Abstract

The purpose of this study was to compare 4 methods for the reduction of aerosol transmission of Porcine reproductive and respiratory syndrome virus (PRRSV): high-efficiency particulate air (HEPA) filtration, 2×-low-cost filtration, bag filtration, and use of a filter tested against particles derived from dioctylphthalate (DOP). The HEPA-filtration system used a prefilter screen, a bag filter (Eurovent [EU] 8 rating), and a HEPA filter (EU13 rating). The low-cost-filtration system contained mosquito netting (prefilter), 2 fiberglass furnace filters, and 2 electrostatic furnace filters. Bag filtration involved the use of a filter rated EU8 and a minimum efficiency reporting value (MERV) of 14. The 95%-DOP, 0.3-μm-filtration system involved a pleat-in-pleat V-bank disposable filter with a 95% efficiency rating for particles 0.3 μm or greater in diameter and ratings of EU9 and MERV 15. No form of intervention was used in the control group. The experimental facilities consisted of 2 chambers connected by a 1.3-m-long duct containing the treatments. Recipient pigs, housed in chamber 2, were exposed to artificial aerosols created by a mechanically operated mister containing modified live PRRSV vaccine located in chamber 1. Aerosol transmission of PRRSV occurred in 0 of the 10 HEPA-filtration replicates, 2 of the 10 bag-filtration replicates, 4 of the 10 low-cost-filtration replicates, 0 of the 10 95%-DOP, 0.3-μm-filtration replicates, and all 10 of the control replicates. Using a similar approach, we further evaluated the HEPA- and 95%-DOP, 0.3-μm-filtration systems. Infection was not observed in any of the 76 HEPA-filtration replicates but was observed in 2 of the 76 95%-DOP, 0.3-μm replicates and 42 of the 50 control replicates. Although the difference between the 95%-DOP, 0.3-μm and control replicates was significant (P < 0.0005), so was the level of failure of the 95%-DOP, 0.3-μm system (P = 0.02). In conclusion, under the conditions of this study, some methods of air filtration were significantly better than others in reducing aerosol transmission of PRRSV, and HEPA filtration was the only system that completely prevented transmission.

Résumé

L’objectif de la présente étude était de comparer quatre méthodes de réduction de la transmission par aérosol du virus du syndrome respiratoire et reproducteur porcin (PRRSV) : une filtration à l’aide de filtre de haute efficacité (HEPA) constitué d’un grillage comme pré-filtre, d’un filtre à sac (cote Eurovent [EU] 8) et un filtre HEPA (cote EU13); un système peu dispendieux constitué d’une moustiquaire (pré-filtre), de deux filtres à fournaise en fibre de verre et de deux filtres électrostatiques à fournaise; une filtration à l’aide d’un sac impliquant l’utilisation d’un filtre coté EU8 et «minimum efficiency reporting value» (MERV) 14; une filtration à l’aide des filtres pli-sur-pli jetables avec une cote d’efficacité de 95 % pour les particules de dioctylphthalate (DOP) ayant un diamètre de 0,3 μm ou plus et des cotes EU9 et MERV 15; et un groupe témoin (aucune intervention). Les installations expérimentales consistaient en deux chambres reliées par un tuyau de 1,3 m de long à l’intérieur duquel on installait les unités de filtration à tester. Les porcs receveurs, installés dans la pièce 2, furent exposés à des aérosols artificiels créés par un nébuliseur opéré mécaniquement contenant un vaccin à virus PRRSV vivant modifié et localisé dans la pièce 1. La transmission par aérosol du PRRSV ne s’est produite lors d’aucune des 10 réplications faites avec la filtration HEPA; elle s’est produite dans 2 des 10 réplications avec le sac à filtration, 4 des 10 réplications utilisant le système peu dispendieux, 0 des 10 réplications du système DOP 95 % à 0,3 μm, et toutes les réplications témoins. En utilisant une approche similaire, nous avons étudié plus attentivement les systèmes HEPA et DOP 95 % à 0,3 μm. L’infection n’a pas été notée lors d’aucune des réplications effectuées utilisant la filtration HEPA alors qu’elle s’est produite lors de 2 des 76 réplications avec la filtration DOP 95 % à 0,3 μm et 42 des 50 réplications témoins. Bien que la différence entre la filtration par DOP 95 % à 0,3 μm et le système témoin était significative (P < 0,0005), il en était de même pour l’échec du système DOP 95 % à 0,3 μm (P = 0,02). En conclusion, dans les conditions expérimentales de cette étude, certaines méthodes de filtration de l’air étaient significativement meilleures que d’autres à réduire la transmission par aérosol du PRRSV, et la filtration HEPA était la seule méthode empêchant complètement la transmission du virus.

(Traduit par Docteur Serge Messier)

Introduction

Throughout the global swine industry, extensive efforts have been made to protect commercial swine farms from infection with Porcine reproductive and respiratory syndrome virus (PRRSV). One of the biggest obstacles to maintaining a PRRSV-naïve status is preventing the entry of virus via indirect routes of transmission such as contaminated transport vehicles and insects (1,2). Another potential indirect route of PRRSV transmission is via contaminated aerosols. Studies indicate that PRRSV-contaminated aerosols can infect naïve pigs over distances ranging from 0.5 to 150 m, and epidemiologic studies have suggested that aerosol transmission is an important component of indirect PRRSV transmission throughout swine-producing regions (3–5).

To reduce the risk of airborne spread of PRRSV, producers in Europe and North America are beginning to implement systems to filter the air entering their swine facilities. These systems use positive-pressure ventilation principles, and incoming air is passed through a series of filters of decreasing pore size in conjunction with propulsion via a centrifugal turbine. These systems involve the use of high-efficiency particulate air (HEPA) filters that are capable of blocking the passage of particles 0.3 μm or more in diameter. Recently, a commercially available air filtration system based on this principle was evaluated experimentally (6). In this study, HEPA-filtered air or nonfiltered air was allowed to pass from experimentally infected PRRSV-positive pigs to naïve recipient pigs housed in experimental chambers. Under the conditions of this study, a significant reduction (P < 0.01) was observed in aerosol transmission of PRRSV to naïve pigs housed in nonfiltered chambers (6/20 replicates) when compared with pigs housed in HEPA-filtered chambers (0/20 replicates).

However, owing to the cost of such systems, the question of whether similar results could be obtained with alternative methods of filtration has been raised. In a recently completed trial, different methods (HEPA filtration, low-cost filtration, and ultraviolet [UV] light irradiation) were compared for efficacy in reducing aerosol transmission of PRRSV (7). In that study, the HEPA-filtration system used a prefilter screen, a bag filter (Eurovent [EU] 8 rating), and a HEPA filter (EU 13 rating). The low-cost system contained mosquito netting (prefilter), a fiberglass furnace filter, and an electrostatic furnace filter. The UV light irradiation was applied to PRRSV-contaminated air by a lamp emitting UVC radiation at 253.7 nm. The design included a control group in which no form of intervention was used. With this approach, transmission of PRRSV was observed in 9 of the 10 control replicates, 8 of the 10 UVC-irradiation replicates, 4 of the 10 low-cost-filtration replicates, and 0 of the 10 HEPA-filtration replicates. It was concluded that, under the conditions of that study, HEPA filtration was significantly more effective at reducing aerosol transmission of PRRSV than the other methods evaluated. However, owing to cost, it was still uncertain whether such a system could be applied to commercial swine production. Therefore, a follow-up study was conducted to further the investigation of alternative methods of air filtration to reduce the risk of PRRSV transmission by aerosol. The methods tested in this study consisted of HEPA filtration, bag filtration, 2×-low-cost filtration, and use of a filter tested against particles derived from dioctylphthalate (DOP), a synthetic material used to fashion particles of designated sizes in order to test the efficiency of air filters. This particular filter had been tested against DOP-derived particles 0.3 μm in diameter and found to have an efficiency ≥ 85% and < 95% for particles 0.3 to 1.0 μm in diameter, an efficiency ≥ 90% for particles 1.0 to 10.0 μm in diameter, an EU9 classification, and a minimum efficiency reporting value (MERV) of 15, as reported by the American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) (Jeff Noack, Filtration Systems Incorporated: personal communication, January 2005). A MERV rating is assigned to a filter after an evaluation of its efficiency across a wide range of particle sizes, thereby allowing for the comparison of different filters. Therefore, it was hypothesized that the efficacy of the 95%-DOP, 0.3-μm-filtration system would equal that of the HEPA-filtration system.

Materials and methods

Experimental facilities

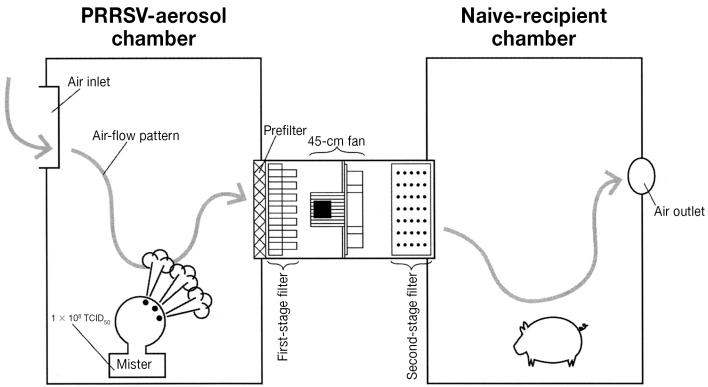

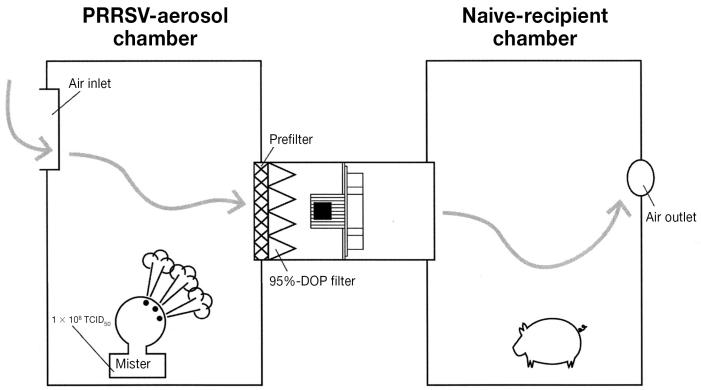

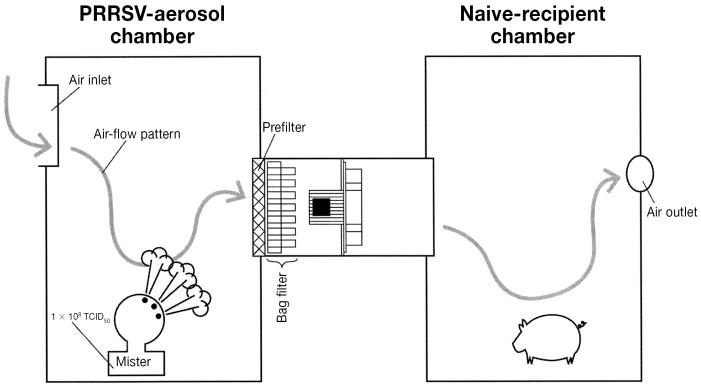

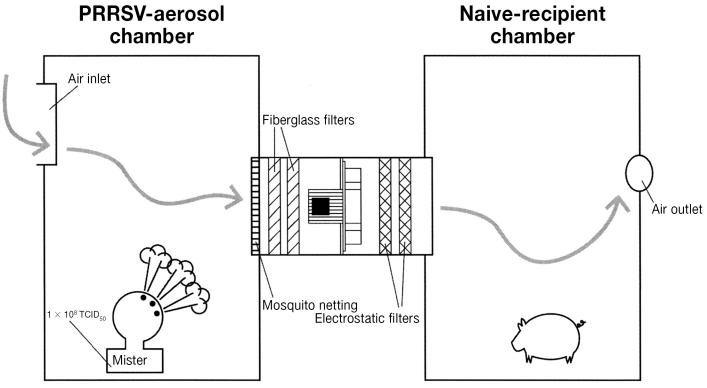

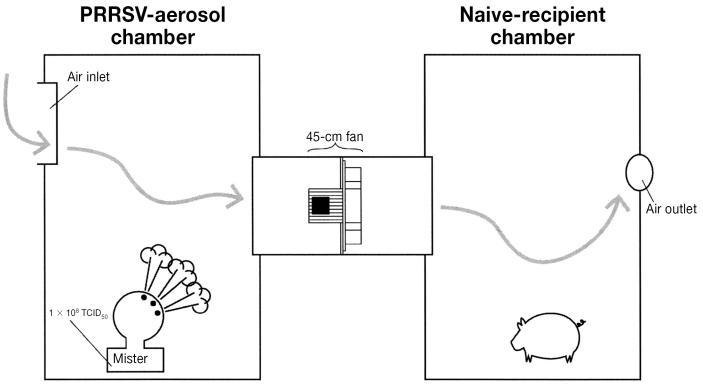

As previously described (6,7), 2 experimental animal facilities were used in this new study. Each experimental facility, located in a separate building at the Swine Disease Eradication Center research farm, consisted of 2 chambers 1.2 m in length and width and 1.8 m in height that were connected via a 650 × 650 mm rectangular duct that was 1.3 m in length. Chambers and ducts were constructed from 1.25-cm-thick sheets of recycled plastic (Snow white board; Environment Control Systems, Morris, Minnesota, USA) reinforced with a frame consisting of lengths of treated plywood 5 × 5 cm. The junctions between the frame and the plastic board were caulked with silicone. The duct allowed ventilating air to flow from chamber 1 to chamber 2 in each experimental facility via a 45-cm variable-speed fan. The duct in facility 1 was specifically designed to house the HEPA-filtration model, and the duct in facility 2 was designed to house the other methods to be tested (Figures 1A to 1D). A 0.4-m2 opening above the entry door of chamber 1 served as the air intake for each experimental facility; a hole 20 cm in diameter above the entry door of chamber 2 allowed air to be exhausted.

Figure 1A.

Diagram of experimental facility 1, used to evaluate the efficacy of high-efficiency particulate air (HEPA) filtration in the reduction of aerosol transmission of Porcine reproductive and respiratory syndrome virus (PRRSV). In each figure, chamber 1 produced an aerosol and chamber 2 housed a PRRSV-naïve recipient pig.

Figure 1D.

Diagram of experimental facility 2, as used to evaluate the efficacy of 95%-DOP, 0.3-μm filtration in the reduction of aerosol transmission of PRRSV.

The HEPA-filtration system

A model of a commercially available system involving HEPA filters was used (6,7). The model was fastened in the duct of an experimental facility (Figure 1A), and the borders of the model and the duct were caulked with silicone. The model (Fancom Agri-Computers, Vitre, France) was 1/16 the size of the commercially available system used on swine farms and was encased in a rectangular aluminum box 1200 × 650 mm in height and width. The exterior of the air-intake port was covered with a prefilter composed of 20% passing gravimetric, galvanized metal. The 1st stage (model OP95 F8; Camfil, Sainte-Colombe, France) consisted of a bag filter 592 × 592 × 533 mm with a MERV rating of 14, a 95% opacimetric efficiency rating, an EU8 classification, and a filtering coefficient of 20 (an efficiency ≥ 75% and < 95% for particles 0.3 to 1.0 μm in diameter and ≥ 90% for particles 1.0 to 3.0 μm in diameter). The 2nd stage consisted of a HEPA filter 610 × 610 × 292 mm (Camfil) with an EU13 classification, a DOP efficiency rating of 99.99%, a filtering coefficient of 2000 (minimum efficiency 99.95%, maximum pass-through 0.05%), and a most penetrating particulate size of 0.1 to 0.2 μm in diameter.

The model was ventilated by a 45-cm variable-speed fan (model 1456 M/C; Fancom) with a maximum capacity of 1495 m3/h that was placed between the 1st- and 2nd-stage filters. The fan was controlled by a ventilation linear regression end-station with an amperage of 6 (model A7110101; Fancom). During the experiment, the fan operated at approximately 25% capacity (375 m3/h), producing the required static pressure of 50 to 60 Pa. Pressure was continuously monitored via a manometer attached to the exterior surface of the recipient pig chamber.

Bag-filtration system

This system was identical to the HEPA-filtration system except that the HEPA filter was removed from the model, leaving the prefilter and the EU8-rated 1st-stage (bag) filter in place (Figure 1B). This filter had an efficiency of ≥ 75% and < 95% for particles 0.3 to 1.0 μm in diameter and ≥ 90% for particles 1.0 to 10.0 μm in diameter and had therefore been assigned a MERV of 14 by ASHRAE.

Figure 1B.

Diagram of experimental facility 2, as used to evaluate the efficacy of bag filtration in the reduction of aerosol transmission of PRRSV.

The 2×-low-cost-filtration system

This system consisted of a combination of commercially available materials commonly found in homes and office facilities (Figure 1C). As a prefilter, fiberglass mosquito netting with a pore size of 1.0 mm (64 openings/cm2) was mounted over the opening to the connecting duct in chamber 1. In contrast to the previous study (7), this system had 2 fiberglass furnace filters (EZ Flow II; Flanders Company, St. Petersburg, Florida, USA) and 2 electrostatic filters (Filtrete Ultra Allergen Reduction Filter; 3M Health Care, St. Paul, Minnesota, USA). Each of the fiberglass filters was capable of capturing 20% of particles 3 to 10 μm in diameter and had a MERV rating of 4; both filters were proximal to the fan. Each of the electrostatic filters had a MERV rating of 12 and an EU3 ranking and was capable of capturing up to 90% of particles 3 to 10 μm in diameter. As before, the filters were secured in place with 2.54-cm-wide plastic tracts on the floor and ceiling of the duct; 1.9-cm-wide adhesive foam rubber weather seal (Frost King, Thermwell Product, Sparks, Nevada, USA) was placed around the borders of the filters and then covered with 2.54-cm-wide duct tape. Filters were changed between replicates.

Figure 1C.

Diagram of experimental facility 2, as used to evaluate the efficacy of 2×-low-cost filtration in the reduction of aerosol transmission of PRRSV.

The 95%-DOP, 0.3-μm-filtration system

This system involved the use of the mosquito-netting prefilter and a pleat-in-pleat V-bank disposable filter 592 × 592 × 533 mm (model DU4V-1511 MV15; Camfil Farr, El Segundo, California, USA). As previously described, this filter had an efficiency ≥ 85% and < 95% for particles 0.3 to 1.0 μm in diameter, an efficiency ≥ 90% for particles 1.0 to 10.0 μm in diameter, an EU9 classification, and a MERV of 15 (Figure 1D).

Control system

As before (6,7), a control system involving the described chambers without intervention was used (Figure 1E).

Figure 1E.

Diagram of experimental facility 2, as used for control purposes.

Animal groups and infection model

Before the study, all procedures and protocols involving pigs were approved by the University of Minnesota Institutional Animal Care and Use Committee. The 1st phase of the study involved 58 PRRSV-naïve 12-kg pigs acquired from a PRRSV-naïve farm whose status had been validated for more than 10 y via monthly blood testing. Upon the animals’ arrival at the research site, blood samples were collected. The pigs were divided into 50 recipients, 4 positive controls, and 4 negative controls.

The source of PRRSV aerosols consisted of a cold fog mister (Hurricane ULV/mister, model 2790; Curtis Dyna-Fog, Westfield, Indiana, USA) filled with 1 L (total dose 1 × 108 TCID50 [median tissue culture infective dose]) of a PRRS modified live virus (MLV) vaccine (Ingel Vac MLV; Boehringer-Ingelheim Vetmedica, St. Joseph, Missouri, USA). The mister was set at a flow rate capable of aerosolizing the liter of virus in 5.5 min and placed on the floor of chamber 1 with the nozzle set at a 40° angle; the entire contents of the mister were expelled into the chamber before the fan was turned on. The particle size of aerosolized droplets produced by the mister was measured with an aerosol counter (model 40-1, catalog #37-19-30; Bausch and Lomb, Rochester, New York, USA) placed on the chamber floor after generation of the aerosol.

Experimental design

The 50 recipient pigs were allocated across the 5 treatments. Each recipient pig represented a replicate; therefore, 10 replicates were conducted per treatment. This sample size allowed for detection of a 30% infection rate at a target alpha level of 0.05 and an 80% study power.

During each replicate, the mister was placed in chamber 1 as described, and a single recipient pig was housed in chamber 2 for a 6-h exposure period. Replicates were conducted in the 2 sets of facilities concurrently, in separate buildings on the farm. During the 6-h period of exposure, air was ventilated from the donor chamber via the connecting duct into the chamber containing the recipient pig. Fans were standardized to deliver an air-flow velocity of 1.5 m/s on the basis of data from testing of the electrostatic filters during manufacturing. During the exposure period, the velocity, temperature, and relative humidity of the air in chamber 2 of each facility were recorded with use of a Kestrel weather meter (Nielsen-Kellerman, Chester, Pennsylvania, USA). After the 6-h period of exposure, the recipient pigs were placed in individual isolated pens on the farm and kept there for 14 d.

Study biosecurity protocols

To minimize the risk of contamination between groups, strict biosecurity protocols were followed at all times. Chambers were sanitized with a combination of 7% glutaraldehyde and 26% quaternary ammonium chloride (Synergize; Preserve International, Atlanta, Georgia, USA) (8): 30 mL of the disinfectant was added to 3840 mL of water and applied to all interior surfaces of the chambers with a Hydro Foamer (Hydro Systems, Cincinnati, Ohio, USA), then the chambers were allowed to dry overnight between replicates. Designated personnel handled the recipient pigs, washing hands and changing gloves, boots, and coveralls between pigs (9). After each replicate, the recipient pigs were housed individually in isolated facilities throughout the farm, with no possibility of nose-to-nose contact with other pigs. The trials were conducted in the winter in Minnesota to eliminate the risk of insect transmission between pens and rooms. Personnel followed the biosecurity protocols for daily inspection and feeding of the pigs, sanitizing their footwear through a 10-s immersion in boot baths containing 6.5% sodium hypochlorite located outside the doorway of each room (10).

Additional controls

To monitor the level of sanitation of the recipient pig chambers between replicates, swabs were collected and tested for the presence of PRRSV RNA. After disinfection and drying of the chambers, a sterile Dacron swab (Fisher Scientific, Hanover Park, Illinois, USA) was applied in a zigzag manner to the floor, all 4 walls, and the ceiling, stored in sterile saline, pooled 10:1, and frozen at −80°C.

To validate the infectivity of the artificial aerosols generated by the mister, 4 naïve pigs (1 pig/treatment group) were placed in chamber 1, exposed for 6 h to the artificial aerosols, isolated, and tested; they served as positive controls. The 4 pigs serving as a sham-inoculated negative-control group were housed in chamber 2 and exposed to PRRSV-negative artificial aerosols produced through the use of misters filled with 1 L of sterile saline.

Diagnostic monitoring

All pigs were blood-tested on arrival at the farm, as well as 7 and 14 d after the 6-h exposure period. Blood samples were tested for the presence of PRRSV RNA and PRRSV antibodies by TaqMan polymerase chain reaction (PCR) (Perkin Elmer, Applied Biosystems, Foster City, California, USA) and IDEXX 2XR enzyme-linked immunosorbent assay (ELISA) (IDEXX Laboratories, Westbrook, Maine, USA) (11,12). All swabs collected from the chambers were also tested by PCR.

Further assessment of selected systems

After the 1st phase of the study, a 2nd phase was planned to further evaluate any of the systems in phase 1 that demonstrated efficacy equal to that of the HEPA-filtration system. The plan was to conduct 76 replicates of the selected system, the HEPA-filtration system, and the control system. This sample size allowed for detection of a 10% infection rate at a target alpha level of 0.05 and an 80% study power.

Data analysis

In the 1st phase of the study, a 1-tailed Fisher’s exact test was used to determine whether there was a significant reduction in transmission of PRRSV via aerosol in the treatment groups as compared with the control group. During the 2nd phase, differences in the efficiency of the filters as compared with the control system were evaluated for significance by the chi-squared test.

Results

All pigs were determined to be PRRSV-naïve upon arrival at the farm. Successful experimental infection of PRRSV was documented by PCR and ELISA in all 4 of the positive-control pigs. In phase 1, infection of PRRSV via aerosol was observed in 0 of the 10 replicates in the HEPA-filtration group, 2 of the 10 in the bag-filtration group, 4 of the 10 in the 2×-low-cost-filtration group, 0 of the 10 in the 95%-DOP, 0.3-μm-filtration group, and all 10 in the negative-control group.

When compared with no intervention, HEPA filtration significantly reduced PRRSV transmission (P < 0.0005), as did 95%-DOP, 0.3-μm filtration (P < 0.0005), 2×-low-cost filtration (P = 0.0054), and bag filtration (P = 0.0004). When compared with HEPA filtration and 95%-DOP filtration, bag filtration did not result in a significantly higher infection rate (P = 0.2368), whereas 2×-low-cost filtration did (P = 0.04333).

After further evaluation (phase 2), transmission of PRRSV was not detected in any of the 76 replicates involving the HEPA-filtration system, whereas with 95%-DOP, 0.3-μm filtration, infection occurred in 2 (3%) of 76 replicates. Of the 50 positive-control replicates, aerosol transmission of PRRSV was observed in 42 (84%). The difference in the reduction of PRRSV transmission by aerosol between the control system and the 95%-DOP, 0.3-μm system was determined to be significant (P < 0.0005). However, the level of failure in the 95%-DOP, 0.3-μm system (3%) was also significant (P = 0.02) by a 1-tailed proportions test.

All swabs collected from sanitized chambers were PCR-negative, and all negative-control pigs were PCR- and ELISA-negative. The particle size of the artificial aerosols ranged from 0.3 to 3.0 μm. The mean temperature was 20°C and the mean relative humidity 60% in the recipient-pig chambers.

Discussion

The objective of this study was to compare the efficacy of different methods of air filtration in an attempt to identify a cost-effective alternative to HEPA filtration for reducing the risk of aerosol transmission of PRRSV. In the 1st phase of the study, all tested systems significantly reduced the spread of PRRSV by aerosol when compared with the control system; however, performance was significantly better with the HEPA-filtration system and the 95%-DOP, 0.3-μm-filtration system than with the others. In the 2nd phase, the HEPA-filtration system proved to be perfect, which is consistent with the results of other studies (6,7). Thus, the HEPA-filtration system can now be considered the gold standard of air filtration for reducing the risk of aerosol transmission of PRRSV. In contrast, aerosol transmission was observed in 2 replicates involving the 95%-DOP system, and this was determined to represent a significant failure rate.

One explanation for the failure of all of the alternative filtration systems may be the relatively small particle size of the artificial aerosols (0.3 to 3.0 μm). This would also include the 95%-DOP, 0.3-μm system, since its collection efficiency was > 90% for particles ranging in diameter from 1.0 to 10.0 μm. Therefore, it is unknown whether similar levels of performance might have been observed across all treatments if aerosols containing larger particles, such as those previously reported for bioaerosols (0.5 to 100 μm), had been used (12). Although this is an acknowledged limitation of the study, the inability to consistently reproduce aerosol transmission of PRRSV in previous studies prompted the use of artificial aerosols to consistently challenge the intervention strategies (6). Furthermore, we wanted to maintain the consistency of the challenge method across studies (7); however, it is also important to realize that the degree of PRRSV challenge in this model may have been excessively high. A large quantity of virus (1 × 108 TCID50) was used to generate the artificial aerosol, and it is not known if such quantities represent those found in naturally produced aerosols. Although concentrations of PRRSV in aerosols from individual pigs up to 1.33 × 103 TCID50 have been reported after experimental infection (13), information on the quantity of PRRSV in aerosols generated from populations of infected pigs is currently not available.

As in our previous air-filtration studies (6,7), a major limitation in this study was that we did not attempt to demonstrate the presence of PRRSV in air samples collected from the recipient pig chambers. Again, this was a conscious decision and was based on the inability in previous experiments to detect PRRSV in air samples with all-glass impingers (14). Furthermore, although air centrifuges appear to be capable of detecting PRRSV in air samples (4), given the limited amount of space in the chamber it was not possible to prevent pigs from physically contacting the instrument and potentially contaminating the sample. However, in an effort to strengthen the conclusion that aerosols were the route of infection of recipient pigs, programs of biosecurity were applied across all the treatment groups to minimize the risk of PRRSV contamination between replicates and groups. The fact that all of the negative-control pigs, as well as all recipient pigs in HEPA-filtered facilities, remained negative, despite being managed by the same personnel, validates these procedures and supports this conclusion.

Other limitations that must be discussed were that study conditions did not represent conditions found on commercial farms; specifically, the degree of challenge, the design of the experimental facilities, the well-controlled environment, and the short period used to house recipient animals. Finally, the lack of coinfection with other significant respiratory pathogens, such as Mycoplasma hyopneumoniae and Swine influenza virus, may have influenced the concentration of PRRSV in aerosols.

However, despite these acknowledged limitations, the study had much strength. We found differences in efficacy across a variety of filtration systems for the reduction of PRRSV-contaminated aerosols using an aggressive challenge model. The 1st phase of the study served to screen several methods with sufficient power for statistical analysis and the use of controls. The 2nd phase of the study used an extensive number of replications (n = 76) to compare the efficacy of the HEPA-filtration system with a possible cost-effective alternative. From the results of this study, although the 2 systems appear to perform at comparable levels, they are not equal in efficacy. Therefore, whether the 95%-DOP, 0.3-μm filter can be considered an acceptable substitute will depend on the cost of implementation, compatibility with the existing ventilation system, and the level of risk that the producer is willing to accept when comparing the superior performance of the HEPA system. Finally, this study has resulted in the development of a model that could be used in future studies to test the ability of air-filtration methods to reduce the risk of aerosol transmission of other swine pathogens, such as M. hyopneumoniae and Swine influenza virus.

In conclusion, the results of this study suggest that certain methods for the filtration of air, in combination with proper transport-vehicle sanitation, the use of on-farm insect-control measures, and proper management of incoming fomites, may provide farms with a high level of biosecurity against PRRSV. Air filtration may be especially useful for seed-stock suppliers and artificial insemination centers, where the risk of PRRSV transmission through the sale of live animals and semen and the cost of an outbreak are very high. Therefore, we need to determine the frequency of aerosol transmission of PRRSV via large-scale epidemiologic studies to assess its significance in area spread of the virus, further test the current system under controlled field conditions, and measure the system’s efficacy against other respiratory pathogens.

Acknowledgments

We thank Bertram Cassou, Michel Lombard, and Olivier Couture of IMV International Corporation, Yvon Lintanff of Fancom Agri-Computers, Dominique Tardif of JOLCO Equipment, and Jeff Noack of Filtration Systems Incorporated for providing materials and technical expertise in the area of air filtration. Funding was provided by the Boehringer-Ingelheim PRRS Research Initiative.

References

- 1.Dee SA, Boorman J, Moon RD, Fano E, Trincado C, Pijoan C. Transmission of porcine reproductive and respiratory syndrome virus under field conditions during a putative increase in the fly population. JSHAP. 2004;12:242–245. [Google Scholar]

- 2.Dee SA, Deen J, Otake S, Pijoan C. An experimental model to evaluate the role of transport vehicles as a source of transmission of porcine reproductive and respiratory syndrome virus to susceptible pigs. Can J Vet Res. 2004;68:128–133. [PMC free article] [PubMed] [Google Scholar]

- 3.Mortensen S, Stryhn H, Sogaard R, et al. Risk factors for infection of herds with porcine reproductive and respiratory syndrome virus. Prev Vet Med. 2002;53:83–101. doi: 10.1016/s0167-5877(01)00260-4. [DOI] [PubMed] [Google Scholar]

- 4.Kristensen CS, Bøtner A, Takai H, Nielsen JP, Jorsal SE. Experimental airborne transmission of PRRS virus. Vet Microbiol. 2004;99:197–202. doi: 10.1016/j.vetmic.2004.01.005. [DOI] [PubMed] [Google Scholar]

- 5.Dee SA, Deen J, Jacobson L, Rossow K, Mahlum C, Pijoan C. A laboratory model to evaluate the role of aerosols in the transport of porcine reproductive and respiratory syndrome virus. Vet Rec. 2005;156:501–504. doi: 10.1136/vr.156.16.501. [DOI] [PubMed] [Google Scholar]

- 6.Dee SA, Batista L, Deen J, Pijoan C. Evaluation of an air-filtration system for preventing aerosol transmission of Porcine reproductive and respiratory syndrome virus. Can J Vet Res. 2005;69:293–298. [PMC free article] [PubMed] [Google Scholar]

- 7.Dee SA, Batista L, Deen J, Pijoan C. Evaluation of systems for reducing the transmission of Porcine reproductive and respiratory syndrome virus by aerosols. Can J Vet Res. 2006;70:28–33. [PMC free article] [PubMed] [Google Scholar]

- 8.Dee SA, Deen J, Burns D, Douthit G, Pijoan C. An evaluation of disinfectants for the sanitation of porcine reproductive and respiratory syndrome virus-contaminated transport vehicles at cold temperatures. Can J Vet Res. 2005;69:64–70. [PMC free article] [PubMed] [Google Scholar]

- 9.Otake S, Dee SA, Rossow KD, et al. Transmission of porcine reproductive and respiratory syndrome virus by fomites (boots and coveralls) Swine Health Prod. 2002;10:59–65. [Google Scholar]

- 10.Dee S, Deen J, Pijoan C. Evaluation of 4 intervention strategies to prevent the mechanical transmission of porcine reproductive and respiratory syndrome virus. Can J Vet Res. 2004;68:19–26. [PMC free article] [PubMed] [Google Scholar]

- 11.Molitor TW, Tune KA, Shin J. Application of TaqMan™ PCR in the detection of porcine reproductive and respiratory syndrome virus. Proc AD Leman Swine Conf 1997:173–175.

- 12.Snyder ML, Mermer B, Anderson PR, et al. Evaluation data for an immunological ELISA for porcine reproductive and respiratory syndrome virus. Proc 2nd Int Symp PRRSV 1995:15.

- 13.Cho JG, Dee SA, Deen J, et al. An evaluation of different variables on the shedding of Porcine reproductive and respiratory syndrome virus in aerosols. Can J Vet Res. In press.

- 14.Trincado C, Dee SA, Jacobson L, Otake S, Rossow K, Pijoan C. Attempts to transmit porcine reproductive and respiratory syndrome virus by aerosols under controlled field conditions. Vet Rec. 2004;154:294–297. doi: 10.1136/vr.154.10.294. [DOI] [PubMed] [Google Scholar]