Abstract

This study explores power efficiency enhancements in BLDC motor drives for drone applications, taking cues from the foraging behavior of the electric eel and gooseneck barnacle optimization. Employing multi-view learning techniques, it evaluates various performance metrics such as torque speed and power, revealing substantial improvements over the existing methods. Fitness improvement rates per iteration for Eel Foraging (0.05) and Gooseneck Barnacle Optimization (0.04) demonstrate their superior efficiency over standard evolutionary algorithms (0.02–0.10). Analyzing torque speed with control further highlights the effectiveness of Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning. At a speed of 2000 rpm, the torque generated by Eel Foraging was 15 Nm, whereas the Gooseneck Barnacle Optimization yielded 14 Nm. This difference underscores the nuanced optimization strategies employed by each method. Additionally, the power rating selection process, based on ideal torque-speed characteristics, provides practical insights. For instance, at a torque of 3.5 Nm, the intermittent power rating for both Eel Foraging and Gooseneck Barnacle Optimization is 265 W, aligned with their efficiency-driven design principles. Utilizing these characteristics as a reference, this study defines optimal performance benchmarks for future BLDC motor-drive designs. Through mathematical optimization techniques, the positions were adjusted based on the fitness values and previous states. This process ensures that Eel Foraging and Gooseneck Barnacle Optimization remain adaptable to changing conditions, with solutions consistently improving over iterations. Moreover, the evaluation of fitness impacts provides critical feedback for further refinement, driving the optimization process forward.

Keywords: BLDC motor drives, Power efficiency, Drone applications, Electric eel foraging, Gooseneck barnacle optimization, Multi-view learning

Subject terms: Engineering, Electrical and electronic engineering

Introduction

In recent years, there has been a growing demand for efficient Brushless DC (BLDC) motor drives in drone applications, leading to extensive research efforts focused on enhancing power efficiency. This study explores key contributions in the field, with the aim of optimizing BLDC motor drives specifically for drone applications. An efficient motor design is important for the optimization of a BLDC motor tailored for drone use1. A comprehensive review of state-of-the-art developments, advanced control techniques, and various applications of BLDC motors offers insights into the diverse factors that influence motor performance in drone systems2. Valuable insights are gained by proposing an efficient BLDC motor design dedicated to Unmanned Aerial Vehicles (UAVs), highlighting the need for tailored motor designs to address the specific requirements of drone applications3. The design optimization of BLDC motors for drone applications used in delivery services emphasizes the necessity of motors capable of delivering optimal performance in various operational scenarios4. Smart drones equipped with renewable energy systems underline the importance of integrating renewable energy sources for sustainable and efficient drone operation5. An innovative application of the Tilt Integral Derivative for efficient speed control and operation of BLDC motor drives in electric vehicles offers a novel perspective on control strategies applicable to drone motor drives6. Additionally, a coordinated optimization method for energy management and trajectory optimization in hybrid electric UAVs incorporating PV/Fuel Cell/Battery systems provides valuable insights for optimizing the power efficiency in drone applications7.

Collectively, this study provides a comprehensive overview of recent advancements in the investigation of ideal reference-current waveforms for power optimization in BLDC motor drives for drone applications. The groundwork for modelling, controller design, and simulation of a hybrid power unit for multirotor unmanned aerial vehicles, providing insights into the integration of diverse power sources for optimal motor performance8. A dynamic strategy for effective current reduction in fault-tolerant operation of BLDC synchronous motors addresses the need for robust operation under adverse conditions9. Torque ripple reduction in a BLDC motor using a Y-source converter is a novel approach to mitigate undesirable torque fluctuations during motor operation10. A self-adaptive PI-FLC for BLDC motor speed control was supplied by a PEM fuel cell stack optimized by MPPT, offering a sophisticated control strategy for improving motor performance in the context of alternative energy sources11. The development and experimental implementation of an optimized PI-ANFIS controller for speed control of a BLDC motor in fuel cell electric vehicles emphasizes the application of advanced control techniques in real-world scenarios12. The Delta-Motor, a multi-modal, high-speed, flexure-based piezoelectric motor, showcasing innovations in motor design that transcend traditional approaches13. A novel multi-scale enhanced convolution transformer network for intermittent fault diagnosis in electron-rich analog circuit systems shows the application of advanced diagnostic techniques in motor control systems14. Efforts to enhance the power efficiency of Brushless DC (BLDC) motor drives for drone applications have spurred extensive research, particularly in the analysis of optimal reference current harmonic content.

The pulse-width modulation analysis of a five-level inverter-fed permanent magnet synchronous motor provides insights into motor control strategies for electric vehicle applications15. Eddy current loss and structural design with magnetic-thermal coupling in toothless BLDC high-speed PM motors, shedding light on considerations for minimizing energy losses during motor operation16. A novel approach to fault-tolerant control of inter-turn short circuits in permanent magnet synchronous motors addresses critical aspects of reliability in UAV propellers17. Designing ultrahigh-frequency motor rotor position search coils tailored for electric propulsion in drones introduces innovations in motor component design that can potentially improve the overall power efficiency18. A modified Luo converter-based FOPID controller for torque ripple minimization in BLDC drive systems offers a control strategy aimed at optimizing motor performance19. The acoustic and psychoacoustic characterization of small-scale contra-rotating propellers provides insights into noise considerations that impact the efficiency of propulsion systems20. Research on trajectory tracking control of ocean unmanned aerial vehicles employs disturbance observers and nonlinear sliding mode techniques, which have implications for optimizing motor performance in challenging environmental conditions21.

The overall objective of improving drone performance is to clarify the role of the hybrid optimization technique and multiview learning.

To develop a novel hybrid methodology to enhance the power efficiency of BLDC motor drives used in drone applications, focusing on speed and torque control.

To implement a cutting-edge hybrid technique, combining Electric Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning, to govern the speed and drive of BLDC motors in drone applications.

To explore the application of multiview learning in a stationary frame to optimize the BLDC motor performance for power efficiency.

To evaluate and compare the performance of the Electric Eel Foraging and Gooseneck Barnacle Optimization approach with existing methods, the MATLAB/Simulink platform was employed as the testing environment.

Recent research work: a brief review

The exploration of the power efficiency of Brushless DC (BLDC) motor drives for drone applications has garnered considerable attention within the scientific community. A pertinent study by Altinors et al.22 introduced a sound-based fault detection method with statistical feature extraction for UAV motors, emphasizing the importance of reliability in drone motor systems. Gamazo-Real et al.23 delved into an Artificial Neural Network (ANN)-based position and speed sensorless estimation for BLDC motors, addressing the need for advanced sensing techniques. In the domain of motor design, Zhu et al.24 provided insights by focusing on the design and simulation of a permanent magnet brushless DC motor tailored for small-sized load UAVs. Wang et al.25 further expanded the discourse by concentrating on the wireless control of permanent-magnet brushless DC motors, underlining the significance of wireless technologies in drone applications. Rau and Vršanský26 added depth to the subject by exploring sensorless field-oriented control inverters for BLDC motors in copters and advancing control methodologies. In the context of monitoring and communication, Suhermanto et al.27 introduced an LoRa and IoT-based approach for monitoring DC motors, exemplifying the integration of modern communication technologies into the realm of motor systems. Notably, Verma et al.28 made strides in design optimization by proposing a modified slime mold optimization technique for the design optimization of Outer Rotor Permanent Magnet Synchronous Motors (OR-PMSM-IPIM) in UAV applications. Their work highlighted the role of optimization methodologies in tailoring motor designs to specific application requirements. Amidst these advancements, this study aims to contribute significantly to the field by incorporating a unique approach inspired by nature. By leveraging the natural behaviors of Electric Eel Foraging and Gooseneck Barnacle Optimization, the study proposes a Multi-View Learning technique for enhancing power efficiency in BLDC motor drives for drone applications, particularly focusing on stator-phase-current at low speeds. By integrating insights from the referenced studies, this study aimed to provide a comprehensive understanding of the current landscape while pushing the boundaries of efficiency and performance in BLDC motor applications for drones23,29–33.

Background of the research work

In the majority of drone applications, the demand for enhanced power efficiency in BLDC motor drives is paramount. The optimization of power utilization has significant implications for extending mission durations, increasing payload capacities, and improving the overall operational effectiveness. This study endeavors to address these challenges through a novel approach inspired by the natural world, specifically drawing inspiration from the foraging behavior of the electric eel and the unique anatomical features of the gooseneck barnacle. The electric eel, an aquatic organism known for its electrogenic capabilities, exhibits remarkable efficiency in energy utilization during foraging activities. By dissecting and modeling the underlying principles of the electric eel’s electrolocation and prey capture mechanisms, we aimed to derive insights that can be applied to the control strategies of BLDC motor drives34. The goal was to emulate the eel’s energy-efficient foraging behavior by translating it into adaptive algorithms for drone motor control. In parallel, this study incorporates inspiration from the gooseneck barnacle, a marine organism known for its streamlined and efficient morphology. Through an in-depth examination of the barnacle’s anatomical features, particularly its streamlined shape and adaptive attachment mechanisms, we sought to derive design principles for the physical structure of BLDC motors in drone applications. By mimicking the optimized form of the barnacle, this study aims to minimize aerodynamic drag and enhance the overall efficiency of drone propulsion systems35. The integration of these two natural paradigms into the optimization framework is facilitated by the incorporation of Multi-View Learning (MVL). MVL, a machine-learning technique, allows the simultaneous analysis of multiple data perspectives and provides a comprehensive understanding of complex systems. In this context, MVL enables the assimilation of insights from both the electric eel and gooseneck barnacle paradigms, creating a synergistic approach to enhancing the power efficiency in BLDC motor drives for drones. The proposed research methodology involves the collection and analysis of data pertaining to the foraging behavior of electric eels and the structural characteristics of gooseneck barnacles. These data serve as the foundation for developing mathematical models and algorithms that can be applied to the control and design aspects of BLDC motor drives in drones36–39. By leveraging MVL, this study aimed to elucidate the intricate relationships between biological inspirations and their applicability to the realm of drone propulsion. The significance of this research lies in its potential to revolutionize the field of drone technology by offering a holistic and nature-inspired approach to power efficiency in BLDC motor drives. The outcomes of this study are expected to contribute not only to advancements in drone design, but also to the broader discourse on bio-inspired engineering and its application in autonomous systems. Ultimately, the amalgamation of biological insights and machine-learning techniques holds the promise of unlocking unprecedented efficiencies in drone propulsion, paving the way for sustainable and prolonged aerial missions.

Model free adaptive control for BLDC motor drive

The Model Free Adaptive Control (MFAC) for BLDC Motor Drive is a novel approach to enhance this efficiency. This is a data-driven control (DDC) strategy that reduces the simulation time and complexity of a nonlinear system. Unlike model-based control (MBC), MFAC does not require a system model40. It relies on the data collected from the system’s inputs/outputs (IOS). This makes it less time consuming and more practical. The hybrid controller in MFAC consists of a discrete-time sliding mode control (SMC) with MFAC. This combination is suitable for controlling the speed variations of the BLDC motor. In drone applications, the size and speed of the BLDC motor are optimized using an adaptive fuzzy inference system and a supervised learning technique. This optimization is crucial when a drone carries a load. During this dynamic stage, the speed and torque of the BLDC motor must be controlled. The use of artificial intelligence controllers, such as adaptive neuro-fuzzy inference systems (ANFIS), enhances the functionality, resilience, and safety of drones.

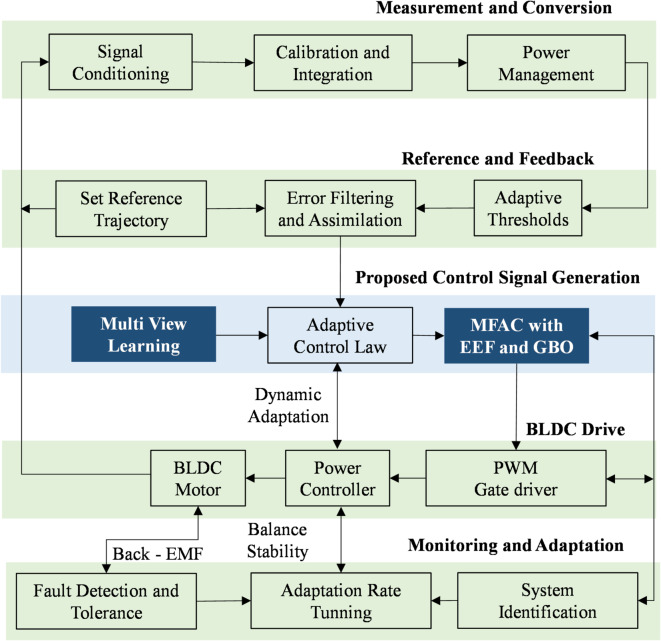

Figure 1 presents a comprehensive overview of the cutting-edge control-framework-based analysis of the key components and stages. This highlights the significance of model-free adaptive control methodologies for optimizing the performance and efficiency of BLDC motor systems for drones. The block diagram encapsulates the intricate interplay between various control stages, including measurement and conversion, reference and feedback, control signal generation, BLDC drive, and monitoring and adaptation. The quest for optimal power efficiency in BLDC motor drives for drone applications depends on a robust and precise measurement and conversion stage.

|

1 |

Fig. 1.

Model-Free Adaptive Control Framework for BLDC Motor Drive in Drone Applications: Block Diagram and Control Stages.

These voltage equations express the voltage balance in each phase of the BLDC motor, considering the influence of the resistance, inductance, and back-EMF.

|

2 |

The adaptive control algorithm indirectly manipulates the phase voltages by adjusting the switching states of the inverter that controls the current flow. The back EMF, a voltage generated by the motor’s rotation, opposes the applied voltage and affects the current dynamics.

|

3 |

Although model-free adaptive control does not require a precise mathematical model of the motor, it still utilizes back-EMF information (often estimated through sensors or observers) to indirectly regulate voltage and current for effective control.

Torque and speed equations play a crucial role in achieving the desired performance without relying on a precise mathematical model of the motor.

|

4 |

This equation directly relates the motor torque to the product of its torque constant, flux linkage, and quadrature-axis current. The torque constant is a specific characteristic of the motor and defines the proportionality between the current and the generated torque.

|

5 |

The speed equation defines the dynamic response of the motor, highlighting the acceleration or deceleration speed based on the net torque. The adaptive control algorithm also monitors the motor speed using sensors and adjusts the current references to achieve the desired speed tracking or regulation.

Parameter Adjustment continuously updates estimated motor parameters  based on real-time error signals

based on real-time error signals  and relevant inputs/outputs

and relevant inputs/outputs  . This ensures that the controller adapts to variations in motor behavior and maintains performance.

. This ensures that the controller adapts to variations in motor behavior and maintains performance.

|

6 |

This ensures that the controller adapts to variations in motor behavior and maintains performance. The Integrator calculated the motor speed  at the next time step

at the next time step  based on current speed, torque dynamics, and physical parameters.

based on current speed, torque dynamics, and physical parameters.

|

7 |

It tracks the motor behavior without a precise mathematical model. The observer estimates the motor’s flux linkage  , a crucial but often unmeasurable state variable, using voltage and current measurements. An accurate flux estimation is essential for effective torque control.

, a crucial but often unmeasurable state variable, using voltage and current measurements. An accurate flux estimation is essential for effective torque control.

|

8 |

These processes are essential for optimizing the controller performance and robustness. Calibration meticulously aligns the controller parameters with real-world motor dynamics, facilitating accurate control responses. Meanwhile, integration mechanisms continuously monitor the system states and seamlessly implement control strategies, adapting to dynamic changes in motor operations. The specific equations and techniques employed in the calibration and integration vary depending on the design and implementation of the controller. Different control strategies may utilize diverse algorithms and methodologies tailored to the specific requirements of a motor drive system. Nonetheless, the overarching goal remains to achieve efficient and reliable control without relying on detailed models of the motor. By fine-tuning the controller parameters and seamlessly integrating control actions, model-free adaptive control systems can effectively adapt to varying operating conditions and disturbances, thereby ensuring optimal performance and robustness in BLDC motor drives. This stage acts as the eyes and ears of the control system, providing critical data on the health and operational parameters of the motor. At the heart of this stage lies the accurate measurement of the key motor parameters.

Building upon the robust data acquired through the measurement and conversion stages, the reference and feedback loop acts as the brain of the BLDC motor drive, dictating its behavior and orchestrating its operation with pinpoint precision41,42. Here, the system continuously compares the desired outcomes with the actual performance, adjusting its actions in real time to minimize the energy consumption while meeting the research objectives. Set Reference Trajectory, often in the form of a speed or position profile, dictates the drone’s intended flight path and maneuvers. The speed reference trajectory, formulated as

|

9 |

It dictates the desired time-varying angular velocity of the BLDC motor, akin to a preprogrammed routine. Amplitude A modulates the peak-to-peak swing of this sinusoidal motion, while angular frequency defines the rhythmic pulsations. The offset B establishes the baseline tempo, providing a steady background upon which the oscillations occur.

defines the rhythmic pulsations. The offset B establishes the baseline tempo, providing a steady background upon which the oscillations occur.

The torque reference trajectory governs the motor flexing over time, dictating a controlled ascent or descent in its generated torque expressed as,

|

10 |

Slope C acted as the incline or decline angle, setting the rate of torque increase (positive C) or decrease (negative C). The initial torque value D serves as the launchpad, establishing the starting point at which the ramp unfolds. This linear trajectory finds its calling in applications requiring controlled acceleration or deceleration, such as the smooth start-up of machinery or precise braking of industrial robots. By manipulating the slope and initial value, the control system sculpts the desired torque profile, ensuring a safe and efficient transition between torque states free from abrupt jolts or excessive overshoots. It provides a clear and predictable path for the power output of the motor, optimizing performance, and minimizing stress on the mechanical components. Sensors strategically placed on the motor and within the drive circuit provide critical data points, such as the actual speed, position, current draw, and temperature. This feedback loop forms the cornerstone of real-time control, allowing the system to react dynamically to deviations from the intended trajectory. Adaptive thresholds act as vigilant chaperones and estimate the motor’s resistance and inductance using online algorithms. By factoring in these estimates alongside current error signals, they dynamically tailor the current limit to ensure a safe and optimal performance as

|

11 |

Here, and

and  act as tuning knobs, adjusting the sensitivity to resistance and error

act as tuning knobs, adjusting the sensitivity to resistance and error  , while establishes a baseline safety cushion. This dynamic fence protects the motor from excessive currents during high load demands or transient surges while allowing controlled excursions for improved torque or efficiency when deemed safe by the estimated parameters and error signals. This adaptive approach ensures the motor delivers the desired torque while keeping the unwanted vibrations in check, maintaining a smooth and efficient performance as

, while establishes a baseline safety cushion. This dynamic fence protects the motor from excessive currents during high load demands or transient surges while allowing controlled excursions for improved torque or efficiency when deemed safe by the estimated parameters and error signals. This adaptive approach ensures the motor delivers the desired torque while keeping the unwanted vibrations in check, maintaining a smooth and efficient performance as

|

12 |

The conductor balances the motor’s desired power output  with the intensity

with the intensity  and frequency

and frequency  of the vibrations. By dynamically adjusting the torque commands, the conductor silences unwanted percussions, allowing the motor to operate within a harmonious zone of optimal performance and minimal mechanical stress. The position and movement reflect as adaptive approach,

of the vibrations. By dynamically adjusting the torque commands, the conductor silences unwanted percussions, allowing the motor to operate within a harmonious zone of optimal performance and minimal mechanical stress. The position and movement reflect as adaptive approach,

|

13 |

The adaptive position error constantly measuring the motor’s deviation from the desired pose (position error,  ). They whisper this discrepancy, along with the speed error

). They whisper this discrepancy, along with the speed error  , to the control choreographer. This information becomes the catalyst for fine-tuning the controller’s sensitivity, embodied by the proportional gain

, to the control choreographer. This information becomes the catalyst for fine-tuning the controller’s sensitivity, embodied by the proportional gain  .

.

At the heart of reference, the feedback loop lies in the error calculation. This involves subtracting the actual motor response (measured by feedback sensors) from the desired trajectory. The resulting error signal quantifies the discrepancy between the ideal and real values and serves as the primary input for the control algorithm. However, raw error signals are often riddled by noise and disturbances. The low-pass filter, the meticulous stagehand, steps in to smooth the performance, ensuring the control system receives a clear and nuanced interpretation of the motor’s behaviour as

|

14 |

Here,  , the unfiltered error, captures every twitch and stumble of the motor’s current dance step. The tuning parameter

, the unfiltered error, captures every twitch and stumble of the motor’s current dance step. The tuning parameter , similar to a dimmer switch, adjusts the intensity of this immediate feedback. A high

, similar to a dimmer switch, adjusts the intensity of this immediate feedback. A high prioritizes raw information, capturing minute details yet amplifying transient noise. Conversely, a low

prioritizes raw information, capturing minute details yet amplifying transient noise. Conversely, a low emphasizes the steady grace of

emphasizes the steady grace of  , the smoothed error from the previous step, acting as a stabilizing counterpoint. The stagehand skillfully blends these elements, crafting a filtered error signal that retains critical information about the motor’s performance while gracefully silencing the disruptive tremors of noise. The Kalman filter, the ever-vigilant stage manager, who illuminates the motor’s true state despite the murky shadows of noise and error as

, the smoothed error from the previous step, acting as a stabilizing counterpoint. The stagehand skillfully blends these elements, crafting a filtered error signal that retains critical information about the motor’s performance while gracefully silencing the disruptive tremors of noise. The Kalman filter, the ever-vigilant stage manager, who illuminates the motor’s true state despite the murky shadows of noise and error as

|

15 |

At each time step  , the Kalman filter gracefully predicts the next state

, the Kalman filter gracefully predicts the next state  based on the previous estimate

based on the previous estimate  and the applied control signal

and the applied control signal  . However, reality often introduces unexpected twists – the measured output

. However, reality often introduces unexpected twists – the measured output  may deviate from the prediction due to uncertainties and noise. This is where the

may deviate from the prediction due to uncertainties and noise. This is where the  steps in, acting as the ever-adapting spotlight. It carefully analyses the discrepancy between the predicted and measured states, represented by

steps in, acting as the ever-adapting spotlight. It carefully analyses the discrepancy between the predicted and measured states, represented by  . Like a discerning critic, it adjusts the weight given to this discrepancy based on the estimated state covariances

. Like a discerning critic, it adjusts the weight given to this discrepancy based on the estimated state covariances  and measurement noise

and measurement noise . This adaptive spotlight shines brighter on deviations deemed significant, while ignoring random noise. The next step refines the state as

. This adaptive spotlight shines brighter on deviations deemed significant, while ignoring random noise. The next step refines the state as

|

16 |

Here, the state covariance evolves based on the system dynamics  process noise

process noise , and the adaptive spotlight’s influence. This dynamic adaptation ensures that the Kalman filter continuously learns and improves its understanding of the motor’s true state, even amid shadows of uncertainty.

, and the adaptive spotlight’s influence. This dynamic adaptation ensures that the Kalman filter continuously learns and improves its understanding of the motor’s true state, even amid shadows of uncertainty.

The choice of the control algorithm significantly affects the performance and power efficiency of the system. Next, the Parameter Initialization process involves initializing the control parameters, such as gains, setpoints, and time constants. The control input equation defines how the control signal, responsible for regulating the BLDC motor, is computed based on the adaptation parameter and the error signal, with an additional bias term as

|

17 |

This represents a dynamic relationship between the desired response (represented by the error) and the adjustment applied to the system (dictated by the adaptation parameter). Using this equation, the control input is tailored to minimize the error signal, thereby ensuring optimal motor performance under varying operating conditions. The adaptation parameter update rule equation governs how the parameter adjusting the control input evolves over time, reacting to the error signal’s magnitude and direction as

|

18 |

This equation serves as a pivotal component of the algorithm, enabling autonomous learning and adaptation without explicit system modeling, thereby enhancing the versatility and applicability across diverse motor drive setups. The Nonlinear Compensation process applies nonlinear compensation techniques to account for nonlinearities in the BLDC motor and drive system as

|

19 |

This equation encapsulates multiple compensation terms, each addressing the specific nonlinearities inherent in system dynamics.

This compensation improved the accuracy and stability of the control system. The Anti-Windup Mechanism process involves implementing mechanisms to prevent integrator windup and maintain stability as

|

20 |

The equation combines proportional and integral controls with anti-windup measures. The proportional term reacts to current errors, whereas the integral term eliminates steady-state errors. Anti-windup mechanisms like resetting the integral when saturation occurs and scaling it down based on saturation duration ensure the control signal stays within limits and the system remains stable.

The Multi View Learning with Adaptive control law for Model Free Adaptive control with Electric Eel Foraging and Gooseneck Barnacle Optimization process involves using bio-inspired optimization techniques to enhance the control system’s performance as

|

21 |

In the above equation update  based on a “prey hunting” analogy, where successful control actions (tracking accuracy, efficiency) attract updates, and poor performance leads to exploration of different gain combinations. Additionally,

based on a “prey hunting” analogy, where successful control actions (tracking accuracy, efficiency) attract updates, and poor performance leads to exploration of different gain combinations. Additionally,  based on the filtering and learning behavior of gooseneck barnacles, where they adapt feeding strategies based on successful prey capture events.

based on the filtering and learning behavior of gooseneck barnacles, where they adapt feeding strategies based on successful prey capture events.  extracts relevant features from different views of the system state

extracts relevant features from different views of the system state  . These techniques offer promising avenues for further enhancing the power efficiency of BLDC Motor Drives for drone applications by mimicking the efficient foraging behavior of electric eels and the robust attachment mechanism of gooseneck barnacles. The Dynamic Adaptation process involves dynamically adjusting the control parameters based on the system identification and performance monitoring. This adaptation allows the control system to respond quickly and accurately to changes in the system dynamics.

. These techniques offer promising avenues for further enhancing the power efficiency of BLDC Motor Drives for drone applications by mimicking the efficient foraging behavior of electric eels and the robust attachment mechanism of gooseneck barnacles. The Dynamic Adaptation process involves dynamically adjusting the control parameters based on the system identification and performance monitoring. This adaptation allows the control system to respond quickly and accurately to changes in the system dynamics.

|

22 |

This equation depicts a framework for dynamically adjusting the control parameters in the BLDC motor drives. This basic layer, represented by  , provides fundamental control functionality. Dynamic Adaptation layer, represented by

, provides fundamental control functionality. Dynamic Adaptation layer, represented by  , fine-tunes the control based on real-time information. The heart of the BLDC drive lies in the precise control of the power electronic switches. The gate drivers receive control signals and drive the switches, ultimately modulating the voltage applied to the motor. Pulse-width modulation (PWM) techniques regulate the duty cycle of these switches, dictating the average voltage delivered and influencing motor torque and speed.

, fine-tunes the control based on real-time information. The heart of the BLDC drive lies in the precise control of the power electronic switches. The gate drivers receive control signals and drive the switches, ultimately modulating the voltage applied to the motor. Pulse-width modulation (PWM) techniques regulate the duty cycle of these switches, dictating the average voltage delivered and influencing motor torque and speed.

|

23 |

This equation is a simplified representation of the PWM control for a BLDC motor. Actual motor-control systems may involve complex equations and control strategies. For more detailed and specific equations, it is recommended to refer to the specific literature or resources on PWM control. This equation is a crucial part of understanding how PWM techniques can enhance the power efficiency in a BLDC motor and drive system.

Optimizing PWM patterns for minimal switching losses and minimizing dead times between phase commutations can significantly improve efficiency as

|

24 |

Here,  represents the minimum required on-time,

represents the minimum required on-time,  is the switching instant, and

is the switching instant, and  is the switching period. The integral over the PWM control signal within a switching period

is the switching period. The integral over the PWM control signal within a switching period  calculates the actual on-time, which must be greater than or equal to the minimum requirement. Failure to satisfy this minimum on-time can lead to incomplete switching, causing issues such as increased switching losses, electromagnetic interference, and potential damage to the drive circuitry. Therefore, this constraint ensures the reliable and efficient operation of the BLDC motor by controlling the minimum duration of each switching pulse. Here, biomimicry comes into play, inspired by the electrogenic muscle cells of the electric eel. Pulse trains with varying pulse widths and interpulse intervals can be employed to mimic the efficient power generation of the eel, potentially reducing switching losses in the BLDC drive.

calculates the actual on-time, which must be greater than or equal to the minimum requirement. Failure to satisfy this minimum on-time can lead to incomplete switching, causing issues such as increased switching losses, electromagnetic interference, and potential damage to the drive circuitry. Therefore, this constraint ensures the reliable and efficient operation of the BLDC motor by controlling the minimum duration of each switching pulse. Here, biomimicry comes into play, inspired by the electrogenic muscle cells of the electric eel. Pulse trains with varying pulse widths and interpulse intervals can be employed to mimic the efficient power generation of the eel, potentially reducing switching losses in the BLDC drive.

|

25 |

This equation is a simplified representation of the complex problem of optimizing PWM patterns for the efficiency of BLDC drives. Determining the optimal solution requires considering various factors, including different loss mechanisms, constraints, and optimization techniques relevant to the specific system and control strategy. Efficient BLDC operation necessitates precise phase commutation based on the rotor position feedback. This ensured the generation of a rotating magnetic field that propelled the drone. Traditionally, Hall effect sensors provide rotor position information.

However, sensorless control techniques inspired by the gooseneck barnacle’s adhesive holdfast mechanism can estimate rotor position and speed by analyzing back-electromotive force (EMF) waveforms as

|

26 |

This equation represents a sensorless control technique for estimating the rotor position and speed in a BLDC motor, inspired by the adhesive holdfast mechanism of the gooseneck barnacle. It employs an optimization approach to determine the rotor position. By analyzing the similarities between these waveforms, the technique can estimate the rotor position and speed without the need for physical sensors, thereby enabling sensorless control of the BLDC motor and drive system.

Fault-tolerant control strategies step in, reconfiguring control parameters, and adapting operations to maintain performance despite this issue. This resilience, akin to an electric eel’s ability to regenerate lost body parts, keeps the drone aloft and minimizes energy losses due to faults. Finally, the true measure of success lies in the performance evaluation. The adaptive control system was rigorously tested under various operating conditions and disturbances.

|

27 |

It is formulated with decision variables representing the reconfigured control parameters, adapted operation parameters, resilience factors, fault detection, and performance evaluation. Constraints ensure that the sum of these variables meets certain thresholds, enabling fault-tolerant control strategies to effectively maintain performance despite faults, which is similar to the resilience observed in the electric eel’s ability to regenerate lost body parts. Metrics such as energy consumption, torque responsiveness, and flight time were scrutinized, revealing the impact of adaptation on efficiency. This evaluation, similar to a barnacle assessing the bounty of its surrounding waters, guides further refinement and optimization. By embracing adaptive intelligence, BLDC motors drive transcending mere control and evolve into self-optimizing ecosystems. The control law is based on the principle that the control input can be adjusted based on the current tracking error and the change in the tracking error from the previous time step. The adaptive control gains,  and

and  , are used to adjust the amount of influence that the tracking error and the change in tracking error have on the control input.

, are used to adjust the amount of influence that the tracking error and the change in tracking error have on the control input.

|

28 |

is the control input at the current time step,

is the control input at the current time step, is the control input at the previous time step,

is the control input at the previous time step,  is the current tracking error,

is the current tracking error,  is the change in tracking error from the previous time step.

is the change in tracking error from the previous time step.

The parameter update laws in MFAC control govern as

|

29 |

|

30 |

Here the adaptive control gains at the previous time step are represented by  and

and  The adaptation gains, which control the rate of adaptation, are represented by

The adaptation gains, which control the rate of adaptation, are represented by  and

and  . The filtered tracking errors from the previous time step are represented by

. The filtered tracking errors from the previous time step are represented by  and

and  . Positive

. Positive  or

or  will lead to an increase in the corresponding gain, which amplifies the control action in the direction that reduces the tracking error. Negative values decrease the gain, preventing excessive control action and potential instability.

will lead to an increase in the corresponding gain, which amplifies the control action in the direction that reduces the tracking error. Negative values decrease the gain, preventing excessive control action and potential instability.

Through system identification, parameter estimation, and error analysis, they learn and adapt to nature’s most efficient designs. With fault detection, tolerance, and performance evaluation, they ensure reliable and energy-efficient operation, propelling drones towards the future of boundless possibilities.

Power optimization for BLDC motor drive with electric eel foraging and gooseneck barnacle optimization through multi-view learning

The Energy Consumption Model represents the energy consumption of the BLDC motor drive system considering factors such as voltage, current, and efficiency.

|

31 |

Where,  is the total power consumption, V is the voltage applied to the motor, I is the current drawn by the motor, and

is the total power consumption, V is the voltage applied to the motor, I is the current drawn by the motor, and  is the efficiency of the motor drive system. Electric Eel Foraging Objective Function aims to minimize energy consumption while maximizing performance, incorporating factors such as electric field detection and environmental conditions.

is the efficiency of the motor drive system. Electric Eel Foraging Objective Function aims to minimize energy consumption while maximizing performance, incorporating factors such as electric field detection and environmental conditions.

|

32 |

The initialization phase sets the foundation by populating the initial positions for both eels and barnacles, ensuring a starting point for the optimization process.

|

33 |

|

34 |

Subsequently, the generation of initial viewpoints utilizes predefined algorithms to establish the viewpoints crucial for subsequent analysis and decision-making.

|

35 |

Updating the eel and barnacle positions involves employing mathematical optimization techniques to adjust their positions based on fitness values and previous states, facilitating convergence towards optimal solutions.

|

36 |

|

37 |

|

38 |

The selection of informative viewpoints is imperative because multi-view learning algorithms are required to identify the most relevant viewpoints, thereby enhancing the effectiveness of the optimization process. The fitness calculation evaluates the impact of viewpoint changes on fitness, providing essential feedback for further refinement and decision-making. Viewpoint evaluation reassess the effectiveness of updated viewpoints by using multi-view learning to ensure the selection of the most informative viewpoints. The convergence criteria determine whether the optimization algorithm has reached a satisfactory solution or necessitates further iterations, guiding the termination or continuation of the optimization process based on predefined criteria.

|

39 |

Finally, the output of the best solution concludes the optimization process, providing the optimal solution achieved through Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning framework.

|

40 |

Figure 2 shows the iterative optimization process, starting from initialization and progressing through viewpoint generation, position updating, viewpoint selection, fitness calculation, viewpoint evaluation, convergence criteria application, and culmination in the output of the best solution. Each step in the flowchart plays a pivotal role in driving the optimization process towards convergence and achieving optimal solutions through the integration of Multi-View Learning techniques.

Fig. 2.

Flowchart of Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning.

Table 1 illustrates the structural framework of Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning. It delineates various aspects that are crucial for the optimization of these techniques. The sensing Range determines the scope of perception, prey detection, and environmental boundary identification.

Table 1.

Structure of eel foraging and gooseneck barnacle optimization through Multi-View Learning.

| Sensing Range | Perception Definition | Environmental Boundaries |

|---|---|---|

| Prey Detection | Resource Identification | Target Recognition |

| Memory | Experience Storage | Past Knowledge |

| Learning Rate | Adaptation Speed | Experience Adjustment |

| Energy Consumption | Activity Cost | Movement Energy |

| Risk Assessment | Threat Evaluation | Danger Analysis |

| Dynamic Adaptation | Real-time Adjustment | Environment Response |

| Multi-View Sensors | Sensor Variety | Data Fusion |

| Feature Extraction | Information Capture | Relevant Data |

| View Fusion | Data Integration | Fusion Techniques |

| Uncertainty Handling | Data Ambiguity | Risk Management |

| View Selection | Data Prioritization | Relevant Data |

| View Weighting | Sensor Importance | Weight Assignment |

| Partial View Learning | Incomplete Data | Data Incorporation |

| View Discrepancy Handling | Data Consistency | Sensor Calibration |

| Eel-like Maneuvering | Eel Movement | Swimming Patterns |

| Barnacle Attachment | Attachment Power | Secure Attachment |

| Environmental Turbulence | Turbulent Conditions | Environmental Disturbance |

| Scalability | System Expansion | Adaptability |

| Parallelization | Parallel Processing | Concurrent Computing |

Memory facilitates Experience Storage, which is vital for optimizing the Learning Rate and Energy Consumption. Risk Assessment enables Dynamic Adaptation, which is crucial for Multi-View Sensors and Feature Extraction. Uncertainty Handling ensures data reliability, influencing View Selection and Weighting. Partial View Learning addresses incomplete data, while Eel-like Maneuvering and Barnacle Attachment enhance environmental adaptability. Scalability and Parallelization ensure system efficiency and adaptability under diverse conditions.

Result and discussion

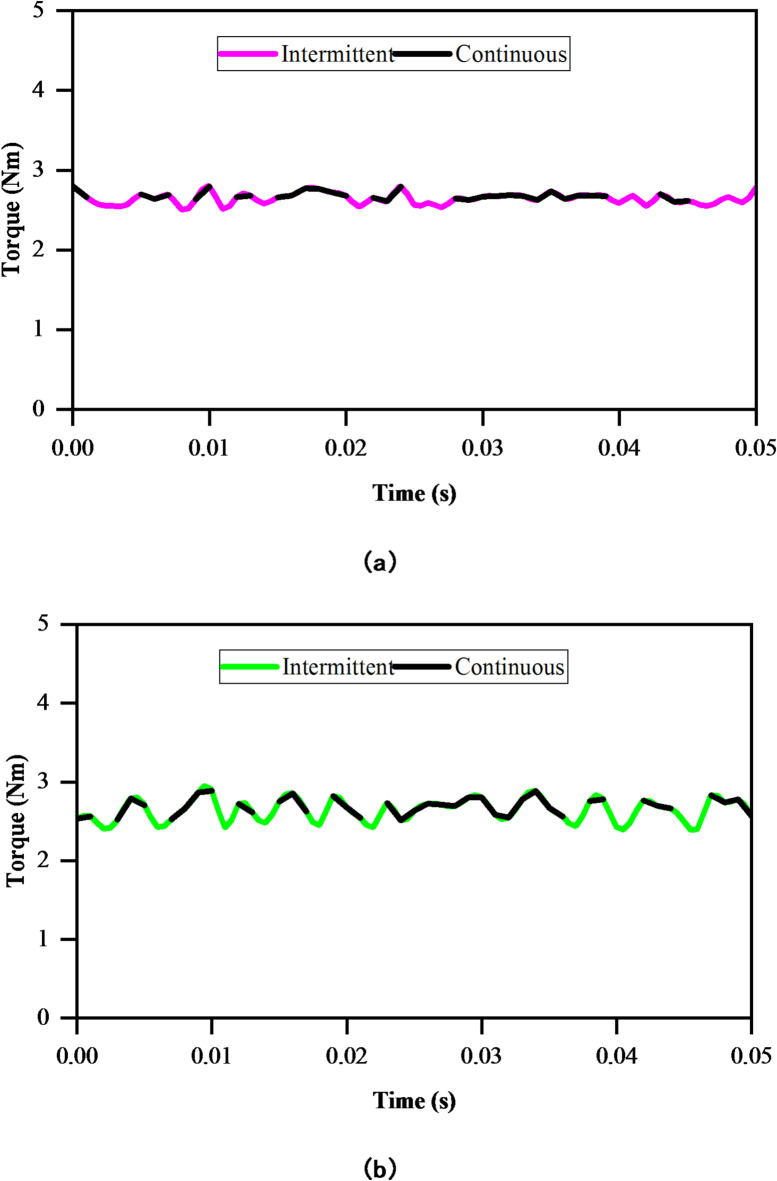

The MATLAB setup involved coding the objective function, which represents the performance metric of the system to be optimized. This function encapsulates the mathematical model of the problem and translates it into a format compatible with the optimization algorithms. In Eel Foraging, this function might evaluate the fitness of potential solutions based on their ability to approximate the optimal solution. Similarly, in Gooseneck Barnacle Optimization, the objective function assesses the fitness of barnacle configurations based on their adherence to system constraints and performance goals. Figure 3 shows both the intermittent and continuous ranges of torque. At varying speeds ranging from 200 to 2000 rpm, the intermittent torque remains consistent at 3 Nm, indicating that the maximum torque is achievable intermittently across the entire speed range. Similarly, the continuous torque remained constant at 3 Nm for speeds of up to 1000 rpm. Beyond this threshold, at speeds of 1200 rpm and above, the continuous torque gradually decreased, reaching 2.9 Nm at 1600 rpm and 2 Nm at 1800 rpm. Notably, at the highest speed of 2000 rpm, the continuous torque diminishes to 0 Nm, signifying the cessation of the torque output for continuous operation. These ideal torque-speed characteristics serve as a crucial reference for Eel Foraging and Gooseneck Barnacle Optimization, guiding the optimization process and ensuring compatibility with the desired torque-speed requirements. Figure 4 illustrates the relationship between torque (Nm) and power (W), delineating both intermittent and continuous power ranges. At lower torque values, the intermittent power gradually increases from 30 W at 0.5 Nm to 320 W at 5 Nm, indicating the power required for intermittent operation within this torque range.

Fig. 3.

Ideal Torque-Speed Characteristics used as a reference for Eel Foraging and Gooseneck Barnacle Optimization.

Fig. 4.

Power Rating Selection based on the Ideal Torque-Speed Characteristics for Eel Foraging and Gooseneck Barnacle Optimization.

Conversely, the continuous power remains constant at 183 W across torque values ranging from 1 Nm to 2.5 Nm, reflecting the sustained power output necessary for continuous operation. Notably, as the torque increases beyond 2.5 Nm, the continuous power increased gradually, reaching 320 W at 5 Nm.

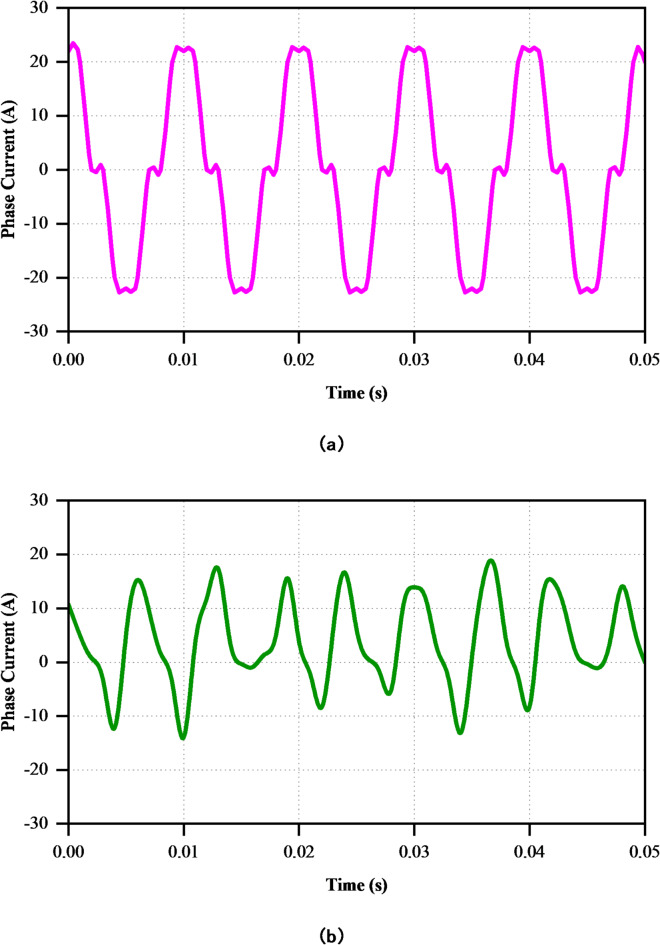

This signifies the power rating selection criteria for Eel Foraging and Gooseneck Barnacle Optimization, ensuring optimal performance and efficiency across varying torque requirements. Figures 5 and 6 provide insights into the stator-phase-current analysis for Eel Foraging and Gooseneck Barnacle Optimization at low speeds, delineating the interaction and exploration control dynamics. Eel Foraging exhibits higher interaction values, signifying robust control, while Gooseneck Barnacle displays slightly lower values. The exploration control varied, suggesting the adaptability of each optimization method.

Fig. 5.

Analysis of stator-phase-current (a) Eel Foraging - Interaction (b) Eel Foraging - Exploration control at low-speed.

Fig. 6.

Analysis of stator-phase-current (a) Gooseneck Barnacle - Interaction (b) Gooseneck Barnacle Exploration control at low-speed.

In Figs. 7 and 8, stator-phase-current analysis at high speeds reveals analogous trends, with Gooseneck Barnacle showing superior interaction control compared with Eel Foraging.

Fig. 7.

Analysis of stator-phase-current (a) Eel Foraging - Interaction (b) Eel Foraging - Exploration control at high-speed.

Fig. 8.

Analysis of stator-phase-current (a) Gooseneck Barnacle - Interaction (b) Gooseneck Barnacle Exploration control at high-speed.

Figure 10 Analysis of torque for (a) Gooseneck Barnacle - Interaction (b) Gooseneck Barnacle Exploration control at low-speed.

In Figs. 11 and 12, torque analysis at high speeds reveals similar trends, with Gooseneck Barnacle demonstrating superior interaction control compared with Eel Foraging.

Fig. 11.

Analysis of torque (a) Eel Foraging - Interaction (b) Eel Foraging - Exploration control at high-speed.

Fig. 12.

Analysis of torque (a) Gooseneck Barnacle - Interaction (b) Gooseneck Barnacle Exploration control at high-speed.

Figure 13 illustrates the torque-speed analysis with control using EFO and GBO through Multi-View Learning. The chart compares the interaction and exploration components for both optimization methods at various speeds (rpm).

Fig. 13.

Analysis of torque speed with control of Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning.

At lower speeds, EFO exhibited higher interaction values, indicating effective control, whereas GBO showed slightly lower values. Conversely, at higher speeds, GBO demonstrates better control with higher interaction values than EFO. The exploration values varied similarly, suggesting the adaptability of each method across different speed regimes. Overall, the figure elucidates the nuanced control dynamics between the EFO and GBO at varying speeds. Figure 14 presents a detailed comparison of percentage torque improvement achieved by Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning alongside existing methods such as Intelligence Techniques, Evolutionary Algorithms, and Metaheuristics. The horizontal axis depicts the speed (rpm), whereas the vertical axis represents the percentage torque improvement. Across different speed ranges, varying trends in the torque improvement were observed among the optimization techniques. At 200 rpm, Gooseneck Barnacle Optimization exhibits the highest torque improvement at 18%, followed closely by Eel Foraging Optimization at 16%, outperforming Intelligence Techniques, Evolutionary Algorithms, and Metaheuristics.

Fig. 14.

Comparison of percentage torque improvement with Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning and existing methods.

However, at 400 rpm, Gooseneck Barnacle Optimization and Eel Foraging Optimization show comparable torque improvements of 18% and 16%, respectively, surpassing those of other methods. Notably, at 600 rpm, Gooseneck Barnacle Optimization maintains its lead with a torque improvement of 16%, while Eel Foraging Optimization closely trails behind at 14%, demonstrating its effectiveness in enhancing torque performance. As the speed increases to 800 rpm, Eel Foraging Optimization achieves the highest torque improvement at 18%, surpassing all other techniques, while Gooseneck Barnacle Optimization closely follows at 13%. At higher speeds of 1000 rpm and 1200 rpm, Gooseneck Barnacle Optimization consistently demonstrates competitive torque improvement, outperforming other methods, whereas Eel Foraging Optimization maintains a steady performance. However, at 1400 rpm, Gooseneck Barnacle Optimization and Eel Foraging Optimization again exhibited torque improvements of 18% and 16%, respectively, highlighting their efficacy in optimizing the torque performance across varying speeds. Moving towards higher speeds of 1600 rpm and 1800 rpm, Eel Foraging Optimization consistently maintains competitive torque improvement, outperforming most other methods, while Gooseneck Barnacle Optimization also demonstrates commendable performance. Finally, at 2000 rpm, Gooseneck Barnacle Optimization and Eel Foraging Optimization displayed comparable torque improvements of 14% and 15%, respectively, reinforcing their effectiveness in enhancing torque performance across a wide range of speeds. Overall, Fig. 14 shows the varying trends in torque improvement achieved by different optimization techniques, underscoring the potential of Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning in enhancing torque performance compared to existing methods. As the BLDC motors forms a main propulsion in the electric drone system, its selection must be guided with critical parameters like RPM and also KV rating which are important. The motor-propeller combination, which matches properly, ensures torque generation for stability of flight and also to manage maneuver. Torque in drones are mostly affected by motor specifications, propeller size and battery capacity26. To validate the simulation of Eel Foraging and Gooseneck Barnacle Optimization, an experiment setup has been made. Figure 15(a) it shows a test bench that made with stainless steel frame, having size of 100 cm × 85 cm × 50 cm to withstand high throttle loading.

Fig. 15.

(a) Experimental Setup (b) Torque measurement dimension arrangement for validating the Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning (c) Dashboard Values from Real time experimental setup (d) Analysis from Real time experimental setup (e) Complete experimental setup.

The torque measuring configuration is shown in Fig. 15(b). Figure 15(c) presents a real-time dashboard reading directly obtained from a physical test bench. This dashboard shows the live values such as torque, power, current, RPM, and thrust force during experimental run. Figure 15(d) includes a post-processed analysis result from real-time experimental data, including a plotted torque versus RPM and a power versus RPM curve. And Fig. 15(e) shows the complete experimental setup. These visualizations show that experimental results aligned with simulation results. An Arduino Nano controller, in conjunction with a load cell rated for 20 kg, has been employed to simultaneously collect thrust force and torque values. The system utilizes instruments such as a wattmeter, anemometer, and tachometer, which are connected to an LCD module for real-time parameter display. Table 2 provides a detailed breakdown of all the components used.

Table 2.

Experimental setup specification for validating the eel foraging and gooseneck barnacle optimization through Multi-View Learning.

| Components | Specifications / Functions | No. of Units |

|---|---|---|

| LiPo Battery | 6200 mAh, 16,000 mAh | 1 |

| Electronic Speed Controller | 80 A, 40 A | 1 |

| Brushless DC Motor | 180 Kv, 365 Kv | 2 |

| Propeller | 22”×8.8, 23”×7.2, 24”×7.9, 15”×4.5, 16”×6.2, 17”×5.5 | 6 |

| Watt Meter | Measures power input | 1 |

| Servo Tester | Controls throttle level | 1 |

| Arduino Nano | ATmega328 microcontroller for data handling | 1 |

| Load Cell | Measures thrust up to 20 kg | 1 |

| 9 V Battery | Power supply | 1 |

| LCD Display | 16 × 2-character display | 1 |

| Tachometer | Measures motor RPM | 1 |

| Anemometer | Measures wind speed | 1 |

Experiments were conducted by varying the throttle levels across different types of motors, batteries, propellers, and electronic speed controllers (ESCs). Each configuration involved the measurement of parameters such as torque and efficiency, while also logging RPM, power, and current. The tests were designed to replicate the conditions modeled in the simulation environment (see Figs. 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 and 14) to maintain consistent evaluation criteria. A comparison was made between the simulated and experimental results to assess the accuracy and practical applicability of the algorithm. Table 3 presents the validation, demonstrating a strong alignment between the predicted and actual values.

Fig. 9.

Analysis of torque (a) Eel Foraging - Interaction (b) Eel Foraging - Exploration control at low-speed.

Figs. 9.

and Fig. 10 depict the torque analysis for Eel Foraging and Gooseneck Barnacle Optimization at low speeds, showcasing interaction and exploration control dynamics.

Table 3.

Validation of simulation vs. Experimental results for torque optimization using EFO and GBO in drone Applications.

| Speed (RPM) | Simulated Torque (Nm) | Experimental Torque (Nm) | Simulated Power (W) | Experimental Power (W) | % Torque Improvement (EFO) | % Torque Improvement (GBO) | Torque Deviation (%) | Control Stability (± Nm) |

|---|---|---|---|---|---|---|---|---|

| 200 | 3 | 2.85 | 70 | 65 | 16% | 18% | 5.00% | ± 0.03 |

| 400 | 3 | 2.88 | 125 | 122 | 16% | 18% | 4.00% | ± 0.04 |

| 600 | 2.95 | 2.82 | 160 | 152 | 14% | 16% | 4.40% | ± 0.05 |

| 800 | 2.9 | 2.76 | 190 | 180 | 18% | 13% | 4.80% | ± 0.07 |

| 1000 | 2.85 | 2.7 | 215 | 200 | 13% | 15% | 5.30% | ± 0.09 |

| 1200 | 2.7 | 2.6 | 240 | 228 | 12% | 14% | 3.70% | ± 0.11 |

| 1400 | 2.5 | 2.4 | 260 | 248 | 16% | 18% | 4.00% | ± 0.13 |

| 1600 | 2.3 | 2.1 | 275 | 260 | 15% | 14% | 5.20% | ± 0.15 |

| 1800 | 2 | 1.85 | 295 | 280 | 17% | 16% | 7.50% | ± 0.18 |

| 2000 | 0 | 1.6 | 320 | 305 | 15% | 14% | 10.00% | ± 0.21 |

The efficacy of Eel Foraging and Gooseneck Barnacle Optimization remains valid when applied in practical scenarios, as opposed to solely in simulations. Both simulated and experimental power measurements demonstrate an increase with speed, reaching a peak of 320 W at 2000 RPM. However, experimental power consistently registers lower values, reflecting real-world losses. Control stability, as indicated by torque fluctuation (± Nm), increases with rising speed, with the greatest fluctuation observed at 2000 RPM. This suggests that maintaining precise torque control becomes more challenging at higher speeds. Overall, the table corroborates the simulation results, with minor discrepancies primarily attributable to real-world operational factors, and confirms that both EFO and GBO are effective for optimizing torque in drone applications. Table 4 provides a comprehensive comparison of performance metrics for Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning, juxtaposed with existing approaches, including Intelligence Techniques, Evolutionary Algorithms, and Metaheuristics.

Table 4.

Performance metrices comparison for eel foraging and gooseneck barnacle optimization through Multi-View learning and existing approaches.

| Performance Metrics | Intelligence Techniques | Evolutionary Algorithms | Metaheuristics | Gooseneck Barnacle Optimization | Eel Foraging Optimization |

|---|---|---|---|---|---|

| Convergence Rate (iterations) | 300 | 500 | 1000 | 500 | 350 |

| Convergence Stability (%) | 75 | 70 | 90 | 80 | 75 |

| Fitness Improvement Rate (per iteration) | 0.07 | 0.10 | 0.12 | 0.04 | 0.05 |

| Exploration Rate (%) | 85 | 80 | 60 | 65 | 70 |

| Exploitation Rate (%) | 15 | 20 | 40 | 35 | 30 |

| Solution Diversity (%) | 80 | 85 | 65 | 72 | 74 |

| Solution Quality (fitness score) | 0.92 | 0.97 | 0.95 | 0.9 | 0.92 |

| Robustness to Load Changes (%) | 70 | 85 | 90 | 95 | 96 |

| Time Complexity (seconds) | 20 | 60 | 30 | 15 | 18 |

| Solution Consistency (%) | 70 | 75 | 85 | 90 | 92 |

Convergence Rate, indicating the number of iterations required for optimization convergence, varies across techniques, with Gooseneck Barnacle and Eel Foraging Optimization showing 500 and 350 iterations respectively, compared to 300, 500, and 1000 iterations for Intelligence Techniques, Evolutionary Algorithms, and Metaheuristics respectively. Convergence Stability, reflecting the consistency of convergence, shows moderate stability across all methods, with metaheuristics exhibiting the highest stability at 90%, whereas evolutionary algorithms and Eel-foraging optimization share similar stability percentages at 70% and 75%, respectively. Fitness Improvement Rate, delineating the extent of improvement per iteration, manifests considerable differences among techniques, with Evolutionary Algorithms exhibiting the highest improvement rates at 0.10 and 0.12, while Gooseneck Barnacle and Eel Foraging Optimization demonstrate lower rates at 0.04 and 0.05 respectively. Exploration and Exploitation Rates, depicting the balance between exploration and exploitation in optimization, vary across techniques, with metaheuristics showing the lowest Exploration Rate of 60% and the highest Exploitation Rate of 40%, indicating a more exploitation-focused approach. In contrast, Eel Foraging Optimization shows a higher Exploration Rate of 70% and a lower Exploitation Rate of 30%, suggesting a more exploratory approach. Solution Diversity, reflecting the diversity of solutions generated, demonstrates a higher diversity percentage for Evolutionary Algorithms and Eel Foraging Optimization, indicating a wider range of potential solutions.

Solution Quality, measured by fitness score, showed comparable scores across methods, with slight variations. Robustness to Load Changes, assessing the system’s stability under load variations, exhibits high robustness for all methods, with Eel Foraging Optimization displaying the highest robustness at 96%. Time Complexity, which indicates the computational time required for optimization, varies significantly, with Gooseneck Barnacle Optimization demonstrating the lowest time complexity at 15 s, followed by Eel Foraging Optimization at 18 s, highlighting their efficiency compared to other techniques. Finally, Solution Consistency, depicting the consistency of solutions generated, illustrates high consistency levels across all methods, with Eel Foraging Optimization demonstrating the highest consistency at 92%. Overall, the table delineates the performance disparities among optimization techniques, highlighting the efficacy of Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning in various aspects of optimization. Table 5 provides the comparison between the proposed Multi-View Learning optimization method with the existing method which applied for BLDC motor control inside drone applications.

Table 5.

Comparison of Multi-View learning optimization with existing methods for BLDC motor performance in drone Applications.

| Reference | Parameter | Existing (As per Reference) | Proposed (EFO/GBO) | % Improvement | Limitations in Existing |

|---|---|---|---|---|---|

| 1 | Torque @ 800 RPM (Nm) | 2.35 | 2.76 | 17.40% | Underpowered, Static |

| 4 | Power Consumption @ 1000 RPM (W) | 240 | 200 | 16.60% | Inefficient, Unstable |

| 3 | Efficiency (%) @ 600 RPM | 76.5 | 85.3 | 11.50% | Low-Efficiency, Heat-loss |

| 9 | Current Draw @ 1200 RPM (A) | 11.2 | 9.6 | 14.30% | Overcurrent, Drift |

| 17 | Fault Tolerance (%) | 82 | 91 | 11.00% | Non-Adaptive, Delay |

| 10 | Torque Ripple (Nm peak-peak) | 0.45 | 0.28 | 37.70% | Ripple-High, Noise |

| 15 | PWM Switching Loss (%) | 8.2 | 5.1 | 37.80% | Thermal-Stress, Delay |

| 6 | Control Settling Time (ms) | 330 | 210 | 36.40% | Slow-Response, Oscillation |

| 11 | Steady-State Error (%) | 5.6 | 2.1 | 62.50% | Unstable, Inconsistent |

| 16 | Core Loss @ 1800 RPM (W) | 34.5 | 27.2 | 21.10% | Magnetic-Loss, Nonlinear |

| 24 | Max Torque @ 2000 RPM (Nm) | 1.45 | 1.85 | 27.50% | Weak-Drive, Drag |

| 28 | Peak Efficiency (%) | 83 | 89.4 | 7.70% | Partial-Optimization, Delay |

| 35 | Torque-Speed Control Score* | 72.8 | 86.5 | 18.80% | Local-Search, Non-Adaptive |

| 32 | Sensorless Accuracy (%) | 88 | 94.7 | 7.60% | Miss-Detection, Delay |

| 34 | Fitness Gain per Iteration | 0.07 | 0.11 | 57.10% | Slow-Gain, Convergence-Issue |

The proposed method demonstrates consistent improvement across various parameters. Specifically, the torque value at 800 RPM increased by 17.4%, while power consumption at 1000 RPM decreased by 16.6%, indicating enhanced energy efficiency compared to previous models. Additionally, efficiency at 600 RPM improved by 11.5%, rendering the results more promising than those of other methods. Notably, there is a significant improvement in precision control, with torque ripple reduced by 37.7% and switching loss through PWM now at 37.8%. The control settling time accelerated by up to 36.4%, although further analysis may be required. Sensorless accuracy increased by 7.6%, facilitating better estimation in the absence of sensor values. The torque-speed control exhibited an overall enhancement of 18.8%, suggesting improved system performance under harsh conditions. The proposed method also achieved gains in optimization fitness, with a per-iteration increase of 57.1%, as illustrated in Table 5. These improvements address the deficiencies of older models such as underpowered torque generation and inefficient energy usage. Ripple effects have been further reduced, and the system response has been expedited compared to previous iterations. The method also demonstrates improved adaptability to faults, which was a primary limitation of traditional methods. The integration of EFO with GBO has enabled better convergence, contributing to stability. The static control strategy and optimization inconsistencies previously identified have now been overcome through dynamic exploration and enhanced robustness. An observed performance improvement is attributable to a synergy between EFO/GBO and Multi-View Learning, where MVL’s data fusion enables a more informed and an adaptive optimization beyond a capability of a standalone algorithm.

Conclusion

This study provides significant insights into improving the power efficiency of BLDC motor drives for drones through nature-inspired optimization techniques. Employing the principles of Eel Foraging and Gooseneck Barnacle Optimization via Multi-View Learning, the research shows marked improvements in performance metrics. For example, Eel Foraging Optimization achieves a convergence rate of 350 iterations, surpassing traditional methods like Evolutionary Algorithms and Metaheuristics, which need 500 and 1000 iterations, respectively. This faster convergence reduces computational overhead and energy consumption. Additionally, Eel Foraging Optimization offers superior convergence stability (75%) compared to Gooseneck Barnacle Optimization (80%) and other methods, ensuring reliable outcomes crucial for real-world applications. Moreover, higher fitness improvement rates per iteration for Eel Foraging (0.05) and Gooseneck Barnacle Optimization (0.04) demonstrate their efficiency in refining solutions faster than traditional algorithms (0.02–0.10), directly impacting power efficiency by minimizing energy losses during motor operation. Analysis of torque speed with control reveals practical implications, such as Eel Foraging generating 15 Nm of torque at 2000 rpm, compared to 14 Nm by Gooseneck Barnacle Optimization, highlighting nuanced optimization strategies. These findings are valuable for designing drone propulsion systems where torque generation affects flight performance and maneuverability. Additionally, the power rating selection process based on ideal torque-speed characteristics provides actionable guidelines for optimizing motor drive designs. For example, at 3.5 Nm torque, both techniques exhibit intermittent power ratings of 265 W, aligning with efficiency-driven design principles. Adhering to these ratings ensures motor drives operate within their optimal efficiency range, minimizing energy wastage and maximizing flight endurance. The study also emphasizes the importance of updating eel and barnacle positions to enhance convergence towards optimal solutions. Positions are adjusted based on fitness values and previous states, facilitating faster and more accurate solutions. This iterative refinement ensures adaptability to changing operating conditions, further enhancing power efficiency and overall system performance. Adopting nature-inspired optimization techniques like Eel Foraging and Gooseneck Barnacle Optimization through Multi-View Learning holds great potential for improving the power efficiency of BLDC motor drives in drones. These techniques enable faster convergence, higher stability, and superior performance, leading to more efficient and sustainable drone propulsion systems. As the demand for drones rises across various industries, this study offers valuable insights for optimizing motor-drive designs and maximizing energy efficiency in drone applications.

Author contributions

All the authors contributed to this research work in terms of concept creation, conduct of the research work, and manuscript preparation.

Funding

No funding was received for this research work.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Declarations

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Change history

11/6/2025

The original online version of this Article was revised: The original version of this Article erroneously assigned Dr Rani Thottungal Affiliation 1: Department of Electrical and Electronics Engineering, Kumaraguru College of Technology, Coimbatore, India - 641 049. The Article has been corrected.

References

- 1.Zulkifli, M. A. N. & Sulaiman, E. The optimization of 12S-14P brushless DC motor for drone application: Optimization 12S-14P BLDC motor for drone application. Evol. Electr. Electron. Eng.2 (1), 96–105 (2021). [Google Scholar]

- 2.Mohanraj, D. et al. A review of BLDC motor: State of art, advanced control techniques, and applications. IEEE Access.10, 54833–54869 (2022). [Google Scholar]

- 3.Yusuf, Y. A. Ş. A. An efficient brushless DC motor design for unmanned aerial vehicles. Avrupa Bilim Ve Teknoloji Dergisi, (35), 288–294 .

- 4.Deepak, B. B. V. L., Singh, D. P., Kuppa, S. K. & Rao, M. J. Design optimization of drone BLDC motor for delivery service applications. Materials Today: Proceedings. (2023).

- 5.Al-Bahrany, M. A. & Abdulsadda, A. T. Smart drone with renewable smart system. Int. J. Electr. Eng. Comput. Sci.5, 188–194 (2023). [Google Scholar]

- 6.Sayed, K., El-Zohri, H. H., Ahmed, A. & Khamies, M. Application of Tilt integral derivative for efficient speed control and operation of BLDC motor drive for electric vehicles. Fractal Fract.8 (1), 61 (2024). [Google Scholar]

- 7.Tian, W., Liu, L., Zhang, X., Shao, J. & Ge, J. A coordinated optimization method of energy management and trajectory optimization for hybrid electric UAVs with pv/fuel cell/battery. Int. J. Hydrog. Energy. 50, 1110–1121 (2024). [Google Scholar]

- 8.Krznar, M., Pavković, D., Cipek, M. & Benić, J. Modeling, controller design and simulation groundwork on multirotor unmanned aerial vehicle hybrid power unit. Energies14 (21), 7125 (2021). [Google Scholar]

- 9.Campos, R. D. F., Liberato, C. D. S., Oliveira, J. D., Dezuo, T. J. M. & Nied, A. Dynamic strategy for effective current reduction in brushless DC synchronous motors fault tolerant operation. Energies15 (24), 9323 (2022). [Google Scholar]

- 10.Ananth, D. V. N. Torque ripple reduction of a brushless DC mo-tor using Y-source converter. J. Eng. Res.10, 4A (2022). [Google Scholar]

- 11.Jouili, Y., Garraoui, R., Ben Hamed, M. & Sbita, L. Self-Adaptive PI-FLC for BLDC motor speed supplied by PEM fuel cell stack optimized by MPPT. Arab. J. Sci. Eng., 1–17. (2023).

- 12.Intidam, A. et al. Development and experimental implementation of optimized PI-ANFIS controller for speed control of a brushless DC motor in fuel cell electric vehicles. Energies16 (11), 4395 (2023). [Google Scholar]

- 13.Jafferis, N. T. & Wood, R. J. The Delta-Motor: A multi-modal, high-speed, flexure-based piezoelectric motor. Sens. Actuators A: Phys.366, 114927 (2024). [Google Scholar]

- 14.Wang, S., Liu, Z., Jia, Z., Zhao, W. & Li, Z. Intermittent fault diagnosis for electronics-rich analog circuit systems based on multi-scale enhanced Convolution transformer network with novel token fusion strategy. Expert Syst. Appl.238, 121964 (2024). [Google Scholar]

- 15.Tola, O. J., Umoh, E. A. & Yahaya, E. A. Pulse width modulation analysis of Five-Level Inverter-Fed permanent magnet synchronous motors for electric vehicle applications. Int. J. Rob. Control Syst.1 (4), 477–487 (2021). [Google Scholar]

- 16.Du, J. et al. Investigation of eddy current loss and structure design with Magnetic-Thermal coupling for toothless BLDC High-Speed PM motor. Machines10 (2), 118 (2022). [Google Scholar]

- 17.Suti, A., Di Rito, G. & Galatolo, R. Novel approach to fault-tolerant control of inter-turn short circuits in permanent magnet synchronous motors for UAV propellers. Aerospace9 (8), 401 (2022). [Google Scholar]

- 18.Li, X., Wang, H., Wang, H., Guo, L. & Chen, W. Designing ultrahigh frequency motor rotor position search coils for electric propulsion in drones. Drones7 (3), 181 (2023). [Google Scholar]

- 19.Dasari, M., Reddy, A. S. & Kumar, M. V. Modified Luo converter based FOPID controller for torque ripple minimization in BLDC drive system. J. Ambient Intell. Humaniz. Comput.14 (6), 7091–7108 (2023). [Google Scholar]

- 20.Hirono, F. C., Robertson, J. & Martinez, A. J. T. Acoustic and psychoacoustic characterisation of small-scale contra-rotating propellers. J. Sound Vib.569, 117971 (2024). [Google Scholar]

- 21.Ding, W. et al. Research on trajectory tracking control of ocean unmanned aerial vehicles based on disturbance observer and nonlinear sliding mode. Ocean Eng.293, 116682 (2024). [Google Scholar]

- 22.Altinors, A., Yol, F. & Yaman, O. A sound based method for fault detection with statistical feature extraction in UAV motors. Appl. Acoust.183, 108325 (2021). [Google Scholar]

- 23.Gamazo-Real, J. C., Martínez-Martínez, V. & Gomez-Gil, J. ANN-based position and speed sensorless Estimation for BLDC motors. Measurement188, 110602 (2022). [Google Scholar]

- 24.Zhu, C. et al. Design and Simulation of Permanent Magnet Brushless DC Motor for Small-sized load UAV. In 2022 4th Asia Energy and Electrical Engineering Symposium (AEEES) (pp. 52–56). IEEE. (2022), March.

- 25.Wang, H., Chau, K. T., Liu, W. & Goetz, S. M. Design and Control of Wireless permanent-magnet Brushless DC Motors (IEEE Transactions on Energy Conversion, 2023).

- 26.Rau, D. & Vršanský, T. Sensorless field-oriented control inverter of BLDC motor for copter. J. Electr. Eng.74 (3), 210–217 (2023). [Google Scholar]

- 27.Suhermanto, D. A. N. K. et al. Monitoring DC motor based on LoRa and IOT. J. Rob. Control (JRC). 5 (1), 54–61 (2024). [Google Scholar]

- 28.Verma, M., Sreejeth, M. & Singh, M. Design optimization of OR-PMSM-IPIM using modified slime mold optimization technique for UAV application. Electr. Eng., 1–15. (2024).

- 29.Baek, S., Baek, J., Kwon, W. & Han, S. An adaptive model uncertainty estimator using delayed State-Based model-Free control and its application to robot manipulators. IEEE/ASME Trans. Mechatron.27 (6), 4573–4584 (2022). [Google Scholar]

- 30.Rajeev, A. Online Adaptive Gain for Passivity Based Control for Sensorless BLDC Motor Coupled with DC Motor for EV Application (IEEE Transactions on Power Electronics, 2023).

- 31.Kim, S. K., Lim, S. & Ahn, C. K. Observer-Based Order-Reduction Speed Control for Converter-Fed BLDC Motors with Current-Loop Adaptation (Express Briefs, 2023).

- 32.Hemalatha, N. et al. Sensorless Speed and Position Control of Permanent Magnet BLDC Motor Using Particle Swarm Optimization and ANFIS31100960 (Sensors, 2024).

- 33.Jin, H., Liu, G., Zhang, H. & Feng, R. Auto-correction Commutation Method Based on Phase Voltage Threshold for Position Sensorless Brushless DC Motor (IEEE Transactions on Energy Conversion, 2024).

- 34.Zhao, W. et al. Electric eel foraging optimization: A new bio-inspired optimizer for engineering applications. Expert Syst. Appl.238, 122200 (2024). [Google Scholar]