Abstract

Automobile emissions have significantly intensified environmental degradation, contributing to climate change. Extensive research is underway to identify alternative fuels that can be renewable and enhance engine efficiency while minimising emissions. This study evaluates the performance and emission characteristics of a diesel engine powered by novel ternary blends of diesel, biodiesel derived from waste cooking oil (WCO), waste plastic oil (WPO), and ethanol (DBE blend). The blends were tested at varying load conditions and cold Exhaust Gas Recirculation (EGR) rates of 7% and 14% on a single-cylinder, 4-stroke, and 3.2 kW power CRDI (Common rail direct injection) diesel engine. Biodiesel was synthesised via a two-step esterification process, meeting ASTM standards. Key findings include improved BTE and reduced emissions with increased ethanol content. The D40CB10E10 blend demonstrates the highest BTE among the biodiesel blends. EGT decreases with rising ethanol content compared to diesel. The D60CB20E20 blend exhibited the lowest NOx emissions (9.98% lower than diesel) and the lowest smoke density. Ethanol’s oxygenation and heat of vaporisation improved combustion, reducing EGT and CO emissions. However, HC emissions increased with ethanol. These results demonstrate that DBE blends can enhance engine efficiency and reduce emissions, offering a sustainable alternative to conventional diesel.

Keywords: Diesel, Waste cooking oil, Waste plastic oil, Ethanol, Performance, Emission

Subject terms: Environmental sciences, Energy science and technology, Engineering

Introduction

As the global population grows, the energy demand steadily increases1. Rising living standards and rapid industrial development intensify this growing challenge2. Various sectors, including industry, construction, transportation, and agriculture, widely use diesel engines due to their superior fuel efficiency, lower maintenance costs, and higher power output compared to other engines3. However, their use contributes to significant environmental issues, including air and water pollution, habitat loss, and climate change4. Additionally, the rapid depletion of fossil fuels and rising global energy consumption have driven the search for alternative fuels5. Biodiesel emerges as a viable substitute for petroleum-based diesel, reducing toxic emissions and aiding in the pursuit of global carbon neutrality6. It is compatible with diesel engines without mechanical modifications and can blend with diesel at any ratio7.

Biodiesel is mainly obtained from edible or non-edible oils, waste sources, animal fats, and microalgae8. Transesterification involves producing biodiesel from their raw oil9. Blending diesel with biodiesel notably reduces emissions of UHC, CO, SOx, and PM from diesel engines10. Rao and Prasad11 found that using a 20% Palmyra oil methyl ester (POME 20) blend improved brake thermal efficiency (BTE) by 6.91%, reduced brake specific fuel consumption (BSFC) by 10.2%, and decreased smoke, CO, and HC emissions, though NOx emissions increased. Singh et al.12 reported that jatropha biodiesel blends decreased BTE and increased BSFC due to their lower calorific value, raising NOx emissions but reducing HC, CO, and PM emissions. Mandal et al.13 observed that higher biodiesel blends (B40, B80) increased BSFC and NOx emissions while reducing BTE and smoke opacity. The use of edible oils for biodiesel raises concerns about the food supply. Alternatives include using inedible oil crops, waste cooking oils or waste plastic oil (WPO)14. Plastic waste, originating from both household and industrial sectors, has become a significant environmental challenge due to its vast quantities and non-biodegradable nature. These wastes take hundreds of years to decompose, posing a severe burden on waste management systems causing environmental issues like soil pollution. Plastic waste primarily comprises hydrocarbons, the same components found in conventional fuels. It creates an opportunity for converting into valuable energy resources through pyrolysis15. WPO has been shown to possess properties such as calorific value, density, and viscosity that are compatible with diesel engines, enabling its direct use or blending with diesel. Numerous studies have evaluated the viability of WPO as a substitute for diesel fuel, focusing on its performance and emission characteristics in diesel engines. Mangesh et al.16 found that increasing the proportion of WPO in the fuel blend led to a decline in BTE while simultaneously causing an increase in CO, HC, NOx emissions, and BSFC. These higher emission levels were primarily attributed to the elevated carbon content and the presence of unsaturated hydrocarbons in the WPO. This study employs a mixture of WCO and WPO. Naima et al.17 compared the performance of a diesel engine using waste plastic oil (WPO) and eucalyptus biofuel (EB) against conventional diesel. The findings reveal that both WPO and EB are viable and sustainable alternatives, with WPO offering superior BTE and EB significantly reducing unburned HC and particulate matter emissions. This research provides a direct comparative assessment, highlighting the unique benefits of each fuel.

Blending diesel/biodiesel with ethanol addresses technical issues related to biodiesel use in diesel engines, enhancing blend properties to resemble regular diesel18. Ethanol’s higher oxygen content and latent heat can lower combustion temperatures, reducing NOx and PM emissions19,20. Its lower boiling point and higher volatility may cause “micro-explosions,” improving air–fuel mixing and combustion21. Crops like barley, sugarcane, corn, and cassava root yield ethanol22. Biodiesel acts as an emulsifier in diesel-ethanol blends, stabilising the mixture and enhancing long-term storage. By decreasing the interfacial tension force and increasing the attraction between diesel and ethanol, biodiesel improves the stability of the emulsion. As an emulsifier, biodiesel keeps the combination stable and increases the blend’s resistance to water, making adding more ethanol to diesel fuel easier. Furthermore, it facilitates the long-term storage of blends23. Various studies have examined diesel engines running on biodiesel-diesel-ethanol blends in terms of performance and emission characteristics compared to diesel, as summarised in Table 1.

Table 1.

The performance and exhaust emission of diesel engines fuelled with a blend of diesel, biodiesel, and ethanol with diesel.

| Fuel blend type (Vol.%) | Engine type & Test condition |

BTE | BSFC | EGT | CO | HC | CO2 | NOx | Smoke | References |

|---|---|---|---|---|---|---|---|---|---|---|

|

Soybean BD (7), E (3, 10) |

4-cylinder, 4-stroke, water-cooled, 80 kW@1500 rpm |  |

– | – |  |

|

|

– | 24 | |

|

Azadirachtaindica BD (20, 80) E (20) |

Single-cylinder, 4-stroke, CR-18, water-cooled, 5.2kw @ 1500 rpm |  |

– | – |  |

|

|

|

25 | |

|

BD (0) E (5, 10, 15) |

Turbocharged CRDI diesel engine, 4-cylinder, 4-stroke, 82 kW @ 4000 rpm | – |  |

– |  |

|

|

|

26 | |

|

Jatropha + Karanja BD (10, 20) E (10, 20) Al2O3 nanoparticle (100 ppm) |

Kirloskar make TV1 DICIVCR Engine, Single-cylinder, 4-stroke, 5.2 kW @ 1500 rpm, water-cooled, CR-17.5 |

|

|

– |  |

|

|

– | 27 | |

|

Soybean BD (80, 85, 90, 95) E (5%, 10%, 15%, 20%) |

4-cylinder, 4-stroke, turbocharged, 72 kW @ 1800 rpm |

|

|

– |  |

– | – |  |

|

28 |

|

Waste cooking oil BD (50, 60, 75, 90) E (10, 25, 40, 50) |

Diesel OM314, 4-cylinder, 4-stroke, water-cooled 82 kW at 2800 RPM, CR-16 Genetic Algorithm |

|

|

– |  |

– | – |  |

|

29 |

|

Tamanu oil BD (40, 100) E (10, 15, 20) |

Kirloskar TAFI, Single-cylinder, 4-stroke, water-cooled, 4.4 kW @1500 RPM, CR-17.5 |  |

|

|

– | – | – | – |  |

30 |

| Neem BD (20) | Single-cylinder, 4-Stroke 3.5 kW @ 1500 rpm, naturally aspirated VCR diesel engine, CR-17.5 |  |

– | – |  |

|

– |  |

|

23 |

|

Palm BD (10, 20, 100) E (5, 10) |

Isuzu 4JJ1 TC, 4-cylinder, 4-stroke, water-cooled, 107kw@3600 rpm |  |

|

– | – | – | – |  |

|

31 |

|

Karanja BD (10, 20) E (5, 10) |

Single-cylinder, 4-stroke, water-cooled, 3.5 KW @ 1500 rpm Taguchi method |

|

|

|

|

|

|

|

– | 32 |

|

Palm BD (30, 40) E (10, 30) |

4-cylinder, 4-stroke, Turbocharged inter-cooled, CR-18, 113 kW @ 2300 rpm EGR (10, and 20%) |

|

|

– | – |  |

|

– | 33 | |

|

Waste cooking oil BD (40, 45) E (10, 20) |

DEUTZ FL 4-stroke, air fan cooling, CR-17. 5.2 kW @ 1500 rpm |  |

– | – |  |

|

|

– | 34 | |

|

Palm BD (7, 100) E (10, 20) |

1-cylinder, Natural aspirated, diesel Engine 4-cylinder, Turbo Charged, Direct injection, CI Engine |

|

|

– | – | – | – | – |  |

35 |

|

Alge BD (5, 10, 20) E (5, 10) |

Kirloskar Model TV 1, Single-cylinder, 4-stroke, water-cooled, 3.5 kW @ 1500 rpm |

|

|

– | – | – |  |

|

|

36 |

|

Acid oil BD (50) E (4, 8, 12, 16) |

4-stroke 4-cylinder, CRDI engine |  |

|

– |  |

|

– |  |

– | 37 |

|

Palm BD (0, 100) E (0.21, 0.24, 0.28, 0.32 and 0.36 g/s) |

Mitsuki, MIT-186FG model, single-cylinder, air-cooled, 406 cc, 8.5 kW @ 3000 rpm |  |

|

– |  |

|

|

– | 38 |

Existing literature confirms the environmental and performance benefits of using diesel, biodiesel, and ethanol (DBE) mixtures, particularly for mitigating fossil fuel depletion and greenhouse gas emissions. However, significant research gaps remain. While many studies have focused on binary blends, there is a notable scarcity of research on the synergistic effects of a novel ternary blend that combines WCO and WPO biodiesels with ethanol in CRDI diesel engines. The potential benefits of using high ethanol concentrations in these specific blends, especially under varying EGR conditions, have not been fully investigated. Furthermore, the economic efficiency of using WCO and WPO as primary biodiesel sources makes their application a critical area for study. This research addresses these gaps by systematically assessing the stability, fuel properties, and engine performance of novel waste-derived biodiesel–ethanol–diesel blends. Our findings provide a comprehensive analysis demonstrating these sustainable fuels’ practical viability for existing CRDI engines while enhancing performance and reducing emissions.

Therefore, this study presents a novel approach to improving diesel engine performance and emissions by using a unique ternary blend of diesel, biodiesel derived from WCO and WPO and ethanol. The research shows the synergistic effects of this innovative fuel composition and its sustainability-centric sourcing from waste materials. Through a comprehensive experimental analysis, the study quantifies the impact of these blends on engine performance and emissions at different EGR rates (7% and 14%) and load conditions. The findings highlight the ability of the D100, D80CB20, D60CB40, D80CB10E10, and D60CB20E20 blends to improve BTE and EGT while reducing pollutants such as CO, CO2, HC, NOx, and smoke. The research confirms that these blends are compatible with existing CRDI diesel engines without any mechanical modifications, facilitating immediate applicability in real-world scenarios.

Materials and methods

Synthesis of waste cooking oil (WCO) biodiesel

The study focuses on the CRDI diesel engine, fuelled with a DBE blend, and the partnership between Zomato and BioD Energy (India) Private Limited to convert waste cooking oil (WCO) into biodiesel. By 2022, India aims to transform 22 crore litres of WCO into biodiesel, considering 30% of India’s vegetable oil waste. The Indian government plans to establish a system for collecting used cooking oil as part of its 2018 biofuel strategy. In 2024, India is expected to use 125,000 metric tons of used cooking oil to produce biodiesel fuel. This is an increase from 2023, when India used 70,000 metric tons. In 2024, India’s used cooking oil market is expected to be worth $144.24 million38.

WCO biodiesel is developed in Delhi Technological University’s biofuel research laboratory using waste cooking oil collected from college canteens and dormitories. The oil is heated to remove moisture and suspended particles and then passed through filter paper for filtration. Essential chemicals like methanol, KOH, and H2SO4 are used in biodiesel manufacturing. The free fatty acid (FFA) level significantly impacts the process of producing high-quality biodiesel. The two-step process involves acid-catalysed esterification followed by alkali-catalysed transesterification. In the acid-catalysed esterification step, concentrated H2SO4 and methanol are used, and the mixture is agitated for one to two hours at 60 °C. The second stage involves combining leftover WCO oil with methanol and potassium hydroxide (KOH), which is stirred and maintained at 60 °C. A separating funnel separates the glycerine from the mixture, and the biodiesel is washed with warm water (40 °C) to eliminate residual water particles. Finally, the WCO biodiesel is heated to 105 °C to eliminate residual water particles39,40. An 88% yield of pure waste cooking oil biodiesel was produced, contributing to India’s efforts to reduce vegetable oil waste. The chemical reactions involved during the transesterification process are represented in Fig. 1.

Fig. 1.

The chemical reaction takes place during the transesterification process.

In this investigation, the WPO and ethanol used were purchased from a local provider with 99% purity. Equal ratios of WCO biodiesel and WPO (CB) at 10%, 20%, and 40% were combined, along with 10% and 20% ethanol. The 5 test fuels were labelled as D100, D80CB20, D60CB40, D80CB10E10, and D60CB20E20, as shown in Fig. 2. The components were mixed thoroughly for 15 min at a constant stirring speed. After mixing, the stability of the prepared blends was assessed by allowing the mixtures to remain undisturbed for a duration of 24 h to observe any potential phase separation. The absence of visible separation confirmed the stability of the blends throughout the testing period. Including biodiesel in the mixture served a crucial function as a natural emulsifier, effectively reducing the interfacial tension between diesel and ethanol, thereby ensuring homogeneous blends suitable for engine applications.

Fig. 2.

All 5 test fuels used in the engine.

The selection of blending ratios for WCO, WPO, and ethanol was informed by several considerations: (a) ensuring phase stability without separation for a minimum duration of 24 h, (b) achieving fuel properties such as density, viscosity, and calorific value by ASTM D6751 and D7467 standards, and (c) referencing prior studies31,32 that documented stable diesel engine operation with up to 20% biodiesel and 20% ethanol without necessitating engine modifications. Preliminary mixing trials indicated that ethanol proportions exceeding 20% resulted in separation, while biodiesel levels surpassing 40% led to viscosity levels beyond acceptable limits. Consequently, the selected blends (D80CB20, D60CB40, D80CB10E10, and D60CB20E20) represent the most suitable and stable combinations for engine testing. The blended fuel was evaluated based on ASTM standards for density, calorific value, and kinematic viscosity to determine its suitability as a diesel engine fuel, which is presented in Table 2.

Table 2.

The physiochemical properties of diesel, biodiesel, ethanol and its blend.

| Properties | Density @15 °C (g/cm3) |

Kinematic Viscosity @40 °C (mm/s2) |

Calorific value (kJ/kg) |

Cetane number | Flash point (°C) |

|---|---|---|---|---|---|

| ASTM Method | D1298 | D445 | D240 | D976 | D93 |

| Diesel | 830 | 2.978 | 42,000 | 52 | 55 |

| WCO | 882 | 4.684 | 38,640 | 56 | 158 |

| WPO | 870 | 3.821 | 41,190 | 58 | 49 |

| Ethanol | 790 | 1.14 | 28,000 | 11 | 14 |

| D80CB20 | 839 | 3.234 | 41,581 | 53 | 71 |

| D60CB40 | 849 | 3.488 | 41,166 | 55 | 81 |

| D80CB10E10 | 820 | 2.92 | 40,385 | 49 | 53 |

| D60CB20E20 | 829 | 2.85 | 38,778 | 44 | 50 |

Fourier-transform infrared spectroscopy (FTIR) analysis of waste cooking oil and waste plastic oil biodiesel

FTIR spectra of WCO and WPO biodiesel in the band range from 4000 to 500 cm−1 are shown in Figs. 3 and 4. The test result was obtained using an instrument, FTIR Nicolet IS-50, at IIT (Indian Institute of Technology), Delhi. The FTIR spectrum was utilised to analyse the various functional groups and metal-oxide bonds present in the compounds. Based on Fig. 3, the following characteristic peaks of biodiesel were observed: asymmetric and symmetric stretching vibration peaks of the −CH2 group were identified at 2922.37 cm−1 and 2852.82 cm−1, respectively. The anti-symmetric and symmetric stretching vibration absorption peaks of C–O–C were observed at 1029.08 cm−1 and 1168.46 cm−1. Additionally, the symmetrical stretching vibrational peak of C=C was located at 1457.23 cm−1. A similar observation was noticed in Fig. 4 for waste plastic oil biodiesel.

Fig. 3.

FTIR spectra of the waste cooking oil biodiesel.

Fig. 4.

FTIR spectra of the waste plastic oil biodiesel.

Experimental setup and test procedure

The research was conducted at Apex Innovations Pvt. Ltd. in Sangli, Maharashtra, using a single-cylinder diesel engine built by Kirloskar. The experimental setup, illustrated in Fig. 5, involved a single-cylinder, 4-stroke CRDI diesel engine equipped with a cold exhaust gas recirculation (EGR) system and an eddy current dynamometer. The detailed specification of the engine is depicted in Table 3. The experiment tested diesel and diesel–biodiesel-ethanol blends, using the ‘Enginesoft 9.0’ programme software for performance analysis. Emissions were measured using an AVL DIGAS 444 model exhaust gas analyser for HC, CO, CO2, smoke, and NOx, and smoke levels were analysed using an AVL 437 smoke meter meeting ASTM standard emission requirements. The measurement range, resolution, and uncertainty of various instruments are detailed in Table 4.

Fig. 5.

The schematic diagram of CRDI VCR diesel engine.

Table 3.

The technical specification of the CRDI diesel engine.

| Product and Engine | CRDI VCR Engine test, Make Kirloskar |

| No. of cylinder | 1 |

| Stroke(mm) × Bore(mm) | 110 × 87.5 |

| Compression ratio (12–18) | 18 |

| Rated power | 3.2 kW @ 1500 rpm |

| Capacity | 661 cc |

| EGR | Water-cooled, Limit 15% |

Table 4.

The measurement range, resolution, and %uncertainty of gas analyser parameters.

| Parameters | Measurement range | Resolution | Percentage uncertainty |

|---|---|---|---|

| CO | 0–15% vol | 0.001vol.% | ± 0.2% |

| HC | 0–100 ppm | 1 ppm = 0.2 ppm | ± 1.1% |

| CO2 | 0–20% vol | 0.1vol.% | ± 0.6% |

| NOx | 0-5000 ppm | 1 ppm vol | ± 2.1% |

| Smoke | 0–100% | 0.1% | ± 1.2% |

| Temperature Sensor | − 30–500 °C | 1 °C | ± 2.2% |

Exhaust gas recirculation (EGR) is a widely employed technique in internal combustion engines that controls nitrogen oxide (NOx) emissions. NOx formation occurs primarily due to the high combustion temperatures and excess oxygen present in the cylinder. By recirculating a portion of exhaust gases back into the engine’s intake manifold, EGR lowers the peak combustion temperature, thus reducing NOx emissions. EGR redirects exhaust gases back into the engine’s intake manifold to mix with the incoming fresh air. This dilutes the oxygen content in the intake charge, lowering the combustion temperature. Additionally, the inert gases in the recirculated exhaust absorb some of the heat generated during combustion, further reducing the peak temperature. To enhance its effectiveness, the exhaust gases are often cooled before recirculation. This cooling ensures that the thermal load on the engine is minimised while optimising the density of the recirculated gases. Hot EGR involves directly recirculating exhaust gases into the intake manifold without intermediate cooling. Since the gases are not cooled, the peak combustion temperature reduction is less effective than cold EGR, leading to higher NOx emissions. In this investigation, cold EGR is incorporated. The EGR rate was determined using this equation41.

|

The engine operated at constant 1500 rpm with the EGR set to 7% and 14%, and the intake temperature was kept at 30 °C during the experiment. Temperatures for lubricant and coolant were maintained at 85 °C. The primary injection timing and fuel injection pressure were set at 23° bTDC (before the top dead centre) and 600 bar, respectively.

Uncertainty analysis

Measurement uncertainties were evaluated using J.P. Holman’s uncertainty analysis approach42. Based on the percentage uncertainties connected to the instruments mentioned in Table 4, percentage uncertainties for various performance and emission metrics were calculated. Equation (1) was used to get the experiment’s total uncertainty percentage43.

|

1 |

Results and discussion

Engine performance based on biodiesel-ethanol fuel blends

The performance of the engine was assessed using blends of biodiesel, ethanol, and diesel, focusing on BTE, BSFC, and EGT with or without EGR. BTE measures how well the fuel’s chemical energy is transformed into usable power, whereas BSFC denotes the fuel needed for each unit of power produced. EGT serves as a vital measure of combustion efficiency in a diesel engine. Elevated EGT levels may indicate incomplete combustion or an overly rich air–fuel mixture, potentially leading to decreased engine efficiency and increased thermal stress on parts. Thus, maintaining a stable EGT, especially with enhanced performance, indicates a more efficient and thorough combustion process.

Exhaust Gas Recirculation (EGR) plays a crucial role in the performance of diesel engines. By recirculating a portion of exhaust gases into the intake air, EGR reduces the oxygen concentration and peak combustion temperature within the cylinder. This typically results in a decrease in BTE and an increase in BSFC due to incomplete combustion.

Brake thermal efficiency (BTE)

This section highlights the importance of Brake Thermal Efficiency (BTE) in this research, as it measures the energy derived from the fuel relative to the engine’s usable power output for the different fuel types investigated. Figure 6 visually represents the BTE of each fuel at different EGR levels, providing a comprehensive overview of their performance.

Fig. 6.

Brake thermal efficiency of various blends at different EGR rates.

Figure 6(i)–(iii) illustrates the variation in BTE (%) with engine load for the test fuels at various EGR rates (%). BTE increases with engine load, rising from nearly zero load to full load. This trend is attributed to the reduction in fractional heat losses and the enhancement of combustion completeness at higher loads, increasing fuel energy conversion into useful work. At 0% EGR, D100 exhibited the highest BTE (27.54%), followed by ethanol blends D80CB10E10 (26.77%) and D60CB20E20 (26.33%), while biodiesel-rich blends D80CB20 (25.77%) and D60CB40 (24.53%) demonstrated lower efficiency. Compared to diesel, the reductions at full load were 6.4%, 10.9%, 2.8%, and 4.4% for D80CB20, D60CB40, D80CB10E10, and D60CB20E20, respectively. The lower BTE of biodiesel-rich blends can be attributed to their higher density and viscosity and lower CV compared to diesel. These properties adversely affect atomization and spray breakup, increase ignition delay, and reduce combustion completeness, thereby lowering thermal efficiency. The addition of ethanol partially mitigates this penalty by reducing blend viscosity and providing oxygenates that promote complete combustion and faster burn rates. However, the lower heating value of ethanol results in these blends remaining below conventional diesel in terms of BTE. This result aligns with observations on various biodiesel and ethanol blends by Madiwale et al.44.

For fuel D100, BTE decreases from 27.54% at 0% EGR to 25.46% at 7% EGR (↓ 7.55%) and to 24.74% at 14% EGR (↓ 10.17%). Other fuels exhibit similar reductions: 7% EGR reduces BTE by 6.9–7.6%, and 14% EGR results in reductions of approximately 10.4–11.1% relative to 0% EGR. The order of fuel efficiency remains consistent: D100 > ethanol blends > biodiesel-heavy blends. The reduction in BTE with increasing EGR is due to intake charge dilution, reduced oxygen availability, and increased specific heat of the charge. These effects lower the peak combustion temperature and flame speed, thereby reducing fuel energy conversion into mechanical work. At all EGR levels, D80CB10E10 exhibited BTE closest to that of diesel (↓ 2.8% compared to D100 at EGR 0%), while D60CB40 showed the lowest efficiency. The results indicate that a modest addition of ethanol can recover much of the efficiency lost by biodiesel, while EGR reduces efficiency for all fuels. These findings are in agreement with those reported by Chandravanshi et al.45.

Brake-specific fuel consumption (BSFC)

Brake-specific fuel consumption (BSFC) is the ratio of fuel mass rate to engine power unit in kg/kWh. Figure 7(i)–(iii) illustrate the variation in BSFC with load for diesel and diesel–biodiesel-ethanol (DBE) blends under different EGR rates. Density, viscosity, and calorific value all have a significant impact on BSFC, which determines fuel consumption efficiency within the engine.

Fig. 7.

Brake-specific fuel consumption of various blends at different EGR rates.

BSFC is elevated under no-load conditions for all fuel types and decreases as the load increases, reaching its minimum at full load. This trend is consistent with theoretical expectations, as frictional and auxiliary losses are most pronounced at low power, resulting in higher BSFC at no load conditions. As the load increases, both thermal and mechanical efficiencies improve, thereby reducing BSFC. It was revealed from Fig. 7(i), that at 0% EGR, D100 exhibited the lowest BSFC of 0.33 kg/kWh at full load, whereas D80CB20 and D60CB40 recorded values of 0.36 and 0.38 kg/kWh, representing increases of 8.3% and 13.2% compared to diesel. The ethanol-containing blends D80CB10E10 and D60CB20E20 achieved BSFC values of 0.35 and 0.37 kg/kWh, which are 5.7% and 10.8% higher than D100, yet lower than those of biodiesel-only blends. The elevated BSFC of biodiesel blends is attributed to their higher density and viscosity, as well as lower CV, which adversely affect atomization and combustion efficiency. The addition of ethanol mitigates these effects by reducing viscosity and providing oxygen, resulting in lower BSFC compared to biodiesel-only blends. However, ethanol’s lower heating value necessitates increased mass flow to achieve equivalent power, thereby increasing BSFC relative to 100% diesel fuel. This finding aligns with observations by Krishna et al.46.

Figures 7(ii) and (iii) depict the impact of the EGR rate (7% and 14%) on BSFC under different engine load conditions. At 7% EGR, BSFC increased to 0.336 kg/kWh for D100 and to 0.3951 and 0.4198 kg/kWh for D80CB20 and D60CB40, respectively. Ethanol blends recorded 0.3917 and 0.4148 kg/kWh for D80CB10E10 and D60CB20E20, indicating increases of 16.6–23.5% relative to D100. At 14% EGR, BSFC increased to 0.3794 kg/kWh for D100, while D80CB20, D60CB40, D80CB10E10, and D60CB20E20 recorded values of 0.4095, 0.4350, 0.4060, and 0.4299 kg/kWh, respectively, corresponding to penalties of 7–15% compared with D100. EGR increases BSFC by diluting the intake charge with inert gases, thereby reducing oxygen availability and flame speed, and increasing the charge’s specific heat, necessitating more fuel to maintain power output. Among the blends, D80CB10E10 offers the best balance: it reduces the BSFC penalty compared to biodiesel-heavy blends while retaining much of the practical advantage of using waste-derived biodiesel and ethanol as fuel extenders. EGR increases BSFC in all scenarios, so any NOx reduction achieved by EGR must be considered against the fuel consumption penalty. These trends are consistent with the findings of Qi et al.33.

Exhaust gas temperature (EGT)

Figure 8(i)–(iii) illustrates the relationship between exhaust gas temperature (EGT) and load (%) for various test fuels, measured using a thermocouple mounted on the exhaust pipe. The EGT exhibited a monotonic increment with engine load, attributable to the augmented fuel energy input and enhanced in-cylinder heat release at elevated engine loads. Under neat diesel operation with 0% EGR, EGT escalates from 470 K at no load to 740 K at full load, indicating a 57.44% increment as shown in Fig. 8(i). All fuel blends adhere to this trend but consistently demonstrate lower EGT values compared to D100 across the load spectrum. D100 records the highest EGT, whereas blends with increased biodiesel and ethanol content exhibit a progressive reduction. At full load and 0% EGR, the peak EGTs for D80CB20, D80CB10E10, D60CB40, and D60CB20E20 are 710 K, 660 K, 680 K, and 600 K, respectively, compared to 740 K for D100. This corresponds to reductions of 4%, 11%, 8%, and 19% relative to diesel. The lower EGT observed with the addition of biodiesel and ethanol is attributed to their lower heating values, higher latent heat of vaporisation, and oxygen content, which result in reduced flame temperature and shorter diffusion-controlled combustion phases. At partial loads, the EGT difference between D100 and D60CB20E20 ranges from 18–22%. These results are consistent with findings reported by Vishnoi et al.30.

Fig. 8.

Exhaust gas recirculation of various blends at different EGR rates.

From Fig. 8(ii), it was found that at 7% EGR, the EGT for D100 decreases to 690 K at full load, representing a decline of 7% compared to 0% EGR. At 14% EGR Fig. 8(iii) showed that, D100 at full load records approximately 590–600 K, a 20% reduction from 0% EGR. All blends exhibit similar reductions, with oxygenated fuels displaying the lowest values. At a 12 kg load and 14% EGR, D60CB20E20 records an EGT of 470–480 K, which is 120 K (20%) lower than D100 and 260 K (35%) lower than neat diesel without EGR at full load. EGR induces a systematic reduction in EGT across loads and blends due to thermal dilution and oxygen displacement effects. Among all test fuels, the lowest EGT is consistently achieved with D60CB20E20 at 14% EGR, resulting in roughly 35% reductions compared to conventional diesel.

Engine exhaust emission based on biodiesel-ethanol fuel blends

The emissions produced by a diesel engine serve as a direct indicator of the fuel’s environmental characteristics. Emission parameters, including CO, HC, NOx, CO2, and smoke, are essential in assessing the efficiency and environmental impact of diesel engines. CO and HC are indicative of incomplete combustion, whereas CO2 signifies the degree of complete oxidation of fuel carbon. The formation of NOx is closely associated with elevated combustion temperatures and excess oxygen, rendering it a significant pollutant in diesel engines. Smoke opacity reflects soot and particulate matter formation, which directly influences air quality. Collectively, these parameters offer a comprehensive evaluation of how biodiesel–ethanol blends affect combustion quality and their potential environmental impact in comparison to conventional diesel.

EGR also significantly impacts the emission parameters in diesel engines. It functions by redirecting a portion of the engine’s exhaust gas back into the combustion chamber. This process lowers the in-cylinder combustion temperature, which is the primary method for reducing the formation of NOx. Additionally, the reduced oxygen content can potentially lead to an increase in emissions related to incomplete combustion, such as CO, unburned HC, and smoke. Conversely, changes in the EGR rate may also affect CO2 emissions due to shifts in overall combustion efficiency. Understanding these effects is essential for comprehending the performance and emission trends discussed in the following sections.

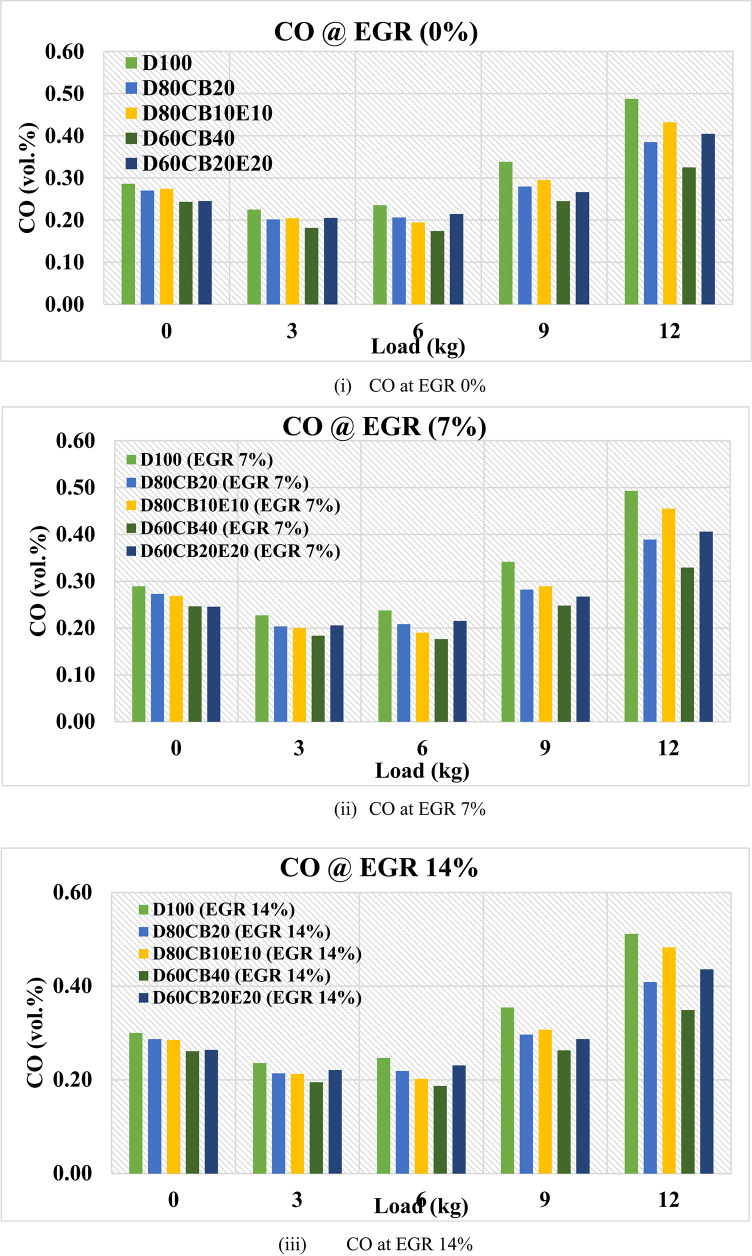

Carbon monoxide (CO) emission

Carbon monoxide (CO) emissions are invisible, odourless, and toxic gases produced by the incomplete combustion of carbon in the fuel. The CO forms when carbon and hydrogen in fuels react incompletely with oxygen during combustion. Figure 9(i)–(iii) depict the impact of load on CO emissions for neat diesel (D100) and its blends with biodiesel and ethanol, across varying EGR rates.

Fig. 9.

Carbon monoxide of various blends at different EGR rates.

Figure 9(i) shows a parabolic increase in CO emission concentration as the engine load increases. CO emissions decrease from no-load to 3–6 kg due to enhanced combustion temperature and oxidation kinetics, but then sharply rise at higher loads because of fuel-rich zones and reduced residence time for CO oxidation. Compared to D100, ethanol-containing blends exhibit lower CO emissions at low and medium loads but higher emissions at full load. As shown in Fig. 9 (i), at maximum load and 0% EGR, D80CB10E10 records 0.44 vol.% CO, compared to 0.49 vol.% for D100, marking a ↓ 10%. This reduction is less than that of D80CB20 (0.38 vol.%, ↓ 22%) and D60CB40 (0.33 vol.%, ↓ 33%). While ethanol provides additional oxygen for CO oxidation, its lower CN and higher latent heat of vaporisation delay ignition and reduce in-cylinder temperatures, impeding CO oxidation at high load. Ethanol blends outperform D100 in reducing CO, but not as effectively as pure biodiesel blends. Geng et al.47 similarly observed increased CO emissions with ethanol addition compared to a biodiesel blend.

As EGR introduces, it alters trends of decreasing CO emission by lowering oxygen concentration and combustion temperature, leading to less completion of CO oxidation. At 7% EGR, CO levels increase slightly compared to 0% EGR, with differences of 0.01–0.02 vol.% across fuels. At a 12 kg load, D100 rises from 0.49 vol.% (0% EGR) to 0.50 vol.% (7% EGR), while D80CB10E10 increases from 0.44 to 0.46 vol.% shown in Fig. 9(ii). Figure 9(iii) revealed that at 14% EGR, CO emissions rise more significantly. At full load, D100 increases to 0.52 vol.% (↑ 6% over baseline), while D80CB10E10 rises to 0.48 vol.% (↑ 9% compared to 0% EGR). Ethanol blends show a steeper increase in CO under high EGR than diesel or biodiesel-only blends due to ethanol’s ignition delay and reduced oxygen availability47. D60CB40 consistently yields the lowest CO emissions across all conditions, indicating that a higher-biodiesel formulation offers the most effective balance between fuel-bound oxygen, CN, and in-cylinder temperature for CO oxidation. While ethanol enhances CO performance under oxygen-rich conditions, its effects on ignition quality and temperature become limiting factors under high load and EGR operations.

Carbon dioxide (CO2) emission

Public concern over carbon dioxide (CO2) emissions from the transportation and electricity sectors is increasing due to their significant environmental and air quality impacts. CO2 is a colourless and non-combustible gas released during the complete combustion of carbon fuels, making it a crucial parameter for exhaust emissions. Figure 10(i)–(iii) illustrate the progression of CO2 concentration with brake load for neat diesel (D100) and four oxygenated blends at 0, 7, and 14% EGR. The study indicates that an increase in engine load leads to a rise in CO2 emissions, as more fuel in the combustion chamber completes the combustion of CO and converts it into CO2 emissions.

Fig. 10.

Carbon dioxide of various blends at different EGR rates.

CO2 concentration increases nearly linearly with load for each fuel and EGR scenario, indicating higher carbon throughput and more complete oxidation at elevated fuelling rates. As depicted in Fig. 10(i), at 0% EGR, the CO2 concentration for D100 rises from 1.5% at no-load to 5.1% at full load, representing an increase of 3.6%. The oxygenated blends exhibit a similar monotonic trend but consistently remain below D100 at each load. At maximum load, the blends register CO2 concentrations of 4.7% (D80CB20), 4.5% (D80CB10E10), 4.6% (D60CB40), and 4.1% (D60CB20E20), corresponding to reductions of approximately 8%, 12%, 10%, and 20% relative to D100. These reductions are attributed to the lower elemental carbon content and lower heating value of the oxygenated fuels (biodiesel and particularly ethanol), resulting in less CO2 in the exhaust per unit mixture volume despite effective overall oxidation. This outcome is consistent with observations by Krishna et al.46 for various biodiesel-ethanol mixtures.

Figure 10(ii) and (iii) illustrate the impacts of 7% and 14% EGR rates on CO2 emissions for all mixes at various loads, respectively. EGR introduces a systematic increase in measured CO2 at medium to high loads while leaving low-load values largely unchanged. From 0 to 14% EGR, the CO2 concentration for D100 at full load increases from 5.1% to 5.5% (↑ 8%); the ethanol-rich D60CB20E20 increases from 4.1% to 4.5% (↑ 10%). This behaviour is due to EGR recirculating CO2 back into the intake, thereby elevating the background CO2 fraction in the exhaust stream; the modest EGR levels employed here do not sufficiently reduce global oxidation to counteract this dilution effect. Notably, although EGR slightly increased CO in the companion figures, its influence on CO2 is primarily governed by the added diluent CO2, resulting in a net increase in CO2 percentage with EGR48.

Unburned hydrocarbon (HC) emission

Hydrocarbons (HC) in exhaust emissions indicate incomplete fuel combustion, typically resulting from inadequate temperatures or oxygen levels. Figure 11 shows the variation of HC emissions with load at different EGR rates for all test fuels.

Fig. 11.

Unburned hydrocarbon of various blends at different EGR rates.

Figure 11(i)–(iii) illustrates a predominant trend of a monotonic increase in unburned HC emissions with load, which aligns with the larger fuelling rates, thicker diffusion flames, and increased wall wetting observed at higher torque levels. Ethanol mixed fuels were observed to have higher HC compared to diesel and biodiesel-only blends at medium and high loads. As observed, the D60CB20E20 blend reaches 50 ppm at a maximum load, approximately 14% higher than neat diesel, which records 44 ppm. Similarly, the D80CB10E10 blend registers 45 ppm at the same load, slightly exceeding diesel. In contrast, the biodiesel-rich D60CB40 blend consistently yields the lowest HC emissions, measuring 35 ppm at full load, which is 21% lower than diesel, thereby demonstrating the beneficial effect of fuel-borne oxygen in biodiesel.

Figures 11(ii) and (iii) depict the impact of different EGR rates, 7% and 14%, on HC emissions for all blends under varying loads. With the introduction of 7% EGT as shown in Fig. 11(ii), HC emissions increase for all fuels due to oxygen dilution and a reduction in combustion temperature. At a full load, diesel emissions rise to 51 ppm, D80CB10E10 to 53 ppm, and D60CB20E20 to 56 ppm. The biodiesel-only blend D60CB40 continues to perform better, emitting 39 ppm, which is 24% lower than diesel. At 14% EGR, the HC penalty becomes more pronounced as shown in Fig. 11(iii). Diesel emissions climb to 58 ppm, while ethanol blends exhibit the highest values: D80CB10E10 reaches 60 ppm, and D60CB20E20 peaks at 63 ppm. This penalty is even more severe for ethanol blends, whereas the biodiesel-rich blend D60CB40 remains the cleanest fuel at 46 ppm, still 21% below diesel even under high EGR conditions. Overall, the addition of ethanol amplifies HC emissions, and this effect becomes more pronounced with increasing EGR levels49.

Oxide of nitrogen (NOx) emission

Under typical conditions, atmospheric nitrogen (N2) remains inert during combustion. However, the high temperatures generated by fuel combustion in the engine cause nitrogen in the air to react with oxygen, resulting in nitrogen oxide. Several factors, including the oxygen level in the combustion chamber, retention period at high temperatures, and flame temperature, influence the rate at which NOx forms.

Figure 12(i)–(iii) shows the nitrogen oxides (NOx) emissions for each fuel type that was tested at 0%, 7%, and 14% EGR rates and different loads. NOx emissions increase with engine load, especially at medium and high loads. This is because higher loads necessitate burning more fuel to maintain a fixed power output, thereby raising gas temperature inside the cylinder and consequently increasing nitrogen oxide emissions.

Fig. 12.

Oxides of nitrogen of various blends at different EGR rates.

Adding biodiesel (without ethanol) increases NOx emissions by 5–15% at different loads. Adding ethanol reduces NOx by 4–20%, with more ethanol leading to a stronger effect. This happens because biodiesel has O2 molecules that raise flame temperatures and heat release. Ethanol lowers NOx because it has a high latent heat of vaporisation, which cools the combustion process and absorbs heat, reducing NOx production. Ethanol’s cooling effect lowers combustion temperatures, leading to less NOx. Factors like lower blend temperatures, peak pressure, and higher latent heat of vaporisation, lower CN, CV, and peak cylinder temperatures also contribute to this reduction. At full load, D100 reaches 1040 ppm. More biodiesel without ethanol raises NOx at every load: D80CB20 and D60CB40 peak at 1100 and 1120 ppm (↑ 6–8% vs. D100). Adding ethanol lowers NOx: D80CB10E10 gives 1000 ppm (↓ 4% vs. D100) and D60CB20E20 gives 950 ppm (↓ 9%). The findings of Dineshkumar et al.50 were similar in that they found that increasing ethanol content in fuel blended with biodiesel further reduces NOx emissions.

The graphs presented in Figs. 12 (ii) and (iii) illustrate the variation in NOx emissions with EGR rates of 7% and 14% across different engine loads. Using EGR reduces NOx for all fuels by lowering oxygen and peak temperatures. At 7% EGR, NOx drops to 920 ppm (D100), 960 ppm (D80CB20), 990 ppm (D60CB40), 880 ppm (D80CB10E10), and 820 ppm (D60CB20E20), about 11–14% lower than without EGR at full load conditions. At 14% EGR, the reduction is bigger: at maximum load, D100 is 760 ppm, D80CB20 is about 800 ppm, D60CB40 is about 840 ppm, D80CB10E10 is 720 ppm, and D60CB20E20 is 660 ppm, nearly 25–31% below the no-EGR case. NOx emissions decrease as EGR levels rise in all load scenarios. This is common with EGR in diesel engines because it lowers flame temperatures and oxygen in the mix. Inert gases in EGR are more noticeable at higher loads and EGR rates. These gases absorb energy during combustion, lowering peak temperatures and NOx production. Asad et al.51 reported a similar characteristic for different EGR rates. The most significant reduction was measured at 14% EGR with D60CB20E20 showing 660 ppm at maximum load condition (versus 760 ppm for diesel), which served as the absolute lowest level across all of the tests.

Smoke emission

Several factors influence smoke emission in diesel engines, including incomplete combustion, inadequate oxygen, ineffective fuel atomisation, and the fuel’s self-ignition temperature. Fuel properties such as viscosity, volatility, and air–fuel mixture formation also contribute to smoke emissions. Figure 13(i–iii) illustrate the variation in smoke opacity with load under varying EGR levels (0%, 7%, and 14%) for neat diesel and its blends. In all scenarios, smoke emissions increase with load, attributed to higher fuel injection quantities, incomplete combustion in fuel-rich zones, and increased diffusion burning.

Fig. 13.

Smoke emission of various blends at different EGR rates.

It was found from Fig. 13(i) that neat diesel exhibited the highest smoke levels, increasing from 9% at zero load to 32% at a full load at 0% EGR. The biodiesel-containing blends demonstrate lower smoke emissions due to their inherent oxygen content, which enhances the oxidation of soot precursors. D80CB20 and D60CB40 record 28% and 24% at a maximum load condition, representing reductions of 13% and 25% compared to diesel, respectively. The ethanol–biodiesel–diesel blends exhibit an even stronger reduction effect, as ethanol not only contributes oxygen but also improves fuel atomization through its low viscosity and high volatility. D80CB10E10 and D60CB20E20 register 26% and 22% at full load, which are 19% and 31% lower than diesel, respectively. The superiority of ethanol blends is particularly evident at low and medium loads, with D60CB20E20 emitting only 4–9% smoke compared to 9–18% for diesel. These findings are consistent with previous studies, such as Wai et al.52, which demonstrated similar reductions in smoke emission with biodiesel and ethanol blends.

Figure 13(ii) and (iii) show the impact of EGR rates of 7% and 14%, respectively, on smoke opacity for all blends at different loads. With 7% EGR, smoke levels increase for all fuels due to oxygen dilution, which impairs soot oxidation as shown in Fig. 13(ii). At full load, diesel smoke rises from 32% (0% EGR) to 34% (↑ 6%). D80CB20 increases from 28 to 31%, and D60CB40 from 24 to 26%. Ethanol blends remain superior but show an increase: D80CB10E10 rises from 26 to 28%, and D60CB20E20 from 22 to 24%. While ethanol reduces baseline smoke, EGR impact remains consistent across blends, adding 2–3% at full load. At 14% EGR, the smoke penalty intensifies as found in Fig. 13(iii). At full load, diesel smoke increases to 36% (↑ 12% than 0% EGR). D80CB20 and D60CB40 record 33% and 29%. Ethanol blends remain lowest but elevated: D80CB10E10 reaches 30%, and D60CB20E20 25%. Compared to diesel, smoke reductions range from 14 to 31% across blends under heavy EGR. Ethanol-rich blends like D60CB20E20 maintain the lowest smoke across conditions, showing strong potential for soot reduction under high EGR. Similar trends were documented by Tan et al.53.

Conclusions

This study investigates the effects of a novel combination of biodiesel made from waste cooking and waste plastic oil mixed with ethanol on a CRDI diesel engine’s efficiency and emissions. Characterizing the engine’s wide operating range is a crucial component of the research. The key findings are as follows:

A two-step transesterification process was used to develop WCO biodiesel, which satisfies ASTM requirements for fuel characteristics.

To increase the solubility of ethanol in diesel fuel, WCO and WPO biodiesel were added to the blend of diesel and ethanol.

A slight decline in BTE was observed with increased EGR rates across the test fuels. The BTE of the CRDI engine improved with increased ethanol content in diesel and biodiesel blends (WCO and WPO) compared to biodiesel and diesel blends, though still below pure diesel levels.

The EGT drops as the test fuel’s ethanol content rises, attributed to the intrinsic oxygen content of ethanol promoting complete combustion, its heat of vaporization, and reduced heat losses in exhaust gases. For all blends, EGT decreases as EGR rates rise, mainly due to reduced peak combustion temperatures.

Ethanol and biodiesel blends had lower CO emissions than diesel, with D60CB40 having the lowest CO emission at 0.325 vol%. However, rising EGR rates cause a modest increase in CO and HC emissions due to decreased surplus oxygen leading to rich air–fuel mixtures.

Compared to diesel, the CRDI engine emits less HC when using a biodiesel blend and more when using an ethanol biodiesel blend. D60CB20E20 has the highest HC emission at 50 ppm, while D60CB40 has the lowest at 35 ppm.

CO2 emissions dropped as ethanol concentration increased in the test fuel. Rising EGR rates causes CO2 levels to rise.

At full load, the blend D60CB20E20 had the lowest NOx emissions, 9.98% lower than diesel. This decrease is attributed to the high latent heat of ethanol vaporisation, which lowers combustion temperatures and reduces NOx generation. NOx emissions decrease under all load scenarios when the EGR level is increased.

Compared to other test fuels, the smoke density of (WCO + WPO) biodiesel was lower. The mix D60CB20E20 showed the least smoke density, attributed to more complete combustion at higher loads.

These findings show that combining ethanol and biodiesel with diesel fuel improves combustion efficiency and reduces emissions. The study found that DBE blends may improve engine efficiency and lower emissions compared to diesel. Mixing ratios must be carefully considered for best results. Ethanol has also shown promise in reducing pollutants, which might make diesel engines greener. Further study should include Waste Heat Recovery (WHR) devices to improve fuel efficiency and lessen environmental effects.

Future scope

Future research could explore the use of higher ethanol concentrations in ternary blends to evaluate their stability, combustion behaviour, and effects on overall engine performance and emissions. Long-term durability studies are also crucial to assess the wear characteristics and potential corrosive effects of these novel fuels on engine components during extended operation. Additionally, investigating innovative feedstocks derived from waste resources, along with the integration of advanced additives like nanoparticles, might further enhance combustion efficiency and emission control. Finally, expanding the evaluation of these blends to a wider range of engine categories, including both vehicular and stationary power generation systems, will be essential to establish their broader applicability and practical feasibility.

Acknowledgements

The author(s) would like to express appreciation to the academic members of the Mechanical Engineering Department at Delhi Technological University in Delhi, India, and Apex Innovations Pvt. Ltd., Sangli, Maharashtra, India for making this experiment feasible by supplying the essential equipment and machinery.

Abbreviations

- ASTM

American Society for Testing and Materials

- BSFC

Brake-specific fuel consumption

- BTE

Brake thermal efficiency

- CN

Cetane number

- CO

Carbon monoxide

- CO2

Carbon dioxide

- CRDI

Common rail direct injection

- CV

Calorific value

- D100

100% diesel

- CB

Combined biodiesel of WCO and WPO (equal proportion)

- D80CB20

80% Diesel + 20% combined biodiesel (WCO & WPO)

- D60CB40

60% Diesel + 40% combined biodiesel (WCO & WPO)

- D80CB10E10

80% Diesel + 10% combined biodiesel + 10% ethanol

- D60CB20E20

60% Diesel + 20% combined biodiesel + 20% ethanol

- EGR

Exhaust gas recirculation

- EGT

Exhaust gas temperature

- E

Ethanol

- FTIR

Fourier-transform infrared spectroscopy

- HC

Hydrocarbons

- NOx

Nitrogen oxide

- PM

Particulate matter

- WCO

Waste cooking oil

- WPO

Waste plastic oil

Author contributions

Manish Kumar: Methodology, conceptualisation, validation, writing-original draft. Naushad Ahmad Ansari: Investigation, writing-review and editing. Raghvendra Gautam: Writing-review and editing.

Data availability

The datasets generated and/or analysed during the current study are available from the corresponding author or the first author on reasonable request.

Declarations

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Kukana, R. & Jakhar, O. P. Effect of ternary blends diesel/n-propanol/composite biodiesel on diesel engine operating parameters. Energy260, 124970 (2022). [Google Scholar]

- 2.Gautam, R., Chauhan, B. S. & Chang Lim, H. Influence of variation of injection angle on the combustion, performance and emissions characteristics of Jatropha Ethyl Ester. Energy254, 124436 (2022). [Google Scholar]

- 3.Sittichompoo, S. et al. Promotion effect of hydrogen addition in selective catalytic reduction of nitrogen oxide emissions from diesel engines fuelled with diesel-biodiesel-ethanol blends. Alexandria Eng. J.61, 5383–5395 (2022). [Google Scholar]

- 4.Kumar, M. et al. Effect of fuel injection pressure and EGR techniques on various engine performance and emission characteristics on a CRDI diesel engine when run with linseed oil methyl ester. Energy Environ.33, 41–63 (2022). [Google Scholar]

- 5.Kumar, M. et al. Prediction of an optimum engine response based on di erent input parameters on common rail direct injection diesel engine: A response surface methodology approach. Sci. Iran.28, 3181–3200 (2021). [Google Scholar]

- 6.Li, Z. et al. Effects of fuel injection timings and methanol split ratio in M/D/M strategy on a diesel/methanol dual-fuel direct injection engine. Fuel325, 124970 (2022). [Google Scholar]

- 7.Kumar, M., Gautam, R. & Ansari, N. A. Performance characteristics optimization of CRDI engine fuelled with a blend of sesame oil methyl ester and diesel fuel using response surface methodology approach. Front. Mech. Eng.9, 1049571 (2023). [Google Scholar]

- 8.Sayyed, S., Das, R. K. & Kulkarni, K. Experimental investigation for evaluating the performance and emission characteristics of DICI engine fueled with dual biodiesel-diesel blends of Jatropha, Karanja, Mahua, and Neem. Energy238, 121787 (2022). [Google Scholar]

- 9.Shanker Yadav, P., Said, Z., Gautam, R., Caliskan, H. & Wu, H. Impact of hydrogen induction on atomization combustion performance and emissions in diesel engines fueled with heated biodiesel blends. Energy313, 134026 (2024). [Google Scholar]

- 10.Kumar, M., Ansari, N. A. & Samsher. Investigation of Combustion, Performance and Emission of Aluminium Oxide Nanoparticles as Additives in CI Engine Fuels: A Review. In International Conference on Advanced Production and Industrial Engineering, 1055–1063 (2021). 10.1007/978-981-15-8542-5_93.

- 11.Prasada Rao, G. & Sathya Vara Prasad, L. Combined influence of compression ratio and exhaust gas recirculation on the diverse characteristics of the diesel engine fueled with novel palmyra biodiesel blend. Energy Convers. Manag. X14, 100185 (2022). [Google Scholar]

- 12.Singh, D. et al. A comprehensive review of physicochemical properties, production process, performance and emissions characteristics of 2nd generation biodiesel feedstock: Jatropha curcas. Fuel285, 119110 (2021). [Google Scholar]

- 13.Mandal, A., Cha, D. & Cho, H. Impact of waste fry biofuel on diesel engine performance and emissions. Energies16, 3711 (2023). [Google Scholar]

- 14.EL-Zohairy, R. M., Attia, A. S., Huzayyin, A. S. & EL-Seesy, A. I. Effect of diethyl ether addition to waste cooking oil biodiesel on the combustion and emission characteristics of a swirl-stabilized premixed flame. Energy Convers. Manag.286, 117052 (2023). [Google Scholar]

- 15.Kumar, A., Pali, H. S. & Kumar, M. Effective utilization of waste plastic derived fuel in CI engine using multi objective optimization through RSM. Fuel355, 129448 (2024). [Google Scholar]

- 16.Mangesh, V. L., Padmanabhan, S., Tamizhdurai, P. & Ramesh, A. Experimental investigation to identify the type of waste plastic pyrolysis oil suitable for conversion to diesel engine fuel. J. Clean. Prod.246, 119066 (2020). [Google Scholar]

- 17.Naima, K. et al. A comparative assessment of combustion behavior and emissions characteristics of DI diesel engine fueled with waste plastic oil and eucalyptus biofuel for sustainable development applications. Int. J. Low-Carbon Technol.17, 1399–1405 (2022). [Google Scholar]

- 18.Gautam, R. & Kumar, N. Effect of ethanol addition on the properties of Jatropha ethyl ester. Energy Sources Part A Recover. Util. Environ. Effects38, 3464–3469 (2016). [Google Scholar]

- 19.Tongroon, M. et al. Combustion and emission characteristics investigation of diesel-ethanol-biodiesel blended fuels in a compression-ignition engine and benefit analysis. Fuel255, 115728 (2019). [Google Scholar]

- 20.Kumar, M., Ansari, N. A. & Gautam, R. Ethanol-diesel and biodiesel blends: enhancing diesel engine efficiency and reducing emissions-a review. Energy Environ. Effic. Resour. Glob.10, 105–125 (2024). [Google Scholar]

- 21.Mukhtar, N. A. M., Hagos, F. Y., Aziz, A. R. A., Abdulah, A. A. & Karim, Z. A. A. Combustion characteristics of tri-fuel (diesel-ethanol-biodiesel) emulsion fuels in CI engine with micro-explosion phenomenon attributes. Fuel312, 122933 (2022). [Google Scholar]

- 22.Mizik, T. Economic aspects and sustainability of ethanol production—A systematic literature review. Energies14, 6137 (2021). [Google Scholar]

- 23.Gawale, G. R. & Naga Srinivasulu, G. Experimental investigation of ethanol/diesel and ethanol/biodiesel on dual fuel mode HCCI engine for different engine load conditions. Fuel263, 116725 (2020). [Google Scholar]

- 24.Freitas, E. S. C. et al. Emission and performance evaluation of a diesel engine using addition of ethanol to diesel/biodiesel fuel blend. Energies15, 2988 (2022). [Google Scholar]

- 25.Sathish, T. et al. Utilization of Azadirachta indica biodiesel, ethanol and diesel blends for diesel engine applications with engine emission profile. Fuel319, 123798 (2022). [Google Scholar]

- 26.Yoon, S. K. Investigation on the combustion and emission characteristics in a diesel engine fueled with diesel-ethanol blends. Appl. Sci.12, 9980 (2022). [Google Scholar]

- 27.Sayyed, S., Das, R. K., Kulkarni, K., Alam, T. & Eldin, S. M. Influence of additive mixed ethanol-biodiesel blends on diesel engine characteristics. Alexandria Eng. J.71, 619–629 (2023). [Google Scholar]

- 28.Zhong, Y., Zhang, Y., Mao, C. & Ukaew, A. Performance, combustion, and emission comparisons of a high-speed diesel engine fueled with biodiesel with different ethanol addition ratios based on a combined kinetic mechanism. Processes10, 1689 (2022). [Google Scholar]

- 29.Shirneshan, A., Bagherzadeh, S. A., Najafi, G., Mamat, R. & Mazlan, M. Optimization and investigation the effects of using biodiesel-ethanol blends on the performance and emission characteristics of a diesel engine by genetic algorithm. Fuel289, 119753 (2021). [Google Scholar]

- 30.Vishnoi, P. K., Gautam, P. S., Maheshwari, P., Samant, T. S. & Gupta, V. K. Experimental evaluation of diesel engine operating with A TERNARY BLEND (BIODIESEL-DIESEL-ETHANOL). IOP Conf. Ser. Mater. Sci. Eng.1168, 012017 (2021). [Google Scholar]

- 31.Wai, P. et al. Experimental investigation of the influence of ethanol and biodiesel on common rail direct injection diesel Engine’s combustion and emission characteristics. Case Stud. Therm. Eng.39, 102430 (2022). [Google Scholar]

- 32.Shrivastava, K., Thipse, S. S. & Patil, I. D. Optimization of diesel engine performance and emission parameters of Karanja biodiesel-ethanol-diesel blends at optimized operating conditions. Fuel293, 120451 (2021). [Google Scholar]

- 33.Qi, D., Ma, L., Chen, R., Jin, X. & Xie, M. Effects of EGR rate on the combustion and emission characteristics of diesel-palm oil-ethanol ternary blends used in a CRDI diesel engine with double injection strategy. Appl. Therm. Eng.199, 117530 (2021). [Google Scholar]

- 34.El-Sheekh, M. M., Bedaiwy, M. Y., El-Nagar, A. A., ElKelawy, M. & Alm-Eldin Bastawissi, H. Ethanol biofuel production and characteristics optimization from wheat straw hydrolysate: Performance and emission study of DI-diesel engine fueled with diesel/biodiesel/ethanol blends. Renew. Energy191, 591–607 (2022). [Google Scholar]

- 35.Karin, P. et al. Influence of ethanol-biodiesel blends on diesel engines combustion behavior and particulate matter physicochemical characteristics. Case Stud. Chem. Environ. Eng.6, 100249 (2022). [Google Scholar]

- 36.Kesharvani, S., Dwivedi, G., Verma, T. N. & Verma, P. The experimental investigation of a diesel engine using ternary blends of algae biodiesel, ethanol diesel fuels. Energies16, 229 (2022). [Google Scholar]

- 37.Nageswara Rao, D. & Sreenivasulu Reddy, A. Effects on the performance and emission characteristics of CRDI diesel engine fueled with ethanol, acid oil methyl ester biodiesel and diesel blends. Mater. Today Proc.10.1016/j.matpr.2023.06.065 (2023). [Google Scholar]

- 38.Chuepeng, S., Pirompugd, W. & Sutheerasak, E. Performance and emissions of a diesel engine fueled with palm oil ethyl ester combined with fumigated ethanol on a dual fuel mode. Energy Rep.9, 470–477 (2023). [Google Scholar]

- 39.Manikandan, G., Kanna, P. R., Taler, D. & Sobota, T. Review of waste cooking oil (WCO) as a feedstock for biofuel—Indian perspective. Energies16, 1739 (2023). [Google Scholar]

- 40.Mercy Nisha Pauline, J., Sivaramakrishnan, R., Pugazhendhi, A., Anbarasan, T. & Achary, A. Transesterification kinetics of waste cooking oil and its diesel engine performance. Fuel285, 119108 (2021). [Google Scholar]

- 41.Kumar, M., Gautam, R. & Ansari, N. A. Optimisation of an experimental and feasibility research on a CRDI diesel engine based on a blend of waste cooking oil and waste plastic oil using RSM: A value addition for disposed waste oil. J. Energy Inst.117, 101564 (2024). [Google Scholar]

- 42.Yogesh, P. & Chandramohan, D. Combustion, performance and emissions characteristics of CRDI engine fueled with biodiesel, ethanol & butanol blends at various fuel injection strategies. J. Appl. Sci. Eng.25, 971–977 (2022). [Google Scholar]

- 43.Esakki, T., Rangaswamy, S. M. & Jayabal, R. An experimental study on biodiesel production and impact of EGR in a CRDI diesel engine propelled with leather industry waste fat biodiesel. Fuel321, 123995 (2022). [Google Scholar]

- 44.Madiwale, S., Karthikeyan, A. & Bhojwani, V. Properties investigation and performance analysis of a diesel engine fuelled with Jatropha, Soybean, Palm and Cottonseed biodiesel using Ethanol as an additive. Mater. Today Proc.5, 657–664 (2018). [Google Scholar]

- 45.Chandravanshi, A., Pandey, S. & Malviya, R. K. Experimental investigation on the effects of using ethanol with biodiesel and diesel blends along with exhaust gas recirculation and magnetization of fuel in the diesel engine. Environ. Prog. Sustain. Energy41, e13844 (2022). [Google Scholar]

- 46.Krishna, S. M., Abdul Salam, P., Tongroon, M. & Chollacoop, N. Performance and emission assessment of optimally blended biodiesel-diesel-ethanol in diesel engine generator. Appl. Therm. Eng.155, 525–533 (2019). [Google Scholar]

- 47.Geng, L., Bi, L., Li, Q., Chen, H. & Xie, Y. Experimental study on spray characteristics, combustion stability, and emission performance of a CRDI diesel engine operated with biodiesel–ethanol blends. Energy Rep.7, 904–915 (2021). [Google Scholar]

- 48.Kurre, S. K. et al. Experimental evaluation of performance and emission of diesel engine fueled with nano-material titanium dioxide (TiO2) nanoparticles supplemented diesel-biodiesel-ethanol blends. Mater. Today Proc.10.1016/j.matpr.2023.01.306 (2023). [Google Scholar]

- 49.Liang, J., Zhang, Q., Chen, Z. & Zheng, Z. The effects of EGR rates and ternary blends of biodiesel/n-pentanol/diesel on the combustion and emission characteristics of a CRDI diesel engine. Fuel286, 119297 (2021). [Google Scholar]

- 50.Dineshkumar, C. et al. Assessment on performance and emission characteristics of the CRDI engine fueled with ethanol/diesel blends in addition to EGR. Int. J. Chem. Eng.2022, 1–13 (2022). [Google Scholar]

- 51.Asad, U., Divekar, P. S. & Zheng, M. High efficiency ethanol–diesel dual-fuel combustion: Analyses of performance, emissions and thermal efficiency over the engine load range. Fuel310, 122397 (2022). [Google Scholar]

- 52.Wai, P. et al. Experimental investigation of the impact ethanol-biodiesel-diesel blended fuels on combustion, emission, and performance of compression ignition diesel engine. Mater. Today Proc.66, 2830–2835 (2022). [Google Scholar]

- 53.Tan, Z., Wang, J., Chen, W., Shen, L. & Bi, Y. Study on the influence of EGR on the combustion performance of biofuel diesel at different ambient simulated pressures. Sustainability13, 7862 (2021). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The datasets generated and/or analysed during the current study are available from the corresponding author or the first author on reasonable request.