Abstract

Adhesive/abrasive wear in ultra-high molecular weight polyethylene (UHMWPE) has been minimized by radiation cross-linking. Irradiation is followed by melting to eliminate residual free radicals and avoid long-term oxidative embrittlement. However, post-irradiation melting reduces the crystallinity of the polymer and hence its strength and fatigue resistance. We proposed an alternative to post-irradiation melting to be the incorporation of the antioxidant α-tocopherol into UHMWPE prior to consolidation. α-Tocopherol is known to react with oxygen and oxidized lipids, stabilizing them against further oxidative degradation reactions. We blended GUR 1050 UHMWPE resin powder with α-tocopherol at 0.1 and 0.3 wt% and consolidated these blends. Then we gamma-irradiated these blends to 100-kGy. We characterized the effect of α-tocopherol on the cross-linking efficiency, oxidative stability, wear behavior and mechanical properties of the blends. (I) The cross-link density of virgin, 0.1 and 0.3 wt% α-tocopherol blended, 100-kGy irradiated UHMWPEs were 175±19, 146±4 and 93±4 mol/m3, respectively. (II) Maximum oxidation indices for 100-kGy irradiated UHMWPE previously blended with 0, 0.1 and 0.3 wt% α-tocopherol that were subjected to accelerated aging at 80 °C in air for 5 weeks were 3.32, 0.09, and 0.05, respectively. (III) The pin-on-disc wear rates of 100-kGy irradiated UHMWPE previously blended with 0.1 and 0.3 wt% α-tocopherol that were subjected to accelerated aging at 80 °C in air for 5 weeks were 2.10±0.17 and 5.01±0.76 mg/million cycles, respectively. (IV) Both accelerated aged, α-tocopherol-blended 100-kGy irradiated UHMWPEs showed higher ultimate tensile strength, higher yield strength, and lower elastic modulus when compared to 100-kGy irradiated, virgin UHMWPE. These results showed that α-tocopherol-blended 100-kGy irradiated UHMWPEs were not cross-linked to the same extent as the 100-kGy irradiated, virgin UHMWPE.

Keywords: Antioxidant, Polyethylene, Wear mechanism, Lipid, Gamma-irradiation, Hip replacement prosthesis

1. Introduction

Adhesive/abrasive wear of ultra-high molecular weight polyethylene (UHMWPE) is the primary source of debris leading to peri-prosthetic osteolysis, compromising the long-term performance of total joint implants [1]. Wear is decreased by radiation cross-linking and melting of UHMWPE [2-5]. Cross-links are imparted between the polyethylene chains by the recombination of free radicals formed by high-dose ionizing radiation. The carbon free radicals formed during radiation (‘primary free radicals’) in the amorphous region of the semi-crystalline UHMWPE possess enough mobility to recombine to form cross-links in the polymer.

The free radicals formed in the crystalline phases of the polymer network, however, lack the mobility to recombine and hence are trapped for prolonged periods of time in the lamellae. These ‘residual free radicals’ can react with diffused oxygen to form peroxy radicals. These peroxy radicals attack other polyethylene chains, which leads to a second generation of free radicals and hence furthers the reactions with oxygen. This cascade of events results in the oxidative embrittlement and reduction in the mechanical properties of UHMWPE.

Post-irradiation melting is used effectively to remove the residual free radicals effectively. Melting releases the trapped free-radicals from the crystalline regions and allows them to recombine in the form of cross-links. Therefore, the irradiated and melted polymer is protected against reactions with diffused oxygen and oxidative embrittlement.

Cross-linking by irradiation reduces the fatigue strength of UHMWPE. Post-irradiation melting leads to a decrease in the crystallinity of the polymer; further decreasing the fatigue strength of irradiated UHMWPE [6]. Fatigue failure of UHMWPE components has been a rare occurrence mostly due to severe oxidation [7,8]. Nevertheless, fatigue damage, especially in components under high cyclic stresses, is a major problem after wear, limiting the longevity of joint implants. Hence, there is a need to find alternative methods of processing UHMWPE to combine decreased wear with higher crystallinity and high fatigue resistance.

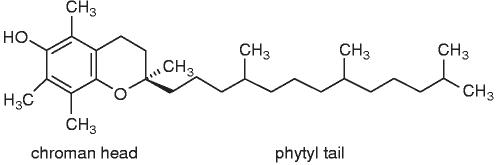

Introducing an antioxidant such as α-tocopherol into UHMWPE is an alternative to post-irradiation melting to render it stable against oxidation without further sacrificing its mechanical strength. α-Tocopherol is biocompatible and is lipophilic owing to its phtyl tail, easily blending with UHMWPE. Furthermore, it is an antioxidant, which can serve the purpose of eliminating long-term adverse effects of post-irradiation oxidation. α-Tocopherol spares free radicals on lipid molecules [9,10] from further reactions with oxygen and each other by the donation of the phenolic hydrogen on its chroman ring (Fig. 1).

Fig. 1.

α-Tocopherol. The chroman head is responsible for abstracting free radicals and stabilizing them within the structure. The long lipophilic chain termed the ‘phytyl tail’ provides compatibility with UHMWPE.

We have diffused α-tocopherol into UHMWPE after high-dose irradiation and shown that α-tocopherol protected high-dose irradiated UHMWPE against oxidation during in vitro accelerated aging and did not detrimentally affect its wear behavior [6]. These high-dose irradiated and α-tocopherol-doped UHMWPEs showed wear resistance comparable to irradiated and subsequently melted UHMWPE. As described above, α-tocopherol incorporated irradiated UHMWPE is sought as an alternative to irradiated and subsequently melted UHMWPE because of the possibility to avoid the decrease in mechanical properties caused by post-irradiation melting. In our previous study, we showed that 100-kGy irradiated, α-tocopherol diffused UHMWPE had 22% increase in fatigue propagation resistance over irradiated/non-melted UHMWPE and 58% increase over irradiated/melted UHMWPE [6].

An alternate way of introducing α-tocopherol into UHMWPE is blending α-tocopherol with UHMWPE resin powder and consolidating the mixture. The blend is then irradiated for cross-linking, machined into components, and packaged. Mori et al. [11] have shown that blending α-tocopherol with UHMWPE and subjecting this blend to 25-kGy gamma-irradiation for sterilization resulted in a more oxidation resistant material than conventional gamma-sterilized UHMWPE. Also, Tomita et al. [12] have shown that α-tocopherol-blended, gamma-sterilized UHMWPE had increased delamination resistance, which they attributed to a decreased hardness in the grain boundaries of the resin.

We hypothesized that α-tocopherol, blended with UHMWPE prior to irradiation, would react with the primary free radicals formed during irradiation; decreasing the cross-linking efficiency of UHMWPE. Parth et al. [13] showed that the gel content of samples taken from α-tocopherol-containing and 10, 17, 22 and 100-kGy irradiated (by e-beam) UHMWPE decreased as the α-tocopherol content increased from 0.1 to 0.8 wt/wt%. A hypothesized decrease in cross-linking density may lead to increase in wear of α-tocopherol-blended and irradiated UHMWPE compared to a virgin, irradiated UHMWPE.

It is also not known if high-dose irradiated and cross-linked UHMWPE has oxidative stability owing to blended α-tocopherol and if this stability is maintained after oxidative aging. We hypothesized that the efficiency of α-tocopherol will be reduced because it will absorb some of the radiation dose intended to cross-link UHMWPE.

To test our hypotheses, we (i) measured the cross-link density in α-tocopherol-blended and high-dose irradiated UHMWPE, and (ii) determined the oxidation and wear resistance and mechanical properties of α-tocopherol-blended high-dose irradiated UHMWPE.

2. Materials and methods

In the following studies, swelling in hot xylene was used to determine cross-link density of blended and virgin UHMWPEs. Accelerated aging and infrared spectroscopy were used to determine the effect of blended α-tocopherol on the oxidative stability of polyethylene. Bidirectional pinon-disc (POD) wear testing was performed to measure the wear rate, thereby, determine the wear resistance. Finally, tensile testing was performed to determine mechanical properties.

2.1. Sample preparation

GUR 1050 powder (Ticona, Houston, TX) was blended with α-tocopherol (Fisher Scientific, Houston, TX) and consolidated (Perplas Technologies, Lancashire, UK). Consolidated GUR 1050 UHMWPE powder was used as virgin material. The concentrations at which α-tocopherol was incorporated in the UHMWPE were 0.1 and 0.3 wt/wt%. The blends were first prepared in 5 wt% for consistency, after which they were diluted down to their respective concentrations by adding UHMWPE powder. These molded blocks were packaged under vacuum and γ-irradiated to 100 kGy (Steris Isomedix, Northborough, MA).

Out of these blocks, cylindrical pins (9 mm diameter, 13 mm length) were machined for oxidative stability experiments and POD wear testing and 3.2 mm thick sections were machined for tensile testing. Dogbone specimens (ASTM D-638) and swelling samples used in measuring cross-link density (approx. 3×3 mm) were cut out from these 3.2 mm thick sections.

2.2. Determination of α-tocopherol content

The presence of α-tocopherol was ascertained by calculating an α-tocopherol index for each sample. A thin section (100–200 μm) was microtomed using a LKB Sledge Microtome (Sweden). A BioRad UMA 500 infrared microscope (Natick, MA) was used to measure the α-tocopherol content. The infrared spectra were analyzed to calculate an ‘α-tocopherol index’, as the ratio of the areas under the α-tocopherol absorbance at 1276 cm−1 and the polyethylene skeletal absorbance at 1895 cm−1. The limits of integration for the α-tocopherol absorbance were adjusted to 1245 and 1275 cm−1 to achieve a more sensitive measurement. Therefore, the index reported here is different than our previously published results [6].

2.3. Determination of cross-linking density

Cross-link density measurements were performed with a thermal mechanical analyzer (TMA) (DMA 7e, Perkin Elmer, Wellesley, MA). Thin sections were machined out of virgin, 0.1 and 0.3 wt% α-tocopherol-blended and 100-kGy irradiated UHMWPE (thickness 3.2 mm). These thin sections were melted at 170 °C under flowing nitrogen to remove residual stresses from the consolidation process that might result in additional swelling.

Small sections were cut out by razor blade from these thin sections to be analyzed (approximately 3 mm × 3 mm). These small pieces were placed under the quartz probe of the TMA and the initial height of the sample was recorded. Then, the probe was immersed in xylene, which was subsequently heated to 130 °C and held for at least 100 min. The UHMWPE samples swelled in hot xylene until equilibrium was reached. The final height was recorded.

The cross-link density of the blends was calculated as described previously [5] and are reported as mol/m3.

2.4. Accelerated aging and oxidative stability

Accelerated aging was performed on some of the cylindrical samples (9 mm diameter, 13 mm length) to determine the extent of oxidation in blends of α-tocopherol and UHMWPE under adverse conditions.

One cylindrical sample each of irradiated, virgin, and irradiated 0.1 and 0.3 wt% blocks was aged at 80 °C in a convection oven for 5 weeks in air. After aging, the cylinders were microtomed to thin sections (100–200 μm) using a LKB Sledge Microtome (Sweden). A BioRad UMA 500 infrared microscope (Natick, MA) was used to measure the extent and depth of oxidation. Infrared spectra were collected with an aperture size of 50 × 50 μm as a function of depth away from one of the edges that coincided with the free surface of the sample. The infrared spectra were analyzed to calculate an oxidation index, as the ratio of the areas under the 1740 cm−1 carbonyl and 1370 cm−1 methylene stretching absorbances.

2.5. Bidirectional pin-on-disc (POD) wear testing

Three cylindrical samples (9 mm in diameter and 13 mm in length) out of each of the three irradiated blocks (virgin, 0.1%, and 0.3 wt%) were used for POD wear testing. These pins were accelerated aged at 80 °C in air for 5 weeks and tested on our custom-built bi-directional POD tester at a frequency of 2 Hz for 2 million cycles (MCs) with gravimetric assessment of wear at every 0.5 MCs. Undiluted bovine serum was used as lubricant with 0.3 wt% sodium azide as antibacterial agent and 1mm EDTA as chelating agent. The wear rate was determined by linear regression of the weight change of each pin over number of cycles from 0.5 to 2 MCs.

2.6. Determination of percent crystallinity by differential scanning calorimetry (DSC)

The DSC specimens were weighed with a Sartorius CP 225D balance to a resolution of 0.01 mg and placed in aluminum sample pans. The pan was crimped with an aluminum cover and placed in a Q-1000 Differential Scanning Calorimeter (TA Instruments, Newark, DE). The sample and the reference were then heated at a heating rate of 10 °C/min from −20 to 180 °C, cooled to −20 °C at −10 °C/min and subjected to another heating cycle from −20 to 180 °C at 10 °C/min. Heat flow as a function of time and temperature was recorded and the cycles are referred to as 1st heat, 1st cool and 2nd heat.

Crystallinity of the irradiated virgin, 0.1 and 0.3 wt% α-tocopherol-blended UHMWPEs was determined by integrating the enthalpy peak from 20 to 160 °C, and normalizing it with the enthalpy of melting of 100% crystalline polyethylene, 291 J/g.

2.7. Mechanical testing

Dogbone specimens (n = 5 each) were stamped from virgin, 0.1 and 0.3 wt% α-tocopherol-blended and 100-kGy irradiated UHMWPE in accordance with ASTM D638, standard test method for tensile properties of plastics. The dogbone specimens were accelerated aged at 80 °C for 5 weeks in air. These samples were then tested in accordance with ASTM D-638 using a MTS II machine (Eden Prarie, MN) at a crosshead speed of 10 mm/min.

Tensile specimens prepared in the same manner from unirradiated GUR 1050, 100-kGy irradiated GUR 1050 and 100-kGy irradiated and subsequently melted (at 150 °C) GUR 1050 were also tested as control.

In the following studies, where , statistical analysis was performed using a Student's t-test for two-tailed distributions with unequal variance.

3. Results

The content of α-tocopherol in the 0.1 and 0.3 wt% blended UHMWPE was ascertained by determining α-tocopherol index. α-Tocopherol index was determined to be 0.012±0.003 and 0.030±0.003 for 0.1 and 0.3 wt% blended samples, respectively.

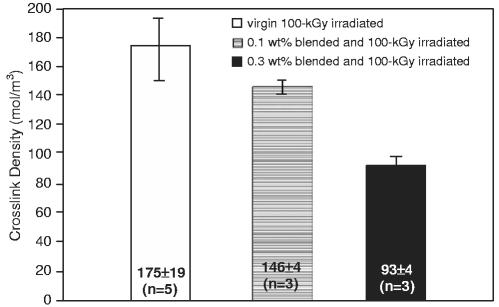

Cross-link density of both 100-kGy irradiated 0.1 and 0.3 wt% α-tocopherol-blended UHMWPE was lower than 100-kGy irradiated virgin UHMWPE. These values for 0.1 and 0.3 wt% blends were 146±4 and 93±4 mol/m3, respectively, compared to 175±19 mol/m3 for virgin UHMWPE (Fig. 2).

Fig. 2.

Cross-link density measurements of virgin, and 0.1 and 0.3 wt% α-tocopherol-blended, 100-kGy irradiated UHMWPE.

Neither of the irradiated α-tocopherol blends oxidized when subjected to accelerated aging compared to virgin irradiated UHMWPE. The maximum oxidation levels were 0.09, 0.04 and 3.32 for blends with 0.1, 0.3 wt% α-tocopherol and virgin irradiated polyethylene, respectively. An oxidation profile as a function of depth is shown in Fig. 3 for all three samples.

Fig. 3.

The oxidation levels of control, 0.1 and 0.3 wt% α-tocopherol-blended UHMWPE post-irradiation and accelerated aging. Aging was done at 80 °C for 5 weeks in air.

The POD wear rates of 0.1 and 0.3 wt% blended and irradiated UHMWPE were both higher than the wear rates that our group published for 100-kGy irradiated and melted UHMWPE [14]. The in vitro wear rates obtained from POD testing for 0.1 and 0.3 wt% α-tocopherol-blended, and 100-kGy irradiated UHMWPE following accelerated aging were 2.10±0.17 and 5.01±0.76 mg/MC, respectively (Fig. 4). The wear rate for the 0.3 wt% blended UHMWPE was higher than that for 0.1 wt% blended UHMWPE (p = 0.018).

Fig. 4.

The wear rates of accelerated aged 0.1 and 0.3 wt% α-tocopherol-blended UHMWPE. Accelerated aging was done at 80 °C for 5 weeks in air. For comparison, 127-kGy irradiated and α-tocopherol-diffused UHMWPE [6], 38-kGy sterilized and 100-kGy irradiated and melted GUR 1050 [14] are also included. Accelerated aging for the 38 and 100-kGy irradiated samples taken from Muratoglu et al. [14] were done at 80 °C for 3 weeks in air.

Percent crystallinity of 0, 0.1 and 0.3 wt% α-tocopherol-blended UHMWPE all increased as a result of irradiation and accelerated aging; however, the increase in crystallinity due to aging for the sample containing no α-tocopherol was greater than either blend (Table 1).

Table 1.

Percent crystallinity of 0, 0.1 and 0.3 wt% α-tocopherol-blended GUR 1050 UHMWPE before and after irradiation and accelerated aging

| Unirradiated | 100-kGy irradiated | 100-kGy accelerated aged | |

|---|---|---|---|

| No α-tocopherol | 60.9±2.0 | 65.4±1.1 | 68.4±0.3 |

| 0.1 wt% α-tocopherol | 63.9±0.1 | 66.3±0.6 | 64.2±0.3 |

| 0.3 wt% α-tocopherol | 63.7±0.4 | 65.0±0.3 | 65.7±0.1 |

The ultimate tensile strength (UTS) of 0.1 and 0.3 wt% α-tocopherol-blended, unirradiated UHMWPEs were comparable to unirradiated GUR 1050 control and to each other (Table 2, p = 0.25, 0.60, 0.15, respectively). After irradiation and accelerated aging, their UTS was still not different from unirradiated GUR 1050 (p = 0.09, 0.5), whereas the UTS of virgin, 100-kGy irradiated and accelerated aged GUR 1050 was lower than before aging (p<0.00001). The same effect was seen on the yield strength (YS).

Table 2.

Mechanical properties of α-tocopherol-blended and 100-kGy irradiated GUR 1050 UHMWPE as compared to unirradiated GUR 1050 and 100-kGy irradiated GUR 1050

| Ultimate tensile strength (MPa) | Yield strength (MPa) | Elongation at break (%) | |

|---|---|---|---|

| α-Tocopherol-blended GUR 1050 | |||

| Virgin | 52±2 | 23±1 | 521±16 |

| 0.1 wt% α-tocopherol | 55±3 | 23±1 | 423±8 |

| 0.3 wt% α-tocopherol | 51±3 | 23±1 | 392±16 |

| Accelerated aged 100-kGy irradiated and melted GUR 1050 | |||

| Virgin | 33±2 | 21±1 | 301±18 |

| Unaged 100-kGy irradiated GUR 1050 | |||

| Virgin | 45±1 | 24±1 | 213±33 |

| Accelerated aged 100-kGy irradiated GUR 1050 | |||

| Virgin | 20±1 | 19±1 | NA |

| 0.1 wt% α-tocopherol | 49±2 | 24±1 | 282±2 |

| 0.3 wt% α-tocopherol | 51±2 | 25±1 | 349±10 |

4. Discussion

The α-tocopherol content of the samples was established by using the α-tocopherol index. The ratio of the index for 0.3 wt% blended sample was three times that for 0.1 wt% blended sample, showing that an α-tocopherol content of 0.1 wt% could be detected by our technique, and that the ratio of α-tocopherol concentration of the blends was maintained during consolidation.

The first aim of this study was to calculate the cross-link density of α-tocopherol-blended and subsequently irradiated UHMWPE. According to our hypothesis, α-tocopherol would react with the primary free-radicals formed on the UHMWPE chains during irradiation, thereby decreasing the amount of free radicals available for the formation of cross-links.

The 17% and 47% decrease in the cross-link density of 0.1 and 0.3 wt% α-tocopherol-blended and 100-kGy irradiated UHMWPE compared to the virgin material (Fig. 2) supports the hypothesis that α-tocopherol stabilized some of the primary free-radicals required for cross-linking of UHMWPE. As a result, increasing α-tocopherol concentration to 0.1 and 0.3 wt% led to fewer primary free-radicals available for cross-linking UHMWPE and a decrease in overall cross-linking proportional to α-tocopherol concentration. Hence, the efficiency of cross-linking was reduced in 0.1 and 0.3 wt% α-tocopherol-blended UHMWPE.

The interference of α-tocopherol in the cross-linking reaction did not detrimentally affect the oxidation resistance of the two α-tocopherol blends subjected to accelerated aging (Fig. 3). α-Tocopherol was able to react also with the residual free-radicals, stabilizing UHMWPE against oxidation.

Although α-tocopherol is a potent antioxidant at room temperature and ambient pressure, it is heat and light-sensitive. Thus, the effect of high consolidation temperatures and pressures on α-tocopherol's efficiency to stabilize the residual free radicals subsequently caused by ionizing irradiation was not known. The oxidation resistance shown by these blends demonstrated that despite high temperatures and pressures under consolidation conditions, the resulting antioxidant efficiency was not detrimentally affected. Blended α-tocopherol with UHMWPE resin powder prior to irradiation was able to stabilize 100-kGy irradiated UHMWPE against oxidation.

The high oxidation of irradiated and accelerated aged virgin UHMWPE was accompanied by an increase in crystallinity, which was not observed in the two α-tocopherol blends (Table 1). The slight increase in crystallinity due to irradiation in all samples was an expected result since chain scission due to free radical formation and rearranging of these new chains into crystals occurred to some extent in the blends as well as virgin UHMWPE. The increase in crystallinity as a result of accelerated aging, however, is a result of the rearranging of smaller chains formed as a part of the oxidation and chain scission cascade. This effect was observed only in the virgin UHMWPE, which was highly oxidized, and not observed in the α-tocopherol blends, which did not oxidize. Highly oxidized UHMWPE showing high crystallinity was also brittle, whereas the α-tocopherol blends did not show embrittlement.

The decrease in cross-link density of 0.1 and 0.3 wt% α-tocopherol-blended, 100-kGy irradiated UHMWPE resulted in increased wear rates that were higher than that for 100-kGy irradiated and subsequently melted UHMWPE after accelerated aging [14] (Fig. 4). At the same time, these values were lower than that for gamma-sterilized GUR 1050 (38 kGy) [14]. Since the cross-link density of 0.3 wt% blended UHMWPE was lower than that for 0.1 wt% blended samples, the wear rate was significantly higher with the former.

The wear rate of 100-kGy irradiated, and α-tocopherol-diffused (at room temperature for a duration of 16 h) and gamma-sterilized UHMWPE (27 kGy) [6] was lower than that of 0.1 and 0.3 wt% α-tocopherol-blended UHMWPE in this study. This was because α-tocopherol-diffused samples received 100-kGy irradiation before the introduction of α-tocopherol; hence, there was no decrease in the cross-linking density due to the presence of α-tocopherol during the cross-linking process.

Wear rate of those materials that contain some unstabilized residual free radicals increase due to cascading oxidation and chain scission reactions when subjected to accelerated aging [14]. The difference in the wear rates of unaged and aged gamma-sterilized UHMWPE (Fig. 4) demonstrated this phenomenon since the residual free-radicals caused by 38 kGy of ionizing radiation in this material had not been stabilized. However, this type of increase in wear rate was not expected for α-tocopherol-blended samples, since these UHMWPEs showed very low oxidation indicative of stabilization of residual free-radicals. These results further corroborated the cross-link density measurements and showed that some of the radiation dose was absorbed by α-tocopherol such that the intended cross-link density was not imparted on α-tocopherol-blended UHMWPE.

Tensile testing of 0.1 and 0.3 wt% α-tocopherol-blended UHMWPE showed small changes from their unirradiated state to their irradiated and accelerated aged state (Table 2): a decrease in UTS, an increase in YS; and a decrease in elongation at break (EB).

The effects of oxidation and chain scission caused large decreases in UTS and YS in the accelerated aged, irradiated virgin UHMWPE. The UTS of α-tocopherol-blended, irradiated and accelerated aged UHMWPEs was between that of unirradiated and 100-kGy irradiated virgin material. YS values were similar to that of unirradiated material. There was a decrease in EB of irradiated and accelerated aged α-tocopherol blends compared to unirradiated blends, which can presumably be associated with cross-linking. This measure of mechanical property perhaps provided a more sensitive measurement of the effects of the degree of cross-linking on UHMWPE because of the difference that it showed as a function of α-tocopherol concentration. Since 0.1 and 0.3 wt% α-tocopherol-blended UHMWPE showed very low oxidation after irradiation and accelerated aging and no differences in crystallinity (Table 1), the difference in EB for the two concentrations were attributed to differences in cross-link density.

α-tocopherol blending with UHMWPE prior to irradiation presents some advantages compared to introducing α-tocopherol after irradiation; very small amounts of α-tocopherol can be introduced into the polymeric material reliably and the concentration, low or high, would be uniform throughout. Based on previous studies, very small concentrations of α-tocopherol are enough to stabilize high-dose irradiated (∼ 100-kGy) UHMWPE against oxidation even when the concentration is not uniform and only the surface is α-tocopherol-rich [6]. In terms of mechanical properties, a concentration of 0.2 wt% has been proposed for optimal results [15].

In this study, we have shown that α-tocopherol can react with the free radicals induced by ionizing radiation during and after irradiation. Therefore, interactions between the free-radicals and α-tocopherol as well as absorbed dose for cross-linking as a function of concentration of α-tocopherol warrant further investigation in order to render UHMWPE more wear resistant by blending with α-tocopherol and cross-linking by irradiation.

5. Conclusion

We have shown that α-tocopherol-blending with UHMWPE prior to irradiation imparts considerable oxidation resistance to irradiated UHMWPE and is a good stabilization method. However, cross-link density measurements and wear testing showed that α-tocopherol hinders cross-linking by reacting with some of the free-radicals during irradiation. Therefore, it is more desirable to diffuse α-tocopherol into previously irradiated UHMWPE to obtain a highly oxidation and wear-resistant cross-linked UHMWPE.

Acknowledgements

This work was funded by National Institutes of Health Grant R01 AR051142-01.

Footnotes

This study was funded by NIH R01 AR051142-01.

References

- 1.Harris W. The problem is osteolysis. Clin Orthop. 1995;311:46–53. [PubMed] [Google Scholar]

- 2.McKellop H, Shen F-W, Lu B, Campbell P, Salovey R. Development of an extremely wear resistant ultra-high molecular weight polyethylene for total hip replacements. J Orthop Res. 1999;17(2):157–67. doi: 10.1002/jor.1100170203. [DOI] [PubMed] [Google Scholar]

- 3.Muratoglu O, Bragdon D, O'Connor D, Jasty M, Harris W. A novel method of crosslinking UHMWPE to improve wear with little or no sacrifice of mechanical properties. Society for biomaterials 25th annual meeting transactions. 1999:496. [Google Scholar]

- 4.Muratoglu OK, Bragdon CR, O'Connor DC, Jasty M, Harris WH. A unique crosslinking technique to improve the wear resistance of UHMWPE without sacrificing mechanical properties. Annual meeting of Academy of Orthopaedic Surgeons. 1999 [Google Scholar]

- 5.Muratoglu OK, Bragdon CR, O'Connor DO, Jasty M, Harris WH, Gul R, McGarry F. Unified wear model for highly crosslinked ultra-high molecular weight polyethylenes (UHMWPE) Biomaterials. 1999;20(16):1463–70. doi: 10.1016/s0142-9612(99)00039-3. [DOI] [PubMed] [Google Scholar]

- 6.Oral E, Wannomae KK, Hawkins NE, Harris WH, Muratoglu OK. α-Tocopherol doped irradiated UHMWPE for high fatigue resistance and low wear. Biomaterials. 2004;25(24):5515–22. doi: 10.1016/j.biomaterials.2003.12.048. [DOI] [PubMed] [Google Scholar]

- 7.McGovern TF, Ammeen DJ, Collier JP, Currier BH, Engh GA. Rapid polyethylene failure of unicondylar tibial components sterilized with gamma irradiation in air and implanted after a long shelf life. J Bone Jt Surg. 2002;84-A(6):901–6. doi: 10.2106/00004623-200206000-00002. [DOI] [PubMed] [Google Scholar]

- 8.Chiu YS, Chen WM, Huang CK, Chiang CC, Chen TH. Fracture of the polyethylene tibial post in a NexGen posterior-stabilized knee prosthesis. J Arthroplasty. 2004;19(8):9. doi: 10.1016/j.arth.2004.04.013. [DOI] [PubMed] [Google Scholar]

- 9.Kamal-Eldin A, Appelqvist L. The chemistry and antioxidant properties of tocopherols and tocotrienols. Lipids. 1996;31(7):671–701. doi: 10.1007/BF02522884. [DOI] [PubMed] [Google Scholar]

- 10.Burton G, Ingold K. Autoxidation of biological molecules. 1. The antioxidant activity of vitamin E and related chain-breaking phenolic antioxidants in vitro. J Am Chem Soc. 1981;103:6472–7. [Google Scholar]

- 11.Mori A, Sakuramoto I, Tomita N, Kawano S, Nagata K, Utsumi K, Moriya H. Mechanical behavior of UHMWPE when mixed with vitamin E. 47th annual meeting, Orthopaedic Research Society. 2001 [Google Scholar]

- 12.Tomita N, Kitakura T, Onmori N, Ikada Y, Aoyama E. Prevention of fatigue cracks in ultrahigh molecular weight polyethylene joint components by the addition of vitamin E. J Biomed Mater Res. 1999;48(4):474–8. doi: 10.1002/(sici)1097-4636(1999)48:4<474::aid-jbm11>3.0.co;2-t. [DOI] [PubMed] [Google Scholar]

- 13.Parth M, Aust N, Lederer K. Studies on the effect of electron beam radiation on the molecular structure of ultra-high molecular weight polyethylene under the influence of alpha-tocopherol with respect to its application in medical implants. J Mater Sci—Mater Med. 2002;13(10):917–21. doi: 10.1023/a:1019892004830. [DOI] [PubMed] [Google Scholar]

- 14.Muratoglu OK, Merrill EW, Bragdon CR, O'Connor DO, Hoeffel D, Burroughs B, Jasty M, Harris WH. Effect of radiation, heat, and aging on in vitro wear resistance of polyethylene. Clin Orthop Relat Res. 2003;417:253–62. doi: 10.1097/01.blo.0000093004.90435.d1. [DOI] [PubMed] [Google Scholar]

- 15.Luisetto Y. Degradation mechanism and effects of vitamin E addition in UHMWPE hip implants. Lund Institute of Technology; Lund: 2003. PhD Thesis in polymer science and engineering. [Google Scholar]