Abstract

Biocide inactivation of Bacillus anthracis spores in the presence of food residues after a 10-min treatment time was investigated. Spores of nonvirulent Bacillus anthracis strains 7702, ANR-1, and 9131 were mixed with water, flour paste, whole milk, or egg yolk emulsion and dried onto stainless-steel carriers. The carriers were exposed to various concentrations of peroxyacetic acid, sodium hypochlorite (NaOCl), or hydrogen peroxide (H2O2) for 10 min at 10, 20, or 30°C, after which time the survivors were quantified. The relationship between peroxyacetic acid concentration, H2O2 concentration, and spore inactivation followed a sigmoid curve that was accurately described using a four-parameter logistic model. At 20°C, the minimum concentrations of peroxyacetic acid, H2O2, and NaOCl (as total available chlorine) predicted to inactivate 6 log10 CFU of B. anthracis spores with no food residue present were 1.05, 23.0, and 0.78%, respectively. At 10°C, sodium hypochlorite at 5% total available chlorine did not inactivate more than 4 log10 CFU. The presence of the food residues had only a minimal effect on peroxyacetic acid and H2O2 sporicidal efficacy, but the efficacy of sodium hypochlorite was markedly inhibited by whole-milk and egg yolk residues. Sodium hypochlorite at 5% total available chlorine provided no greater than a 2-log10 CFU reduction when spores were in the presence of egg yolk residue. This research provides new information regarding the usefulness of peroxygen biocides for B. anthracis spore inactivation when food residue is present. This work also provides guidance for adjusting decontamination procedures for food-soiled and cold surfaces.

Decontamination procedures for bacterial spores are often more rigorous than procedures used for vegetative bacteria. For instance, some disinfectants can inactivate spores if they are applied for a longer time, at a higher temperature, or at a higher concentration than normal. However, many of these liquid biocides/disinfectants respond differently to time, temperature, or concentration adjustment (16, 18). Some biocides, such as quaternary ammonium compounds and phenol-based agents, are unable to provide meaningful spore reductions (16).

Bacillus anthracis spore decontamination has been important both historically and more recently in relation to bioterrorism (3, 6). Improved methods for B. anthracis decontamination could be especially useful to bioterrorism response teams. The mitigation response to an intentional contamination would likely be broad in scope and may include application of gaseous, vapor phase, and liquid biocides. Since many food processing facilities already use liquid biocides (i.e., food contact surface sanitizers) for routine sanitation, these facilities may benefit a great deal from research examining the efficacies of sanitizers against B. anthracis spores. Three commonly used biocides also known to be sporicidal are peroxyacetic acid, sodium hypochlorite, and hydrogen peroxide.

Biocide efficacy also can be influenced by the presence of interfering substances. For example, protein layers between a bacterium and a biocide can prevent interactions. Blood serum can reduce biocide efficacy by neutralizing active agents (7) and is used as an interfering substance in standard test methods for evaluating disinfection performance claims. In such tests, serum is added to the bacterial culture prior to biocide exposure (24).

Government regulations allow biocides to carry broad performance claims like “general disinfectant” or “sporicide” if they inactivate certain marker organisms (23). A key advantage to using nonpathogenic marker organisms is increased worker safety and efficiency. The safety challenges in working with Bacillus anthracis spores have led many researchers to conduct research using surrogate organisms. Some of the surrogates used include nonvirulent strains of B. anthracis and other Bacillus species: Bacillus subtilis, Bacillus atrophaeus, Bacillus cereus, Bacillus thuringiensis, Geobacillus stearothermophilus, and Bacillus megaterium (13, 17, 27).

Previous research suggests that peroxyacetic acid and hydrogen peroxide may be particularly useful in food processing environments due to their effectiveness in the presence of organic residues (11). The goal of this study was to more specifically characterize the influence of food residues and temperature on the abilities of peroxyacetic acid, sodium hypochlorite, and hydrogen peroxide to inactivate B. anthracis spores after a 10-min treatment time. A better understanding of the effect of food residues may guide further research to develop decontamination procedures for food processing facilities intentionally contaminated with B. anthracis spores.

MATERIALS AND METHODS

Biocides.

Biocides used in this study included 5.8% peroxyacetic acid with 27.5% hydrogen peroxide (Oxonia Active; Ecolab Inc., St. Paul, MN), 10% sodium hypochlorite (XY-12; Ecolab Inc., St. Paul, MN), and 50% food grade hydrogen peroxide (Sigma-Aldrich Inc., St. Louis, MO). Working solutions of each biocide were prepared by dilution in AOAC synthetic hard water (19) with a total hardness equivalent to 500 ppm CaCO3. All working solutions were used within 2 h of preparation. The active-ingredient concentrations in the working solutions were checked using titration test kits supplied by Ecolab (inaccuracy no greater than 6%, imprecision no greater than 3%). Sodium hypochlorite concentration was characterized by total-available-chlorine analysis. This analysis measured free available chlorine (i.e., elemental chlorine, hypochlorous acid, and hypochlorite ions) and combined chlorine (chloramines) in the working solutions. Since no nitrogenous compounds were added to the working solutions, the combined chlorine level was assumed to be zero. Thus, total available chlorine levels also represented free available chlorine levels. The alkaline pH levels of the working solutions (Table 1) caused the hypochlorite ion to be the predominant form of free available chlorine. The pH levels of the working solutions at 20°C were measured using a benchtop analyzer with a silver/silver chloride electrode (sympHony SB80I; VWR International Inc., West Chester, PA). In accordance with biocide label directions and normal-use practices, the pH levels of the working solutions were not adjusted prior to testing. Diluting biocides in hard water with no pH adjustment can reduce their performance. However, including these challenges increased the potential for the study results to be more broadly applicable.

TABLE 1.

pH values of selected working solutions

| Concna (wt %) | pH value of biocide solution at 20°Cb

|

||

|---|---|---|---|

| Sodium hypochlorite (as total available chlorine)c | Hydrogen peroxide | Peroxyacetic acid | |

| 0.02 | * | * | 4.5 |

| 0.05 | * | * | 4.1 |

| 0.1 | 9.3 | * | 3.5 |

| 0.25 | 10.0 | * | * |

| 0.5 | 10.8 | * | * |

| 1.0 | 11.4 | * | 2.4 |

| 2.5 | 12.1 | * | 2.0 |

| 3.0 | * | 7.0 | * |

| 5.0 | 12.4 | 6.7 | 1.9 |

| 10.0 | * | 6.1 | * |

| 20.0 | * | 5.0 | * |

| 40.0 | * | 3.6 | * |

For reference, full-strength (undiluted) concentrations for the sodium hypochlorite, hydrogen peroxide, and peroxyacetic acid biocides were 10%, 50%, and 5.8%, respectively. Directions for sanitizing food contact surfaces with the sodium hypochlorite and peroxyacetic acid biocides called for diluting to maxima of 0.02% and 0.28% in water, respectively. The hydrogen peroxide biocide did not contain any directions for sanitizing hard surfaces.

*, not used in this study.

Total available chlorine levels also represented free available chlorine levels.

Carriers.

Brushed stainless-steel disks (1 by 0.7 cm), AISI type 430 (Muzeen & Blythe Co., Winnipeg, Manitoba, Canada), were prepared by hand washing them in hot water containing dish detergent (Express; Ecolab Inc., St. Paul, MN) at 1% by volume. Washed disks were rinsed in hot water, followed by a triple rinse in deionized water prepared to meet Clinical and Laboratory Standards Institute (CLSI) type I water guidelines (8). Disks were dried using clean paper towels. Clean, dry disks were sterilized in a dry-heat oven at 180°C for 3 h. Disks with obvious damage or scratches were not used. No disks were reused.

Bacillus anthracis strains.

Three nonvirulent B. anthracis strains were provided by Theresa Kohler (University of Texas Medical School, Houston, TX), including (i) B. anthracis Sterne 7702, a pXO1+, pXO2− strain; (ii) B. anthracis Ames derivative ANR-1, a pXO1+, pXO2− strain; and (iii) B. anthracis Sterne derivative 9131, a pXO1−, pXO2− strain.

Preparation of spores.

Each test organism was subcultured to tryptic soy agar with 5% sheep blood and incubated at 30°C for 2 days to check purity and confirm identification. From a pure culture on tryptone glucose extract (TGE) agar, suspensions of the test organism in phosphate-buffered dilution water (0.31 mM KH2PO4, pH 7.2) were prepared. The turbidities of the suspensions were adjusted to match a 0.5 McFarland turbidity standard by visual examination (to yield approximately 8 log10 CFU/ml). One milliliter of the standardized suspensions was spread on sporulation agar plates (0.8% nutrient broth, 0.4% yeast extract, 2.0% agar, and 0.1 ml of 3.1% solution of MnSO4 per liter) by using a sterile spreader. Sporulation agar plates were incubated at 30°C until the growth on the plates consisted of more than 90% spores (3 to 5 days). Sporulation progress was checked daily using a phase contrast microscope, spores being phase bright. Spores were harvested by adding 5 ml of chilled (4°C), sterile distilled water to each plate and rubbing it with a sterile spreader. The washings from multiple plates were combined into sterile 50-ml centrifuge tubes and centrifuged at 9,000 × g for 15 min at 4°C. Following centrifugation, the supernatants were removed and the pellets were resuspended in approximately 25 ml of chilled sterile distilled water. The pellets were resuspended by tilting the tube up and down. This washing procedure was repeated four times. Spore suspensions were stored for no more than 1 month at 4°C. Before the study began, testing was conducted to verify that spores did not germinate during the drying period included in sporicidal testing. Verification was done using phase contrast microscopy (making sure that the spores remained phase bright) and by heat shocking at 70°C for 15 min and comparing colony counts to those of a nonheated control.

Preparation of food residues.

Three different foods were used to simulate food residue on the test carrier: flour, whole milk, and egg yolk. Whole milk was purchased locally and sterilized by autoclaving it at 121°C for 13 min. Sterile whole milk was stored at 4°C and used within 1 month. Flour pastes were prepared using multiple steps. Suspensions that contained 2.5% (by weight) flour (Pillsbury BEST all-purpose flour; J. M. Smucker Company Inc., Orrville, OH) in CLSI type I deionized water were autoclaved at 121°C for 13 min. After sterilization, the resulting flour pastes were vortex mixed with sterile glass beads until they achieved a smooth consistency. The pastes were then centrifuged for 30 min at 15,000 × g. Following centrifugation, clear supernatants were removed to achieve a 10% flour paste. The pastes were stored at 4°C and used within 1 month. The egg yolk was purchased as a sterile 50% egg yolk emulsion in normal saline (EMD Chemicals Inc., Gibbstown, NJ). The egg yolk emulsions were stored at 4°C and used within the specified shelf life of 1 year. All foods were mixed before they were used for testing. The 10% flour pastes required vortex mixing with 2-mm-diameter sterile glass beads to achieve a smooth consistency.

Sporicidal testing. (i) Experimental design.

The efficacies of the biocides were evaluated using a method modeled after ASTM standard E 2197-02 (1), which is a quantitative test method designed to evaluate the abilities of liquid biocides to inactivate vegetative bacteria, viruses, fungi, mycobacteria, and bacterial spores in the presence of a soil load on disk carriers that represent environmental surfaces. The range of concentrations of the biocide working solutions and the resulting pH values are shown in Table 1.

The sporicidal efficacy of each biocide, under each unique set of conditions (e.g., temperature, food residue, and concentration), was tested against each B. anthracis strain individually. Each of the three B. anthracis strains was tested at least once, and up to three times, under each set of conditions.

(ii) Inoculation of carriers.

Each spore suspension was tilted by hand to resuspend any pellet formed during storage. Equal volumes (400 μl) of the test organism suspension and a sterile food (or water) sample were combined and manually swirled to mix. Aliquots of 20 μl of the test suspension (i.e., the spore-food mixture) were placed in the center of a carrier, using a positive-displacement pipette to avoid splashing or bubbles. Inoculated carriers were dried in an uncovered petri plate in a biosafety hood at room temperature until visually dry. Drying required approximately 60 min. If the inocula spilled off the carriers during drying, the carriers were not used for testing.

(iii) Temperature equilibration.

To prepare the disks for testing, they were transferred to the bottom of a sterile 15-ml Teflon vial (40-mm height by 29-mm outside diameter; Cole-Parmer, Vernon Hills, IL). The inoculated side of the disk was facing upward. The capped Teflon vials, biocide working solutions, and transfer pipettes were placed in a controlled-temperature walk-in chamber and allowed to equilibrate to the test temperature. Temperature equilibration required approximately 30 min.

(iv) Biocide treatment and efficacy measurement.

Biocide treatments were conducted inside the same walk-in chamber used for temperature equilibration. The dried inoculant on the disk carrier was covered with 100 μl of the biocide working solution and held for 10 min at 10, 20, or 30°C. The resultant biocide volume per surface area was approximately 1.3 liter/m2; this is consistent with published disinfection guidelines (20). Immediately following the treatment, the contents of the Teflon vial, including the disk, were poured into a 50-ml plastic centrifuge tube containing 9.9 ml of neutralizer/growth medium and five to seven sterile glass beads (2-mm diameters).

The neutralizer/growth medium was used to stop the antimicrobial action of the biocide when the treatment was complete. The neutralizer/growth medium consisted of Columbia broth supplemented with 0.5% sodium thiosulfate, 2.6% KH2PO4, and 0.5% NaOH. The supplements were individually added to the Columbia broth in the order listed. The neutralizer/growth medium for peroxyacetic acid and hydrogen peroxide working solutions was additionally supplemented with 0.2% (by weight) bovine liver catalase (2,860 units/mg; Sigma-Aldrich, St. Louis, MO). The neutralizer/growth media were prepared fresh each day that they were used. Before use, the neutralizer/growth media were filtered through a 0.45-μm membrane. The final pH values were 7.0 to 7.2.

The contents of the centrifuge tubes were vortex mixed for 2 min. To quantify survivors, 1 ml and 0.1 ml of the eluate were plated using TGE agar pour plates. In addition, 1 ml and 0.1 ml of a 100-fold dilution of the eluate were plated. The TGE agar plates and the remainder of the eluate were incubated for 3 days at 30°C. Following incubation, CFU on agar plates were counted and the presence/absence of turbidity in the eluate was noted. A 0.1-ml quantity from visibly turbid eluate tubes was plated using tryptic soy agar with 5% sheep blood agar streak plates and incubated for 3 days at 30°C to check for viable B. anthracis.

(v) Controls.

On each test day, the inoculum numbers were determined following the method described above, substituting sterile CLSI type I deionized water for the biocide. Testing was also conducted to verify the effectiveness of biocide neutralization and the absence of neutralizer toxicity. An inoculated disk carrier was added to each of three test tubes: (i) one containing 10 ml of phosphate buffered dilution water, (ii) one containing 10 ml of neutralizer/growth medium, and (iii) one containing 9.9 ml of neutralizer/growth medium plus 0.1 ml of the biocide working solution. These tubes were allowed to stand at room temperature for 30 to 40 min before plating was performed in the manner described above.

Data analysis.

Colony counts were transformed to log10 numbers for calculations. The theoretical limit of detection of biocide treatment survivors was 1.122 CFU/carrier (0.05 log10 CFU/carrier). Tests showing no growth or growth in the eluate (broth) only were assigned a value of 1.0 CFU/carrier (0 log10 CFU/carrier). Colony counts were used to calculate log10 reductions from the mean starting population.

The nonlinear sigmoid relationship between biocide concentration (dose) and log10 reduction (response) was analyzed using a four-parameter logistic model to provide a dose-response model over the entire dose range. This model also allowed calculation of concentrations that resulted in a 50% response. XLSTAT (version 2006.5; Addinsoft Inc.) software was used for data analysis. The equation for the model was as follows:

|

where log reduction is the response variable, antimicrobial wt % is the explanatory variable, and the four parameters of the model are top (the upper asymptote), bottom (the lower asymptote), LR50 (the antimicrobial concentration giving 50% of that compound's maximal response), and slope (the slope factor).

Preliminary studies with no food residue indicated that the responses of all three B. anthracis strains to biocide treatments were not significantly different (P < 0.05) at concentrations in the near-linear region of the dose-response curve adjacent to the inflection point. A general linear model following Tukey's method for multiple comparisons of means was used to identify strains that responded differently within this area of interest. Because there were no significant differences in responses among the strains, the results from all three strains were analyzed as a group rather than by separating out results individually.

RESULTS

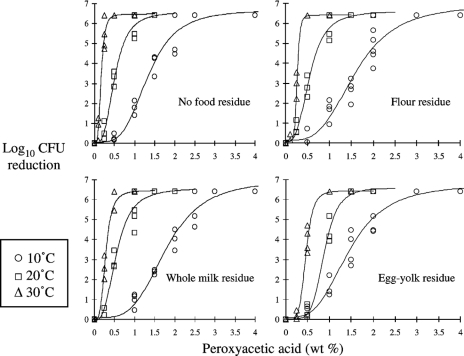

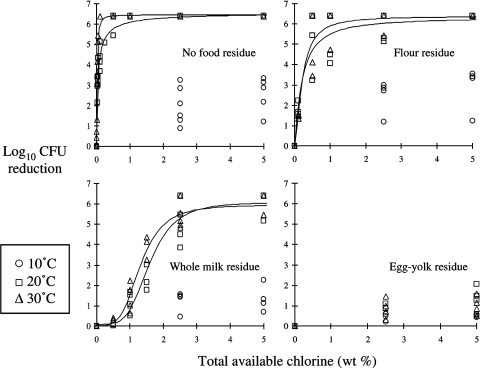

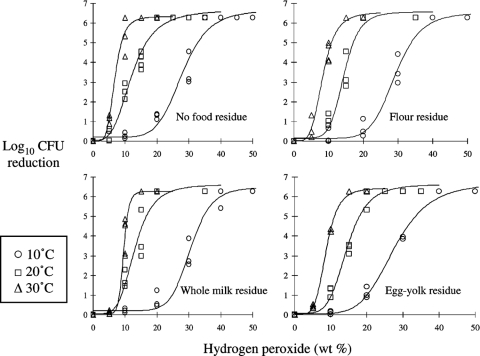

A summary of all experimental data is presented in Fig. 1, 2, and 3. The mean spore count in suspensions used to prepare the inocula was 8.40 log10 CFU/ml (standard deviation = 0.13, standard error of the mean = 0.02). The mean spore count on dried, untreated carriers was 6.35 log10 CFU/carrier (standard deviation = 0.22, standard error of the mean = 0.03). Accounting for subsequent dilution and the inoculation volume, the recovery rate of spores from untreated samples was 89%.

FIG. 1.

Inactivation of Bacillus anthracis spores with peroxyacetic acid. Strains 7702, ANR-1, and 9131 were suspended in water, 10% flour paste, whole milk, and 50% egg yolk emulsion. Suspensions were dried onto stainless-steel coupons for 1 h and then exposed to peroxyacetic acid solutions for 10 min.

FIG. 2.

Inactivation of Bacillus anthracis spores with sodium hypochlorite. Strains 7702, ANR-1, and 9131 were suspended in water, 10% flour paste, whole milk, and 50% egg yolk emulsion. Suspensions were dried onto stainless-steel coupons for 1 h and then exposed to sodium hypochlorite solutions for 10 min. Total available chlorine levels also represented free available chlorine levels.

FIG. 3.

Inactivation of Bacillus anthracis spores with hydrogen peroxide. Strains 7702, ANR-1, and 9131 were suspended in water, 10% flour paste, whole milk, and 50% egg yolk emulsion. Suspensions were dried onto stainless-steel coupons for 1 h and then exposed to hydrogen peroxide solutions for 10 min.

All of the biocides exhibited a nonlinear dose-response relationship. Typically, log10 CFU reductions followed a sigmoid curve as the antimicrobial agent concentration increased. The model parameters of the dose-response relationships are shown in Table 2. All of the curve fit coefficient (r2) values were at least 0.94. The concentration of each biocide could be increased to result in no detectable survivors after 10 minutes under all test conditions, with two exceptions: sodium hypochlorite at 10°C and sodium hypochlorite in the presence of egg yolk (Fig. 2). In these exceptions, the sodium hypochlorite at 5% total available chlorine provided a <4-log10 reduction.

TABLE 2.

Inactivation models for Bacillus anthracis spores using a 10-min static liquid treatmenta

| Antimicrobial agent | Food residueb | Temp (°C) | Model parameterc

|

Model fit (r2) | |||

|---|---|---|---|---|---|---|---|

| Top | Slope | LR50 | Bottom | ||||

| Peroxyacetic acid | None | 10 | 6.687 | 3.809 | 1.337 | 0.059 | 0.972 |

| 20 | 6.590 | 3.168 | 0.506 | −0.011 | 0.986 | ||

| 30 | 6.477 | 3.908 | 0.167 | 0.001 | 0.983 | ||

| Flour | 10 | 6.954 | 3.420 | 1.598 | 0.150 | 0.950 | |

| 20 | 6.630 | 3.125 | 0.544 | 0.074 | 0.985 | ||

| 30 | 6.422 | 7.953 | 0.260 | 0.108 | 0.989 | ||

| Whole milk | 10 | 6.967 | 3.830 | 1.785 | 0.093 | 0.972 | |

| 20 | 6.588 | 2.958 | 0.546 | −0.038 | 0.977 | ||

| 30 | 6.467 | 3.637 | 0.279 | 0.000 | 0.980 | ||

| Egg yolk | 10 | 6.780 | 3.350 | 1.451 | 0.104 | 0.966 | |

| 20 | 6.584 | 5.590 | 0.879 | 0.034 | 0.991 | ||

| 30 | 6.449 | 5.687 | 0.459 | 0.006 | 0.991 | ||

| Sodium hypochlorite | None | 10 | NM | NM | NM | NM | NM |

| 20 | 6.612 | 0.769 | 0.040 | 0.005 | 0.985 | ||

| 30 | 6.464 | 1.372 | 0.017 | 0.009 | 0.982 | ||

| Flour | 10 | NM | NM | NM | NM | NM | |

| 20 | 6.348 | 1.180 | 0.203 | −0.013 | 0.940 | ||

| 30 | 6.389 | 1.621 | 0.213 | 0.001 | 0.956 | ||

| Whole milk | 10 | NM | NM | NM | NM | NM | |

| 20 | 6.085 | 4.210 | 1.594 | 0.094 | 0.942 | ||

| 30 | 5.953 | 3.847 | 1.318 | 0.030 | 0.962 | ||

| Egg yolk | 10 | NM | NM | NM | NM | NM | |

| 20 | NM | NM | NM | NM | NM | ||

| 30 | NM | NM | NM | NM | NM | ||

| Hydrogen peroxide | None | 10 | 6.660 | 6.706 | 27.887 | 0.202 | 0.972 |

| 20 | 6.679 | 3.467 | 12.148 | 0.052 | 0.979 | ||

| 30 | 6.346 | 5.003 | 6.785 | 0.001 | 0.980 | ||

| Flour | 10 | 6.530 | 7.866 | 29.142 | 0.139 | 0.985 | |

| 20 | 6.577 | 6.607 | 14.430 | 0.169 | 0.973 | ||

| 30 | 6.563 | 4.448 | 8.324 | 0.017 | 0.988 | ||

| Whole milk | 10 | 6.490 | 9.287 | 30.474 | 0.218 | 0.983 | |

| 20 | 6.625 | 4.583 | 13.029 | 0.054 | 0.959 | ||

| 30 | 6.284 | 11.357 | 9.512 | 0.051 | 0.979 | ||

| Egg yolk | 10 | 6.700 | 5.583 | 27.573 | 0.055 | 0.922 | |

| 20 | 6.634 | 5.160 | 14.459 | 0.083 | 0.986 | ||

| 30 | 6.449 | 5.225 | 8.694 | 0.035 | 0.992 | ||

Strains 7702, ANR-1, and 9131 dried onto stainless steel coupons for 1 h.

No food (water only), 10% flour paste, whole milk, or 50% egg yolk emulsion.

Four-parameter logistic model using the following equation: log10 reduction = top + {(bottom − top)/[1 + (antimicrobial wt %/LR50)slope]}. NM, no model.

The potencies of biocides, as indicated by the locations of their response curves along the x axis, differed based on application conditions. Peroxyacetic acid was the most potent antimicrobial agent at 10°C. The most potent agent at 20 and 30°C was either peroxyacetic acid or sodium hypochlorite, depending on the presence and type of food residue. For example, the minimum concentrations predicted for a 6-log10 reduction in 10 min at 20°C with no food residue present were 0.78% total available chlorine and 1.05% peroxyacetic acid. However, when whole-milk residue was present, the concentrations predicted for a 6-log10 reduction were 4.37% total available chlorine and 1.20% peroxyacetic acid.

The dose-response relationships for peroxyacetic acid and hydrogen peroxide showed little variation when tested in the presence of flour, whole-milk, or egg yolk residue. Conversely, the presence of food residue caused an obvious decline in the sporicidal efficacy of sodium hypochlorite. Egg yolk residue caused the largest drop in efficacy, followed by whole milk and then flour.

The ability to adjust antimicrobial agent concentrations to maintain a certain log10 reduction result when treatment temperature changed was analyzed. The antimicrobial concentrations needed for a 3- to 6-log10 reduction of spores under all test conditions were calculated using the inactivation models in Table 2. For the same test conditions (i.e., the same biocide and food residue), the concentration needed for a certain log10 reduction at 10°C was divided by the concentration needed for the same log10 reduction at 20°C. In this way, concentration reduction factors were calculated for all test conditions (Table 3). This same analysis was carried out on the 20-to-30°C temperature change data.

TABLE 3.

Impact of a 10°C temperature increase on the antimicrobial concentration needed to inactivate Bacillus anthracis sporesa

| Antimicrobial agentb | Food residuec | Temp increase | Fold reduction in antimicrobial concn predicted to result in indicated log10 reductiond

|

|||

|---|---|---|---|---|---|---|

| 3-log10 R | 4-log10 R | 5-log10 R | 6-log10 R | |||

| Peroxyacetic acid | None | 10 to 20°C | 2.63 | 2.55 | 2.44 | 2.24 |

| 20 to 30°C | 2.98 | 3.08 | 3.19 | 3.30 | ||

| Flour | 10 to 20°C | 2.86 | 2.79 | 2.69 | 2.44 | |

| 20 to 30°C | 1.99 | 2.24 | 2.55 | 3.08 | ||

| Whole milk | 10 to 20°C | 3.19 | 3.02 | 2.81 | 2.39 | |

| 20 to 30°C | 1.93 | 1.99 | 2.06 | 2.13 | ||

| Egg yolk | 10 to 20°C | 1.58 | 1.69 | 1.82 | 1.99 | |

| 20 to 30°C | 1.90 | 1.90 | 1.89 | 1.84 | ||

| Sodium hypochlorite | None | 10 to 20°C | NA | NA | NA | NA |

| 20 to 30°C | 2.05 | 2.88 | 4.19 | 7.09 | ||

| Flour | 10 to 20°C | NA | NA | NA | NA | |

| 20 to 30°C | 0.94 | 1.09 | 1.32 | 1.97 | ||

| Whole milk | 10 to 20°C | NA | NA | NA | NA | |

| 20 to 30°C | 1.19 | 1.17 | 1.13 | NA | ||

| Egg yolk | 10 to 20°C | NA | NA | NA | NA | |

| 20 to 30°C | NA | NA | NA | NA | ||

| Hydrogen peroxide | None | 10 to 20°C | 2.35 | 2.16 | 1.97 | 1.70 |

| 20 to 30°C | 1.72 | 1.80 | 1.88 | 1.89 | ||

| Flour | 10 to 20°C | 2.04 | 2.01 | 1.97 | 1.93 | |

| 20 to 30°C | 1.74 | 1.67 | 1.58 | 1.45 | ||

| Whole milk | 10 to 20°C | 2.39 | 2.24 | 2.08 | 1.87 | |

| 20 to 30°C | 1.32 | 1.43 | 1.55 | 1.71 | ||

| Egg yolk | 10 to 20°C | 1.91 | 1.89 | 1.87 | 1.81 | |

| 20 to 30°C | 1.64 | 1.64 | 1.63 | 1.56 | ||

Strains 7702, ANR-1, and 9131 dried onto stainless steel coupons for 1 h.

Liquid agent applied for 10 min with static exposure.

No food (water), 10% flour paste, whole milk, or 50% egg yolk emulsion.

R, reduction; NA, not available.

In general, the concentration of peroxyacetic acid needed for a 3- to 6-log10 reduction was reduced 1.6- to 3.3-fold when the treatment temperature was increased by 10°C (Table 3). Similarly, the concentration of hydrogen peroxide required for a 3- to 6-log10 reduction decreased 1.3- to 2.4-fold when the treatment temperature increased by 10°C. The 20-to-30°C temperature change data from sodium hypochlorite experiments were analyzed, but the 10-to-20°C data were not. Analysis of the 10°C sodium hypochlorite data was not completed, because of the low number of concentrations tested, an outcome of the poor efficacy observed at high concentrations. In experiments with no food residue present, increasing the treatment temperature from 20 to 30°C had variable impacts on antimicrobial concentration needs. Larger concentration adjustment factors were observed at higher log10 reduction targets. This effect was not observed when sodium hypochlorite was tested in the presence of flour or whole milk.

The effects of temperature on spore decontamination seen when the antimicrobial concentration was held constant were also evaluated. For peroxyacetic acid, temperature had the most influence on spore inactivation at concentrations between 0.1 and 2.5% (Fig. 1). Spore inactivation results outside this concentration range were minimally responsive to temperature adjustment. The sporicidal efficacy of hydrogen peroxide was influenced more when treatment concentrations were in the range of about 5 to 35% (Fig. 3). Outside this concentration range, the impact of temperature on spore inactivation was minimal.

Temperature and the presence of food residue had a profound effect on sodium hypochlorite performance. For this reason, data observations regarding temperature effects are drawn from experiments without food residue. Sodium hypochlorite efficacy was influenced the greatest at concentrations between 0.01 and 0.25% (Fig. 2).

DISCUSSION

The goal of this study was to investigate the abilities of peroxyacetic acid, sodium hypochlorite, and hydrogen peroxide to inactivate B. anthracis spores over a range of conditions that could be encountered following an intentional contamination event. Rapid inactivation of Bacillus spores with oxidizing biocides is largely dependent on the agent's ability to degrade the spore coats (4, 13). Once the coats are penetrated, the inner membrane and cell wall can be damaged, causing hydration of the cell core, leading to death (29). The hydrophobic nature of the exosporium may also contribute to biocide resistance (28). In general, oxidizing biocides can degrade the spore coats by interacting with disulfide bonds and thiol groups that stabilize the protein structure (11, 15). When spores are surrounded by another layer of material, such as a food, inactivation can be much more difficult.

The presence of flour, milk, and egg yolk in these tests provided an indication of decontamination outcomes when starch- or protein-rich foods are present along with spores. When hypochlorite reacts with sulfhydryl groups from sulfur-containing amino acids, some loss of active agents occurs (9, 10). Egg protein contains a relatively high quantity of sulfur-containing amino acids, which could have been responsible for the destructive effect on sodium hypochlorite efficacy. Carbon-carbon splitting by oxidizing chemicals can depolymerize the glucose chains in starch.

The results of this study provide guidance for more-effective utilization of peroxyacetic acid, sodium hypochlorite, and hydrogen peroxide for B. anthracis spore decontamination. A more complete understanding the biocide dose-response relationship after a 10-min treatment provides insight regarding the potential chemical hazards, material compatibility issues, and treatment costs. For cases in which high chemical concentration is a concern, the results of this study provide more-specific information about how an increase in treatment temperature may mitigate these concerns; however, consideration must be given to the liquid's evaporation rate. Increasing treatment time should also be considered as a method for reducing chemical concentration. Results also illustrate that significant decontamination efficacy improvements may be possible by accounting for any food residue that may be present with the spores; this was particularly evident in sodium hypochlorite experiments.

In general, the results of this study are in agreement with other research and decontamination guidelines (20, 21, 22, 25). The high potency of sodium hypochlorite as a sporicide under clean conditions at room temperature has been described previously (2, 16, 17). The sporicidal efficacy of sodium hypochlorite in this study may have been greater if the working solutions had been adjusted closer to neutral pH (5, 16). The dramatic decrease in sodium hypochlorite bactericidal efficacy caused by organic matter, especially proteins, is described in the literature (5, 18). A large decline in sporicidal efficacy at temperatures near 10°C was also observed by Sagripanti and Bonifacino (16).

In contrast to that of sodium hypochlorite, the sporicidal efficacies of the peroxygen compounds were less affected by temperature and the presence of food residue. Although this study did not attempt to quantify the effects the food residues on sporicidal efficacy, future work in this area may be quite useful. The observation that log10 CFU reductions tended to increase approximately twofold with each 10°C rise in treatment temperature is consistent with other reports (14) and may have some practical value when decontamination guidance documents are created. Given the relatively high concentrations of peroxyacetic acid and hydrogen peroxide needed for significant inactivation at 10 to 30°C, additional studies with higher temperatures and longer exposure times may also prove useful.

Overall, the information from this study on the effects of temperature and food residue on sporicidal efficacy may be important if a food processing facility is intentionally contaminated with B. anthracis. U.S. Environmental Protection Agency reviews of chemical decontamination procedures used in response to B. anthracis attacks on U.S. government buildings in 2001 illustrate how differences in application conditions affect the success of decontamination processes (26). The results from this study may be useful for the improvement of three-step B. anthracis decontamination procedures that employ preliminary disinfection, cleaning, and final disinfection (20). Additional studies with higher spore loads, under conditions closely resembling a food processing environment, are needed to rigorously demonstrate the concentrations of sodium hypochlorite, peroxyacetic acid, and hydrogen peroxide needed for a 6-log10 or greater reduction of B. anthracis spores.

Acknowledgments

This research was supported by the U.S. Department of Homeland Security through the National Center for Food Protection and Defense at the University of Minnesota (grant number N-00014-04-1-0659).

The opinions, findings, and conclusions or recommendations in this document are those of the authors and do not necessarily reflect the views of the U.S. Department of Homeland Security.

Footnotes

Published ahead of print on 24 August 2007.

REFERENCES

- 1.ASTM International. 2002. Standard quantitative disk carrier test method for determining the bactericidal, virucidal, fungicidal, mycobactericidal and sporicidal activities of liquid chemical germicides. ASTM E2197-02. Annual book of ASTM standards, vol. 11.05. ASTM International, West Conshohocken, PA.

- 2.Babb, J. R., C. R. Bradley, and G. A. J. Ayliffe. 1980. Sporicidal activity of glutaraldehyde and hypochlorites and other factors influencing their selection for the treatment of medical equipment. J. Hosp. Infect. 1:63-75. [DOI] [PubMed] [Google Scholar]

- 3.Bales, M. E., A. L. Dannenberg, P. S. Brachman, A. F. Kaufmann, P. C. Klatsky, and D. A. Ashford. 2002. Epidemiologic response to anthrax outbreaks: field investigations, 1950-2001. Emerg. Infect. Dis. 8:1163-1174. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Bloomfield, S. F., and M. Arthur. 1992. Interaction of Bacillus subtilis spores with sodium hypochlorite, sodium dichloroisocyanurate and chloramine-T. J. Appl. Bacteriol. 72:166-172. [DOI] [PubMed] [Google Scholar]

- 5.Bloomfield, S. F., and E. E. Uso. 1985. The antibacterial properties of sodium hypochlorite and sodium dichloroisocyanurate as hospital disinfectants. J. Hosp. Infect. 6:20-30. [DOI] [PubMed] [Google Scholar]

- 6.Centers for Disease Control and Prevention. 2001. Update: investigation of anthrax associated with intentional exposure and interim public health guidelines. Morb. Mortal. Wkly. Rep. 50:889-893. [PubMed] [Google Scholar]

- 7.Christensen, R. P., R. A. Robison, D. F. Robinson, B. J. Ploeger, R. W. Leavitt, and H. L. Bodily. 1989. Antimicrobial activity of environmental surface disinfectants in the absence and presence of bioburden. J. Am. Dent. Assoc. 119:493-505. [DOI] [PubMed] [Google Scholar]

- 8.Clinical and Laboratory Standards Institute. 2006. Preparation and testing of reagent water in the clinical laboratory. Approved guidelines, 4th ed., CLSI document C3-A4. Clinical and Laboratory Standards Institute, Wayne, PA.

- 9.Fukayama, M. Y., H. Tan, W. B. Wheeler, and C.-I. Wei. 1986. Reactions of aqueous chlorine and chlorine dioxide with model food compounds. Environ. Health Perspect. 69:267-274. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Hawkins, C. L., and M. J. Davies. 1999. Hypochlorite-induced oxidation of proteins in plasma: formation of chloramines and nitrogen-centered radicals and their role in protein fragmentation. Biochem. J. 340:539-548. [PMC free article] [PubMed] [Google Scholar]

- 11.Lensing, H. H., and H. L. Oei. 1984. A study of the efficacy of disinfectants against anthrax spores. Tijdschr. Diergeneeskd. 109:557-561. [PubMed] [Google Scholar]

- 12.Reference deleted.

- 13.Rogers, J. V., C. L. K. Sabourin, Y. W. Choi, W. R. Richter, D. C. Rudnick, K. B. Riggs, M. L. Taylor, and J. Chang. 2005. Decontamination assessment of Bacillus anthracis, Bacillus subtilis, and Geobacillus stearothermophilus spores on indoor surfaces using a hydrogen peroxide gas generator. J. Appl. Microbiol. 99:739-748. [DOI] [PubMed] [Google Scholar]

- 14.Russell, A. D. 1990. Bacterial spores and chemical sporicidal agents. Clin. Microbiol. Rev. 3:99-119. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Russell, A. D., J. R. Furr, and J.-Y. Maillard. 1997. Microbial susceptibility and resistance to biocides. ASM News 63:481-487. [Google Scholar]

- 16.Sagripanti, J.-L., and A. Bonifacino. 1996. Comparative sporicidal effects of liquid chemical agents. Appl. Environ. Microbiol. 62:545-551. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Sagripanti, J.-L., M. Carrera, J. Insalaco, M. Ziemski, J. Rogers, and R. Zandomeni. 2007. Virulent spores of Bacillus anthracis and other Bacillus species deposited on solid surfaces have similar sensitivity to chemical decontaminants. J. Appl. Microbiol. 102:11-21. [DOI] [PubMed] [Google Scholar]

- 18.Spotts Whitney, E. A., M. E. Beatty, T. H. Taylor, R. Weyant, J. Sobel, M. J. Arduino, and D. A. Ashford. 2003. Inactivation of Bacillus anthracis spores. Emerg. Infect. Dis. 9:623-627. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Tomasino, S. 2005. Disinfectants: AOAC official method 960.09, germicidal and detergent sanitizing action of disinfectants, p. 9-12. In W. Horwitz and G. W. Latimer, Jr. (ed.), Official methods of analysis of AOAC International, 18th ed. AOAC International, Gaithersburg, MD.

- 20.Turnbull, P. C. B. 1998. Guidelines for the surveillance and control of anthrax in human and animals, 3rd ed. World Health Organization document WHO/EMC/ZDI/98.6. http://www.who.int/csr/resources/publications/anthrax/whoemczdi986text.pdf.

- 21.U.S. Department of Agriculture, Food Safety and Inspection Service. 2006. Guidelines for the disposal of intentionally adulterated food products and the decontamination of food processing facilities. http://www.fsis.usda.gov/PDF/Disposal_Decontamination_Guidelines.pdf.

- 22.U.S. Environmental Protection Agency. 2006, accession date. Anthrax spore decontamination using bleach (sodium hypochlorite). http://www.epa.gov/pesticides/factsheets/chemicals/bleachfactsheet.htm.

- 23.U.S. Environmental Protection Agency. 1982. Disinfectants for use on hard surfaces. http://www.epa.gov/oppad001/dis_tss_docs/dis-01.htm.

- 24.U.S. Environmental Protection Agency. 1979. Supplemental recommendations. http://www.epa.gov/oppad001/dis_tss_docs/dis-02.htm.

- 25.U.S. Environmental Protection Agency. 2006, accession date. Anthrax spore decontamination using hydrogen peroxide and peroxyacetic acid. http://www.epa.gov/pesticides/factsheets/chemicals/hydrogenperoxide_peroxyaceticacid_factsheet.htm.

- 26.U.S. Environmental Protection Agency, Office of Research and Development, National Homeland Security Research Center. 2006. Report on the 2006 workshop on decontamination, cleanup, and associated issues for sites contaminated with chemical, biological, or radiological materials. http://www.epa.gov/NHSRC/pubs/reportDeconWorkshop121406.pdf.

- 27.U.S. Environmental Protection Agency, Office of Research and Development, National Homeland Security Research Center. 2006. Test/QA plan for evaluating liquid and foam sporicidal spray decontaminants. http://www.epa.gov/nhsrc/pubs/tpLiquidDecon072406.pdf.

- 28.Wiencek, K. M., N. A. Klapes, and P. M. Foegeding. 1990. Hydrophobicity of Bacillus and Clostridium spores. Appl. Environ. Microbiol. 56:2600-2605. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Young, S. B., and P. Setlow. 2003. Mechanisms of killing Bacillus subtilis spores by hypochlorite and chlorine dioxide. J. Appl. Microbiol. 95:54-67. [DOI] [PubMed] [Google Scholar]