Abstract

The global demand for Plant-based meat analogues (PBMAs) is rising due to increasing vegetarianism, health and environmental concerns, and animal-welfare issues. However, PBMAs encounter several challenges that limit widespread acceptance, including inadequate physico-chemical, sensory, and nutritional attributes, and concerns about over-processing and potential food-safety risks. To address these challenges, initiatives such as using high-quality raw materials, blending various plant protein sources, and employing innovative processing techniques are underway. Consumer acceptance of PBMAs also depends on the type of in-home cooking method used to prepare these foods, and the goal in many cases is for the quality attributes after cooking to resemble that of meat. The objective of this review is to compare the effects of in-home cooking methods on the quality of meat products to better understand how PBMAs will perform relative to their animal-based counterparts. Here, research articles that evaluate the impact of different cooking methods (e.g., baking and pan-frying) on the quality of meat and PBMAs were systematically summarized and compared to demonstrate trends in changes related to the physicochemical, sensory, and nutritional attributes of these products. The results revealed that the type of cooking method significantly influenced consumers’ acceptance of meat and PBMAs. Changes in physical properties such as cooking loss and water holding capacity (WHC) can affect texture and were dependent on cooking temperatures. However, these changes were not independent of the protein source (PBMAs) or muscle type (meat). For example, cooking at 70 °C decreased the amount of sulfhydryl content in PBMAs compared to pork and beef burgers (20 µmol/g vs. 65 µmol/g protein, respectively). Conversely, when cooking temperatures (> 120 °C) were used, maillard reaction resulted in favourable sensory (appearance and flavour) attributes in both types of products, however, in the presence of sugars and the amino acid asparagine, concerns about the presence of chemical hazards such as acrylamide increased. Microwave cooking also increased WHC and oil absorption properties of plant proteins which improved the mouthfeel of PMBAs. In conclusion, there is a need to optimize in-home cooking techniques to enhance desirable textures and flavours in PBMAs which will improve consumer acceptability of these products.

Graphical Abstract

Keywords: Plant-based meat analogues, In-home cooking, Plant proteins, Sensory, Meat

Introduction

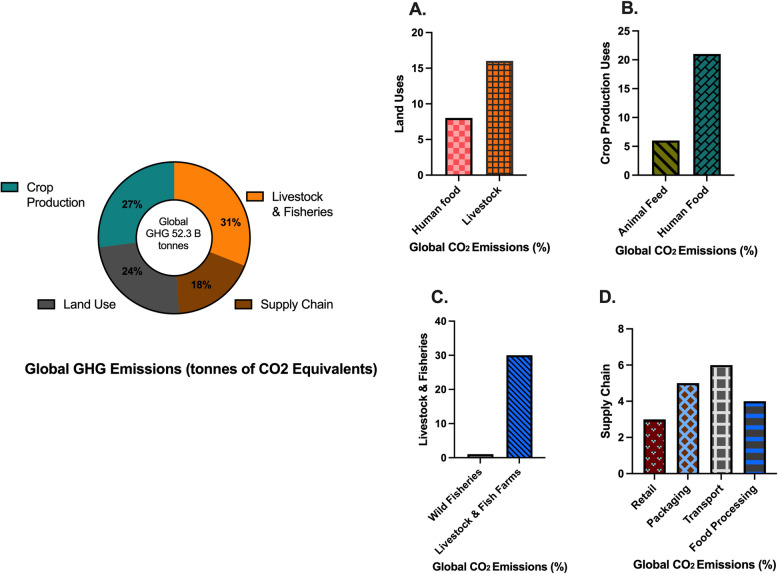

Plant-based meat analogues (PBMAs) have gained significant attention as sustainable and ethical alternatives to traditional meat products. Designed to replicate the physico-chemical, sensory, and nutritional aspects of meat, PBMAs address critical concerns related to health, environmental sustainability, and animal welfare (Don & van der Goot, 2020). Several interrelated factors contribute to the growing interest in PBMAs. PBMAs are often perceived as healthier, offering lower levels of saturated fat and cholesterol (Vila-Clarà et al., 2024), while excessive meat consumption is linked to heightened risks of cardiovascular disease and obesity (Satija et al., 2017). Moreover, meat production accounts for approximately 52.3 billion tonnes of global anthropogenic greenhouse gas emissions (carbon dioxide—equivalents) with livestock-related emissions (methane from cattle, manure management, pasture management, fuel use in fisheries), accounting for approximately 31% (Fig. 1) (Cheng et al., 2022). Conversely, fuel use in fisheries and emissions arising from land-use changes, such as feed production, and energy consumption in livestock systems, account for about 24% of emissions (Cheng et al., 2022; Rajan et al., 2023). The high energy and water requirements for the production of animal products, such as beef (approximately 15,400 L/kg and 43 square meters of land), for meat production compared to plant-based foods like cereals (about 1,644 L/kg of water and 2–7 square meters of land) and plant-based protein sources such as legumes and pulses (about 2,000–4,000 L/kg of water) highlight the sustainability benefits of PBMAs (Cheng et al., 2022; Rajan et al., 2023). Ethical concerns, including animal welfare and the environmental costs of factory farming, have also driven consumer interest (He et al., 2020). In addition, the COVID-19 pandemic underscored the need for resilient and sustainable food systems, further accelerating the development of PBMAs (Li, 2020).

Fig. 1.

Global greenhouse gas emissions caused by food production

PBMA production involves selecting key ingredients (e.g., proteins, fats, binders, and flavourings) and employing advanced processing techniques to achieve desirable physico-chemical, sensory, and nutritional aspects (Singh et al., 2022). High-quality plant proteins, such as those derived from soy, pulses, and legumes, are frequently used due to their protein content and functional properties (Thavamani et al., 2020). Common protein extraction methods include wet extraction, dry fractionation, and enzymatic hydrolysis yield isolates or concentrates while influencing protein functionality (Kyriakopoulou et al., 2021). Optimizing processing conditions, such as pH, temperature, and salt concentration, is critical to ensure appropriate texture and flavor development in PBMAs (Vatansever et al., 2020). Techniques like extrusion are particularly effective in creating fibrous, meat-like textures (Wang et al., 2022).

Despite their benefits, PBMAs face challenges that can impede widespread consumer adoption (Don & van der Goot, 2020). Texture, mouthfeel, and flavor remain key areas for improvement, as suggested by consumer studies (Fiorentini et al., 2020; Michel et al., 2021; Palanisamy et al., 2018). Additionally, PBMAs may lack the nutritional equivalence of meat, particularly in terms of protein quality and micronutrient content (Rizzolo-Brime et al., 2023; Costa et al., 2023). Perceptions of PBMAs as ultra-processed products with artificial additives and preservatives further challenge consumer acceptance (Don & van der Goot, 2020). Producers also grapple with maintaining quality while ensuring affordability (Fiorentini et al., 2020; Sogari et al., 2023).

To address these issues, the PBMA industry is adopting strategies such as sourcing higher-quality plant proteins and blending diverse protein sources to enhance physicochemical, sensory, and nutritional aspects (Wang et al., 2023). Innovative processing techniques, including high-moisture extrusion, shear cell technology, 3D printing, and flavor encapsulation, are improving the sensory attributes of PBMAs (Wang et al., 2023; Zhang et al., 2023).

Some work has been done to review the use of innovative processing technologies (e.g., extrusion) and their effects on the physicochemical, sensory, and nutritional aspects of PBMAs (Jang & Lee, 2024; Singh & Sit, 2022). One critical aspect that has not been extensively studied is the effect of the final cooking step performed by consumers on the overall quality of PBMAs. Moreover, there is limited understanding of the role that different consumer in-home cooking methods might have on the physicochemical, sensory, and nutritional aspects of PBMAs. Various cooking methods as well as their effects on the quality of meat have been previously investigated (Schwartz et al., 2022; Corriea et al., 2024), thus, direct comparisons of meat products are critical for understanding how PBMAs perform relative to their animal-based counterparts. Accordingly, the objective of this review is to evaluate the impact of different consumer in-home cooking methods (e.g., baking, frying) on the physicochemical, sensory, and nutritional aspects of meat and PBMAs. A fundamental understanding of the effect of these processing methods will be crucial for enhancing product quality and consumer acceptability of PBMAs.

Food safety concerns specific to PBMAs

For PBMAs, various food safety risks may be introduced during different stages of production, starting from the raw plant materials through to the processing and storage of the final products (Lin et al., 2023). Contamination of PBMAs can occur due to contact of ingredients with soil, dust, and water during harvest and post-harvest processes (Alp & Bulantekin, 2021). Raw plant ingredients are also at risk of contamination by various fungi species such as Fusarium, Aspergillus, Penicillium, Alternaria, and Claviceps which can produce mycotoxins as secondary metabolites (Janik et al., 2020). Ochratoxin A and zearalenone were the main mycotoxins found in soybeans, soy-based products, and peas (Kunz et al., 2020; Owolabi et al., 2022). When these contaminated materials are used as protein sources for PBMAs, mycotoxins can be transferred to the final products (Romero et al., 2023). Thus, mycotoxins represent a significant food safety risk in PBMAs. Furthermore, food processing can introduce food pathogens such as Staphylococcus aureus, mainly through food handling practices (skin contact), or Listeria monocytogenes, which can be found in food processing facilities where poor sanitation occurs (Gräfenhahn & Beyrer, 2024).

It is also known that many of the proteins used in PBMAs belong to either the cupin family, such as vicilins and legumins, or the prolamin family and these proteins can trigger allergic reactions (Mills et al., 2004). Indeed, soy is one of the major food allergens, and approximately 30 allergens, including profilin, vicilin (i.e., β-conglycinin), and legumin (i.e., glycinin), have been identified in soybeans (Pi et al., 2021). β-conglycinin and glycinin make up approximately 70% of the proteins in soybeans, and thus, these will be the predominant proteins in commercial PBMAs (Gräfenhahn & Beyrer 2024).

One of the main goals of cooking meat and PBMAs is to destroy food pathogens and reduce contaminants (Schwartz et al., 2022). Thermal processes such as extrusion are methods which use high temperatures (150–170 °C) inactivate microbial cells and bacterial endospores (Gräfenhahn & Beyrer, 2024). When soy flour was extruded, it resulted in minimal levels of Staphylococci, Salmonella, Shigella, yeasts, molds (Gräfenhahn & Beyrer, 2024), and allergenicity of soybean protein (Pi et al., 2021). Moreover, extrusion was recorded to decrease various mycotoxins such as fumonisin, aflatoxins, and zearalenone (> 83%), while the reduction of deoxynivalenol, ochratoxin A, and moniliformin was less pronounced (30–55%) (Zheng et al., 2015). However, the literature has shown that during subsequent storage processing and reformulation, (re)-contamination can be observed. For example, Hai et al. (2023) recorded the presence of some pathogenic bacteria, such as Acinetobacter, Staphylococcus, and Klebsiella, in PBMAs.

Apart from biological hazards (microbial pathogens), allergens, and other chemical hazards can make food unsafe. For instance, the presence of reducing carbohydrates and asparagine in PBMAs promotes the formation of acrylamides (toxic Maillard reaction by-products) and particular combinations of sugars (maltose) and amino acids (containing aldehyde groups) have been shown to influence the formation of furan derivatives during cooking (Pospiech et al., 2024). Pospiech et al. (2024) reported that cooking temperatures exceeding 120 °C are needed for acrylamide formation. These authors also observed that the acrylamide concentration of soy and sunflower protein-based burger patties was significantly increased (p < 0.05) up to 72.3 µg/kg and 69.2 µg/kg, from an initial value of 14.5 µg/kg, after frying at 200 °C. This is likely due to the presence of high levels of glucose, fructose, and free asparagine in both samples (Pospiech et al., 2024). The study further illustrated that the acrylamide level in ground beef burgers was below the quantification limit of their method (7.6 µg/kg), after pan-frying at 200 °C. The absence of the amino acid asparagine in the meat patties may account for their low acrylamide content (Pospiech et al., 2024). Data from this study also showed that the highest levels (above 30 µg/kg) of furan derivatives (acetylfuran, ethylfuran, furfural, furfuryl alcohol) were present in the uncooked soy, pea, sunflower protein-based burger samples, and that pan-frying led to lower amounts of most furan derivatives, while furfuryl alcohol significantly increased (above 300 µg/kg) in the soy protein-based burgers, due to the highest maltose content (Pospiech et al., 2024). In contrast, acetylfuran and furfuryl alcohol were not detectable in ground beef burgers (BB) (Pospiech et al., 2024).

Cooking methods

The main purpose of cooking is to improve the sensory properties and digestibility of food as well as to ensure food safety (Hassoun et al., 2020). The earlier definitions of cooked meat tended to focus on changes that occurred when the meat protein was heated (Schwartz et al., 2022). For example, Davey and Gilbert (1974) defined meat cooking as heating the meat to adequately high temperatures to denature protein (Schwartz et al., 2022). Later, Tornberg (2005) introduced the denaturation temperature to describe the temperature at which conformational changes occur when meat protein is heated. Although the main protein found in meat (connective tissue in the form of collagen) is absent in PBMAs, plant protein denaturation also plays an important role in the texture changes observed during the cooking of these foods (Petrat-Melin & Dam, 2023).

Traditional in-home cooking methods may be classified as moist–heat or dry-heat methods (Brown, 2017). Moist–heat cooking methods use water or steam as a cooking medium to transfer heat to PBMAs (for e.g. boiling or poaching) (Chumngoen et al., 2018). A key limitation of moist–heat cooking methods is that colour, flavour, as well as vitamins and minerals may leach out and can be lost in the liquid (Brown, 2017). Conversely, dry-heat cooking methods such as roasting, oven-cooking, or frying involve the transfer of dry-heat from a flame, oven, or other heat sources to the surface of the PBMAs. Compared to moist–heat methods, higher temperatures are usually achieved when using dry heat since water can only heat at its boiling point of 100 °C (Brown, 2017). Baking involves heating the PBMA by hot air in an oven, and grilling involves cooking the PBMAs above a heat source.

The effect of cooking on the appearance and texture of PBMAs

Effects of cooking on the appearance of PBMAs

Appearance is a key quality attribute that impacts food choice and the initial acceptability of a product (He et al., 2020). Visual attributes such as colour and surface characteristics provide cues about the food's flavour, freshness, overall quality, and safety (Murano, 2017). In fact, light striking a food can be absorbed, reflected, or transmitted, and it is the “reflected” light that determines the colour of a food (Murano, 2015). For meats and PBMAs, desirable appearance typically includes uniform browning and minimal shrinkage (He et al., 2020). However, cooking changes the appearance of food, which in turn impacts consumer perceptions and acceptance.

One significant area of research focuses on the relationship between cooking time and temperature on the appearance of PBMAs and meat. Moderate pan-frying for about 6 min at 150 °C resulted in better browning (L* 38.7 ± 4.0 for PB burgers, and L* 46.6 ± 2.0 for beef burgers) and crust formation. These changes are visually appealing due to direct heat transfer from the pan indicating the occurrence of the Maillard reaction and caramelization (Correia et al., 2024; Vu et al., 2022). Similarly, in the same study, PBMAs and meat burgers cooked for 12 min at 150 °C resulted in greater browning which almost had a burnt look (L* 25.7 ± 0.5 for plant-based (PB) burgers, and 33.7 ± 0.9 for beef burgers). The longer cooking time may also have increased the intensity of the Maillard reaction leading to darker browning for both PB and beef patties but particularly for the PB product. PBMAs with their high carbohydrate and low protein content, have a different composition from beef burgers, which are low in carbohydrate and high in protein (Starowicz & Zieliński, 2019). Thus, it could be hypothesized that the key factors responsible for the Maillard reaction (amino acids (from proteins) and reducing sugars) are high in PBMAs when compared to beef resulting in more browning particularly in Impossible burgers (Starowicz & Zieliński, 2019).

Moisture retention and shrinkage are also crucial factors that influence the appearance of cooked meats and PBMA's (Hassoun et al., 2020). Typically, when meat burgers are cooked for longer times and at higher temperatures, there is greater moisture loss and shrinkage which makes the appearance of these products less appealing. For example, a study by Vu et al. (2022) examined beef patties and PBMAs cooked at various times (3, 6, 9, and 12 min) and temperatures (150 °C and 196 °C). The study found that PBMAs cooked for longer times (12 min) and at higher temperatures (195–200 °C) resulted in more pronounced browning (L* of 30.7 ± 1.0, oven-baked PBMAs) while showing minimal shrinkage (Area (cm2), 66.8 ± 0.4; Height (cm), 1.53 ± 0.05; and Volume (cm3), 102.4 ± 3.8) and maintaining their cylindrical form after cooking. This desirable surface colour and shape in the PBMAs resulted from their specific composition and structure, which in turn impacts their fluid retention capabilities (cooking loss of about 15%). In contrast, beef patties cooked at 70 to 75 °C released significant amounts of fluid (about 30% cooking loss) during cooking due to the denaturation of muscle proteins like collagen, actin, and myosin (Purslow et al., 2018). Cooking loss, exacerbated by increasing cooking time and temperature, which resulted in greater shrinkage.

On the other hand, PB patties, composed of pre-denatured soy proteins, maintained a stable polymer network throughout cooking. Ingredients such as starch and methylcellulose aid in water retention through hydration, capillary, and osmotic forces, thereby minimizing shrinkage. Similarly, Hernandez et al. (2023) reported that beef patties cooked on an enamel-lined cast-iron skillet, at elevated temperatures (200 ± 10 °C) showed less juiciness (51.3 score from the descriptive texture attribute of ground beef compared to 55.1 score of PBMA). These changes were attributed to protein denaturation and moisture loss.

In addition to changes observed due to high cooking temperatures, cooking can also result in moisture loss which impacts the texture and the overall juiciness of the PBMAs (Schwartz et al., 2022). As noted earlier both the cooking temperature used (Hassoun et al., 2020) as well as the cooking time (Vu et al., 2022) are important factors in heat transfer, protein denaturation as well as in moisture loss. Ingredients such as starch and hydrocolloids that are often used in PBMAs can also impact the water-holding capacity (WHC), which is the ability of a food to retain its moisture when exposed to heating and pressing (Kyriakopoulou et al., 2021; Vu et al., 2022). Other factors, such as water-polymer mixing, salt ion distribution, and elastic deformation, control the fluid retention properties of PBMAs and meat matrices (Tornberg, 2005). Tornberg et al. (2005) found that changes in molecular interactions, osmotic pressure differences, and mechanical resistance to deformation all influence fluid dynamics within the food matrix. The products evaluated in this study included traditional meat products such as pork, beef, and chicken, as well as PBMAs made from soy and wheat proteins. The cooking methods used in this study were primarily moist–heat methods, boiling and steaming, which allowed for a controlled assessment of how thermal processing influenced the fluid retention and texture properties of the products.

Colour in meat is primarily attributed to pigments such as hemoglobin and myoglobin which are absent in PBMAs (Jang & Lee, 2024). Thus, obtaining PBMAs with similar colour and appearance to traditional meat products can be challenging but presents unique opportunities. Indeed, Zhou et al. (2022a, 2022b) reported less desirable colour and appearance of PBMA patties because they lacked the muscle fibre structures that contribute to the visual and textural changes in cooked meat. As a result, PBMA formulations often require the use of different plant-based ingredients including beetroot juice and carrot juice extracts, lycopene, and soy leghemoglobin to achieve an appearance comparable to meat (Jang and Lee, 2024; Zhou et al., 2022a, 2022b). Zhou et al. (2022a, 2022b) recently showed that incorporating beetroot extracts in the formulation of PB burgers resulted in colour coordinates observed in raw beef. For example, the PB burgers displayed intermediate lightness (53.8 ± 3.8 L*), moderate redness (11.2 ± 1.5 a*), and moderate yellowness (15.3 ± 4.0 b*), resulting in a pink brown colour similar to beef burger (BB) (Table 1). These colour changes are important since they significantly influence consumer perceptions of quality.

Table 1.

The effects of cooking on the appearance and texture of PBMAs

| Sl. No | Name of PB Burger | Cooking method | Time & Temp(◦C) | Internal Temp(◦C) | Effect on Appearance | Effect on Texture | Reference |

|---|---|---|---|---|---|---|---|

| 1. |

1.Ultimate PB burger 2.Veggie Grillers Prime 3.XURGER 4.Burger patties, impossible foods 5.Perfect Burger, Dr. Praeger’s |

Pan Frying | 150 °C, flip every 2 min | 72 |

L*a↓b a*c↑d b*e↓ The lightness and yellowness of the beef and PB burgers were similar in the uncooked and cooked states The redness of the PB burgers was fairly similar to that of the BB before cooking but increased after cooking |

Hardness, gumminess, and chewiness were lower than those of BB | (Zhou et al., 2022a, 2022b) |

| 2. | Impossible Foods, Redwood City, CA | Pan Frying | 150 °C, cooked and flipped every 1.5 min (3-min) | 42.2 ± 7.6 |

L*↓ a*↑ b*↓ L*, a*, b* values were similar to different cooking methods, but decreased with increased time The type of cooking method had little effect after cooking There was little shrinkage Remained cylindrical, No irregular shape |

The textural attributes of the products varied based on cooking method and time Lower texture properties compared to beef patties Texture properties of both types of patties increased with increasing cooking time |

(Vu et al., 2022) |

| 150 °C, cooked and flipped every 1.5 min (6-min) | 58.8 ± 2.0 | ||||||

| 150 °C, cooked and flipped every 1.5 min (9-min) | 74.7 ± 9.0 | ||||||

| 150 °C, cooked and flipped every 1.5 min (12-min) | 85.2 ± 8.6 | ||||||

| Air Frying | 196 °C, flip every 1.5 min (3 min) | 42.0 ± 7.6 | |||||

| 196 °C, flip every 1.5 min (6 min) | 65.7 ± 2.1 | ||||||

| 196 °C, flip every 1.5 min (9 min) | 87.0 ± 0.4 | ||||||

| 196 °C, flip every 1.5 min (12 min) | 91.3 ± 4.0 | ||||||

| Oven Baking | 196 °C, flip every 1.5 min (3 min) | 49.0 ± 8.3 | |||||

| 196 °C, flip every 1.5 min (6 min) | 64.0 ± 1.1 | ||||||

| 196 °C, flip every 1.5 min (9 min) | 79.0 ± 2.2 | ||||||

| 196 °C, flip every 1.5 min (12 min) | 86.3 ± 0.1 | ||||||

| 3. | Pea or soy-based patties | Grilled | - | 72 | - | Analog B and S textures close to beef. While analogue D displayed significantly lower texture values | (Ilic et al., 2023) |

| 4. |

Albert Heijn (AH)—Deluxe Burger Beyond Meat—Beyond Burger Fry’s—Traditional Burgers Gardein—Ultimate Beefless Burger Garden Gourmet—Incredible Burger Greenway—Burger Linda McCartney—Quarter Pounder Moving Mountains—Veggie Burger Quorn—Supreme Vegan Burger SoPeace—Burger Vegafit—Gehaktschijf Vegetarische Slager—Mc2 No-Beef Burger VegiDeli—Quarter Pounder Vivera—Vegetable Burger Patty |

Pan fry | 200 | 74 |

Sensory Evaluation: Raw products- more appealing and more meat like Cooked products- Beyond Burger, Garden Gourmet Incredible Burger, Quorn Supreme Burger retained red colour which resulted in negative responses: ‘Looks too red/raw after cooking’, ‘Artificial/fake colour’, ‘Takes too long to cook’, ‘I don’t know when it’s cooked’ |

Quorn Supreme Burgers, Garden Gourmet and AH Burger Deluxe registered similar attributes to beef burgers Lower hardness compared to beef burger Comparable springiness and cohesiveness |

(Godschalk-Broers et al., 2022) |

| 5. |

Beyond Burger (BEY), Impossible Burger (IMP), and Plant-based protein (GEN) |

Enamel-lined cast-iron skillet | 200 ± 10 | 71 | - |

Sensory Evaluation BEY patties were juicier than all other products Juiciness was similar between both Ground beef (GB) and IMP products Among all products, GEN patties were the driest (p < 0.05) IMP patties were more cohesive than lean ground beef (LGB), BEY, and GEN (p < 0.05) Both GB products were harder than PBMA (p < 0.05) Among all products, GEN patties were softer (p < 0.05) The particle sizes of masticated patties were similar among both lean levels of GB and BEY and IMP (p < 0.05) BEY patties had a larger particle size compared to IMP and GEN patties (p < 0.05) |

(Hernandez et al., 2023) |

| 6. | Minced PBMA Beyond Mince, Beyond Meat®, The New Plant | sous vide (SV) and double-plate grill(G) |

SV- 60,70,80,90(◦C) for 60 min G—200(°C), 1 min |

Cooled down to 60(°C) G – cooled down to 55(°C) |

TPA—No significant differences in peak force, resilience, and adhesiveness across different cooking temperatures Sensory Evaluation Juiciness negatively correlated with dryness (r = − 0.67) and positively correlated with fattiness Hardness and chewiness were positively correlated At lower cooking temperatures, samples were perceived to be juicer |

(Zhang et al., 2024) |

aL*indicates lightness/brightness of a sample

b ↓ indicates a lesser value of PBMAs compared to meat-based counterparts

ca*indicates Redness/greenness of a sample

d ↑ indicates a higher value of PBMAs compared to meat-based counterparts

eb* indicates Yellowness/blueness of a sample

The in-home cooking method used also significantly impacts the appearance of both meat and PBMAs. For instance, grilling imparts desirable grill marks and a characteristic char that enhances visual appeal and flavour profiles. However, excessively high temperatures (above 190 °C) during grilling can lead to uneven cooking and burning, which detracts from the overall appearance. Vu et al. (2022) compared the effects of various cooking methods, pan frying at 150 °C, oven baking, and air frying at 196 °C for different cooking times (3–12 min), on the appearance of both meat and PB patties. They found that pan-fried patties had lower lightness (25.7 ± 0.5—12 min L*) than those cooked by air frying (27.3 ± 0.8—12 min L*) or oven baking (30.7 ± 1.0—12 min L*), which were attributed to Maillard browning (Correia et al., 2024) (Table 1). The Maillard reaction is a complex, non-enzymatic browning process that occurs between reducing sugars and amino groups during heating, typically above 120 °C (Sun et al., 2022). Some of the desirable outcomes of the Maillard reaction include the changes in the colour, flavour, and overall sensory properties of cooked foods, especially those rich in protein. Temperature, time, moisture content and food compositions are all factors that can accelerate the Maillard reaction (Sun et al., 2022). Recently Vu et al. (2022) observed that pan frying, with its more direct and intense surface heating, promoted greater browning and lower lightness values, in plant-based patties compared to similar patties that were oven-baked. The latter yielded products with lighter hues due to more uniform and less intense heat exposure. Conversely, grilled PBMA patties often exhibited attractive brown and grill marks, which enhanced their visual appeal (Vu et al., 2022). In these instances, the differences in lightness values (L*) observed among the cooking methods used were primarily due to variations in the heat exposure/intensity as well as the extent of the Maillard reaction.

Furthermore, different internal cooking temperatures even with the same cooking times can have different effects on appearance in PB burger patties when compared to meat burgers. The internal temperatures of PB patties cooked for 12 min (Pan-fried, 85.2 ± 8.6 °C; Air-fried, 91.38 ± 4.0 °C; Oven-baked, 86.3 ± 0.1 °C) tended to be higher in meat patties also cooked for 12 min (Pan-fried, 79.5 ± 5.2 °C; Air-fried, 78.4 ± 0.6 °C; and oven-baked, 77.0 ± 0.2 °C) due to differences in specific heat capacities and thermal conductivities (Vu et al., 2022). Air frying uses hot air circulation to cook the food, creating an environment that enables moderate browning without direct contact. In air frying, the heat transfer is less intense than that observed in pan frying but there is still sufficient heat to promote the Maillard reaction, resulting in intermediate lightness values (91.38 ± 4.0 in PB vs. 78.4 ± 0.6 in meat burger patties).

Although there are no standardized guidelines for determining the degree of doneness, changes in colour have been used to evaluate the level of doneness in cooked meat and PBMAs. In this context, sensory studies have proven to be an invaluable tool to better understand the sensory factors influencing consumer perceptions of raw and cooked meat analogue samples. Godschalk-Broers et al. (2022) conducted a sensory evaluation study using a non-trained consumer panel of 71 non-vegetarians, ages 19–41 years (63% female and 37% male) to investigate the factors that impacted consumer decisions when purchasing PBMAs. The data demonstrated that, raw burger samples were generally perceived as more attractive and meat-like based on their appearance, smell and colour. In the same study, the Golden & Green’s Pulled Oats registered the highest (30%) plant protein content among the PBMAs, with plant protein sources such as pea (21%) and fava bean (12%) registering the least score rating of 1.98 ± 1.08 for the attractiveness of raw samples based on their look, smell, colour (scales 1–5). Similarly, the Greenway Burger (PBMA) containing plant protein source from pea (22%) and potato scored 1.96 ± 0.93 rating for the attractiveness of the raw samples. In addition, the Gardein-Ultimate Beefless Burger which contained soy, wheat, and pea as protein sources, also received a low rating (1.88 ± 0.91, Scale 1–5) (Table 1). Conversely, PBMA samples such as the Albert Heijn (AH) Deluxe Burger which contained only soy and/or wheat as protein sources received high ratings (3.62 ± 0.97, scale 1–5) despite their precooked appearance.

Some PBMAs samples such as (Beyond Burger, Garden Gourmet Incredible Burger, Quorn Supreme Burger; data not shown in the published article) retained a red hue after cooking, leading to negative feedback such as"Looks too red/raw after cooking,""Artificial/fake colour,""Takes too long to cook,"and"I don’t know when it’s cooked (Table 1)."These observations may be due to the use of heat-sensitive colourants such as beetroot, which are added to give the appearance of raw meat. Importantly, if these colourants do not break down quickly enough, the persistent pink colour can result in longer cooking times and reduced food quality, which ultimately decreases consumer satisfaction( Godschalk-Broers et al., 2022).

The studies reviewed highlight the complex interplay between the cooking temperature used, the type of cooking method and the amount of moisture retained which ultimately impacts the appearance of cooked meat and PBMAs. While higher cooking temperatures enhance browning and visual appeal, they can also lead to increased moisture loss and shrinkage. The unique structural properties of PBMAs present additional challenges in replicating the appearance of traditional meat. Optimizing cooking techniques and formulations as well as advancements in food technology are all needed to ensure that PBMAs better meet consumer expectations for appearance and overall quality.

Effects of cooking on the texture of PBMAs

Sensory analysis plays a crucial role in understanding consumer perceptions of textures for PBMAs. Hernandez et al. (2023) conducted a descriptive sensory analysis with trained panelists (n = 9) and reported that the Beyond Burger cooked on an enamel-lined cast-iron, with a surface temperature of about 200 °C was juicier (55.1, p < 0.05) compared to the Impossible Burger and a third Brand of PBMA (51.3 and 42.9 respectively, p > 0.05) burgers. The ingredient list for the Beyond Burger product showed that there were proteins from peas and mung beans and starch from rice; this formulation could have possibly improved the water-holding properties and resulted in less moisture loss in the Beyond burger during cooking, and thus a juicier texture (p < 0.05) compared to the Impossible Burger. On the other hand, different proteins were used in the Impossible Burger including soy protein concentrate, potato protein and textured wheat protein which could also influence the texture and other sensory attributes of these products.

In a sensory perception study (n = 71) by Godschalk-Broers et al. (2023), the fibrous-like structure of Albert Heijn’s Pieces Like Chicken, made primarily from wheat protein, was highlighted as a key feature. This product exhibited a homogeneous distribution of very small mycoprotein fibers, a texture largely attributed to the extrusion process used in producing PBMA. The extrusion process not only shapes the structural integrity of the protein but also impacts the sensory attributes, particularly texture, which are critical for consumer acceptance. The study underscores that the choice of protein source and the specific processing methods employed directly influence the final texture and sensory experience of PBMA. In terms of consumer feedback, Albert Heijn’s Pieces Like Chicken scored a texture liking of 7.11 ± 1.68 (on a 1–9 scale), closely mirroring the texture of real chicken pieces, which scored 7.99 ± 1.04. In contrast, Gold & Green’s Pulled Oats PBMA received a significantly lower texture liking score of 4.01 ± 1.98, suggesting that protein source and structural processing play pivotal roles in consumer texture preferences. A similar trend was observed in plant-based burgers. Albert Heijns’ Deluxe Burger, which contains a blend of soy (53%) and wheat (13%) proteins, achieved a texture liking score of 6.99 ± 1.53 and a juiciness rating of 50.69 ± 20.12 (on a 0–100 scale). These scores were notably close to those of real beef burgers, which scored 7.58 ± 1.59 for texture liking and 74.73 ± 19.66 for juiciness. Conversely, So Peace’s burger, made with pea protein (45%), was rated poorly, with a texture liking score of 2.65 ± 2.09 and a juiciness rating of 28.04 ± 21.45. These findings suggest that juiciness—a sensory attribute closely tied to texture and mouthfeel—plays a significant role in consumer perception and overall acceptance of PBMAs. The study highlights how protein source, structural composition, and processing methods collectively shape the sensory experience, emphasizing the need for targeted innovations in PBMA production to meet consumer expectations.

Vu et al. (2022) also noted that Impossible (PB) cooked using different cooking methods (pan-fried, air-fried and oven-baked) all showed major differences in texture-profile-analysis measurements compared to beef burger patties. In this study, different dry-heat cooking temperatures were used (pan fryer at 150 °C, air fryer at 196 °C and oven baking at 196 °C. Moisture loss during cooking generally increased with higher temperatures and longer cooking times. For instance, pan-fried PBMAs exhibited cooking losses of approximately 5%, 7%, 14%, and 20% after 3, 6, 9, and 12 min, respectively, compared to meat burgers, which showed significantly (p < 0.05) higher losses of 10%, 20%, 30%, and 45% under the same conditions. This indicates that PBMAs have better WHC, enabling better moisture retention. This is because of their pre-denatured protein matrix and the inclusion of polymeric ingredients like methylcellulose and starch, which form porous networks that effectively bind water (Vu et al., 2022). Zhou et al. (2022a, 2022b) also compared plant burgers (PB) and beef burgers (BB) and found that PB had a higher WHC (94 ± 4%) compared to BB (88 ± 3%), further indicating that PB burgers are better able to retain fluids. Similarly, Hernandez et al. (2023) showed that the WHC of different commercial PB burgers consistently had higher WHC values compared to BB. Regarding sensory attributes, juiciness and hardness were comparable among PB products, with Beyond Burger patties showing the highest juiciness (55.1, p < 0.001) and lowest hardness (27.9, p < 0.001). In contrast, ground beef patties had lower juiciness (52.1, p < 0.001) and greater hardness (30.6, p < 0.001), contributing to a drier texture and improved firmness (Table 2). Water retention and water holding capacity are also factors that significantly affect the textural attributes of PB meat burgers (Aaslyng et al., 2003). Water loss during cooking can also lead to a firmer and drier texture, which may be less appealing to consumers seeking a juicy burger product (Vu et al., 2022; Zhou et al., 2022a, 2022b). Improved water holding capacity results in a better texture that more closely resembles beef and enhances the perception of juiciness as the burger retains less fluids released during mastication (Table 2) (Zhang et al., 2024). Thus, managing water loss is essential to maintaining the tenderness, juiciness and hardness of PBMAs, which are key sensory attributes that contribute to consumer satisfaction.

Table 2.

The effects of different cooking methods and conditions on the flavour attributes of PBMAs

| Sl. No | Name of Burger | Cooking method | Time & Temp. (°C) | Internal Temp. (°C) | Effect on Sensory attributes | Effect on flavour (GC–MS) | Reference |

|---|---|---|---|---|---|---|---|

| 1 |

Bean Supreme, New Zealand Veggie Delights, New Zealand Minced beef patties Countdown, New Zealand |

Commercial grill |

5 Min, 180 °C 5 Min, 180 °C 7 Min, 180 °C |

- |

Compared to soy and hemp, beef patties received the highest overall liking scores and exhibited intense meaty aromas Conversely, soy patties were described as smoky, with aromatic spices and salty tastes However, hemp patties were the least liked and were perceived as bitter with beany and nutty aromas Hedonic scores did not change for the PB patties when they were combined with a bun and/or with a sauce |

- | (Gonzalez-Estanol et al., 2023) |

| 2 |

Mince samples Frozen ready-to-cook patties |

Pan fry |

180–200 °C for 3 min 180–200 °C, 4 min per side |

70–75 °C |

Animal protein samples were positively associated with meaty odours and flavours. In contrast, PB samples, were positively associated with off-flavours and aromas However, meaty odour and flavour intensity of Impossible™ (SM- 1) samples were comparable to the animal protein samples |

Key odourants correlated with meaty flavours and odours included 2-methyl- 3-furanthiol, dimethyl trisulfide, and furfuryl mercaptan. Conversely, compounds correlated with off flavours and odours were putatively identified as (E,E)− 3,5-octadien2-one, 2-undecanol, and (E,E)− 2,4-decadienal | (Thong et al., 2024) |

| 3 |

Albert Heijn—Burger Deluxe Beyond Meat—Beyond Burger Fry’s—Traditional Burgers Gardein—Ultimate Beefless Burger Garden Gourmet—Incredible Burger Greenway—Burger Linda McCartney—Quarter Pounder Moving Mountains—Veggie Burger Quorn—Supreme Vegan Burger SoPeace—Burger Vegafit—Gehaktschijf Vegetarische Slager—Mc2 No-Beef Burger VegiDeli—Quarter Pounder Vivera—Vegetable Burger Patty |

Pan fry | 200 °C | 74 °C |

Chicken analogues were frequently described as having meaty flavours However, compared with real beef, the analogue burgers were generally perceived to have lower meaty flavour intensity The textural properties of chicken analogues and analog burgers were similar. However, stepwise linear regression analysis showed that meaty flavour and juiciness were predictive of 48% liking in chicken analogue pieces (B = 0.589 and 0.240, respectively) and 47% in analogue burgers (B = 0.572 and 0.236, respectively) |

- | (Godschalk-Broers et al., 2022) |

| 4 |

The Beyond Burger (BEY), Impossible Burger (IMP), The third available brand of plant-based protein (GEN) |

Enamel-lined cast-iron skillet | 200 ± 10 | 71 |

All 17 flavour attributes were different due to product type (p ≤ 0.031) Among the PBMA samples, GEN had the lowest beef flavour intensity (p < 0.05) Compared to all other products buttery flavour was most intense in BEY and IMP patties s (p < 0.05) Both types of GB samples had lower overall sweet notes compared to the PBMAs (p < 0.05). However, the smokey-charcoal intensity was greater in PBMAs compared to both GB products (p < 0.05) Umami intensity was the lowest in both GB products compared to PBMA (p < 0.05). Among PBMA, BEY was most intense for umami Nutty and musty/earthy notes were more intense in PBMA compared to GB (p < 0.05). Among PBMA, BEY and IMP were nuttier than GEN (p < 0.05) LGB, IMP, and GEN patties were more bitter than BEY (p < 0.05). However, all the PBMAs were saltier than both GB products (p < 0.05) |

PBMA produced greater concentrations of Maillard reaction products Of the PBMA, the volatile flavour profile of IMP was most similar to GB regarding Strecker aldehydes BEY and GEN patties showed increased production of furfural, 2-furanmethanol, and 5-methylfurfural compared to IMP and GB patties Additionally, IMP and GEN patties had higher levels of 2-methyl- 3-furanthiol, and GEN had increased 2-methyltetrahydro- 3-furanone RGB patties produced the highest acetoin and 2,3-butanedione concentrations, with LGB following closely PBMA patties had greater concentrations of methylpyrazine and 2,5-dimethylpyrazine, with GEN showing the highest trimethylpyrazine levels BEY and GEN patties also produced more 2-acetylpyrrole than GB patties |

(Hernandez et al., 2023) |

| 5 |

Beyond Burger™ (plant-based burger 1) Lightlife™ (plant-based burger 2) Great Value™ (plant-based burger 3), Veggie Cuisine™ (plant-based burger 4), Great ValueTM beef burger (beef burger) |

electric griddle | 230 ± 5 °C | 74 °C | - |

64 VFCs were detected and quantified in the samples. Including 9 aldehydes, 7 ketones, 7 alcohols, 6 carboxylic acids, 4 esters, 7 pyrazines, furan or pyran, 15 sulphur-containing compounds, 5 aromatic compounds, and 4 other compounds The different ingredients, as well as the Maillard reaction, and lipid oxidation contributed to flavour formation For uncooked samples, the VFC profiles of PB 3 and PB 4 were more similar to the BB samples. On the other hand, in the cooked samples, PB 1 had a similar VFC profile to BB. These changes illustrate the importance of the cooking process on aroma formation |

(He et al., 2021) |

In addition to sensory studies and WHC, Texture Profile Analysis (TPA) can also be used to evaluate the mechanical properties of food and provide insights into how cooking affects the texture of PBMAs. Vu et al. (2022) demonstrated that plant-based patties exhibited lower hardness (300—500 g), cohesiveness (0.25—0.35), springiness (30%—45%), resilience (6—11%), and chewiness (< 100 g) compared to beef patties (hardness (700—4000 g), cohesiveness (0.5—0.6), springiness (60%—85%), resilience (18—21%), and chewiness (200—2000 g), with textural attributes increasing at longer cooking times (3–12 min) and higher temperatures (150–200 °C) across pan-frying, air-frying, and oven-baking methods. The greater changes in beef patties were attributed to protein denaturation, matrix shrinkage, and collagen transitions, while the minimal changes in plant-based patties were linked to their pre-denatured soy proteins and water-binding ingredients like methylcellulose and starch. Although textural differences between plant-based and meat alternatives varied with cooking methods, cooking time had a more pronounced effect on texture than the choice of method, offering flexibility in preparation based on consumer preferences.

Ilic et al. (2023) and Godschalk-Broers et al. (2022) reported that certain plant-based meat analogues (PBMAs), such as Quorn Supreme Burgers, Garden Gourmet, AH Burger Deluxe, and analogues B and S, exhibit textural properties comparable to those of conventional meat. For instance, the springiness values of PBMAs ranged from 0.6 to 0.91, while real chicken measured 0.69 ± 0.03 (Godschalk-Broers et al., 2022). However, other PBMAs, like chicken analogue pieces, demonstrated significantly lower hardness values, approximately 24 kPa, compared to 142 kPa for real meat, where higher hardness indicates greater toughness (Godschalk-Broers et al., 2022; Ilic et al., 2023). The authors noted that it is challenging to attribute specific textural characteristics to distinct features of meat analogues. Nonetheless, the findings suggest that the denseness of the structure, along with the inclusion of fat, air pockets, and fibrous components, plays a critical role in defining the texture of PBMAs relative to meat. This highlights the intricate relationship between the texture and structural attributes of PBMAs and their meat counterparts.

Cooking temperature and time are pivotal in determining the final texture of burgers. Zhou et al. (2022a, 2022b) and Vu et al. (2022) have shown that PB burgers typically exhibit lower hardness around 500 g, and chewiness below 100 g compared to BB (hardness around 1000 g and chewiness approximately 700 g) when pan-fried at 150 °C and flipped every two minutes for 6 min until reaching an internal temperature of 72 °C. This indicates that PB burgers may require shorter cooking times or lower temperatures to achieve a texture similar to that of beef. Furthermore, as cooking time increases, the textural attributes such as hardness and chewiness also increase, suggesting a risk of overcooking and producing less palatable attributes (Vu et al., 2022). This is a crucial consideration for both home cooks and commercial kitchens aiming to replicate the mouthfeel of traditional meat. In addition, cooking temperature significantly affected the juiciness intensity for both PB and beef patties. Zhang et al. (2024) reported that lower core temperatures (60 °C) significantly enhanced sensory attributes such as juiciness, tenderness, and fattiness while reducing dryness, hardness, chewiness, and crumbliness in beef patties, according to a rank-test analysis. Juiciness intensity increased by 56% in PB patties, from 45 ± 20 for 90 °C to 70 ± 16 for 60 °C, and by 128% in beef patties, from 26 ± 15 for 90 °C to 58 ± 17 for 60 °C. Additionally, juiciness was found to be negatively correlated with dryness, hardness, and chewiness, and positively correlated with tenderness and fattiness in beef sensory patties, emphasizing the impact of lower cooking temperatures on sensory quality.

In a sensory study conducted by Gonzalez-Estanol et al. (2023), consumer perceptions of soy-and hemp-based plant-based (PB) patties, as well as traditional beef patties, were evaluated when combined with a bun and tomato sauce. The PB patties were grilled at 180 °C for 5 min, while beef patties were grilled for 7 min. The study hypothesized that integrating PB patties with complementary components such as buns and sauces could help mask undesirable textural attributes often associated with plant-based alternatives. The sensory Rapid Attribute Testing Analysis (RATA) revealed that hemp-based patties contain a high number of chunks, which was one of a key driver of consumer disliking. However, the addition of a bun and tomato sauce notably diminished the prominence of these negative textural attributes, although not eliminating them completely. This suggests that while the inclusion of other food components can mitigate some texture-related issues, they may not fully overcome inherent sensory shortcomings of PB patties. The findings highlight that combining PBMAs with other food elements can generate a more favourable sensory experience by partially masking texture defects. This approach simulates real-world consumption scenarios, where PBMAs are typically consumed as part of a complete meal. Importantly, the study highlights the potential of pairing PBMAs with complementary ingredients to enhance consumer acceptance and overall enjoyment, particularly when textural attributes are a primary concern. This insight highlights the interplay between individual food components and their combined influence on sensory perception, providing insights for both product development and culinary applications in the plant-based food industry.

In conclusion, the texture of PB meat burgers is significantly influenced by the type and intensity (temperatures, times) of cooking as well as the composition and structure of the food ingredients. While PB burgers can mimic the texture of beef to some extent, there is still considerable room for improvement in their formulation and cooking instructions to better meet consumer expectations. Water loss and water holding capacity are critical factors affecting textural attributes, and optimal management of these factors is essential for achieving a satisfying texture. Ongoing research and development are vital to enhancing the sensory qualities of PB burgers, ensuring they are nutritious and enjoyable to eat. The microstructure of PB products and ingredients play a crucial role in determining the final product's textural properties, mouthfeel, and overall acceptability. Advanced imaging and microscopy techniques can be utilized to obtain an increased understanding of the microstructural properties of PBMA which will be good for developing better PBMA with improved functional properties. Methods such as dynamic shear rheometry, diffusing wave spectroscopy, nuclear magnetic resonance, and differential scanning calorimetry can be employed to analyze changes in their properties with temperature. Additionally, correlating the data from these analytical instruments with sensory analysis results is essential. As the demand for PB options grows, addressing these challenges through technological innovations and consumer education will be key to the success of these products in the marketplace.

Effects of cooking on the key aroma active compounds present in PBMAs

Understanding how cooking methods influence the presence of aroma active compounds present in PBMAs is pivotal for optimizing the sensory quality particularly the flavour of these foods. Here we focus on some of the key volatile aroma active components identified by Gas Chromatography-Mass Spectrometry (GC–MS) that contribute to the flavour profiles of PBMAs.

He et al. (2021) focused on the volatile, aroma active flavour compounds in commercial PB burgers and highlighted the impact of consumer cooking methods on flavour development. The authors identified several key volatile, aroma compounds, including pyrazines, which contribute to nutty, roasted, and popcorn-like aromas. Pyrazines are formed during the Maillard reaction, a chemical reaction that occurs when amino groups and reducing sugars are heated at high temperatures (Shakoor et al., 2022). Additionally, sulphur-containing compounds such as thiol derivatives were noted for their contributions to savoury, meaty, and onion or garlic-like aromas, which enhance the overall umami and savoury profiles of PB burgers. Maillard reaction products also contributed to complex meaty, roasted, and caramelized flavours, which are essential for achieving a savory and appealing flavour profile in PBMAs.

Hernandez et al. (2023) also evaluated the volatile compounds in PBMA, and ground beef cooked under controlled conditions. The GC–MS data from this study showed that PBMAs like the Beyond Burger and Impossible Burger exhibited higher levels of pyrazines, such as 2-ethyl- 3,5-dimethyl pyrazine and 2,5-dimethyl- 3-isoamyl pyrazine, which impart nutty aromas absent in animal-based meats. Conversely, traditional meats showed higher levels of sulphur-containing volatiles like dimethyl trisulfide and 5,6-dihydro- 2,4,6-trimethyl- 4H- 1,3,5-dithiazine, which contribute to their characteristic meaty aroma. These findings highlight the challenge of replicating meat-like aromas using PB ingredients alone and highlight the need for innovative approaches in PBMA formulation and different cooking methods.

Thong et al. (2024) conducted a comparative analysis of various commercial PBMAs cooked via pan-frying at specific temperatures (180–200°C for 3 min 180–200°C, 4 min per side) to achieve internal temperatures of 70–75 °C. Their GC–MS analysis focused on the volatile compounds present, and observed distinct profiles based on the protein sources used. Legume odourants, prevalent in PBMAs derived from soy and pea proteins, contributed to characteristic bean-like aromas. Conversely, meaty odourants, aimed at replicating the aroma of animal-based counterparts, were identified as crucial for enhancing the perception of meat-like qualities in PB alternatives; similar findings were reported in other studies (De Angelis et al., 2020). The study also highlighted the challenges related to off-flavour compounds such as metallic, oxidized, and earthy notes, which can affect overall flavour perception and the difficulties in achieving consistent sensory profiles across different PB products.

In addition to flavours derived from Maillard browning, lipids also play a crucial role in flavour development during cooking, influencing the types of volatile compounds produced. Thong et al. (2024) noted higher levels of certain aldehydes such as (E, E)- 2,4-decadienal in PBMAs, contributing to fatty odours resulting from the breakdown of PB lipids during cooking. This contrasts with the lipid-derived volatiles observed in animal meats. He et al. (2021) also pointed out that the lipid profiles of PBMAs often included vegetable oils such as coconut and canola, which differed significantly from those of animal meats. This variation in lipid composition leads to differences in flavour compounds and makes replication of traditional meat flavours in PBMAs more challenging. Furthermore, PBMAs like Beyond Burger contain higher percentages of mono- and polyunsaturated fatty acids, which degrade differently than the saturated fats predominant in animal meats.

Cooking time and temperature are also critical in determining the extent of chemical reactions such as the Maillard reaction and lipid degradation, thereby influencing the flavour profiles of PBMAs. Thong et al. (2024) and Hernandez et al. (2023) both emphasized the need for optimized cooking techniques to enhance desirable flavours in PBMAs. Maximizing the Maillard reaction is also pivotal for developing meaty flavours in PBMAs. Thong et al. (2024) demonstrated that higher levels of Maillard Reaction Products (MRPs) in certain PBMAs correlate with stronger meaty odours. However, achieving this effect uniformly across different PBMAs is challenging due to variations in base proteins and ingredient formulations. Moreover, the presence of pyrazines and other MRPs varies significantly among products, underscoring the need for precise control over cooking conditions to maximize flavour development.

Significant progress has been made in understanding the role of cooking in flavour attributes of PB meats, yet challenges persist in achieving sensory equivalency with conventional meat products. The Maillard reaction and the formation of key volatile aroma active compounds play key roles in flavour development, and contribute to the sensory perception of savoury, umami, and grilled notes. Future research should concentrate on identifying optimal amino acid and sugar combinations in PB proteins to enhance the Maillard reaction. Additionally, exploring the effects of different cooking methods as well as the temperatures and duration of these cooking methods can be instrumental in understanding the key Maillard reaction products formed and can aid in developing standardized cooking guidelines for PBMAs. The differences in volatile compound profiles between PBMAs and traditional meats highlight the complexity of replicating meat-like aromas using PB ingredients. While PBMAs generally produce higher levels of pyrazines, traditional meats generate more sulphur-containing volatiles, which are crucial for their characteristic aroma. This discrepancy highlights the ongoing challenge researchers and food manufacturers face in achieving sensory parity between PB alternatives and conventional meats. Research to optimize cooking methods and ingredient formulations should be ongoing to further advance the sensory quality and market competitiveness of PBMAs.

Effects of cooking on the flavour (taste and aroma) of PBMAs

Sensory characteristics such as flavour play a significant role in shaping consumers' perception of PBMAs. Flavour is a complex quality attribute that involves taste and aroma and trigeminal stimuli; and consumers rely on a multisensory mechanism influenced by sensory cues as well as memory and personal variables to perceive flavour (Abotsi et al., 2024). The methods and conditions used in the cooking process profoundly influence these sensory attributes, either enhancing desirable flavours or exacerbating undesirable ones. Here we compare how different cooking methods impact the sensory profiles of PBMAs, highlighting the challenges and progress made in replicating the sensory characteristics of traditional meat.

Gonzalez-Estanol et al. (2023) investigated the effects of cooking techniques and food combinations on the sensory attributes of PB and beef burger patties, using a commercial grill at 180 °C. PB patties were cooked for 5 min and beef patties for 7 min. The study involved 91 consumers who evaluated a range of sensory attributes and data was analyzed using Rate-All-That-Apply using a 9-box scale ranging from ‘low’ to ‘high’. Sensory attributes such as saltiness, sweetness, bitterness, umami, smokiness, meaty flavour, and more were analyzed in the study. The results highlighted a preference for beef patties over soy and hemp patties in terms of overall liking (7.3 ± 0.9 for beef; 6.6 ± 1.5 for soy; and 5.0 ± 2.0 for hemp), texture linking (6.9 ± 1.3 for beef; 6.1 ± 1.6 for soy; and 4.4 ± 2.0 for hemp) and flavour liking (7.3 ± 1.1 for beef; 6.5 ± 1.7 for soy; and 5.2 ± 2 for hemp). Whereas, Soy patties were noted for their pronounced smokiness (6 ± 2.4), aromatic spices (6.0 ± 2.3), and saltiness (4.8 ± 2.1), whereas hemp patties were perceived as the most bitter (0.9 ± 1.2 for beef; 1.9 ± 2.1 for soy; 2.1 ± 2.4 for hemp), with high intensities of beany flavour (1.3 ± 1.5 for beef; 3.8 ± 2.5 for soy; 6.3 ± 2.5 for hemp) and nutty flavour (1.6 ± 1.9 for beef; 3.3 ± 2.5 for soy; 6.0 ± 2.6 for hemp). Importantly, the study found that pairing the patties with buns and tomato sauce slightly mitigated the inherent off-flavours and texture defects of plant-based patties, particularly for soy. However, these additions were not sufficient to fully mask strong off-flavours. One observation was that grilling at 180 °C notably enhanced smokiness and aromatic spices notes in soy patties, highlighting the critical role of choosing the right cooking methods and food combinations in influencing the sensory attributes of PBMAs.

Thong et al. (2024) also compared the sensory attributes and volatile profiles of various commercial PBMAs and animal-based burgers. The study involved pan frying at temperatures ranging from 180 to 200 °C, and the products achieved internal temperatures of 70–75 °C. Key sensory attributes evaluated included odour intensities (meaty, legume, off-odour) and taste/flavour intensities (meaty, legume, salty, savoury, off-flavour). Distinct sensory profiles between animal protein samples and plant-based samples were observed and animal protein samples exhibited higher perceptions of meaty odour and flavour, whereas plant-based samples were associated with legume odour and off-flavours. Specifically, Impossible™ (SM- 1) demonstrated comparable meaty odour and flavour intensities to animal protein samples, whereas Seitenbacher™ (GM) and Amy’s™ (GP) showed elevated legume odour and flavour intensities. Although different sources of protein were used in the formulations tested (soy vs. pea), SM- 1 (composed of water soy protein concentrate, coconut oil, sunflower oil, flavourings) and PM (composed of water, pea protein, pressed canola oil, refined coconut oil, rice protein, and natural flavouring) achieved high meaty flavour intensity, indicating potential advancements in flavour mimicry within plant-based products. Additionally, volatile profile analysis revealed similar odour-active compounds across PBMAs made from different plant protein sources, suggesting certain commonalities in flavour chemistry despite ingredient diversity.

Godschalk-Broers et al. (2022) explored the sensory attributes and consumer perception of various PBMA compared to chicken and beef. The study involved pan-frying 14 types of burger patties at 200 °C until they reached an internal temperature of 74 °C. Key sensory attributes evaluated included meaty flavour, flavour intensity, juiciness, and overall liking, with comparisons drawn against real chicken and beef as reference points. One significant finding was that chicken analogue pieces generally scored higher on meaty flavour compared to real chicken, although these differences were not statistically significant across all samples. Conversely, PBMAs tended to have lower flavour intensity and perceived meatiness compared to real beef, with most attributes showing no statistically significant differences from the reference.

Stepwise linear regression analysis was also used to delve deeper into the factors influencing consumer liking (Godschalk-Broers et al., 2022). Meaty flavour and juiciness were critical predictors of overall liking for both chicken analogue pieces and burgers, which explained a substantial proportion of variance in consumer preference. Interestingly, attributes such as flavour intensity and fattiness did not significantly contribute to liking, suggesting that consumer acceptance is more closely tied to specific flavour profiles (meaty flavour) rather than the intensity or richness of flavours. Moreover, correlations between liking and sensory attributes revealed strong associations between liking flavour and meaty flavour intensity, highlighting the importance of meaty flavour in consumer preference.

Furthermore, recent studies on PBMAs emphasize the significance of cooking methods on consumer perceptions. In a similar study, Gonzalez-Estanol et al. (2023) found that grilling at 180 °C enhanced desirable attributes in soy patties but struggled to mask off-flavours and texture issues. The inability to fully mask strong off-flavours, highlights the need for optimized cooking techniques and complementary food pairings. Indeed, Thong et al. (2024) compared PBMAs and animal-based burgers, and noted that some PBMAs achieved comparable meaty odour and flavour intensities similar to animal-based samples. Godschalk-Broers et al. (2022) also focused on consumer perception and showed that meaty flavour and juiciness were the most critical predictors of overall consumer liking.

In conclusion, while progress has been made in improving the sensory characteristics of PBMAs, there are research gaps, particularly in addressing persistent off-flavours in PBMAs. Current strategies for mitigating off-flavours in PBMA burger patties involve using neutral-tasting plant proteins and employing processing techniques such as extrusion and flavour masking with artificial and natural enhancers. Future research should focus on careful ingredient selection (including novel ingredients), leveraging science-based (micro)structure engineering, advanced flavour-masking techniques, and optimized formulation and cooking methods. Moreover, there is still a need for more comprehensive research on a broader range of cooking methods and their impact on sensory attributes. In addition, emerging approaches are poised to revolutionize flavour enhancement, including advanced flavour chemistry to pinpoint and neutralize specific off-flavour compounds. The use of novel plant-derived ingredients rich in umami flavours, and the incorporating innovative processing methods such as high-pressure processing and microbial fermentation to improve texture and impart authentic meaty flavours are all under-explored paths. Consumer-centric research, utilizing sensory analysis and personalized formulation, could also be applied to better tailor PBMAs burger patties to meet diverse consumer taste preferences and enhance appeal in the marketplace.

Effects of cooking on the nutritional properties of PBMAs

Healthy and sustainable food systems emphasize the importance of both the quantity and quality of nutrients. Many studies have shown that PBMAs contain essential micronutrients such as vitamin B12, calcium, iodine and zinc, which are crucial for human health, alongside macronutrients such as proteins, ranging from 3 to 36 g per 100 g of the food product (Bakaloudi et al., 2021; Hunt, 2003; Smetana et al., 2021). Protein quality is a critical consideration due to the significant variability in amino acid composition and the digestibility of plant proteins (Adhikari et al., 2022). Incorporation of protein quality into a nutrition involves quantifying individual amino acids because processing and cooking techniques can transform amino acids and influence digestive outcomes (Adhikari et al., 2022).

According to Hoffman and Falvo (2004), three essential factors i.e., amino acid arrangement, human need for indispensable amino acids, and digestibility of the indispensable amino acids, are crucial in the quantitative determination of protein quality. Some of the widely used methods to measure protein quality are Protein Digestibility Corrected Amino Acid Score (PDCAAS), Digestible Indispensable Amino Acid Score (DIAAS), and Protein Efficiency Ratio (PER). Although DIAAS is the most recent method, introduced by FAO (Food and Agricultural Organization of United Nations) in 2011, to claim protein quality, the USA and Europe still use the PDCAAS method and Canada uses PER method (Hertzler et al., 2020; Nosworthy et al., 2018). Generally, most animal proteins have a PDCAAS value near 1.00, while plant proteins typically have values lower than 1.00. For instance, legumes range between 0.60 and 0.80, whereas soy protein scores 1.00 (Hertzler et al., 2020).

During cooking techniques such as grilling, baking, frying, and microwaving, amino acids can undergo multiple chemical transformations because of high thermal load. The Maillard reaction is a well- studied chemical reaction, where lysine in PBMAs gets conjugated with reducing sugars to form a complex mixture of glycated lysine (Nyakayiru et al., 2020; Salazar-Villanea et al., 2018). The extent of glycation can vary depending on the cooking type, intensity (temperature, time), and storage conditions (Rérat et al., 2002). PB burgers are mostly made from pea proteins which contain large amounts of lysine, meaning that glycation of lysine can influence the total absorption of the amino acids. This is in part because glycation of lysine residues can diminish the cleavage of peptide bonds in proteins by reducing the activity of digestive enzymes (Rérat et al., 2002). Furthermore, in wheat-containing PB burgers, lysine is the first limiting amino acid, therefore Maillard-type reactions can negatively affect the protein quality. Thermal alteration of amino acids can also affect the overall bioavailability of amino acids (Sarwar Gilani et al., 2012).

Protein quality measures a food source’s sufficiency and availability of essential amino acids (Pathania et al., 2019). Plant-derived proteins are often incomplete, lacking one or more of the 9 essential amino acids (tryptophan, histidine, threonine, leucine, isoleucine, lysine, phenylalanine, methionine, and valine), the protein quality of PBMA is naturally poor (Ismail et al., 2020). To enhance the amino acid profile, plant proteins are often combined with other protein sources. The most effective blends typically involve mixing pulse proteins (high in lysine) with cereal proteins (rich in methionine and cysteine) (Cutroneo et al., 2023). A study revealed that beef burger alternatives and regular beef burgers had comparable non-essential amino acid profiles, while PBMA were notably lacking in histidine, methionine, and lysine in comparison to ground beef burgers (Narayanan Nair, 2021). Another study by Cutroneo et al. 2023, used the Kjeldahl method to determine the protein content of pan-fried (150 °C, 3 min) and raw beef, soy, and pea protein burgers. Beef burgers showed a statistically higher (p < 0.05) protein content in both cooked (48 g/100 g of dry matter) and uncooked stages (52 g/100 g of dry matter) stages, while pea-based burgers also exhibit a comparable protein content to beef burgers in both cooked (47 g/100 g of dry matter) and uncooked stages (50 g/100 g of dry matter) stages.

Another study by Zhou et al. (2022a, 2022b) observed that pan frying at 160 °C for 2 min can denature PB proteins, resulting in 44% loss of protein. Zhou et al. (2022a, 2022b) also showed that pan frying at the previously described conditions resulted in a decrease in glutamate (66%), aspartate (58%), arginine (65%), alanine (62%), glycine (61%), and total essential amino acids (56%). Some of these amino acids (glutamate, aspartate, arginine, alanine, and glycine) are accountable for palatable tastes in food (Liu et al., 2016), suggesting that thermal treatments not only compromise the nutrition but also the taste of food. With reference to minerals such as potassium, magnesium and phosphorus, pan frying with oil can cause a decrease in between 23 and 38% of PBMA due to the increased proportion of fat (Lee et al., 2019). Frying at 160 °C can also lead to a loss of nearly 35% of dietary fibres in PB burgers (Su et al., 2017).

Deep fat-frying has two main advantages: it uses a short frying time, and the core food temperature doesn’t exceed 100 °C if the food contains some water. Therefore, micronutrients such as vitamin C and thiamine in plant proteins are better preserved than they are in oven baking and stir frying. Also, deep fat-frying can increase the dietary fibre content in potato starch in PBMA by converting starch molecules to a resistant starch, possibly type 3 (Fillion & Henry, 1998). Although, stir-frying at a high temperature and with a shorter cooking time can increase the absorption of beta carotene and lycopene levels of vegetables in PB burgers (Ghavami et al., 2012), this technique can result in loss of vitamin A in these vegetables by 24% (Mosha et al., 1997). Microwave cooking is a good approach to preserving antioxidant activity in mushrooms and garlic use in PBMA, but this method also can decrease vitamin C levels of vegetables in PBMA by 20–30% (Fillion & Henry, 1998). In the published literature, different cooking methods have been shown to affect the nutrient content of PBMA, and it is challenging for any cooking technique to preserve all nutrients. A better understanding of the nature of the ingredients selected for PBMAs formulations and the conditions for processing (cooking method selected, including the duration and temperatures used) will provide the fundamental knowledge needed to address nutrient loss in PBMA products.

Effects of cooking on the digestibility of PBMAs

In addition to modifying amino acid composition and functional properties of proteins, preparation and cooking techniques also can influence the digestibility of proteins. In one study, thermal processing approaches such as frying, baking, and grilling (all dry-heat cooking methods) were found to develop crosslinked peptides due to inducing L-amino acids racemization. These crosslinks can minimize the availability of amino acids and suppress the activity of gastrointestinal enzymes, reducing digestibility (Adhikari et al., 2022).

The digestibility of plant proteins in the digestive tract tends to be low, and is influenced by both internal and external factors. For example, in simulated digestion trials, ground beef analogue displayed lower (70%) in vitro intestinal protein digestibility than real ground beef (95%), despite having higher digestibility in the gastric phase (Xie et al., 2022). Zhou et al. (2021) also compared the digestibility of PBMA and beef in the gastrointestinal phase, and the total digestibility for PBMA was registered as 70% whereas real beef was 95%. This difference in digestibility was attributed to the presence of various protein sources and fibres in the tested samples (Xie et al., 2022; Zhou et al., 2021). Dietary fibres in PB meat can boost the viscosity of digests in both stomach and small intestine which relates to lower digestibility (Xie et al., 2022). Thermal processing techniques can also impact anti-nutritional factors such as polyphenols (e.g., tannins), non-starch polysaccharides (e.g., pectin), protease inhibitors (e.g., trypsin-chymotrypsin inhibitor), and phytate available in various PB analogues which in turn improves protein digestibility (Adhikari et al., 2022; Samtiya et al., 2020).

A study by Xie et al. 2022 was conducted to evaluate in vitro protein digestion for pork, beef, and PB versions of pork and beef (containing soybean, peas, and rice proteins). The authors observed a significant decrease (P < 0.01) in the digestibility of real meat and PB meat proteins during simulated gastrointestinal digestion. During the gastric phase, the digestibility of pork (40%) was significantly higher compared to PB pork (38%), while the digestibility of beef (35%) was noticeably lower than that of PB beef (40%). However, following the treatment with pepsin and pancreatin in the intestinal phase, both real pork and beef exhibited higher protein digestibility (nearly 80%) than their plant-based counterparts (nearly 60%). The authors used liquid chromatography/mass spectrometry techniques to identify the obtained peptides from gastric and intestinal digestion and found that, greater number of small-molecular peptides and fewer large-molecular peptides were present in the real pork and beef samples compared to the PB pork and beef samples, which align with the observed digestibility results, suggesting that real pork and beef are easier to digest than PB pork and beef.

Another study by Bax et al. 2012, has shown that thermal treatments have varying temperature-dependent impacts on the pork protein digestion rate and degradation capacity using in vitro pepsin digestion tests. At 70 °C, the proteins underwent denaturation, which accelerated the rate of pepsin digestion by improving enzyme access to protein cleavage sites. Above 100 °C, oxidation-induced protein aggregation slowed pepsin digestion, but enhanced the overall digestibility of meat protein. This change was attributed to the action of pepsin cleaving hydrophobic aromatic amino acids such as phenylalanine, tyrosine, and tryptophan. Pepsin’s activity is temperature dependent and can be described in two steps. In the first step, heating (a temperature of 70 °C) induces protein conformational changes, which improves the hydrolyzing ability of pepsin. The second step is activated at higher temperatures (i.e., 100 °C), where protein oxidation processes are introduced, leading to protein aggregation and a reduction in protein hydrolysable by pepsin.

Another common in-house cooking technique is microwaving. This cooking technique relies on an electromagnetic field due to a high frequency range of 300 MHz to 300 GHz and the movement of dipoles in water molecules present in the food material (Wen et al., 2019). When PBMAs are cooked in these environments, partial unfolding of the secondary and tertiary protein structure can occur by the breaking of hydrogen bonds and disulphide covalent linkages. These changes can enhance the digestion kinetics of proteins (Phongthai et al., 2016). One study revealed that 10 min of microwave heating at 85 °C, can minimize the effect of trypsin inhibitors and deliver changes in the secondary structure of soy proteins, which can result in a better digestion profile (Wen et al., 2019). Another study by (Xiang et al., 2020) reported that, extended microwave treatment (up to 1000 W for 5 min) of gluten proteins can form isopeptide bonds and encourage cross-linking among certain amino acid functional groups and this status can inhibit enzymatic digestion and reduce the availability of amino acids for digestion. At the same time, longer microwave treatments can diminish the availability of lysine, and this can cause a reduction in the rate and extent of gastric digestion (Xiang et al., 2020).

Another dry-heat method of cooking, pan frying above 50 °C can cause phosphorylation of specific amino acids, and affect protein digestibility. Xue et al. (2019), highlighted that phosphorylated gliadins in gluten proteins can be digested more easily than raw gliadin which shows a partial resistance to gastric enzymes. In addition, a combination of plant proteins with polysaccharides such as xanthan gum can raise the viscosity of digestive matter while reducing access to digestive enzymes (Niu et al., 2019). Heat can also initiate several chemical mechanisms between negatively charged groups on polysaccharides and amino as well as carboxyl groups of proteins which can lead to an inhibition of protein digestion (Niu et al., (2019).

Although salt concentrations in PBMA vary depending on the raw materials, almost all PB meat products contain relatively high amounts of salt (Alpos et al., 2021). Salts (such as NaCl) can change the bio accessibility of proteins in cooking water, by promoting changes to the surface charges of proteins (Alpos et al., 2021). Furthermore, salt can damage the hydration layer on the surface of proteins while allowing several binding sites for pepsin digestion (Wen et al., 2019). When cooking PBMAs at temperatures above 95 °C in an electric cooktop, other salts including calcium salt (CaCl2) hindered the hydrolysis of black bean proteins, which is an essential raw material in some PBMA (Alpos et al., 2021). The presence of fats in PBMA formulations can also reduce protein hydrolysis by inhibiting the binding sites of protease during cooking. A decrease in protein digestion (from 37 to 29%) was reported for cooked soybean, however, the authors noted that the observed effect of lipids on protein digestion in soybean was limited compared to other food matrices (Zahir et al., 2018). In general, it is evident that cooking can have a significant impact on protein quality through altering amino acids as well as protein digestibility.

Effects of cooking on the functional properties of proteins used in PBMAs