Abstract

With the increasing incidence of tuberculosis and drug resistant disease in developing countries due to HIV/AIDS, there is a need for vaccines that are more effective than the present bacillus Calmette–Guérin (BCG) vaccine. We demonstrate that BCG vaccine can be dried without traditional freezing and maintained with remarkable refrigerated and room-temperature stability for months through spray drying. Studies with a model Mycobacterium (Mycobacterium smegmatis) revealed that by removing salts and cryoprotectant (e.g., glycerol) from bacterial suspensions, the significant osmotic pressures that are normally produced on bacterial membranes through droplet drying can be reduced sufficiently to minimize loss of viability on drying by up to 2 orders of magnitude. By placing the bacteria in a matrix of leucine, high-yield, free-flowing, “vial-fillable” powders of bacteria (including M. smegmatis and M. bovis BCG) can be produced. These powders show relatively minor losses of activity after maintenance at 4°C and 25°C up to and beyond 4 months. Comparisons with lyophilized material prepared both with the same formulation and with a commercial formulation reveal that the spray-dried BCG has better overall viability on drying.

Keywords: aerosolization, bacillus Calmette–Guérin, spray drying, dry powder, mycobacterium

Bacillus Calmette–Guérin (BCG), the most widely administered childhood vaccine in the world with 100 million infant administrations annually (1), is presently delivered by needle injection, requires refrigerated storage, and has shown in different parts of the world variable degrees of protection against tuberculosis (TB) ranging from 0% to 80% (2). Given the increasing global burden of TB, its coupling to the HIV/AIDS epidemic, and the emerging problem of drug resistance, there is a clear need for alternatives to the traditional BCG vaccine and current treatment strategies (2, 3). An optimal new vaccine would obviate needle injection, not require refrigerated storage, and provide a safe and more consistent degree of protection.

Current commercial BCG vaccine preparations are filled as bacterial suspensions in vials, dried through lyophilization, and stabilized through refrigeration for up to 1 year on the shelf (4). Lyophilization, or freeze-drying, however, is known to produce significant losses of BCG viability after freezing (5). Moreover, lyophilized BCG fails to exhibit satisfactory shelf stability at room temperature, a major liability for transport and distribution, particularly in low-income environments, where the TB epidemic is most seriously concentrated (4, 6). Most importantly for our work, lyophilized BCG does not exhibit a particle form conducive for potential noninjectable delivery, notably through an aerosol route.

In the search for a more effective vaccine against TB, spray drying provides an attractive alternative to lyophilization. It is less costly to operate (6), can be scaled up in sterile conditions, avoids cell freezing (7), and has the potential to be inhaled (8). Previous published attempts to spray dry bacteria, although successful at producing viable material, have not yet succeeded in producing highly viable and room-temperature stable bacteria, of any kind, nor have they been applied to BCG. Desmond et al. (9) showed that Lactobacillus paracasei could be spray dried with gum acacia to increase survival of bacteria 1,000-fold when stored for 4 weeks at 15°C, and viability dropped even further by 99.9% over 4 weeks at 30°C. Similar losses of viability at room temperature were seen in this study for spray dried Spirulina platensis; survival dropped to 50% after only 6 days of storage at 30°C and dropped to 0% after 3 days of storage at 45°C.

We present here a unique approach to spray drying of bacteria. We show that by limiting osmotic stress on bacterial membranes during drying, i.e., by removing extracellular salts and cryoprotectants from suspensions of bacteria, bacterial viability on drying can be significantly improved relative to standard spray drying (with salts and cryoprotectants) and relative to lyophilization; bacteria dried by this unique approach also show better room-temperature shelf-life stability than with lyophilization. We demonstrate that BCG can be prepared by this process and filled reproducibly into vials at meaningful vial weights for vaccination purposes, providing a potential avenue to improve on the current (lyophilized) TB vaccine.

Results and Discussion

We hypothesized that because drying of sprayed droplets containing bacteria in the presence of nonvolatile salts and cryoprotectants must exert precipitously rising osmotic pressure on the exteriors of bacterial membranes as droplets dry, eliminating salts and cryoprotectants in bacterial suspensions can increase cell viability on spray drying. To estimate the osmotic pressure acting on bacterial membranes, we analyzed theoretically the osmotic pressure formed on model spherical membranes suspended within a drying droplet, employing the theoretical analysis of Batycky et al. (10). Our analysis indicated that complete drying of water droplets at the conditions of our spray drying experiments occurs within <400 ms, which is at least an order of magnitude faster than the time of water diffusion across cellular membranes (10). These calculations confirmed that osmotic pressure on the external membrane walls increases precipitously owing to the inability of water to diffuse across membranes to counterbalance transmembrane concentration differences in salts and cryoprotectants; thus, these latter osmotically active substances, which are either helpful or at least not harmful to drying through lyophilization, can be seriously detrimental to drying through spray drying. To estimate the bacterial membrane tolerance of (extracellular and intracellular) osmotic stress experimentally, we simulated the osmotic environment experienced by bacteria when suspended within drying droplets by placing Mycobacterium smegmatis in aqueous solutions of varying salt and leucine concentrations. Whereas bacteria suspended in vitro within isotonic sodium chloride solutions (with and without leucine) survived at 37°C for 24 h, doubling the salt concentration from isotonic levels (0.9% salt) (as would occur in the initial instants of droplet drying) led to 80% cell death in ≈30 min; doubling the salt concentration again reduced time to cell death to ≈5 min. Removing sodium chloride completely from the suspensions of M. smegmatis, with or without leucine, did not lead to cell death over a period of 24 h. This result suggests that the (relatively rigid) bacterial membranes tolerated intracellular, and not extracellular, osmotic pressure and, therefore, that eliminating salt and cryoprotectant in bacterial suspensions could be explored as a means to eliminate the escalating osmotic pressure that occurs during spray drying of bacteria.

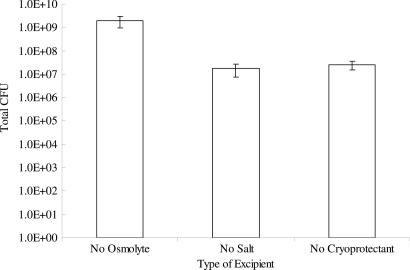

To test the hypothesis that eliminating salts and cryoprotectants in bacterial suspensions increases cell viability on spray drying, we spray dried three solutions containing M. smegmatis. These were as follows: (i) 95% leucine and 5% M. smegmatis in isotonic saline (0.9% NaCl), (ii) 95% leucine and 5% M. smegmatis in distilled water (no salt), and (iii) 95% leucine and 5% M. smegmatis in 0.9% glycerol. As illustrated in Fig. 1, M. smegmatis spray dried with either isotonic saline or glycerol showed a viability of the spray-dried powder on the order of 107 total CFU (with input CFU on the order of 1010 CFU), representing a 3-log loss in viability. In contrast, in the absence of all osmotically active substances, survivability was on the order of 109 CFU (P < 0.05). These experiments confirmed that bacteria survivability could be enhanced by removing salt and cryoprotectants from the spray-drying solution.

Fig. 1.

Total CFU after spray drying of three formulations of M. smegmatis (n = 5). All formulations possessed 95% leucine by weight and were sprayed from an aqueous solution. The “no osmolyte” formulation had no salt or cryoprotectant; the “no salt” formulate contained 1.0% glycerol (by weight) and no salt; and the “no cryoprotectant” formulation contained 0.9% (by weight) sodium chloride (no glycerol).

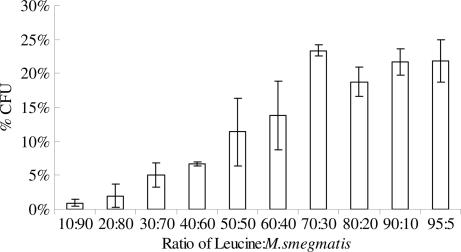

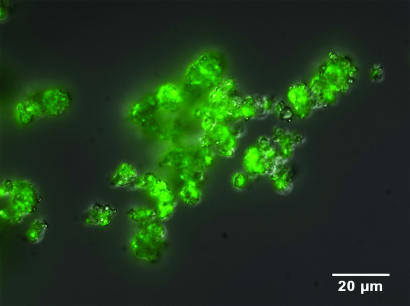

We next hypothesized that high excipient concentration would be necessary to achieve good viability, owing to the need to preserve sufficient intracellular water in the bacteria after spray drying and maintain relatively dry conditions in the sprayed powder as a whole for acceptable shelf-life stability. Consequently, we spray dried M. smegmatis without osmolytes at leucine concentrations of 10%, 20%, 30%, 40%, 50%, 70%, 90%, and 95% and measured the percent viability (% CFU) by taking the final CFU as a percentage of initial CFU and normalized by total mass yield. As can be seen in Fig. 2, higher concentrations of leucine led to higher viability. The percent yield as indicated in Fig. 2 represents viable bacteria yield following two sources of loss: (i) yield loss owing to the inefficiency of the spray drying and collection process, which can be improved through scale-up and process optimization; and (ii) yield loss related to cell death on drying. In the case of M. smegmatis, Fig. 3 shows a micrographic vision of a sample of the 95:5 l-leucine:GFP-labeled M. smegmatis spray dried powder, revealing live GFP-labeled bacteria associated with leucine. We continued our work with the 95:5 l-leucine:M. smegmatis formulation, both owing to the results shown in Fig. 2 and because preliminary stability experiments indicated that this formulation exhibits the most optimal shelf stability of the formulations tested.

Fig. 2.

Percent CFU of M. smegmatis relative to CFU in original spray dried solution as a function of leucine concentration (n = 5).

Fig. 3.

Electron micrograph of GFP-labeled M. smegmatis spray dried with leucine.

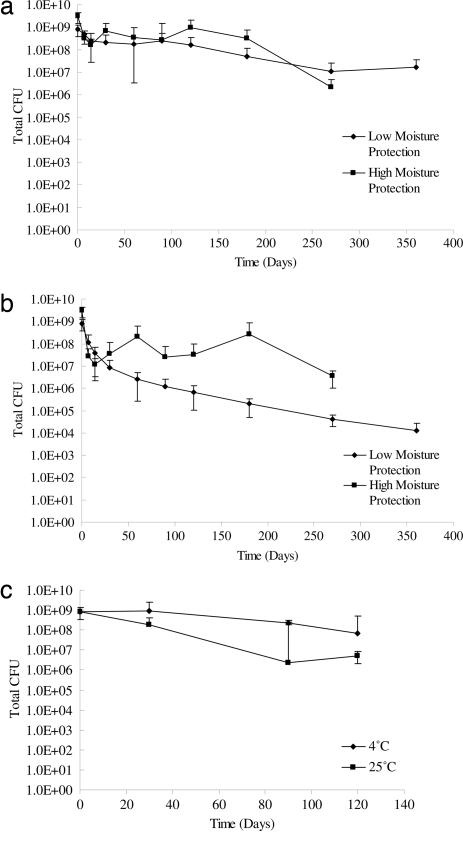

To test the hypothesis that the absence of (external) osmotic pressure on the spray dried cells during drying might lead to improved shelf storage, the stability of our M. smegmatis (95% leucine) formulations was studied at 4°C, 25°C [60% relative humidity (RH)] and 40°C (75% RH) in two kinds of packaging, as described in Materials and Methods. The dried powder displayed ideal flow properties and mass yield with tap density of 0.56 mg/ml. Fig. 4 a and b illustrate bacterial viability after several months of storage at 4°C and 25°C in “low moisture protection” and “high moisture protection” packaging, respectively. The spray-dried M. smegmatis formulations showed a well maintained stability at refrigerated conditions in the two kinds of packaging (Fig. 4a), with moisture protection showing modest stability advantage (P < 0.05). At the 25°C room temperature condition (Fig. 4b), the advantage of moisture protection is much clearer. From 1 to 2 orders of magnitude cell viability is gained through moisture protection at 25°C through day 280 (P < 0.05). Heat becomes a greater threat to the activity of the packaged-dried bacteria at the accelerated (40°C) condition. After 30 days of storage, the viability of spray-dried material diminished by ≈4 orders of magnitude in both the high and low moisture protection conditions; specifically, after 1 month of storage, viability was maintained at 2.3 × 104 CFU in the low moisture protection and 1.2 × 104 CFU in the high moisture protection. This result compares favorably with past experiments on spray dried bacteria (8), where viability in accelerated (≈40°C) conditions has been observed to approach 0% of spray-dried bacteria over similar periods of time.

Fig. 4.

Total CFUs after spray drying vs. days on the shelf for 95:5 l-leucine: M. smegmatis and M. bovis BCG spray dried bacteria. Results (n = 5) from bacterial powders not completely sealed to allow for humidity protection are labeled low moisture protection and those completely sealed labeled high moisture protection. (a) Spray dried M. smegmatis stability at 4°C and 0% RH. (b) Spray dried M. smegmatis stability at 25°C and 60% RH. (c) Spray dried M. bovis BCG at 4°C and 20% RH and at 25°C and 60% RH in high moisture protection vials.

We next evaluated the shelf stability of the dried BCG powders in the high moisture protection packaging to ascertain whether the same spray drying approach established for M. smegmatis might be applicable to BCG vaccine. To test this hypothesis, we spray dried BCG with 95% leucine (by weight) and in the absence of salt and cryoprotectants. The dried powder displayed ideal flow properties and mass yield, similar to the M. smegmatis powders. Fig. 4c shows the viability of the spray dried BCG powder over time at 4°C and 25°C. The spray dried BCG demonstrates shelf stability of a similar magnitude as that observed for M. smegmatis in Fig. 4 a and b (P < 0.05). At stressed or accelerated conditions (40°C), viability diminished from 1 × 109 at days 7 to 5 × 106 at day 56, again representing relatively good viability in comparison with previously published results for spray dried bacteria at high temperature (≈40°C) conditions.

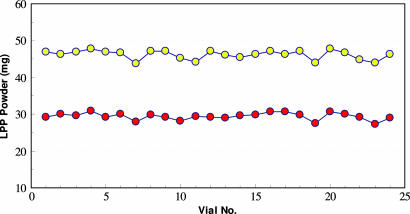

Our next step was to assure that spray dried powder could be reproducibly filled into vials in sterile conditions and at masses relevant to commercial BCG formulations by using commercial filling equipment (filling into vials small mass quantities of lyophilized BCG is typically avoided by freezing BCG solutions within vials). We performed filling experiments by using the modular aseptic compact line (MAC) commercial equipment of IMA (Bologna, Italy). Fig. 5 shows the results of these experiments, illustrating that powders with properties similar to our BCG powders can be filled reproducibly and in aseptic conditions in vials. With target fill weights of 30 and 45 mg, the average fill weight of the batches produced were 29.4 and 46.2 mg, respectively, with standard deviations of 1.26 and 0.97.

Fig. 5.

Fill weights of spray dried leucine powder possessing similar flow and aerosolization properties as the bacterial powders using commercial sterile filling equipment. Each point represents a single fill weight for n = 24 with target fill weights of 30 and 45 mg.

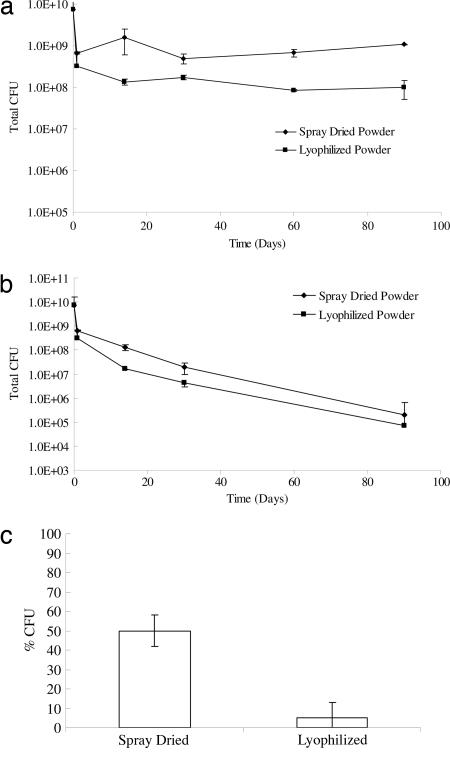

Finally, to compare our efficiency (Fig. 1) and stability (Fig. 4) results with those obtained by using bacterial freeze-drying, we lyophilized BCG in a formulation identical to that used to spray dry BCG. A batch of BCG in 95% leucine (by weight) was split into two parts: one half was spray dried and the other half lyophilized. To determine the percent viable cells after drying, we used a live/dead assay of the sprayed powder, as briefly described above. This method involved auramine rhodamine staining of the M. bovis BCG powders. Whereas the live/total bacterium ratio performed at day 1 indicated that the spray dried material retained 48% viability, the lyophilized material retained 3.8% viability relative to the original suspended material, amounting to an improvement of viability on spray drying of ≈10-fold (Fig. 6c). The day 1 viabilities for spray dried powder ranged from 8 × 108 to 2 × 109 CFU, whereas the lyophilized powders ranged from 3 × 107 to 6 × 108 CFU.

Fig. 6.

Total CFUs of 95:5 l-leucine: M. bovis BCG spray dried vs. lyophilized after spray drying and vs. days on the shelf. (a) Spray dried vs. lyophilized M. bovis BCG stability at 4°C and 20% RH. (b) Spray dried vs. lyophilized M. bovis BCG stability at 25°C and 60% RH. (c) Viability at Day 1 of spray dried vs. lyophilized M. bovis BCG.

We next compared the shelf stability of the lyophilized material with that of the spray dried material. The results of these experiments are shown in Fig. 6 a and b, which illustrates that at 4°C and 25°C, the spray dried material has significantly greater viability than the lyophilized material after 1 month's storage and in high moisture protection conditions (P < 0.05).

Conclusions

Our results show that the TB vaccine, BCG, can be prepared through spray drying to provide a dry, flowable powder that is more viable and more stable over time at room temperature conditions than conventionally lyophilized BCG. Because spray drying is a low-cost, highly scaleable pharmaceutical manufacturing process, and moreover can be used for preparation of (noninvasive) aerosol formulations, it may therefore provide a practical approach toward engineering an improved future TB vaccine, with possible advantages including lower cost, greater room temperature stability, greater viability (with potential benefits to vaccine efficacy), and noninvasive delivery.

Materials and Methods

Materials.

l-Leucine (MW = 131.2, ≥98.5% purity), glycerol (1,2,3-propanetriol, MW = 92.10), and tyloxapol [4-(1,1,3,3-tetramethylbutyl)phenol, MW = 1066] were purchased from Sigma–Aldrich (St. Louis, MO). Deionized Sterile Milli-Q Biocel A10 Filtered Water filters were purchased from Millipore (Billerica, MA). PBS (phosphate buffer solution; pH 7.4) was purchased from Invitrogen (Grand Island, NY).

Bacterial Culture.

M. smegmatis mc2155 was cultured in standard minimal liquid medium, Middlebrook 7H9 with 10% OADC (BD Diagnostics, Rockville, MD), 0.2% glycerol (Sigma), and 0.05% Tween 80 (Sigma), supplemented with 50 μg/ml hygromycin (Roche, Indianapolis, IN) where appropriate. For fluorescent imaging, M. smegmatis mc2155 [16] was transformed with a hygromycin-marked episomal plasmid carrying a constitutively expressing GFP gene and designated M. smegmatis mc2155:gfp. For all other studies, M. smegmatis mc2155 was transformed with pSS3 (an episomal plasmid carrying a hygromycin resistance cassette), a designated M. smegmatis mc2155:pSS3. M. smegmatis was cultured for 2–3 days until an OD of 0.8 to 1.0 was reached. Cells were pelleted, washed with PBS/0.05% Tween 80, and then resuspended in an equal volume of H2O/0.05% tyloxapol for spray-drying. (The role of Tyloxapol is to maintain dispersion of the bacteria before spray drying, as established in previous optimization work performed by the Aeras Global TB Vaccine Foundation.) Typically, the suspension for spray drying contained ≈109 CFU/ml.

M. bovis BCG Danish 1331 was supplied by Aeras Global TB Vaccine Foundation (Rockville, MD). M. bovis BCG was cultured in 10-liter fermentation batches, pelleted, washed, and resuspended in 0.05% tyloxapol with proprietary formulations of glycerol/saline or sucrose/raffinose. These large batches were separated into 50-ml tubes, which were frozen into pellets by using the proprietary formulations from Aeras for shipment. Before use, cells were thawed, washed with PBS/0.05% Tween 80, and then resuspended in an equal volume of H2O/0.05% tyloxapol for spray drying. Typically, the suspension for spray drying was on the order of 108 CFU/ml.

Bacterial counts were determined by serial dilution plating on Middlebrook 7H10 agarose with 10% OADC/0.5% glycerol (supplemented with 50 μg/ml hygromycin for M. smegmatis mc2155:pSS3).

Solution Preparation.

Spray drying solutions were prepared by mixing l-leucine (Sigma) solution and previously prepared M. smegmatis or M. bovis BCG suspensions in various desired ratios (wt/wt). We used leucine because it is an accepted FDA binder and, as shown in our studies, does not exert damaging osmotic pressure effects on bacterial membranes at the concentrations used. The leucine:bacteria suspension was stirred and used immediately after preparation.

Spray Drying Conditions.

We spray dried solutions with a Mini Spray Dryer B-290 (Büchi, Flawil, Switzerland), using a 0.7-mm pressure nozzle tip located above the spray drying cylinder with drying air flow rate of 35 liters/h. Spray dried particles were collected in 6-inch collection vessels from the high-performance cyclone. The inlet temperature was varied between 100 and 125°C to maintain a constant outlet temperature of 40°C with a solution feed rate of 7 ml/min. Powder was collected immediately for characterization or stored as described below.

Characterization of Spray Dried Powders.

Serial dilution plating followed by CFU determination was used to assess the number of viable M. smegmatis or M. bovis BCG bacteria in cell suspensions before spray drying and in powders after spray drying. Powders were resuspended in PBS/0.05% Tween 80 to dissolve excipient and vortexed to homogeneously disperse the sample. To assess the stability of bacterial viability under different conditions over time, powders were placed under various temperatures and monthly time points to determine viability in CFU. Powders were placed at −20°C/10% RH (freezer conditions), 4°C/25% RH (refrigerated conditions), 25°C/60% RH (ambient room temperature conditions), and 40°C/75% RH (accelerated conditions). Powders were placed in individual vials and plated at monthly time point intervals (months 1, 2, 3, 4, 6, 9, and 12).

To determine the fine particle fraction of viable bacterium of each powder for filling purposes, we used a six-stage Anderson Cascade Impactor (ACI-6; Thermo Anderson, Smyrna, GA). Capsules containing 10 ± 2.5 mg of powder were placed in a hand-held dry powder inhaler device (Plastiape, Osnago Lecco, Italy). The capsule in the inhaler was punctured, and a pump simulating an inspiration (28.3 liters/min during 4.2 s) deposited the dried bacteria powder on different stages dependent on the aerodynamic diameter of the particles. Powder was collected at each stage and plated on 7H10 agarose plates to determine CFU of each powder on each stage. We determined the mass-median aerodynamic diameter of our M. smegmatis or M. bovis BCG powders from these studies to be in the range of 3–5 μm.

For a visual analysis of the live and dead M. smegmatis or M. bovis BCG bacteria in the dry powder, the powder was resuspended in PBS, plated on agarose plates, and after 24 h studied under an Axio Imager fluorescent microscope (Zeiss, Gottingen, Germany), using a ×20 Zeiss epiplan objective (NA 0.5). Excitation and emission wavelengths were selected by using the Zeiss GFP filter set with an excitation bandpass filter of 450–490 nm, dichroic mirror of 500 nm, and emission bandpass filter 500–550 nm. Images were captured on a CoolsnapEZ CCD camera (Roper Scientific, Tucson, AZ) controlled by IPLab Spectrum software (BD Biosciences, Rockville, MD).

The total number of M. smegmatis and M. bovis BCG bacterium in our spray dried powders was determined by using an auramine/rhodamine fluorescent stain. BCG powder was vortexed for 10 min to remove clumps. The bacteria were dissolved in PBS/0.05% Tween 80, and 20 μl of BCG solution was placed on a slide with 0.2 × 0.2-mm grids. BCG was fixed onto the slide by heating at 80°C for 2 h and stained with auramine/rhodamine fluorescent stain for 15 min at 37°C. Slides were then washed with buffer, and the number of bacteria was counted in 10 squares on the slide grid and multiplied by corresponding dilution factors to determine the total number of BCG bacteria per milliliter of solution.

Lyophilization of Cellular Material.

Lyophilization was conducted with a Freezemobile Freeze Dryer (Virtis, Gardiner, NY). Solution preparation followed the same approach used for the spray-dried material. Samples were frozen on the side of sterilized glass vials using dry ice and placed on the lyophilizer. At a pressure of 50 psi/cc, the temperature was lowered to −20°C for 28 h until the water sublimed to leave a dry powder.

Vial Filling of Dried Cellular Material.

A spray dried placebo powder (without bacteria) was formulated and produced at Eratech (Piacenza, Italy) with similar aerosolization characteristics to the BCG powders. The composition of this powder was 20% leucine/80% lactose by weight, a composition chosen to meet the need to manufacture large amounts of powder and yet to achieve powders of similar aerosolization (i.e., filling) properties as the bacterial powders. The solvent mixture of choice for spray drying consisted of 70/30 water/ethanol. The spray-drying process was carried out by using a Labplant SD-06 spray drier with a 1-mm nozzle at 160°C inlet temperature and 67°C outlet temperature at a feed rate of 7 ml/min and 2 bars of nebulization pressure. Two kilograms of placebo powder was obtained in a relatively short period with a mass-median aerodynamic diameter of 4.43 μm, i.e., in the range of the aerodynamic diameters of the bacterial powders. The powder was used to perform a vial filling simulation using the filling unit of a modular aseptic equipment (MAC) manufactured by IMA for aseptic filling of vials. This equipment is designed to potentially fill vials at a maximum rate of 4,200–6,000 per hour. The equipment operates via a so-called “vacuum/pressure” mechanism, using vacuum to fill a volumetric chamber and to compact a powder pellet, which is then expelled by pressured air in the vial. In our experiments, 2 kg of placebo powder was placed in the hopper of the filling equipment, and the filling chamber volume and vacuum were adjusted to the filling target of 30 and 45 mg, respectively. The net weight of the powder filled was individually calculated.

Packaging of Dried Material.

To investigate the roles of moisture and temperature on dry powder stability, we placed the spray dried powders in two kinds of packaging. Low moisture protection packaging permitted moisture within 2 weeks of stability testing to leak through the packaging such that the atmosphere within the packaging equilibrated with the atmosphere outside the packaging. The atmosphere within the vials therefore reached 60% and 75% RH in their respective stability conditions within 2 weeks of stability testing. High moisture protection packaging maintained dessicated conditions throughout the stability tests.

Acknowledgments

We thank Brian Pulliam, Katharina Elbert, Nicholas A. Geisse, Ron Mayner, Nitin Goel, and Manoj Kole for helpful assistance. This work was supported by a Grand Challenge Grant from the Bill & Melinda Gates Foundation and National Institutes of Health Grant AI02545.

Abbreviations

- BCG

bacillus Calmette–Guérin

- RH

relative humidity

- TB

tuberculosis.

Footnotes

The authors declare no conflict of interest.

References

- 1.Roche P, Triccas JA, Winter N. Trends Microbiol. 1995;3:397–401. doi: 10.1016/s0966-842x(00)88986-6. [DOI] [PubMed] [Google Scholar]

- 2.Orme IM, McMurray DN, Belisle J. Trends Microbiol. 2001;9:115–118. doi: 10.1016/s0966-842x(00)01949-1. [DOI] [PubMed] [Google Scholar]

- 3.Kaufmann SHE. Nat Med. 2000;6:955–960. doi: 10.1038/79631. [DOI] [PubMed] [Google Scholar]

- 4.Lind A. Scand J Respir Dis. 1967;48:343–347. [Google Scholar]

- 5.Kim T, Kubica GP. Appl Microbiol. 1972;24:311–317. doi: 10.1128/am.24.3.311-317.1972. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Millqvist-Fureby A, Malmsten M, Bergenstahl B. J Colloid Interface Sci. 2000;225:54–61. doi: 10.1006/jcis.2000.6740. [DOI] [PubMed] [Google Scholar]

- 7.Mumenthaler M, Hsu CC, Pearlman R. Pharm Res. 1994;11:12–20. doi: 10.1023/a:1018929224005. [DOI] [PubMed] [Google Scholar]

- 8.Vanbever R, Mintzes JD, Wang J, Nice J, Chen D, Batycky R, Langer R, Edwards DA. Pharm Res. 1999;16:1735–1742. doi: 10.1023/a:1018910200420. [DOI] [PubMed] [Google Scholar]

- 9.Desmond C, Stanton C, Fitzgerald GFF, Collins K, Ross RP. Int Dairy J. 2002;12:183–190. [Google Scholar]

- 10.Batycky R, Hammerstedt R, Edwards D. Philos Trans R Soc London Ser A. 1996;355:2459–2488. [Google Scholar]