Abstract

Contamination of foods with the human pathogen Listeria monocytogenes may occur during processing, and the purpose of this study was to determine whether genetically similar strains colonize different processing plants or whether specific persistent strains are unique to each processing plant. We hypothesized that specific L. monocytogenes strains may be better adapted to specific environmental niches in the processing environment. L. monocytogenes contamination patterns were identified by the collection of 686 and 267 samples from the processing environments: raw fish and products of four fish smokehouses and four fish slaughterhouses, respectively. Samples were collected both during production and after cleaning and disinfection. Typically, these samplings were separated by 1 to 3 months. Sampling sites were targeted toward areas likely to harbor the bacterium. L. monocytogenes was isolated from 213 samples, and one strain from each positive sample was typed by RAPD (random amplified polymorphic DNA) analysis with four different primers. The 213 strains were divided into 37 RAPD types. One RAPD type was predominant; 86 of 213 strains belonged to this type. This type was found in three smokehouses and two slaughterhouses and was predominant in three of these plants. A subset of 35 strains was also analyzed by amplified fragment length polymorphism typing, which confirmed the genetic similarity of the groups. Moreover, strains of the dominant RAPD type were indistinguishable from strains isolated frequently from smoked fish products 10 years ago. One smokehouse was surveyed for a year and a half, and the dominant RAPD type persisted throughout the survey period and accounted for 94 of 118 isolates. Our study indicates that strains of L. monocytogenes that are genetically very closely related may be especially adapted to colonizing the processing equipment or especially resistant to cleaning and disinfection.

Listeria monocytogenes is an important food-borne pathogen in ready-to-eat (RTE) foods, and immunocompromised individuals, infants, and the elderly may develop invasive listeriosis following the consumption of foods with high levels of the organism (7, 22, 27). Only a few case of listeriosis are reported per year, and the level is typically 2 to 8 cases per million people, with the current level in the United States being 3.4 cases per million people per year (11). Listeriosis accounts for only a small percentage of all food-borne disease cases; however, the mortality rate of up to 30% (22) is considerably higher than for other food-borne pathogens, and listeriosis causes 28% of the annual deaths attributable to food-borne pathogens (16).

Although most raw materials in food processing may harbor the organism, its presence in RTE foods is primarily caused by contamination during processing (1, 9, 23). Subsequent growth of L. monocytogenes in the product is an important risk factor since the disease is primarily caused by the ingestion of high levels of the organism (11). Products such as cold-smoked salmon, in which the bacterium is detected in ca. 4% of retail packages and in which it can grow, are therefore a significant public health concern. The risk of listeriosis on a per-serving basis for smoked seafood is 6.2 × 10−9, which categorizes smoked seafood as a high-risk food (11). A number of countries have established a zero-tolerance policy for L. monocytogenes in RTE products, whereas other countries accept levels up to 100 CFU/g depending on the potential for growth of the organism in the product (19). Recalls of products due to the zero-tolerance policy has severe economic consequences for producers all over the world. Elucidating the sources of food contamination and the factors influencing this are important parameters in controlling the organism.

The incidence of L. monocytogenes in raw fish is typically low, whereas the contamination on the processing equipment in cold-smoking fish plants can be quite high. Molecular subtyping of strains from raw fish, processing environments, and packed products has suggested that contamination during processing rather than contamination directly from raw fish is the principal cause of product contamination (1, 9, 23, 24). The production process for cold-smoked salmon and other cold-smoked fish does not include a listeriacidal step, and only a better understanding of the sources and contamination routes of L. monocytogenes can specifically reduce the contamination of the product. Some types of L. monocytogenes can persist for months or years in cold-smoked fish producing plants (2, 6, 9, 13, 17, 23). Such persistent types appear to be unique to each processing unit; however, a multiple-processing-plant comparison has not been made since most studies have investigated only few smokehouses in parallel. A recent study of four fish smokehouses found that between 0 and 30% of the samples from the processing environment were positive for L. monocytogenes (24). A total of 83 strains were isolated and ribotyped; however, none of the ribotypes appeared to reside in more than one processing environment. It could, however, be hypothesized that specific traits are required for a specific L. monocytogenes strain to persist, e.g., a special resistance to cleaning and disinfecting agents or a special attachment capability. In that case, control procedures targeting such specific strains must be established.

Despite several studies addressing the contamination patterns of cold-smoked fish (1, 9, 23, 24), it is still not clear how important raw material contamination is and whether particular physiological traits allow some strains to persist over many years. Also, most studies have sampled only during processing and have not addressed the issue of strains surviving the regular cleaning and disinfection schedule.

In the present study, the objective was to compare the contamination patterns of L. monocytogenes in a number of fish smoke- and slaughterhouses to determine the similarity of strains that dominate the processing environment across the sector. Two levels of cold-smoked fish production were examined by the inclusion of both fish slaughterhouses and smokehouses (four of each plant type), and an overview of the contamination levels was determined by examination for the presence of L. monocytogenes both during production and after cleaning and disinfection. L. monocytogenes strains have been typed by the random amplified polymorphic DNA (RAPD) technique, and the RAPD grouping of strains was verified by using the amplified fragment length polymorphism (AFLP) technique. The presence of Listeria spp. was also determined to approach the long-debated question of whether Listeria spp. could be used as an indicator for the possible presence of L. monocytogenes.

MATERIALS AND METHODS

Slaughterhouses and product manufacturing.

Samples were collected from two Danish and two Faroese fish slaughterhouses during production (56, 26, 30, and 29 samples) and after cleaning and disinfection (66, 20, 21, and 19 samples) with at least 1 month between sampling. One slaughterhouse slaughtered ocean-raised rainbow trout (Oncorhyncus mykiss), whereas one received both ocean-raised and pond-raised rainbow trout. These slaughterhouses manufactured only in the season (October to January). The other two slaughterhouses slaughtered both ocean-raised salmon (Salmo salar) and ocean-raised rainbow trout. The fish were killed either by CO2 or “by hand.” The fish were gutted, rinsed, washed, and sorted by weight and either packed in ice or frozen as whole fish with or without the head.

Cleaning was carried out in the four plants at the end of each production day using low-pressure chloride foam cleaners in three plants, whereas one plant used high-pressure chloride-based foam cleaning. Once a week a decalcification procedure was performed in two plants. Three plants used a daily cleaning and disinfection procedure with hypochlorite as the disinfecting agent. A similar cleaning and disinfection procedure was performed only on the weekend in the fourth plant.

Smokehouses and product manufacturing.

Environmental samples and samples of raw material and products were collected between November 2002 and April 2003 at four Danish smokehouses. Totals of 134, 99, 111, and 121 samples were collected during production, and 44, 79, 47, and 51 samples were collected after cleaning and disinfection from smokehouses 1, 2, 3, and 4, respectively. Samplings were done 1 to 3 months apart. Cold-smoked salmon was the main product of the smokehouses; however, they also produced products such as cold-smoked rainbow trout, cold-smoked Greenland halibut, cold-smoked tuna, and “gravad” salmon. The main raw material was Norwegian or Faroese ocean-raised salmon (Salmo salar) received iced (0°C) or occasionally frozen. Head cutting, washing by commercial fish washers, filleting, pinboning, and manual trimming were done in one flow in the raw fish processing area of the smokehouses. The fillets were brined either by injection of saturated brine or by dry salting (ripening at 0°C for at least 12 h). The fish were transported by conveyer belts between the different steps of raw material manufacture. The skin was removed mechanically either before smoking or after smoking. The cold smoking and drying were performed in ovens (22 to 27°C for 8 to 16 h). Most fillets were quick-frozen and then brought to −14°C before slicing; however, in some instances, the fillets were sliced when cooled to 0 to 5°C. Frozen fillets were sliced on mass slicers, whereas thawed or cooled fillets were sliced on other types of slicing machines, separated into portions, and vacuum packed.

Complete cleaning and disinfection programs were carried out in the four plants at the end of each production day, fulfilling legal requirements, and once a week a decalcification procedure was performed. Cleaning was performed by using low-pressure and foam cleaners. Peroxyacetic acid was used as the disinfecting agent in one smokehouse, whereas hypochlorite was used in the other three smokehouses.

Surveillance program sampling.

To determine whether the very frequently occurring RAPD type of L. monocytogenes was a true persistent strain, samples from the processing environment of one of the smokehouses were collected over a 1.5-year period both during processing and after cleaning and disinfection. Between 12 and 22 samples were collected at 22 visits between February 2003 and September 2004; a total of 167 samples were collected during production, and 213 samples were collected after cleaning and disinfection.

Sampling procedure.

Raw fish were sampled by swabbing five fish using dry sponges (CS-100-1 Solar-Cult; Solar Biological, Inc., Ogdensburg N.Y.) for each sample. Samples from the processing environments in the smokehouses were collected by using swabs or sponges moistened with 0.1% peptone-0.85% saline (BS-10BPW-5 Solar-Cult; Solar Biological) and were taken no sooner than 2 h after the start of production. The area of sampling varied depending on the sampling location. Minimum areas were screw heads or needles for brine injection (ca. 1 cm2); maximum areas were surfaces of conveyor belts, floors, or doors (up to 1 m2). Sampling locations were chosen to represent those most likely to harbor L. monocytogenes. Sampling sites included zone 1 (product contact surfaces, e.g., equipment surfaces such as conveyer belts, knifes, and gloves), zone 2 (surfaces close to the product, e.g., the back side of tables or other equipment or the floor below the equipment), and zone 3 areas (surfaces away from product, e.g., walls, trucks, drains, and equipment not in use). Sampling of surface areas after cleaning and disinfection was done with sterile sponges remoistened with neutralizing buffer (BS-10NB-1 Solar-Cult; Solar Biological) Product samples consisted of 25 g taken from two retail packages of cold-smoked salmon, gravad salmon, or other cold-smoked fish (e.g., halibut).

Bacteriological analyses.

Swabs, sponges, or 25-g fish samples were suspended in 10, 40, or 225 ml of UVM 1 (Oxoid Listeria enrichment broth base [CM863] with Oxoid Listeria selective supplement UVM 1 [SR 142]), respectively. After 24 h of incubation at 30°C, 1 ml was transferred to tubes containing 10 ml of UVM2 broth (Oxoid Listeria selective supplement UVM 2 [SR 143]) and incubated for 24 h at 30°C, followed by selection on PALCAM agar. To enhance the possibility of obtaining both L. monocytogenes and other Listeria species, three putative Listeria colonies, preferably of different morphological appearances, were isolated, pure cultured, and identified by biochemical criteria according to NMKL 136 (18).

BAX PCR.

For the specific detection of L. monocytogenes by PCR, the commercial BAX for screening Listeria monocytogenes (DuPont Qualicon) was used on the majority of environmental samples where growth was seen on PALCAM after the UVM enrichment. A total of 100 μl of UVM 2 enrichment culture was transferred to 10 ml of morpholinepropanesulfonic acid-buffered Listeria enrichment broth (MOPS-BLEB), followed by incubation at 37°C for 24 h. Then, 5 μl of MOPS-BLEB culture was transferred to 200 μl of lysis buffer (provided with the BAX kit) and lysed for 60 min at 55°C, followed by 10 min at 95°C and 10 min at 4°C. Next, 50 μl of the lysed cells was transferred to the BAX PCR tubes, which contained tablets consisting of all PCR reagents and a positive control. The reaction mixtures were amplified at 94°C for 2 min, followed by 38 cycles of 15 s at 94°C and 3 min at 70°C, and then cooled to 25°C. Then, 15 μl of loading dye (provided with the BAX kit) was added to each tube. A portion (12 μl) of the mixture was analyzed on a 2% agarose gel and visualized by staining with ethidium bromide. A portion (12 μl) of a mass ladder (provided with the BAX kit) was included as a standard.

RAPD typing.

One L. monocytogenes isolate from each positive sample was typed by RAPD analysis with four primers. RAPD typing was performed as described previously (10), using the primers UBC155 (5′-CTGGCGGCTG-3′), HLWL85 (5′-ACAACTGCTC-3′), OMP-01 (5′-GTTGGTGGCT-3′), and DAF4 (5′-CGGCAGCGCC-3′) (DNA Technology, Aarhus, Denmark). The PCR was run as follows. After denaturing for 2 min at 95°C, the next 10 cycles consisted of 1 min of denaturing at 95°C, followed by annealing at 45 to 36°C, reducing the temperature with 1°C for each cycle, and this was followed by 2 min at 72°C. The last 30 cycles used denaturing at 95°C for 1 min, followed by annealing at 35°C for 1 min and extension at 72°C for 2 min, followed by 10 min at 72°C. The patterns from the four primers were compared visually for all strains and, when required, amplification or gel separation was repeated. RAPD types identified in our earlier studies (9, 10) were given the same numbers, whereas new types were numbered after identification. Assignment to a RAPD type required that the strain was identical to specific patterns with all four primers.

AFLP typing.

A subset of 35 strains containing 23 strains of the most frequently occurring RAPD types (types 6, 7, 9, and 57) and 12 strains originating from other studies were also typed by AFLP analysis as described previously (9). Briefly, genomic DNA was extracted by using the Easy-DNA kit (Invitrogen, De Schelp, The Netherlands) according to the manufacturer's instructions. Bacterial DNA was digested with BamHI and EcoRI, ligated to adaptors, and PCR amplified. Amplification products and internal-lane size standards labeled with ROX (GeneScan-500 [ROX] size standard [Perkin-Elmer Applied Biosystems, Warrington, England]) were analyzed by electrophoresis in 5% denaturing polyacrylamide gels for 3.5 h using an ABI 377 automated sequencer (Applied Biosystems, Foster City, CA). The AFLP patterns were collected by using GeneScan software (Applied Biosystems, Foster City, CA). Numerical pattern analyses were performed as described previously (8). AFLP types identified in our earlier study (8) were given the same numbers, whereas new types were numbered after identification.

PCR-RFLP typing.

The hly virulence gene was characterized by PCR-restriction fragment length polymorphism (RFLP) analysis of the subset of 35 strains according to the method of Wiedmann et al. (26).

RESULTS

Occurrence of L. monocytogenes in slaughterhouses.

A total of 267 samples were collected from four slaughterhouses, and 243 of these samples were collected from the processing environment, 9 were collected from unprocessed raw fish samples (representing 45 fish), and 15 were collected from processed fish (representing 75 fish) (Table 1).

TABLE 1.

Distribution based on sample type and on zones of total numbers of samples collected and numbers of L. monocytogenes-positive samples from slaughterhouses A to D

| Slaughter- house | Sampling sitea |

L. monocytogenes-positive samplesb

|

|||||

|---|---|---|---|---|---|---|---|

| No. of samples

|

No. positive

|

% Positive

|

|||||

| P | C&D | P | C&D | P | C&D | ||

| A | Unprocessed fish | 2 | 0 | 0 | |||

| Processing area | 52 | 66 | 26 | 18 | 50 | 27 | |

| Zone 1 | 25 | 28 | 11 | 5 | 44 | 18 | |

| Zone 2 | 17 | 27 | 7 | 7 | 41 | 26 | |

| Zone 3 | 10 | 11 | 8 | 6 | 80 | 55 | |

| Fish in process | 2 | 2 | 100 | ||||

| B | Unprocessed fish | 3 | 0 | 0 | |||

| Processing area | 20 | 20 | 5 | 2 | 25 | 10 | |

| Zone 1 | 10 | 9 | 3 | 1 | 30 | 11 | |

| Zone 2 | 4 | 5 | 1 | 1 | 25 | 20 | |

| Zone 3 | 6 | 6 | 1 | 0 | 17 | 0 | |

| Fish in process | 3 | 0 | 0 | ||||

| C | Unprocessed fish | 1 | 0 | 0 | |||

| Processing area | 24 | 21 | 16 | 12 | 67 | 57 | |

| Zone 1 | 5 | 9 | 5 | 6 | 100 | 67 | |

| Zone 2 | 9 | 8 | 6 | 3 | 67 | 38 | |

| Zone 3 | 10 | 4 | 5 | 3 | 50 | 75 | |

| Fish in process | 5 | 1 | 20 | ||||

| D | Unprocessed fish | 3 | 0 | 0 | |||

| Processing area | 21 | 19 | 5 | 1 | 24 | 5 | |

| Zone 1 | 10 | 6 | 2 | 0 | 20 | 0 | |

| Zone 2 | 7 | 11 | 2 | 0 | 29 | 0 | |

| Zone 3 | 4 | 2 | 1 | 1 | 25 | 50 | |

| Fish in process | 5 | 1 | 20 | ||||

| Total | Unprocessed fish | 9 | 0 | 0 | |||

| Processing area | 117 | 126 | 52 | 33 | 44 | 26 | |

| Zone 1 | 50 | 52 | 21 | 12 | 42 | 23 | |

| Zone 2 | 37 | 51 | 16 | 11 | 43 | 22 | |

| Zone 3 | 30 | 23 | 15 | 10 | 50 | 43 | |

| Fish in process | 15 | 4 | 27 | ||||

Zone 1, product contact surfaces; zone 2, surfaces close to the product; zone 3, surfaces away from the product.

P, production; C&D, cleaning and disinfection. Summarized numbers are in boldface.

The number of L. monocytogenes-positive samples in two of the slaughterhouses varied between 50 and 67% of samples taken during processing. Cleaning and disinfection reduced the numbers to 27 and 57%, respectively. The remaining two slaughterhouses were less contaminated; only 1 of 19 samples taken after cleaning and disinfection was positive for L. monocytogenes in one of the slaughterhouses, and no positive samples were found in zone 1 or 2.

None of the unprocessed raw fish were positive for L. monocytogenes, but 4 of 15 (27%) fish samples, each sample taken by swabbing five fish, were positive after processing (Table 1).

Occurrence of L. monocytogenes in smokehouses.

A total of 686 samples were collected from the four smokehouses, and 600 of these were collected from the processing environment, 12 were collected from unprocessed raw fish (representing 60 fish), and 74 were collected from finished products (representing 148 retail packages) (Table 2).

TABLE 2.

Distribution based on sample type and on zones of total numbers of samples collected and numbers of L. monocytogenes-positive samples from smokehouses 1 to 4

| Smoke- house | Sampling sitea |

L. monocytogenes-positive samplesb

|

|||||

|---|---|---|---|---|---|---|---|

| No. of samples

|

No. positive

|

% Positive

|

|||||

| P | C&D | P | C&D | P | C&D | ||

| 1 | Unprocessed fish | 5 | 3 | 60 | |||

| Processing area | 105 | 44 | 17 | 4 | 16 | 9 | |

| Zone 1 | 28 | 11 | 4 | 1 | 14 | 9 | |

| Zone 2 | 58 | 27 | 10 | 2 | 17 | 7 | |

| Zone 3 | 19 | 6 | 3 | 1 | 16 | 17 | |

| Products | 24 | 4 | 17 | ||||

| Smoked salmon | 12 | 0 | 0 | ||||

| Other products | 12 | 4 | 33 | ||||

| 2 | Unprocessed fish | 1 | 1 | 100 | |||

| Processing are | 78 | 79 | 25 | 13 | 32 | 16 | |

| Zone 1 | 22 | 9 | 6 | 1 | 27 | 11 | |

| Zone 2 | 48 | 60 | 14 | 10 | 29 | 17 | |

| Zone 3 | 8 | 10 | 5 | 2 | 63 | 20 | |

| Products | 20 | 4 | 20 | ||||

| Smoked salmon | 16 | 1 | 6 | ||||

| Other products | 4 | 3 | 75 | ||||

| 3 | Unprocessed fish | 1 | 0 | 0 | |||

| Processing area | 100 | 47 | 32 | 13 | 32 | 28 | |

| Zone 1 | 27 | 3 | 2 | 1 | 7 | 33 | |

| Zone 2 | 52 | 29 | 17 | 10 | 33 | 34 | |

| Zone 3 | 21 | 15 | 13 | 2 | 62 | 13 | |

| Products | 10 | 1 | 10 | ||||

| Smoked salmon | 8 | 1 | 13 | ||||

| Other products | 2 | 0 | 0 | ||||

| 4 | Unprocessed fish | 5 | 1 | 20 | |||

| Processing area | 96 | 51 | 19 | 8 | 20 | 16 | |

| Zone 1 | 19 | 9 | 2 | 0 | 11 | 0 | |

| Zone 2 | 57 | 28 | 10 | 4 | 18 | 14 | |

| Zone 3 | 20 | 14 | 7 | 4 | 35 | 29 | |

| Products | 20 | 4 | 20 | ||||

| Smoked salmon | 15 | 0 | 0 | ||||

| Other products | 5 | 4 | 80 | ||||

| Total | Unprocessed fish | 12 | 5 | 42 | |||

| Processing area | 379 | 221 | 93 | 38 | 25 | 17 | |

| Zone 1 | 96 | 32 | 14 | 3 | 15 | 9 | |

| Zone 2 | 215 | 144 | 51 | 26 | 24 | 18 | |

| Zone 3 | 68 | 45 | 28 | 9 | 41 | 20 | |

| Products | 74 | 13 | 18 | ||||

| Smoked salmon | 51 | 2 | 4 | ||||

| Other products | 23 | 11 | 48 | ||||

Zone 1, product contact surfaces; zone 2, surfaces close to the product; zone 3, surfaces away from the product.

P, production; C&D, cleaning and disinfection. Summarized numbers are in boldface.

On average, 25% of the environmental samples were positive for L. monocytogenes during processing (Table 2), and the number of positive samples varied between the smokehouses from 16 to 32%. After cleaning and disinfection, the average numbers of positive samples decreased to 17%. Overall, the highest levels of positive samples were found in zone 3 areas, whereas the numbers of positive samples in zone 1 areas were lower.

Of 12 samples of unprocessed fish, 5 (42%), each taken by the swabbing of five fish, received at the smokehouses were positive for L. monocytogenes, whereas 13 of 74 samples of finished product (each sample representing two retail packages) were positive (18%). However, the prevalence in cold-smoked salmon was much lower (4%) than in other types of smoked products, where 11 of 23 samples (48%) were positive (Table 2).

Distribution of RAPD types in slaughterhouses.

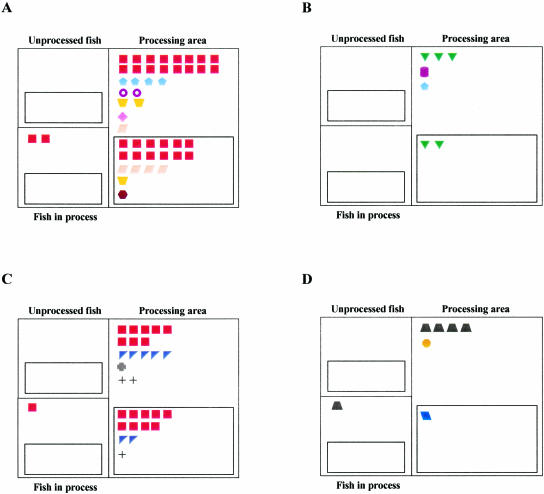

Slaughterhouse A was dominated by the presence of RAPD type 9 (Fig. 1A and Table 3). This RAPD type was isolated from 64% of the L. monocytogenes-positive samples during production and from 67% of the positive samples taken after cleaning and disinfection. RAPD types 5 and 30 were also found both during production and after cleaning and disinfection.

FIG. 1.

Distribution of L. monocytogenes RAPD types in slaughterhouses A, B, C, and D. Each symbol represents an L. monocytogenes-positive sample. Symbols denote different RAPD types. “+” represents an L. monocytogenes-positive sample detected only by PCR and from which no isolates were recovered. Strains in boxes were found after cleaning and disinfection.

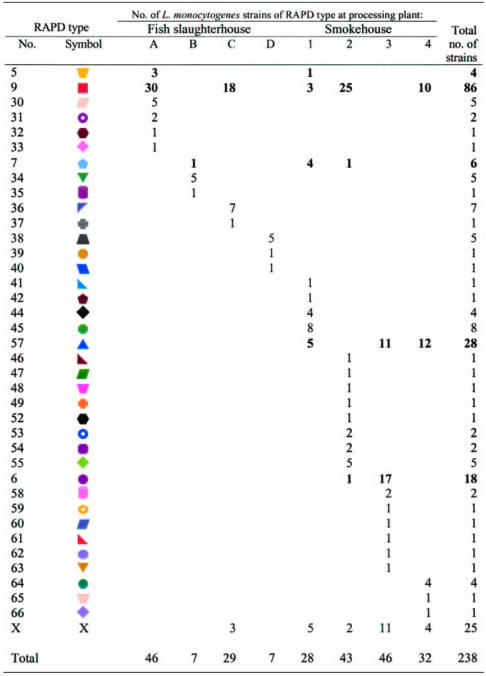

TABLE 3.

Distribution of L. monocytogenes RAPD types in smokehouses and slaughterhousesa

Strains were isolated during production and after cleaning and disinfection 1 to 3 months apart at each fish processing plant. The numbers of RAPD types found in more than one fish plant are in boldface. X, the number of L. monocytogenes-positive samples detected only by PCR and from which no strains were recovered.

RAPD type 9 was also found in slaughterhouse C, where it constituted 53% of the L. monocytogenes-positive samples during production and 75% after cleaning and disinfection. Only two other RAPD types (types 36 and 37) were found in this slaughterhouse. Of these one (RAPD type no. 36) was found both during production and after cleaning and disinfection; however, isolates were not obtained from three positive samples (Fig. 1C and Table 3). Although the two remaining slaughterhouses were much less contaminated, dominating RAPD types were also found in these slaughterhouses. In slaughterhouse B, one RAPD type (type 34) was found in 60% of the L. monocytogenes-positive samples during production and in 100% after cleaning and disinfection (Fig. 1B and Table 3). One RAPD type (type 38) occurred in 83% of the positive samples during production at the fourth slaughterhouse (Fig. 1D and Table 3).

Distribution of RAPD types in smokehouses.

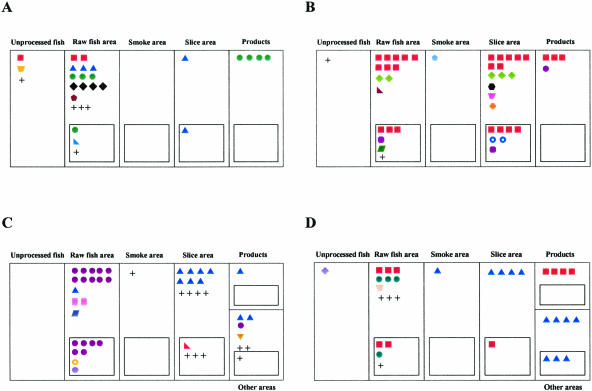

The L. monocytogenes contamination patterns were different in the different smokehouses (Fig. 2). Many different RAPD types were identified in the first smokehouse and the organism was mainly found in the raw fish area where six different RAPD types (types 5, 9, 42, 44, 45, and 57) were detected on unprocessed fish and in the raw fish processing environment during production (Fig. 2A and Table 3). Two RAPD types (types 41 and 45) were also detected at sampling after cleaning and disinfection. None of the RAPD types were dominant. RAPD type 45 was found in the four L. monocytogenes-positive samples of finished products, and this RAPD type was also found in the raw fish area both during production and after cleaning and disinfection (Fig. 2A).

FIG. 2.

Distribution of L. monocytogenes RAPD types in smokehouses. Each symbol represents an L. monocytogenes-positive sample. Symbols denote different RAPD types. “+” represents an L. monocytogenes-positive sample detected only by PCR and from which no isolates were recovered. Strains in boxes were found after cleaning and disinfection.

One RAPD type dominated in the second smokehouse, where more than half of the L. monocytogenes strains found in raw fish and the processing areas were RAPD type 9. This RAPD type was identified in processed raw fish, in the raw fish area, and in the slicing area. Furthermore, it was found in 75% of the L. monocytogenes-positive product samples (Fig. 2B and Table 3).

A different contamination pattern was seen in the third smokehouse, where two dominant RAPD types (types 6 and 57) were found during production. RAPD type 6 was mainly seen in the raw fish area, whereas the RAPD type 57 dominated the areas situated after the smoking process. Only RAPD type 6 was isolated after cleaning and disinfection in the raw fish area, and only RAPD type 57 was found in finished products (Fig. 2C and Table 3). The two RAPD types were found regularly at later samplings (data not shown); however, they were both detected in all parts of the plant, and the initial division between the raw fish section and the slicing area was not a constant pattern.

One dominant RAPD type (type 57) was also found in the processing areas of the fourth smokehouse; however, this RAPD type was only found outside the raw fish area. The occurrence of this RAPD type was 43% during production and 38% after cleaning and disinfection. This RAPD type was not detected in finished products; however, RAPD type 9, also found in smokehouses 1 and 2, was present in four L. monocytogenes-positive product samples.

Frequently occurring RAPD types.

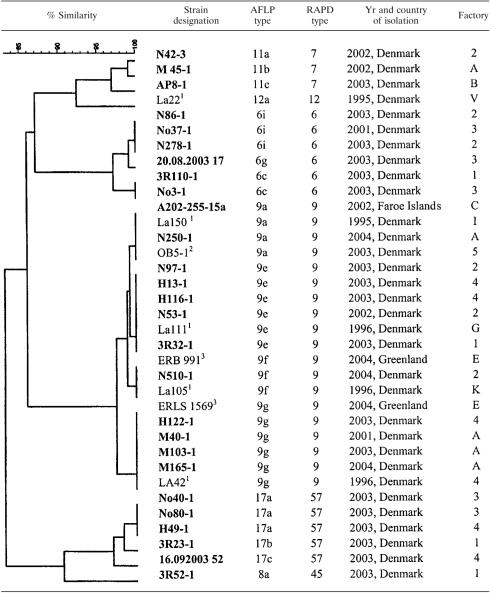

The 213 strains isolated from smoke- and slaughterhouses were divided into 37 different RAPD types (Table 3). At least three different RAPD types were present in all processing plants, and most plants harbored one or two dominating RAPD types. Each plant had its own specific groups of RAPD types; however, five RAPD types (RAPD types 5, 6, 7, 9, and 57) were recovered from more than one smoke- and/or slaughterhouse. RAPD types 6, 9, and 57 were the most frequently occurring RAPD types, and especially RAPD type 9 was very common and was found in three of four smokehouses and in two of four slaughterhouses. RAPD type 9 persisted in one of the smokehouses, where it was reisolated repeatedly over a 1.5-year period and clearly was the dominant strain. RAPD type 9 also appeared to persist in three of the other processing environments (smokehouse 4 and slaughterhouses A and C), as indicated by its reisolation as the dominant type after 1 to 3 months. Of the 213 strains typed by RAPD, 86 were RAPD type 9 (Table 3). In two other studies we RAPD typed L. monocytogenes strains from smoked salmon products produced in 10 different smokehouses (10) and from the processing environments of 2 smokehouses (9), and in these studies RAPD types 5, 6, 7, and 9 were also found. A subset of 35 strains was both subjected to RAPD typing and profiled by AFLP and PCR-RFLP analysis and included representatives of strains of RAPD types 6, 7, 9, and 57. All of the 35 strains belonged to L. monocytogenes lineage 2 according to PCR-RFLP analysis. AFLP confirmed the RAPD clustering (Table 4), and grouped the dominant RAPD type 9 into four closely related AFLP types (9a, 9e, 9f, and 9g). Ten years ago, we RAPD typed L. monocytogenes strains from smoked salmon products (10), and RAPD type 9 was also more frequent than other RAPD types in the present study. The three RAPD types 6, 7, and 57 were divided into three (6c, 6g, and 6i), three (11a, 11b, and 11c), and three (17a, 17b, and 17c) closely related types, respectively.

TABLE 4.

Dendrogram for 35 L. monocytogenes strains analyzed by AFLP typinga

The dendrogram was constructed by using Bionumerics software with the Dice correlation and cluster analysis by UPGMA. The percentages of similarity are shown above the dendrogram. Designations of strains isolated in this study are in boldface. Superscript numbers indicate the following: 1, isolated from cold-smoked salmon (10); 2, isolated from equipment of a Danish smokehouse not included in the study; 3, isolated from equipment of a shrimp processing plant in Greenland.

One-and-a-half year survey of RAPD types in a smokehouse.

To determine whether RAPD type 9 was a true persistent strain, we sampled from one smokehouse over a 1.5-year period. L. monocytogenes-positive samples were found at each sampling except one at the smokehouse visited during the 1.5-year survey (Table 5). The percentage of L. monocytogenes-positive samples varied between 17% (2 of 12) and 95% (19 of 20). The percentage of positive L. monocytogenes samples after cleaning and disinfection was lower and varied between 0 and 60% (12 of 20). A total of 380 samples were taken over the 1.5-year period (Table 5). L. monocytogenes was detected in 118 of these, and in 94 of these RAPD type 9 was isolated. At some samplings, this was the only RAPD type found (Table 5).

TABLE 5.

Number of L. monocytogenes-positive samples and number of RAPD type 9 in an environmental sampling program of smokehouse 2

| Yr | Wk | No. of samples

|

|||||

|---|---|---|---|---|---|---|---|

| During production

|

After cleaning and disinfection

|

||||||

| Total | L. monocytogenes positive | Positive for RAPD type 9 | Total | L. monocytogenes positive | Positive for RAPD type 9 | ||

| 2003 | 7 | 20 | 1 | 0 | |||

| 8 | 21 | 3 | 2 | ||||

| 9 | 18 | 5 | 4 | ||||

| 10 | 21 | 4 | 2 | ||||

| 11 | 20 | 6 | 5 | ||||

| 12 | 20 | 2 | 1 | ||||

| 14 | 19 | 5 | 5 | ||||

| 15 | 20 | 4 | 3 | ||||

| 17 | 22 | 8 | 6 | ||||

| 18 | 21 | 2 | 1 | ||||

| 36 | 12 | 8 | 4 | 12 | 6 | 4 | |

| 43 | 12 | 4 | 3 | 12 | 2 | 2 | |

| 2004 | 6 | 12 | 2 | 2 | 12 | 0 | 0 |

| 12 | 12 | 3 | 3 | 12 | 1 | 1 | |

| 22 | 20 | 13 | 11 | 22 | 8 | 7 | |

| 36 | 20 | 19 | 17 | 20 | 12 | 11 | |

| Total | 167 | 73 | 60 | 213 | 45 | 34 | |

Occurrence of Listeria spp.

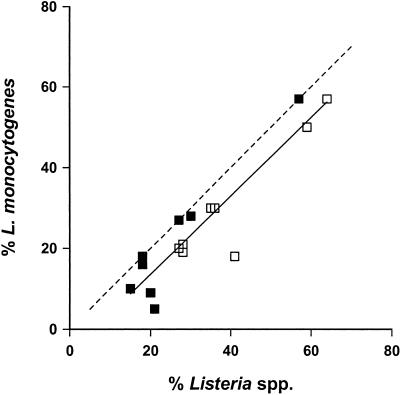

The occurrence of Listeria species other than L. monocytogenes in the smoke- and slaughterhouses was also investigated. Some samples harbored only L. monocytogenes, others had only non-L. monocytogenes listeriae, and in some samples both L. monocytogenes and non-L. monocytogenes Listeria species were detected. The samples positive for L. monocytogenes dominated in three of the smokehouses and in all of the slaughterhouses during production (Fig. 3). In contrast, in the fourth smokehouse, 23% of the samples contained Listeria species other than L. monocytogenes, whereas only 18% had L. monocytogenes. After cleaning and disinfection, samples with L. monocytogenes exceeded the number of samples with non-L. monocytogenes Listeria spp. However, samples positive for Listeria spp. other than L. monocytogenes exceeded the number of L. monocytogenes-positive samples in one smokehouse (1) and in one slaughterhouse (D) after cleaning and disinfection.

FIG. 3.

Comparison of percentages of samples positive for Listeria spp. and percentages of samples positive for L. monocytogenes in eight fish processing plants (four slaughterhouses and four smokehouses). Open squares represent samples taken during production, and closed squares represent samples taken after cleaning and disinfection. The dashed line represents y = x. The solid line indicates the linear regression comparing the two percent positives. Values were calculated as follows: % L. monocytogenes = 0.97 × % Listeria spp. − 5.81, with a correlation coefficient of r2 = 0.85.

DISCUSSION

The processing environment of several fish processing plants harbored L. monocytogenes, and the level of contamination was comparable to other studies (1, 9, 13, 23, 24). Some plants had quite high numbers of positive samples even after cleaning and disinfection, indicating that these procedures could be improved. Each processing plant had its own profile of RAPD types of L. monocytogenes, and most of the plants had persistent in-house L. monocytogenes RAPD types. However, some RAPD types were found in several processing plants, and one RAPD type was especially dominant and found in three of four smokehouses and in two of four slaughterhouses. This RAPD type was found both in Denmark and on the Faroe Islands and in products from Greenland. The contamination patterns did not appear to be linked to a particular way of processing, although the one smokehouse with the lowest contamination level during slicing was the smokehouse in which peracetic acid was used as a disinfectant.

It has been suggested that contamination during processing rather than contamination from raw fish is the principal cause of product contamination (9, 23), and we therefore sampled in particular from the processing environment. The relatively high L. monocytogenes contamination levels in the processing areas of the smokehouses are in agreement with findings of other studies, although the number (or percentage) of positive samples may vary greatly: from 1 to 43%, with the typical level being ca. 30% (1, 9, 13, 23, 24). We found moderate to high levels of L. monocytogenes contamination in the four smokehouses after cleaning and disinfection (9, 16, 16, and 28%, Table 2), and since several positive samples were found on zone 1 and zone 2 sites, cleaning and disinfection procedures could probably be improved. Almost half of the unprocessed fish samples taken as pooled samples at the smokehouses were positive for L. monocytogenes. This may be higher than previously reported in other studies (1, 9, 13, 14, 20, 23, 24); however, only a limited number of raw fish was examined in the present study, and we cannot determine whether one or all five of the fish in a sample were positive.

The L. monocytogenes contamination in the slaughterhouse environments was relatively substantial. Up to 50 to 67% of the samples during production were positive for L. monocytogenes, and these levels are significantly above earlier reported levels of 7% (23). Several positive samples were found after cleaning and disinfection, and these procedures did not reduce the level of contamination satisfactorily. Interestingly, L. monocytogenes was not isolated from any of the samples of raw unprocessed fish in the four slaughterhouses, representing a total of 45 fish. This finding is in agreement with other studies of ocean-reared fish, where the prevalence of L. monocytogenes has been very low (12). In contrast, the prevalence in freshwater fish appears to be higher (14). The number of fish sampled in the present study is limited; however, the data indicate that the processing environment, whether at the slaughterhouse or at the smokehouse, is the major source of contamination.

Although L. monocytogenes was detected more or less at the same level in all smokehouses, the patterns of contamination differed markedly between smokehouses (Fig. 2). In smokehouse 1, the relatively low level of L. monocytogenes and the identification of several different RAPD types indicate the control of L. monocytogenes contamination within the smokehouse. In contrast, the presence of an in-house persistent strain was especially distinct in smokehouse 2, where more than 50% of the examined strains both during production and after cleaning and disinfection were of the same RAPD type. Repeated samplings at this smokehouse over a year and a half from the first sampling confirmed that this RAPD type was ubiquitous and dominant in the smokehouse (Table 4).

Some of the L. monocytogenes-positive samples were detected only by PCR and, theoretically, these samples could have contained one or more RAPD types, which in principle could have changed the RAPD type patterns, especially for the third smokehouse, where RAPD types of 11 positive samples remained unknown (Table 3).

The presence of a persistent strain may indicate deficiencies in the cleaning and disinfection procedures and the need for more-thorough cleaning of potential niches in the processing environment. Several studies suggest that contamination of finished products is more likely to be caused by contaminated processing equipment than due to the contamination of incoming raw fish (1, 9, 13, 23, 24). However, the raw material can be an important initial contamination source of L. monocytogenes in smokehouses (9, 15).

Our study is the first to assess the contamination pattern of L. monocytogenes in fish slaughterhouses and, as in the smokehouses, the contamination patterns varied. Two were colonized by a persistent strain (RAPD type 9), and this RAPD type was even more dominant at samplings a year later at the slaughterhouse (data not shown). Even though the occurrence of L. monocytogenes-positive samples was very low in two of the slaughterhouses, one RAPD type was found both before and after cleaning and disinfection in one plant, and one RAPD type dominated with an occurrence of 83% during production in the other plant. Thus, the ability of L. monocytogenes to establish itself in a processing environment also seems to be a characteristic in a raw fish processing environment.

Our study clearly demonstrates that each processing plant harbors its own population of L. monocytogenes RAPD types (Table 3) but that some RAPD types may occur in more than one plant. Furthermore, four RAPD types (5, 6, 7, and 9) found in the present study have also been found in our earlier studies of L. monocytogenes diversity in smokehouses (9, 10). Thimothe et al. (24) found that 2 of 14 distinct ribotypes (dividing 71 strains) were detected in more than one smokehouse (five sampled). In our study, a very similar ratio was seen since 5 of 37 RAPD types (dividing 213 strains) were detected more than once. However, noticeable is the very frequent occurrence of RAPD type 9, which was found in five of the eight processing plants. Although some of these processing plants had an inter-trade relationship, some had never had contact with one another. Also, this RAPD type was the dominant RAPD type in three plants. The discriminatory ability of RAPD using two primers is slightly higher than that of ribotyping (8); however, AFLP subdivides even the RAPD groups. The RAPD types 6, 7, 9, and 57 were divided by AFLP typing but into very closely related AFLP types, and we believe that these strains are very closely related on a genetic level. RAPD type 9 and AFLP types 9a, 9e, 9f, and 9g were found in processing plants both in Denmark and on the Faroe Islands and in a shrimp processing plant in Greenland. Furthermore, this RAPD type was isolated 10 years earlier from cold-smoked salmon produced in several other fish smokehouses (10).

The finding of specific or closely genetic related L. monocytogenes strains in more smoke- and slaughterhouses could indicate (i) that these strains are more common than other RAPD types and thus the plant is more often exposed to the specific RAPD type (23); (ii) that the specific RAPD type is a better colonizer, e.g., more able to adhere to surfaces (3); (iii) that the RAPD type is more resistant to disinfectants; or (iv) that the RAPD type is able to outcompete other RAPD types on the processing equipment or during the enrichment procedure (4). RAPD type 9 belongs to L. monocytogenes lineage 2, and other studies indicate a survival advantage for lineage 2 compared to lineage 1 (3, 4, 28). Thus, lineage 2 strains could be capable of more-efficient uptake and be more stress tolerant in competition situations and/or during nutrient depletion and so better suited to survive (4). The persistence of RAPD type 9 did not appear to correlate with the type of disinfection procedure used, and further studies specific to RAPD type 9 are necessary to determine why it establishes so successfully in fish processing plants.

A number of studies have evaluated whether the number of samples positive for Listeria spp. can be used as an indication of the level of L. monocytogenes-positive samples and found no universal link between the two (24, 25). In our study, Listeria sp.-positive samples did correlate with samples positive for L. monocytogenes except for at one smokehouse. This plant in particular was colonized by non-L. monocytogenes Listeria spp. Non-L. monocytogenes Listeria spp. may outcompete L. monocytogenes strains during the enrichment procedure (4, 5, 21), and the dominance of L. monocytogenes in seven of eight plants is therefore striking and indicates the strong ability of this organism to colonize the food processing niche.

In conclusion our findings demonstrate that certain RAPD types of L. monocytogenes may carry specific traits (either inherent or adapted) that enable them to persist in the food processing environment. Future control of this pathogenic organism would be greatly facilitated by elucidating the factors influencing this ability to persist. Also, it is essential that the virulence properties of such frequently dominant strains must be elucidated to determine whether their widespread persistence increases or decreases the risk from particular food products.

Acknowledgments

This study was made possible by a grant from the Danish Directorate for Food, Fisheries, and Agri Business (project 93S-24F4-Å02).

We are thankful to the fish processing plants involved and are indebted to Højmarklaboratoriet A/S for collaboration, including the handling of industrial samples and analysis. We thank Marjun Wilhelm and Óluvu Niclassen for participation in sampling of two of the slaughterhouses. We also thank Anemone Bundvad, Yin Yoke Ng, and Tina Nørgaard for excellent technical assistance.

REFERENCES

- 1.Autio, T., S. Hielm, M. Miettinen, A. M. Sjoberg, K. Aarnisalo, J. Bjorkroth, T. Mattila-Sandholm, and H. Korkeala. 1999. Sources of Listeria monocytogenes contamination in a cold-smoked rainbow trout processing plant detected by pulsed-field gel electrophoresis typing. Appl. Environ. Microbiol. 65:150-155. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Bagge-Ravin, D., K. Gardshodn, L. Gram, and B. F. Vogel. 2003. Comparison of sodium hypochlorite-based foam and peroxyacetic acid-based fog sanitizing procedures in a salmon smokehouse: survival of the general microflora and Listeria monocytogenes. J. Food Prot. 66:592-598. [DOI] [PubMed] [Google Scholar]

- 3.Borucki, M. K., J. D. Peppin, D. White, F. Loge, and D. R. Call. 2003. Variation in biofilm formation among strains of Listeria monocytogenes. Appl. Environ. Microbiol. 69:7336-7342. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Bruhn, J. B., B. Fonnesbech Vogel, and L. Gram. 2005. Bias in the Listeria monocytogenes enrichment procedure: lineage II strains out-compete lineage I strains. Appl. Environ. Microbiol. 71:961-967. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Curiale, M. S., and C. Lewus. 1994. Detection of Listeria monocytogenes in samples containing Listeria innocua. J. Food Prot. 57:1048-1051. [DOI] [PubMed] [Google Scholar]

- 6.Dauphin, G., C. Ragimbeau, and P. Malle. 2001. Use of PFGE typing for tracing contamination with Listeria monocytogenes in three cold-smoked salmon processing plants. Int. J. Food Microbiol. 64:51-61. [DOI] [PubMed] [Google Scholar]

- 7.FAO-WHO. 2004. Risk assessment of Listeria monocytogenes in ready-to-eat foods: interpretative summary. FAO-WHO, Rome, Italy.

- 8.Fonnesbech Vogel, B., V. Fussing, B. Ojeniyi, L. Gram, and P. Ahrens. 2004. High-resolution genotyping of Listeria monocytogenes by fluorescent amplified fragment length polymorphism analysis compared to pulsed-field gel electrophoresis, random amplified polymorphic DNA analysis, ribotyping, and PCR-restriction fragment length polymorphism analysis. J. Food Prot. 67:1656-1665. [DOI] [PubMed] [Google Scholar]

- 9.Fonnesbech Vogel, B., H. H. Huss, B. Ojeniyi, P. Ahrens, and L. Gram. 2001. Elucidation of Listeria monocytogenes contamination routes in cold-smoked salmon processing plants detected by DNA-based typing methods. Appl. Environ. Microbiol. 67:2586-2595. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Fonnesbech Vogel, B., L. V. Jorgensen, B. Ojeniyi, H. H. Huss, and L. Gram. 2001. Diversity of Listeria monocytogenes isolates from cold-smoked salmon produced in different smokehouses as assessed by random amplified polymorphic DNA analyses. Int. J. Food Microbiol. 65:83-92. [DOI] [PubMed] [Google Scholar]

- 11.FSIS-FDA. 2003. Interpretative summary: quantitative assessment of the relative risk to public health from food-borne Listeria monocytogenes among selected categories of ready-to-eat foods. Food Safety and Inspection Services, U.S. Food and Drug Administration, Washington, D.C.

- 12.Gram, L. 2001. Potential hazards in cold-smoked fish: Listeria monocytogenes. J. Food Safety Suppl. 66:S1072-S1081. [Google Scholar]

- 13.Hoffman, A. D., K. L. Gall, D. M. Norton, and M. Wiedmann. 2003. Listeria monocytogenes contamination patterns for the smoked fish processing environment and for raw fish. J. Food Prot. 66:52-60. [DOI] [PubMed] [Google Scholar]

- 14.Jemmi, T., and A. Keusch. 1994. Occurrence of Listeria monocytogenes in fresh-water fish farms and fish-smoking plants. Food Microbiol. 11:309-316. [Google Scholar]

- 15.Markkula, A., T. Autio, J. Lunden, and H. Korkeala. 2005. Raw and processed fish show identical Listeria monocytogenes genotypes with pulsed-field gel electrophoresis. J. Food Prot. 68:1228-1231. [DOI] [PubMed] [Google Scholar]

- 16.Mead, P. S., L. Slutsker, V. Dietz, L. F. Mccaig, J. S. Bresee, C. Shapiro, P. M. Griffin, and R. V. Tauxe. 1999. Food-related illness and death in the United States. Emerg. Infect. Dis. 5:607-625. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Nakamura, H., M. Hatanaka, K. Ochi, M. Nagao, J. Ogasawara, A. Hase, T. Kitase, K. Haruki, and Y. Nishikawa. 2004. Listeria monocytogenes isolated from cold-smoked fish products in Osaka City, Japan. Int. J. Food Microbiol. 94:323-328. [DOI] [PubMed] [Google Scholar]

- 18.NMKL. 1999. Listeria monocytogenes: detection in foods and feeds, 2nd ed. Nordic Committee on Food Analysis, Oslo, Norway.

- 19.Norrung, B. 2000. Microbiological criteria for Listeria monocytogenes in foods under special consideration of risk assessment approaches. Int. J. Food Microbiol. 62:217-221. [DOI] [PubMed] [Google Scholar]

- 20.Norton, D. M., M. A. McCamey, K. L. Gall, J. M. Scarlett, K. J. Boor, and M. Wiedmann. 2001. Molecular studies on the ecology of Listeria monocytogenes in the smoked fish processing industry. Appl. Environ. Microbiol. 67:198-205. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Petran, R. L., and K. M. J. Swanson. 1993. Simultaneous growth of Listeria monocytogenes and Listeria innocua. J. Food Prot. 56:616-618. [DOI] [PubMed] [Google Scholar]

- 22.Rocourt, J., P. BenEmbarek, H. Toyofuku, and J. Schlundt. 2003. Quantitative risk assessment of Listeria monocytogenes in ready-to-eat foods: the FAO/WHO approach. FEMS Immunol. Med. Microbiol. 35:263-267. [DOI] [PubMed] [Google Scholar]

- 23.Rorvik, L. M., D. A. Caugant, and M. Yndestad. 1995. Contamination pattern of Listeria monocytogenes and other Listeria spp. in a salmon slaughterhouse and smoked salmon processing plant. Int. J. Food Microbiol. 25:19-27. [DOI] [PubMed] [Google Scholar]

- 24.Thimothe, J., K. K. Nightingale, K. Gall, V. N. Scott, and M. Wiedmann. 2004. Tracking of Listeria monocytogenes in smoked fish processing plants. J. Food Prot. 67:328-341. [DOI] [PubMed] [Google Scholar]

- 25.Tompkin, R. B. 2002. Control of Listeria monocytogenes in the food-processing environment. J. Food Prot. 65:709-725. [DOI] [PubMed] [Google Scholar]

- 26.Wiedmann, M., J. L. Bruce, C. Keating, A. E. Johnson, P. L. McDonough, and C. A. Batt. 1997. Ribotypes and virulence gene polymorphisms suggest three distinct Listeria monocytogenes lineages with differences in pathogenic potential. Infect. Immun. 65:2707-2716. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Wing, E. J., and S. H. 2002. Gregory Listeria monocytogenes: clinical and experimental update. J. Infect. Dis. 185:S18-S24. [DOI] [PubMed] [Google Scholar]

- 28.Zhang, C. M., M. Zhang, J. L. Ju, J. Nietfeldt, J. Wise, P. M. Terry, M. Olson, S. D. Kachman, M. Wiedmann, M. Samadpour, and A. K. Benson. 2003. Genome diversification in phylogenetic lineages I and II of Listeria monocytogenes: identification of segments unique to lineage II populations. J. Bacteriol. 185:5573-5584. [DOI] [PMC free article] [PubMed] [Google Scholar]