Abstract

Stainless steel surfaces coated with paints containing a silver- and zinc-containing zeolite (AgION antimicrobial) were assayed in comparison to uncoated stainless steel for antimicrobial activity against vegetative cells and spores of three Bacillus species, namely, B. anthracis Sterne, B. cereus T, and B. subtilis 168. Under the test conditions (25°C and 80% relative humidity), the zeolite coating produced approximately 3 log10 inactivation of vegetative cells within a 5- to 24-h period, but viability of spores of the three species was not significantly affected.

Metals such as silver and zinc have long been recognized for their broad-spectrum antimicrobial properties, and a number of preparations containing silver and/or zinc have been formulated for reducing infections of indwelling catheters and stainless steel orthopedic devices (reviewed in references 1, 2, 7, 9, 11, and 13). An interesting advance in technology has been to trap silver and zinc ions within zeolites (inorganic ceramics) and to apply these compounds to various materials as long-lasting antimicrobial treatments (8, 14). Commercial concerns have claimed that application of silver-zinc zeolite coatings to stainless steel surfaces such as air ducts, countertops, or food preparation areas can reduce the bacterial load, hence lowering the risk of contamination by pathogenic or food spoilage microorganisms. However, controlled studies testing the efficacy of such preparations are scarce. Therefore, the present study was undertaken to test claims of the antibacterial properties of a particular silver-zinc zeolite preparation, the AgION antimicrobial, applied to stainless steel sheets. The challenge organisms used were species of the genus Bacillus, chosen for their environmental ubiquity, their ability to form resistant spores, and their known roles as agents of food poisoning (B. cereus, B. anthracis), food spoilage (B. subtilis), and bioterrorism (B. anthracis).

The bacterial strains used, namely, B. cereus strain T (WN129), B. subtilis strain 168 (WN131), and B. anthracis Sterne (WN742), were from the communicating author's laboratory collection. Vegetative cells of all strains were produced as follows. Overnight cultures grown in liquid Luria-Bertani (LB) medium (5) were diluted to an optical density of 10 Klett units (Klett-Summerson colorimeter, no. 66 red filter) into 10 ml of fresh LB medium and incubated in a rotary shaker (New Brunswick G76; 300 rpm, 37°C) to 300 Klett units (∼108 CFU/ml). (Note that to prevent sporulation during the course of experiments, B. anthracis Sterne vegetative cells were grown to only 160 Klett units [∼5 × 107 CFU/ml] in LB.) Spores of all strains were produced by incubation in liquid Schaeffer's sporulation medium (12) at 37°C for 72 h in a rotary shaker with vigorous aeration. Spores were harvested by centrifugation (10,000 × g for 10 min at 25°C), purified using the lysozyme and buffer-washing technique described by Nicholson and Setlow (6), heat shocked (80°C, 10 min), and stored at 4°C in phosphate-buffered saline (PBS) (10 mM potassium phosphate, 150 mM NaCl [pH 7.4]).

Stainless steel coupons (5 by 5 cm), either uncoated or coated with AgION antimicrobial, were kindly provided by AK Coatings, Middletown, Ohio. AgION antimicrobial contained 2.5% (wt/wt) silver and 14% (wt/wt) zinc and was applied onto stainless steel coupons to a final thickness of 0.5 mm (0.2 mil). In preliminary experiments, it was observed that the inactivation efficiency of AgION antimicrobial-coated steel was reduced after autoclaving (data not shown). Therefore, before use, all coupons were disinfected by swabbing thoroughly with 95% ethanol, rinsing with 95% ethanol, and air drying inside sterile petri dishes. Vegetative cells or spores were diluted in PBS to ∼106 to 107 CFU/ml, and samples of diluted suspensions (0.5 ml) were spotted directly onto the center of AgION antimicrobial-coated or uncoated stainless steel coupons contained within sterile petri dishes. Dishes were covered and placed within a humidity chamber (25°C, 80% relative humidity) to prevent drying. At intervals of 0, 2, 6, 24, 46, or 48 h, samples were harvested by adding 9.5 ml of sterile PBS directly onto the coupon in the petri plate, and cells or spores were resuspended by swabbing the coupon extensively with a sterile disposable inoculation loop. The resulting resuspended cells (total volume, 10 ml) were diluted serially 10-fold in PBS. Aliquots of 0.1 ml from each dilution were plated in duplicate on Schaeffer's sporulation medium solidified with 1.7% agar, plates were incubated overnight at 37°C, colonies were counted, and the concentration of viable spores or cells was calculated. The surviving fraction of spores or cells (S/S0) was calculated by dividing the viable titer at any given time point (S) by the viable titer at 0 h (S0), and the log10(S/S0) was computed. Each experiment was repeated three times (four times with B. anthracis Sterne vegetative cells). Basic statistics were calculated and analysis of variance was performed using Minitab version 10.5 software.

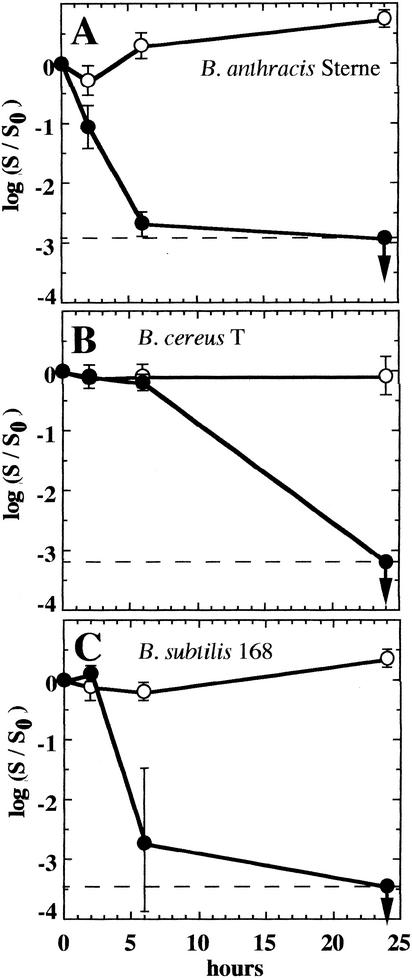

Vegetative cells of the three Bacillus spp. were not inactivated after 24 h of contact with uncoated stainless steel; in fact, viable counts of B. anthracis Sterne and B. subtilis 168 were observed to increase slightly (Fig. 1). In contrast, vegetative cells were inactivated by at least 3 orders of magnitude by 24 h of contact with AgION antimicrobial-coated stainless steel (Fig. 1). Interestingly, the kinetics of vegetative cell inactivation differed for each of the three species tested. Statistically significant inactivation by AgION antimicrobial-coated steel relative to the control was first detected at 2 h with B. anthracis Sterne (P = 0.011), at 6 h with B. subtilis 168 (P = 0.024), and not until 24 h with B. cereus T (P < 0.001) (Fig. 1).

FIG. 1.

Inactivation of vegetative cells of B. anthracis Sterne (A), B. cereus T (B), and B. subtilis 168 (C) plated on uncoated stainless steel coupons (○) or coupons coated with AgION antimicrobial (•). Dashed lines indicate the lower limit of resolution (approximately 400 CFU/ml), and downward arrows indicate that the data were at or below the limit of resolution. Results are the averages and standard deviations of three (B and C) or four (A) independent determinations at 25°C and 80% relative humidity.

Using the same protocol described above for vegetative cells, spores of B. subtilis 168, B. cereus T, and B. anthracis Sterne were exposed to either bare stainless steel or AgION-coated stainless steel for up to 46, 48, and 24 h, respectively (Table 1). No spore inactivation was apparent, and plotting of the data yielded no discernible trend lines (data not shown). Testing of the data by analysis of variance yielded no significant differences in the spore titers on bare steel versus AgION-coated steel (Table 1). Therefore, in sharp contrast to the data showing efficacy of the AgION antimicrobial for inactivation of vegetative cells, spores of the three Bacillus spp. appeared to be completely resistant to inactivation under the same conditions.

TABLE 1.

AgION antimicrobial does not inactivate spores of three Bacillus species

| Organism | Incubation (h) | Spore titer (CFU/ml) on:

|

|

|---|---|---|---|

| Bare steel | AgION-coated steel | ||

| B. subtilis 168a | 0 | 5.88 × 106 | 8.7 × 106 |

| 2 | 5.5 × 106 | 5.78 × 106 | |

| 6 | 5.72 × 106 | 6.48 × 106 | |

| 46 | 7.12 × 106 | 1.05 × 107 | |

| Mean + SD | 6.06 × 106 + 7.5 × 105 | 7.87 × 106 + 2.2 × 106 | |

| B. cereus Tb | 0 | 5.41 × 105 | 7.48 × 105 |

| 6 | 4.64 × 105 | 6.03 × 105 | |

| 48 | 4.8 × 105 | 2.61 × 105 | |

| Mean + SD | 4.95 × 105 + 4.1 × 104 | 5.37 × 105 + 2.5 × 104 | |

| B. anthracis Sternec | 0 | 2.8 × 105 | 2.76 × 105 |

| 2 | 1.96 × 105 | 3.24 × 105 | |

| 6 | 2.68 × 105 | 2.92 × 105 | |

| 24 | 2.76 × 105 | 2.8 × 105 | |

| Mean + SD | 2.55 × 105 + 4.0 × 104 | 2.93 × 105 + 2.2 × 104 | |

P = 0.162 for comparison of results on bare steel and coated steel; no significant difference by analysis of variance.

P = 0.787 for comparison of results on bare steel and coated steel; no significant difference by analysis of variance.

P = 0.144 for comparison of results on bare steel and coated steel; no significant difference by analysis of variance.

In conclusion, the silver-zinc zeolite present in AgION antimicrobial-coated stainless steel is effective at inactivating vegetative cells of three Bacillus spp. tested. However, it should be stressed that the efficacy of the AgION antimicrobial was determined under laboratory conditions where parameters such as the suspension medium, ionic strength, pH, temperature, and relative humidity were strictly controlled. In actual practice, such environmental parameters will of course exhibit considerable variation, as cells may be (i) contained in food or other biological materials containing large amounts of organic matter and having various pH values and ionic strengths; (ii) subjected to drying and variations in relative humidity; or (iii) subjected to wide-ranging temperatures, including refrigeration, for example. Clearly, additional studies are needed to assess the efficacy of the AgION antimicrobial under conditions which much more closely simulate field applications. Also, the data suggest that in vegetative cells of the three Bacillus laboratory strains tested, there may be species-specific differences in the intrinsic sensitivity to the silver and zinc ions within the AgION antimicrobial, suggesting the need for further testing of the coating for efficacy against known food-borne and clinical Bacillus isolates.

Consistent with the above observations, Takai et al. (14) have recently reported strain-, species-, and environment-specific differences in the inactivation rates of various bacteria exposed to silver zeolites. What could account for these differences? Recent evidence indicates that the antibacterial activity of silver zeolites results from the generation of reactive oxygen species (ROS) derived from dissolved oxygen in aerobic environments, including superoxide anions, hydrogen peroxide, hydroxyl radicals, and singlet oxygen, and that the antibacterial activity of silver zeolites can be inhibited by ROS scavengers (4). In this context, it makes sense that the different species of Bacillus used in this study exhibited greater or lesser sensitivity to antibacterial zeolites due to intrinsic differences in their abilities to handle oxidative stress (3).

Furthermore, it is not surprising that dormant spores are resistant to silver-zinc zeolites owing to the high resistance to ROS conferred by the spore coat layers (10). Addressing such considerations could lead to the design and development of more effective antimicrobial coatings.

Acknowledgments

We thank Fred Myers and Lee Price of AK Coatings for their generous donation of the stainless steel coupons used in this study, and we acknowledge the anonymous reviewers for their insightful comments.

This work was supported in part by a grant from the Arizona Agriculture Experimental Station (USDA Hatch) to W.L.N.

REFERENCES

- 1.Donelli, G., and I. Francolini. 2001. Efficacy of antiadhesive, antibiotic and antiseptic coatings in preventing catheter-related infections: review. J. Chemother. 13:595-606. [DOI] [PubMed] [Google Scholar]

- 2.Guggenbichler, J. P., M. Boeswald, S. Lugauer, and T. Krall. 1999. A new technology of microdispersed silver in polyurethane induces antimicrobial activity in central venous catheters. Infection 27:S16-S23. [DOI] [PubMed] [Google Scholar]

- 3.Herbig, A. F., and J. D. Helmann. 2002. Metal ion uptake and oxidative stress, p. 405-414. In A. L. Sonenshein, J. A. Hoch, and R. Losick (ed.), Bacillus subtilis and its closest relatives: from genes to cells. ASM Press, Washington, DC.

- 4.Inoue, Y., M. Hoshino, H. Takahashi, T. Noguchi, T. Murata, Y. Kanzaki, H. Hamashima, and M. Sasatsu. 2002. Bactericidal activity of Ag-zeolite mediated by reactive oxygen species under aerated conditions. J. Inorg. Biochem. 92:37-42. [DOI] [PubMed] [Google Scholar]

- 5.Miller, J. M. 1972. Experiments in bacterial genetics. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, N.Y.

- 6.Nicholson, W. L., and P. Setlow. 1990. Sporulation, germination, and outgrowth, p. 391-450. In C. R. Harwood and S. M. Cutting (ed.), Molecular biological methods for Bacillus. John Wiley and Sons, Sussex, England.

- 7.Pai, M. P., S. L. Pendland, and L. H. Danziger. 2001. Antimicrobial-coated/bonded and -impregnated intravascular catheters. Ann. Pharmacother. 35:1255-1263. [DOI] [PubMed] [Google Scholar]

- 8.Quintavalla, S., and L. Vicini. 2002. Antimicrobial food packaging in meat industry. Meat Sci. 62:373-380. [DOI] [PubMed] [Google Scholar]

- 9.Raad, I. I., and H. A. Hanna. 2002. Intravascular catheter-related infections: new horizons and recent advances. Arch. Intern. Med. 162:871-878. [DOI] [PubMed] [Google Scholar]

- 10.Riesenman, P. J., and W. L. Nicholson. 2000. Role of the spore coat layers in Bacillus subtilis spore resistance to hydrogen peroxide, artificial UV-C, UV-B, and solar UV radiation. Appl. Environ. Microbiol. 66:620-626. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Saint, S., J. G. Elmore, S. D. Sullivan, S. S. Emerson, and T. D. Koepsell. 1998. The efficacy of silver alloy-coated urinary catheters in preventing urinary tract infection: a meta-analysis. Am. J. Med. 105:236-241. [DOI] [PubMed] [Google Scholar]

- 12.Schaeffer, P., J. Millet, and J.-P. Aubert. 1965. Catabolic repression of bacterial sporulation. Proc. Natl. Acad. Sci. USA 54:704-711. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Spencer, R. C. 1999. Novel methods for the prevention of infection of intravascular devices. J. Hosp. Infect. 43:S127-S135. [DOI] [PubMed] [Google Scholar]

- 14.Takai, K., T. Ohtsuka, Y. Senda, M. Nakao, K. Yamamoto, J. Matsuoka-Junji, and Y. Hirai. 2002. Antibacterial properties of antimicrobial-finished textile products. Microbiol. Immunol. 46:75-81. [DOI] [PubMed] [Google Scholar]