Abstract

This project examined dry, fluidized spore reaerosolization in a heating, ventilating, and air conditioning duct system. Experiments using spores of Bacillus atrophaeus, a nonpathogenic surrogate for Bacillus anthracis, were conducted to delineate the extent of spore reaerosolization behavior under normal indoor airflow conditions. Short-term (five air-volume exchanges), long-term (up to 21,000 air-volume exchanges), and cycled (on-off) reaerosolization tests were conducted using two common duct materials. Spores were released into the test apparatus in turbulent airflow (Reynolds number, 26,000). After the initial pulse of spores (approximately 1010 to 1011 viable spores) was released, high-efficiency particulate air filters were added to the air intake. Airflow was again used to perturb the spores that had previously deposited onto the duct. Resuspension rates on both steel and plastic duct materials were between 10−3 and 10−5 per second, which decreased to 10 times less than initial rates within 30 min. Pulsed flow caused an initial spike in spore resuspension concentration that rapidly decreased. The resuspension rates were greater than those predicted by resuspension models for contamination in the environment, a result attributed to surface roughness differences. There was no difference between spore reaerosolization from metal and that from plastic duct surfaces over 5 hours of constant airflow. The spores that deposited onto the duct remained a persistent source of contamination over a period of several hours.

The threat from a bioweapon agent such as anthrax remains problematic. Because of the biological, technical, and pathological characteristics of Bacillus anthracis, it is attractive as a bioweapon (2, 10). When used as a weapon of mass destruction, the agent is dispersed in particles less than 5 μm in diameter, a size that allows penetration into the pulmonary alveoli (18). Minimal data on human infective doses for inhalational Bacillus anthracis are available (14, 24, 25). The problem is further compounded by variations in individual susceptibility, B. anthracis strain virulence and spore preparation technique, and physical characteristics of the bioparticle. Thus, studying the fate and transport of fluidized spore concentrations is necessary in order to better predict the area of contamination and to more accurately model potential health risk.

Ventilation systems provide a conduit to contaminate a building and the surrounding area. Such systems can become entry points or distribution systems for hazardous contaminants, including biological weapon agents (BWA) (15). Air circulation in ordinary buildings can assist the spread of airborne disease and can disperse contaminants (11, 22). Reaerosolization of these hazardous bioparticles deposited onto surfaces can be a continuing source of contamination. For example, a study of reaerosolization of B. anthracis after dispersal in a postal facility found that a mail sorter remained contaminated many days after processing B. anthracis-contaminated letters (5). Many factors affect potential particle deposition and reaerosolization in heating, ventilation, and air conditioning (HVAC) systems. Particles may be deposited onto and reaerosolized from duct surfaces at different rates, depending on particle size, velocity, physical configuration of bioparticulate, duct surface, and other environmental factors, such as humidity, dirt, and biofilm formation (9, 11, 12, 21).

The term reaerosolization as used in this paper describes spores that have settled onto surfaces in the duct and subsequently have been resuspended into the duct airflow. The specific mechanism of spore particle detachment in turbulent flow is not well understood. Both normal lift and tangential shear forces are proposed as responsible for resuspension (19). According to the work of Braaten et al. (1) determining source mechanisms for particles is difficult because the removal of particles from a surface involves a complex interaction of forces including fluid drag and lift, adhesion of particles to the surface, and the impact from particles in the flow striking particles on the surfaces. The authors further state that the forces that promote or resist resuspension are dependent on properties of the mean flow, surface roughness, and physical characteristics of the particle. It is not surprising, then, that resuspension of particles has been observed to vary over many orders of magnitude. Sehmel (21) stated that a particle resuspension average should be qualified as being uncertain within 2 to 3 orders of magnitude, and Wu et al. (28) reported values of resuspension rates varying from 10−13 to 10−4/s.

In previous deposition experiments surrogate BWA were used in three common ventilation duct materials: flexible plastic, galvanized steel, and internally insulated fiberglass. Spore transport efficiency ranged from 9 to 13% in steel and fiberglass ducts; transport efficiency was far less (0.1 to 4%) in plastic duct (12). Results showed that the deposition of surrogate BWA was significantly different in the three duct materials evaluated. Dominant factors affecting the deposition velocity included the static charge attraction between spores and the plastic duct, the macroroughness of folds in the plastic film, the wire helix in the plastic duct, or the joint-seam and corrugated connectors in galvanized steel. A difference of 2 orders of magnitude between the charge of plastic and that of fiberglass and steel was determined (12). The static charge from plastic was negative and may have attracted the positively charged spores. The question of electrostatic effect on spore reaerosolization potential is explored in this study.

An investigation by Weis et al. (25) found secondary aerosolization of viable B. anthracis spores from contaminated surfaces during simulated active office conditions. The B. anthracis spores used in the terrorist incident reaerosolized under semiquiescent conditions, and the reaerosolization rates increased during simulated active office conditions. Exposure to B. anthracis spores following discharge may be from the initial aerosol release or by disruption and reaerosolization of the spores that have settled onto environmental surfaces. Bioparticles of <10 μm move with the airflow (27). The degree to which fluidized endospores resuspend in the environment is not well characterized. Thus, experiments to determine the concentration of spores that resuspend from a surface back into the air are important in order to determine the extent of contamination and to establish adequate decontamination strategies.

In this study we designed an experiment that would subject settled, fluidized bacterial endospores to turbulent airflow to determine the extent of reaerosolization in ventilation ducts. Culturable airborne spores in the air fraction and on duct surfaces were quantified in this study because viable spores are the best indication of a health hazard. Estimates of the reaerosolization potential were based on resuspension rates and resuspension factor determinations. Such estimates may provide useful data for predictive transport models (16).

MATERIALS AND METHODS

Test overview.

Experiments were conducted at the U.S. Army Dugway Proving Grounds in Utah over a 3-year period. A spore deposition experiment was followed by a reaerosolization experiment, so that properties of aerosolized spores could be explored. Deposition experiments consisted of dissemination of a quantity of spores into turbulent airflow that deposited on the walls of the HVAC test apparatus (Fig. 1). The first series of tests studied deposition velocity of powdered spores in short-term (five air-volume exchange) experiments. Each test in the deposition series was immediately followed by a reaerosolization test. Next, a series of longer-term tests (up to 21,000 air-volume exchanges) followed by reaerosolization tests were conducted. Third, a series of cyclic tests were executed to investigate reaerosolization under simulated HVAC operational conditions. Tests were then conducted to determine the concentration of spores that reaerosolized with increasing airflows.

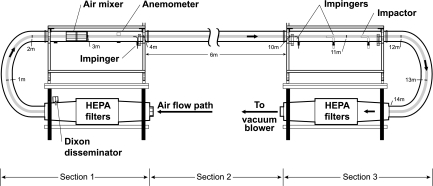

FIG. 1.

Test apparatus.

Powdered spores were aerosolized into the duct airflow for predetermined periods of time using a Dixon disseminator. In earlier tests the spore plume moved through the ventilation duct in about 25 s (12). The tunnel was shut down for a rest period of 15 min, and then a downwind section of the section 2 ducting material was removed and replaced with clean ducting. Then airflow in the tunnel was restarted with spores previously deposited on section 1 and the first 3 m of section 2 duct providing a source. Then the tunnel and impingers were shut down for a rest period of 15 min. A replicate was conducted for each test. Impinger isokinetic probes were cleaned thoroughly between experiments. High-efficiency particulate air (HEPA) filter cartridges were added upstream of section 1. This was done so that the spores deposited onto the surfaces of section 1 duct were the source of reaerosolized spores.

Data collected during each test included air velocity, temperature, relative humidity, spore counts in air, aerodynamic particle size (APS) distribution profiles, and spore counts on interior duct surfaces made by using wet swabs on surfaces. Environmental conditions such as relative humidity and air temperature were monitored but not controlled. Ambient conditions were considered useful field simulation information.

The test environmental conditions were typical of normal fluctuations found in high-desert conditions (1,219 m above sea level). The percent relative humidity ranged from 9.0 up to 39.9, and temperatures of intake air fluctuated from 9.6 to 31.4°C during the test periods in Dugway, UT (Table 1). The mean intake percent relative humidity was 24.26 (standard deviation, ±9.77), and the mean exhaust was 23.55 (standard deviation, ±9.94) during the testing. In the summer the percent relative humidity ranged from 19.3 up to 36.9 and air temperatures ranged from 25.5 to 31.4°C.

TABLE 1.

Ranges of ambient temperature and relative humidity during testinga

| Test duct type and duration | Relative humidity (%) | Temp (°C) |

|---|---|---|

| Plastic, 5 air-vol exchanges | 9.0-28.0 | 11.6-15.7 |

| Steel, 5 air-vol exchanges | 25.3-39.9 | 9.6-15.6 |

| Plastic, 1,200 air-vol exchanges | 20.1-24.9 | 26.5-30.0 |

| Steel, 2,100 air-vol exchanges | 26.4-33.9 | 27.4-31.4 |

| Plastic, cyclic airflow, 5 h | 26.6-34.1 | 19.1-21.4 |

| Steel, cyclic airflow, 5 h | 22.0-22.3 | 24.1-24.9 |

Relative humidity was highest in the morning and decreased during the day as the temperature rose. The tests took place in the high desert over a 3-year period.

Experimental apparatus.

The test apparatus consisted of 15.2-cm-diameter ducting divided into three sections that were a total of approximately 13.7 m in length. As shown in Fig. 1, the apparatus included four bends of approximately 90° each, two 2-m vertical rises, and 10 m of horizontal duct. A vacuum blower drew air into section 1 of the test apparatus, through a HEPA filtration system, and into a 2-m section of galvanized steel duct. An air mixer of two perforated metal screens (63%-open-area mesh) 15 cm apart was placed within the proximal end of the duct to ensure turbulent airflow. An anemometer (series 2440; Kurz, Monterey, CA) attached to a personal computer logged the airflow. Airflow through the duct was balanced to 2.83 ± 0.05 m3/min, a flow rate typical in ventilation ducting of this size. The Reynolds number (26,000) reflected turbulent airflow. The duct airflow velocity profile was measured 3.05 m from the spore release point with an anemometer. Spores were released using a Dixon disseminator (U.S. Army), a metal chamber containing a measured weight of spores and attached to a port on the duct system. The disseminator contained a diaphragm that ruptures under an external pulse of pressurized air, resulting in the near-instantaneous release of spores into the duct system. Air pressure was exerted in the chamber, resulting in a dispersion of spore powder into the duct airstream. The target value for spore deposition densities was in the range of 107 CFU per 25 cm2 of sample area. Release of spores into the duct did not perturb the airflow above normal operational fluctuations.

The APS distribution was characterized by an APS system (model 332000; TSI, Maplewood, MN) located in section 1 of the test apparatus. Spores traveled past the isokinetic probes and APS system located 3.5 m downstream from the spore release location. Section 1 included an all-glass impinger (Ace Glass, Inc.; model 7540, reference no. AGI-30) with an intake velocity that is internally limited by a critical orifice to 12.6 liter/min (standard temperature and pressure). A 1-minute air sample was withdrawn from the ductwork via the impinger into 17.5 ml of phosphate-buffered saline (PBS). Samples were mixed, serially diluted, vortexed, plated onto Trypticase soy agar, and incubated for 24 h at 37°C.

Section 2 of the test apparatus contained a removable 6.1-m section of duct. Two duct materials were tested in this study. The first material was flexible plastic (Master Flow, R-6.0 insulated; L. L. Building Products Inc., Irwindale, CA). The second material was galvanized (zinc-coated by the hot-dip process) steel (L. L. Building Products Inc., Irwindale, CA). The plastic and steel ducts had smooth internal surfaces. The flexible plastic duct was composed of two layers of polyester film that encapsulated a galvanized steel wire helix with multiple 0.1- to 0.3-cm folds. Physical roughness was estimated by measuring the difference between the highest and lowest points within the sampling length: for flexible plastic, 0.005 ± 0.002 mm, and for steel, 0.15 ± 0.05 mm. The aerodynamic roughness for the materials was estimated as 1/30 of the physical roughness according to the work of Sutton (23); flexible plastic was 1.67 × 10−4 mm, and steel was 0.005 mm. Because of duct seams and connections and the wire helix in the flexible plastic duct, internal macrosurfaces were not smooth. The 6-m section of duct was used for collecting spores that had settled onto the internal duct surfaces. In the experiments the duct was purchased from stock material and no precleaning was conducted. In the case of steel duct no wiping of any surface occurred because the act of wiping the duct caused a strong static charge on the steel and thereby changed the spore deposition velocity.

Section 3 of the apparatus was a 2-m length of steel ducting equipped for air sampling. This section was instrumented with three impingers for repetitive sample collection. Each instrument was on a separate, rotary vane pump set to the manufacturer's recommended flow rate. The APS system included an internal pump that produced a sample flow rate of 1 liter/min. Airflow through the test duct was exhausted through a second HEPA unit. Isokinetic probes and rotary vane pumps that supported the test apparatus were able to accommodate a variety of testing configurations.

Spore surrogate.

The surrogate organism for B. anthracis was the spore-forming bacterium Bacillus atrophaeus, also known as Bacillus globigii. B. atrophaeus is a gram-positive, durable, spore-forming bacterium that is common in certain soils, noninfectious, easily grown in culture, and easily detected. B. atrophaeus spores are morphologically different from B. anthracis spores; however, because the spores are nonpathogenic and commonly used in bioaerosol studies, B. atrophaeus was chosen for these tests. The B. atrophaeus used was a dry powder (2.33 × 1011 spores/g) that was characterized by scanning electron microscopy and an APS measurement for aerodynamic size in the aerosol state. Dried spores were prepared and characterized by scientists at Dugway Proving Ground, Dugway, UT. Spores ranged from 0.6 to 1.1 μm in three separate analyses. Fluidized spores are reasonable facsimiles of weaponized spores. One-tenth of a gram of material was released for each short-term test and 2 g for each long-term or cyclic test. The spores and disseminator were weighed together before and after each test so that the precise amount of material released was known.

Spore deposition on duct materials.

Fluidized B. atrophaeus was introduced into the turbulent airflow (2.83 m3/min) of the test fixture. Initial dispersal of B. atrophaeus spores ranged from approximately 7 × 109 to 1 × 1010 spores. Initial spore release resulted in about 2.5 × 107 ± 6.4 × 106 CFU/liter air. The background spore count was 2.0 ± 0.01 CFU/liter air. During the short-term tests, after spore dissemination, air samples were collected while 5 volumes of air were exchanged followed by airflow shutdown for 15 to 30 min.

Duct surface samples.

Surface samples were collected from the second half of the duct, located in section 2 of the apparatus. The size of each surface sample area was 25 cm2. For each of nine locations at approximately 30- to 38-cm intervals along the duct, four samples were collected: at the bottom, left side, right side, and top of the duct. Sterile polyfiber-tipped swabs (Puritan Medical Products Co., Guilford, ME) were moistened with sterile PBS solution and rolled vertically and horizontally within a 25-cm2 area of duct, one sample per location. Sample areas were identified with clean Teflon sample template that delineated sample collection boundaries. Swabs were then placed in a test tube containing 10 ml of PBS with 0.1% Triton X-100 (Sigma) and mixed for 10 min on a wrist action shaker. Samples were serially diluted, vortexed, plated on Trypticase soy agar (ATCC medium 18) in triplicate, and incubated at 37°C for 24 h. Field blanks comprised approximately 10% of the total number of samples.

Standardized negative controls.

Biological control samples were run with manipulations similar to those for the samples of contaminated duct surfaces. Five percent of the samples were method blanks. Background counts were assessed after a total of 10 air volumes had passed through the ducts for each duct material tested. The airflow was turned on for 5 air volumes, turned off for a rest period of 15 to 30 min, and turned on for another 5 air volumes followed by background air sample collection. The impingers were sampled and analyzed for total microbial counts using standard method 9215 (3). After each test set, sterile impingers with sterile media were reconnected to the appropriate probes. No B. atrophaeus was detected on either of the two duct materials tested prior to B. atrophaeus release.

Static measurements.

Static measurements were obtained using a JCI 140 static monitor and Faraday pail (John Chubb Institute, Unit 30, Cheltenham, England). Such measurements quantified the surface voltage (kV) in coulombs (C). The level of detection was 0.01 nC. Steel duct samples were grounded, whereas plastic samples were not grounded because those materials do not conduct an electrical charge. The static measurements of fluidized B. atrophaeus spores used in these tests ranged from +31.3 ± 1.1 to +31.5 ± 1.1 nC/g. Flexible plastic duct ranged from −6.29 ± 0.62 to −5.84 ± 0.56 nC/g, and steel was +0.01 ± 0.01 nC/g. Each value is the average of five measurements.

Statistical analysis.

Data were logarithmically transformed to best represent the central tendency of the data. Once the results were transformed, further tests were based on the assumption that the data were sampled from a Gaussian population. The B. atrophaeus counts from each test were compared to those for all other tests. The analysis of variance, a comparison of the means and deviations of all tests, was conducted. Analysis of covariance was used to compare regression analysis of the data sets.

RESULTS

Short-term reaerosolization tests in steel and plastic duct.

Airborne concentration of B. atrophaeus spores dispersed in steel duct after dissemination of 0.1 g B. atrophaeus into an active airflow resulted in an average concentration of 5.57 × 105 ± 4.1 × 105 CFU/liter. This is the average from four tests. The average concentration of airborne spores in plastic duct following spore dispersal was 5.33 × 104 ± 4.1 × 104 CFU/liter.

The average concentration of spores that reaerosolized into the airflow of steel duct was 1.90 × 103 ± 2.5 × 103 CFU/liter. The average from two tests in plastic duct resulted in a spore concentration of 115 ± 78 CFU/liter. Reaerosolized concentrations normalized by dividing the airborne spore concentrations by the spore concentration that deposited onto the duct following the initial release resulted in a reaerosolized spore concentration of 1.95 × 103 CFU/liter for both duct materials.

Spores deposited onto duct surfaces during the short-term tests resulted in an average concentration of 4.08 × 105 ± 2.5 × 105 CFU/cm2. Table 2 shows the spore reaerosolization from steel and plastic after five air-volume exchanges. The average reaerosolized spore concentration was 2.09 × 103 ± 1.9 × 103 CFU/cm2 from the duct surface. These data suggests that spores on the surface move from a source location to some other location on the duct surfaces. The average reaerosolization potential over the short-term tests was 0.74% (Table 2). The percentage of spores that settled on the uncontaminated duct (section 2) by reaerosolization from section 1 duct was determined by calculating the ratio of surface concentrations, [S/S0 × 100], where S (CFU/cm2) is the surface concentration of spores that settled in the uncontaminated duct and S0 is the source spore concentration that initially settled onto the upstream duct. The reaerosolization potential was 0.4 to 1.2%. Initial reaerosolization may be underestimated because air sample collection began after airflow was established in the test apparatus. Some spores may have become airborne and lost in the first few seconds prior to start of air collection.

TABLE 2.

Spore reaerosolization from steel and plastic surfaces after five air-volume exchanges

| Duct material | Initial spore deposition source (CFU/cm2) | Redeposited spores (CFU/cm2) | Normalized reaerosolizationa (%) |

|---|---|---|---|

| Steel | 2.82 × 105 | 1.43 × 103 | 0.51 |

| Steel | 2.27 × 105 | 1.93 × 103 | 0.85 |

| Steel | 4.31 × 105 | 5.25 × 103 | 1.22 |

| Steel | 4.31 × 105 | 1.68 × 103 | 0.39 |

| Plastic | 2.30 × 104 | 1.72 × 102 | 0.75 |

Average value was 0.74.

Long-term, continuous reaerosolization tests in steel and plastic duct.

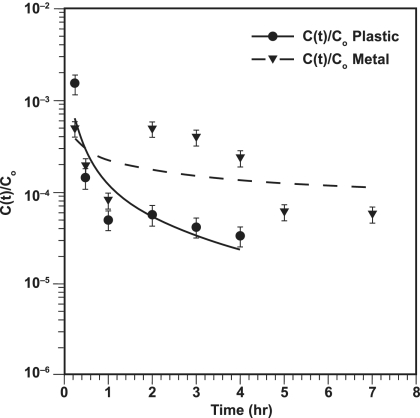

Four hours of continuous airflow (1,200 air-volume exchanges) following spore dispersal and deposition in plastic duct resulted in an average concentration of spores in the air of 1.2 × 104 ± 0.8 × 104 CFU/liter (Fig. 2). In steel, over 7 h of continuous airflow (2,100 air-volume exchanges) the average concentration of spores in air was 3.3 × 103 ± 5.4 × 103 CFU/liter. Regression analysis was conducted in order to calculate spore concentration decay over time (t) using Ct/C0, where C0 = C(t = 0). The resuspension decay curves had the equation Ct/C0 = 0.00026t−0.45, R = 0.94, for steel and Ct/C0 = 7.64e5t−0.60, R = 0.92, for plastic duct (Table 3). Resuspension concentration ratios were fitted to a power function of time as the dependent variable to determine the decay of resuspension over time (13, 17). The Mann-Whitney test used to compare reaerosolized spore concentrations in plastic versus those in steel duct resulted in no significant difference (P = 0.035).

FIG. 2.

Long-term reaerosolization test. Results are from a constant airflow test that exchanged up to 21,000 duct air volumes following spore dissemination. Error bars are the standard errors of the means.

TABLE 3.

Application of exponential regression to model time decay of normalized spore concentrations in air in continuous and cyclic airflow modes

| Duct material | Flow operation | Duration (h) | Regression equation | 1-log decay time (h) |

|---|---|---|---|---|

| Steel | Continuous | 7 | Ct/C0 = 0.00026t−0.45 | 174 |

| Plastic | Continuous | 4.5 | Ct/C0 = 7.64e−5t−0.60 | 48 |

| Steel | Pulsed | 5 | Ct/C0 = 1.1e−5t−0.29 | 53 |

| Plastic | Pulsed | 5 | Ct/C0 = 0.00052t−0.30 | 46 |

Exponential regression was applied to model the time decay of normalized spore concentration in air in continuous and cyclic airflow modes. Spore reaerosolization was observed up to 7 h following the spore dispersal. The initial cloud of spores moved through the ventilation duct in about 25 s. However, spores continued to reaerosolize off the duct surface over a period of hours. The time required for the spore concentration to decrease by one-half on steel is about 3 h, whereas on plastic the decay rate was about 1 h.

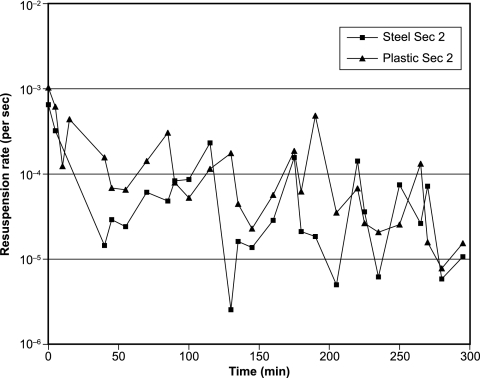

Long-term, cycled reaerosolization tests in steel and plastic duct.

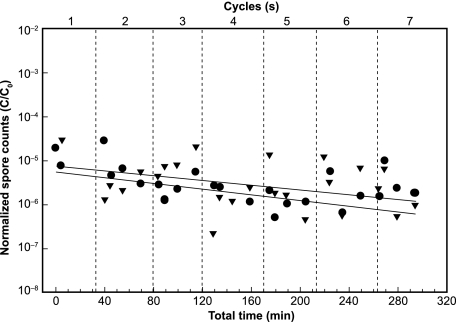

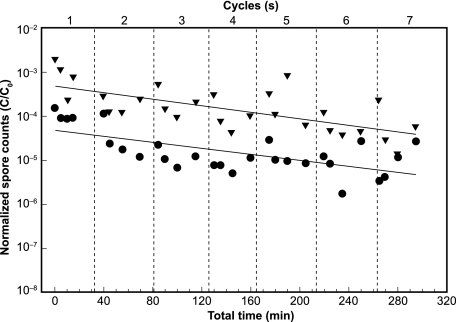

Figures 3 and 4 show reaerosolization of spores in steel and plastic duct over a 5-hour period in turbulent airflow, where the airflow was cycled on and off every 15 min with periods between to remove and replace samplers. The data were normalized to the initial air contamination concentration, Ct/C0.

FIG. 3.

Cyclic reaerosolization of spores in 15-cm-diameter steel duct normalized to the initial deposition concentration over a 5-hour period in turbulent airflow. Circles show incoming spores, and inverted triangles show outgoing spores.

FIG. 4.

Cyclic reaerosolization of spores in 15-cm-diameter plastic duct normalized to the initial deposition concentration over a 5-hour period in turbulent airflow. Circles show incoming spores, and inverted triangles show outgoing spores.

Figures 3 and 4 show the cyclic reaerosolization of spores in plastic and steel duct in turbulent airflow. The two plotted lines had different slopes and different intercepts. Analysis of covariance was used to compare the two lines simultaneously for differences in both slope and intercept. However, for data shown in the figures the difference is due to the intercepts being different, not the slopes. Therefore, the reaerosolization of spores from plastic is no different from that from steel. When a cycled on-off operational mode was tested, the decay rates of steel and of plastic were similar, 1.86 and 1.34 h, respectively. The reaerosolized concentration increased to about 62% in steel and 52% in plastic duct (about a half-log) with the starting of a new cycle and returned to the normal decay curve in 5 to 10 min.

Reaerosolization with increasing airflow.

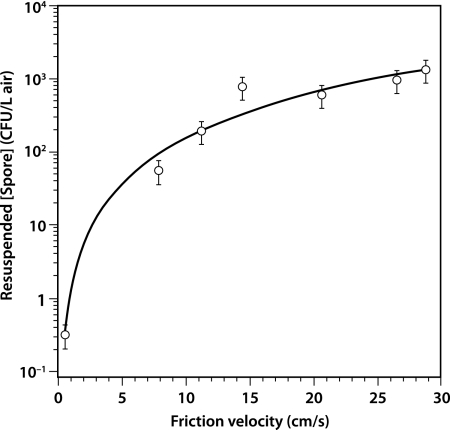

The concentration of spores that resuspended when the air velocity increased is shown in Fig. 5 for steel duct. Results are presented with the friction velocity, u*, as the abscissa, where the friction velocity was calculated using equations from the work of Davies (4):

|

where the friction factor, f, is calculated using the Blasius empirical expression

|

and U is the free stream velocity.

FIG. 5.

Reaerosolized spore concentration in increasing airflows.

Airborne spore concentration during initial contamination was 5.34 × 107 CFU/liter. HEPA filters were inserted downstream of the spore dissemination location. Air samples were collected after 15 min of continuous flow at each velocity. The test was conducted in new steel duct inserted into section 2. The equation for the power curve fit was C = 1.42u*2.04 with R = 0.93. The spore concentrations in Fig. 5 may underestimate the resuspension rate because each sample taken during the test had the previous flow history and aerosolization.

Resuspension rates using mass balances.

The data were analyzed by means of a mass balance; the depositions served as a source of spores into a defined control volume while the cross-sectional velocity and concentrations were assumed to be homogeneous. Effects of probes on deposition, resuspension, or concentration measurements were not considered. The flux (e.g., CFU/area-time) of spores resuspending from the surface may correlate with the initial deposition, so that surfaces with higher levels of initial contamination would provide higher fluxes. The focus of these tests is the net resuspension fluxes. Material will resuspend and redeposit during an experiment; while these processes could be explored separately, ultimately it is the downwind concentration that is of interest, and those downwind spores come from the net resuspension from the surface. The resuspension fluxes derived here were compared to resuspension rates and factors found in the literature.

To estimate the resuspension rate in section 2 where impinger data were available before (section 1 all-glass impinger) and after (section 3 all-glass impinger) section 2, the following was done.

A simple, mass balance flux model was used. The flux of material entering the section, Fin (section 2), is given by

|

where Cin = air concentration of spores entering (CFU/cm3), Q = airflow (cm3/s), and A = cross-sectional area of the duct (cm2).

A similar expression can be written for the flux leaving the section, Fout. Then, introducing the resuspension flux in the section to be Fr, the following mass balance equation can be written as Fin + Fr = Fout.

The resuspension rate (per s) is determined by normalization of the resuspension flux to the source term, or that material previously deposited to the surface in the section. The resuspension rate is

|

where S = the concentration of spores deposited on the duct surface (CFU/cm2). Resuspension has also been characterized by the term resuspension factor (Rf). It is defined by the ratio of the particle concentration of contaminant in the air to the source on the surface, or Rf = C/S.

The deposition of spores on the surface was not measured in all experiments but was conducted the same as in previous experiments (12). For those experiments where direct measurement of the surface deposition was not available, deposition was estimated by using the ratio Smeas/Cmeas from data collected in prior experiments and using the following equation:

|

where “type” represents the ducting material, steel or plastic. The measured Smeas/Cmeas ratio in steel was 2.25 × 101 cm; that in plastic was 4.35 × 102 cm.

Resuspension rates from steel and plastic surfaces.

The resuspension rates decreased by approximately a factor of 10 over a 5-hour period (Table 4; Fig. 6). This is an average of two data sets incorporating both continuous and cycled airflow. Within 30 min the resuspension rate decreased 10-fold compared to the initial rates. No difference between reaerosolization rates of steel and plastic duct surfaces was found (Fig. 6). Initial resuspension rates were approximately 10−3/s and decreased to 10−5/s in 5 h. The level of detection resulted in a minimum measured resuspension rate of about 10−6/s.

TABLE 4.

Resuspension rate and factor in galvanized steel and plastic ducta

| Duct material | Resuspension rate (1/s)

|

Resuspension factor (1/cm)

|

||

|---|---|---|---|---|

| Immediate | After 5 h | Immediate | After 5 h | |

| Steel | 5.56 × 10−4 | 3.17 × 10−5 | 1.35 × 10−6 | 1.77 × 10−7 |

| Plastic | 2.24 × 10−3 | 4.26 × 10−5 | 8.89 × 10−6 | 5.50 × 10−7 |

Data represent the averages of several tests.

FIG. 6.

Resuspension rate of spores from steel and plastic duct. Data are based on airborne spore concentrations normalized to surface concentrations of spores.

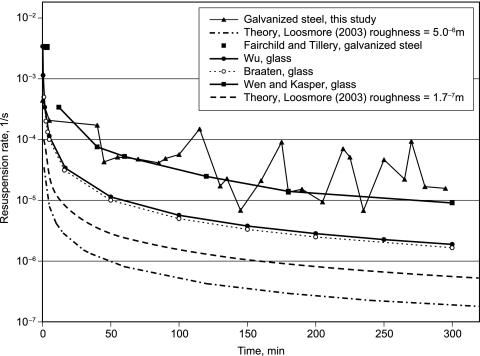

DISCUSSION

We compared our spore resuspension rates to other experimental studies and empirical models of resuspension. The experimental studies that we chose were those involving smoother surfaces than those in many studies whose interest lies in environmental-type surfaces.

Empirical models developed by Loosmore (13) predicted the resuspension of particles in the natural environment for time periods up to days. The more robust of the models expressed the resuspension rate to be proportional to the powers of 5 parameters. The resuspension rate (1/s) as determined by the best fits using data wind tunnel experiments from three investigations was given as

|

where the parameters and their dimensions are u* = friction velocity (m/s); dp = particle diameter (μm); t = time (s); z0 = inferred, or aerodynamic, surface roughness (m); and ρp = particle density (kg/m3).

The three data sets used for as the basis for the model were the experiments of Nicholson (17), Garland and Pomeroy (7), and Giess et al. (8). Nicholson measured the removal fraction of 4- to 22-μm-diameter silica particles from grass and concreted surfaces, Giess et al. measured the resuspension rates of 0.3- to 1.4-μm-diameter silica from grass, and Garland and Pomeroy reported the resuspension rates of 0.2- to 0.8-μm-diameter tungsten oxide particles from bare soil. The time of the observed resuspension ranged from 2 s in the Nicholson experiments to 108,000 s in the Garland and Pomeroy studies. Inferred roughness ranged from 0.003 to 0.3 m. The order of importance of the parameters in the empirical model is friction velocity, time, particle density, roughness, and particle size.

The results of this study were compared to the empirical model using the following parameters: u* = 0.144 m/s, dp = 0.91 μm, and ρp = 1,200 kg/m3. Time ranged from 60 to 18,000 s. Figure 7 shows the model for the roughness values for the plastic duct and steel duct. The resuspension rates predicted by the empirical model fall about 1.5 to 2 orders of magnitude below our data.

FIG. 7.

Spore resuspension from steel compared with those in other studies.

Wu et al. (28) conducted experiments to investigate resuspension over time (up to 1 h) using monodispersed particles ranging from 5 to 42 μm in diameter. The wind tunnel experiments used glass, Plexiglas, and leaves as surfaces. We compared data to resuspension of Lycopodium spores (diameter, 27.8 μm) from a glass surface as reported in the paper. The resuspension was reported as a fraction resuspended, or loss, from a known area. The fraction resuspended is the integral of the resuspension rate from start to the time of observation. To convert to resuspension rate, we began with the relation in the work of Wu et al. that resuspension rate is ∼At−1. This inverse time dependence is also consistent with the empirical models of Loosmore. We then integrated from 1 s to the time reported for the fraction loss for the data set to obtain the constant A. We found the resuspension rate to be Λ = 0.14 t−1. We further adjusted the rate for the difference in friction velocity between the work of Wu et al. (estimated at 0.24 m/s) and our study (0.144 m/s) by using a power of 2.13 from the Loosmore empirical model. This adjustment is (0.144/0.24)2.13, or 0.167. The results of the work of Wu et al. are about 1 log below our data.

Wind tunnel experiments were also performed by Braaten et al. (1); these authors used Lycopodium spores (diameter, 27.8 μm) on glass surfaces. As in the studies by Wu et al., the fraction for particles resuspended, not resuspension rate, was reported. We calculated resuspension rates in a manner similar to that above for the data from the work of Wu et al. Using the 6-m/s data reported in the work of Braaten et al., we found Λ = 0.043 t−1. In this case the adjustment for friction velocity was (0.144/0.17)2.13, or 0.70. Results are very close to those of the work of Wu et al. and again fall below our data.

Fairchild and Tillery (6) performed investigations of resuspension of spherical aluminum particles with 0.8- and 7-μm diameters, with and without saltation induced by soil particles. Experiments were conducted in a 20-cm-diameter wind tunnel with a steel surface. Surface roughness was estimated to be 3.4 ± 3.0 μm from velocity profiles and the Schlichting (20) relation for turbulent shear flow. Friction velocities for the free stream velocities of 9.8 to 11.0 m/s were 0.39 to 0.42 m/s. Resuspension rates were determined by integrating the horizontal mass flux profile as estimated from air sampler data. Only initial resuspension rates (∼20 s) were observed in the work of Fairchild and Tillery, so we compared the study results for the resuspension for the 0.8-μm-diameter particles with no saltation. The authors state that the size distribution contained aggregates of 3.5 μm in diameter with a geometric standard deviation of 1.7. In our comparison we compensated for the difference in friction velocity between this study and ours by using the power for the friction velocity parameter in the Loosmore empirical relation, 2.13. The resuspension reported by Fairchild and Tillery of 0.028/s, lowered by the factor of (0.397/0.144)2.13, is shown as one point in Fig. 7 residing at 0.0033/s. This value is an order of magnitude above the initial resuspension rates that we observed, but as previously mentioned, we believe that our experiments underestimated the initial rate.

Wen and Kasper (26) performed resuspension studies using latex particles ranging from 0.4 to 1 μm in diameter in a steel capillary tube with a diameter of 0.125 cm. Results are presented as the air concentration of reentrained particles. For 1-μm-diameter particles we have converted their data to resuspension rate using the reported flow of 2.7 m3/h and estimated surface concentration of the source, 105 particles/cm2, and adjusting for friction velocity difference by a factor of (0.667/0.144)2.13, or 26.2. As can be seen in Fig. 7, the experimental results from the work of Wen and Kasper fall very close to the data of this work.

In our tests we determined that the power of friction velocity was 2.04. In a review of particle resuspension, Sehmel (21) summarized from the work of many investigators that resuspension increases to the power of wind speed or friction velocity where the power can range from 1.1 to 6.4. In Sehmel's own field investigations, the resuspension rate increased with wind speed to a power ranging from 3.4 to 13.8. In a more recent study Loosmore (13) developed two empirical models based on data from three investigators. Powers of 1.43 and 2.13 were determined for the friction velocity relation.

Prior to these tests a commonly held idea was that spores would, once deposited, remain on the surface indefinitely. As an example, according to the National Institute for Occupational Safety and Health (15) air sampling might be of limited value in areas that are undisturbed or in which ventilation systems have continued to function for long periods after a known or suspected release. In the tests conducted for this study a proportion of the spore concentration did settle onto duct surfaces and later reaerosolized from the surface over a period of time (hours). In these tests, reaerosolization was observed after >7 h and the half-life ranged from 0.7 to 2.8 h.

Spore reaerosolization rates from this study were greater than that predicted by the Loosmore empirical model. Large numbers of spores reaerosolized from contaminated surfaces hours after the initial release. Dry fluidized spores move about faster and were not as fixed as the models predict. The 1-log decay times were shorter than what was predicted for other particle types of like size.

Charged aerosol particles can be attracted or repelled from charged surfaces or other particles. For aerosol particles that are highly charged the electric forces may exceed the gravitational force by several orders of magnitude (27). Weis et al. (25) observed that B. anthracis spores deposited on the charged monitors, indicating the influence of electrostatic effects on spore behavior. In a recent study we found that spores deposited onto plastic had a greater deposition velocity than those deposited onto steel or fiberglass duct materials, likely due to charge forces between spores and surfaces (12). Even though the deposition velocity was higher between steel and plastic potentially due in part to electrostatic charge, the reaerosolization velocity was the same. Electrostatic charge forces may affect spore deposition velocity more than spore reaerosolization, possibly due to charge dissipation once the spore deposits onto a charged surface. Resuspension rates on both steel and plastic were between 10−3 and 10−5 per second, which decreased to 10 times lower than initial rates within 30 min. Pulsed flow caused an initial spike in spore resuspension concentration that rapidly decreased. The resuspension fluxes estimated from the data set are not unexpected by comparison to earlier studies on surrogate outdoor materials. The resuspension rates are greater than those predicted by the Loosmore model due to surface roughness differences. The Loosmore model was designed for surfaces that have a greater aerodynamic roughness than the surfaces used in this study. Also, the fluidized spores used in this study are engineered to remain airborne rather than settle. Although our resuspension data are higher than those predicted by the empirical theory, they are closer to agreement with previous work involving smoother surfaces (6, 26).

Acknowledgments

We extend our gratitude to Gwen Loosmore, Joe Shinn, and Lloyd Larsen for their expert advice and critical review of the manuscript and to Don Schwartz, George Metzger, and Willard Rome for their involvement in building the test apparatus.

This work was performed under the auspices of the U.S. Department of Energy by University of California, Lawrence Livermore National Laboratory, under contract W-7405-Eng-48.

Footnotes

Published ahead of print on 9 February 2007.

REFERENCES

- 1.Braaten, D. A., U. K. T. Paw, and R. H. Shaw. 1990. Particle resuspension in a turbulent boundary layer—observed and modeled. J. Aerosol Sci. 21:613-628. [Google Scholar]

- 2.Centers for Disease Control and Prevention. 2001. Update: investigation of bioterrorism-related anthrax 2001. Morb. Mortal. Wkly. Rep. 50:1008-1010. [PubMed] [Google Scholar]

- 3.Clesceri, L. S., A. E. Greenberg, and A. E. Eaton (ed.). 1989. Standard methods for the examination of water and wastewater, 17th ed. American Public Health Association, Washington, DC.

- 4.Davies, C. N. 1966. Aerosol science, p. 384. Academic Press, London, United Kingdom.

- 5.Dull, P. M., K. E. Wilson, B. Kournikakis, E. A. S. Whitney, C. A. Boulet, J. Y. W. Ho, et al. 2002. Bacillus anthracis aerosolization associated with a contaminated mail sorting machine. Emerg. Infect. Dis. 8:1044-1047. http://www.cdc.gov/ncidod/EID/vol8no10/02-0356.htm. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Fairchild, C. I., and M. I. Tillery. 1981. Wind tunnel measurements of the resuspension of ideal particles. Atmos. Environ. 16:229-238. [Google Scholar]

- 7.Garland, J. A., and I. R. Pomeroy. 1994. Resuspension of fall-out material following the Chernobyl accident. J. Aerosol Sci. 25:793-806. [Google Scholar]

- 8.Giess, P., J. H. Goddard, and G. Shaw. 1997. Factors affecting particle resuspension from grass swards. J. Aerosol Sci. 28:1331-1349. [Google Scholar]

- 9.Ibrahim, A. H., P. F. Dunn, and R. M. Brach. 2003. Microparticle detachment from surfaces exposed to turbulent air flow: controlled experiments and modeling. J. Aerosol Sci. 34:765-782. [Google Scholar]

- 10.Inglesby, T. V., D. A. Henderson, J. G. Bartlett, M. S. Ascher, E. Eitzen, A. M. Friedlander, et al. 1999. Anthrax as a biological weapon: medical and public health management. JAMA 281:1735-1745. [DOI] [PubMed] [Google Scholar]

- 11.Kowalski, W. J. 2002. Immune building systems technology. McGraw-Hill, New York, NY.

- 12.Krauter, P. W., A. H. Biermann, and L. Larsen. 2005. Transport efficiency and deposition velocity of fluidized spores in ventilation ducts. Aerobiologia 21:155-172. [Google Scholar]

- 13.Loosmore, G. A. 2003. Evaluation and development of models for resuspension of aerosols at short times after deposition. Atmos. Environ. 37:639-647. [Google Scholar]

- 14.Meselson, M., J. Guillemin, M. Hugh-Jones, A. Langmuir, I. Popova, A. Shelokov, et al. 1994. The Sverdlosk anthrax outbreak of 1979. Science 266:1202-1208. [DOI] [PubMed] [Google Scholar]

- 15.National Institute for Occupational Safety and Health. 2002. Guidance for protecting building environments from airborne chemical, biological, or radiological attacks. NIOSH publication no. 2002-139. National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention, Department of Health and Human Services, Cincinnati, OH.

- 16.Nicholson, K. C. 1988. A review of particle resuspension. Atmos. Environ. 22:2639-2651. [Google Scholar]

- 17.Nicholson, K. W. 1993. Wind tunnel experiments on the resuspension of particulate material. Atmos. Environ. 27A:181-188. [Google Scholar]

- 18.Oncu, S., S. Oncu, and S. Sakarya. 2003. Anthrax—an overview. Med. Sci. Monit. 9:RA276-RA283. [PubMed] [Google Scholar]

- 19.Phares, D. J., K. P. Rhoads, and A. S. Wexler. 2000. Enhancement of aerodynamic focusing of ultrafine particles using slots, p. 350. Proc. Am. Assoc. Aerosol Res. St. Louis, MO.

- 20.Schlichting, H. 1968. Boundary layer theory, p. 580-583. McGraw-Hill, New York, NY.

- 21.Sehmel, G. A. 1980. Particle resuspension: a review. Environ. Int. 4:107-127. [Google Scholar]

- 22.Sippola, M. R., and W. W. Nazaroff. 2003. Modeling particle deposition in ventilation ducts. Atmos. Environ. 37:5597-5610.

- 23.Sutton, O. G. 1955. Atmospheric turbulence, p. 54. John Wiley, New York, NY.

- 24.Watson, A., and D. Keir. 1994. Information on which to base assessments of risk from environments contaminated with anthrax spores. Epidemiol. Infect. 113:479-490. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Weis, C. P., A. J. Intrepido, A. K. Miller, P. G. Cowin, M. A. Durno, J. S. Gebhardt, and R. Bull. 2002. Secondary aerosolization of viable Bacillus anthracis spores in a contaminated US Senate office. JAMA 288:2853-2858. [DOI] [PubMed] [Google Scholar]

- 26.Wen, H. Y., and G. Kasper. 1989. On the kinetics of particle reentrainment from surfaces. J. Aerosol Sci. 20:483-498. [Google Scholar]

- 27.Willeke, K., and P. A. Baron (ed.). 1993. Aerosol measurement, principles, techniques and applications. Van Nostrand Reinhold, New York, NY.

- 28.Wu, Y. L., C. I. Davidson, and A. G. Russell. 1992. Controlled wind tunnel experiments for particle bounceoff and resuspension. Aerosol Sci. Technol. 17:245-262. [Google Scholar]