SUMMARY

An enhanced etched electrochemical detection technique has been developed for capillary electrophoresis in micron inner diameter capillaries. The design improvements allow for better alignment between the capillary bore and the electrode. This new method involves utilizing a carbon fiber microelectrode and etching both the carbon fiber and the detection end of a micrometer-sized inner diameter capillary to limit dead volume and analyte diffusion at the amperometric electrochemical detector. To understand the factors affecting enhanced detector efficiency, a detailed examination of the relationship between detector design and performance has been completed by exploring the effects of varying electrode diameter, tip shape, and size, in addition to the etch length of the capillary outlet. The enhanced detection provides peak efficiencies as high as 75,000 theoretical plates and estimated detection limits as low as 40 nM for dopamine. This etched detection method should further facilitate volume-limited sample analysis by capillary electrophoresis.

Keywords: capillary electrophoresis, electrochemical detection, carbon fiber electrodes

1 INTRODUCTION

Capillary electrophoresis (CE) is a rapid, straightforward separation technique, which yields extremely high separation efficiency in a relatively short time period. The overwhelming power of CE to resolve analytes must also be matched by efficient and sensitive detection methodologies. CE has been successfully coupled to a wide variety of detection techniques including mass spectrometry, fluorescence and electrochemical (EC) detection [1]. However, CE combined with EC detection has an advantage over the other detection strategies, largely because the concentration limits of detection are maintained even with miniaturization [2]. Indeed, EC is arguably one of the most sensitive detection methods for CE, capable of detecting analytes present at femtomole to attomole levels [3, 4]. Moreover, it can be used for the analysis of a broad range of analytes and does not require chemical derivatization of these electroactive compounds thereby limiting interference from nonelectroactive species in complex sample matrices [4, 5]. The excellent sensitivity, selectivity, and relatively simple, inexpensive design make EC detection a very versatile and useful analytical tool.

Whereas CE with EC detection is a powerful technique, its performance is highly dependent on the design of the detector [6-9]. Alignment between the capillary bore and the electrode must be precise and easily maintained to ensure high sensitivity. Interference between the separation potential and EC detection must also be limited to minimize noise and instability in the detector [2, 7]. Several variations of EC detection for CE have been investigated; in particular, two main methods of isolating the electrode from the separation potential have been developed, off-column and end-column EC detection [2, 7]. Off-column EC detection for CE utilizes a decoupling joint to reduce the interference of the high voltage electric field used in CE from the EC detection circuit. Wallingford and Ewing demonstrated the first fracture decoupler with a porous glass capillary to join a larger inner diameter (i.d.) to the EC detection assembly [10]. Subsequently, several studies have examined a variety of off-column decoupler materials and designs; however, these decoupling joints are fragile and difficult to maintain [11, 12]. Alternatively end-column EC detection, which eliminates the need for decoupler joints, has been developed [7, 8, 13, 14]. In the end-column scheme, the detection electrode is place in the CE buffer reservoir near or inside the end of the capillary. This method permits the use of a variety of i.d. capillaries due to several electrode-positioning formats that have been developed. These include placement of electrodes close to the capillary outlet, inside a conically etched capillary end, mounted across the capillary outlet, and sputtered onto the end of the capillary [2]. Clearly, the geometry and the alignment of the capillary and electrode are critical to a reproducible end-column detection method.

This paper explores an end-column detection method in which a carbon fiber microelectrode is inserted into the etched i.d. of a capillary. Here, we expand upon the etched EC detection technique that was developed for CE in nanometer i.d. capillaries [9], adapting the same techniques for use in micron i.d. capillaries. This new scheme involves using a larger electrode and etching both the electrode and the detection end of the capillary to limit dead volume and analyte diffusion in the detector. These design improvements allow for better alignment between the capillary bore and the electrode. As we reported for etched EC detection in nanometer i.d. capillaries [9], improvements in sensitivity due to increased peak efficiency and detection limits are also found by coupling etched EC detection to CE in micron i.d. capillaries. To better understand this result, a detailed examination of the relationship between detector design and performance is presented.

2 EXPERIMENTAL

2.1 Chemicals

Dopamine (DA), catechol (CAT) and N-tris-[hydroxymethyl]methyl-2-aminoethanesulfonic acid (TES) were obtained from Sigma (St. Louis, MO). A 48 % aqueous solution of hydrofluoric acid was obtained from Aldrich (Milwaukee, WI). All chemicals were used as received. The separation buffer used was 10 mM TES containing 5 % 1-propanol adjusted to pH 7.2 with sodium hydroxide. All standards were prepared as 100 mM stock solutions in 0.1 M perchloric acid and were diluted to the desired concentration with buffer.

2.2 Instrumentation

A CE system with end-column amperometric detection was utilized. This system has been previously described [8, 13] Briefly, 30 to 40 cm of fused-silica capillary with an outer diameter of 150 μm and an i.d. of 16 or 13 μm (Polymicro Technologies, Phoenix, AZ) was employed. Amperometric detection was performed using a two-electrode configuration. Carbon fibers with diameters of 5, 10 and 30 μm (Amoco Performance Products, Greenville, SC) were employed as working electrodes. The carbon fiber microelectrode was positioned inside the end of the capillary using micromanipulators. EC detection was performed at 0.7 mV vs. a Ag/AgCl reference electrode (World Precision Instruments, Sarasota, FL). Faradaic currents were amplified with a Keithley Model 427 current amplifier (Cleveland, OH) and collected with a LabView 5.1 interface (National Instruments, Austin, TX). The detection system was enclosed in a copper-mesh Faraday cage to minimize external noise. Injections were performed electrokinetically and injection volumes were calculated based on electroosmotic flow measured with a neutral marker to be between 1-2 nL.

2.3 Capillary Procedures

To enhance microelectrode placement, the capillary i.d. was enlarged via HF etching as similar to a previous description [8]. Approximately 2 mm of the polyimide coating was removed from the capillary to expose the fused silica. The exposed portion of the capillary was placed in hydrofluoric acid. The i.d. of the capillary was etched open to accommodate the carbon fiber microelectrode by pumping He gas through the capillary at a low flow rate. This ensures only a few hundred microns of the i.d. of the capillary are exposed to HF. Thus, the length of the capillary etch was controlled by changing the rate of gas flow through the capillary during the etching procedure. After the etching was complete, the exposed portion of the capillary was placed in a sodium bicarbonate solution to neutralize the acid and then washed with water. Capillaries were filled for separation with the separation buffer using a stainless steel reservoir with an applied He pressure of 400 psi.

2.4 Electrode Flame-Etching Procedures

Carbon fiber microelectrodes with varied tip diameters were etched to a conical tip in an acetylene flame at an angle of 45°. Electrodes with 30-μm diameter carbon fibers were held in the flame for between 5 and 15 s. This technique was used to create microelectrodes with tip diameters of 2.5, 10 and 20 μm. Using a scalpel, the electroactive lengths of these electrodes were cut to between 1300 and 1100 μm.

3 RESULTS AND DISCUSSION

3.1 Etched EC detection for micrometer-bore CE

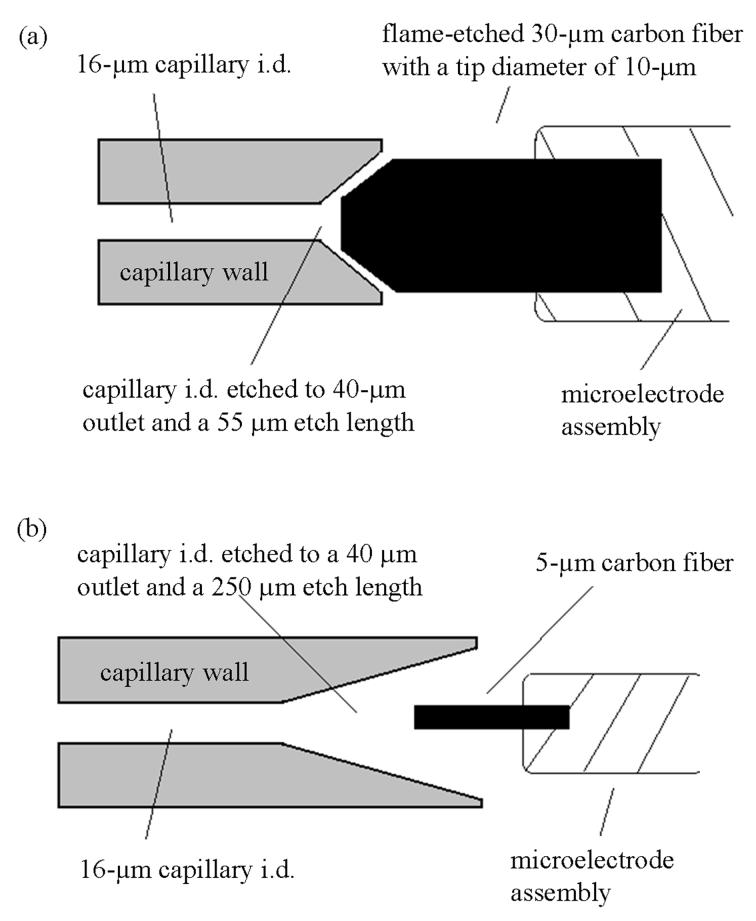

A method for end-column amperometric detection in CE with an etched 16-μm i.d. capillary and an etched electrode tip has been developed (Figure 1a). This design involves etching the i.d. of the detection end of the capillary to taper from 40 μm at the outlet to approximately 16 μm over a length of 55 μm. A 30-μm diameter microelectrode is utilized to decrease the dead volume of the detector. The electrode is etched in a flame to create a 10 μm tip on the carbon fiber. For comparison, a diagram of a standard EC detector for CE is shown in Figure 1b. In this instance, the capillary is also etched to taper from 40 μm at the outlet to approximately 16 μm; however, the length of the etch can be as long as 250 μm. In both designs the etch allows for better alignment between the capillary bore and microelectrode. Employing a larger electrode and a shorter etch length, as shown in Figure 1a, has enabled reduced dead volume in the detector. The detection volume, defined as the total volume of the etched portion of the capillary less the volume displaced by the microelectrode, can be determined for each detector design. The geometry of the etched portion of the capillary is a frustum and has been described in a previous publication [9]. The displacement volume of the unetched 5-μm diameter microelectrodes is calculated as the volume of a cylinder while the displacement volume for the etched 30-μm diameter microelectrodes is also calculated from the volume of a frustum.

Figure 1.

Diagram of the (a) etched and (b) standard end-column amperometric detectors. The etched detector consists of a flame-etched 30-μm diameter microelectrode with a 10-μm tip positioned inside the etched detection end of the capillary. The detection end of the capillary is etched to create a capillary outlet with a length of 55 μm and a diameter at its tip of approximately 40 μm. The standard detector consists of a 5-μm diameter microelectrode positioned just inside the detection end of the capillary. The detection end of the capillary is etched to create a capillary outlet with a length of 250 μm and a diameter at its tip of approximately 40 μm.

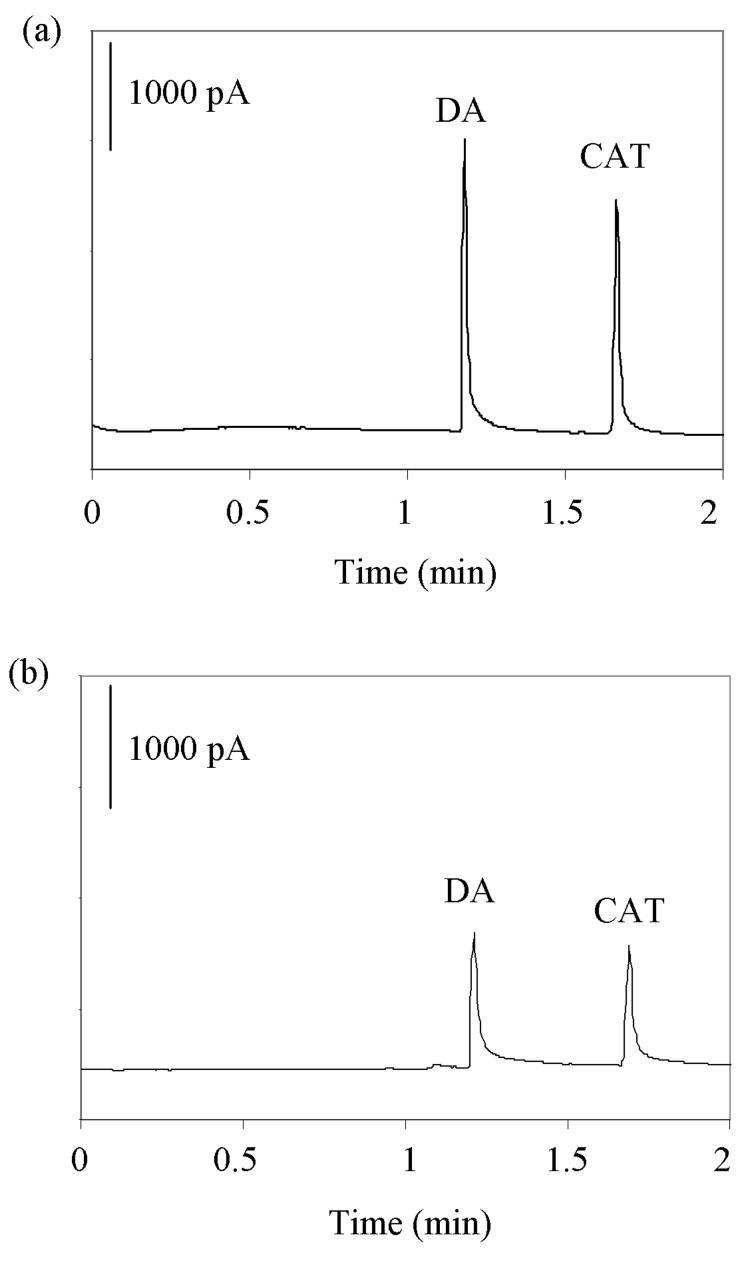

The performance of the etched detector design has been examined because detector dead volume is hypothesized to be important for detector efficiency and sensitivity. The most efficient and sensitive separation of DA and CAT in a 16 μm i.d. capillary obtained using an etched detector is shown in Figure 2a. Using the peak widths at half-height, the peak efficiencies for this separation have been calculated to be 80,000 theoretical plates for both DA and CAT. These are larger than the peak efficiencies for the identical separation obtained using the traditional detector (Figure 2b). The efficiencies in this separation are approximately 20,000 and 38,000 theoretical plates for DA and CAT, respectively. The peak efficiencies evaluated with the etched EC detection scheme are comparable to those obtained using improved end-column amperometric detection, where the peak efficiencies ranged from 60,000 to 160,000 theoretical plates for a similar separation in a 2 μm i.d. capillary [8].

Figure 2.

Comparison of the electropherograms obtained using a 50 μM solution of DA and CAT, a 5-s injection at 5 kV, a 25-kV separation potential and a 10 mM TES (pH = 7.2) separation buffer with 5 % 1-propanol in a 16 μm i.d. capillary with (a) an etched and (b) a standard end-column amperometric detector.

Furthermore, the limits of detection are improved by improved etched EC detection. The detection limits for the separation obtained using the etched detector design (Figure 2a) are approximately 40 nM for both DA and CAT. The detection limits achieved for the identical separation using the standard detector (Figure 2b) have been estimated to be 270 nM for both DA and CAT. The etched EC detection method presented here falls between the improved detection end-column amperometric detection, where the detection limit for DA was 400 nM, and the integrated decoupler DA detection limit of 5 nM [7, 8].

The detection volumes for the etched and standard detectors used to obtain the separations shown in Figure 2 have been calculated as 30 and 160 pL, respectively. This significant reduction in detector volume seems to have facilitated improvements in detector performance. Therefore, a detailed investigation of the relationship between the performance of the detector and various aspects of detector design has been carried out in 16 μm i.d. capillaries.

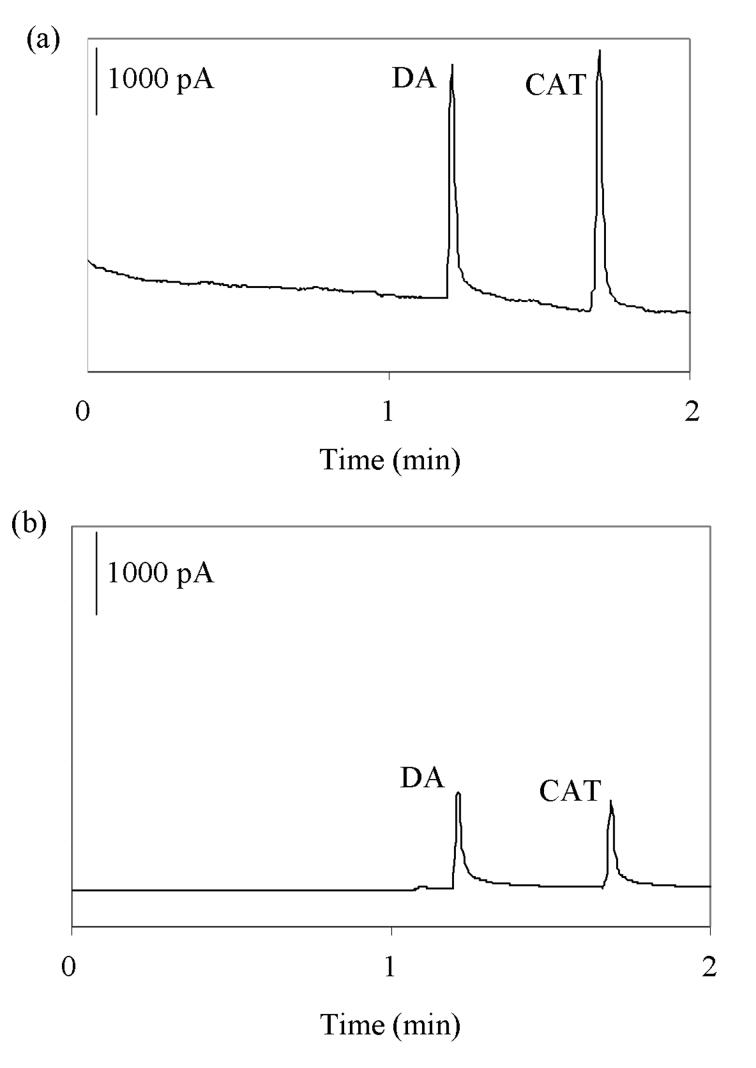

3.2 Effect of Electrode Diameter

Electrophoretic separations have been carried out in a 16 μm i.d. capillary coupled to EC detection with microelectrodes made with carbon fibers of two different diameters utilizing the traditional capillary etch technique (illustrated in Figure 1b). A separation of DA and CAT in a 16 μm i.d. capillary obtained using a 30-μm diameter carbon fiber microelectrode is shown in Figure 3a. An identical separation was performed using a 5-μm carbon fiber (Figure 3b). The corresponding peak efficiencies, peak asymmetry factors, peak areas, signal-to-noise ratios, coulometric efficiencies, and estimated detection limits for CAT are given in Table 1. As the diameter of the carbon fiber increases from 5 μm to 30 μm, the average peak area for CAT increases from 50 to 130. The increase in the diameter of the carbon fiber also creates a smaller dead volume in the detector. The corresponding detection volumes decrease from 160 to 100 pL as the diameter of the carbon fiber is increased from 5 μm to 30 μm (Table 1).

Figure 3.

Comparison of the electropherograms obtained using a 50 μM solution of DA and CAT, a 5-s injection at 5 kV, a 25-kV separation potential and a 10 mM TES (pH = 7.2) separation buffer with 5 % 1-propanol in a 16 μm i.d. capillary with (a) a 30-μm diameter carbon fiber microelectrode and (b) a 5-μm diameter carbon fiber microelectrode.

Table 1.

Relationship between detector performance and microelectrode diameter measured for CAT.

| 5 μm Carbon Fiber Microelectrode | 30 μm Carbon Fiber Microelectrode | |

|---|---|---|

| Detection Volume (pL) | 160 | 100 |

| Peak Asymmetry (a) | 1.04 ± 0.00211 | 1.03 ± 0.00428 |

| Peak Efficiency (N) | 38000 ± 300 | 38000 ± 300 |

| Peak Area (pA*min) | 50 ± 8 | 130 ± 10 |

| S/N Ratio | 400 ± 100 | 250 ± 50 |

| Coulometric Efficiency | 43 ± 8 % | 78 ± 3 % |

| Detection Limits (nM) | 230 ± 50 | 430 ± 80 |

Separations were performed in a 16 μm i.d. capillary with a 5-μm and a 30-μm diameter carbon fiber microelectrode. Detector volumes represent the total volume of the etched portion of the capillary less the volume displaced by the microelectrode. Peak asymmetries, obtained by measuring the front and back of the peak at 10 % of the peak height, are reported as the mean ± the standard error. Peak efficiencies are reported as the mean ± standard error from three separations, calculated using the peak widths at half-height. Peak areas and coulometric efficiencies are reported as the mean ± standard error from three separations. Concentration detection limits are reported as the mean ± standard error from three separations and were estimated using twice the signal-to-noise (S/N) ratio. Sample concentrations and buffer conditions as in Figure 2.

The increase in surface area of the electrode significantly impacts the coulometric efficiency of the amperometric detector. However, the use of a carbon fiber with a larger diameter results in increased noise with this capillary etch design. This result could be due to the increased surface area of exposed electrode and due to interference between the separation potential and the potential of the microelectrode. The increase in noise causes the average signal-to-noise ratio to decrease from 400 to 250 for CAT as the diameter of the carbon fiber increases from 5 μm to 30 μm. The lower average signal-to-noise ratio leads to an increase in the estimated detection limit from 230 to 430 nM for CAT despite the increase in peak area achieved with a larger diameter carbon fiber. The average peak efficiencies for CAT do not significantly change with carbon fiber diameter. Some tailing is observed in these separations, thus the asymmetry of the peaks has been examined. While some analyte molecules may be oxidized at the portion of the electrode outside of the capillary, the combination of spherical diffusion in open solution and high coulometric efficiency in the detection zone, particularly for the 30 μm electrode, should make this negligible. While the data is not shown, similar relationships between detector performance and design have also been observed for DA.

3.3 Employing Etched Electrodes

The use of 30-μm diameter microelectrodes has been continued with the goal of minimizing the electrical noise resulting from interference from the separation potential. The effect of altering the size and shape of the tip of these 30-μm diameter microelectrodes using a flame-etching technique has been investigated. Microelectrodes with tapered tip diameters of 20, 10 and 2.5 μm have been created by positioning the carbon fiber in an acetylene flame at an angle of 45°. While the 10- and 20-μm tips maintain a slightly blunt shape, the 2.5-μm diameter tips are conical. Electrophoretic separations have been carried out in a 16 μm i.d. capillary with the traditional capillary etch coupled to EC detection using each of these three different microelectrodes. The corresponding peak areas, signal-to-noise ratios and estimated detection limits for CAT are shown in Table 2. As the diameter of the tip of the carbon fiber decreases from 20 to 2.5 μm, the average peak areas for CAT do not significantly change. Utilizing the carbon fiber etched to a blunt 10-μm tip, however, yields the most reduced noise and therefore the highest average signal-to-noise ratio, 700, for CAT. This signal-to-noise ratio corresponds to the best average detection limit of 150 nM for CAT. While the data is not shown, similar relationships between detector performance and design have also been observed for DA. The blunt tip might provide the best signal-to-noise ratio and thus detection limits owing to a better fit into to the larger center bore (16-μm) of the etched capillary by the blunt tip (10-μm ) vs. a sharp tip (2.5-μm). Based upon these experiments, the 30-μm diameter etched carbon fiber with a blunt 10-μm tip has been utilized for the remaining experiments.

Table 2.

Relationship between detector performance and the size and shape of the microelectrode tip measured for CAT.

| Conical 2.5-μm tip | Blunt 10-μm tip | Blunt 20-μm tip | |

|---|---|---|---|

| Peak Efficiency (N) | 30000 ± 1000 | 30000 ± 1000 | 38000 ± 800 |

| Peak Area (pA*min) | 120 ± 20 | 110 ± 10 | 130 ± 20 |

| S/N Ratio | 300 ± 50 | 700 ± 100 | 250 ± 90 |

| Detection Limits (nM) | 350 ± 50 | 150 ± 20 | 400 ± 100 |

Separations were performed in a 16 μm i.d. capillary with a 30-μm diameter carbon fiber microelectrode. Microelectrode tips were flame-etched to diameters of 20, 10 and 2.5 μm. Peak efficiencies, peak areas and concentration detection limits are calculated as reported in Table 1. A signal-to-noise ratio of 2/1 was used. Sample concentrations and buffer conditions as in Figure 2.

3.4 Etched Capillary Outlet

The effect of decreasing the length of etch in the capillary outlet also has been investigated. This length of the etch can be controlled by changing the rate of gas flow through the capillary during the etching procedure. Varying the gas flow rate between 100 and 250 psi results in etch lengths between 55 and 175 μm. Electrophoretic separations of DA and CAT have been carried out in 16 μm i.d. capillaries with etch lengths of 175, 88 and 55 μm using a 30-μm diameter carbon fiber microelectrode with a tip diameter of 10 μm. The corresponding detection volumes are also shown in Table 3. As the length of etch in the capillary outlet decreases from 175 μm to 55 μm, these detection volumes decrease from 110 to 30 pL. The average peak efficiencies for DA increase from 19,500 to 75,400 as shown in Table 3. The smaller dead volume leaves less room for analyte dilution to occur and causes an increase in sensitivity.

Table 3.

Relationship between detector performance and length of etch in capillary outlet reported for DA.

| 175-μm etch length | 88-μm etch length | 55-μm etch length | |

|---|---|---|---|

| Detection Volume (pL) | 110 | 50 | 30 |

| Peak Efficiency (N) | 19500 ± 100 | 31300 ± 600 | 75400 ± 400 |

| Peak Area (pA*min) | 30 ± 5 | 50 ± 6 | 60 ± 6 |

Separations were performed in a 16 μm i.d. capillary with etched capillary outlet lengths of 175, 88 and 55 μm. EC detection was performed using a 30 μm diameter carbon fiber microelectrode with a flame-etched 10 μm diameter tip. Detector volumes, peak efficiencies, and peak areas are calculated as reported as in Table 1. Sample concentrations and buffer conditions as in Figure 2.

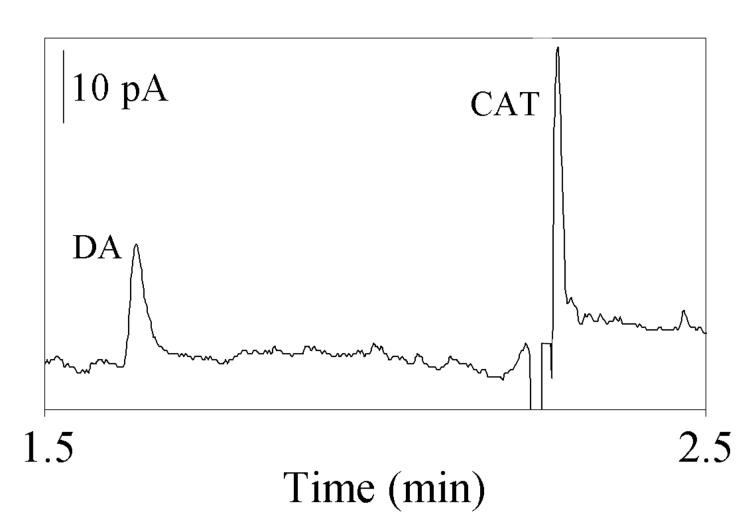

Electrophoretic separations of DA and CAT have also been performed on 13 μm i.d. capillaries with varying etch lengths and a similarly etched microelectrode to further evaluate the linearity of the detector. An example of a 1 μM separation of DA and CAT obtained from a 55-μm outlet etched capillary is shown in Figure 4. As the length of etch in the capillary outlet decreases from 175 μm to 55 μm, an analyses of the average detector coulometric efficiency can yield as much as a two-fold increase in efficiency with the smaller capillary etch. This is consistent with the decrease in dead volume. We have investigated the linearity of detection over concentrations ranging from 500 nM to 20 μM and found the calibration plot to be linear with a correlation coefficient of 0.99. The peak heights and concentration values for DA and CAT have been plotted to further examine the dynamic range of the detector. A line with a slope of 40 pA/μM illustrates the correlation between peak height and detection limit for DA. For CAT, a line with a slope of 30 pA/μM describes the correlation between peak height and detection limit.

Figure 4.

Electropherogram obtained using a 1 μM solution of DA and CAT, a 5-s injection at 5 kV, a 25-kV separation potential and a 10 mM TES (pH = 7.2) separation buffer with 5 % 1-propanol in a 13 μm i.d. capillary with a capillary outlet etch length of 55 μm and a 30-μm diameter carbon fiber microelectrode flame-etched and blunt cut to a 10 μm tip.

Estimated detection limits have been calculated from two times the peak to peak signal to noise at a concentration of 500 nM in all three etch lengths. The estimated limits for DA detection are approximately 60 nM (175 μm etch), 40 nM (88 μm etch), and 50 nM (55 μm etch), while for CAT similar trends between outlet etch length and estimated limits of detection are determined to be 30 nM (175 μm etch), 10 nM (88 μm etch), and 20 nM (55 μm etch). The estimated detection limits for both DA and CAT are an improvement over the traditional standard detector (Figure 2b) as discussed in section 3.1. Decreasing the dead volume has produced a lower limit of detection compared to previous work where average detection limits for DA obtained using improved end-column amperometric detection are approximately 400 nM [8]. The estimated detection limit for DA reported here is slightly higher than work performed utilizing an integrated decoupler for EC detection, where the limit of detection for DA is approximately 5 nM [7]. While less dramatic than the improvements in sensitivity reported for etched EC detection in nanometer i.d. capillaries (zeptomole versus attomole) [9], improvements in sensitivity have been found by coupling etched EC detection to CE in micron i.d. capillaries.

The clear advantage for using capillaries with smaller outlet etch lengths is decreased detector dead volume facilitated by improved alignment between the electrode and the capillary etch. The results reported in Table 3 illustrate the alignment between the outlet etch length of 55 μm and the 30 μm blunt cut electrode yield the best peak efficiency and the largest peak area. Examination of the linearity of detection suggests that in these experiments, the 88 μm etch length provides the best detector alignment and thus the best estimated detection limit for both DA and CAT. Together the results indicate alignments based upon outlet etch length and flame-etched, blunt cut electrode should be evaluated on an individual basis. Generally, however, improvements are observed in peak efficiency, peak height, and detection limits as dead volume is decreased using this capillary-detector arrangement.

4 CONCLUDING REMARKS

The studies presented here evaluate several factors exploited for improved alignment and decreased detector dead volume for optimized amperometric detection in micrometer i.d. capillaries. This enhanced etched EC detection technique minimizes dead volume by allowing for better alignment between the capillary bore and the electrode. An over 80 % reduction in detector volume has been achieved utilizing a 30-μm diameter carbon fiber microelectrode in place of a traditional 5-μm diameter fiber. To better understand this result, a detailed investigation of the relationship between the performance of a detector and various aspects of detector design has been carried out in 16 and 13 μm i.d. capillaries. The effects of varying electrode diameter and shape clearly show a 30-μm diameter carbon fiber flame-etched to 10 μm yields the best signal-to-noise ratio and thus lowest detection limits. Further experimentation shows that the length of the capillary outlet etch is critical to improved detector performance. The overall improvements in detector performance should yield enhanced detection efficiency for volume-limited sample analysis.

ACKNOWLEDGEMENTS

This work was supported by the National Science Foundation and the National Institute of Health. The authors would like to thank Nick Kuklinski for his assistance in etching the carbon fiber electrodes.

ABBREVIATIONS

- CE

capillary electrophoresis

- EC

electrochemical

- i.d.

inner diameter

- DA

dopamine

- CAT

catechol

- TES

N-tris-[hydroxymethyl]methyl-2-aminoethanesulfonic acid

REFERENCES

- 1.Cannon DM, Winograd N, Ewing AG. Annu. Rev. Biophys. Biomolec. Struct. 2000;29:239–263. doi: 10.1146/annurev.biophys.29.1.239. [DOI] [PubMed] [Google Scholar]

- 2.Matysik FM. Electroanalysis. 2000;12:1349–1355. [Google Scholar]

- 3.Swinney K, Bornhop D. Crit. Rev. Anal. Chem. 2000;30:1–30. doi: 10.1021/ac000261r. [DOI] [PubMed] [Google Scholar]

- 4.Timperman AT, Sweedler JV. Analyst. 1996;121:R45–R52. doi: 10.1039/an996210045r. [DOI] [PubMed] [Google Scholar]

- 5.Baldwin RP. Electrophoresis. 2000;21:4017–4028. doi: 10.1002/1522-2683(200012)21:18<4017::AID-ELPS4017>3.0.CO;2-5. [DOI] [PubMed] [Google Scholar]

- 6.Ewing AG, Mesaros JM, Gavin PF. Anal. Chem. 1994;66:A527–A537. doi: 10.1021/ac00081a002. [DOI] [PubMed] [Google Scholar]

- 7.Qian JH, Wu YQ, Yang H, Michael AC. Anal. Chem. 1999;71:4486–4492. doi: 10.1021/ac990338f. [DOI] [PubMed] [Google Scholar]

- 8.Sloss S, Ewing AG. Anal. Chem. 1993;65:577–581. [Google Scholar]

- 9.Woods LA, Ewing AG. Chemphyschem. 2003;4:207–211. doi: 10.1002/cphc.200390032. [DOI] [PubMed] [Google Scholar]

- 10.Wallingford RA, Ewing AG. Anal. Chem. 1987;59:1762–1766. doi: 10.1021/ac00141a005. [DOI] [PubMed] [Google Scholar]

- 11.Lu WZ, Cassidy RM. Anal. Chem. 1994;66:200–204. doi: 10.1021/ac00085a029. [DOI] [PubMed] [Google Scholar]

- 12.Park S, Lunte SM, Lunte CE. Anal. Chem. 1995;67:911–918. [Google Scholar]

- 13.Huang XH, Zare RN, Sloss S, Ewing AG. Anal. Chem. 1991;63:189–192. doi: 10.1021/ac00002a020. [DOI] [PubMed] [Google Scholar]

- 14.Park S, Lunte CE. Anal. Chem. 1995;67:4366–4370. doi: 10.1021/ac00119a026. [DOI] [PubMed] [Google Scholar]