.[ 10 , 17 ] Introducing the concept of ‘AI programmable ideas’ is introduced into the binary assembly process of colloidal nanoparticles can provide a new perspective on assembly. Considering the binary co‐assembly of nanocrystals as a process analogous to computer programmable, where nanocrystal units are akin to the basic elements “0s” and “1s” in programmable languages, precise control over the positions and connections of these units, similar to writing a program, can enable the design of specific functional nanomaterials. Machine learning models trained on multimodal characterization data can accelerate the exploration of assembly parameter spaces through active learning algorithms, while physics‐informed neural networks enable the prediction of non‐equilibrium assembly pathways. This suggests the potential for a fundamental shift from traditional passive assembly to active intelligent design, while also introducing a new approach to material design: AI‐guided programmable assembly concepts into the design of nanomaterials.

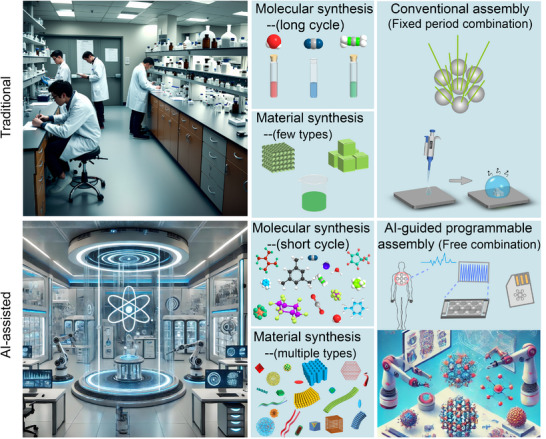

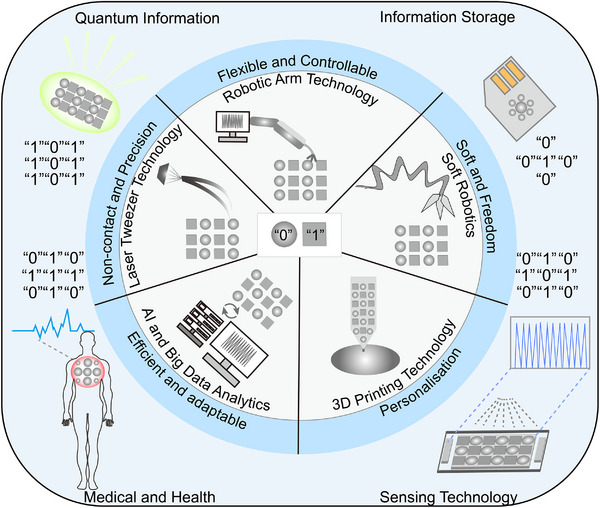

In this review, we briefly recap the developmental trajectory of nanoparticle assembly, tracing the property changes it has brought from initial single‐type nanoparticles to monocomponent assembly structures. Subsequently, we introduce the evolutionary process from monocomponent assembly to more advanced and complex binary nanoparticle assemblies combining different types of nanoparticles, focusing on exploring the unique properties of binary nanoparticle assembly and discussing the related application prospects it brings. Finally, we attempt to explore the future trends of colloidal nanoparticle binary co‐assembly technology from the unique perspective of AI‐guided programmable assembly (Figure 1 ). By AI‐guided programmable assembly concepts, researchers can design nanomaterials with complex logical structures, thereby achieving a fundamental shift from passive assembly to active intelligent design. Through continuous exploration of new synthetic pathways, optimization of assembly strategies, and drawing inspiration from other disciplines such as information science and biology, it is possible to create more disruptive functional new materials. These new materials are poised to trigger profound changes in multiple fields, including energy conversion and storage, information processing and transmission, disease diagnosis and treatment, and beyond.

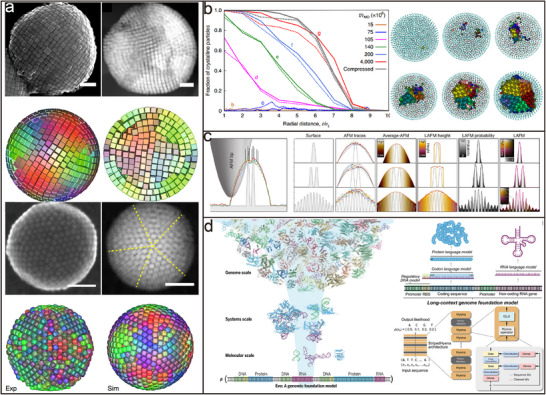

Figure 1.

AI‐guided programmable idea self‐assembly of multiple colloidal nanocrystalline materials.

2. Colloidal Nanoparticle Self‐Assembly

Colloidal nanoparticle self‐assembly is a powerful technique for the bottom‐up fabrication of functional complex superstructures.[ 18 ] The lower‐level assembly units of colloidal superstructures can have various forms, such as spherical,[ 1 , 9 , 10 , 19 ] polyhedral,[ 1 , 20 ] rod‐shaped,[ 1 , 12 , 14 , 21 ] and branched inorganic cores.[ 1 , 22 ] The physical and chemical properties of these units, as well as the modulation of their spatial arrangement through different assembly paths in the self‐assembled system, together determine the properties and characterization of the final superstructure.[ 23 ] The collective properties of the superstructure are not only controlled by the characteristics of the lower‐level nanoparticles themselves but also influenced by the symmetry, orientation, phase, and size of the superstructure.[ 8 , 20 ] The regulation of the superstructure is achieved by controlling the interactions between colloidal nanoparticles, including but not limited to van der Waals forces, electrostatic interactions, and magnetic interactions.[ 1 , 7 , 8 , 24 ] By adjusting the strength and direction of these forces[ 25 ], the arrangement of nanoparticles and the resulting structure can be effectively controlled. This method enables precise control over the spatial organization of nanoparticles into ordered superstructures, leading to the emergence of collective properties and specific functions that are not achievable with individual nanoparticles.

2.1. Methods of Colloidal Nanoparticles Self‐Assembly

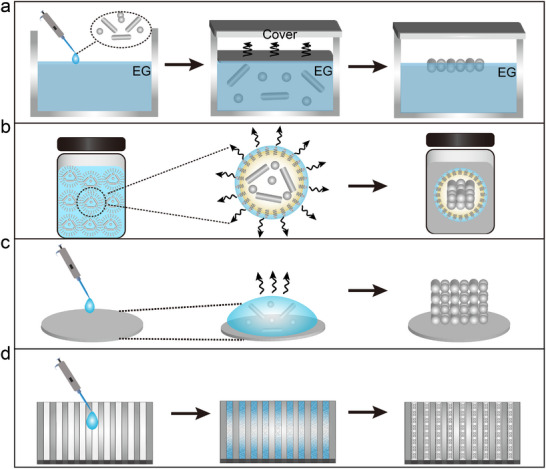

Colloidal nanoparticle self‐assembly methods are the cornerstone for the preparation of metamaterials with different functions and structures. These methods, which mainly include gas‐liquid interfacial assembly[ 9 , 13 , 26 ], microemulsion assembly, solvent evaporation assembly, and template‐induced assembly, utilize different physicochemical mechanisms to orchestrate the ordered arrangement of nanoparticles. Among them, the gas–liquid interfacial assembly method (Figure 2 a) uses the interfacial tension between the two phases to promote the self‐assembly of nanoparticles on the contact surface and the formation of an ordered structure. Microemulsion assembly involves both normal (oil‐in‐water) and reverse (water‐in‐oil) systems, where the interface between the two immiscible phases serves as a soft template. The size and stability of the microemulsion droplets (Figure 2b), controlled by surfactant concentration and type, determine the assembly process and final structure.[ 27 ] Solvent evaporation assembly (Figure 2c) [ 28 ] directs the self‐assembly of nanoparticles into a highly ordered superlattice by controlling evaporation kinetics, environmental conditions (temperature and humidity), and substrate properties. Induced self‐assembly (Figure 2d), employs various guiding factors, such as physical templates (hard or soft) and external fields (electric, magnetic, or optical), to direct the spontaneous organization of nanoparticles into predetermined architectures.[ 29 ]

Figure 2.

a) Schematic illustration of the self‐assembly mechanism at the gas‐liquid interface. b) Graphic representation of the microemulsion formation and assembly procedure. c) Visual depiction of the assembly process driven by solvent evaporation. d) Illustrative diagram of the induced self‐assembly mechanism.

2.1.1. Gas–Liquid Interfacial Assembly Method

The gas–liquid interfacial assembly method, as one of the earliest colloidal nanoparticle self‐assembly techniques, can be used to prepare superlattice structures, which is based on the principle of inducing nanoparticles to self‐assemble employing interfacial tension at the contact surfaces between an aqueous phase and a non‐aqueous phase (e.g., oil or air), which results in the formation of ordered structures.[ 26a ] This self‐assembly capability was made possible by advances in synthesis techniques that achieved near‐atomic‐level size uniformity of nanograins, allowing them to self‐assemble into ordered superlattice structures in a solution environment, similar to the formation of larger structures by atoms or molecules through chemical bonding. With the development of this method, researchers have proposed a series of improvements and strategies aimed at precisely regulating the morphology and size of the nano‐assembled materials,[ 13c ] such as controlling the arrangement of nanocrystalline grains at the interface by adjusting the solution concentration, the interfacial curvature, and the interaction force between the nanoparticles and the interface.[ 6 , 9 , 15 , 30 ]

Of particular note is the work of Murray and colleagues,[ 26a ] who have made important contributions to this field. They showed how CdSe nanograins self‐assemble into a 3D quantum dot superlattice, which provides an important example of the self‐assembly of nanomaterials. Their study shows that by precisely controlling the size and spacing of the nanocrystals, an ordered arrangement of these nanostructures can be achieved and their unique optical and electronic properties further explored. Elena V. Shevchenko, Dmitry V. Talapin, and Nicholas A. Kotov, and colleagues have further applied this method to nanocrystal assembly and binary nanocrystal assembly.[ 1 , 10 , 14 , 24 , 31 ] Their studies revealed that the superlattices formed by binary assembly of nanocrystals have many different structural forms, which provide new ideas and directions for the design and application of nanomaterials. Furthermore, focusing on the self‐assembly mechanism of nanocrystals at gas–liquid interfaces, Tobias Hanrath and his team have achieved large, homogeneous nanocrystalline layers through optimized treatments and have explored the optical and electrical properties of these structures, providing new routes and techniques for the fabrication of high‐performance electronic and optoelectronic devices.[ 32 ] In addition, Vanmaekelbergh's team also demonstrated the self‐assembly of 2D honeycomb superlattices at the gas–liquid interface on the basis of specific crystalline surfaces between nanocrystals using the oriented attachment,[ 33 ] a mechanism by which nanocrystals of PbSe, PbS, and, CdSe are oriented at interfaces to form honeycomb structures with long‐range periodic and atomically coherent honeycomb structure. These advances provide new routes for superlattice structure manipulation of a wide range of nanoparticles, including insulators, magnetic, and metallic materials, and open the way for the development of 2D semiconductor materials with novel electronic properties.

2.1.2. Microemulsion Assembly Method

Microemulsion assembly method,[ 5 , 34 ] as a soft chemical technique widely used in the field of nanomaterials synthesis, forms water‐in‐oil (W/O) or oil‐in‐water (O/W) type microemulsions by dispersing nanoparticles in an oil phase and mixing them with the aqueous phase containing surfactants, using the oil droplets therein as the microreactor.[ 27 ] Within the microemulsion system, the nanoparticles are aggregated, assembled, and finally immobilized inside the oil droplets through the hydrophobic van der Waals forces between the surfactant ligands adsorbed on the surface.[ 34 ] As the low‐boiling oil solvent gradually evaporates in the restricted 3D space, the nanoparticles spontaneously aggregate and assemble into colloidal spheres with precisely controlled size, shape, and composition. This technique overcomes the limitations of traditional methods where only ‘soluble’ or dispersible aggregates of controlled size, shape, and composition can be prepared on substrates such as mica or silicon plates. Cao's team has reported multiple research focusing on the use of microemulsion self‐assembly techniques to achieve the assembly of nanoparticles with different morphologies, demonstrating the simplicity, broad applicability, ease of scalability, and ability to precisely control the size, shape, and composition of this approach.[ 1 , 5 , 34 ]

In addition, Alfons van Blaaderen and his group have explored in depth the microemulsion assembly of colloidal spheres by synthesizing a variety of nanoparticles and colloids into emulsions, which were solvent evaporated to achieve self‐assembly.[ 35 ] The resulting colloidal superparticles exhibit a variety of structures depending on their size, and the formation of icosahedral clusters is entropy‐driven, which offers novel insights into cluster formation and self‐assembly mechanisms. Meanwhile, Nicolas Vogel and his team have further expanded the application of microemulsion assembly technology.[ 23 , 36 ] Their research not only focuses on the structural changes during colloidal self‐assembly, but also explores how these structures affect the functional properties of the final materials. For example, they have used microemulsions to prepare colloidal aggregates with specific optical properties, suggesting that this ‘structural coloring’ could be a tool for exploring structural and dynamic processes, and Vogel's research has also involved directing the crystallization process by controlling surface modifications of colloidal particles to enable the selection of crystal polymorphs, which could have implications for the development of novel functional materials. which is important for the development of novel functional materials. In addition, Andries Meijerink et al. further investigated the doping mechanism of hydrophobic quantum dots in silica spheres, and successfully prepared silica microspheres containing quantum dots by the reversed‐phase microemulsion method, which extends the scope of application of microemulsion assembly technology.[ 37 ] This series of studies not only demonstrates the potential of microemulsion assembly in the preparation of complex structural materials but also provides a theoretical basis for understanding the self‐assembly process at the nanoscale.

Colloidal superparticles,[ 5 , 34 ] as an emerging building block, can exhibit both short‐range disordered amorphous features and long‐range ordered superlattice properties by the arrangement of nanoparticles inside them. These superparticles not only inherit the basic chemical and physical properties of the constituent nanoparticles but also exhibit entirely new collective properties due to the coupling of electrons, plasmons, and magnetism.[ 1 , 22 , 38 ] In addition, due to their colloidal form, these superparticles can be easily assembled into mesoscopic and even macroscopic structures by solution treatment, showing great potential for applications in solar cells, light‐emitting diodes, and catalysts.

2.1.3. Solvent Evaporation Method

The solvent evaporation method is widely used as an efficient preparation technique for the synthesis of colloidal nanoparticle superlattices.[ 39 ] The core mechanism of this method is to induce the self‐assembly of nanoparticles into highly ordered structures through solvent evaporation.[ 28 , 40 ] In the specific operation, the pre‐synthesized and surfactant‐functionalized colloidal nanoparticles are first dispersed in a suitable solvent to form a solution, which ensures the stability of the nanoparticles in the solution and the ordering during the subsequent self‐assembly process.[ 28 ] The choice of solvent plays a critical role in this process; solvents with specific physical and chemical properties, such as boiling point and polarity, significantly influence the self‐assembly behavior. Solvents with higher boiling points can slow down the evaporation rate, allowing for more controlled assembly processes, while the polarity of the solvent affects the interaction between nanoparticles and their environment, impacting how they align and aggregate. Moreover, the properties of the substrate surface, including its hydrophobicity/hydrophilicity and roughness, also have a profound impact on the self‐assembly of nanoparticles. A hydrophobic substrate tends to promote the formation of ordered superlattices by minimizing unwanted interactions with the solvent, whereas a hydrophilic substrate might lead to different assembly patterns or even disordered structures depending on the nature of the nanoparticles and the solvent. Additionally, the roughness of the substrate can affect the uniformity and quality of the assembled structure. Smooth substrates facilitate the creation of defect‐free, highly ordered assemblies, while rough surfaces may introduce defects or variations in the arrangement of nanoparticles.

After preparing the nanoparticle solution, it is deposited onto a selected substrate, and gradual solvent evaporation is induced by modulating environmental parameters like temperature and humidity. With the slow evaporation of the solvent, the distance between the nanoparticles gradually shrinks, which ultimately leads to the enhancement of inter‐particle attraction and self‐assembly into a superlattice structure.[ 41 ] Precise control of the solvent evaporation rate is crucial in this process, as too fast an evaporation rate may lead to random deposition of nanocrystalline particles instead of the expected ordered arrangement. Zhao et al. found that when a suspension of gold nanoparticles (GNPs) containing excess oleic acid (OA) ligand is dried on a hydrophobic substrate,[ 42 ] the nanoparticles undergo a series of transitions from disordered stacking to ordered superlattices. The key to this transition is the aggregation behavior of the nanoparticles at the evaporation front due to the rapid withdrawal of the solvent during evaporation. This series of observations provides important insights into understanding and controlling the ordered assembly of nanoparticles.

2.1.4. Induced Assembly Method

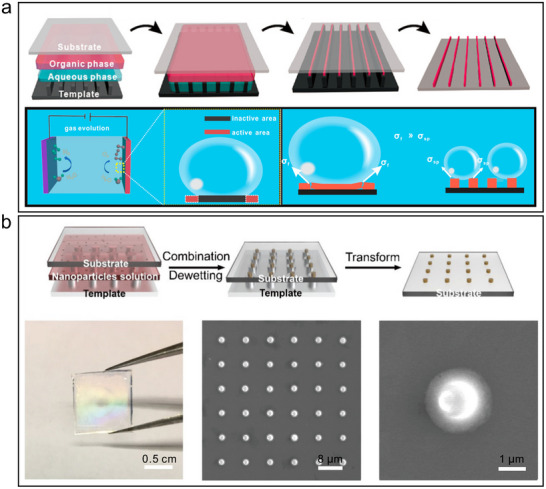

Induced self‐assembly is a process that uses external factors to guide the spontaneous assembly of nanocrystalline materials into ordered structures. By precisely regulating external conditions or introducing specific templates, the self‐assembly process can be highly directed and controlled to prepare nano‐assemblies with specific geometries, structural features, and functional properties. The template‐induced nanoparticle self‐assembly method has many advantages, such as the ability to precisely control the morphology and structure of the nanoparticles, ease of mass production, and reproducibility.[ 29 ] Song et al. report a general strategy (Figure 3a) for assembling platinum (Pt) NPs into striped superlattices via template‐assisted printing to improve the efficiency of the hydrogen evolution reaction (HER).[ 43 ] Compared to flat Pt NPs films prepared by the drop‐coating method, the striped superlattices not only improved the mass transfer efficiency but also reduced the bubble stretching force, demonstrated a versatile strategy to improve the efficiency and durability of existing Pt catalysts, and demonstrated higher current densities than those of commercial Pt/C, Pt NPs films, and other Pt‐based or non‐Pt‐based HER catalysts reported in the literature. The versatility of the template‐assisted printing technique allows flexibility in the composition, size, and shape of the nanoparticles or molecules, thus extending the scope of this accelerated technique for oxygen evolution reaction (OER) and electrochemical reduction of carbon dioxide to carbon monoxide applications. Meanwhile, we prepared AuNP superlattice films using a template printing method (Figure 3b) for the construction of wearable sweat sensors.[ 44 ] By adjusting the size of the AuNP superlattice domains below the fracture critical size, the mechanical stability was improved, and a long‐term, reliable high‐performance signal output was achieved. These two works not only demonstrate the potential of template assembly techniques in improving catalyst performance but also reveal that improvements in the mechanical stability of materials can be achieved by controlling the way nanomaterials are assembled.

Figure 3.

a) Schematic illustration of the method for fabricating SP superlattices using the template‐induced self‐assembly and the schematic illustration of the growth of gas bubbles on a flat film electrode, which caused a large number of inactive sites to form. Reproduced with permission.[ 43 ] Copyright 2019, ACS. b) Fabrication of patterned AuNP superlattice film by template‐induced self‐assembly. Reproduced with permission.[ 44 ] Copyright 2024, ACS.

2.2. Characterization of Colloidal Nanoparticle Superstructures

The development of characterization techniques has laid a solid foundation for the study of nanoparticle superstructures. From traditional scanning transmission electron microscopy (STEM) to today's cryogenic electron tomography (cryo‐ET), liquid‐phase transmission electron microscopy (LPEM), as well as the integration of advanced image processing and reconstruction algorithms, these technological advancements have made it possible to characterize the 3D structures of nanoparticles in conditions close to their natural environments in detail. Among them, LPEM allows for real‐time observation of nanoparticles in a liquid medium, which is crucial for studying processes like self‐assembly and nanoparticle‐liquid interactions that occur in liquid environments.[ 45 ] One particularly important method is electron tomography, which is used to form a 3D model of a sample by taking 2D projected images from multiple angles and combining these images using computational methods.[ 46 ] This technique has the advantage of high resolution and 3D reconstruction, allowing structural features to be resolved at the nano‐ or even sub‐nanometer scale, and is particularly suitable for the study of nanomaterials with complex internal structures or those that are difficult to analyze by other methods. Traditional STEM techniques are limited by the vacuum environment and struggle to reflect the true state of nanoparticles in their natural liquid settings. Cryogenic electron tomography overcomes issues related to solvent evaporation or changes in 3D configuration due to contact with support grids by rapidly freezing samples to preserve their original state. However, subtle structural changes may still occur in experimental settings.

To address these issues, Sara Bals and her team have made particularly notable contributions by developing liquid‐phase fast electron tomography (LP fast electron tomography),[ 47 ] solving the problem of structural distortion caused by solvent evaporation or capillary forces in a vacuum environment, thus allowing for 3D characterization studies of colloidal assemblies in water or various solvents. Initially, using a K‐kit liquid cell system and robust principal component analysis (RPCA) methods, researchers were able to efficiently acquire and process 3D structural data of samples in liquids.[ 47 ] They optimized image registration through the iterative closest point (ICP) algorithm and addressed the missing wedge issue caused by a limited angular range with a novel 3D reconstruction algorithm. Research shows that this technology enables detailed structural analysis of nanoparticles while maintaining their native state, providing a powerful new tool for exploring biomolecules, soft matter, and nanomaterials.

Initial attempts used amorphous silicon nitride microfluidic chambers as liquid cells, but reconstruction accuracy was compromised due to inadequate angular sampling. The application of graphene liquid cells (GLCs) significantly improved the signal‐to‐noise ratio (SNR) and allowed for the study of growth,[ 47 ] self‐assembly, and dynamic processes of nanomaterials. Through the use of high‐quality GLCs, researchers observed that CTAB ligands do not form conventional bilayer structures but may exist in micellar form, exhibiting dynamic characteristics in a liquid environment, which differs from observations under dry conditions. This work not only provides new insights into the local structure and distribution of CTAB on the surface of individual gold NRs but also proposes a new 3D reconstruction algorithm to solve the missing wedge problem caused by a limited angular range, highlighting the shortcomings of traditional reconstruction algorithms.

In the field of structural characterization of colloidal nanoparticles, computer simulation plays a crucial and multidimensional role. First, computer simulation can assist in predicting the formation of complex structures, and the algorithms developed by Glotzer and Engel et al. have the ability to predict the structure of self‐assembled polyhedral nanoparticles, allowing researchers to know in advance what structures are likely to emerge, and thus allow them to carry out experimental studies in a more targeted manner.[ 48 ] Focusing on the areas of dense stacking of crystals and disordered materials, Torquato and team have provided a theoretical basis for understanding the stacking mode of polyhedra and the formation of crystal structures, which is an important guide for material design and structural studies in related fields.[ 49 ] Second, computer simulation and experiment verify each other, and together they construct a closed‐loop optimization system of ‘simulation guides experiment‐experiment verifies simulation’. Taking the research of Dijkstra and his co‐workers as an example, they used theoretical calculations and Monte Carlo simulation methods to thoroughly investigate the process of self‐assembly of colloidal hexagonal biconical and double‐truncated conical ZnS nanocrystals into a 2D superlattice, and found that small truncations change the symmetry of the superlattice. In addition, they showed experimentally and through simulations that entropy and spherical confinement are sufficient for the self‐assembly of hard spheres into icosahedral clusters.[ 35 , 50 ] Furthermore, Vanmaekelbergh and his team successfully revealed the formation of 2D PbSe superstructures with the help of in‐situ grazing incidence X‐ray scattering, non‐in‐situ electron microscopy, and Monte Carlo simulations.[ 51 ]

In addition, computer simulations have helped to investigate the self‐assembly of different nanoparticles, and Manna's team has found that octopod nanocrystals can self‐assemble into linear chains and further form 3D superstructures through a combination of experiments and simulations.[ 52 ] Yang et al. demonstrated experimentally and through computer simulations that nanoscale Ag polyhedra can self‐assemble into the putative most densely packed structures, and even into superstructures with complex helical patterns.[ 53 ] Chen et al. on the other hand, combined liquid‐phase transmission electron microscopy with computational modelling to reveal the control of the thermodynamic equilibrium by van der Waals forces and electrostatic interactions during the self‐assembly of tetrahedral gold nanoparticles, as well as the mechanism by which the fine‐tuning of the chirality of the variable corner‐to‐corner connections is achieved.[ 54 ] In summary, the computational tools in these studies greatly accelerate the structure resolution process, successfully establish a closed‐loop optimization system of ‘simulation guides experiment‐experiment verifies simulation’, and strongly promote the development of the field of colloidal nanoparticle structure characterization.

In summary, advancements in characterization technologies, including but not limited to cryo‐ET, LPEM, and advanced image processing and reconstruction algorithms, have provided us with a powerful toolbox for thoroughly investigating the 3D structures and dynamic behaviors of nanoparticles under conditions close to their natural environment. This not only deepens our understanding of the self‐assembly mechanisms of nanoparticles but also provides theoretical support and technical assurance for the design of new types of nanomaterials. In the future, continuous optimization and improvement of these technologies are expected to achieve a more precise and comprehensive 3D analysis of nanoparticle superstructures.

2.3. Colloidal Nanoparticle Superstructure

The assembled superstructures of colloidal nanoparticles can be classified into two categories based on their degree of spatial and orientational order: crystalline superstructures and amorphous superstructures. Each type of superstructure offers distinct advantages for specific applications. Crystalline superstructures usually refer to nanoparticles arranged in a long‐range ordered manner to form a superlattice similar to a crystal structure,[ 24 , 55 ] which exhibits unique optical, magnetic, and electrical properties. In contrast, amorphous superstructures, in which nanoparticles are arranged in a disordered or short‐range ordered manner, lack long‐range periodicity but can achieve specific functional properties by tuning their local ordering, and exhibit significant advantages in applications that require mechanical properties or a broad spectrum of homogeneous optical response from the material.[ 56 ]

2.3.1. Crystalline Superstructures

Crystalline superstructures are material systems with long‐range ordered structures formed by the self‐assembly of colloidal nanoparticles, in which the nanoparticles follow a certain regular arrangement and exhibit periodic crystal‐like structures, also known as superlattice materials.[ 24 , 57 ] At the heart of building such crystalline superstructures lies the precise modulation of the interaction forces between nanoparticles to induce them to self‐organize at specific locations, leading to the formation of highly ordered superlattices. This process requires fine control of multiple factors, such as the surface properties of the nanoparticles, the environmental conditions of the solution, and external stimuli, to ensure that the nanoparticles are arranged according to predefined rules, thus generating advanced ordered materials with periodic structures.[ 58 ] The study of superlattice materials not only deepens the knowledge in the field of fundamental optical science but also promotes the development of cutting‐edge applications, including optoelectronic devices and biosensing.

Optical Properties

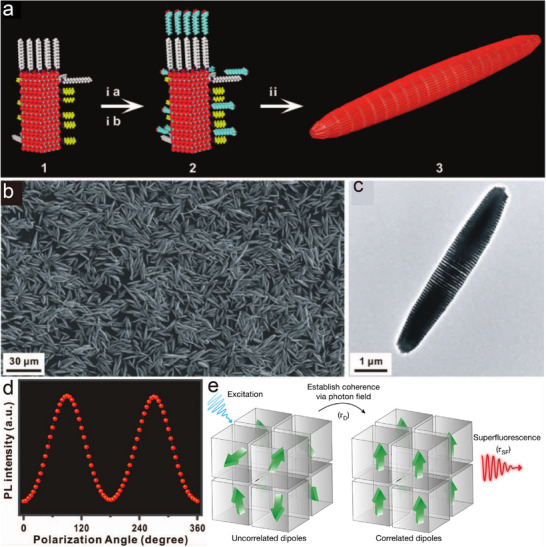

Superlattice materials show great potential for optical properties due to their unique energy band engineering and quantum effects.[ 1 , 35 , 59 ] Through in‐depth study of the energy band structure and quantum effects of superlattice materials, scientists can design new materials with excellent optical properties suitable for light‐emitting devices such as light‐emitting diodes and lasers.[ 1 , 26 60 ] In 2009, Cao's research team reported a self‐assembly study of anisotropic cadmium selenide/cadmium sulfide (CdSe/CdS) NRs.[ 34 ]In the presence of different ligands, the CdSe/CdS nanorods formed colloidal superparticles in cylindrical disks or stacked disk arrays, which exhibited linearly polarized photoluminescence properties along the axial direction. The superlattice structure can finely modulate the energy band structure of electrons and holes, thus affecting the carrier injection, transport, and compounding processes, and thus optimizing the luminous efficiency and other performance parameters of light‐emitting diodes. In 2012, additional research expanded our understanding of the assembly of colloidal superparticles. These studies demonstrated that it was possible to create colloidal superparticles with multiple well‐defined superlattice domains by leveraging the geometric morphology and structural orientation inherent to nanorods. By introducing kinetic anisotropic interactions based on functional requirements, scientists were able to successfully prepare single‐domain needle‐like superparticles (Figure 4a–c).[ 1 ] Notably, these superparticles exhibited optoelectronic properties that were linearly polarized along their axial direction (Figure 4d). This finding suggested potential applications in areas such as polarized light‐emitting diodes (PLEDs) and electro‐optical modulators, highlighting the promise of these materials in advanced optoelectronic devices.

Figure 4.

a) Scheme of needle‐like superparticle synthesis. b–c) Scanning electron microscope (SEM) image and TEM image of needle‐like superparticle. d) PL intensity versus polarization angle as the polarization was manually rotated while measuring a typical superparticle‐embedded PDMS thin film under the excitation wavelength of 380 nm. Reproduced with permission.[ 1c ] Copyright 2012, AAAS. e) Schematic of the build‐up process of superfluorescence. Reproduced with permission.[ 7b ] Copyright 2018, Springer Nature.

It has been found that lead‐halide chalcogenide quantum dots exhibit hyperfluorescence when they self‐organize to form a 3D‐ordered superlattice (Figure 4e).[ 7 ] The study shows that under high excitation density conditions, these chalcogenide nanoparticles exhibit key features of superfluorescence such as dynamic red‐shifted emission, radiative decay with more than 20‐fold acceleration, more than the fourfold extension of the first‐order coherence time, photon clustering effect, and Burnham‐Chiao oscillatory behavior. This discovery heralds potential applications in the field of high‐performance optoelectronic devices and multiphoton quantum light sources and is expected to promote the development of long‐distance quantum information transmission and ultra‐narrow tunable lasers. In addition, it was found that the long‐chain sulfobetaine‐capped CsPbBr₃ nanoparticles also exhibit monodispersity and hyperfluorescent assembly properties.[ 61 ] The study also developed theoretical models to explain the size dependence of the first and second exciton jumps in the anisotropic shapes and absorption spectra of the nanoparticles, while elucidating the exciton lifetimes at room temperature. This advancement helps to reveal the fundamental photophysical properties of such nanoparticles and promotes their applications in optoelectronic devices and quantum optics. These remarkable properties not only position superlattice materials as an ideal and indispensable choice for the cutting‐edge domains of modern optical technology and quantum information science but also provide a new direction for the development of new materials, which further promotes the progress of related technologies.

Photoelectrical Properties

Due to its special periodic arrangement and interfacial properties, the superlattice structure is indeed capable of absorbing incident photons efficiently and separating carriers effectively, thus exhibiting excellent optoelectronic properties.[ 13 ] For example, the use of PbS as superlattice materials in infrared detectors has demonstrated excellent performance;[ 62 ] and silicon‐based superlattice structures have also been extensively studied in the visible range.[ 63 ] By adjusting the parameters such as layer thickness, material combination, and doping level, the response of the sensor to specific wavelengths of light can be optimized, which gives it a broad application prospect in the fields of environmental monitoring, biomedical detection, and communication technology.

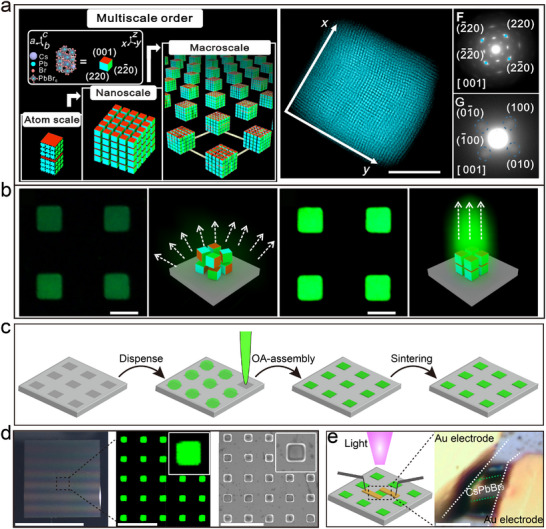

Meanwhile, perovskite nanoparticles have attracted much attention in the field of optoelectronic devices due to their unique optoelectronic properties, especially when they form a superlattice structure, where their optical and electronic properties are significantly enhanced. Li et al.[ 20 ] demonstrated that by precisely controlling the self‐assembly process, a large‐scale ordered arrangement of CsPbBr3 perovskite nanocubes can be achieved to form superlattice arrays with excellent optical properties (Figure 5a). These nanocubes self‐assembled into a superlattice exhibited a diffraction pattern similar to that of single crystals on the microscopic scale, and their fluorescence intensity was 5.2 times higher than that of randomly arranged nanocube arrays. In addition, the team demonstrated how to prepare a micropixel luminescent layer containing arrays of nanocubic superlattices acting as primary color photon emitters on a meter‐scale panel by printing technology (Figure 5b), foreshadowing its potential application in the development of high‐performance opto‐electronic devices and highly efficient directional quantum light sources. Based on these studies, we further improved the assembly method and developed a low‐temperature sintering technique assisted by nanoparticle self‐assembly (Figure 5c),[ 64 ] which led to the highly ordered arrangement of perovskite nanostructures and the successful preparation of single‐crystal microstructures (Figure 5d). With the help of atomically oriented superlattice templates formed by nanoparticle self‐assembly, we were able to grow single‐crystal CsPbBr3 microstructures on different substrates, which exhibit consistent vertical orientation, extended carrier lifetime, and rapid, sensitive, and reproducible optical response, making them ideal for use in high‐performance photodetectors and optical sensing microarray chips (Figure 5e). This technology not only provides a new path for large‐scale production of high‐quality perovskite single‐crystal materials but also enhances the flexibility and broad applicability of chalcogenide materials in optoelectronic device integration and practical applications.

Figure 5.

a) Schematic diagram of a single superlattice projected along the z direction and high‐angle toroidal dark‐field scanning transmission electron microscopy image. Scale, 200nm. b) Preparation process of superlattice array. Reproduced with permission.[ 20 ] Copyright 2022, AAAS. c) Schematic of the preparation of the CsPbBr3 single‐crystal microstructure array via NSALS. d) Detailed characterization of the CsPbBr3 single‐crystal microstructure array. e) Schematics of the CsPbBr3 single‐crystal microstructure array photodetector and the optical microscopy image of the photodetector prepared using a gold patch electrode; scale bar: 5 µm. Reproduced with permission.[ 64 ] Copyright 2024, ACS.

Raman Enhancement Effect

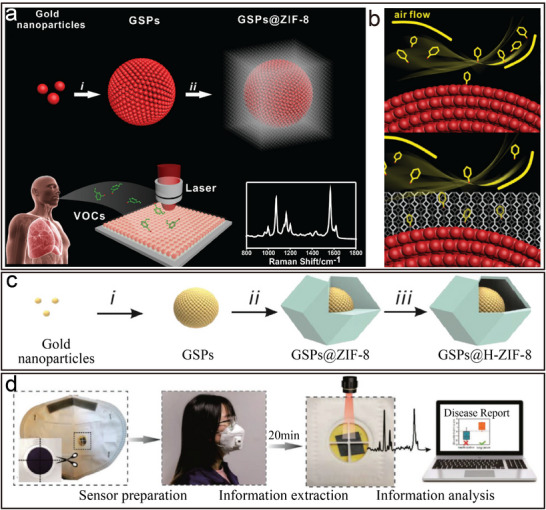

In addition to possessing excellent optoelectronic properties, superlattice materials have demonstrated great potential for the Raman enhancement effect. The successful application of superlattice structures in biosensing relies on the precise modulation of the size, shape, and surface chemistry of their constituent nanoparticles. When these parameters are optimized, superlattice materials can achieve amplified signals, thereby enhancing the sensitivity of biosensors.[ 65 ] For instance, research conducted by Qiao et al. demonstrated the highly sensitive and selective detection of lung cancer biomarkers in exhaled breath using the enhanced Raman effect of assembled GNPs, known as gold superparticles (GSPs) (Figure 6a).[ 1 ] Due to the ordered and precise arrangement of AuNPs, coating the surface of gold superparticles with ZIF‐8 exhibited strong Raman enhancement, which enhanced the Raman signal of the analyte aldehyde molecules. The experimental results showed that the structure could track gaseous aldehyde molecules (Figure 6b), indicating significant application prospects. To further enhance the performance of the structure, Li et al. designed an egg yolk‐shell‐like hollow GSPs@ZIF‐8 (Figure 6c).[ 66 ] Compared to the previous structure, this design not only maintained the effect of Raman enhancement but also enriched the gas through the hollow layer ZIF‐8, producing a stronger response (Figure 6d). Moreover, the structure selectively excluded interfering molecules, leading to a dramatic reduction in the detection limit and demonstrating immense potential in human exhaled breath detection.

Figure 6.

a) Schematic diagram of the preparation of GSPs@ZIF‐8 and schematic diagram of the detection of volatile organic compound (VOC) via surface‐enhanced Raman scattering (SERS) spectroscopy. b) Schematic illustration of GSPs and GSPs@ZIF‐8 with gas collisions. Reproduced with permission.[ 1 ] Copyright 2018, Wiley‐VCH. c) Schematic diagram of the synthetic route of GSPs@H‐ZIF‐8. d) Diagram of a SERS sensor for VOC detection and digital photos of paper‐based SERS substrate and mask sensing device for the breath test. Reproduced with permission.[ 66 ] Copyright 2022, Wiley‐VCH.

Emerging advances in nanomaterial assembly have positioned monolithic architectures as focal points in materials science, driven by their exceptional physicochemical characteristics and versatile application potential. However, despite demonstrating remarkable capabilities, single‐component systems face intrinsic limitations in functional diversity and adaptability to dynamic operational demands, restricting their utility in multifaceted real‐world scenarios. This critical gap has catalyzed a strategic shift toward binary assembly frameworks, where two distinct nanomaterials are synergistically integrated. By harnessing interfacial synergy, such systems transcend the inherent constraints of monolithic designs, merging complementary attributes of individual components while generating emergent properties unattainable in isolated materials. These synergistic interactions not only address scalability challenges but also enable programmable customization of material behaviors for targeted applications. The following section will critically analyze contemporary breakthroughs in binary assembly methodologies, with emphasis on structure‐property correlations and performance optimization strategies.

3. Binary Co‐assembly of Colloidal Nanoparticles

With the continuous progress of nanosynthesis technology, the binary co‐assembly of different types of colloidal nanoparticles according to specific design principles to achieve more complex functions and structures has attracted extensive attention.[ 9 , 10 , 14 , 67 ] Compared with single types of nanoparticles, the binary assembly of colloidal nanoparticles offers several potential advantages. First, the contact interfaces between different nanoparticles exhibit unique chemical and physical properties, which are important for a deeper understanding of interfacial effects and interfacial reaction processes. Second, the performance of optoelectronic devices can be optimized through the integration of nanoparticles with diverse optical and electronic properties. Additionally, the self‐assembly of binary nanoparticles can regulate both the interfacial reactions and the photoelectron transfer behaviors involved in photocatalytic reactions and photosensing processes, thereby enhancing photocatalytic activity and photosensing performance. Finally, the co‐assembly of two nanoparticles with complementary electronic properties provides the possibility of designing and fabricating new types of electronic devices, such as nanocrystalline transistors, nano‐circuits, and nano‐sensors. This approach opens up new paths and methods for the development of the field of nanoelectronics, demonstrating great potential in practical applications.

3.1. Binary Co‐Assembly of Spherical Colloidal Nanoparticles

In more than two decades of research on the binary self‐assembly of colloidal nanoparticles, most efforts have focused on the two‐sphere system.[ 9 , 10 , 13 , 31 , 68 ] In this context, Murray's group has made significant contributions, advancing the field substantially. In 2003, they reported the first binary superlattice composed of two groups of nanoparticles with size‐controllable properties.[ 9 ] Each group could interact with or couple to neighboring particles with diameters of less than 2 nm. The increasing availability of monodisperse nanocrystalline systems has facilitated the development of a wide range of materials, including various BNLSs. In 2006, further studies using semiconducting, metallic, and magnetic nanoparticles as building blocks successfully synthesized more than fifteen different BNLSs [ 9 ] These studies revealed that nanoparticle surface charges determine the stoichiometric ratios of these superlattices and that entropic, van der Waals, spatial repulsive, and dipolar forces are crucial factors in their formation. By 2010, researchers had achieved the rapid growth of large‐scale, well‐ordered BNLS films using a method involving the co‐crystallization of multi‐component nanoparticles at the liquid‐gas interface.[ 13 ] The scalability of this technique greatly facilitates the fabrication of nanocrystalline devices and holds promise for accelerating further exploration of these novel materials.

Subsequently, Talapin's research team focused on the study of the assembly mechanism and explored the role of hydrocarbon ligands in the self‐assembly of nanocrystalline superlattices through a series of experiments.[ 9e ] They demonstrate the deformability of the ligand overlayer, a property that leads to efficient tuning of the nanoparticle size in response to changes in the coordination environment. The role of the ligand corona in the thermodynamics and kinetics of the formation of BNLS assemblies was further elucidated by a set of systematic experiments.[ 31c ] Using gold (Au) and lead sulfide (PbS) nanoparticles containing hydrocarbon ligands as a model system, the researchers systematically tuned the core radius (R) and ligand chain length (L) of the particles and assembled them into binary superlattices. The resulting binary structure database allows for a detailed analysis of the role of the effective nanoparticle size ratio as well as the softness, expressed in terms of L/R, in guiding the binary structure assembly. This superlattice library allows not only the study of the frequencies of different phases but also the systematic measurement of the geometrical parameters of the superlattice. Based on this analysis, the researchers evaluated new theoretical models dealing with the co‐crystallization of deformable spheres and proposed new hypotheses on the factors affecting the nucleation and growth of binary superlattices.

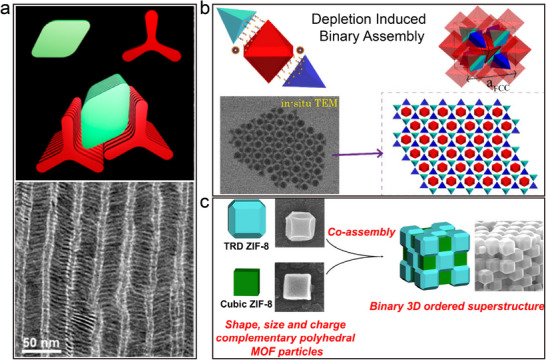

3.2. Binary Co‐assembly of Anisotropic Colloidal Nanoparticles

In contrast to the study of spherical nanomaterials, binary self‐assembly explorations involving anisotropic nanomaterials, although emerging at a later stage, have witnessed remarkable progress in recent decades.[ 67 , 69 ] These studies have not only demonstrated the potential for more precisely orientated assembly and interaction between two colloidal nanomaterials with different shapes and compositions but also revealed new mechanisms to control the formation of nanoscale structures. By finely tuning the interactions between nanoparticles and their ratios, such as by using surface modification and introducing functional molecules, researchers have opened up new avenues for nanomaterial assembly.[ 9 , 10 , 19 , 70 ]

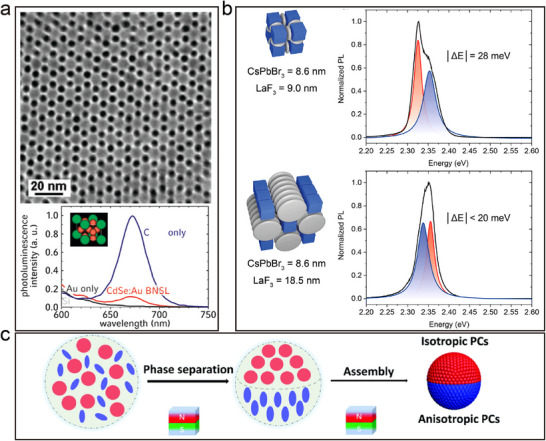

Anisotropic nanomaterials exhibit more complex interaction patterns due to their unique geometries and compositional differences. It is found that the binary combination of spherical metal nanoparticles with CdSe/CdS nanorods is kinetically limited and that suitable additives and spherical nanoparticles with high dielectric constants and large Hamaker's constants have a significant effect on the formation process.[ 14b ] Subsequently, Murray's group combined experimental and computational approaches to investigate how nanorods can overcome the natural entropic tendency towards macroscopic phase separation and aggregate into three distinct phases on the centimeter scale.[ 14c ] Monte Carlo simulations indicated that while the alloy is entropically stable at high stacking fractions, it tends to phase‐segregate at experimental densities. The simulations also revealed that short‐range attractive forces, induced by ligand stabilizers and/or depletion effects, could stabilize the alloy structure. In 2015, the group further demonstrated the successful construction of binary and ternary superlattices by combining colloidal 2D LaF₃ nanodiscs with 1D CdSe/CdS nanorods via a liquid‐phase interfacial assembly technique.[ 12 ] By regulating the liquid‐phase subenvironment used in the self‐assembly process, the researchers achieved effective tuning of the macroscopic orientation of the superlattices and ultimately prepared lamellar binary liquid crystal superlattice structures. This series of studies not only enriches our understanding of the self‐organization behavior of nanomaterials but also provides the theoretical basis and technical means for the design of novel functional materials.

3.3. Properties and Applications of BNLSs

3.3.1. Optical Collective Phenomenon

Binary superstructure materials offer limitless opportunities for innovation across various fields due to their unique properties that surpass those of single‐component materials. By selecting nanoparticles with different optical properties for co‐assembly, it is possible to achieve precise modulation of light absorption and emission, generating new optical collective phenomena and expanding their potential applications in a wide range of fields.[ 67 , 71 ] For example, the BNLSs consisting of CdS and Au nanoparticles (Figure 7a) establish the conditions to achieve fluorescence quenching of CdS nanoparticles through the coupling between excitons in the CdS nanoparticles and plasmon resonance in the Au nanoparticles. This interaction creates an additional non‐radiative decay channel by transferring resonance energy to the metal nanoparticles.[ 31 ] Additionally, layered and ReO₃‐type superlattices containing large‐sized 8.6 nm CsPbBr₃ nanoparticles exhibit collective ultrafast photoemission, a phenomenon induced by coherent coupling of the emitting dipoles in the excited state (Figure 7b).[ 67 ] These properties highlight the potential for tuning collective behaviors through interparticle distances, relative nanoparticle orientations, and interparticle media, such as band charge transport in semiconductor nanoparticle superlattices, dipole interactions in magnetic nanoparticle arrays, or near‐field couplings in plasmonic nanoparticle superlattices. This provides a theoretical and technological foundation for the development of novel optical materials and devices.

Figure 7.

a) TEM images of (001) projections of BNSLs self‐assembled from 8.7 nm CdSe and 5.5 nm Au nanoparticles and fluorescence spectroscopy. Reproduced with permission.[ 31 ] Copyright 2008, ACS. b) Emission spectrum of ReO3‐type SLs and lamellar SLs employing 8.6 nm CsPbBr3 nanoparticles and 9 nm LaF3 disks. Reproduced with permission.[ 67 ] Copyright 2021, ACS. c) Schematic illustration showing the formation of Janus PCSs from an aqueous droplet containing nonmagnetic spheres and magnetic ellipsoids. Reproduced with permission.[ 71 ] Copyright 2021, RSC.

The ordering and periodicity of BNLSs offer a wide range of applications in photonic crystallography.[ 67 ] For instance, a colloidal system consisting of a mixture of nonmagnetic SiO₂ spheres and magnetic Fe₃O₄@SiO₂ ellipsoids (Figure 7c) can be manipulated using a non‐uniform magnetic field to induce phase separation and assist in the subsequent crystallization process.[ 71 ] This results in the formation of Janus photonic crystal superstructures with distinct regions of isotropic and anisotropic optical properties. Specifically, the non‐magnetic regions exhibit isotropic optical properties, while the magnetic ellipsoidal regions show anisotropic optical properties dependent on the crystal structure. Structural colors can be magnetically tuned by changing the orientation of the hyperparticles. Binary building units, incorporating anisotropic ellipsoids alongside spheres, markedly enhance the structural and functional intricacy of photonic crystals. This combination leads to the development of multifunctional photonic crystals that boast innovative architectures and characteristics. Moreover, such binary systems offer a novel modeling framework for probing the complexities of binary colloidal assembly, thereby advancing our comprehension of these materials' organization principles and potential applications.

3.3.2. Energy Technologies

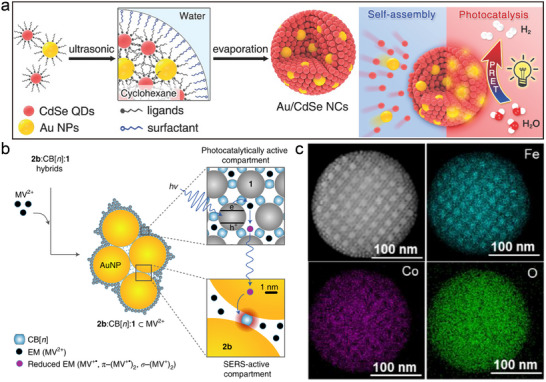

BNLS technology shows great potential in energy technology, especially in enhancing catalytic performance and improving energy storage performance.[ 13 , 26 , 72 ] By cleverly designing the interactions between different nanomaterials, BNLSs can achieve more efficient electron transfer and increase the reactive sites in the photocatalytic process, which significantly improves the catalytic efficiency. For example, Au/CdSe nanoclusters are formed by self‐assembly, and the plasmonic resonance property of GNPs promotes charge separation on the CdSe quantum dots, which improves the efficiency of photocatalytic hydrogen production (Figure 8a).[ 72 ] This enhanced effect stems from the plasma‐induced energy transfer mechanism, which enables the generation of additional electron/hole pairs under visible light irradiation, and these high‐energy carriers participate in the reduction reaction, increasing the efficiency of hydrogen production. By adjusting the size and number ratio of nanoparticles as well as the type of surface ligands, the local electric field can be enhanced, which in turn increases the number of electron/hole pairs generated by plasma‐induced generation to optimize the catalytic performance.

Figure 8.

a) Schematic illustration of the self‐assembly process used to synthesize the Au/CdSe NCs. Reproduced with permission.[ 72 ] Copyright 2017, Wiley‐VCH. b) Schematic of hybrid aggregates emphasizing the role of their compartmentalization and sorption capabilities. Reproduced with permission.[ 26 ] Copyright 2021, Springer Nature. c) HAADF‐STEM image and the corresponding elemental mapping of AB13‐type CoFe2O4−Fe3O4 binary superparticles. Reproduced with permission.[ 13 ] Copyright 2018, ACS.

In addition, InP/ZnS core‐shell nanoparticles (Figure 8b) and gold nanoparticles can achieve precise assembly control between semiconductor and metal nanoparticles through a self‐limiting assembly mechanism to form colloidally stable hybrid aggregates.[ 26e ] These aggregates can efficiently harvest light energy under light conditions and induce non‐equilibrium electron transfer processes, providing the possibility of real‐time monitoring of photogenerated electron transfer. In particular, by combining surface‐enhanced Raman spectroscopy, the researchers were able to directly observe the production of photogenerated radical species and their subsequent kinetic changes, which provides a valuable tool for an in‐depth understanding of complex photochemical reaction mechanisms. The method also provides new ideas for the development of novel and efficient photocatalysts, which can help to advance the development of energy conversion technologies.

Furthermore, the large‐scale preparation of binary superstructure materials provides a new opportunity for the development of high‐performance energy storage materials. Different types of superlattice structures (e.g., AB₁₃, AlB₂, MgZn₂, NaCl, and CaCu₅) can be realized by controlling the ratio of the size to the number of CoFe₂O₄ and Fe₃O₄ nanoparticles (Figure 8c).[ 13a ] These BNLSs not only exhibit enhanced magnetic coupling effects but also excellent lithium storage performance, thanks to their characteristic non‐compact stacking arrangement, which helps to maintain structural stability and improve the lithium‐ion diffusion rate during charging and discharging. This tunable assembly method provides an important tool to accelerate the exploration of multicomponent nanocrystalline superlattice materials and heralds the great potential for electrochemical energy storage devices and other high‐tech applications. With the continuous improvement and refinement of their synthesis methods, these materials will play an even more important role in future technological applications.

3.3.3. Biomedical Technology

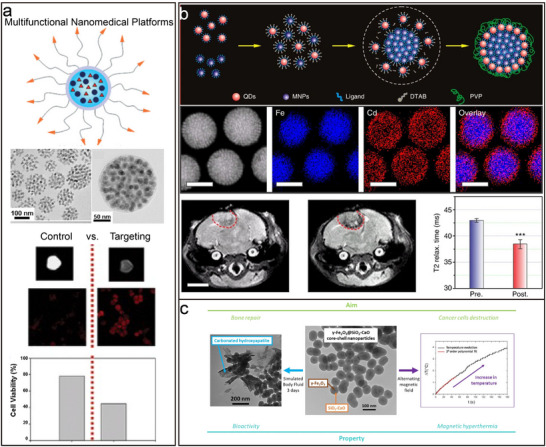

In modern research at the intersection of nanotechnology and biomedicine, NLSs have great potential for application in bioimaging, drug delivery systems, and biosensor development due to their unique biological activities.[ 1 , 73 ] Studies on the bioactivity of BNLSs usually involve the integration of different types of inorganic nanoparticles, such as magnetic iron oxide nanoparticles (Fe₃O₄) or quantum dots (CdSe/ZnS) (Figure 9a), into biodegradable polymer matrices, such as polylactic‐hydroxyglycolic acid copolymer (PLGA).[ 73 ] This combination not only provides drug carrier functionality but also acts as a magnetic resonance imaging (MRI) contrast agent as well as for optical imaging, enabling deep tissue non‐invasive imaging in living animal models, overcoming the depth limitations of conventional visible light imaging techniques. In addition, Chen et al. have made further advancements in the design of nanomaterials, developing multimodal imaging tools suitable for both magnetic MRI and near‐infrared fluorescence imaging (Figure 9b).[ 1 ] Their innovative magneto‐fluorescent core‐shell superstructures are self‐assembled from magnetic iron oxide nanoparticles and quantum dots within a polymer matrix. This configuration bestows the super‐nanoparticles with robust magnetic responsivity alongside excellent fluorescence properties. Notably, after surface polyethylene glycosylations, these silica‐coated magneto‐fluorescent super‐nanoparticles can be magnetically manipulated within living cells while maintaining their optical tracking capabilities. Additionally, these materials can serve as in vivo multiphoton and magnetic resonance dual‐modality imaging probes, providing a powerful toolkit for biomedical research. These findings demonstrate the potential of BNLSs in improving diagnostic accuracy and therapeutic efficacy.

Figure 9.

a) A multifunctional polymer nanomedicine platform for both MRI and optical imaging of cancer and effective in vitro drug delivery. Reproduced with permission.[ 73 ] Copyright 2008, Wiley‐VCH. b) Synthesis, characterizations, and biological applications of core‐shell‐structured SPs. Reproduced with permission.[ 1 ] Copyright 2014, Springer Nature. c) Superparamagnetic and Bioactive Multicore–Shell Nanoparticles (γ‐Fe2O3@SiO2‐CaO) can repair bone tissue at the same time as being used as a cancer treatment. Reproduced with permission.[ 74 ] Copyright 2020, ACS.

Due to their unique physicochemical properties, BNLSs show great potential in the biomedical field to directly intervene in the physiological processes of living organisms.[ 74 ] For example, BNLSs of magnetic nanoparticles (e.g., Fe₃O₄) and bioactive glasses (e.g., SiO₂‐CaO‐P₂O₅ tethered glass) (Figure 9c) formed by self‐assembly can be guided to the site of injury by using an external magnetic field to promote the local blood circulation and accelerate the tissue repair process.[ 74 ] Furthermore, Tasar and Ercan's study showed the possibility of combining superparamagnetic iron oxide nanoparticles (SPIONs) with bioactive glass by preparing magnetic bioactive glass nanoparticle composites through two different routes.[ 74 ] Both approaches successfully yielded magnetic bioactive glass nanoparticles with biocompatible and targeted properties. In in vitro experiments, the presence of SPIONs increased the proliferation rate of osteoblasts in both cases, and in the presence of an external static magnetic field, SDBG nanoparticles specifically increased osteoblast survival, demonstrating the potential for a wide range of biomedical applications, including targeted therapies. Together, these studies demonstrate that nanomaterials with integrated magnetic and bioactive properties can be effectively used in a variety of biomedical fields, including tissue engineering, cancer therapy, and bone regeneration, through rational design and synthesis.

Furthermore, due to its controllable structure, the superlattice can interact with other functional molecules, facilitating the development of multi‐purpose diagnostic and therapeutic platforms.[ 75 ] For example, encapsulating photosensitizers within vesicles formed by GNPs with strong plasmonic coupling effects can lead to a novel platform capable of three‐modal imaging—near‐infrared fluorescence (NIR), thermal, and photoacoustic imaging—alongside the ability to perform synergistic photothermal and photodynamic therapies.[ 75 ] By adjusting the size of the vesicles and tuning the position of the Local Surface Plasmon Resonance (LSPR) peak, the light absorption properties are optimized to meet diverse therapeutic needs. Experimental results indicate that under laser irradiation, these superstructures can efficiently penetrate cells, primarily localizing in lysosomes and being internalized via an energy‐dependent endocytosis mechanism. This platform not only enhances therapeutic efficacy but also ensures good biocompatibility and stability, opening new possibilities for biomedical applications, particularly in the diagnosis and treatment of cancer.

Advances in binary assembly research have unveiled fundamental physical‐chemical principles governing self‐organization while demonstrating precision control over nanoscale to microscale architectures through environmental manipulation. Despite progress, conventional methods remain constrained by challenges including unpredictable assembly outcomes, limited scalability, and environmental sensitivity, hindering industrial adaptation, and multifunctional material development. The integration of artificial intelligence is redefining this paradigm. AI‐driven systems employ machine learning to decode assembly behaviors across variable conditions, enabling adaptive control beyond static experimental frameworks. Unlike rule‐based approaches, these platforms utilize real‐time feedback to dynamically optimize assembly pathways, fostering structurally intricate and functionally tailored architectures. This synergy between AI and assembly science amplifies precision in nanoscale engineering while accelerating the creation of next‐generation smart materials and devices.

4. AI‐Guided Programmable Assembly of Colloidal Nanoparticles

The current binary assembly of colloidal nanoparticles is mainly based on the concept of passive design, which assembles two different types of nanoparticles through natural interactions such as electrostatic forces, van der Waals forces, etc. Although this method has been successful in some applications, with the advancement of technology and the increasing demand for applications, traditional passive assembly methods are no longer able to meet the increasingly complex and diverse practical needs. Based on the substrate selectivity and arrangement diversity of BNLSs, we can foresee that an important future trend in this field will be the realization of on‐demand fabrication of highly complex materials by AI‐guided programmable assembly.[ 76 ] We envisage that in the future, it will be possible, similar to writing a computer software programme, the rules for combining nanocrystals will be precisely designed by a variety of advanced technological means. In this way, nanostructures can be carefully programmed and positioned to achieve specific arrangements and functions, just like writing computer code. We envisage that in the future, it will be possible, similar to writing a computer software programme, the rules for combining nanocrystals are precisely designed by a variety of advanced technological means. In this way, nanostructures can be carefully programmed and positioned to achieve specific arrangements and functions, just like writing computer code. The term ‘AI‐guided programmable assembly’ here differs from traditional computer programming. It refers to controlling the assembly and precise positioning of nanocrystals through various technological means, guided by the desired structure and properties of the target nanomaterials. This approach allows for precise manipulation and customization using advanced technologies and AI techniques to ensure that the generated material meets specific requirements.

AI‐guided programmable assembly aims to reduce common disorders and structural defects in passive assembly through enhanced control over functionality, position, and arrangement of nanoparticles. Through precise control of the assembly process, binary assembly ensures high consistency and efficiency in large‐scale production, reducing batch‐to‐batch variations. AI‐guided binary assembly can achieve flexibility and diversity in material combinations. By encoding the functionality of each nanoparticle, researchers can flexibly select particle types, assembly methods, and arrangement sequences according to needs, allowing different functional modules to be combined as required, thereby creating new multifunctional materials. In addition, the AI‐guided binary assembly gives a greater opportunity to endow nanomaterials with ‘smart’ properties, enabling them to self‐regulate in response to changes in the external environment, thus becoming a smart material capable of responding to external stimuli and performing specific tasks.

The ability to control the arrangement and composition of nanoparticles opens up new avenues for designing materials with highly tunable properties. For example, by precisely controlling the spacing between nanoparticles, it is possible to modulate their electronic, optical, or catalytic properties to meet specific needs. This programmability also enables the design of dynamic materials that can adapt to environmental changes or stimuli, such as light, heat, or chemical signals. These materials could find applications in fields ranging from sensors and energy storage to drug delivery and environmental monitoring. As the technology continues to mature, the integration of AI‐guided programmable assembly with other nanotechnologies could lead to the creation of multifunctional materials with unprecedented capabilities, further bridging the gap between fundamental research and real‐world applications.

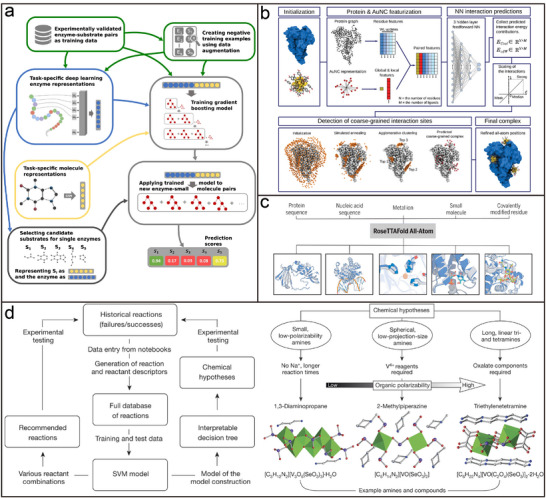

4.1. AI‐Guided Programmable Assembly Research Basis

Advancements in mono‐ and binary assembly techniques for colloidal nanoparticles have established a robust foundation for exploring more complex, AI‐guided programmable assembly. By investigating these fundamental assembly methods, researchers have significantly enhanced their understanding of the physicochemical interactions among nanoparticles, including van der Waals forces and electrostatic interactions. This accumulated knowledge enables scientists to guide nanoparticles into self‐assembling according to predefined patterns, leveraging various physicochemical forces to create innovative functional materials. These materials range from efficient photoelectric conversion materials and highly sensitive sensors to advanced catalysts and cutting‐edge photonic devices. With the rapid development of artificial intelligence (AI) technology, its unique advantages in resolving complex multi‐scale interactions, predicting dynamic assembly behaviors, and optimizing material properties have injected a revolutionary momentum into nanoscience. Such progress not only drives the field of nanotechnology toward greater practical utility but also encapsulates a systematic assembly approach. This methodical process consists of four critical stages, each essential for developing nanomaterials with specific structures and functionalities. Through the disciplined execution of these stages, scientists ensure that the final assemblies possess the desired characteristics and performance tailored for targeted applications, thereby propelling nanotechnology into new realms of possibility and application.

4.1.1. Advances in Nanoparticle Synthesis Technology

The initial step in the process of AI‐guided programmable assembly of colloidal nanoparticles involves material synthesis, which is essential to ultimately obtain nanomaterials with specific structures and functions. With the continuous advancement of nanomaterial synthesis techniques, researchers are now able to achieve highly precise control over the size and morphology of nanoparticles. Through precise manipulation of reaction conditions, nanoparticles with diverse morphologies—ranging from spherical and rod‐like to sheet‐like and even polyhedral—can be synthesized. Concurrently, advancements in synthesis technology have enabled the fabrication of multi‐component nanoparticles, encompassing alloy nanoparticles, core‐shell nanoparticles, heterojunctions, and other intricate structures. These multi‐component nanoparticles exhibit remarkable potential for application owing to their distinctive physicochemical properties.[ 1 , 4 , 77 ] However, conventional nanoparticle synthesis relies heavily on manual processes based on intuition and trial‐and‐error methods, which typically require a significant amount of time and resources to explore the vast synthesis parameter space. To overcome these challenges, researchers have begun to adopt machine learning (ML) methods for a data‐driven approach to material discovery. ML can analyze vast datasets derived from experimental results and theoretical models to predict optimal conditions for synthesizing nanoparticles with desired properties. Machine learning models can be trained on historical data to identify patterns that are not immediately apparent to human researchers, leading to the discovery of new synthesis pathways or optimization of existing ones. AI‐driven systems can also perform real‐time monitoring and adjustment during the synthesis process, ensuring consistent quality and performance of the nanoparticles produced.

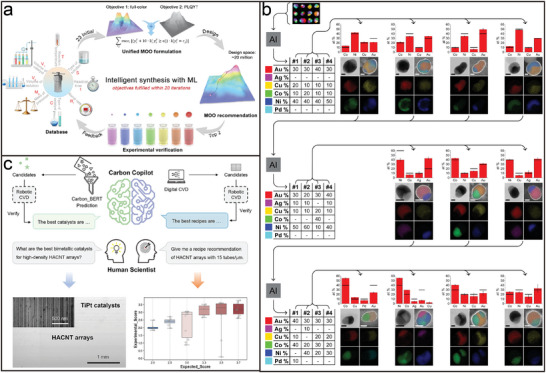

In recent years, research in ML‐assisted nanoparticle synthesis has grown rapidly, providing new avenues for accelerated material discovery and optimization.[ 78 , 81 ] This field combines advanced experimental techniques with computational science, aiming to explore nanoparticle synthesis conditions and optimize performance through data‐driven approaches. For example, Guo et al.[ 78 ] proposed a multi‐objective optimization strategy to guide the hydrothermal synthesis of carbon quantum dots (CQDs) using gradient‐boosting decision tree models such as XGBoost (Figure 10a). They achieved a high quantum yield (more than 60%) of panchromatic fluorescent CQDs in only 63 experiments, demonstrating that ML‐guided experiments can drastically shorten the research cycle and outperform conventional methods. On the other hand, Bayesian optimization, as an effective global optimization algorithm, has been applied to the synthesis of many types of nanomaterials. Wahl et al.[ 79 ] explored and successfully synthesized 18 never‐before‐seen complex heterojunction nanomaterials (Figure 10b) in 8D chemical space (including gold, silver, copper, cobalt, nickel, palladium, tin, and platinum) by using the Bayesian optimization algorithm to guide experimental processes, including extremely complex biphasic nanoparticles. In addition, high‐throughput synthesis of organic semiconductors was combined to create large datasets, and Bayesian optimization was used to discover novel hole‐transporting materials with tailored properties for solar cell applications. Predictive models are based on molecular descriptors, making it possible to relate the structure of these materials to their properties and achieve photovoltaic conversion efficiencies of up to 26.2% in chalcogenide solar cells.[ 81 ] These researches demonstrate how machine learning‐driven materials discovery can accelerate the development of complex nanomaterials and have the potential to change the way materials are explored across multiple applications.

Figure 10.

a) Workflow of ML‐guided synthesis of carbon quantum dots (CQDs) with superior optical properties. Reproduced with permission.[ 78 ] Copyright 2024, Springer Nature. b) Closed‐loop optimization for the discovery of quaternary metallic SINPs. Reproduced with permission.[ 79 ] Copyright 2021, AAAS. c) Schematic diagram of the artificial intelligence‐driven Carbon Copilot (CARCO) platform. Reproduced with permission.[ 80 ] Copyright 2025, Cell.

In addition, the development of automated experimental workstations is critical to improving the efficiency of nanoparticle synthesis. Such platforms are capable of automating a range of operations, reducing human error, and speeding up experiments. Li et al.[ 80 ] developed an AI‐driven platform called CARCO (Figure 10c), specifically targeting CBNs, specifically horizontally aligned carbon nanotube (HACNT) arrays. The platform identified a breakthrough titanium–platinum bimetallic catalyst through high‐throughput screening of catalysts, surpassing iron catalysts, which have been considered the best catalysts for growing high‐density HACNT arrays since the 2000s. CARCO has also achieved controllability of the growth density of HACNT arrays with the help of virtual experiments, which greatly enhances customization capabilities. Combined with an efficient autonomous flow chemistry system, real‐time Bayesian optimization algorithms, and other means allows the production of high‐quality nanomaterials at multiple target peaks, enabling fully autonomous materials chemistry exploration while improving experimental efficiency and material quality. As the research progresses and the technology matures, it is expected that ML will play an increasingly important role in the field of nanoparticle synthesis, facilitating the discovery and application of more high‐performance materials and providing the necessary conditions for the AI‐guided assembly of nanoparticles.

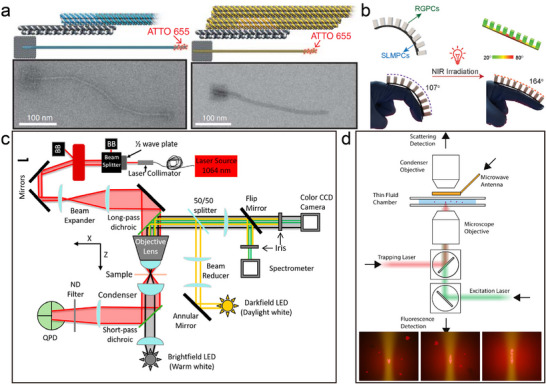

4.1.2. Development of Surface Modification and Functionalization Technologies with Fine Regulation of Nanoparticle Interactions