Abstract

The purpose of this study was to evaluate the ability of a commercial air-filtration system to reduce aerosol transmission of Porcine reproductive and respiratory syndrome virus (PRRSV). The system consisted of a pre-filter and 2 filters with EU8 and EU13 ratings. In each of 4 trials, 5 PRRSV-infected donor pigs and 1 naïve recipient pig (each 25 kg) were housed in opposing chambers connected by a 1.3-m-long duct. The system filtered air entering 1 recipient-pig chamber (filtered facility) from the donor- chamber but not a 2nd recipient-pig chamber (nonfiltered facility). The donor pigs had been experimentally infected with PRRSV MN-184, an isolate previously documented to be shed at a high frequency in contagious aerosols. On days 3 to 7 after infection of the donors, the 2 groups were housed in their respective chambers for 6 h and then in separate facilities, where samples were collected for testing by polymerase chain reaction and enzyme-linked immunosorbent assay over 14 d. Aerosol transmission was observed in 6 of the 20 replicates in the nonfiltered facility, whereas all pigs remained PRRSV-negative in the filtered facility; the difference was significant at P < 0.01. Thus, under the conditions of this study, the air-filtration system evaluated appeared to be highly effective at reducing aerosol transmission of PRRSV.

Résumé

Cette étude avait pour but d’évaluer l’efficacité d’un système de filtration d’air commercial à réduire la transmission par aérosol du virus du syndrome respiratoire et reproducteur porcin (PRRSSV). Le système était constitué d’un pré-filtre et de deux filtres avec une cote de rendement de EU8 et EU13. Lors de chacun de 4 essais, 5 porcs donneurs infectés par le PRRSSV et 1 porc naïf receveur (chacun pesant 25 kg) ont été gardés dans des chambres opposées reliées par un conduit de 1,3 m de longueur. Le système filtrait l’air entrant dans une pièce contenant un porc récepteur (pièce filtrée) mais pas celui entrant dans une seconde pièce contenant un porc récepteur (pièce non filtrée). Les porcs donneurs avaient été infectés expérimentalement avec la souche MN-184, un isolat préalablement reconnu pour être excrété à une fréquence élevée dans des aérosols contagieux. Entre les jours 3 et 7 après l’infection des donneurs, les 2 groupes ont été logés dans leur chambre respective pendant 6 heures et ensuite dans des installations séparées, où des échantillons ont été prélevés pour des tests d’amplification en chaîne par la polymérase (PCR) et par épreuve immuno-enzymatique (ELISA) pendant une période de 14 jours. Une transmission par aérosol a été observée lors de 6 des 20 réplications dans les pièces non filtrées alors que tous les porcs sont demeurés négatifs pour le PRSSV dans la pièce filtrée, cette différence étant significative (P < 0,01). Ainsi, dans les conditions de cette étude, le système de filtration d’air évalué semble très efficace à réduire la transmission par aérosol du PRSSV.

(Traduit par Docteur Serge Messier)

Introduction

Throughout the world, extensive efforts have been made to eliminate Porcine reproductive and respiratory syndrome virus (PRRSV) from commercial swine farms. Methods such as depopulation and repopulation, test and removal, and herd closure have been shown to be effective over a large number of farms (1–3). However, farms often become reinfected by new isolates of PRRSV, the origin of which is often unknown (4). Reported routes of PRRSV transmission include infected pigs and semen, and it has been shown experimentally that contaminated transport vehicles, insects, and fomites may play an epidemiologic role (5–10). Aerosol transmission is also a potential route of PRRSV spread between farms: studies indicate that PRRSV-contaminated aerosols can infect naïve pigs over distances of 0.5 to 150 m (11–14). Data from a large-scale epidemiologic study also suggested that aerosols are an important component of indirect PRRSV transmission throughout swine-producing regions (15).

To reduce the risk of PRRSV infection in their herds, swine producers use stringent biosecurity methods, including quarantine and testing of animals before introduction, downtime rules and shower-in/shower-out protocols for personnel, insect-control measures, and transport vehicle sanitation (16–18). In spite of these precautions, local spread of PRRSV between farms still occurs, lending support to the hypothesis that PRRSV transmission is possible via aerosols. Therefore, it has become important to investigate additional biosecurity strategies that might reduce this risk.

One such strategy is filtering incoming air in swine facilities (19,20). Air-filtration systems for swine facilities are commercially available and have been applied in France and, to a lesser extent, in Canada. These systems operate with the use of positive-pressure ventilation. Incoming air is passed through a series of filters with decreasing pore size in conjunction with a centrifugal turbine. Systems of this type frequently incorporate high-efficiency particulate air (HEPA) filters capable of blocking particles ≥ 0.3 mm in diameter.

Despite their growing acceptance in the swine industry, systems of this type have not been scientifically evaluated. Preliminary assessment indicated that weaned piglets housed in air-filtered rooms within a conventional pig farm remained free of PRRSV, whereas infection and seroconversion occurred in animals housed under conventional conditions (20). However, this field study lacked controls and did not involve experimental infection with PRRSV. Thus, no conclusions could be drawn. The purpose of our study was to scientifically evaluate the ability of a commercial air-filtration system to reduce aerosol transmission of PRRSV under experimental conditions. We hypothesized that systems incorporating HEPA filters would significantly reduce the aerosol transmission of PRRSV.

Materials and methods

Air-filtration model

A scale model of a commercially available air-filtration system was used. The model (Fancom Agri-Computers, Panningen, the Netherlands) was 1/16 the size of the commercially available system used on swine farms and was encased in a rectangular aluminum box 1200 × 650 mm in height and width. The exterior of the air-intake port was covered with a pre-filter, composed of 20% passing gravimetric, galvanized metal. The 1st stage (model OP95 F8; Camfil, Sainte-Colombe, France) consisted of a bag filter 592 × 592 × 533 mm with a 95% opacimetric efficiency (OPA) rating, a EU 8 classification, and a filtering coefficient of 20. The 2nd stage consisted of a HEPA dioctylphthalate (DOP) filter 610 × 610 × 292 mm (Camfil) with an EU13 classification, a DOP efficiency rating of 99.99%, a filtering coefficient of 2000 (minimum efficiency 99.95%, maximum pass-through 0.05%), and a most penetrating particulate size of 0.1 to 0.2 μm. The model was ventilated by a 45-cm variable-speed fan (model 1456 M/C; Fancom) with a maximum capacity of 1495 m3/h placed between the 1st- and 2nd-stage filters. The fan was controlled by a ventilation linear regulation (VLR 6) end station (model A7110101; Fancom). During the experiment, the fan operated at approximately 25% capacity (375 m3/h), producing the required static pressure of 50 to 60 Pa. Pressure was continuously monitored via a manometer attached to the exterior surface of the recipient pig chamber.

Infection model and animal groups

Before the study, all procedures and protocols involving pigs were approved by the University of Minnesota Institute of Animal Care and Use Committee. The study included 94 PRRSV-naïve 25-kg pigs acquired from a PRRSV-naïve farm whose status had been validated for more than 10 y via monthly blood testing. Blood samples were collected from all animals upon arrival at the research site and were tested at the Minnesota Veterinary Diagnostic Laboratory for PRRSV RNA and antibodies by TaqMan polymerase chain reaction (PCR) (Perkin Elmer, Applied Biosystems, Foster City, California, USA) and the IDEXX 2XR enzyme-linked immunosorbent assay (ELISA) (IDEXX Laboratories, Westbrook, Maine, USA) (21,22). The pigs were divided into 4 groups: donors (n = 40), recipients (n = 40), sentinels (n = 8), and protocol controls (n = 6). Donor animals served as the source of PRRSV-contaminated aerosols for transfer to naïve recipients.

For the inoculation of donor pigs, 2 mL of a highly virulent isolate of PRRSV (MN-184) was administered intranasally (1 mL per naris), for a total concentration of 2 × 104 TCID50 (23). This isolate was selected on the basis of data indicating that pigs infected with it shed PRRSV in aerosols at a significantly higher frequency (P = 0.0005) than did pigs infected with an avirulent isolate (Jenny Cho, Scott Dee, John Deen, et al, University of Minnesota College of Veterinary Medicine: unpublished data, 2003–2005). Further studies indicated that the aerosols generated by animals infected with PRRSV MN-184 were significantly more contagious (P = 0.04) than aerosols from pigs infected with the avirulent isolate MN-30100.

Experimental facilities

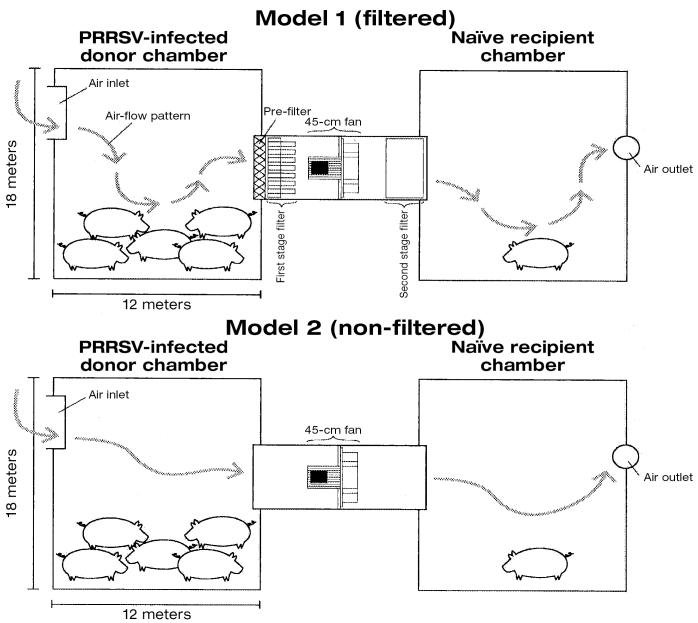

Two experimental animal facilities were constructed in separate buildings at the Swine Disease Eradication Center research farm. Each facility consisted of 2 chambers 1.3 m long and wide and 1.8 m high that were connected by a rectangular duct 650 × 650 mm and 1.3 m long (Figure 1). The chambers and ducts were made of 1.25-cm-thick sheets of recycled plastic (Snow white board; Environment Control Systems, Morris, Minnesota, USA) reinforced with a frame of treated plywood boards 5 × 5 cm. The junctions between the frame and the plastic were caulked with silicone.

Figure 1.

Diagram of experimental facilities used in the study. PRRSV — Porcine eproductive and respiratory syndrome virus.

Donor pigs were housed in chamber 1 and recipient pigs in chamber 2. Free-choice water was available to the pigs. When multiple pigs were housed in a chamber, the stocking density was 0.29 m2 per pig; the pigs were able to freely move about the chamber, lie down, and turn around with ease. The duct allowed air to flow from chamber 1 to chamber 2 in each experimental facility. One facility was designated the “filtered facility” and the other the “nonfiltered facility”. In the filtered facility, the air-filtration model served as the duct; in the nonfiltered facility, the duct contained only the fan. A 0.4-m2 opening above the entry door of chamber 1 served as the air inlet for each facility; a hole 20 cm in diameter above the entry door of chamber 2 allowed for air to be exhausted.

Experimental design

The design of the experiment is summarized in Table I. The 40 donor pigs were divided into 8 groups of 5 pigs each (group numbers 1 to 8). The 40 recipient pigs were divided into 2 groups of 20 pigs each: the “filtered group” (pig numbers 1 to 20) and the “nonfiltered group” (pig numbers 21 to 40). It was planned that each recipient pig would represent a replicate; therefore, 20 replicates were conducted in the filtered facility and 20 in the nonfiltered facility. This sample size allowed for detection of a 25% infection rate in the nonfiltered facility at a target α level of 0.05 and study power of 80%.

Table I.

Experimental design for the comparison of filtered facilities (model 1) and nonfiltered facilities (model 2) for the prevention of aerosol transmission of Porcine reproductive and respiratory syndrome virus from experimentally infected donor groups a to individual recipient pigs;b those in which transmission occurred are in boldface

| Day after inoculation of donor pigs

|

|||||

|---|---|---|---|---|---|

| Model number | Day 3 | Day 4 | Day 5 | Day 6 | Day 7 |

| Trial 1 | |||||

| 1 | Donor group 1 | Donor group 2 | Donor group 1 | Donor group 2 | Donor group 1 |

| Recipient 1 | Recipient 2 | Recipient 3 | Recipient 4 | Recipient 5 | |

| 2 | Donor group 2 | Donor group 1 | Donor group 2 | Donor group 1 | Donor group 2 |

| Recipient 6 | Recipient 7 | Recipient 8 | Recipient 9 | Recipient 10 | |

| Trial 2 | |||||

| 1 | Donor group 3 | Donor group 4 | Donor group 3 | Donor group 4 | Donor group 3 |

| Recipient 11 | Recipient 12 | Recipient 13 | Recipient 14 | Recipient 15 | |

| 2 | Donor group 4 | Donor group 3 | Donor group 4 | Donor group 3 | Donor group 4 |

| Recipient 16 | Recipient 17 | Recipient 18 | Recipient 19 | Recipient 20 | |

| Trial 3 | |||||

| 1 | Donor group 5 | Donor group 6 | Donor group 5 | Donor group 6 | Donor group 5 |

| Recipient 21 | Recipient 22 | Recipient 23 | Recipient 24 | Recipient 25 | |

| 2 | Donor group 6 | Donor group 5 | Donor group 6 | Donor group 5 | Donor group 6 |

| Recipient 26 | Recipient 27 | Recipient 28 | Recipient 29 | Recipient 30 | |

| Trial 4 | |||||

| 1 | Donor group 7 | Donor group 8 | Donor group 7 | Donor group 8 | Donor group 7 |

| Recipient 31 | Recipient 32 | Recipient 33 | Recipient 34 | Recipient 35 | |

| 2 | Donor group 8 | Donor group 7 | Donor group 8 | Donor group 7 | Donor group 8 |

| Recipient 36 | Recipient 37 | Recipient 38 | Recipient 39 | Recipient 40 | |

Donor groups were rotated between facilities on alternate days

A new recipient pig was used on each exposure day

Four trials were conducted with the same design. The exposure period of each trial was 5 d (days 3, 4, 5, 6, and 7 after donor inoculation). On each of these days, a donor group (5 pigs) was housed for 6 h in chamber 1 of the filtered facility, another donor group in chamber 1 of the nonfiltered facility, and a single recipient pig in chamber 2 of each facility. The 2 facilities were tested concurrently. During the 6-h exposure period, air was ventilated from the donor chamber via the connecting duct (with or without filtration) into the recipient chamber; the velocity, temperature, and relative humidity of the air in chamber 2 was recorded with a Kestrel weather meter (Nielsen-Kellerman, Chester, Pennsylvania, USA). After exposure, the donors were returned to their pens and the recipients placed in individual isolated facilities on the farm for assessment of PRRSV status. On alternate days, the donor pig groups were rotated between chambers to minimize bias (Table I), and a different recipient pig was used each day. At the end of the 5-d exposure period, the donor pigs were euthanized. This method was repeated 3 more times with different groups of donor pigs and recipient pigs.

Biosecurity protocols

To minimize the risk of contamination between the groups, strict biosecurity protocols were followed at all times. The chambers were sanitized with a combination of 7% glutaraldehyde and 26% quaternary ammonium chloride (Synergize; Preserve International, Atlanta, Georgia, USA) (24): 30 mL of the disinfectant was added to 3840 mL of water and applied to all interior surfaces with a Hydro Foamer (Hydro Systems, Cincinnati, Ohio, USA), then the surfaces were allowed to dry overnight between replicates. Donors and recipients were housed in different buildings on the farm. Recipient pigs were handled before donors during placement and removal from the chambers. Designated personnel handled either donors or recipients, and personnel handling recipient pigs washed their hands and changed gloves, boots, and coveralls between pigs (25). Separate traffic patterns for the transfer of donors and recipients were established to prevent contact between personnel. Personnel followed these protocols for daily inspection and feeding of pigs, and footwear was sanitized through a 10-s immersion in boot baths containing 6.5% sodium hypochlorite outside the doorway of each room (26). Finally, after each replicate, recipient pigs from the filtered and nonfiltered facilities were housed in individual isolation facilities throughout the farm, in individual pens in separated rooms with no possibility of nose-to-nose contact. The trials were conducted in the winter in Minnesota to eliminate the risk of insect transmission between pens and rooms.

The protocol-control group was used during each exposure period to monitor whether unintentional mechanical transmission of PRRSV via personnel or improper sanitation of the experimental facilities occurred. Five pigs sham-inoculated intranasally with 2 mL of PRRSV-free cell culture fluid and a single recipient pig were housed for 6 h in the filtered and nonfiltered chambers before each of the 4 trials. The pigs’ PRRSV status was monitored according to protocol.

Diagnostic monitoring

To ensure that experimental infection and shedding occurred during the exposure period, blood samples and nasal swabs were collected from all of the donor pigs. A different donor pig was sampled each day to ensure that all pigs were sampled during the 5-d exposure period. Furthermore, age-matched sentinel pigs were co-mingled with the donors (1 sentinel to 5 donors) in the holding pens after the donors had been removed from the chambers. The sentinels were tested at the end of the exposure period. The recipient pigs were blood-tested 7 and 14 d after exposure. Samples from the donor pigs and sentinels were tested by TaqMan PCR; for the recipient pigs, day-7 samples were tested by PCR and day-14 samples by ELISA. Blood samples from the protocol controls were tested at the end of the exposure period by ELISA.

Data analysis

A 1-tailed Fisher’s exact test was used to determine whether there was a significant difference in aerosol transmission of PRRSV from infected to noninfected pigs in the filtered facility versus the nonfiltered facility.

Results

All the pigs were determined to be PRRSV-naïve upon arrival at the farm. The air in the recipient-pig chambers had a mean velocity of 5.0 m/s, mean temperature of 20°C, and mean relative humidity of 48%. Experimental infection and shedding of PRRSV were documented in the donor pigs; specifically, all 40 pigs were viremic, and 38 (95%) had PCR-positive nasal swabs. Blood samples from all 8 sentinel pigs were PCR-positive, indicating that the donor pigs were shedding PRRSV during the exposure period. Clinical signs in the donor pigs included fever (temperature 40°C to 42°C), anorexia, and dyspnea. One donor pig died. Aerosol transmission of PRRSV was detected in 6 (30%) of the 20 recipient pigs housed in nonfiltered facilities. The 6 pigs (numbers 7, 9, 20, 29, 38, and 40) were PCR-positive and ELISA-positive on days 7 and 14, respectively, after completion of the 5-d exposure. The remaining 14 recipient pigs housed in nonfiltered facilities had negative results of both tests. In contrast, all 20 recipient pigs housed in filtered facilities were PCR-negative and ELISA-negative. This difference was significant (P < 0.01). The protocol-control group remained PCR-negative and ELISA-negative throughout the study.

Discussion

The objective of this study was to evaluate the ability of a scale model of a commercially available air-filtration system to reduce the transmission of PRRSV from experimentally infected pigs to naïve pigs by aerosols under controlled experimental conditions. The growing body of clinical evidence supporting the use of air-filtration systems to prevent the introduction of PRRSV to naïve farms in the endemically infected pig-dense regions, the rapid adaptation of air-filtration systems to swine facilities, and the lack of a truly scientific assessment of their efficacy justified such an experiment (27).

Under the conditions of the study, the air-filtration system evaluated appeared to be highly effective at reducing the spread of PRRSV by aerosols when compared with nonfiltered facilities. The reported diameter of bioaerosols can range from 0.5 to 100 mm (28); therefore, it is not known whether similar results would have been obtained with the use of filters with larger pores.

As with all experimental studies, this one had several limitations. Clearly the major limitation was that we did not attempt to demonstrate PRRSV in air samples collected from the donor or recipient chambers. However, this was a conscious decision based on the inability to detect PRRSV in air samples using all-glass impingers in previous experiments (29,30). Furthermore, although air centrifuges appear to be capable of detecting PRRSV in air samples (14), given the limited amount of space in the chamber it was not possible to prevent the pigs from physically contacting the instrument and potentially contaminating the sample. However, in an effort to strengthen the conclusion that aerosols were the route of infection of the recipient pigs housed in nonfiltered facilities, biosecurity measures were applied across all groups of pigs to minimize the risk of PRRSV contamination between groups. The fact that all of the protocol-control pigs as well as all the recipient pigs in the filtered facilities remained PRRSV-negative, despite being managed by the same personnel, validates these procedures and supports this conclusion. However, to avoid the air-sampling limitation in future experiments that utilize the chambers, we are planning to secure the air centrifuge above the animals so as to minimize the risk of contamination and enhance sample collection.

The study conditions were highly artificial and did not represent in any way conditions found on commercial farms. The size of the chambers allowed for use of only a very small number of age-matched donor and recipient pigs, the environment was well controlled, and the animals remained in the chambers for only short periods. It is unknown whether this system would have performed in an identical manner under field conditions, in which large populations of pigs housed in commercial facilities might produce higher concentrations of virus-contaminated aerosols during different seasons. Other limitations include the lack of co-infection with other significant respiratory pathogens, such as Mycoplasma hyopneumoniae or swine influenza virus, which might have led to a greater concentration of PRRSV in the aerosols from the experimentally infected pigs.

However, despite these limitations, the study had much strength. This was the first controlled study that evaluated the ability of air filtration to prevent the aerosol transmission of PRRSV. The scale model had a design and materials identical to those of the commercial system. The study used experimental PRRSV infection of swine known to be susceptible, had sufficient power for statistical analysis, and involved controls. The PRRSV isolate had been well documented to be shed with high frequency in aerosols that were highly contagious to recipient pigs. However, despite the use of this isolate, the model transmitted PRRSV by aerosol in the nonfiltered facility only 30% of the time. Potential explanations are the short period of exposure (6 h) to PRRSV-contaminated aerosols and the small number of donor and recipient pigs (5 and 1, respectively) per trial. In contrast, other studies that have demonstrated aerosol transmission of PRRSV have used large groups of infected pigs (n = 25 to 50) or prolonged exposure (21 to 56 d), or both (11–13). Furthermore, in working with this model, we observed substantial variability in the shedding of PRRSV via aerosols within individual pigs as well as between pigs. Some or all of these factors may have influenced the results.

In conclusion, the results of this study suggest that air filtration, in combination with proper sanitation of transport vehicles, on-farm insect-control measures, and proper management of incoming fomites, may provide farms with a high level of biosecurity against PRRSV. Air filtration may be especially useful for seedstock suppliers and artificial-insemination centres, where the risk of PRRSV transmission through the sale of live animals and semen and the cost of an outbreak are very high. Therefore, we need large-scale epidemiologic studies to determine the frequency of aerosol transmission of PRRSV and the significance in terms of area spread of the virus, further testing of the current system under controlled field conditions, and an assessment of the system’s efficacy against other respiratory pathogens.

Acknowledgments

Funding for this study was provided by the Boehringer-Ingelheim PRRS research initiative. The authors are extremely grateful to Bernard Cassou, Michel Lombard and Olivier Couture of IMV International, Yvon Lintanff of Fancom Agri-computers, and Dominique Tardiff of JOLCO Equipment for providing materials and technical expertise in the area of air filtration. The authors are also very appreciative of the donation of the animals used in the study by Mr. Jeff Zick of Genetporc USA.

References

- 1.Dee SA, Deen J. Establishment of a PRRS ELISA-negative boar population using previously exposed boars. Vet Rec. 2001;149:678–680. doi: 10.1136/vr.149.22.678. [DOI] [PubMed] [Google Scholar]

- 2.Dee SA. Elimination of porcine reproductive and respiratory syndrome virus by test and removal on 30 farms. Swine Health Prod. 2004;12:129–133. [Google Scholar]

- 3.Torremorell M, Christianson WT. PRRS eradication. Proc 1st Int Symp Swine Dis Erad. 2001:7–10. [Google Scholar]

- 4.Lager KM, Mengeling WL, Wesley RD. Evidence of local spread of porcine reproductive and respiratory syndrome virus. Swine Health Prod. 2002;10:167–170. [Google Scholar]

- 5.Dee SA, Joo HS, Pijoan C. Controlling the spread of PRRS virus in the breeding herd through management of the gilt pool. Swine Health Prod. 1994;3:64–69. [Google Scholar]

- 6.Christopher-Hennings J, Benfield DA, Nelson E, et al. Persistence of PRRS virus in serum and semen of adult boars. J Vet Diagn Invest. 1995;7:456–464. doi: 10.1177/104063879500700406. [DOI] [PubMed] [Google Scholar]

- 7.Otake S, Dee SA, Rossow KD, et al. Transmission of porcine reproductive and respiratory syndrome virus by fomites (boots and coveralls) Swine Health Prod. 2002;10:59–65. [Google Scholar]

- 8.Dee SA, Deen J, Otake S, Pijoan C. An assessment of transport vehicles as a source of porcine reproductive and respiratory syndrome virus transmission to susceptible pigs. Can J Vet Res. 2004;68:124–133. [PMC free article] [PubMed] [Google Scholar]

- 9.Otake S, Dee SA, Rossow KD, et al. Transmission of porcine reproductive and respiratory syndrome virus by houseflies (Musca domestica Linnaeus) Vet Rec. 2003;152:73–76. doi: 10.1136/vr.152.3.73. [DOI] [PubMed] [Google Scholar]

- 10.Dee SA, Deen J, Rossow KD, et al. Mechanical transmission of porcine reproductive and respiratory syndrome virus throughout a coordinated sequence of events during cold weather. Can J Vet Res. 2002;66:232–239. [PMC free article] [PubMed] [Google Scholar]

- 11.Kristensen CS, Bøtner A, Takai H, Nielsen JP, Jorsal SE. Experimental airborne transmission of PRRS virus. Vet Microbiol. 2004;99:197–202. doi: 10.1016/j.vetmic.2004.01.005. [DOI] [PubMed] [Google Scholar]

- 12.Wills RW, Zimmerman JJ, Swenson SL, et al. Transmission of PRRSV by direct, close or indirect contact. Swine Health Prod. 1997;5:213–218. [Google Scholar]

- 13.Torremorell M, Pijoan C, Janni K, Walker R, Joo HS. Airborne transmission of Actinobacillus pleuropneumoniae and porcine reproductive and respiratory syndrome virus in nursery pigs. Am J Vet Res. 1997;58:828–832. [PubMed] [Google Scholar]

- 14.Dee SA, Jacobson L, Rossow K, Pijoan C. A laboratory model to evaluate the role of aerosols in the transport of porcine reproductive and respiratory syndrome virus. Vet Rec. In press. [DOI] [PubMed]

- 15.Mortensen S, Stryhn H, Sogaard R, et al. Risk factors for infection of herds with porcine reproductive and respiratory syndrome virus. Prev Vet Med. 2002;53:83–101. doi: 10.1016/s0167-5877(01)00260-4. [DOI] [PubMed] [Google Scholar]

- 16.Moore C. Biosecurity for minimal disease herds. In: Tubbs RC, Leman AD, eds. Veterinary Clinics of North America: Swine Reproduction. Philadelphia: WB Saunders, 1992;8:461–474 [DOI] [PubMed]

- 17.Schurrer JA, Dee SA, Moon RD. An evaluation of intervention strategies for the control of insects on a commercial swine farm. Proc AD Leman Swine Conf. 2004:18. [Google Scholar]

- 18.Dee SA, Torremorell M, Thompson B, Deen J, Pijoan C. An evaluation of the Thermo-Assisted Drying and Decontamination (TADD) system for the elimination of porcine reproductive and respiratory syndrome virus from contaminated livestock transport vehicles. Can J Vet Res. 2005;69:58–63. [PMC free article] [PubMed] [Google Scholar]

- 19.Cariolet R, Marie P, Moreau G, Robert H. Summary of the different methods for producing, maintaining and benefitting from piglets of high health status. Journees Rech Porc Fr. 1994;26:1–12. [Google Scholar]

- 20.Cariolet R, Callerec J, Dutertre C, et al. Assessment and management of protected pig units. Journees Rech Porc Fr. 2000;32:25–32. [Google Scholar]

- 21.Molitor TW, Tune KA, Shin J. Application of TaqMan™ PCR in the detection of porcine reproductive and respiratory syndrome virus. Proc AD Leman Swine Conf. 1997:173–175. [Google Scholar]

- 22.Snyder ML, Mermer B, Anderson PR, et al. Evaluation data for an immunological ELISA for porcine reproductive and respiratory syndrome virus. Proc 2nd Int Symp PRRSV. :1995–15. [Google Scholar]

- 23.Johnson W, Roof M, Vaughn E, Christopher-Hennings J, Johnson CR, Murtaugh MP. Pathogenic and humoral immune responses to porcine reproductive and respiratory syndrome virus (PRRSV) are related to viral load in acute infection. Vet Immunol Immunopathol. 2004;102:233–247. doi: 10.1016/j.vetimm.2004.09.010. [DOI] [PubMed] [Google Scholar]

- 24.Dee SA, Deen J, Burns D, Douthit G, Pijoan C. Evaluation of disinfectant efficacy for sanitizing porcine reproductive and respiratory syndrome virus-contaminated transport vehicles. Can J Vet Res. 2005;69:64–70. [PMC free article] [PubMed] [Google Scholar]

- 25.Otake S, Dee SA, Rossow KD, et al. Transmission of porcine reproductive and respiratory syndrome virus by fomites (boots and coveralls) Swine Health Prod. 2002;10:59–65. [Google Scholar]

- 26.Dee SA, Deen J, Pijoan C. An evaluation of four intervention strategies to prevent mechanical transmission of porcine reproductive and respiratory syndrome virus. Can J Vet Res. 2004;68:19–26. [PMC free article] [PubMed] [Google Scholar]

- 27.Desrosiers R. Epidemiology, diagnosis and control of swine diseases. Proc AASV. 2004:9–40. [Google Scholar]

- 28.Hirst JM. Bioaerosols: introduction, retrospect and prospect. In: Cox CS, Wraths CM, eds. Bioaerosol Handbook. Boca Raton, Florida: CRC Lewis Publishers, 1995:1–10.

- 29.Otake S, Dee SA, Jacobson L, Torremorell M, Pijoan C. Evaluation of aerosol transmission of porcine reproductive and respiratory syndrome virus under field conditions. Vet Rec. 2002;150:804–808. doi: 10.1136/vr.150.26.804. [DOI] [PubMed] [Google Scholar]

- 30.Trincado C, Dee SA, Jacobson L, Otake S, Rossow K, Pijoan C. Attempts to transmit porcine reproductive and respiratory syndrome virus by aerosols under controlled field conditions. Vet Rec. 2004;154:294–297. doi: 10.1136/vr.154.10.294. [DOI] [PubMed] [Google Scholar]