Abstract

Objective:

To describe the evolution and implementation of standards for head, face, and eye protection in sports.

Background:

Recent changes in testing standards for head, face, and eye protection include the development of new equipment, the mandating of tougher standards, and the coverage of additional products by these standards, all in an effort to improve athletes' safety and reduce their risk of injury. The person selecting equipment needs to understand these standards, how they are developed for each piece of equipment, and which standards the piece of equipment is purported to meet.

Conclusions/Recommendations:

The sports medicine clinician must recommend only the use of personal protective equipment that meets a current standard; must ensure that the equipment is maintained in its original form and that all parts and labels are present; and must ascertain that equipment is refurbished by a qualified reconditioner. By following these guidelines, we improve sport safety for our athletes and lessen their risk of injury.

Keywords: helmet, headgear, face protector, NOCSAE, ASTM, eyewear

Over the last several years, a number of changes have occurred with regard to the standards for testing headgear and eyewear. New equipment has been developed and used, tougher requirements mandated, and additional products covered by standards. Consequently, today's marketplace provides a much wider variety of athletic equipment than was available 20 years ago. Some of today's equipment might meet only one of the current standards, whereas other equipment might meet multiple standards. Unfortunately some equipment in the sports arena today might meet no standard! Most importantly, the person selecting equipment today needs to understand what these standards are, how they are written to ensure specific characteristics in a piece of equipment, and which standards a particular piece of equipment is purported to meet. It is also essential to note that, in many instances, only the manufacturer claims that the product meets a standard. With few exceptions, such as the Consumer Product Safety Commission (CPSC), the Snell Memorial Foundation (SNELL), the Safety Equipment Institute (SEI), and the Hockey Equipment Certification Council (HECC), no independent body is checking on the manufacturers to be sure that their claims are factual.

STANDARDS-SETTING PROCESS

Different types of helmets and eyewear are tested to different standards established by different standards-setting bodies. These standards, as well as those for most other protective equipment in North America, can usually be described as falling into one of several gross categories. Government standards, such as those mandated by the CPSC, and voluntary, or industry, standards are the most common. Among the voluntary standards, those mandated by a particular governing body seem to be the most effective. For example, if a piece of personal protective equipment is required for some type of play, such as an HECC-certified helmet is required by USA Hockey, then players will likely wear such equipment because they cannot participate without doing so. Governing bodies, however, rarely write or create such standards because that is not in their area of expertise. Rather, they rely upon other organizations, such as the American Society for Testing and Materials (ASTM) or the National Operating Committee on Standards for Athletic Equipment (NOCSAE) to arrive at a viable and effective standard. The ASTM is a premier standards-setting organization with more than 30 000 members that is well respected for its consensus standards. Other organizations, such as NOCSAE, operate using a smaller format. This more limited group is capable of setting standards much more quickly than the consensus approach allows. It could be argued that this second approach involves less input from concerned parties, but a “public” review period before actual implementation eliminates most of this criticism.

Governing bodies such as the National Collegiate Athletic Association (NCAA) and the National Federation of State High School Associations (NFHSA) can and do mandate that certain equipment worn or used by players in their programs meet a particular standard. In the case of helmets (football, baseball batter, and lacrosse), these governing bodies require that the helmets meet NOCSAE standards, and further, that all participants playing within the control of the governing body wear equipment clearly identified as being in compliance. In the preceding example, helmets must meet the NOCSAE standard for that particular activity and must clearly display the appropriate NOCSAE logo certifying compliance.

EVOLUTION OF STANDARDS

Early headgear standards were typically a force-transmission, measurement-based protocol. In this test, the headgear was usually mounted to a rigid (or semirigid) headform. A standard, malleable material (often a specific grade of aluminum) was placed between the headform and the inner surface of the helmet. An indenter of some type (usually a ball bearing) was placed so as to indent the malleable material on impact. Typically, a falling object—frequently a heavy block of wood with a specified mass and surface area—generated the impact energy. After impact, the depth of the dent was measured and used to determine the helmet's effectiveness. One example of this method is an early Canadian Standards Association (CSA) standard for hockey headgear issued in 1975 and revised in 1983.1 Although these methods are not without merit, the injury-producing accelerations resulting from head impact were not measured.

Today's headgear standards attempt to measure these accelerations and set performance limits for that headgear. Two basic approaches to this type of testing exist. One method uses anthropometric (humanlike) headforms, triaxial acceleration transducers, and a mathematical integration to measure helmet energy attenuation (NOCSAE). The other approach uses a simple, skull-shaped metallic headform with a single-axis accelerometer to provide acceleration data (ASTM, SNELL, CPSC).

In addition to creating new standards, the standards-setting bodies are constantly reviewing standards with an eye toward making them more stringent but still practical to meet. As an example, in 1993, NOCSAE commissioned research to improve the consistency of test results obtained with the NOCSAE Drop System.2 This was ultimately accomplished with several modifications, including changing the type of guide wires used by the system to reduce friction, improving the steps to calibrate the NOCSAE headform, and improving the carriage that holds the test helmet for impact.3,4 At the same time, NOCSAE tightened the pass-fail criterion by 20% (even though the revised method resulted in up to a 5% impact energy gain) because it was believed that manufacturers could produce helmets that met this tougher standard.5 Since that time, NOCSAE has continued standards improvement with the publication of important document revisions in 1998,6 and further revisions are currently under review. NOCSAE testing methods7 and performance requirements for batters' and catchers'8 headgear have followed a similar evolution. NOCSAE standards for baseballs and softballs are currently in the review phase, with publication of new criteria anticipated in late 2001.

The NOCSAE test equipment includes an anthropometric headform that is very humanoid in its mechanical properties and appearance compared with other headforms used for helmet testing; this headform was first developed in the 1970s. The headforms used with other types of standards (ASTM, CPSC, etc) are typically a solid piece of metal cast or milled to look like a portion of the human head and skull. In 1999, NOCSAE decided to gather more comprehensive anthropometric data and to redesign the NOCSAE headforms to make them even more humanoid than the earlier version. This work is nearing completion at the time of this writing, with some of the new headforms being beta tested at several sites. Along with improved facial anthropometry (a key to better testing of eye and facial protective products), increased biofidelity with decreased frangibility are the goals of these changes.

Similarly, ASTM standards are constantly undergoing modification. For example, the ASTM test method for testing many types of headgear has undergone at least 7 important revisions in the last decade.9 ASTM standards for hockey headgear,10 baseball face protectors,11 football helmets,12,13 and equipment for several other sports have also undergone revision to improve either test repeatability or product performance.

DETAILS OF KEY HEADGEAR STANDARDS

Both the current NOCSAE and ASTM headgear standards are based on the helmet's falling in a guided free fall. In each case, the helmet is positioned on a headform instrumented to provide a measure of the helmet's ability to attenuate the kinetic energy imparted during the test. The energy is based on the drop velocity and the mass of the headform. In each test procedure, the drop mass and velocity are similar but vary with the type of headgear being tested. In some cases, the impact surface is different to allow testing of specific potential hazards that a particular type of headgear might encounter when in use. For example, in addition to falling onto other anvils, bicycling helmets fall onto a curbstone anvil that is shaped very much like a section of street curbing, as the name implies.14 The measurement is usually plotted as acceleration in relation to time.

Both approaches measure linear acceleration only. Both standards require subject helmets to be “conditioned” (hot or cold, wet, etc) during some impacts. Conditioning environments are also variable depending on the type of headgear being tested. Despite these similarities, the tests have important differences. The most basic are outlined subsequently.

National Operating Committee on Standards for Athletic Equipment

From a technical standpoint, the NOCSAE standard is unique. The headform is anthropometric and complex in function, which allows for a wider area of impact locations, as the head is complete in its shape. Because of this feature, some impacts are not aligned exactly with the center of gravity (CG) of the system. In addition, data are gathered via a triaxial accelerometer to compensate for these geometric complexities. This method is similar to the way in which one would instrument a cadaver head for impact testing, using all 3 data channels and summing the signals, then using the square root of the summed squares for the resultant. The headform, like a human head, attenuates a large amount of energy during the test. The results are reported in severity index (SI) units, in which SI = ∫t0 a2.5dt. The standard requires a series of impacts in specific locations and then the application of impacts to a random location, which can be any location within the protective area of the helmet. NOCSAE standards call for aggressive quality control measures from manufacturers claiming certification to the standard. These quality assurance requirements were clarified further in the 1996 and later revisions of the standards. Manufacturers claiming such certification must submit their testing facility to routine audits. NOCSAE does not police manufacturers for compliance but reviews laboratory competence and offers technical assistance to licensees. Football equipment (uniforms, helmets pads, etc) is typically reconditioned at the end of every season. The reconditioner then recertifies that the reconditioned football helmets meet the NOCSAE standard. In 1997, NOCSAE created highly specialized software for recertifiers in an effort to continue quality improvement. A second generation of this software is currently being developed for introduction in 2001.

American Society for Testing and Materials

The ASTM Committee F08 on Sports and Recreation establishes the ASTM Standards for Headgear used in sports; subcommittee F08.53 for headgear leads this effort. The ASTM criterion for most headgear uses the International Standards Organization (ISO) headform as the basis for the testing. This headform is typically made of a magnesium alloy with an outer shape similar to that of the skull. The headform comprises only a partial head, as it does not reach much below the basic plane (an imaginary plane drawn from the lowest part of the eye socket through the ear hole). Therefore, some impacts along the lower edge of a helmet's protective area may not be accurately tested. The headform has no biofidelity beyond its skull-like shape. Data are acquired via a uniaxial accelerometer mounted at the CG of the headform. Since all impacts are on the CG, only a single-channel accelerometer is needed.

Data output is usually provided in peak g levels, such that Amax < N (maximum acceleration allowed is less than some N, which is usually 300 g). The pass-fail criterion may vary with headgear type but is normally 300 g or below. The standard closely relates to most other (non-NOCSAE) types of helmet testing protocols in use around the world today.

APPLICATION OF THE HEADGEAR STANDARDS

Both the ASTM and NOCSAE standards have a useful application. The ASTM standard seems a good choice for quality control and process control work, as it is highly repeatable. The NOCSAE standard is perhaps better suited to research, development, and the potential prediction of serious injury onset. When each organization has a standard published on a particular type of headgear, it is recommended that those responsible for selecting headgear verify that the product or brand selected meets both requirements, as they are not typically mutually inclusive.

EFFECT OF HEADGEAR STANDARDS

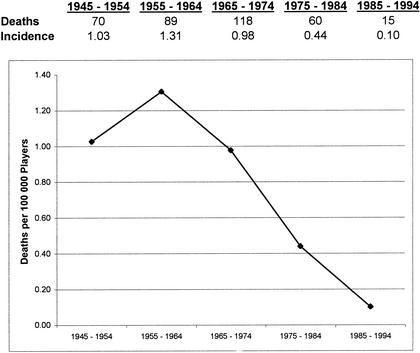

Cantu and Cantu15 reported the incidence of deaths resulting from subdural hematoma in football for each decade in the period of 1945–1994. Incidence rates can be derived for each of those decades by relying on the data provided by the National Federation of High Schools and the NCAA as reported by Dr Frederick O. Mueller. While much of the injury reduction can be attributed to rule changes, improved coaching techniques, and better medical care, the positive effect on head injury reduction can be attributed in large part to the establishment of testing standards for headgear.

MECHANISMS OF HEAD INJURIES

Rather than attempt to review the available data on head injury mechanisms, I provide a brief description to serve as a simple foundation for understanding the rudiments of the primary head injury mechanisms seen in sports. Basically, there are 2 mechanisms: linear acceleration and rotational acceleration.

Linear Acceleration

As the name implies, linear acceleration is acceleration along a line and is the acceleration typically used for helmet testing at this time. It is reasonably well understood, and helmets in use today seem to tolerate very well the linear accelerations to which they are subjected in the standard test methods. Threshold limit values have been established, and helmets that meet those values have worked well in the field.

Rotational Acceleration

As the name implies, rotational, or angular, acceleration is nonlinear and can have many vector components. The injuries caused by angular acceleration are not well understood. Many of the remaining head injuries that occur on the field today may have rotational acceleration as the primary injury mechanism. Threshold limit values have not been established, although many levels have been suggested, and some data exist; no recognized test methods are in use. Helmets would not prevent these injuries, as they can occur without any head impact.

Combined Mechanisms

Most injuries on the playing field today are likely the result of combinations of linear and rotational acceleration, or they may even involve some unknown mechanics. Helmets may contribute to the management of these types of head injuries to some degree by managing linear accelerations and not unnecessarily exacerbating other motions. New test methods are under development that may allow products to be tested for both forms of acceleration simultaneously. It should also be noted that concussion is not addressed in any standard to date. Concussion is the threshold injury involving the brain. Ongoing research suggests several potential actions that may be implicated in concussion. Any investigation into that area requires an understanding of these mechanics on a molecular level. For our purposes, the basic mechanics involve tissue stretch.16–18 This type of tissue strain may not be preventable by headgear, as it is not necessary to receive a blow to the head to incur such injury. Work is under way on a device to measure the combined effects of head impact in both linear and rotational acceleration, which may allow standards to one day soon address concussion. It appears that SIs as low as 250 and rotational accelerations of 4500 to 9000 rad·s−2 may be potential thresholds. A combined system of measure expressed as power with limits in the area of 12.8 kW may also be of value.19

Over the years, the decline in football players' deaths due to subdural hematomas has been significant and sustained (Figure). Although we might like to attribute this decline totally to improved equipment that met the new standards and changes in rules, as they surely had some effect, perhaps the most likely cause for this trend is improved medical treatment.

Incidence of deaths in football due to subdural hematomas between 1945 and 1994.15,28

STANDARDS FOR EYEWEAR, GOGGLES, AND FACE PROTECTORS

In the area of eye and facial protection standards for athletes in nonmotorized sports, the development of standards has followed a similar evolution. One important development was the American National Standards Institute (ANSI) Z87.1 standard for eye and face protectors.20 This standard (and later versions) is likely to be the one used most often in industrial safety eyewear. Although this is often viewed as a good standard for nonindustrial applications (such as sports), more appropriate standards, including ASTM F 803-97,21 are much more demanding and preferable for sports protection. For example, although you may trust your safety glasses in the hobby shop (where an avoided injury perhaps demonstrated the value of protective eyewear), those same safety glasses would be a poor choice for racquetball. The mass and energy of most sport-related, impact-based ocular threats are significantly higher than those specified by the typical industrial impact requirements.

The Protective Eyewear Certification Council certifies many types of sports eyewear, and its logo is an indicator that the selected eyewear is equal to the particular task. The council is a relatively new organization, very similar in concept to the HECC. Protective eyewear performance capabilities can be very deceiving, which is why certification to a standard is important. In addition to the obvious impact protective requirements, most eyewear standards include specific optical requirements. When using protective eyewear not in compliance with these optical requirements, the wearer may experience unanticipated visual distortion or interruption, vertigo, and other visual distractions that increase the potential for injury.

Although NOCSAE has no eyewear standards per se, NOCSAE standards exist for face protectors used by football players, baseball catchers, and lacrosse athletes. While these are also very demanding standards, devices that meet these requirements may not prevent objects such as fingers from entering the eye. If an athlete is playing with an eye injury or limited vision in one eye, the clinician should consult with the treating ophthalmologist to develop a protective plan that is likely to include eye protection that meets ASTM F 803 and a face protector that meets NOCSAE standards. The visors that some players attach to football face protectors are not covered by any standards at this time, although reputable manufacturers make several of these add-on visors and test them to their own internal performance requirements. Although faceguard-mounted visors offer some benefit, particularly when vision is already compromised, these devices do not offer the protective capability of the combat-style goggle eyewear that meets ASTM F 803.

In addition to the optical requirements, sports protective eyewear and facial protectors are also subjected to dynamic impact testing. This testing can include high-velocity impacts from hockey pucks22 and baseballs11 and low-velocity, high-mass impacts generated in football.23 Unlike the previously discussed helmet testing protocols, the impact testing done for facial and eye protection products is typically limited to a contact–no contact, pass-fail criterion. Although sophisticated electronic methods can be used to determine contact, simple methods (such as a paste transfer) have long been used with good results. In the case of facial protectors that are not clear or see through (ie, wire-based product or molded gridlike components), optical clarity requirements may not be used. However, other testing to rule out the presence of scotoma (blind spots), particularly bilateral scotoma, may be used. This testing helps ensure that the wearer's field of view is not blocked in both eyes simultaneously.

Face protectors are often supplied with varying levels of coverage. Many styles of football faceguards are available, but most are variations on 1 of 3 basic types: an oral protector that covers only the mouth, leaving the nose and lower jaw exposed; a jaw protector that covers the mouth down to the jaw; and a nose protector with a bar running vertically down the middle to protect the nose. Obviously, the more facial area covered, the more protection the player is afforded. Nowhere is this effect more pronounced than in ice hockey, in which full-face protectors have a 100% success rate in preventing eye loss. Half shields, or visors, while better than nothing, can still allow enough penetration to cause a blinding injury. Recent and ongoing activities include standards for face and eye protectors used in paintball sports, as well as specialty additions to ASTM F 803-97.

EFFECT OF EYEWEAR STANDARDS

Pashby24 identified how eye injuries in hockey were reduced in youths by requiring them to wear face protectors. The incidence of eye injury in Canadian amateur hockey players declined sharply, from 257 cases in the 1974–1975 season to 124 cases in the 1983–1984 season, since face protectors certified by the CSA and attached to CSA-certified helmets became mandatory for minor hockey players in this country. None of the reported cases in 1983–1984 occurred in players wearing such equipment. The average age of the injured players was 14 years in 1974–1975 but 24 years in 1983–1984; that is, younger players were now protected, but older players were not. Blows from hockey sticks and pucks were the top causes of eye injury in both seasons, but hyphema became the most common type of injury in 1983–1984, surpassing soft tissue damage. The frequency of legal blindness as the visual outcome fell from 19% in 1974–1975 to 11% in 1983–1984.

STANDARDS IMPLEMENTATION

When a standards-setting body establishes a new standard for a particular piece of athletic equipment, that action by itself does not mean that available equipment (or equipment made available after the standard's effective date) will meet the new standard. Usually, reputable manufacturers honor the new standard and produce products in compliance with the standard, even if no governing body has yet mandated the use of equipment that meets that standard. In many cases, products are self-certified to meet the appropriate standards. Typically, the manufacturer's testing of the product in its own facility accomplishes this objective. In many cases, the manufacturer will, from time to time, use an outside independent laboratory to verify certification. Although this sounds like the honor system, and to a degree it is, competitive climates and possible litigation usually cause the self-certifier to be vigilant. Later, a governing body (NCAA, NFHSA, etc) may eventually mandate that athletes wear only products that meet the new standard, but this all takes time. As an example, NOCSAE introduced a standard for baseball and softball catcher's helmets25 effective January 1, 1999. The NFHSA plans on making the use of a headgear certified to meet the NOCSAE catcher's helmet standard mandatory on January 1, 2003; the NCAA has no plans yet to make it mandatory. Even so, many manufacturers are introducing products that meet this new standard.

Another example is the implementation of standards for skiing and snowboarding helmets. ASTM finalized a standard for helmets used in all recreational snow sports in the spring of 2000.26 No governing body has mandated the use of helmets that meet this standard at the time of this writing.

On the other hand, the CPSC's nationwide mandatory standard for bicycle helmets was issued in early 1998 and made effective immediately.27 When standards are government mandated, the added inspection by government entities to verify compliance and the threat of criminal action if noncompliance is discovered are strong incentives for manufacturers' compliance.

SUMMARY

Many of the standards that have been created to judge the performance of protective equipment for athletic activities routinely undergo revision. It can be misleading to simply state that a particular standard is x number of years old. It is likely that the standards-setting body has had a standard in effect on that product for that period of time, but it is also very likely that the document in place today is quite different from the original of the same name. Typically, the latest revision date is prominently displayed on the document or as part of the title. For both NOCSAE and ASTM standards, the standard's numeric identification is followed by a dash or hyphen, followed by the year, as in NOCSAE DOC 001-98. When a midyear revision is developed, the designation is alphabetically added as a suffix to the year, as in ASTM F1446-95a. This designation means that after the 1995 revisions but before the end of 1995, the document was revised and reissued in 1995 as 95a.

Recent standards updates include the changes made to NOCSAE standards for headgear used in football, baseball, and lacrosse. These changes made clear demands on manufacturers' quality control while also increasing performance requirements. In addition to improving existing standards in areas of impact performance, helmet stability, and the like, the ASTM has introduced new headgear standards for skiing, downhill mountain biking, speed skating, roller and inline skating, and infant and toddler bicycling, while several others remain under development. This same ASTM committee has made similar strides in eye and face protection by revising and improving existing standards and creating new ones in areas of need. The formation of the Protective Eyewear Certification Council is an important advancement in athlete protection and should be relied upon by governing bodies. Both NOCSAE (http://www.nocsae.org) and ASTM (http://www.astm.org) have Web sites that can be used to gain more information about their efforts.

Measurement methods and standards, while continually being refined, seldom duplicate the on-field use conditions of the products they govern. However, within those limitations, products that meet specific standards of performance have been shown to be effective in reducing injury.28

For the sports medicine clinician, it is important to recommend only personal protective equipment that claims to meet a current standard. It is also necessary to maintain that equipment in its original form, being sure that all of the parts and labels are there before the start of each sports season. It may be wise to use a qualified sports equipment reconditioner (for example, a member of the National Athletic Equipment Reconditioners Association) to have the equipment refurbished periodically. Clinicians should not hesitate to ask the manufacturer claiming to meet a standard to supply independent proof of compliance. Clinicians can participate in the NOCSAE standard process by contacting the National Athletic Trainers' Association member who serves on the NOCSAE board to be sure that the group has the latest information and input. Clinicians can also become members of the ASTM. Participation in ASTM task groups does not require ASTM membership, but membership entitles the member to vote on any ASTM standard action.

REFERENCES

- 1.Hockey Helmets. Toronto, Ontario, Canada: Canadian Standards Association; 1983. CSA Z 262.1-M83. [Google Scholar]

- 2.Recommendations for Mechanical Test System Revisions. Overland Park, KS: National Operating Committee on Standards for Athletic Equipment; 1994. Technical report. [Google Scholar]

- 3.Standard Drop Test Method and Equipment Used in Evaluating the Performance Characteristics of Protective Headgear. Overland Park, KS: National Operating Committee on Standards for Athletic Equipment; 1996. NOCSAE DOC 001-96. [Google Scholar]

- 4.Equipment Calibration Procedures. Overland Park, KS: National Operating Committee on Standards for Athletic Equipment; 1996. NOCSAE DOC 101-96. [Google Scholar]

- 5.Standard Performance Specification for Newly Manufactured Football Helmets and Standard Performance Specification for Recertified Football Helmets. Overland Park, KS: National Operating Committee on Standards for Athletic Equipment; 1996. NOCSAE DOC 002-96, NOCSAE DOC 004-96. [Google Scholar]

- 6.Standard Drop Test Method and Equipment Used in Evaluating the Performance Characteristics of Protective Headgear. Overland Park, KS: National Operating Committee on Standards for Athletic Equipment; 1998. NOCSAE DOC 001-98. [Google Scholar]

- 7.Standard Projectile Impact Test Method and Equipment Used in Evaluating the Performance Characteristics of Protective Headgear, Faceguards or Projectiles. Overland Park, KS: National Operating Committee on Standards for Athletic Equipment; 1998. NOCSAE DOC 021-98. [Google Scholar]

- 8.Standard Performance Specification for Newly Manufactured Baseball/Softball Batter's Helmets. Overland Park, KS: National Operating Committee on Standards for Athletic Equipment; 1998. NOCSAE DOC 022-98. [Google Scholar]

- 9.Standard Test Method for Equipment and Procedures Used in Evaluating the Performance Characteristics of Protective Headgear. West Conshohocken, PA: American Society for Testing and Materials; 1999. ASTM F 1446-99. [Google Scholar]

- 10.Standard Performance Specification for Ice Hockey Helmets. West Conshohocken, PA: American Society for Testing and Materials; 1997. ASTM F 1045-97. [Google Scholar]

- 11.Standard Specification for Face Guards for Youth Baseball. West Conshohocken, PA: American Society for Testing and Materials; 1992. [under revision and out for ballot at time of this writing] ASTM F 910-86 (reapproved 1992) [Google Scholar]

- 12.Standard Test Method for Shock-Attenuation Characteristics of Protective Headgear for Football. West Conshohocken, PA: American Society for Testing and Materials; 1997. ASTM F 429-97. [Google Scholar]

- 13.Standard Specification for Football Helmets. West Conshohocken, PA: American Society for Testing and Materials; 1995. ASTM F 717-89 (reapproved 1995) [Google Scholar]

- 14.Standard Specification for Protective Headgear Used in Bicycling. West Conshohocken, PA: American Society for Testing and Materials; 1998. ASTM F 1447-98. [Google Scholar]

- 15.Cantu RC, Cantu RI. Neurologic Athletic Head and Spine Injuries. Philadelphia, PA: WB Saunders; 2000. p. 243. [Google Scholar]

- 16.Gurdjian ES. Studies on experimental concussion. Neurology. 1954;4:674–681. doi: 10.1212/wnl.4.9.674. [DOI] [PubMed] [Google Scholar]

- 17.Friede RL. Experimental acceleration concussion. Arch Neurol. 1961;4:449–462. doi: 10.1001/archneur.1961.00450100097012. [DOI] [PubMed] [Google Scholar]

- 18.Bakay L, Lee JC, Lee GC. Experimental cerebral concussion, part I: an electron microscopic study. J Neurosurg. 1977;47:525–531. doi: 10.3171/jns.1977.47.4.0525. [DOI] [PubMed] [Google Scholar]

- 19.Newman JA, Shewchenko N, Welbourne E. 44th Stapp Car Crash Conference Proceedings; November 6–8, 2000; Atlanta, GA. Stapp Paper OOS-80. [Google Scholar]

- 20.Practice for Occupational and Educational Eye and Face Protectors. Washington, DC: American National Standards Institute; 1979. ANSI Z87.1. [Google Scholar]

- 21.Standard Specification for Eye Protectors for Selected Sports. West Conshohocken, PA: American Society for Testing and Materials; 1997. ASTM F 803-97. [Google Scholar]

- 22.Standard Safety Specification for Eye and Face Protective Equipment for Hockey Players. West Conshohocken, PA: American Society for Testing and Materials; 1998. ASTM F 513-98. [Google Scholar]

- 23.Standard Method of Impact Test and Performance Requirements for Football Faceguards. Overland Park, KS: National Operating Committee on Standards for Athletic Equipment; 1990. [Google Scholar]

- 24.Pashby T. Eye injuries in Canadian amateur hockey. Can J Ophthalmol. 1985;20:2–4. [PubMed] [Google Scholar]

- 25.Standard Performance Specification for Newly Manufactured Baseball/Softball Catcher's Helmets With Faceguards. Overland Park, KS: National Operating Committee on Standards for Athletic Equipment; 1998. NOCSAE DOC 024-98. [Google Scholar]

- 26.Standard Specification for Helmets Used for Recreational Snow Sports. West Conshohocken, PA: American Society for Testing and Materials; 2000. ASTM F 2040. [Google Scholar]

- 27.Washington, DC: Consumer Product Safety Commission; 1998. Safety standard for bicycle helmets: final rule. 16 CFR Part 1203. [Google Scholar]

- 28.Mueller FO, Blyth CS. An update on football deaths and catastrophic injuries. Physician Sportsmed. 1986;14(10):134–142. doi: 10.1080/00913847.1986.11709202. [DOI] [PubMed] [Google Scholar]