Abstract

Decimal reduction time (time to inactivate 90% of the population) (D) values of Bacillus anthracis spores in milk ranged from 3.4 to 16.7 h at 72°C and from 1.6 to 3.3 s at 112°C. The calculated increase of temperature needed to reduce the D value by 90% varied from 8.7 to 11.0°C, and the Arrhenius activation energies ranged from 227.4 to 291.3 kJ/mol. Six-log-unit viability reductions were achieved at 120°C for 16 s. These results suggest that a thermal process similar to commercial ultrahigh-temperature pasteurization could inactivate B. anthracis spores in milk.

In 2001, the intentional release of anthrax spores through the U.S. Postal Service prompted increasing concern for a potential bioterrorist attack, including food terrorism. Due to the vulnerability of the food supply system, food and water could be deliberately contaminated and are considered two of the most viable targets for bioterrorism (7). Milk, as a product consumed every day especially by children, poses a high probability/high severity risk potential if Bacillus anthracis spores were purposely added to it at the farm, truck delivery, or processor level (23). In order to enhance milk safety against purposeful contamination with a biological agent, it is necessary to develop effective heat treatments capable of inactivating biological agents, such as large amounts of anthrax spores, that could be deployed immediately by milk processors in the event of a bioterrorist attack (23).

Bacillus anthracis is a spore-forming, gram-positive bacillus that causes anthrax. There is very limited information about heat inactivation of B. anthracis spores in the literature, as most studies have focused on the heat resistance of other Bacillus species. The effects of different heating methods (boiling, moist heat, and dry heat) on heat inactivation of B. anthracis spores have also been reported (6, 12, 17, 19, 20). In general, it was reported that in different buffer solutions B. anthracis spore counts could be reduced by at least 106 CFU/ml if the spores were heated at 90°C for 20 min, at 100°C for 10 min, and 105°C for 5 to 10 min (12, 19). At 120°C, the spores were destroyed after 5 to 15 min (20). The thermal kinetics of B. anthracis inactivation in buffer solutions, however, cannot be used to predict its destruction in foods, because the heat resistance can be increased by food components, such as protein and fat (3, 18).

Because milk is not considered a vehicle of natural B. anthracis infections, very few studies have investigated the thermal resistance of B. anthracis spores in milk. In one recent study, standard pasteurization conditions (63°C, 30 min; 72°C, 15 s) killed 4 log CFU/ml vegetative B. anthracis cells but had no effect on spores (14). The authors concluded that standard pasteurization processes had little effect on the viability of B. anthracis spores (14). In another study, Novak et al. (13) reported the inactivation of B. anthracis strain Sterne in skim milk by 0.45 log CFU/ml after 90 min at 72°C, 8.1 log CFU/ml after 60 min at 100°C, and 7.7 log CFU/ml after 2 min at 130°C. The authors also calculated decimal reduction time (time to inactivate 90% of the population) (D) values at those temperatures, but they acknowledged that some of those values “were considered invalid for the low R2 values.” In a recent study by Montville et al. (11), the D values of spores of three B. anthracis strains (Sterne, Pasteur, and Vollum) at 90°C were 1.5, 1.0, and 6.7 min, and the Z values (calculated increases of temperature needed to reduce the D value by 90%) were 10.2, 8.7 and 13.6°C, respectively. In that study, the thermal resistance of B. anthracis spores was similar to that of other Bacillus species. The same report, however, focused on a narrow temperature range (70 to 90°C).

Further research is needed to identify the time and temperature conditions necessary to inactivate B. anthracis spores in milk at higher temperatures. One of the objectives of our study was to determine the kinetics of the heat resistance of B. anthracis spores in milk. This study was undertaken to generate a set of thermal death kinetics data that include the D, Z, and Arrhenius activation energy (Ea) values of B. anthracis strains over a relatively wide temperature range in milk. The ultimate goal was to establish combinations of time and temperature for the inactivation of defined B. anthracis spore populations in milk.

Bacillus anthracis Sterne strains 7702, ANR-1, and Sterne derivative 9131 were provided by Theresa Kohler, University of Texas—Houston Medical School. The plasmid-less strain 9131 was obtained by curing strain RP31 from the pXO1 plasmid (15). Bacillus cereus D17 was obtained from Amy Wong, University of Wisconsin—Madison. Stock cultures were maintained in tryptic soy agar (TSA) (Acumedia Manufacturers, Inc., Lansing, MI) slants that were transferred every 2 weeks. A protocol was adapted to produce Bacillus spore suspensions (14). Single colonies from TSA incubated at 37°C overnight were transferred to tryptic soy broth (TSB) (Acumedia Manufacturers, Inc., Baltimore, MD). The tubes were incubated at 37°C for 18 h. Cultures were then spread onto new sporulation medium (NSM) that contained the following (per liter of distilled water): 3 g tryptone (Difco, Inc., Sparks, MD), 3 g yeast extract (Difco, Inc.), 2 g Bacto agar (Difco, Inc.), 23 g Lab-Lemco agar (Difco, Inc.), and 0.01 g MgSO4 · 4H2O (ICN Biomedicals, Inc., Irvine, CA) (14). The plates were incubated at 37°C for 48 h and then at room temperature for 24 h. The biomass from three plates was suspended in 30 ml sterile distilled water (dH2O). The suspension was incubated at room temperature for 72 h to allow the lysis of vegetative cells. Spores were harvested by centrifugation at 8,000 × g for 10 min at 4°C, washed with dH2O, centrifuged again, and resuspended in dH2O. The spore suspension was stored at 4°C for no more than 2 weeks until used. The spore suspensions were observed using a Nikon phase-contrast microscope (Leeds Precision Instruments, Minneapolis, MN) which could distinguish between spores and vegetative cells. It was verified that at least 90% of the observed bodies were the characteristic bright refractive spores. The viability of spores was determined by plating serial dilutions of spore suspensions, with and without a heat shock (75°C for 30 min), onto TSA plates and incubated overnight at 37°C.

Since our study covered a wide temperature range that included temperatures above 100°C, the use of a small volume (50 μl) inoculated into capillary tubes (0.8 to 1.1 × 90 mm; catalog no. 34507; Kimble, Vineland, NJ) that were in a heated oil bath (High-Temp bath 160A; Fisher Scientific, Hampton, NH) was used (2). Commercially available whole milk and skim milk were inoculated with the spore suspensions to obtain a concentration of 107 CFU/ml and transferred into capillary tubes. Tubes were heat sealed and completely submerged into an oil bath at the selected temperatures. The tubes were submerged into the oil bath for 10 seconds before starting to sample for D value determinations (24). At each sampling time, capillary tubes were removed from the oil bath, immediately placed into an ice-water bath for at least 5 min, transferred to a 525 ppm hypochlorite solution for 10 min, and rinsed with sterile dH2O. The capillary tubes were transferred to test tubes containing 5 ml of sterile peptone water and a magnetic stirrer and crushed by vortex mixing. The samples were serially diluted in peptone water, plated onto TSA, and incubated overnight at 30°C before colonies were counted. Two inoculated tubes (no heating) were used as controls at each trial.

Decimal reduction time values (time to inactivate 90% of the population) were determined from the linear portion of the survival curves by plotting the log of survival counts against heating times at each temperature. Z values corresponding to the temperature increase needed to decrease the D value by 10-fold were determined from the slopes of the linear regression of the decimal reduction time curves (mean log D values versus temperature) as Z = −slope−1 for a semilog (base 10 plot). Arrhenius plots of natural logarithm of the death rate constant k (where k = 2.303/D) versus reciprocal of the absolute temperature (kelvin) were made to determine the activation energies [Ea = slope × R, where R = 8.314 J/(mol K)]. Three thermal inactivation trials with duplicate samples at each time interval were completed. The difference of D values among strains was analyzed by using analysis of variance procedure and Duncan multiple-range test (SAS version 8.2, Cary, NC, 2004) with a significance level of 0.05.

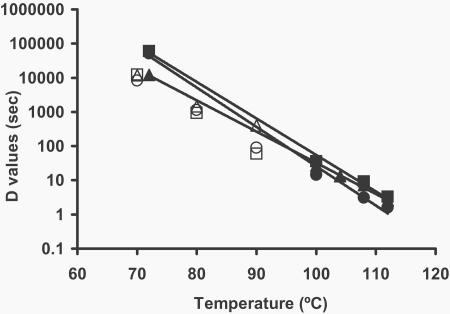

Table 1 summarizes the temperature dependence of the D values of the different strains of Bacillus spores heated in whole milk. The R2 values obtained from the linear regressions indicated a relatively high correlation (greater than 0.85) except for one condition (strain 9131 at 100°C). The Sterne strain 7702 had the greatest D values at each temperature. At 72°C, strain 7702 had a D value fivefold greater than the most sensitive strain, strain 9131 (3.4 versus 16.7 h). At 112°C, the difference in D values between strain 7702 and the most sensitive strain ANR-1 was only twofold (1.6 versus 3.3 s). On the basis of the D value data, the calculated increase of temperature needed to reduce the D value by 90% were 9.4, 8.7, 11.0°C for strains 7702, ANR-1, and 9131, respectively (Fig. 1), and in all three plots, the R2 was greater than 0.99. A similar Z value of 9.5°C was found for B. cereus D17.

TABLE 1.

D values of Bacillus spores in whole milk

| Strain | Parameter | Value at the following temp (°C):

|

||||

|---|---|---|---|---|---|---|

| 72 | 100 | 104 | 108 | 112 | ||

| B. anthracis 7702 | Mean D value (s)a | 60,120 A | 35.7 A | NDc | 9.2 A | 3.3 A |

| D value's upper CL (s)b | 74,160 | 39.3 | 11.1 | 4.1 | ||

| D value's lower CL (s) | 50,400 | 32.6 | 7.9 | 2.8 | ||

| R2 | 0.88 | 0.96 | 0.89 | 0.88 | ||

| B. anthracis ANR-1 | Mean D value (s) | 51,120 B | 14.4 C | ND | 3.1 B | 1.6 C |

| D value's upper CL (s) | 64,800 | 17.4 | 3.6 | 1.9 | ||

| D value's lower CL (s) | 42,120 | 12.2 | 2.7 | 1.4 | ||

| R2 | 0.86 | 0.88 | 0.91 | 0.95 | ||

| B. anthracis 9131 | Mean D value (s) | 12,240 D | 27.1 B | 13.3 | 7.3 A | 2.6 B |

| D value's upper CL (s) | 13,680 | 42.5 | 15.8 | 9.4 | 3.1 | |

| D value's lower CL (s) | 10,800 | 19.9 | 11.4 | 6.0 | 2.3 | |

| R2 | 0.94 | 0.68 | 0.90 | 0.86 | 0.92 | |

| B. cereus D17 | Mean D value (s) | 33,480 C | 21.0 BC | 10.3 | ND | 2.8 B |

| D value's upper CL (s) | 39,600 | 23.1 | 10.9 | 3.3 | ||

| D value's lower CL (s) | 28,800 | 19.2 | 9.8 | 2.4 | ||

| R2 | 0.89 | 0.96 | 0.92 | 0.91 | ||

Mean D values in the same column followed by the same letter are not significantly different (P > 0.05).

CL, 95% confidence level.

ND, not determined.

FIG. 1.

Comparison of thermal resistance data for B. anthracis spores in milk. B. anthracis strains used in this study were 7702 (▪), ANR-1 (•), and 9131(▴). In the study conducted by Montville et al. (11), the strains were Sterne (○), Vollum (▵), and Pasteur (□).

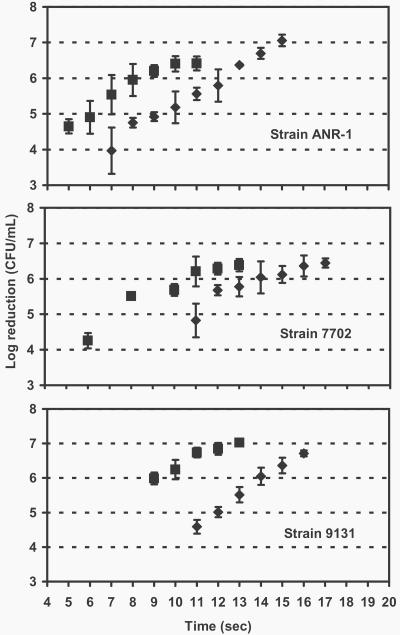

The Arrhenius activation energy values were 270.0, 291.3, 227.4, and 265.0 kJ/mol for strains 7702, ANR-1, 9131, and D17, respectively. No significant difference was determined among the Ea values, and all Arrhenius plots had a very good fit (R2 >0.99). The thermal death kinetics of B. anthracis spores in whole milk and skim milk were not significantly different among the three strains (data not shown). On the basis of the regression of the measured D values of all three B. anthracis spores (log D = −0.1062 × T + 12.209 where T is temperature; R2 = 0.996), the times needed to obtain a 6-log-unit reduction at several temperatures were determined (Table 2). The 6-log-unit inactivation time would be reduced more than 10-, 100-, 1,000-, and 10,000-fold at 100, 110, 120, and 130°C, respectively. When capillary tubes filled with 50 μl milk containing approximately 109 spores were heated at 120 and 130°C, the number of surviving spores was determined from 5 to 17 s and the extent of inactivation was calculated for the three B. anthracis strains (Fig. 2). After a total heating time of 11 seconds (that included heating up time) at 120°C, the reduction of the three strains ranged from 4.5- to 5.5-log-unit cycle reductions. At this temperature a 6-log-unit reduction was first observed after 16 s for all strains. At 130°C, 6-log-unit reductions were not consistently observed until a total heating time of 12 s.

TABLE 2.

Estimated thermal resistance for Bacillus anthracis spores in milk

| Temp (°C) | Estimated D value (s) | Estimated time (s) needed to achieve 6-log-unit reduction |

|---|---|---|

| 90 | 447.7 | 2,686.3 |

| 95 | 131.8 | 791.0 |

| 100 | 38.8 | 232.9 |

| 105 | 11.4 | 68.6 |

| 110 | 3.37 | 20.2 |

| 115 | 0.99 | 5.94 |

| 120 | 0.29 | 1.75 |

| 130 | 0.03 | 0.15 |

FIG. 2.

Thermal inactivation of B. anthracis spores in whole milk at 120°C (♦) and 130°C (▪).

Our results were consistent with those of the study by Perdue et al. (14) who demonstrated that standard pasteurization conditions cannot inactivate B. anthracis spores, but our study provided more detailed information. At the typical pasteurization temperature of 72°C, more than 80 h would be necessary to inactivate 105 CFU/ml spores (Table 1). The heat resistance values of Sterne strains (7702 and ANR-1) with one virulent plasmid were very similar to that of strain 9131, which has no virulent plasmids. The thermal resistance data in our study were comparable with the data of Montville et al. (11) (Fig. 1). The Z values reported by that study were very similar to this work's values (8.7 to 11.0°C). The thermal resistance of the Sterne and 9131 strains did not appear to be significantly different from those of the pathogenic Vollum and Pasteur strains. This observation suggests that the plasmids of B. anthracis strains might not play any role in their heat resistance.

The results in our study were significantly different from those reported by Novak et al. (13). In that paper, one Sterne strain and one B. cereus strain were examined for their thermal resistance parameters in skim milk. The D values reported by Novak and coworkers for the Sterne strain were 1,189 min at 72°C, 513 min at 78°C, 7 min at 100°C, and 1.1 min at 130°C. The D values at 100°C were significantly higher than our values, but it should be noted that their calculations were based on very poor death kinetics data at each test temperature, some with R2 values of <0.3. Despite the reported lack of linearity of the D values, that study reported a Z value of 20.4°C, which was almost twofold greater than our values and than most of the Z values reported in the literature for spores.

The magnitude of Ea indicates the temperature dependence of the heat inactivation reaction. A higher Ea represents a more temperature-sensitive reaction. If the Z value is smaller, the Ea value will be larger. In this study, strain ANR-1 yielded the lowest Z value of 8.7°C (Fig. 1) and the highest Ea value of 291.3 kJ/mol. In the study conducted by Wescott et al. (25), the Ea values ranged from 313 to 335 kJ/mol for B. cereus strain T and from 366 to 405 kJ/mol for Bacillus stearothermophilus strain ATCC 12980 in sodium phosphate buffer. Activation energies of 282.2 and 293 kJ/mol were reported for spores of B. subtilis in 0.1% sodium chloride solution (5).

Our results also showed that the B. cereus strain D17 could act as a good surrogate of B. anthracis in thermal death kinetics studies (Table 1). This result was in agreement with the data published by Montville et al. (11). In our study, the D value for strain D17 spores at 100°C was 21.0 s and the Z value was 9.5°C. In whole-milk medium, the D values were reported to be 18.6 s at 100°C and 3.18 s at 106°C for B. cereus ATCC 7004 (8). Z values for B. cereus spores ranged from 7.7 to 9.3°C (9). Mazas et al. (8) also reported a D value at 100°C of 16.2 s for strain ATCC 7004 in skim milk. However, strain T spores were observed to have a higher D value at 100°C of 2.7 min in skim milk (21).

The results of our validation experiments conducted at 120 and 130°C (Fig. 2) indicated that there was a significant difference between the predicted 6-log-unit reduction based on D value data extrapolation and the observed values. Because previous researchers have measured a heating up time of only 6 s and other studies have used a more conservative time of 10 s for this capillary tube method, we estimated that the time needed to inactivate 6-log-unit spores at 120°C was between 6 and 10 s. However, this time was more than threefold longer than the predicted 1.75 s. Differences between predicted and observed spore inactivation times have been documented in the literature with a variety of spore-forming bacteria, and this phenomenon has been referred to as tailing (4). According to Ababouch et al. (1), tailing can be explained by the clumping of spores during heating and/or the presence of a subpopulation of spores with greater resistance than the average spore. This discrepancy between predicted and observed values stresses the importance of conducting thorough validation studies.

Our findings indicate that the adoption of a thermal process could be a feasible alternative as a response to mitigate an eventual terrorist attack with Bacillus anthracis spores into the milk supply. On the basis of our results, ultrahigh-temperature pasteurization processing plants could adopt a process of 120°C for 6 to 10 seconds to inactivate suspended spores if they have the equipment to achieve and hold these conditions. Given the obvious flavor differences between milk treated by ultrahigh pasteurization and milk treated by high temperature for a short time, it would be expected that the quality would be affected to some extent. Recent data, however, indicate that color deterioration at this temperature would not be greatly increased (16). While the different flavor of milk treated at 120°C for 10 to 14 seconds could be a consumer acceptance issue, in the event of an intentional adulteration, it could also serve as an indicator that the milk had been treated. Alternatively, our data also suggest that boiling milk for about 4 min would be sufficient to inactivate B. anthracis spores. Further validation work is needed to determine a time/temperature combination that could easily be adopted by typical pasteurization plants that use a high temperature for a short time in the event of an emergency.

The eventual adoption of a time/temperature combination to inactivate B. anthracis spores would need to take into consideration more-thorough risk assessments that should include infectious dose data. The U.S. Department of Defense has estimated that the infectious dose expressed as the 50% lethal dose for inhalation anthrax in humans ranges from 8,000 to 10,000 spores (10, 22). There is no publicly available report that had specifically determined the infectious dose for intestinal anthrax, but experts have suggested that this number may be approximately 106 spores (Jeffrey Bender [College of Veterinary Medicine, University of Minnesota], personal communication). On the basis of these numbers, further risk assessment studies should consider such a level of infectious dose for a final process recommendation of spore inactivation. Additional factors that would need to be included in the risk assessment are the ability of B. anthracis to germinate and multiply in the milk over time and the likelihood of such a bioterrorist attack and the anticipated outcome.

Our study clearly verified that standard pasteurization treatment (72°C, 15 s) could not inactivate a high concentration of anthrax spores which were purposely added into milk. A series of thermal death kinetics of spore inactivation in milk was also generated. This study also indicates that the thermal resistance of spores in whole milk was not different from that in skim milk. These results provide baseline data that could be used to develop a thermal process that milk plants could use in the event of an intentional addition of Bacillus anthracis to milk. Such process would be primarily used for disposal of milk that has been confirmed to be intentionally contaminated and for treating uncontaminated product to mitigate the collateral damage on the whole-milk market.

Acknowledgments

This research was supported by the U.S. Department of Homeland Security through a grant (number N-00014-04-1-0659) awarded to the National Center for Food Protection and Defense at the University of Minnesota.

Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the authors and do not represent the policy or position of the U.S. Department of Homeland Security.

We thank Theresa Koehler (University of Texas—Houston Medical School) and Amy Wong (University of Wisconsin—Madison), who provided Bacillus strains.

REFERENCES

- 1.Ababouch, L., A. Dikra, and F. F. Busta. 1987. Tailing of survivor curves of clostridial spores heated in edible oils. J. Appl. Bacteriol. 62:503-511. [DOI] [PubMed] [Google Scholar]

- 2.Beard, B. M., B. W. Sheldon, and P. M. Foegeding. 1999. Thermal resistance of bacterial spores in milk-based beverages supplemented with nisin. J. Food Prot. 62:484-491. [DOI] [PubMed] [Google Scholar]

- 3.Behringer, R., and H. G. Kessler. 1992. Thermal destruction of spores of selected Bacillus strains in skim milk and skim milk concentrate. Int. Dairy J. 2:232-242. [Google Scholar]

- 4.Cerf, O. 1977. Tailing of survival curves of bacterial spores. J. Appl. Bacteriol. 42:1-50. [DOI] [PubMed] [Google Scholar]

- 5.Cho, H. Y., S. K. Sastry, and A. E. Yousef. 1999. Kinetics of inactivation of Bacillus subtilis spores by continuous or intermittent ohmic and conventional heating. Biotechnol. Bioeng. 62:368-372. [DOI] [PubMed] [Google Scholar]

- 6.Francis, A. 1956. Observations on time and temperature in the killing of spores by dry heat. Proc. Pathol. Soc. Great Britain Ireland 71:351-352. [Google Scholar]

- 7.Khan, A. S., D. L. Swerdlow, and D. D. Juranek. 2001. Precautions against biological and chemical terrorism directed at food and water supplies. Public Health Rep. 116:3-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Mazas, M., M. Lopez, I. Gonzalez, J. Gonzalez, A. Bernardo, and R. Martin. 1998. Effects of the heating medium pH on heat resistance of Bacillus cereus spores. J. Food Saf. 18:25-36. [Google Scholar]

- 9.Mazas, M., M. Lopez, S. Martinez, A. Bernardo, and R. Martin. 1999. Heat resistance of Bacillus cereus spores: effects of milk constitutes and stabilizing additives. J. Food Prot. 62:410-413. [DOI] [PubMed] [Google Scholar]

- 10.Meselson, M., J. Guillemin, M. Hugh-Jones, A. Langmuir, I. Popova, A. Shelokov, and O. Yampolskaya. 1994. The Sverdlovsk anthrax outbreak of 1979. Science 266:1202-1208. [DOI] [PubMed] [Google Scholar]

- 11.Montville, T. J., R. Dengrove, D. De Siano, M. Bonnet, and D. W. Schaffner. 2005. Thermal resistance of spores from virulent strains of Bacillus anthracis and potential surrogates. J. Food Prot. 68:2362-2366. [DOI] [PubMed] [Google Scholar]

- 12.Murray, T. J. 1931. The thermal death point. J. Infect. Dis. 48:457-467. [Google Scholar]

- 13.Novak, J. S., J. Call, P. Tomasula, and J. B. Luchansky. 2005. An assessment of pasteurization treatment of water, media, and milk with respect to Bacillus spores. J. Food Prot. 68:751-757. [DOI] [PubMed] [Google Scholar]

- 14.Perdue, M. L., J. Karns, J. Higgins, and J. A. V. Kessel. 2003. Detection and fate of Bacillus anthracis (Sterne) vegetative cells and spores added to bulk tank milk. J. Food Prot. 66:2349-2354. [DOI] [PubMed] [Google Scholar]

- 15.Pezard, C., E. Duflot, and M. Mock. 1993. Construction of Bacillus anthracis mutant strains producing a single toxin component. J. Gen. Microbiol. 139:2459-2463. [DOI] [PubMed] [Google Scholar]

- 16.Schamberger, G., and T. P. Labuza. 2006. Use of front-face fluorescence for assessing thermal processing of milk. J. Food Sci. 71:C069-C074.

- 17.Schneiter, R., and R. W. Kolb. 1945. Heat resistance studies with spores of Bacillus anthracis and related aerobic bacilli in hair and bristles. Public Health Rep. Suppl. 2207:1-24. [Google Scholar]

- 18.Shehata, A. E., I. M. Khalafalla, M. N. I. El-Magdoub, and A. A. Hofi. 1977. Heat resistance parameters for spores of some Bacillus species in milk. Milchwissenchaft 32:136-139. [Google Scholar]

- 19.Spotts Whitney, E. A., M. E. Beatty, J. T. H. Taylor, R. Weyant, J. Sobel, M. J. Arduino, and D. A. Ashford. 2003. Inactivation of Bacillus anthracis spores. Emerg. Infect. Dis. 9:623-627. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Stein, C. D., and H. Rodgers. 1945. Observations on the resistance of anthrax spores to heat. Vet. Med. 40:406-410. [PubMed] [Google Scholar]

- 21.Wandling, L. R., B. W. Sheldon, and P. M. Foegeding. 1999. Nisin in milk sensitizes Bacillus spores to heat and prevents recovery of survivors. J. Food Prot. 62:492-498. [DOI] [PubMed] [Google Scholar]

- 22.Watson, A., and D. Keir. 1994. Information on which to base assessments of risk from environments contaminated with anthrax spores. Epidemiol. Infect. 113:479-490. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Wein, L. M., and Y. F. Liu. 2005. Analyzing a bioterror attack on the food supply: the case of botulinum toxin in milk. Proc. Natl. Acad. Sci. USA 102:9984-9989. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Wescott, G. G. 1993. Comparison of thermal inactivation kinetics for batch and continuous flow processing. M.S. thesis. North Carolina State University, Raleigh.

- 25.Wescott, G. G., T. M. Fairchild, and P. M. Foegeding. 1995. Bacillus cereus and Bacillus stearothermophilus spore inactivation in batch and continuous flow systems. J. Food Sci. 60:446-450. [Google Scholar]