Abstract

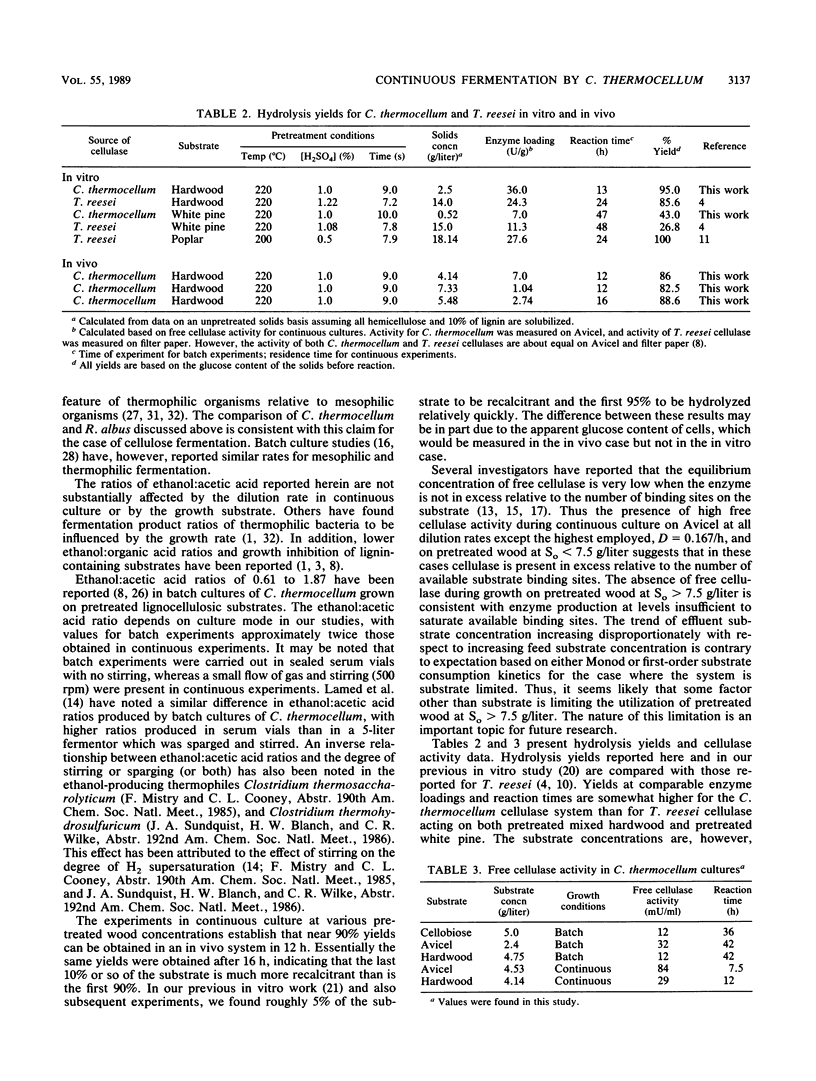

Fermentation of dilute-acid-pretreated mixed hardwood and Avicel by Clostridium thermocellum was compared in batch and continuous cultures. Maximum specific growth rates per hour obtained on cellulosic substrates were 0.1 in batch culture and >0.13 in continuous culture. Cell yields (grams of cells per gram of substrate) in batch culture were 0.17 for pretreated wood and 0.15 for Avicel. Ethanol and acetate were the main products observed under all conditions. Ethanol:acetate ratios (in grams) were approximately 1.8:1 in batch culture and generally slightly less than 1:1 in continuous culture. Utilization of cellulosic substrates was essentially complete in batch culture. A prolonged lag phase was initially observed in batch culture on pretreated wood; the length of the lag phase could be shortened by addition of cell-free spent medium. In continuous culture with ∼5 g of glucose equivalent per liter in the feed, substrate conversion relative to theoretical ranged from 0.86 at a dilution rate (D) of 0.05/h to 0.48 at a D of 0.167/h for Avicel and from 0.75 at a D of 0.05/h to 0.43 at a D of 0.11/h for pretreated wood. At feed concentrations of <4.5 g of glucose equivalent per liter, conversion of pretreated wood was 80 to 90% at D = 0.083/h. Lower conversion was obtained at higher feed substrate concentrations, consistent with a limiting factor other than cellulose. Free Avicelase activities of 12 to 84 mU/ml were observed, with activity increasing in this order: batch cellobiose, batch pretreated wood < batch Avicel, continuous pretreated wood < continuous Avicel. Free cellulase activity was higher at increasing extents of substrate utilization for both pretreated wood and Avicel under all conditions tested. The results indicate that fermentation parameters, with the exception of free cellulase activity, are essentially the same for pretreated mixed hardwood and Avicel under a variety of conditions. Hydrolysis yields obtained with C. thermocellum cellulase acting either in vitro or in vivo were comparable to those previously reported for Trichoderma reesei on the same substrates.

Full text

PDF

Selected References

These references are in PubMed. This may not be the complete list of references from this article.

- Johnson E. A., Sakajoh M., Halliwell G., Madia A., Demain A. L. Saccharification of Complex Cellulosic Substrates by the Cellulase System from Clostridium thermocellum. Appl Environ Microbiol. 1982 May;43(5):1125–1132. doi: 10.1128/aem.43.5.1125-1132.1982. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lacis L. S., Lawford H. G. Thermoanaerobacter ethanolicus in a comparison of the growth efficiencies of thermophilic and mesophilic anaerobes. J Bacteriol. 1985 Sep;163(3):1275–1278. doi: 10.1128/jb.163.3.1275-1278.1985. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lamed R. J., Lobos J. H., Su T. M. Effects of Stirring and Hydrogen on Fermentation Products of Clostridium thermocellum. Appl Environ Microbiol. 1988 May;54(5):1216–1221. doi: 10.1128/aem.54.5.1216-1221.1988. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lamed R., Setter E., Bayer E. A. Characterization of a cellulose-binding, cellulase-containing complex in Clostridium thermocellum. J Bacteriol. 1983 Nov;156(2):828–836. doi: 10.1128/jb.156.2.828-836.1983. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Leschine S. B., Canale-Parola E. Mesophilic cellulolytic clostridia from freshwater environments. Appl Environ Microbiol. 1983 Sep;46(3):728–737. doi: 10.1128/aem.46.3.728-737.1983. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ng T. K., Weimer T. K., Zeikus J. G. Cellulolytic and physiological properties of Clostridium thermocellum. Arch Microbiol. 1977 Jul 26;114(1):1–7. doi: 10.1007/BF00429622. [DOI] [PubMed] [Google Scholar]

- Pavlostathis S. G., Miller T. L., Wolin M. J. Fermentation of Insoluble Cellulose by Continuous Cultures of Ruminococcus albus. Appl Environ Microbiol. 1988 Nov;54(11):2655–2659. doi: 10.1128/aem.54.11.2655-2659.1988. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pavlostathis S. G., Miller T. L., Wolin M. J. Kinetics of Insoluble Cellulose Fermentation by Continuous Cultures of Ruminococcus albus. Appl Environ Microbiol. 1988 Nov;54(11):2660–2663. doi: 10.1128/aem.54.11.2660-2663.1988. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sleat R., Mah R. A., Robinson R. Isolation and Characterization of an Anaerobic, Cellulolytic Bacterium, Clostridium cellulovorans sp. nov. Appl Environ Microbiol. 1984 Jul;48(1):88–93. doi: 10.1128/aem.48.1.88-93.1984. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Weimer P. J., Zeikus J. G. Fermentation of cellulose and cellobiose by Clostridium thermocellum in the absence of Methanobacterium thermoautotrophicum. Appl Environ Microbiol. 1977 Feb;33(2):289–297. doi: 10.1128/aem.33.2.289-297.1977. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zeikus J. G., Ben-Bassat A., Ng T. K., Lamed R. J. Thermophilic ethanol fermentations. Basic Life Sci. 1981;18:441–461. doi: 10.1007/978-1-4684-3980-9_26. [DOI] [PubMed] [Google Scholar]