SUMMARY

Plastic pollution requires urgent global action, including continued Global Plastics Treaty negotiations. A systems change approach is essential, with growing momentum for a plastics circular economy that emphasizes recycling and bio-based plastics derived from vegetable and algae oils. Focusing on downstream solutions and alternative materials presents three challenges: (1) New materials introduce complexity that complicate waste sorting and management; (2) the potential implications of bio-based plastics not reducing overall demand on single-use packaging consumption; and (3) the lost art of repairing plastic and non-plastic products such as clothing, or electronic devices, which exacerbates waste generation. These challenges can be addressed by reducing plastic consumption; improving product design for better recyclability; incorporating reuse, refill, and redesign systems in current practices; and emphasizing regulatory changes that support a repair culture. Ultimately, we argue that a comprehensive approach is essential to mitigate plastic pollution effectively, requiring collaboration across sectors to drive systemic change.

Subject areas: Engineering, Environmental policy, Environmental science

Graphical abstract

Engineering; Environmental policy; Environmental science

Introduction

Plastic production, usage, and waste is a wicked, transboundary problem impacting people, communities, and natural ecosystems.1,2,3 The widespread consequences of mismanaged waste, including social, economic, and environmental costs, are accelerating.4 This has prompted a global coordinated response focusing on the development of a legally binding global plastics treaty.5,6 The scientific literature and the public eye widely accept that plastic in the environment has detrimental effects on marine and coastal fauna,7 facilitates the transportation of invasive species,8,9 and can be a navigation hazard.10 There is also increasing concern about human exposure to plastics through ingestion and inhalation,11,12 with plastic particles found in human blood and tissue.13,14

The shift to a circular plastics economy was highlighted more than a decade ago, emphasizing the need to reduce resource use and waste given the finite resources available.15 Since then, the momentum for a plastics circularity has grown, with a focus on recycled plastics to play a much larger role in consumer goods packaging and products alike.16,17 This idea is not new – over 30 years ago, Achterman18 highlighted proposed plastics recycling mandates across several jurisdictions in the United States. In practice, circular transitions have largely focused on downstream strategies such as improving polymer recycling and building recycled plastic markets.19,20,21 Emerging technologies like enzymatic and microbial degradation22 and chemical recycling23 show promise as a potential solutions for achieving a closed-loop plastic recycling system, however, the circularity potential of polymers remains constrained by complexities in material and product designs.24,25 Today, recycling rates are still only estimated to be 9% globally.26 There has been less emphasis on re-designing polymer materials currently on the market to improve their recyclability, with even less on improving the circularity of product delivery systems through reuse and refill models. This is beginning to change, with sustainability-focused businesses emerging such as CupClub, Muuse, RePack, Algramo, and Banish introducing innovative reuse systems.

The ubiquity of plastics and their demonstration of harm has increased the urgency to identify more sustainable alternatives that result in less negative impact. Attention has turned to technologies that derive polymers from non-petroleum–based oils27,28,29 as a means to decouple plastics from fossil fuels. Bio-based plastic production represented approximately 0.5% of all plastic production; however, the packaging sector accounted for 43% of the 2.18 million tonnes of bioplastics produced in 2023.30 While bio-based plastics may offer environmental benefits in specific contexts, their growing use in single-use applications risks reinforcing unsustainable consumption patterns, displacing rather than reducing environmental burdens, and delaying more transformative change.31,32,33

The transition to a circular economy for plastics has been predominantly examined through the lens of downstream interventions, particularly mechanical and advanced recycling technologies, with comparatively limited attention to upstream strategies targeting the design, production, and use stages of the plastics value chain.34 While improving the efficiency and effectiveness of recycling remains an important research priority,35 current evidence indicates that recycling alone will be insufficient to mitigate the scale of plastic pollution.36,37 Achieving substantive reductions in plastic leakage will require systemic interventions that reduce primary plastic production, increase reuse rates, and stimulate innovation across the value chain.36,37 This paper argues that current efforts to advance a circular economy for plastics have over emphasized recycling and material substitution, and a strategic reorientation toward upstream solutions positioned higher on the waste hierarchy —such as reduction, redesign, and reuse— is required.

To support this argument, this Perspective is structured into two parts. The first part discusses the challenges and opportunities to enhancing material circularity within current recycling systems. Specifically, “strengthening recycling systems through design and system-level innovation” examines the complex barriers to recycling, including consumer choices, material diversity, and systemic infrastructure limitations. “redesign opportunities to increase recycling rate” explores opportunities to improve recycling outcomes through better material design and simplification but argues that these strategies alone are insufficient to drive meaningful circularity. The second part of the paper shifts to upstream circular strategies higher on the waste hierarchy that could reduce plastic production and demand, including the role of alternative materials, reuse systems, extending product lifespans, and advocating for regulatory changes to support repair markets and culture.

This Perspective focuses primarily on single-use plastics (SUPs) and plastic packaging as key drivers of plastic pollution and circular economy challenges. While the majority of our discussion centers on these materials, achieving meaningful circularity also requires addressing systemic barriers across other product sectors. Examples from other plastic products, including textiles and electronic appliances, are selectively included to illustrate broader systemic challenges and opportunities for transitioning to a plastics circular economy. Including this broader range highlights how different plastic types interact with existing recycling systems and how they can contribute to or hinder circularity efforts. Together, these sections illustrate practical opportunities to advance a more sustainable, circular approach.

Strengthening recycling systems through design and system-level innovation

Recycling is often seen as a solution to reduce plastic waste and decrease reliance on non-renewable virgin materials. However, current global recycling rates remain low at just 9%, proving insufficient to counteract the ongoing increase in global plastic production.35 While advancements in mechanical and chemical recycling technologies offer the potential to enhance recycling efficiency and move toward a closed-loop or circular system,38,39,40,41 existing policies have not yet fostered a significant shift from virgin to recycled plastics. Although the recycled plastics market is anticipated to grow more rapidly than the virgin plastics market, it is projected to account for only 12% of overall plastic production by 2060.42 To facilitate the transition to a circular plastics economy, there is a need to boost demand and pricing for recycled plastics, alongside increased investment in recycling advancements.

The effectiveness of recycling as a circular strategy is limited by a range of systemic challenges, including material diversity, consumer confusion, and infrastructure constraints. In response, increasing attention has turned to product and material design as a critical enabler of more effective recycling. Simplifying polymer use, standardizing formats, and designing for disassembly can help reduce contamination, support efficient sorting, and improve the economic viability of recycled materials. While these innovations are necessary to strengthen existing systems, they also highlight the limits of downstream solutions. The following sections examine the interrelated barriers and opportunities in recycling and design, arguing that improvements in both areas are essential —but not sufficient— to deliver a truly circular plastics economy.

Material complexity

Retaining and maximizing the value of materials at their end-of-life is key to enabling a circular economy. A significant challenge in improving efficiencies is the complexity of plastic materials entering the waste stream. Complexities arise in identifying and sorting new and established material streams, contamination at the initial disposal stage, within the recycling facility itself, and in meeting end-market standards. For example, some compostable packaging contains per- and polyfluoroalkyl substances (PFAS),43 which are known to be toxic, are difficult to safely manage, and are becoming banned in many countries. Governments in Australia are refusing to accept compostable packaging in their curbside organic waste stream until new national standards are implemented, as the inclusion of the PFAS-containing-products in the end market compost product could exceed PFAS contamination standards.44,45 Polyolefin-based multi-layer plastic packaging offers food protection and shelf-life extension; however, their complex composition hinders recycling efforts.46 Chemical additives used in the production of plastic packaging, such as plasticizers, flame retardants, ultraviolet (UV) light and heat stabilizers, biocides, and colorants have been associated with adverse human health effects in various categories, including birth, child and adult reproductive and endocrine function, child neurodevelopment, nutritional status, circulatory and respiratory systems, skin health, and cancer outcomes.47

Consumer confusion and choices

Consumers are faced with more complex sorting of their packaging into the correct bin. Simplifying and standardizing the types of materials entering the waste stream, curbside collection, and waste sorting for consumers could improve sorting and reduce contamination.48 Apps, education materials, and standardized labeling (e.g., the new Australasian recycling label; Figure 3) exist to alleviate consumer confusion, however, contamination remains problematic. If efficient sorting of materials is achieved, local waste and recycling systems may still be unable to handle the variety of materials that enter the waste and recycling streams given current infrastructure and systems in place. Additionally, upgrades of management practices and infrastructure are slow and expensive and could exacerbate the divide in standardizing processes across sub-national jurisdictions.49

Figure 3.

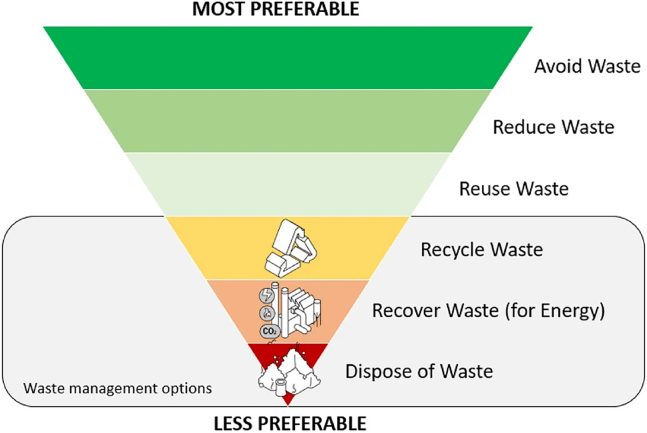

Waste hierarchy from Soenmez et al.53

Infrastructure and market challenges

The development of new materials presents opportunities to strengthen plastic value chains, but also introduces new challenges for recycling systems. An additional challenge is found in new materials on the market, which are not entering the waste and recycling stream in volumes that make their recycling economically viable, nor do these new materials have an established market for material recovery. While material innovation offers opportunities to improve the durability and applicability of plastics, it is critical that new materials are designed with recyclability in mind to ensure they can be effectively re-circularized at end-of-life. Without this consideration, the introduction of new materials may add further complexity to already strained recycling systems. Investment in current practices and systems to improve new and current material end-of-life management50 and secondary material markets is required, alongside building and maintaining consumer trust in recycling systems. For example, in Australia, the lack of adequate end markets and mismanagement of a post-consumer soft-plastics recycling system led to its collapse51 with a resultant loss of public trust in new and replacement recycling schemes.52 Additionally, the recycling scheme did not reduce the consumption of soft-plastic packaging but instead encouraged consumers to continue purchasing at ever increasing levels, with the expectation that these materials would be recycled.

Redesign opportunities to increase recycling rates

Significant advancements in chemical and advanced recycling technologies are improving the recycling rates of difficult-to-recycle materials, such as polyvinyl chloride (PVC) and polystyrene (PS), and are critical to circularizing these plastics. However, opportunities also exist further up the waste hierarchy to improve recycling outcomes within the current system, without requiring the development of new recycling technologies or major infrastructure investments. Practical strategies that enhance recycling outcomes using existing infrastructure are urgently needed to support the transition to a circular plastics economy, where packaging waste is minimized, recovered, and reused. Redesigning plastic packaging plays a central role in this transition, helping to substantially reduce the amount of valuable materials lost to landfilling, incineration, or exportation to low-cost countries.53,54 Design frameworks for plastic circularity include reducing the amount of virgin plastics used in manufacturing, enhancing mechanical recyclability of products, and eliminating hazardous substances from packaging.55 Additionally, efficient plastic separation and mechanical recycling could be facilitated by reducing or eliminating difficult-to-recycle plastics such as PS, PVC and blended multi-layer films.56 By focusing on reducing the diversity of polymers entering the waste stream, improving packaging labeling and consumer incentives, and standardizing packaging materials and design, recycling efficiency and material recovery could be significantly enhanced within the current system. These redesign elements provide an opportunity to assign a new value to plastic.

Simplifying polymers

Simplifying and reducing polymer types used in packaging manufacture could significantly improve recyclability and accelerate transitions to a plastic circular economy. Focusing on a smaller range of polymers, particularly polyethylene terephthalate (PET), polypropylene (PP), high-density polyethylene (HDPE), and low-density polyethylene (LDPE), would make post-consumer plastics easier to sort and separate during recycling. Polyolefins (PP and PE/polyethylene) and PET are the most common plastics used in food packaging, making up 46% of all plastic packaging waste in the UK. These plastics have strong recyclate markets and can be efficiently separated due to differences in their densities, facilitating straightforward mechanical recycling and the production of high-quality recycled materials. For example, a further 10% of UK plastic packaging waste (up to 56%) could be mechanically recycled if it was standardized to either PET or PP, and plastics such as PVC, PS, blends, composites and some PE films were removed.56 Mechanical recycling of plastic packaging waste could approach 100% if a two-stream recycling system was implemented.56 A two-stream system would involve one recycling stream for PET/PP, another stream for HDPE/LDPE, alongside the phase-out of plastics such as PVC, PS, blends, composites, and some PE films used in multi-layer plastic packaging. Maintaining and strengthening the role of polyolefins and PET will be critical for building a robust global plastics circular economy, while designing out plastics that lack strong recyclate markets remains essential to improving recycling efficiency.

The redesign of plastic packaging must also address chemical contaminants, including additives, dyes, and pigments, that complicate recycling and pose potential health risks. A comprehensive database of chemicals associated with plastic packaging has identified numerous hazardous substances used as additives, monomers, and colorants.57 These identified substances include persistent “legacy additives” such as flame retardants, stabilizers, and plasticizers, which are classified as substances of very high concern (SVHC) or persistent organic pollutants (POPs).58 Current recycling processes can transfer these hazardous chemicals into new plastics, which may migrate into food that is in contact with the plastic and expose humans to the chemicals.59 For example, chemicals like bisphenol A (BPA) and di-(2-ethylhexyl) phthalate (DEHP) are known to migrate from plastic packaging into food, posing risks for humans such as endocrine disruption and carcinogenicity.47,60,61 Dyes and pigments used in printing inks and colored plastic fabrication are also among the non-intentionally added substances (NIAS) that can migrate from plastic packaging into food and the environment.58 International regulations such as the EU REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) and the UN Stockholm Convention regulation set thresholds for hazardous chemicals and aim to eliminate or restrict the production and use of POPs in products globally.62 Plastics have been shown to have adverse effects on human health throughout their life cycle, and while efforts to increase the efficiency of their use and reuse are essential, reducing their usage is vital to reducing their harm to the environment and human health.

Standardization of packaging and labeling

Packaging standardization can play a critical role in improving plastic packaging waste recycling systems. Standardization of materials helps to minimize the presence of non-recyclable or difficult-to-recycle plastics, reducing the risk of contamination and degrading the overall quality of recycled materials.56,63 For example, mono-material polymer product design technology is a promising circular solution.64 Collaborations between the recycling industry and packaging manufacturers could standardize design and improve accessibility to new, innovative packaging. Sharing the development and manufacturing cost of new, eco-designed packaging could help brands and retailers shift to a circular plastics economy, supporting a two-stream approach and driving recycling efficiency. The Golden Design Rules are an excellent example of packaging standardization (Figure 1).65 Developed in 2020 by the Consumer Goods Forum (CGF), this set of nine rules aims to reduce plastic waste by eliminating unnecessary packaging, increasing plastic value, and providing clear recycling instructions. This combination of material and design standardization has the potential to improve how plastic packaging waste is separated and processed. However, care must be taken to minimize the health impacts of the recycling process and the resulting recycled products.66,67

Figure 1.

The nine golden design rules, taken from Consumer Goods Forum65

Packaging design plays a crucial role in influencing consumer decision-making for recycling behavior. Packaging that effectively communicates recycling information can enhance consumer sorting behavior.68 However, many consumers find visual recycling elements on packaging unclear and confusing, which hinders their ability to sort correctly.69 Visual elements such as symbols, logos, and text must be clear and prominently placed to catch consumer attention and convey necessary cleaning, sorting and disposal information. Consistent placement and standardization of recycling information, such as Germany’s Der Grüne Punkt (Green Dot) and the Australasian Recycling Label (ARL) across different types of packaging, could further improve sorting behavior68,70,71,72 (Figure 2). Consumers are also more likely to recycle packaging that does not require excessive effort to clean and prepare73 or is perceived as having higher economic value, such as glass and aluminum.71 Additionally, packaging that includes educational elements about the environmental benefits of recycling can positively influence consumer attitudes and increase recycling rates.74 Reducing the complexity of packaging design and materials could positively affect its correct collection, separation and recycling rate.56,75

Figure 2.

Left: features of the Australasian Recycling Label (www.arl.org.au); right: examples of other labeling to assist consumers with correctly sorting and discarding packaging materials (https://www.solinatra.com/news/packaging-labels-composting-recycling)

Incentivizing and harmonizing collection systems

Stakeholders within the plastics value chain can further improve the quality of plastic materials entering the waste stream by incentivizing the collection and return of easily recycled plastics. Implementing and expanding deposit-return systems (DRS) can significantly increase collection rates; for example, Iceland’s DRS for PET bottles achieved a collection rate of 85%, compared to their overall plastic collection rate of 28%.76 Establishing quality benchmarks for recyclates, such as those defined by Germany’s successful Green Dot, has also helped ensure that recycled materials meet the necessary standards for reuse in new products.77 EPR schemes incentivize manufacturers to design products with recyclability in mind and subsidize end-of-life treatment of plastics, promoting better product design and higher recycling rates. Setting mandatory recycled content in plastic packaging, as proposed by the EU, UK and Australia, could also drive demand for high-quality recyclates and encourage better waste management practices.78,79 Finally, harmonizing waste collection systems across municipalities could increase the efficiency and effectiveness of plastic waste collection and recycling.80 At a local level, public education campaigns that support consumers to correctly sort and dispose of their packaging waste, thereby increasing recycling efficiencies would likely yield positive outcomes.

Opportunities to advance circular strategies higher on the waste hierarchy

While improving recycling systems and product design is essential to close material loops, these downstream strategies cannot fully address the scale of plastic production and leakage. Importantly these strategies do not address reducing overall consumption of plastic products, whether they be made from virgin or recycling polymers. More transformative progress toward a circular plastics economy requires upstream interventions that reduce overall plastic consumption and shift away from single-use systems. The next sections explore higher-order circular strategies —including reuse, repair, and critical perspectives on material substitution— to reframe how circularity can be more meaningfully achieved.

Shifting focus toward the higher levels of the waste hierarchy is required to reduce the currently accelerating global plastic packaging consumption and associated waste. SUP packaging is estimated to be the most significant contributor to global plastic waste, accounting for 50% of total plastic waste by weight.81 Although there are readily available reusable alternatives for SUP take-out food and beverage containers, straws and shopping bags, there has been less attention on alternative options for plastic-packaged grocery items. Waste hierarchy options such as avoid, reduce, and reuse (Figure 3) are preferred options for transitioning away from a dominant linear “make-use-waste” systems that utilize SUP packaging.53,82,83,84 Redesigning plastic packaging within current supply chain systems faces a number of challenges due to its role in the protection, containment, communication and convenience of consumer goods.85

Material substitution and reducing continued dependency on single-use plastics

Efforts to reduce petroleum-based single-use packaging have primarily focused on material substitution with the development of bio-based plastics. These materials are made from renewable feedstock and are often marketed as biodegradable, making them an attractive solution for alleviating the demand on non-renewable resources and reducing plastic waste. For example, polyhydroxyalkanoate (PHA) exhibit characteristics similar to those of conventional plastics,86 however, microorganisms can synthesize PHA through fermentation and are completely biodegradable.87 Advancements have improved production efficiency and environmental performance, particularly when utilizing residues and side-streams.88 Bio-based plastics are still only marginally contributing to global plastic output, however the packaging sector accounted for 43% of the 2.18 million tonnes of bioplastics produced in 2023.30

Despite their promise, bio-based plastics do not eliminate the demand for single-use packaging, they may reinforce the disposable culture they aim to replace and could create further challenges for material recovery and waste management systems. Their environmental impacts remain contested, with life cycle assessments showing highly variable outcomes depending on feedstock, processing, and end-of-life treatment.31,89,90 Most compostable bioplastics still require industrial composting and can persist in the environment if mismanaged,91 presenting similar risks to conventional plastics.92 Moreover, increased bioplastic production may shift environmental pressures elsewhere—such as land use change, biodiversity loss, and competition with food systems.32 Critically, substituting plastic types without addressing the scale of consumption may legitimize continued single-use packaging and preclude innovation and adoption of circular strategies higher on the waste hierarchy like reuse and refill systems Lee et al.33 Lasting progress requires rethinking packaging systems altogether — not just the materials they are made from.

Bioplastics should be seen as a transitional solution as their long-term effectiveness in eliminating waste is limited when compared to reusable systems. Reducing the demand for single-use packaging by implementing alternative point-of-sale and packaging systems could retain packaging value and reduce costs of post-consumer material recovery and waste disposal activities. Elimination of unnecessary packaging of products could also further reduce demand for packaging material feedstocks, whether bio-based or petroleum-based. For example, optimizing packaging-to-product ratios can decrease unnecessary space in packaging and eliminate excessive plastic usage.93

Reducing the demand for single-use plastic packaging

The properties of plastic packaging make it an ideal barrier for protecting products against physical, chemical, and biological changes.85 Transportation of fast-moving consumer goods is critical within supply chains, and packaging plays an important role in reducing product weight, plus protecting and preserving products throughout their manufacture, storage, retail and movement into consumer homes.94,95 Packaging design impacts logistical and environmental efficiency96 and minimizes food waste by extending shelf life.97 The New Plastics Economy98 identified unnecessary plastic packaging as items that are “not reusable, recyclable, or compostable in practice and at scale; contain, or require in manufacturing, hazardous chemicals that pose a significant risk to human health or the environment; can be avoided (or replaced by a reuse model) while maintaining utility; hinders or disrupts the recyclability or composability of other items, and; have a high likelihood of being littered or ending up in the natural environment.” These guidelines provide a valuable framework for assessing current plastic packaging with the goal of redesigning packaging to reduce and remove unnecessary plastic.

The ephemeral nature of plastic packaging means an estimated 95% of its value (USD 80–120 billion) is lost to global economies when discarded after a single use.98 There is also a significant additional cost to municipalities and taxpayers, who are obliged to fund the collection, processing and disposal of post-consumer plastic packaging waste. A significant area where consumers could avoid SUP packaging is in the purchase of fresh produce. Producers and retailers promote plastic packaging as essential for reducing food wastage throughout the supply chain, with pre-packaged fresh produce accounting for over half (53%) of the purchases made in Australian supermarkets.99 However, fresh produce is an ideal candidate for the removal of plastic packaging as most fresh produce items require no packaging, relying on their natural structures to protect them from contamination or damage.100 Renewed legislative efforts to reduce unnecessary packaging for fresh produce101,102 have been bolstered by the Global Plastics Treaty negotiations with the Treaty draft text including a mandate for the elimination of unnecessary packaging.6

Evidence suggests that the actual value of plastic packaging may lie outside the realm of food preservation, primarily providing an economic benefit to brands and retailers.103 Labeled “the skin of commerce,”104 packaging has developed into a powerful communication tool within consumption-driven economies, conveying brand identification,105 influencing consumer purchasing decisions106 and conveying essential product information.107,108 Visual elements on packaging, particularly color and product imagery, are crucial for capturing consumer attention and effectively communicating a brand’s message to drive purchasing.109 Understanding the convenience value of packaging for consumers is essential for its redesign to ensure positive experiences for consumers within the store, in transit, and at home. Packaging design may include features that assist in package opening, facilitate product usage, or allow closure of the package for future use.110 Bundling multiple items within packaging can also help consumers transport and store goods at home while also facilitating product sales through predetermined portioning111,112 (Figure 4). Altering these “convenience” and “point-of-sale” packaging features must be considered in any alternative packaging solution. Reusable packaging systems are gaining momentum as many of the aforementioned features can be retained while decreasing demand for SUP production.113

Figure 4.

Packaging as a protection, transport, communication, and convenience device (Author’s images)

Transitioning to reusable and refillable packaging systems for groceries

Reusable packaging systems are a promising circular economy solution to reducing plastic waste throughout the supply chain as they retain the functionality of packaging while reducing single-use packaging.114 Replacing 20% of single-use packaging by weight with returnable or refillable systems could provide a $10 billion business opportunity globally.115 The Ellen Macarthur Foundation identifies four business-to-consumer (B2C) models for reusable packaging: refill at home, refill on the go, return from home, and return on the go.115 Recently, one of the largest-scale reuse operations was pioneered by the Refill Coalition (UK), a group convened by GoUnpackaged, including Ocado Retail, Aldi UK, and supply chain solutions company CHEP. Two trials, including key food staples (e.g., cereals and pasta) and household products (e.g., cleaning and personal care products), were launched in 2024. The first, a “Refill on the go” model, in partnership with Aldi (UK), allowed users to refill personal containers in-store at Aldi. The second trial was designed for e-commerce, with reusable containers pre-filled with products and delivered to customers by Ocado. In this “Return from home” model, containers were collected by Ocado and washed before being refilled for another order. Estimates for these programs suggest that over 1.4 billion pieces of single-use packaging could be eliminated each year if each household in the UK reused one item each week.116 Reusable packaging systems implemented at scale, such as the Aldi UK example, demonstrate that there are opportunities for large retailers to adopt reusable systems and, in turn, eliminate the amount of hard-to-recycle plastic packaging on the market and in the waste stream. In another example, a reuse trial between retailer Tesco and reusable packaging company LOOP showed that reuse systems at scale are a viable business opportunity.117

For reusable packaging systems to work at scale, they need to be convenient for consumers, efficient in the supply chain and affordable. Financial mechanisms such as deposit fees and return refunds can incentivize and encourage the uptake of reusable systems by consumers and operators. As used with bottle programs in Belgium and Germany, container deposit fees create an affordable margin for back-haulers and return-operators to collect and process reusable containers.114 Return refunds incentivize high return rates from consumers, which are essential for reuse ecosystems to thrive. Over longer-term use, reuse systems should require little to no behavior change incentives from consumers, offering options for return methods such as in-store, doorstep collection or the possible use of existing municipal material recovery systems. Reuse systems also present opportunities for retailers and logistics providers. Collecting reusable packaging could build retailer brand strength and support customer retention, while home-collection booking services could improve transport efficiency for logistics providers by utilizing otherwise empty returning vehicles (i.e., reverse logistics).113,118 Finally, utilizing established return infrastructure, such as reverse vending machines in operation for deposit-return systems, provides an expansion opportunity for operational capability—especially when combined with packaging standardization.113,118

Packaging standardization for reuse is crucial to reducing costs throughout the supply chain and supporting the establishment of reusable packaging systems.119 Reducing the number of packaging formats (and polymers therein) could save costs across the logistics, handling and manufacturing supply chain sectors. Stackable and nestable packaging designs optimize storage and transport efficiency.120 Reducing the number of formats could also allow container sharing between multiple manufacturers of different products and increase the ease of collection, cleaning and maintenance of the reusable packaging.120 While many brands utilize packaging unique to their product, the variations are minor, and when standardized across a product segment, individual recognition could be achieved by applying unique visual design through labeling.121 However, labels are typically made with multi-layer laminates, with glues and dyes that lend themselves poorly to recycling. Hence, industry standards which simplify polymers and colors used in labels could substantially reduce single use plastic packaging that is not able to be recycled. Industry collaboration could lead to the development of Reuse Open Standards (in conjunction with ISO), which standardize packaging sizes, materials and labeling formats. There is an opportunity for reusable packaging to become financially viable within a well-designed system of packaging circularity, particularly as Extended Producer Responsibility (EPR) schemes are expected to increase the cost of single-use packaging in some markets by 30% in 2024.122

Barriers to product repair, longevity, and extended use

Although SUPs and packaging remain central concerns, achieving a circular economy requires addressing a broader range of plastic products. Drawing on selective examples from the textile, and electronic sectors, common challenges and opportunities for extending product lifespans are illustrated.

Increasing the functional use lifespan of products is considered one of the most effective strategies for achieving a circular economy. However, product design, planned and perceived obsolescence and the rapid pace of consumption and disposal are generating a mass of products that are difficult to repair.123,124,125 Consequently, these products are discarded. For example, the fashion industry produces over 92 million tonnes of textile waste annually, contributes 35% (190,000 tonnes) of oceanic primary microplastic pollution,126 and consumes 79 trillion liters of water.127 Global electronic waste (e-waste) reached 7.3 kg/capita128 in 2019, with only 17.4% recycled,129 and is projected to exceed 10 kg/capita by 2040.129

Repairing is ranked high on the circular economy R hierarchy130 for its role in extending product lifespans, yet a range of barriers limit its uptake. These include the low price of new products making the cost of repairing uncompetitive; the poor quality of materials used in products contributing to low profitability in repair work for businesses; access to repair technicians and take-back mechanisms; difficulty in disassembling products without damage; lack of access to and high cost of spare parts; and restricted access to appropriate repair software and instructions.123,131,132,133,134 Establishing a repair market will require not only regulatory support but also a focus on building consumer trust, skills and willingness to engage repair.133 For example, in the United States, 55% of study participants (n = 254) in a clothing repair study never or rarely repaired their clothes, finding repairing too time-consuming, alteration services too expensive, and low confidence in their mending skills.135 Additional behavioral barriers such as planned obsolescence, desire for new products and features, fear of further product failure, and poor understanding of the importance of prolonging product lifespans also constrain repair uptake.133,136,137

Rebuilding the repair market through legislation, technology, and consumer education

The shift toward a circular economy necessitates a fundamental change in regulatory frameworks to support a culture of repair over replacement. However, research has found that the repair market is unsupported by adequate policies.138 Effective regulation is crucial to ensure that essential spare parts and repair manuals accompany imported and domestically manufactured products. Current government regulatory initiatives that promote repairing mostly focus on design requirements to counter planned obsolescence and hold manufacturers accountable for the waste generated by their products.138 Policies that standardize components used in products have the opportunity to enable more circular material flows and repair.139 Design-for-repair strategies such as eco-design140 and modularity141 intend for a product to be easily disassembled and repaired, ensuring failures in one component of the product does not affect the lifespan of the whole product.

The “Right to Repair” is a promising regulatory approach as it gives people the right to use, modify and repair their products however, wherever and whenever they choose.123,142 Right to Repair regulations in the United States and the EU, set conditions for manufacturers to make spare parts and information about their products available to consumers and repair shops.143 These initiatives facilitate repair, but do not guarantee the use of high quality materials in product manufacturing, thereby not guaranteeing an extended product lifespan. Extending product longevity is among the most effective strategies for enhancing material efficiency in a circular economy. However, government and commercially attempts are lacking, often focusing on a “closing loop” rather than a “slowing loop.”131,144

Product label standards that convey product quality standards and longevity to consumers are one solution to encourage support for product longevity and repair. In Austria and Germany label standards for electronic products inform consumers of repair-friendly and eco-friendly products.138 As a repair policy landscape evolves, overcoming barriers such as intellectual property, consumer law, and tax law implications will need to be considered.123,142

Technological and business model advancements also play a role in establishing a repair system. Innovative approaches like 3D printing have the potential to produce custom replacement parts on demand.145 Additive manufacturing in repair supply chains could address logistical challenges with acquiring spare parts and reduce repair turnaround times.146 Business models such as take-back schemes could also promote product repair, longevity, and reuse of materials. For example, a take-back scheme for Nestlé Nespresso coffee machines refurbishes returned machines with up to 60% recycled plastic materials and is re-sold on the second-hand market in 10 countries.147

Consumer behavior and awareness are pivotal to fostering a repair-oriented culture. Behavioral research suggest that improving the perceived benefits of repair and strengthening social norms can make “repair” the default solution to product failure.148 Businesses can support this shift by partnering with awareness-raising initiatives. For example, Patagonia’s Common Threads Initiative with iFixit (ifixit.com), which teaches customers across the globe how to repair products.138 Similarly, addressing marketing that drives replacement and emphasizing the advantages of repair, as seen in case studies from Spain, could further shift attitudes.132,149 While 38% of consumers in the EU purchase new digital devices due to breakdowns, 77% are willing to repair them.131 Removing barriers to repair is essential for a circular economy, and an area where improvements can readily be made. Initiatives such as Repair Cafés and Precious Plastics build consumer knowledge, promote repair, and provide a hands-on role in the circular economy.150,151

Conclusion

The successful transition to a plastics circular economy requires a whole-of-system approach. While shifting toward reducing and reusing plastic packaging presents significant opportunities, it also requires overcoming considerable challenges in consumer behavior, infrastructure, and material innovation. Simplification and standardization of material streams, by reducing the diversity of plastics used in packaging, and implementing a two-stream recycling system to separate PET/PP from HDPE/LDPE could improve overall recycling efficiencies. While bio-based plastics are considered a more sustainable choice to their petroleum equivalents, they cannot entirely replace the need for systemic changes in packaging design and reuse models. Prioritizing the waste hierarchy —avoiding, reducing, and reusing plastics— as well as establishing regulatory frameworks that support a repair culture, move closer to achieving a truly circular economy. This transition is vital for reducing plastic waste, conserving resources, and meeting global sustainability goals, ultimately paving the way for a more sustainable future in packaging.

Acknowledgments

This work was supported by CSIRO Environment (K.A.W.and B.D.H.) and the Queensland University of Technology (M.R.).

Author contributions

K.A.W., conceptualization, investigation, writing – original draft, writing – review and editing, visualization, supervision, and project administration; M.R., investigation, writing – original draft, writing – review and editing, and visualization; B.D.H., writing – original draft and writing – review and editing.

Declaration of interests

The authors declare no competing interests.

References

- 1.Vince J., Stoett P. From problem to crisis to interdisciplinary solutions: plastic marine debris. Mar. Pol. 2018;96:200–203. doi: 10.1016/j.marpol.2018.05.006. [DOI] [Google Scholar]

- 2.Stoett P., Scrich V.M., Elliff C.I., Andrade M.M., de M. Grilli N., Turra A. Global plastic pollution, sustainable development, and plastic justice. World Dev. 2024;184 doi: 10.1016/j.worlddev.2024.106756. [DOI] [Google Scholar]

- 3.McIntyre O. Addressing marine plastic pollution as a ‘wicked’problem of transnational environmental governance. Environ. Liabil. Law Policy Pract. 2020;25:282–295. [Google Scholar]

- 4.Jamback J., Walker-Franklin I. The impacts of plastics’ life cycle. One Earth. 2023;6:600–606. [Google Scholar]

- 5.Simon N., Raubenheimer K., Urho N., Unger S., Azoulay D., Farrelly T., Sousa J., van Asselt H., Carlini G., Sekomo C., et al. A binding global agreement to address the life cycle of plastics. Science. 2021;373:43–47. doi: 10.1126/science.abi9010. [DOI] [PubMed] [Google Scholar]

- 6.UNEP . United Nations Environment Programme; 2023. Zero Draft Text of the Internaitonal Leggal Binding Instrument on Plastic Pollution, Including in the Marine Environment. [Google Scholar]

- 7.Gall S.C., Thompson R.C. The impact of debris on marine life. Mar. Pollut. Bull. 2015;92:170–179. doi: 10.1016/j.marpolbul.2014.12.041. [DOI] [PubMed] [Google Scholar]

- 8.García-Gómez J.C., Garrigós M., Garrigós J. Plastic as a vector of dispersion for marine species with invasive potential. A review. Front. Ecol. Evol. 2021;9 doi: 10.3389/fevo.2021.629756. [DOI] [Google Scholar]

- 9.Gregory M.R. Environmental implications of plastic debris in marine settings--entanglement, ingestion, smothering, hangers-on, hitch-hiking and alien invasions. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009;364:2013–2025. doi: 10.1098/rstb.2008.0265. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.McIlgorm A., Raubenheimer K., McIlgorm D.E., Nichols R. The cost of marine litter damage to the global marine economy: Insights from the Asia-Pacific into prevention and the cost of inaction. Mar. Pollut. Bull. 2022;174 doi: 10.1016/j.marpolbul.2021.113167. [DOI] [PubMed] [Google Scholar]

- 11.Lombardi G., Di Russo M., Zjalic D., Lanza T., Simmons M., Moscato U., Ricciardi W., Chiara C. Microplastics inhalation and their effects on human health: a systematic review. Eur. J. Public Health. 2022;32 doi: 10.1093/eurpub/ckac131.152. [DOI] [Google Scholar]

- 12.Pauly J.L., Stegmeier S.J., Allaart H.A., Cheney R.T., Zhang P.J., Mayer A.G., Streck R.J. Inhaled cellulosic and plastic fibers found in human lung tissue. Cancer Epidemiol. Biomarkers Prev. 1998;7:419–428. [PubMed] [Google Scholar]

- 13.Leslie H.A., van Velzen M.J.M., Brandsma S.H., Vethaak A.D., Garcia-Vallejo J.J., Lamoree M.H. Discovery and quantification of plastic particle pollution in human blood. Environ. Int. 2022;163 doi: 10.1016/j.envint.2022.107199. [DOI] [PubMed] [Google Scholar]

- 14.Marfella R., Prattichizzo F., Sardu C., Fulgenzi G., Graciotti L., Spadoni T., D'Onofrio N., Scisciola L., La Grotta R., Frigé C., et al. Microplastics and nanoplastics in atheromas and cardiovascular events. N. Engl. J. Med. 2024;390:900–910. doi: 10.1056/NEJMoa2309822. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Ellen MacArthur Foundation Towards the circular economy. 2013. https://content.ellenmacarthurfoundation.org/m/50c85a620a58955/original/Towards-the-circular-economy-Vol-2.pdf

- 16.Ilie A.G., Jurconi A. New Trends in Sustainable Business and Consumption; 2019. The Implications of a Mandatory rPET Content in the Soft Drinks Plastic Bottles from an Industry-Retail-Consumer Relations Perspective; p. 821. [Google Scholar]

- 17.Dahlbo H., Poliakova V., Mylläri V., Sahimaa O., Anderson R. Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag. 2018;71:52–61. doi: 10.1016/j.wasman.2017.10.033. [DOI] [PubMed] [Google Scholar]

- 18.Achterman G.L. Implementing plastics recycling mandates. Nat. Res. Env. 1994;9:13. [Google Scholar]

- 19.Hossain R., Islam M.T., Ghose A., Sahajwalla V. Full circle: challenges and prospects for plastic waste management in Australia to achieve circular economy. J. Clean. Prod. 2022;368 doi: 10.1016/j.jclepro.2022.133127. [DOI] [Google Scholar]

- 20.Yeh N.-H., Yang C.-H. Exploring the circular solutions for plastic reduction: case studies of new transition journey. J. Serv. Sci. Manag. 2024;17:118–136. doi: 10.4236/jssm.2024.172006. [DOI] [Google Scholar]

- 21.Syberg K., Nielsen M.B., Oturai N.B., Clausen L.P.W., Ramos T.M., Hansen S.F. Circular economy and reduction of micro(nano)plastics contamination. J. Hazard. Mater. Adv. 2022;5 doi: 10.1016/j.hazadv.2022.100044. [DOI] [Google Scholar]

- 22.Dhali S.L., Parida D., Kumar B., Bala K. Recent trends in microbial and enzymatic plastic degradation: a solution for plastic pollution predicaments. Biotechnol. Sustain. Mater. 2024;1:11. doi: 10.1186/s44316-024-00011-0. [DOI] [Google Scholar]

- 23.Garcia J.M., Robertson M.L. The future of plastics recycling. Science. 2017;358:870–872. doi: 10.1126/science.aaq0324. [DOI] [PubMed] [Google Scholar]

- 24.Hahladakis J.N., Iacovidou E., Gerassimidou S. In: Environmental Materials and Waste. Second Edition. Vara Prasad M.N., editor. Elsevier; 2024. Chapter 4 - Plastic waste in a circular economy; pp. 99–134. [DOI] [Google Scholar]

- 25.Hahladakis J.N., Iacovidou E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018;630:1394–1400. doi: 10.1016/j.scitotenv.2018.02.330. [DOI] [PubMed] [Google Scholar]

- 26.Geyer R., Jambeck J.R., Law K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017;3 doi: 10.1126/sciadv.1700782. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Shlush E., Davidovich-Pinhas M. Bioplastics for food packaging. Trends Food Sci. Technol. 2022;125:66–80. [Google Scholar]

- 28.Jabeen N., Majid I., Nayik G.A. Bioplastics and food packaging: a review. Cogent Food Agric. 2015;1 [Google Scholar]

- 29.Rahman R., Sood M., Gupta N., Bandral J.D., Hameed F., Ashraf S. Bioplastics for food packaging: a review. Int. J. Curr. Microbiol. Appl. Sci. 2019;8:2311–2321. [Google Scholar]

- 30.European Bioplastics . Nova Institute; 2023. Bioplastics Market Development Update 2023.https://www.european-bioplastics.org/market/https://docs.european-bioplastics.org/publications/market_data/2023/EUBP_Market_Data_Report_2023.pdf [Google Scholar]

- 31.Brizga J., Hubacek K., Feng K. The unintended side effects of bioplastics: carbon, land, and water footprints. One Earth. 2020;3:45–53. doi: 10.1016/j.oneear.2020.06.016. [DOI] [Google Scholar]

- 32.Islam M., Xayachak T., Haque N., Lau D., Bhuiyan M., Pramanik B.K. Impact of bioplastics on environment from its production to end-of-life. Process Saf. Environ. Prot. 2024;188:151–166. doi: 10.1016/j.psep.2024.05.113. [DOI] [Google Scholar]

- 33.Lee T., Wearne S., Wakefield-Rann R., Scardifield K. Enabling factors and critical extensions for the algal-based bioplastics industry. J. Clean. Prod. 2024;457 doi: 10.1016/j.jclepro.2024.142365. [DOI] [Google Scholar]

- 34.King S., Locock K.E.S. A circular economy framework for plastics: a semi-systematic review. J. Clean. Prod. 2022;364 doi: 10.1016/j.jclepro.2022.132503. [DOI] [Google Scholar]

- 35.Singh N., Walker T.R. Plastic recycling: a panacea or environmental pollution problem. NPJ Mater. Sustain. 2024;2:17. doi: 10.1038/s44296-024-00024-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Borrelle S.B., Ringma J., Law K.L., Monnahan C.C., Lebreton L., McGivern A., Murphy E., Jambeck J., Leonard G.H., Hilleary M.A., et al. Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science. 2020;369:1515–1518. doi: 10.1126/science.aba3656. [DOI] [PubMed] [Google Scholar]

- 37.Lau W.W.Y., Shiran Y., Bailey R.M., Cook E., Stuchtey M.R., Koskella J., Velis C.A., Godfrey L., Boucher J., Murphy M.B., et al. Evaluating scenarios toward zero plastic pollution. Science. 2020;369:1455–1461. doi: 10.1126/science.aba9475. [DOI] [PubMed] [Google Scholar]

- 38.Thiounn T., Smith R.C. Advances and approaches for chemical recycling of plastic waste. J. Polym. Sci. 2020;58:1347–1364. doi: 10.1002/pol.20190261. [DOI] [Google Scholar]

- 39.Zou L., Xu R., Wang H., Wang Z., Sun Y., Li M. Chemical recycling of polyolefins: a closed-loop cycle of waste to olefins. Natl. Sci. Rev. 2023;10 doi: 10.1093/nsr/nwad207. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Chen S., Hu Y.H. Advancements and future directions in waste plastics recycling: From mechanical methods to innovative chemical processes. Chem. Eng. J. 2024;493 doi: 10.1016/j.cej.2024.152727. [DOI] [Google Scholar]

- 41.Schyns Z.O.G., Shaver M.P. Mechanical recycling of packaging plastics: a review. Macromol. Rapid Commun. 2021;42 doi: 10.1002/marc.202000415. [DOI] [PubMed] [Google Scholar]

- 42.OECD . OECD Publishing; 2022. Plastics Use Projections to 2060. [DOI] [Google Scholar]

- 43.Schwartz-Narbonne H., Xia C., Shalin A., Whitehead H.D., Yang D., Peaslee G.F., Wang Z., Wu Y., Peng H., Blum A., et al. Per- and polyfluoroalkyl substances in Canadian fast food packaging. Environ. Sci. Technol. Lett. 2023;10:343–349. doi: 10.1021/acs.estlett.2c00926. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.NSW EPA FOGO information for households. 2023. https://www.epa.nsw.gov.au/your-environment/recycling-and-reuse/household-recycling-overview/fogo-information-for-households

- 45.City of Launceston . City of Launceston; 2023. FOGO Awaits New National Standards for Compostable Packaging. [Google Scholar]

- 46.Matthews C., Moran F., Jaiswal A.K. A review on European Union's strategy for plastics in a circular economy and its impact on food safety. J. Clean. Prod. 2021;283 doi: 10.1016/j.jclepro.2020.125263. [DOI] [Google Scholar]

- 47.Symeonides C., Aromataris E., Mulders Y., Dizon J., Stern C., Barker T.H., Whitehorn A., Pollock D., Marin T., Dunlop S. An umbrella review of meta-analyses evaluating associations between human health and exposure to major classes of plastic-associated chemicals. Ann. Glob. Health. 2024;90:52. doi: 10.5334/aogh.4459. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Burgess M., Holmes H., Sharmina M., Shaver M.P. The future of UK plastics recycling: one bin to rule them all. Resour. Conserv. Recycl. 2021;164 doi: 10.1016/j.resconrec.2020.105191. [DOI] [Google Scholar]

- 49.Offenhuber D. MIT Press; 2023. Waste Is Information: Infrastructure Legibility and Governance. [Google Scholar]

- 50.Cristóbal J., Federica Albizzati P., Giavini M., Caro D., Manfredi S., Tonini D. Management practices for compostable plastic packaging waste: Impacts, challenges and recommendations. Waste Manag. 2023;170:166–176. doi: 10.1016/j.wasman.2023.08.010. [DOI] [PubMed] [Google Scholar]

- 51.Shittu O., Arnautovic K., Lockrey S., Vince J., Vogel R., Bhattacharya A., Stanes E., Garofano N., Retamal M., Harkness M. Governance solutions for soft plastics in Australia: lessons from the discontinuation of REDcycle. Australas. J. Environ. Manag. 2024;31:269–295. doi: 10.1080/14486563.2024.2367960. [DOI] [Google Scholar]

- 52.Vedelago C., Dowling J. Coles, Woolworths recycling scheme collapses after secret stockpiles revealed. Syd. Morning Her. 2022 https://www.smh.com.au/national/coles-woolworths-recycling-scheme-collapses-after-secret-stockpiles-revealed-20221107-p5bw9q.html [Google Scholar]

- 53.Soenmez C., Venkatachalam V., Spierling S., Endres H.-J., Barner L. Environmental potential of recycling of plastic wastes in Australia based on life cycle assessment. J. Mater. Cycles Waste Manag. 2024;26:755–775. doi: 10.1007/s10163-024-01901-1. [DOI] [Google Scholar]

- 54.Defruyt S. 2019. Towards a new plastics economy. The Veolia institute review—facts reports; pp. 1867–8521.http://journals.openedition.org/factsreports/4993 [Google Scholar]

- 55.Zhu Z., Liu W., Ye S., Batista L. Packaging design for the circular economy: a systematic review. Sustain. Prod. Consum. 2022;32:817–832. doi: 10.1016/j.spc.2022.06.005. [DOI] [Google Scholar]

- 56.Novakovic K., Thumbarathy D., Peeters M., Geoghegan M., Go Jefferies J., Hicks C., Manika D., Dai S. Zero-waste circular economy of plastic packaging: The bottlenecks and a way forward. Sustain. Mater. Technol. 2023;38 doi: 10.1016/j.susmat.2023.e00735. [DOI] [Google Scholar]

- 57.Groh K.J., Backhaus T., Carney-Almroth B., Geueke B., Inostroza P.A., Lennquist A., Leslie H.A., Maffini M., Slunge D., Trasande L., et al. Overview of known plastic packaging-associated chemicals and their hazards. Sci. Total Environ. 2019;651:3253–3268. doi: 10.1016/j.scitotenv.2018.10.015. [DOI] [PubMed] [Google Scholar]

- 58.Wagner S., Schlummer M. Legacy additives in a circular economy of plastics: current dilemma, policy analysis, and emerging countermeasures. Resour. Conserv. Recycl. 2020;158 doi: 10.1016/j.resconrec.2020.104800. [DOI] [Google Scholar]

- 59.Hahladakis J.N., Velis C.A., Weber R., Iacovidou E., Purnell P. An overview of chemical additives present in plastics: migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018;344:179–199. doi: 10.1016/j.jhazmat.2017.10.014. [DOI] [PubMed] [Google Scholar]

- 60.Dizon J., Barker T., Whitehorn A., Marin T., Pollock D., Aromataris E., Foundation M., Symeonides C., Mulders Y., Dunlop S. Minderoo Foundation; 2024. Umbrella Review: Impact of Plastic-Associated Chemical Exposure on Human Health.https://cdn.minderoo.org/assets/new/documents/PHH-Umbrella-Review-Full-Report.pdf [DOI] [PMC free article] [PubMed] [Google Scholar]

- 61.Muncke J. Tackling the toxics in plastics packaging. PLoS Biol. 2021;19 doi: 10.1371/journal.pbio.3000961. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.European Chemicals Agency E. Understanding REACH - ECHA. https://echa.europa.eu/regulations/reach/understanding-reach

- 63.Gardas B.B., Raut R.D., Narkhede B. Identifying critical success factors to facilitate reusable plastic packaging towards sustainable supply chain management. J. Environ. Manage. 2019;236:81–92. doi: 10.1016/j.jenvman.2019.01.113. [DOI] [PubMed] [Google Scholar]

- 64.Quinn E.C., Knauer K.M., Beckham G.T., Chen E.Y.X. Mono-material product design with bio-based, circular, and biodegradable polymers. One Earth. 2023;6:582–586. doi: 10.1016/j.oneear.2023.05.019. [DOI] [Google Scholar]

- 65.Consumer Goods Forum . The Consumer Goods Forum; 2020. Golden Design Rules: For Optimal Plastic Design, Production and Recycling.https://www.theconsumergoodsforum.com/wp-content/uploads/2023/10/2024-Plastics-All-Golden-Design-Rules-One-Pager.pdf [Google Scholar]

- 66.Adekanmbi A.O., Emmanuel Chigozie A., Ayodeji A., Uchenna I., Nwakamma N.-E., Alexander O. Assessing the environmental and health impacts of plastic production and recycling. World J. Bio. Pharm. Health Sci. 2024;17:232–241. doi: 10.30574/wjbphs.2024.17.2.0081. [DOI] [Google Scholar]

- 67.Deeney M., Green R., Yan X., Dooley C., Yates J., Rolker H.B., Kadiyala S. Human health effects of recycling and reusing food sector consumer plastics: a systematic review and meta-analysis of life cycle assessments. J. Clean. Prod. 2023;397 doi: 10.1016/j.jclepro.2023.136567. [DOI] [Google Scholar]

- 68.APCO . Australian Packaging Covenant Organisation; 2024. Strategic Plan July 2024- June 2030 (V1)https://documents.packagingcovenant.org.au/public-documents/2030%20Strategic%20Plan [Google Scholar]

- 69.Buelow S., Lewis H., Sonneveld K., Sonneveld K. The role of labels in directing consumer packaging waste. Manag. Environ. Qual. Int. J. 2010;21:198–213. doi: 10.1108/14777831011025544. [DOI] [Google Scholar]

- 70.Punkt G. Closing loops – together for our environment. 2024. https://www.gruener-punkt.de/en/

- 71.Nemat B., Razzaghi M., Bolton K., Rousta K. Design affordance of plastic food packaging for consumer sorting behavior. Resour. Conserv. Recycl. 2022;177 doi: 10.1016/j.resconrec.2021.105949. [DOI] [Google Scholar]

- 72.Ark P. ARL recycling near you. 2024. https://recyclingnearyou.com.au/australasian-recycling-label

- 73.Williams H., Wikström F., Wetter-Edman K., Kristensson P. Decisions on recycling or waste: how packaging functions affect the fate of used packaging in selected Swedish households. Sustainability. 2018;10 doi: 10.3390/su10124794. [DOI] [Google Scholar]

- 74.Boz Z., Korhonen V., Koelsch Sand C. Consumer considerations for the implementation of sustainable packaging: a review. Sustainability. 2020;12:2192. doi: 10.3390/su12062192. [DOI] [Google Scholar]

- 75.Ding Q., Zhu H. The key to solving plastic packaging wastes: design for recycling and recycling technology. Polymers. 2023;15 doi: 10.3390/polym15061485. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 76.Mager M., Traxler I., Fischer J., Finger D.C. Potential analysis of the plastics value chain for enhanced recycling rates: a case study in Iceland. Recycling. 2022;7:73. [Google Scholar]

- 77.Friedrich K., Möllnitz S., Holzschuster S., Pomberger R., Vollprecht D., Sarc R. Benchmark analysis for plastic recyclates in Austrian waste management. Detritus. 2019;9:105–112. doi: 10.31025/2611-4135/2019.13869. [DOI] [Google Scholar]

- 78.Scott A. Europe hardens stance on plastic recycling. C&EN Global Enterp. 2019;97:12. doi: 10.1021/cen-09729-buscon1. [DOI] [Google Scholar]

- 79.Brown A., Börkey P. OECD Environment Working Papers, No. 236. OECD Publishing, Paris; 2024. Plastics recycled content requirements. [DOI] [Google Scholar]

- 80.State Government of Victoria . State Government of Victoria. State Government of Victoria; 2021. Circular economy (waste reduction and reycling) Act 2021. Act Number 55/2021. [Google Scholar]

- 81.UNEP Single-use plastics: a roadmap for sustainability. 2018. https://wedocs.unep.org/handle/20.500.11822/25496

- 82.Olatayo K.I., Mativenga P.T., Marnewick A.L. Pathways to zero plastic waste landfill: Progress toward plastic circularity in South Africa. J. Ind. Ecol. 2024;28:1270–1288. doi: 10.1111/jiec.13533. [DOI] [Google Scholar]

- 83.Blumhardt H. Current and future approaches to shifting businesses towards plastic-free packaging systems based on reduction and reuse. Camb. Prisms. Plast. 2023;1:e18. doi: 10.1017/plc.2023.18. [DOI] [Google Scholar]

- 84.Diprose G., Dombroski K., Sharp E., Yates A., Peryman B., Barnes M. Emerging transitions in organic waste infrastructure in Aotearoa New Zealand. N. Z. Geog. 2023;79:15–26. doi: 10.1111/nzg.12348. [DOI] [Google Scholar]

- 85.Bernal-Carrillo J.G., Chiwo-González F.S., Susunaga-Notario A.d.C., Del Ángel–Monroy M., Arcos-Gutiérrez H., Garduño-Olvera I.E. Development and redesign of flexible packaging under sustainability criteria. Rev. Cien. Tecnol. 2024;7 doi: 10.37636/recit.v7n1e253. [DOI] [Google Scholar]

- 86.Gerngross T.U. Can biotechnology move us toward a sustainable society? Nat. Biotechnol. 1999;17:541–544. doi: 10.1038/9843. [DOI] [PubMed] [Google Scholar]

- 87.Gross R.A., Kalra B. Biodegradable polymers for the environment. Science. 2002;297:803–807. doi: 10.1126/science.297.5582.803. [DOI] [PubMed] [Google Scholar]

- 88.Bishop G., Styles D., Lens P.N.L. Land-use change and valorisation of feedstock side-streams determine the climate mitigation potential of bioplastics. Resour. Conserv. Recycl. 2022;180 doi: 10.1016/j.resconrec.2022.106185. [DOI] [Google Scholar]

- 89.Khoo H.H., Tan R.B.H., Chng K.W.L. Environmental impacts of conventional plastic and bio-based carrier bags. Int. J. Life Cycle Assess. 2010;15:284–293. doi: 10.1007/s11367-010-0162-9. [DOI] [Google Scholar]

- 90.Gadaleta G., De Gisi S., Todaro F., Notarnicola M. Carbon footprint and total cost evaluation of different bio-plastics waste treatment strategies. Clean Technol. 2022;4:570–583. [Google Scholar]

- 91.Taneepanichskul N., Purkiss D., Miodownik M. A review of sorting and separating technologies suitable for compostable and biodegradable plastic packaging. Front. Sustain. 2022;3 doi: 10.3389/frsus.2022.901885. [DOI] [Google Scholar]

- 92.Shen M., Song B., Zeng G., Zhang Y., Huang W., Wen X., Tang W. Are biodegradable plastics a promising solution to solve the global plastic pollution? Environ. Pollut. 2020;263 doi: 10.1016/j.envpol.2020.114469. [DOI] [PubMed] [Google Scholar]

- 93.Stefansson G., Tyssen C., Klaas-Wissing T., Pérez S.G., Labrosse M., Rumler M., Servidio M., Cetinkaya B., Cresswell L., Franke P., et al. In: Sustainable Supply Chain Management: Practical Ideas for Moving Towards Best Practice. Cuthbertson R., Cetinkaya B., Ewer G., Klaas-Wissing T., Piotrowicz W., Tyssen C., editors. Springer Berlin Heidelberg; 2011. Processes and operations cases; pp. 213–258. [DOI] [Google Scholar]

- 94.Yadav P., Silvenius F., Katajajuuri J.-M., Leinonen I. Life cycle assessment of reusable plastic food packaging. J. Clean. Prod. 2024;448 [Google Scholar]

- 95.Farmer N. Elsevier; 2013. Trends in Packaging of Food, Beverages and Other Fast-Moving Consumer Goods (FMCG): Markets, Materials and Technologies. [Google Scholar]

- 96.Pålsson H., Hellström D. Packaging logistics in supply chain practice–current state, trade-offs and improvement potential. Int. J. Logist. Res. Appl. 2016;19:351–368. [Google Scholar]

- 97.Verghese K., Lewis H., Lockrey S., Williams H. Packaging's role in minimizing food loss and waste across the supply chain. Packag. Technol. Sci. 2015;28:603–620. [Google Scholar]

- 98.World Economic Forum . 2016. The New Plastics Economy- Rethinking the Future of Plastics.http://www.ellenmacarthurfoundation.org/publications [Google Scholar]

- 99.Norris M. Pandemic Drives Purchases of Pre-packed Produce. 2020. https://harvesttohome.net.au/static/archive/case-studies/Pandemic%20Drives%20Purchases%20of%20Pre-packed%20Produce.pdf

- 100.White A., Lockyer S. Removing plastic packaging from fresh produce – what’s the impact? Nutr. Bull. 2020;45:35–50. doi: 10.1111/nbu.12420. [DOI] [Google Scholar]

- 101.Patrício Silva A.L., Prata J.C., Walker T.R., Campos D., Duarte A.C., Soares A.M.V.M., Barcelò D., Rocha-Santos T. Rethinking and optimising plastic waste management under COVID-19 pandemic: policy solutions based on redesign and reduction of single-use plastics and personal protective equipment. Sci. Total Environ. 2020;742 doi: 10.1016/j.scitotenv.2020.140565. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 102.Prata J.C., Silva A.L.P., Walker T.R., Duarte A.C., Rocha-Santos T. COVID-19 pandemic repercussions on the use and management of plastics. Environ. Sci. Technol. 2020;54:7760–7765. doi: 10.1021/acs.est.0c02178. [DOI] [PubMed] [Google Scholar]

- 103.Koutsimanis G., Getter K., Behe B., Harte J., Almenar E. Influences of packaging attributes on consumer purchase decisions for fresh produce. Appetite. 2012;59:270–280. doi: 10.1016/j.appet.2012.05.012. [DOI] [PubMed] [Google Scholar]

- 104.Hawkins G. The skin of commerce: governing through plastic food packaging. J. Cultural Econ. 2018;11:386–403. [Google Scholar]

- 105.Orlowski M., Lefebvre S., Back R.M. Thinking outside the bottle: effects of alternative wine packaging. J. Retailing Consum. Serv. 2022;69 doi: 10.1016/j.jretconser.2022.103117. [DOI] [Google Scholar]

- 106.P Govender J., L Govender T. The influence of green marketing on consumer purchase behavior. Environ. Econ. 2016;7:77–85. doi: 10.21511/ee.07(2).2016.8. [DOI] [Google Scholar]

- 107.Ford A., Moodie C., Hastings G. The role of packaging for consumer products: Understanding the move towards ‘plain’ tobacco packaging. Addiction Res. Theor. 2011;20:339–347. doi: 10.3109/16066359.2011.632700. [DOI] [Google Scholar]

- 108.Hawkes C. Food packaging: the medium is the message. Public Health Nutr. 2010;13:297–299. doi: 10.1017/S1368980009993168. [DOI] [PubMed] [Google Scholar]

- 109.Underwood R.L., Klein N.M. Packaging as brand communication: effects of product pictures on consumer responses to the package and brand. J. Market. Theor. Pract. 2015;10:58–68. doi: 10.1080/10696679.2002.11501926. [DOI] [Google Scholar]

- 110.Rundh B. The role of packaging within marketing and value creation. Br. Food J. 2016;118:2491–2511. doi: 10.1108/BFJ-10-2015-0390. [DOI] [Google Scholar]

- 111.Fang Y., Xiao X., Wang X., Lan H. 2018 IEEE Third International Conference on Data Science in Cyberspace (DSC) 2018. Customized Bundle Recommendation by Association Rules of Product Categories for Online Supermarkets; pp. 472–475. [Google Scholar]

- 112.Wikström F., Williams H., Trischler J., Rowe Z. The importance of packaging functions for food waste of different products in households. Sustainability. 2019;11 doi: 10.3390/su11092641. [DOI] [Google Scholar]

- 113.Bradley C.G., Corsini L. A literature review and analytical framework of the sustainability of reusable packaging. Sustain. Prod. Consum. 2023;37:126–141. doi: 10.1016/j.spc.2023.02.009. [DOI] [Google Scholar]

- 114.Beswick-Parsons R., Jackson P., Evans D.M. Understanding national variations in reusable packaging: commercial drivers, regulatory factors, and provisioning systems. Geoforum. 2023;145 doi: 10.1016/j.geoforum.2023.103844. [DOI] [Google Scholar]

- 115.Ellen MacArthur Foundation . 2019. Reuse—Rethinking Packaging.https://www.ellenmacarthurfoundation.org/reuse-rethinking-packaging [Google Scholar]

- 116.GoUnpackaged The UK refill coalition launches frist in-store trial at Aldi to reduce single-use plastic waste. 2024. https://gounpackaged.com/thought-leadership/the-uk-refill-coalition-launches-first-in-store-trial-at-aldi-to-reduce-single-use-plastic-waste

- 117.Tesco . Tesco; 2022. Use. Reuse. Repeat. Sharing Learnings on Reusable Packaging.https://www.tescoplc.com/media/759307/tesco-reuse-report.pdf [Google Scholar]

- 118.Dubisz D., Rokicki R. Standardisation of logistic units in terms of increasing the efficiency of the reverse supply chain of returnable packaging. Eur. Res. Stud. J. 2022;25:428–438. [Google Scholar]

- 119.Fécourt A., Li T. Chalmers University of Technology; 2013. Improving transport packaging sustainability – a case study in a production logistics company. Master of Science Thesis in the Master Degree Programme, Supply Chain Management. [Google Scholar]

- 120.Greenwood S.C., Walker S., Baird H.M., Parsons R., Mehl S., Webb T.L., Slark A.T., Ryan A.J., Rothman R.H. Many happy returns: combining insights from the environmental and behavioural sciences to understand what is required to make reusable packaging mainstream. Sustain. Prod. Consum. 2021;27:1688–1702. doi: 10.1016/j.spc.2021.03.022. [DOI] [Google Scholar]

- 121.Dizzie Dizzie’s journey. 2024. https://medium.com/@goodclub/dizzies-journey-c23dc4520032

- 122.Sarkar M.K., Rao A.C., Singh A.K. “Sustainability and Talent Management”: a two-pronged approach for the evolution of E-commerce in India. Circ. Econ. Sustain. 2024;4:267–285. doi: 10.1007/s43615-023-00282-1. [DOI] [Google Scholar]

- 123.Svensson-Hoglund S., Richter J.L., Maitre-Ekern E., Russell J.D., Pihlajarinne T., Dalhammar C. Barriers, enablers and market governance: A review of the policy landscape for repair of consumer electronics in the EU and the U.S. J. Clean. Prod. 2021;288 doi: 10.1016/j.jclepro.2020.125488. [DOI] [Google Scholar]

- 124.Zhang L., Hale J. Extending the lifetime of clothing through repair and repurpose: an investigation of barriers and enablers in UK citizens. Sustainability. 2022;14 doi: 10.3390/su141710821. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 125.Geangan V. What you can and cannot do with a tractor: advocating for the expansion of right to repair laws. Intell. Prop. Tech. 2022;27:51. [Google Scholar]

- 126.Boucher J., Friot D. IUCN; 2017. Primary Microplastics in the Oceans: A Global Evaluation of Sources.https://portals.iucn.org/library/sites/library/files/documents/2017-002-En.pdf [Google Scholar]

- 127.Niinimäki K., Peters G., Dahlbo H., Perry P., Rissanen T., Gwilt A. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020;1:189–200. doi: 10.1038/s43017-020-0039-9. [DOI] [Google Scholar]

- 128.Forti V., Balde C.P., Kuehr R., Bel G. United Nations University (UNU),United Nations Institute for Training and Research (UNITAR), SCYCLE Programme, International Telecommunication Union (ITU),International Solid Waste Association (ISWA); 2020. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; p. 120. [Google Scholar]

- 129.Vishwakarma A., Kanaujia K., Hait S. In: Global E-Waste Management Strategies and Future Implications. Arya S., Kumar S., editors. Elsevier; 2023. Chapter 2 - Global scenario of E-waste generation: trends and future predictions; pp. 13–30. [DOI] [Google Scholar]

- 130.Reike D., Vermeulen W.J.V., Witjes S. The circular economy: new or refurbished as CE 3.0? — Exploring controversies in the conceptualization of the circular economy through a focus on history and resource value retention options. Resour. Conserv. Recycl. 2018;135:246–264. doi: 10.1016/j.resconrec.2017.08.027. [DOI] [Google Scholar]

- 131.Laitala K., Klepp I.G., Haugrønning V., Throne-Holst H., Strandbakken P. Increasing repair of household appliances, mobile phones and clothing: experiences from consumers and the repair industry. J. Clean. Prod. 2021;282 doi: 10.1016/j.jclepro.2020.125349. [DOI] [Google Scholar]

- 132.Bovea M.D., Pérez-Belis V., Quemades-Beltrán P. Attitude of the stakeholders involved in the repair and second-hand sale of small household electrical and electronic equipment: case study in Spain. J. Environ. Manage. 2017;196:91–99. doi: 10.1016/j.jenvman.2017.02.069. [DOI] [PubMed] [Google Scholar]

- 133.Roskladka N., Jaegler A., Miragliotta G. From “right to repair” to “willingness to repair”: Exploring consumer's perspective to product lifecycle extension. J. Clean. Prod. 2023;432 doi: 10.1016/j.jclepro.2023.139705. [DOI] [Google Scholar]

- 134.Cooper T., Salvia G. Subverting Consumerism. 1st Edition. Routledge; 2018. Fix it: barriers to repair and opportunities for change; pp. 147–165. [Google Scholar]

- 135.Diddi S., Yan R.-N. Consumer perceptions related to clothing repair and community mending events: a circular economy perspective. Sustainability. 2019;11:5306. doi: 10.3390/su11195306. [DOI] [Google Scholar]

- 136.Ackermann L., Mugge R., Schoormans J. Consumers' perspective on product care: An exploratory study of motivators, ability factors, and triggers. J. Clean. Prod. 2018;183:380–391. doi: 10.1016/j.jclepro.2018.02.099. [DOI] [Google Scholar]

- 137.Sabbaghi M., Behdad S. Consumer decisions to repair mobile phones and manufacturer pricing policies: The concept of value leakage. Resour. Conserv. Recycl. 2018;133:101–111. doi: 10.1016/j.resconrec.2018.01.015. [DOI] [Google Scholar]

- 138.Sonego M., Echeveste M.E.S., Debarba H.G. Repair of electronic products: Consumer practices and institutional initiatives. Sustain. Prod. Consum. 2022;30:556–565. doi: 10.1016/j.spc.2021.12.031. [DOI] [Google Scholar]

- 139.Koszewska M., Bielecki M. How to make furniture industry more circular? The role of component standardisation in ready-to-assemble furniture. Entrepren. Sustain. Iss. 2020;7:1688–1707. doi: 10.9770/jesi.2020.7.3. [DOI] [Google Scholar]

- 140.Luttropp C., Lagerstedt J. EcoDesign and the ten golden rules: generic advice for merging environmental aspects into product development. J. Clean. Prod. 2006;14:1396–1408. doi: 10.1016/j.jclepro.2005.11.022. [DOI] [Google Scholar]

- 141.Umeda Y., Fukushige S., Tonoike K., Kondoh S. Product modularity for life cycle design. CIRP Ann. 2008;57:13–16. doi: 10.1016/j.cirp.2008.03.115. [DOI] [Google Scholar]

- 142.Boniface C., Urquhart L., Terras M. Towards a right to repair for the internet of things: a review of legal and policy aspects. Comp. Law Security Rev. 2024;52 doi: 10.1016/j.clsr.2024.105934. [DOI] [Google Scholar]

- 143.Marikyan D., Papagiannidis S. Exercising the “right to repair”: a customer’s perspective. J. Bus. Ethics. 2024;193:35–61. doi: 10.1007/s10551-023-05569-9. [DOI] [Google Scholar]

- 144.Dominish E., Retamal M., Sharpe S., Lane R., Rhamdhani M., Corder G., Giurco D., Florin N. “Slowing” and “Narrowing” the flow of metals for consumer goods: evaluating opportunities and barriers. Sustainability. 2018;10:1096. [Google Scholar]

- 145.Park M. In: Routledge handbook of sustainable product design. Chapman J., editor. Routledge; 2017. Print to repair: 3D printing and product repair; pp. 236–249. [Google Scholar]

- 146.Chekurov S., Salmi M. Additive manufacturing in offsite repair of consumer electronics. Phys. Procedia. 2017;89:23–30. doi: 10.1016/j.phpro.2017.08.009. [DOI] [Google Scholar]

- 147.Nestlé Nespresso Relove by Nespresso. 2024. https://www.nespresso.com/us/en/relove-refurbished-coffee-machines#vertuo-machines

- 148.Davila M.L., Milios L., Richter J.L., Dalhammer C. Verlag der Technischen Universität Graz; 2021. Behavioural Insights into Personal Electronics Repair in Sweden. Held in Graz, Austria; pp. 321–343. [Google Scholar]

- 149.Pérez-Belis V., Braulio-Gonzalo M., Juan P., Bovea M.D. Consumer attitude towards the repair and the second-hand purchase of small household electrical and electronic equipment. A Spanish case study. J. Clean. Prod. 2017;158:261–275. doi: 10.1016/j.jclepro.2017.04.143. [DOI] [Google Scholar]

- 150.Spekkink W., Rödl M., Charter M. Repair Cafés and precious plastic as translocal networks for the circular economy. J. Clean. Prod. 2022;380 doi: 10.1016/j.jclepro.2022.135125. [DOI] [Google Scholar]

- 151.Godfrey D.M., Price L.L., Lusch R.F. Repair, consumption, and sustainability: fixing fragile objects and maintaining consumer practices. J. Consum. Res. 2021;49:229–251. doi: 10.1093/jcr/ucab067. [DOI] [Google Scholar]