The domestic fowl has a long and unique history, serving multiple purposes in society and science. A cursory review of the Nobel Prize awards in physiology or medicine since 1901 points to the significance of birds, and the chicken in particular, as the premier nonmammalian vertebrate animal model (see www.fbresearch.org/education/nobels.htm and http://nobelprize.org/nobel_prizes/medicine/laureates). The domestic fowl aided in the discovery of essential vitamins and gave the first clue to differences between T and B cells. In fact, B cell nomenclature is based on the origin of B cells from the avian bursa of Fabricius. In addition, the chicken model provided the foundation for understanding the chemical processes for vision, insights into animal behavior, and our first introduction to tumor viruses [e.g., Rous sarcoma virus (RSV)] and the cellular origin of retroviral oncogenes. Even today, avian oncogenic viruses provide valuable models for human disease. Furthermore, for many developmental biologists, the avian embryo remains the premier animal model (1). On the practical side, the general public is protected from yearly influenza outbreaks through vaccine production in chicken eggs. In addition to its scientific and biomedical importance, poultry as an agricultural commodity has grown over the last 60 years into a global industry providing billions of people with inexpensive high-quality animal protein in the form of meat and eggs. Much of the success of the poultry industry is directly related to the application of population genetics for the selection of commercial lines for efficient protein production (2). Today, estimates of the cost of egg production in the U.S. hover around 5 cents per egg. Given that the albumin from a single egg contains ≈3.6 g of protein, the domestic laying hen is a very efficient protein bioreactor. Now, with the report of Lillico et al. (3) in this issue of PNAS, the domestic chicken is poised to become the animal bioreactor for the production of commercial quantities of therapeutic proteins in eggs, moving the domestic fowl into the realm of protein bioprocessing.

Generating transgenic chickens has not been a quick and easy goal. Since the emergence of recombinant DNA technology ≈25 years ago, those who work with poultry have recognized the advantage of the avian system as an efficient means of producing medically relevant proteins. The avian egg contains large amounts of protein, and over half of the protein in egg white or albumin is composed of a single species, ovalbumin. Unfortunately, the advantages that make the avian system useful in disciplines such as developmental biology have made the task more difficult for manipulating the avian genome. Scientists who considered the chicken their model organism of choice watched with some envy while methods to manipulate the mammalian genome became increasingly more sophisticated, and reports appeared describing therapeutic protein production in the milk of sheep, goats, cattle, and rabbits (4, 5).

The avian egg, with its large yolk, is not as transparent as mammalian ova, making it a challenge to view for injection and manipulation. After ovulation, fertilization occurs in the upper reproductive tract. Then the egg spends ≈24–26 h traversing the oviduct of the hen to acquire the albumin, shell membranes, and finally the eggshell. During egg formation, the embryo continues to develop, and by the time the egg is laid, the embryo can be composed of as many as 50,000 cells. Once the egg is laid, the self-contained embryo cannot survive manipulation without the development of specific procedures to culture the nascent embryo through hatching.

The domestic laying hen is a very efficient protein bioreactor.

The idea of using the domestic fowl for the production of therapeutic proteins has always centered on methods for making transgenic poultry. Efforts for manipulating the avian genome have focused on three basic approaches: (i) direct DNA injection into the developing zygote, (ii) the culture of avian embryonic stem cells or primordial germ cells, and (iii) viral vectors to deliver DNA. All three methods have been used to produce transgenic birds, but viral vectors are currently the most successful method (6).

Direct DNA injection was investigated by Helen Sang's group (7), the first to produce transgenic chickens through the injection of DNA into the vicinity of the pronuclei of the newly fertilized zygote. This process required surgical harvesting of the ovum from the hen at a precise time after ovulation and the development of a complex three-stage culture system to nurture the embryo through hatching (8). The efficiency of this process was low, and only a few transgenic birds have been produced through DNA injection.

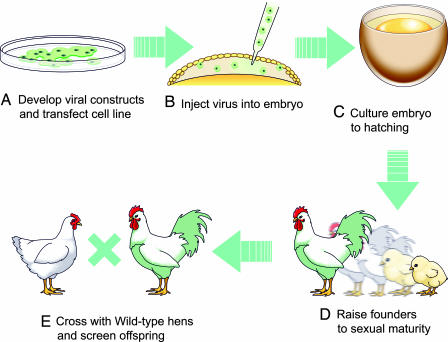

From the beginning, retroviral vectors were recognized as a way to produce transgenic birds (6). Viral stocks could be injected into the egg through a simple window in the eggshell (Fig. 1). Some of the first vectors tested to produce transgenic chicks were replication-competent RSV and avian leukosis virus (ALV) (9, 10). Subsequently, because of the possible pathogenicity associated with replication-competent viral vectors, reticuloendotheliosis virus and ALV replication-defective vectors became the method of choice for the production of transgenic chickens (11, 12). However, early concern over possible recombination with endogenous retroviral sequences dampened efforts to use viral vectors until the last 5 years. Recently, hens were generated that expressed reporter genes such as LacZ and β-lactamase (13–15). Interestingly, the ubiquitous expression of β-lactamase resulted in some secretion of the protein into the egg white. This tantalizing result was later applied to the expression of human IFN-α-2b in egg white (16). However, germ-line transmission was not optimal, making it necessary to screen hundreds to thousands of offspring to find a few transgenic birds (Fig. 1). If this inefficiency is coupled with the phenomenon of transgene silencing (17, 18), the production of useful lines of transgenic chickens appears risky.

Fig. 1.

A schematic outline of the steps to generate transgenic chickens using viral vectors. (A) Suitable viral expression constructs are developed and transfected into the appropriate packing cell line. (B) High-titer virus is injected beneath the blastoderm of the unincubated egg. (C) Injected embryos are cultured for ≈21 days through hatching. (D) Founder (G0) chicks are raised to sexual maturity. (E) Founder roosters positive for the transgene in semen are mated with wild-type hens, and the G1 offspring are screened for the presence of the transgene (illustration by Jennifer Petitte).

The group at the Roslin Institute (3) addressed the issue of germ-line efficiency and gene silencing through the use of self-inactivating pseudotyped lentiviral vectors based on the equine infectious anemia virus (19). Unlike retroviral vectors, lentiviruses do not require cell division for efficient integration into the host genome, resulting in founder birds transmitting the vector to as much as 45% of their offspring. In addition, the effect of gene silencing appeared minimal. The report of Lillico et al. (3) represents a collaboration between the Roslin Institute and two companies, Oxford Biomedica and Viragen (Scotland). Their work yielded a capstone publication in the efforts to develop an efficient system of making transgenic birds that deposit high levels of commercially relevant proteins in eggs using a lentiviral vector. Because of packaging-size limitations, a scaled-down version of the well characterized ovalbumin promoter was constructed to drive the expression of human IFN-β-1a and a humanized single-chain Fv–Fc antibody with the potential for treating malignant melanoma. In the end, the resulting transgenic birds deposited commercially significant amounts of a therapeutic antibody and a therapeutic protein specifically in the egg white. Furthermore, the recombinant IFN was functional in a viral inhibition assay simply by using raw diluted egg white.

Viral vectors are not perfect. Packaging size is limited to ≈10 kb of DNA, so the expression construct must be streamlined. High viral titers are necessary to ensure reasonable rates of germ-line transmission, and viral insertions can occur anywhere throughout the genome. Recently, additional nonviral tools have been developed to complete the repertoire of choices for taking advantage of the efficient protein production of the contemporary laying hen. These methods include the development of pluripotent chicken embryonic stem cells derived from the early blastoderm (20–22) and the long-term culture of chicken primordial germ cells, which have been used to develop transgenic chickens without the use of viral vectors (23). Unlike the state of the art 20 years ago, all of the tools, including a fresh assembly of the chicken genome, appear to be in place to take advantage of the potential applications of transgenic chickens.

No one can really predict the future when it comes to the commercialization of science, but in the next 25 years, it is reasonable to expect that, in basic science, agriculture, and now protein bioprocessing, the chicken will continue to provide benefits to society. In the end, chicken could be the source of several therapeutic proteins that are “good for what ails you.”

Footnotes

The authors declare no conflict of interest.

See companion article on page 1771.

References

- 1.Stern CD. Mech Dev. 2004;121:1011–1013. doi: 10.1016/j.mod.2004.06.009. [DOI] [PubMed] [Google Scholar]

- 2.Havenstein GB, Ferket PR, Qureshi MA. Poultry Sci. 2003;82:1500–1508. doi: 10.1093/ps/82.10.1500. [DOI] [PubMed] [Google Scholar]

- 3.Lillico SG, Sherman A, McGrew MJ, Robertson CD, Smith J, Haslam C, Barnard P, Radcliffe PA, Mitrophanous KA, Elliot EA, Sang HM. Proc Natl Acad Sci USA. 2007;104:1771–1776. doi: 10.1073/pnas.0610401104. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Wheeler MB, Walters EM, Clark SG. Anim Reprod Sci. 2003;79:265–289. doi: 10.1016/s0378-4320(03)00168-4. [DOI] [PubMed] [Google Scholar]

- 5.Castro FO, Limonta J, Rodriguez A, Aguirre A, de la Fuente J, Aguilar A, Ramos B, Hayes O. Genet Anal-Biomol Eng. 1999;15:179–187. doi: 10.1016/s1050-3862(99)00024-8. [DOI] [PubMed] [Google Scholar]

- 6.Petitte JN. In: Poultry Genetics, Breeding and Biotechnology. Muir WM, Aggrey SE, editors. Cambridge, UK: CABI; 2003. pp. 665–684. [Google Scholar]

- 7.Love J, Gribbin C, Mather C, Sang H. Biotechnology (NY) 1994;12:60–63. doi: 10.1038/nbt0194-60. [DOI] [PubMed] [Google Scholar]

- 8.Perry MM. Nature. 1988;331:70–72. doi: 10.1038/331070a0. [DOI] [PubMed] [Google Scholar]

- 9.Souza LM, Boone TC, Murdock D, Langley K, Wypych J, Fenton D, Johnson S, Lai PH, Everett R, Hsu RY, et al. J Exp Zool. 1984;232:465–473. doi: 10.1002/jez.1402320313. [DOI] [PubMed] [Google Scholar]

- 10.Salter DW, Smith EJ, Hughes SH, Wright SE, Crittenden LB. Virology. 1987;157:236–240. doi: 10.1016/0042-6822(87)90334-5. [DOI] [PubMed] [Google Scholar]

- 11.Bosselman RA, Hsu RY, Boggs T, Hu S, Bruszewski J, Ou S, Kozar L, Martin F, Green C, Jacobsen F, et al. Science. 1989;243:533–535. doi: 10.1126/science.2536194. [DOI] [PubMed] [Google Scholar]

- 12.Thoraval P, Afanassieff M, Cosset FL, Lasserre F, Verdier G, Coudert F, Dambrine G. Transgenic Res. 1995;4:369–377. doi: 10.1007/BF01973755. [DOI] [PubMed] [Google Scholar]

- 13.Mozdziak PE, Borwornpinyo S, McCoy DW, Petitte JN. Dev Dyn. 2003;226:439–445. doi: 10.1002/dvdy.10234. [DOI] [PubMed] [Google Scholar]

- 14.Harvey AJ, Speksnijder G, Baugh LR, Morris JA, Ivarie R. Poultry Sci. 2002;81:202–212. doi: 10.1093/ps/81.2.202. [DOI] [PubMed] [Google Scholar]

- 15.Harvey AJ, Speksnijder G, Baugh LR, Morris JA, Ivarie R. Nat Biotechnol. 2002;20:396–399. doi: 10.1038/nbt0402-396. [DOI] [PubMed] [Google Scholar]

- 16.Rapp JC, Harvey AJ, Speksnijder GL, Hu W, Ivarie R. Transgenic Res. 2003;12:569–575. doi: 10.1023/a:1025854217349. [DOI] [PubMed] [Google Scholar]

- 17.Mizuarai S, Ono K, Yamaguchi K, Nishijima K, Kamihira M, Iijima S. Biochem Biophys Res Commun. 2001;286:456–463. doi: 10.1006/bbrc.2001.5422. [DOI] [PubMed] [Google Scholar]

- 18.Kamihira M, Ono K, Esaka K, Nishijima K, Kigaku R, Komatsu H, Yamashita T, Kyogoku K, Iijima S. J Virol. 2005;79:10864–10874. doi: 10.1128/JVI.79.17.10864-10874.2005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.McGrew MJ, Sherman A, Ellard FM, Lillico SG, Gilhooley HJ, Kingsman AJ, Mitrophanous KA, Sang H. EMBO Rep. 2004;5:728–733. doi: 10.1038/sj.embor.7400171. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Petitte JN, Liu G, Yang Z. Mech Dev. 2004;121:1159–1168. doi: 10.1016/j.mod.2004.05.003. [DOI] [PubMed] [Google Scholar]

- 21.Pain B, Clark ME, Shen M, Nakazawa H, Sakurai M, Samarut J, Etches RJ. Development (Cambridge, UK) 1996;122:2339–2348. doi: 10.1242/dev.122.8.2339. [DOI] [PubMed] [Google Scholar]

- 22.van de Lavoir MC, Mather-Love C, Leighton P, Diamond JH, Heyer BS, Roberts R, Zhu L, Winters-Digiacinto P, Kerchner A, Gessaro T, et al. Mech Dev. 2006;123:31–41. doi: 10.1016/j.mod.2005.10.002. [DOI] [PubMed] [Google Scholar]

- 23.van de Lavoir MC, Diamond JH, Leighton PA, Mather-Love C, Heyer BS, Bradshaw R, Kerchner A, Hooi LT, Gessaro TM, Swanberg SE, et al. Nature. 2006;441:766–769. doi: 10.1038/nature04831. [DOI] [PubMed] [Google Scholar]