Abstract

Adhesive/abrasive wear in ultra-high molecular weight polyethylene (UHMWPE) has been minimized by radiation cross-linking. Irradiation is typically followed by melting to eliminate residual free radicals that cause oxidative embrittlement. Irradiation and subsequent melting reduce the strength and fatigue resistance of the polymer. We determined the radiation dose dependence and decoupled the effects of post-irradiation melting on the crystallinity, mechanical properties and fatigue crack propagation resistance of room temperature irradiated UHMWPE from those of irradiation alone. Stiffness and yield strength, were largely not affected by increasing radiation dose but were affected by changes in crystallinity, whereas plastic properties, ultimate tensile strength and elongation at break, were dominated at different radiation dose ranges by changes in radiation dose or crystallinity. Fatigue crack propagation resistance was shown to decrease with increase in radiation dose and with decrease in crystalline content. Morphology of fracture surfaces revealed loss of ductility with increase in radiation dose and more detrimental effects on ductility at lower radiation doses after post-irradiation melting.

Keywords: Polyethylene, Arthroplasty, Plasticity, Electron beam, Fatigue, Cross-linking

1. Introduction

Ultra-high molecular weight polyethylene (UHMWPE) has been the material of choice for the load bearing and articulating components in total joint arthroplasty [1]. One major factor that limits the long-term performance of total joints is the bone resorption around the implants (peri-prosthetic osteolysis) secondary to particulate debris [2,3], which is primarily generated by the adhesive/abrasive wear of UHMWPE [4,5]. One method of increasing the wear resistance of UHMWPE is cross-linking with ionizing radiation.

UHMWPE exists in semi-crystalline form where a network of ordered crystalline lamellae is embedded in an amorphous matrix. The lamellae crystallize during consolidation of UHMWPE powder under isostatic pressure. The glass transition temperature of the amorphous UHMWPE is well below room temperature; therefore, the mechanical properties and fatigue strength of UHMWPE depend directly on the content of the crystalline domains.

Irradiation and melting is currently used to reduce adhesive/abrasive wear of UHMWPE components in total joint arthroplasty [6-8] and has largely replaced gamma-sterilization as a post-processing method of choice in hips. The two steps used in the processing of current highly cross-linked UHMWPEs, namely irradiation and melting serve two separate and important purposes. Irradiation creates covalent cross-links, which are known to increase the wear resistance of UHMWPE. Subsequent melting eliminates the residual free radicals generated during irradiation to prevent long-term oxidative damage.

As a result of ionizing radiation, free radicals are formed on polyethylene chains through cleavage of carbon–carbon and carbon–hydrogen bonds. Most of the free radicals formed in the amorphous phase recombine with each other to form cross-links. Another possibility; the cleavage of carbon–carbon bonds causes chain scission and reduces the molecular weight of an irradiated polymer. In UHMWPE, cross-links form at a higher rate than chain scission, effectively resulting in an increase in the network cross-link density [6,9,10].

There is evidence that cross-links are not formed abundantly in the crystalline regions of polyethylene [11,12]. This is presumably because the free radicals formed on the chains in the lamellae do not possess enough mobility to recombine with each other. Another possible reason is that the lattice spacing in the crystallites is larger than the carbon–carbon bond length needed for a cross-link to form, requiring kinking of the chains, which is not energetically favored. The entropy for these free radicals to move out of the crystallites towards the crystalline–amorphous interface is higher than that for movement between the chains. The resultant is an abundance of free radicals, called ‘residual free radicals’, which are trapped for prolonged periods of time in the crystalline lamellae [13-16].

If irradiated UHMWPE is not treated to stabilize these residual-free radicals and allow them to escape from the crystallites and recombine to form cross-links, diffused oxygen reacts with these free radicals, leading to hydroperoxides, the breakdown of which is accompanied by chain scission and the deterioration of mechanical properties [17].

Melting subsequent to irradiation eliminates the crystals and allows the recombination of the trapped free radicals to form cross-links. During re-crystallization, the ability of the material to form lamellae is inhibited because the cross-links hinder chain mobility. The resulting decreased crystallinity adversely affects the mechanical properties and fatigue strength [18], limiting the use of this material in high-stress applications such as posterior-stabilized knees.

Others have studied the effect of cross-linking on the mechanical properties and fatigue behavior of UHMWPE. They showed that radiation cross-linking at 100 and 150 kGy significantly reduced the fatigue strength of UHMWPE, which was reduced by another 20% due to subsequent melting at 100 kGy [19,20].

The aims of this study are to investigate the separate effects of irradiation and subsequent melting on the mechanical properties and fatigue resistance of UHMWPE as a function of radiation dose and to examine the responsible mechanisms. A better understanding of the effects of radiation and subsequent melting and underlying mechanisms will form a strong foundation in developing the next generation highly cross-linked UHMWPEs with higher strength and higher fatigue resistance than those that are in clinical use today.

2. Materials and methods

2.1. Sample preparation

Consolidated GUR 1050 UHMWPE blocks (Perplas Ltd, Lancashire, UK) were machined (1 cm thick) and irradiated to 25, 50, 75 and 100 kGy in air at room temperature by using a 2.5 MeV Van-de-Graff generator at 12.5 kGy per pass (High Voltage Research Laboratory, Massachusetts Institute of Technology, Cambridge, MA). Compact tension (CT) sample shown in Fig. 1 (ASTM E-647 A1) and 3.2 mm-thick sections (for tensile testing) were machined from these irradiated blocks and stored in nitrogen until they were tested. These samples were labeled CI-25, CI-50, CI-75 and CI-100 to designate that they had been cold irradiated (at room temperature) with their respective radiation dose. An unirradiated control set was machined out of virgin GUR1050 UHMWPE and is referred to as CI-0.

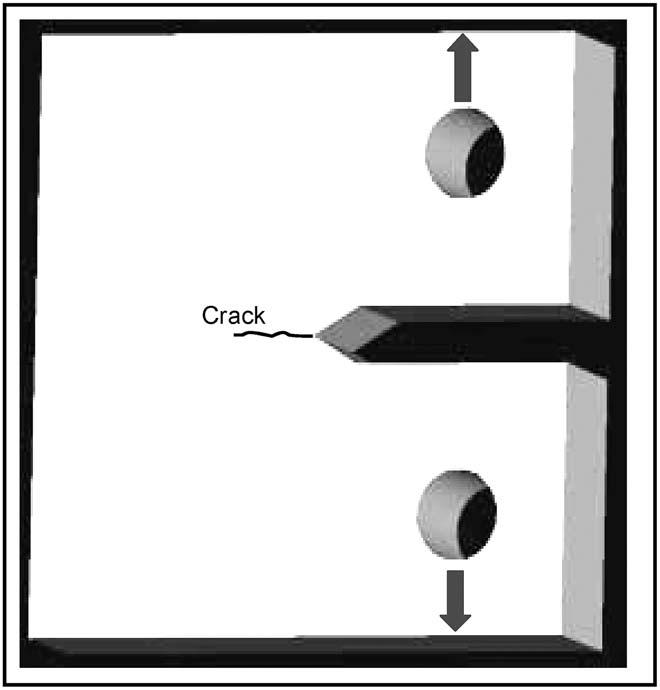

Fig. 1.

3D model of a compact tension (CT) specimen as per ASTM E647 is shown here. The points of application of force and resultant propagation of fatigue cracks are also shown.

Some of the irradiated 1 cm-thick blocks were heated to 170 °C until they melted completely and were held in the melt for at least 2 h and cooled down to room temperature at a cooling rate of approximately 0.5 °C/min. CT samples and 3.2 mm-thick sections for tensile testing were machined from these irradiated blocks. These samples were labeled CISM-25, CISM-50, CISM-75 and CISM-100 to designate that they had been cold irradiated with their respective radiation dose and subsequently melted. An unirradiated control set was prepared by melting a virgin GUR1050 UHMWPE block in the same manner. This control is referred to as CISM-0.

2.2. Determination of percent crystallinity by differential scanning calorimetry (DSC)

The DSC specimens were weighed with a Sartorius CP 225D balance to a resolution of 0.01 mg and placed in aluminum sample pans. The pan was crimped with an aluminum cover and placed in a Q-1000 DSC (TA Instruments, Newark, DE). The sample and the reference were then heated at a heating rate of 10 °C/min from −20 to 180 °C, cooled to −20 °C at −10 °C/min and subjected to another heating cycle from −20 to 180 °C at 10 °C/min. Heat flow as a function of time and temperature was recorded and the cycles are referred to as first heat, first cool and second heat, respectively.

Crystallinity of the cold irradiated and cold irradiated and subsequently melted UHMWPEs was determined by integrating the enthalpy peak from 20 to 160 °C, and normalizing it with the enthalpy of melting of 100% crystalline polyethylene, 291 J/g.

2.3. Tensile testing

Dogbone specimens (n = 5 each) were stamped out from CI and CISM UHMWPE in accordance with ASTM D638, standard test method for tensile properties of plastics. These samples were then tested in accordance with ASTM D-638 using a MTS II machine (Eden Prarie, MN) at a crosshead speed of 10 mm/min. The yield strength (YS) and ultimate tensile strength (UTS) were calculated. In addition, the true elongation at break (EAB) was determined using a video extensometer. The stiffness values reported were calculated from the engineering stress–strain curve by measuring the slope of the secant from 0% strain to 2% strain. The engineering strain was calculated by using the crosshead displacement and the engineering stress by normalizing the load with the original cross-sectional area. Therefore, we could not measure the absolute Young's modulus of the test samples. We rather report a relative stiffness value.

2.4. Fatigue crack propagation testing

Fatigue crack propagation testing was done following ASTM E-647 CT specimen were pre-cracked at the notch using a razor blade. Testing was conducted at a sinusoidal load cycle frequency of 5 Hz and a stress ratio of 0.1 in tension. Crack length was monitored optically every 20,000 cycles. The average of the crack length on both sides of the CT specimen was used as the representative crack length for the computation of crack growth rates.

Stress intensity factor ranges at crack inception (ΔKi) were reported at a threshold crack growth rate of 10−6mm/cycle. All testing was done in an aqueous bath at 40 °C to simulate the physiologic temperature of the joint. At least n = 3 specimens were tested for each material group.

2.5. Fracture surface analysis with scanning electron microscopy

One CT specimen was tested for each irradiation dose until complete failure. The fracture surface was gold-coated to a thickness of 100–250Å by a sputter coater (BOC Edwards sputter coater S150B, Wilmington, MA). Electron microscopy images were obtained by using an environmental scanning electron microscope equipped with a field emission gun (FEI/ Phillips XL30, Hillsboro, OR).

In the following studies, where , statistical analysis was performed using a Student's t-test for two-tailed distributions with unequal variance. The relationship between the stiffness and crystallinity is reported with a Spearman correlation.

3. Results

The crystallinity of CI UHMWPE increased slightly compared to that of CI-0 UHMWPE, but there was no significant difference between the crystallinity of UHMWPE irradiated at different radiation doses (p>0:1). There was not a significant correlation between the stiffness and crystallinity of these test samples with an r2- value of 0.01.

The crystallinity of CISM UHMWPE was significantly less than that of CI UHMWPE at all irradiation doses from 25 to 100 kGy (p<0:005, Table 1). On average 13% of the crystallinity of the irradiated UHMWPE was lost due to post-irradiation melting.

Table 1.

Crystalline content of cold irradiated and cold irradiated and subsequently melted UHMWPE as a function of radiation dose

| Dose (kGy) | Crystallinity (%) of cold irradiated (CI) | Crystallinity (%) of cold irradiated and subsequently melted (CISM) |

|---|---|---|

| 0 | 63±2 | 63±1 |

| 25 | 67±1 | 58±2 |

| 50 | 66±1 | 59±1 |

| 75 | 66±2 | 59±0 |

| 100 | 69±1 | 58±1 |

The stiffness of irradiated UHMWPE increased compared to that of unirradiated UHMWPE (p<0:01) but did not change significantly as a function of radiation dose (p>0:05, Table 2). The UTS of CI-25 did not significantly change compared to that of CI-0 UHMWPE (p = 0:30). The UTS of CI samples decreased as a function of increasing radiation dose from 25 to 75 kGy (p<0:005). The difference in the UTS of CI at 75 and 100 kGy was not significant (p = 0:68). The YS did not significantly change as a function of radiation dose (p>0:05). The EAB did not significantly change at 25 kGy compared to that of unirradiated UHMWPE (p = 0:12) but decreased gradually with increasing radiation dose.

Table 2.

Mechanical properties of cold irradiated and cold irradiated and subsequently melted UHMWPE

| Irradiation dose (kGy) | Stiffness, E (MPa) |

UTS (MPa) |

YS (MPa) |

EAB (%) |

||||

|---|---|---|---|---|---|---|---|---|

| CI | CISM | CI | CISM | CI | CISM | CI | CISM | |

| 0 | 353±5 | 311±12 | 50±6 | 51±3 | 23±0 | 21±1 | 481±40 | 484±29 |

| 25 | 324±15 | 243±17 | 53±3 | 31±3 | 23±1 | 17±2 | 428±47 | 336±24 |

| 50 | 311±19 | 256±4 | 40±2 | 34±3 | 21±2 | 20±1 | 300±11 | 336±19 |

| 75 | 330±18 | 280±6 | 33±3 | 29±2 | 20±2 | 19±1 | 285±23 | 266±6 |

| 100 | 341±10 | 235±6 | 33±1 | 28±2 | 21±2 | 17±0 | 214±7 | 233±16 |

The stiffness of CISM UHMWPE was significantly lower than that of CI UHMWPE at all radiation doses (p<0.005, Table 2). There was not a significant correlation between the stiffness and crystallinity of these CISM test samples with an r2 value of 0.14. The ultimate tensile strength (UTS) of CISM UHMWPE was significantly lower than that of CI UHMWPE at all radiation doses (, Table 2). The YS of CISM was significantly lower than that of CI at all radiation doses except at 50 and 75 kGy (p<0.005). The EAB of CISM was significantly lower than that of CI at 25 (p<0.05) and was not significantly different at 75 and 100 kGy (p = 0.15 and 0.06, respectively).

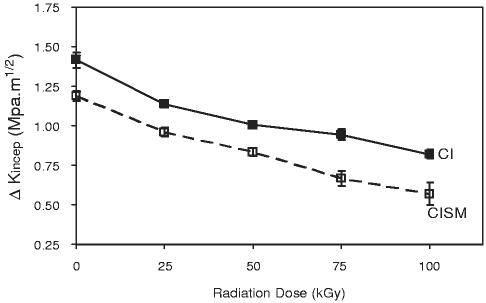

Stress factor ranges at fatigue crack inception, i.e. fatigue crack propagation resistance, were higher for CI UHMWPE than those for CISM UHMWPE at all radiation doses (p<0.05, Fig. 2). The decrease in the value of the fatigue propagation resistance due to post-irradiation melting ranged between 14% and 30%. The fatigue crack propagation resistance of unirradiated UHMWPE was insignificantly higher than that of unirradiated but melted UHMWPE (p = 0.05).

Fig. 2.

Stress factor range at crack inception as a measure of fatigue crack propagation resistance of cold irradiated (CI) and cold irradiated and subsequently melted (CISM) UHMWPE as a function of radiation dose.

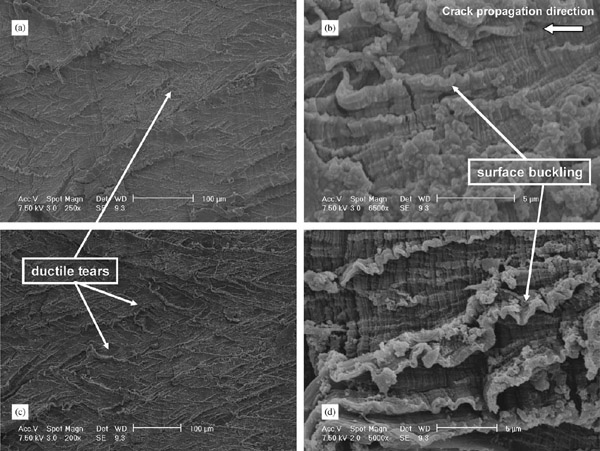

Fracture surfaces of CI-0 and CISM-0 (Fig. 3) showed pronounced striations perpendicular to the fatigue crack propagation direction, ductile tears at 45° and a large amount of surface buckling in both of these features.

Fig. 3.

Scanning electron microscopy images of the failed fracture surfaces of fatigue crack propagation specimens of un-irradiated non-melted and melted UHMWPE.

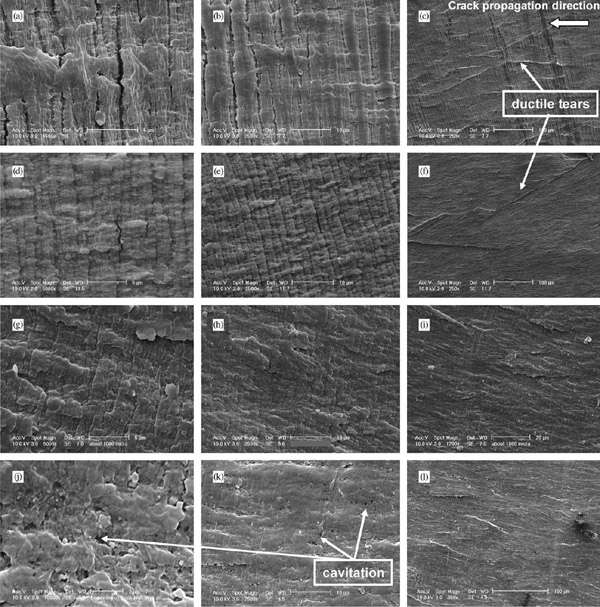

Based on a qualitative analysis for CI UHMWPE, increasing radiation doses decreased the depth of the vertical striations perpendicular to the propagation direction (Fig. 4). This was inferred from the fact that similar size features were easier to distinguish at lower magnifications for CI UHMWPE. These striations were observed only at high magnification at 100 kGy. The distance between striations were about 2–4 μm in CI-0 and CISM-0. As radiation dose increased, ductile tears as well as surface buckling became less prominent (Figs. 4 and 5). The decrease in the depth of the perpendicular lines signaled decreased ductility and the distance between these fatigue lines decreased to 2 μm at 25 kGy, 1 μm at 50 kGy; above 50 kGy, it was difficult to observe continuous striations The frequency and the length of the tears at 45° decreased with increasing radiation dose with CI test samples. A small amount of surface buckling was observed only at 25 kGy; at all doses higher than 25 kGy, no surface buckling was present. In addition to these three prominent features on the fracture surfaces of the CI test samples, cavitation was observed at 100 kGy (Fig. 4).

Fig. 4.

Scanning electron microscopy images of the failed fracture surfaces of fatigue crack propagation specimens of cold irradiated (CI) UHMWPE at 25(a, b, c), 50 (d, e, f), 75 (g, h, i), and 100 kGy (j, k, l).

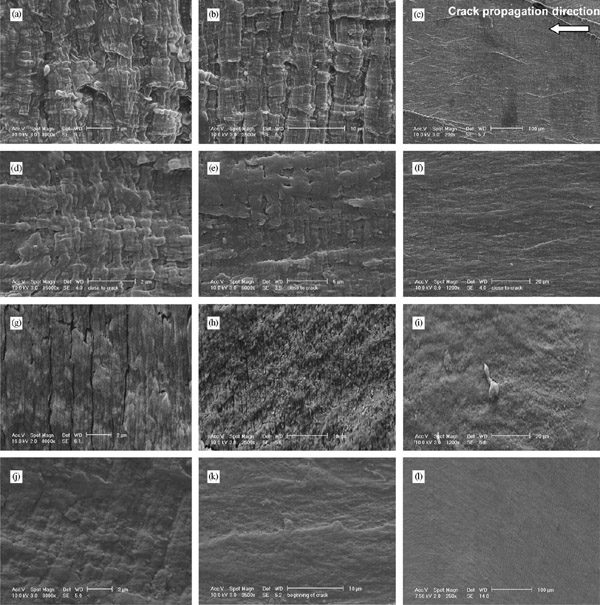

Fig. 5.

Scanning electron microscopy images of the failed fracture surfaces of fatigue crack propagation specimens of cold irradiated and subsequently melted (CISM) UHMWPE at 25 (a, b, c), 50 (d, e, f), 75 (g, h, i), and 100 kGy (j, k, l).

For CISM UHMWPE, qualitative analysis showed that increasing radiation doses also decreased the depth of the vertical striations perpendicular to the propagation direction (Fig. 5). The frequency and the length of the tear lines at 45° decreased with increasing radiation dose in the CISM samples. Some surface buckling was observed at 25 and 50 kGy (Fig. 5). No cavitations were observed in the CISM samples at 100 kGy (Fig. 5).

4. Discussion

The primary aims of this study were to investigate the radiation dose dependence of mechanical properties and fatigue crack propagation resistance of irradiated UHMWPE and to understand the underlying mechanisms responsible for the adverse effects of irradiation and post-irradiation melting on these properties.

Crystallinity increased as a result of irradiation but remained unchanged at different radiation dose levels (Table 1). One possible explanation of this is the rearranging and crystallization of smaller chains formed by chain scission. Another explanation could be the potential increase in the surface energy of the crystals resulting from the decrease in the number of available low-energy conformations to tie-molecules between crystallites and the formation of ‘taut-tie molecules’. The increase in the surface energy of the crystals, thus achieved, could increase the crystallinity as measured by DSC. The former scheme, i.e. recrystallization, would lead to an increase in the stiffness; however, there was no correlation between stiffness and crystallinity of the irradiated test samples. Therefore, it is likely that there was no real increase in the crystallinity upon irradiation; but the apparent crystallinity increased due to the increase in the surface energy of the crystals secondary to the formation of the taut-tie molecules.

The decrease in the crystallinity of the irradiated test samples upon melting (Table 1) may be explained by the relaxation of the taut-tie molecules, reducing the surface energy of the crystals and the decreased mobility of the cross-linked chains, slowing down the crystallization kinetics. The cross-linked chains lack the mobility to arrange into the lowest energy conformations provided by the crystals and also the effective distance between cross-links is smaller, reducing the number of chain segments available for crystallization. The decrease in the yield strength upon melting of the irradiated test samples may also be due to these two mechanisms.

The elongation-at-break was sensitive to changes in radiation dose until 50 kGy but was largely not affected by the crystalline content. Cross-linking is known to reduce the large-strain deformation ability of UHMWPE limiting the ultimate chain stretch [21]. Likely ultimate chain stretch reached a saturation level with increasing cross-link density.

The lack of change in the ultimate tensile strength of CISM UHMWPE with increasing radiation dose for all doses above 25 kGy in contrast with CI UHMWPE was presumably the direct effect of the loss of crystalline content on large-strain plastic deformation. The effect of increasing radiation dose on UHMWPE appeared to dominate over the loss of crystalline content above 50 kGy because there was no observable difference in ultimate tensile strength between CI and CISM UHMWPE above this dose.

Both increase in radiation dose and decrease in crystalline content had a significant detrimental effect on fatigue crack propagation resistance (Fig. 2). CISM UHMWPE consistently showed lower fatigue resistance than CI UHMWPE. It is well documented that cross-link density increases with radiation dose and molecular weight between cross-links decreases correspondingly in UHMWPE [6,10].

To qualitatively analyze the differences between the morphology of CI and that of CISM UHMWPE, surfaces fractured through fatigue were used. There were several features that are associated with ductility (Figs. 3-5): (1) Criss–cross ductile tears are situated at approximately 45° to each other and were previously observed in UHMWPE [22,23]. (2) Surface buckling and striations are features associated with high ductility. (3) Cavitation is the formation of voids in front of a propagating crack front. (4) Particle breakup, which might be an indication of the brittle nature of the fracture.

The presence of criss-cross ductile tears on the fracture surfaces of CI-0 and CISM-0 UHMWPE (Figs. 4 and 5) is attributed to the ability of these materials to undergo large-strain plastic deformation an indication of the material's ability to dissipate energy from the crack tip and resist crack propagation. The surface buckling observed along these tears was likely a result of the surface instability caused by the localized large-strain plastic defomation. Since the substrate material is not deformed and the surface is deformed to large strain levels, buckling is the only way of accumulating these surface changes. The decreased occurance or absence of surface buckling at higher radiation doses was likely related to the reduced ductility of the polymer imposed by the increasing density of cross-links.

Cavitation, the formation of voids ahead of a traveling crack tip, is another energy absorbing mechanism, likely contributing to a slower rate of crack growth. Cavitation was observed at 100 kGy irradiation in CI UHMWPE (Fig. 4), where breakup was observed in the direction of crack growth between striations. After post-irradiation melting, the ductility threshold for particle formation might have been surpassed at a lower radiation dose, which may explain the absence of cavitation at 100 kGy with CISM-100 (Fig. 5). These were direct results of the decrease in stress factor range for crack initiation and the increase in fatigue crack growth rate at similar stresses.

Overall, there were very significant differences between irradiated and irradiated and subsequently melted UHMWPE. The plastic deformation ability of irradiated UHMWPE was decreased with increasing radiation until 75 kGy, after which it did not change appreciably; however any differences between UHMWPE irradiated to different radiation doses were lost after post-irradiation melting presumably due to the overwhelming effect of loss of crystalline content. Post-irradiation melting resulted in a softer cross-linked UHMWPE with less strength. Significant loss of ductility was noted on fatigue fracture surfaces, which was further exacerbated by post-irradiation melting.

5. Conclusion

We identified the effects of post-irradiation melting on radiation cross-linked UHMWPE as well as determining the effects of increasing radiation dose on irradiated and irradiated and melted UHMWPE. Methods to prevent the loss of crystalline content and loss of ductility resulting from post-irradiation melting in first-generation highly cross-linked UHMWPEs are used in second generation highly cross-linked UHMWPEs and could decrease the current limitations of highly cross-linked UHMWPEs in applications with high stresses. The second generation highly cross-linked UHMWPEs are either using deformation after irradiation to eliminate residual free radicals [24] or infusing irradiated UHMWPE with vitamin-E to stabilize the free radicals [19]. Both of these methods have been shown to maintain the crystallinity of the irradiated UHMWPE and hence do not compromise the mechanical and fatigue properties [19,24].

Acknowledgement

This work was funded by National Institutes of Health Grant R01 AR051142-01.

Footnotes

This study was funded by NIH R01 AR051142-01.

References

- 1.Muratoglu OK, Kurtz S. Alternate bearing surfaces in hip replacement. In: Sinha R, editor. Hip replacement. Current trends and controversies. New York: 2002. [Google Scholar]

- 2.Willert H, Bertram H, Buchhorn G. Osteolysis in alloarthroplasty of the hip. The role of bone cement fragmentation. Clin Orthop. 1990;258:108–21. [PubMed] [Google Scholar]

- 3.Willert HG, Bertram H, Buchhorn GH. Osteolysis in alloarthroplasty of the hip: the role of ultra-high molecular weight polyethylene wear particles. Clin Orthop. 1990;258:95–107. [PubMed] [Google Scholar]

- 4.Kurtz SM, Rimnac CM, Pruitt L, Jewett CW, Goldberg V, Edidin AA. The relationship between the clinical performance and large deformation mechanical behavior of retrieved UHMWPE tibial inserts. Biomaterials. 2000;21:283–91. doi: 10.1016/s0142-9612(99)00178-7. [DOI] [PubMed] [Google Scholar]

- 5.Edidin AA, Pruitt L, Jewett CW, Crane DJ, Roberts D, Kurtz SM. Plasticity-induced damage layer is a precursor to wear in radiation-cross-linked UHMWPE acetabular components for total hip replacement. Ultra-high-molecular-weight polyethylene. J. Arthroplasty. 1999;14(5):616–27. doi: 10.1016/s0883-5403(99)90086-4. [DOI] [PubMed] [Google Scholar]

- 6.Muratoglu OK, Bragdon CR, O'Connor DO, Jasty M, Harris WH, Gul R, et al. Unified wear model for highly crosslinked ultra-high molecular weight polyethylenes (UHMWPE) Biomaterials. 1999;20(16):1463–70. doi: 10.1016/s0142-9612(99)00039-3. [DOI] [PubMed] [Google Scholar]

- 7.Muratoglu OK, Bragdon CR, O'Connor DO, Jasty M, Harris WH. 1999 HAP Paul Award. A novel method of crosslinking UHMWPE to improve wear, reduce oxidation and retain mechanical properties. J Arthroplasty. 2001;16(2):149–60. doi: 10.1054/arth.2001.20540. [DOI] [PubMed] [Google Scholar]

- 8.McKellop H, Shen F-W, Lu B, Campbell P, Salovey R. Development of an extremely wear resistant ultra-high molecular weight polyethylene for total hip replacements. J Orthop Res. 1999;17(2):157–67. doi: 10.1002/jor.1100170203. [DOI] [PubMed] [Google Scholar]

- 9.Al-Malaika S. Perspectives in stabilisation of polyolefins. Adv Polym Sci. 2004;169:121–50. [Google Scholar]

- 10.Andjelic S, Richard RE. Crystallization behavior or ultrahigh molecular weight polyethylene as a function of in vacuo gamma-irradiation. Macromolecules. 2001;34(4):896–906. [Google Scholar]

- 11.Luo Y, Wang G, Lu Y, Chen N, Jiang B. Location of radiation-induced cross-links and damage in melt-crystallized polyethylene. Radiat Phys Chem. 1985;25(1–3):359–65. [Google Scholar]

- 12.Yeh GSY, Chen CJ, Boose DC. Radiation-induced crosslinking: effect on structure of polyethylene. Colloid Polym Sci. 1985;263:109–15. [Google Scholar]

- 13.Thomas DE, Jahan MS, Trieu HH, Haggard WO, Conta RL, Parr JE. A study of free radicals in irradiated/aged UHMWPE materials. Wright Medical. 1996 [Google Scholar]

- 14.Jahan MS, Thomas DE, Trieu HH, Haggard WO, Conta RL, Parr JE. Investigation of free radicals in shelf-aged polyethylene tibial components. Wright Medical. 1996 [Google Scholar]

- 15.Jahan MS, King MC, Haggard WO, Sevo KL, Parr JE. A study of long-lived free radicals in gamma-irradiated medical grade polyethlene. Radiat Phys Chem. 2001;62:141–4. [Google Scholar]

- 16.Bhateja S, Duerst R, Aus E, Andrews E. Free radicals trapped in polyethylene crystals. J Macromol Sci-Phys. 1995;B34(3):263–72. [Google Scholar]

- 17.Costa L, Luda MP, Trossarelli L, Brach del Prever EM, Crova M, Gallinaro P. In vivo UHMWPE biodegradation of retrieved prosthesis. Biomaterials. 1998;19:1371–85. doi: 10.1016/s0142-9612(98)00013-1. [DOI] [PubMed] [Google Scholar]

- 18.Pruitt LA. Deformation, yielding, fracture and fatigue behavior of conventional and highly cross-linked ultra high molecular weight polyethylene. Biomaterials. 2005;2615(8) doi: 10.1016/j.biomaterials.2004.03.022. [DOI] [PubMed] [Google Scholar]

- 19.Oral E, Wannomae KK, Hawkins NE, Harris WH, Muratoglu OK. A-tocopherol doped irradiated UHMWPE for high fatigue resistance and low wear. Biomaterials. 2004;25(24):5515–22. doi: 10.1016/j.biomaterials.2003.12.048. [DOI] [PubMed] [Google Scholar]

- 20.Puertolas J, Urries I, Medel F, Madre M, Leiva K, Gomez-Barrena E, et al. Fatigue behavior of electron-beam irradiated UHMWPE. Transactions of the 50th annual meeting of the orthopaedic research society. 2004:211. [Google Scholar]

- 21.Kurtz SM, Pruitt LA, Jewett CW, Foulds JR, Edidin AA. Radiation and chemical crosslinking promote strain hardening behavior and molecular alignment in ultra high molecular weight polyethylene during multi-axial loading conditions. Biomaterials. 1999;20(16):1449–62. doi: 10.1016/s0142-9612(99)00038-1. [DOI] [PubMed] [Google Scholar]

- 22.Baker DA, Bellare A, Pruitt L. The effect of degree of crosslinking on the fatigue crack initiation and propagation resistance of orthopedic-grade polyethylene. J Biomed Mater Res. 2003;66A:146–54. doi: 10.1002/jbm.a.10606. [DOI] [PubMed] [Google Scholar]

- 23.Baker DA, Hastings RS, Pruitt L. Compression and tension fatigue resistance of medical grade ultra high molecular weight polyethylene: the effect of morphology, sterilization, aging and temperature. Polymer. 2000;41(2):795–808. [Google Scholar]

- 24.Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474. [Google Scholar]