Abstract

This review describes recent progresses in the development and applications of smart polymeric gels, especially in the context of biomedical devices. The review has been organized into three separate sections: defining the basis of smart properties in polymeric gels; describing representative stimuli to which these gels respond; and illustrating a sample application area, namely, microfluidics. One of the major limitations in the use of hydrogels in stimuli–responsive applications is the diffusion rate limited transduction of signals. This can be obviated by engineering interconnected pores in the polymer structure to form capillary networks in the matrix and by downscaling the size of hydrogels to significantly decrease diffusion paths. Reducing the lag time in the induction of smart responses can be highly useful in biomedical devices, such as sensors and actuators. This review also describes molecular imprinting techniques to fabricate hydrogels for specific molecular recognition of target analytes. Additionally, it describes the significant advances in bottom–up nanofabrication strategies, involving supramolecular chemistry. Learning to assemble supramolecular structures from nature has led to the rapid prototyping of functional supramolecular devices. In essence, the barriers in the current performance potential of biomedical devices can be lowered or removed by the rapid convergence of interdisciplinary technologies.

Keywords: Stimuli–Responsive, Reversible Volume Transitions, Polyelectrolytes, Molecular Imprinting, Microfluidics, Supramolecular Chemistry, Bottom–Up Design

1 INTRODUCTION

Smart polymeric gels constitute a new generation of biomaterials that are now being developed at a prolific pace for use in a range of applications including templates for nanoscale and other biomedical devices, scaffolds for tissue engineered prostheses, and biosensors and actuators. In tissue engineering, the last few years have witnessed a significant paradigm shift in the design of new biomaterials—from inert biomaterials to extracellular matrix (ECM)–mimetic biomaterials [1-4]. Two main classes of macromolecules make up the ECM: (1) fibrous proteins, including collagen, elastin, fibronectin, and laminin and (2) glycosaminoglycans (GAGs) covalently linked to proteins—proteoglycans (PGs) [5]. The highly hydrated, hydrogel–like properties of PG molecules of the ECM have made synthetic and semi–synthetic counterparts of these native hydrogels versatile candidates for tissue engineering.

The history of synthetic hydrogels dates back to the late 1950s when Wichterle and Lim synthesized the first hydrogels for biomedical applications, specifically the first contact lenses based on poly(hydroxyethyl methacrylate) crosslinked with ethylene dimethacrylate [6]. Although contact lens materials constitute a microcosm in the large domain of biomaterials, the pioneering use of soft hydrogels by Wichterle and Lim ignited a whole new wave of investigations in the quest for novel biomaterials with greater and “smarter” capabilities. Hydrogels are three–dimensional polymeric “swell gels” [7]; they swell in aqueous solutions without dissolving in them. When a hydrogel is in a dehydrated state, the polymer chains are in a collapsed state, allowing little room for molecular diffusion. As the hydrogel swells and attains an equilibrium swelling value, the swelling pressure on the chains is counteracted by the force holding the chains together, namely, the force of crosslinking. At this equilibrium value, the network mesh size (ξ) is the greatest and molecular diffusion reaches its peak values [Figure 1] [8, 9].

Figure 1.

A crosslinked structure of a polymeric hydrogel. The effective area of diffusion for solutes is characterized by the average mesh size (ζ) of the hydrogels. The solutes with diameters smaller than ζ (indicated by dark circles) easily diffuse through the hydrogel network (Modified from Reference [9]).

In the realm of nanotechnology, advances in nanofabrication strategies require a wide range of smart biomaterials. It is now known that biological tissue interfaces have nanoscale roughness [10-15], making the advances in nanotechnology all the more important for fabricating smart biomedical devices. Progresses in nanotechnology have attracted considerable interest in the self–assembling property of various molecules, which is a critical prerequisite for the burgeoning bottom–up design of nanoscale structures. When these molecules undergo molecular self–assembly, the resulting structural components, such as nanotubes or vesicles, can be further modified to confer specific properties to the components. Nanotubes, for example, can be coated with metals or semi–conducting materials to make nanowires [16]

Recent advances in the development of novel biomaterials to supplant cellular damages include the formation of nanofibrillar networks by self–assembling associative blocks, synthesis of artificial polymer networks from protein polymers, or the generation of polymer–peptide bioconjugates that present bioactive ligands on the surface. As an example, polymer–peptide bioconjugates are amenable to proteolytic degradation in response to secreted proteases, such as matrix metalloproteases (MMPs) from cells [17-19]. Such “smart” ECM–mimetics have already found applications in differentiating stem cells into neurons [20, 21], repairing orthopedic defects [22, 23], and inducing vascular angiogenesis [24, 25]. Thus far, synthetic ECMs are proving to be viable substitutes for tissue transplants and in many cases more effective scaffolds to transplant tissue progenitor cells and induce guided tissue morphogenesis. However, the temporal and the spatial complexity of natural tissue microenvironments demand greater synergy between materials engineering concepts and core biochemical principles [2]. The complexity also affords ECM–mimetics a large space of possibilities to explore, in the quest for novel biomaterials

Importantly, in the area of biomaterials research, stimuli–sensitive hydrogels or smart hydrogels has been gaining greater momentum. Response to stimuli is a basic phenomenon in living systems. Mimicking this property of living systems can offer a ready solution to many of the current day biomedical problems. Smart hydrogels respond to diverse stimuli, which can be in the form of pH, temperature, light, pressure, electric field, chemicals, or ionic strength, or a combination thereof. These hydrogels have the ability to respond to minute changes in ambient stimuli and exhibit dramatic property changes. For a biomaterial to be truly smart, the alterations in hydrogel microstructures should be fast and reversible. However, the first challenge with conventional stimuli–responsive hydrogels is the slow response time to stimuli and the hysteresis associated with the on and off states. One way to eliminate this drawback is to have thinner and smaller hydrogels without significantly deteriorating their mechanical properties. The second challenge is to engineer hydrogels that degrade in response to appropriate ambient stimuli in the body. This is in contrast to the current technology where hydrogels degrade at a predetermined rate when implanted in the body. For example, proteolytic stimuli, that is, biochemical signals from cells in the vicinity of an implanted biomaterial scaffold can dynamically transduce signaling cues if the scaffold can degrade and remodel its infrastructure in a stimuli responsive manner. Here, the stimulus is the cascade of biochemical signals from the cells in the vicinity of the biomaterial. The third challenge in the fabrication of smart hydrogels is to make hydrogels biocompatible such that the immune system does not set off immunogenic reactions in the body. In fact, ECM–mimetic hydrogels that evade attacks from the immune system can also be viewed upon as smart hydrogels, responding dynamically to signals from the host tissue. The structure of such ECM–mimetics aims to emulate the ECM, albeit in a much simpler form, capturing the essence of the structural and functional parameters of the ECM.

Russell in his interesting article on “Surface–Responsive Materials” has presented a brilliant analogy between cell adhesion on a receptor–mediated surface and stimuli–responsive materials [26]. The spreading of the cell on the surface is governed by a delicate interplay of surface forces, which include attractive van der Waals forces, electrostatic forces, cell membrane elasticity, steric interactions, and receptor–ligand binding interactions. The cell responds to this set of forces and smartly makes the decision whether to recoil (i.e., not adhere) or to spread on the surface (i.e., adhere). In spite of the enormous progress in engineering smart materials, development of the level of intricacy encoded in living cells is a task of tremendous challenge. One of the main objectives of this review article is to gauge the gap between this daunting challenge and the existing state of the art, and in light of that, describe the directions current biomaterial scientists are pursuing to bridge the gap.

Sections 2, 3, and 4 describe some of the properties and applications of stimuli–sensitive gels, with an emphasis on smart polymeric hydrogels based on the ECM–mimicking property. The stimuli to which polymeric gels respond are discussed in Section 3, and those include pH, temperature, and biochemical analytes, as representative examples of a wide range of possible stimuli. Molecularly imprinted polymers (MIPs) have also been discussed in this section in the context of “imprinting” analyte recognition in the polymer networks using this powerful technology. In Section 4, microfluidics has been selected as a model application to elucidate the potential of polymeric gels as well as hybrid polymeric structures, in actuating microfluidics–based biomedical devices. Also in Section 4, certain applications of the versatile aminopolysaccharide, chitosan, have been discussed in the light of its unique device–biology interfacing potential.

A gel is formed by the use of a crosslinker (physical or chemical) or by supramolecular association to create tie–points or entanglements in the polymeric matrix, resulting in hydrogels or organogels. In fact, self–assembling organogels are evolving as new functional materials based on supramolecular chemistry [27], and they are discussed in the light of self assembling nanofabrication strategies in Sections 4 and 5. Without such crosslinking–based or supramolecular assembling–based entanglements, polymers would react to stimuli by cycling between the sol and the gel states, rather than oscillating between the swollen and the collapsed states. For both kinds of oscillations, there are discrete and (ideally) reversible on and off states triggered by ambient stimuli. This is enough to actuate a device under different system requirements and operating conditions. Further, in hybridizing a polymeric gel with inorganic fillers or protein motifs, one can facilitate the combination of the best of multiple worlds—the polymeric gel world and the inorganic world or the protein world. The polymeric gel world often imparts the smartness (smart polymeric gels) while the inorganic or the protein world often imparts properties such as enhanced mechanical strength (e.g., by the incorporation of carbon nanotubes) or self–assembling potential (e.g., by utilizing variants of coiled–coil motifs). In essence, it is noted that the barriers in the current performance potential of biomedical devices are artificial; produced by the limits of current technology. The power generated by the fabrication of smart polymeric devices as well as their conjugates can elegantly transcend these synthetic barriers by the rapid convergence of interdisciplinary technologies.

2 CLASSIFICATION OF SMART POLYMERIC GELS ON THE BASIS OF STRUCTURAL PROPERTIES

This section is divided into three sub–sections and aims to highlight various material properties that confer “smartness” to polymeric gel networks. For one, superporous hydrogels (SPHs) have been used to increase the responsiveness of hydrogels. In the case of SPHs, the increase in stimuli responsiveness is achieved by engineering interconnected porous networks, as discussed below in Section 2.1. Shape–memory polymers constitute another class of smart biomaterials and function by a ubiquitous mechanism found in our day–to–day lives. Consider the analogy of the intrinsic memorizing ability of an elastic rubber band that is stretched and then allowed to relax; if the entropic energy associated with the stretched rubber band can be stored for use on demand, that itself would be a shape–memory based application. Finally, protein hydrogels unfurl a whole new class of biomaterials by emulating and integrating the self–assembling codes from nature in smart hybrids, as further elaborated in Section 5.

2.1 Superporous Hydrogels

Superporous hydrogels (SPHs) represent a fast–swelling class of hydrogels with pore sizes much larger than the typical mesh size of a conventional hydrogel. They were originally developed as novel gastric retention devices increasing the residence time of drugs in the stomach [28, 29]. Typical mesh size of a conventional hydrogel is below 100 nm [30, 31] compared to the pore size of SPHs which ranges from less than 1 μm to more than 1,000 μm [Figure 2]. The swelling kinetics of SPHs is much faster than that of conventional hydrogels [Figure 3]. This difference can be appreciated in the light of the difference in morphology of the two classes of hydrogels. Since the mesh size of conventional hydrogels is small, the swelling in such relatively closed systems is limited by diffusion of water through the glassy polymer matrix. On the other hand, SPHs have large interconnected pores resulting in the capillary intake of water.

Figure 2.

Scanning electron micrographs of SPHs with pore sizes less than 1 μm (left) and larger than 1 mm (right). The scale bars are 1 μm and 1 mm for the pictures on the left and right, respectively.

Figure 3.

An example of swelling ratio (Sw) as a function of time for SPHs made of acrylic acid (AA) and acrylamide (AM). The straight line representing “hydrogel theoretical” describes a typical example of the increase in Sw with time for a hypothetical non–porous hydrogel.

The same monomer or the same mix of co–monomers can produce different types of water–absorbing networks, depending upon the presence of a foaming agent, a foam stabilizer, and the modulation of foaming and polymerization kinetics. The main challenge in achieving a homogeneous, interconnected SPH matrix by the gas–blowing technique is to uniformly trap the in situ generated gas, when escaping from the polymer matrix [30, 32-35]. Interestingly, the escaping gas confers a distinct directionality to the pore structure, as it escapes from the bottom of the reaction vessel to the top. Compressing SPHs can further enhance their swelling ratio; the swelling property of compressed SPHs was shown to be dependent on the orientation of the SPHs during compression further attesting to the pore structure directionality [34].

Over the years, SPHs have evolved from mechanically weak, first generation SPHs (conventional SPHs), to the mechanically strengthened second generation SPHs (SPH composites), and finally to the third generation SPHs (SPH hybrids) with elastic and rubbery properties in the swollen state [35, 36]. Vinyl monomers, including highly hydrophilic acrylamide, salts of acrylic acid, and sulfopropyl acrylate, have been commonly used for the synthesis of first generation SPHs. The first generation SPHs had compromised mechanical properties due to the small volume fraction of the polymer content. They were subsequently modified to strengthen their mechanical property by including a composite agent, such as the internally crosslinked form of sodium carboxymethylcellulose (NaCMC), Ac–Di–Sol®. Ac–Di– Sol fibers mechanically strengthened the polymer matrix by physically entangling with the polymer chains. This resulted in a polymer matrix with higher mechanical moduli but susceptible to failure due to brittle cleavage fracture. Further modification of SPH composites to form SPH hybrids involved the formation of semi–interpenetrating or fully interpenetrating networks (IPNs) using a hybrid agent. In contrary to the pre–crosslinked composite agent used in SPH composites, the hybrid agent was crosslinked in situ during SPH fabrication. Water–soluble or water–dispersible polymers such as polysaccharides (e.g., sodium alginate), proteins (e.g., chitosan, gelatin), or synthetic hydrophilic polymers (e.g., poly(vinyl alcohol)) have been used as hybrid agents [32, 37]. Along these lines, elastic SPH hybrids exhibiting mechanical resilience and a rubbery property in its fully water–swollen state have been recently reported by Park et al. [36]. These hydrogel hybrids of acrylamide and alginate could be stretched to about two to three times of their original lengths and could be loaded and unloaded cyclically at least 20 times. Further the hybrids could resist a static mechanical pressure of at least 10 N. Also, it was found that an increase in calcium concentration resulted in stronger and smaller IPNs. This was due to the intimate entanglement of the ionotropically crosslinked alginate chains with the synthetic acrylamide chains. Thus, metal complexation of the polysaccharide or protein contents of SPHs affords an innovative modality for the fabrication of elastic and mechanically resilient third generation SPH hybrids with promising potentials in tissue engineering.

Interestingly, Baek et al. coated the surface of poly(acrylamide–co–acrylic acid) SPHs with an amphiphilic block copolymer, namely, poly(ethylene glycol–b–tetramethylene oxide) (PEGTMO) in order to control the swelling kinetics of the fabricated SPHs in aqueous solutions [38]. PEGTMO was dissolved in ethanol for use as the surface coating agent. The SPHs were coated by dipping and equilibrium soaking them in PEGTMO solutions. The delay in swelling of PEGTMO–coated SPHs in aqueous solutions was found to be dependent on the PEGTMO concentrations used. The delay mechanism was postulated to be stemming from the reduced surface hydrophilicity as well as the reduced surface porosity of the SPHs with increasing PEGTMO concentrations. The lowered hydrophilicity of PEGTMO–coated SPHs was recorded via contact angle measurements; scanning electron micrographs revealed a decrease in the surface pores. Thus, the coating of SPHs with the block copolymer of PEG and PTMO was shown to be a promising technique for modulating the SPH swelling kinetics without significantly deteriorating the mechanical properties or the equilibrium swelling value of the SPHs [39, 40]. SPHs exhibiting delayed swelling kinetics could be especially valuable in tissue expansion systems where a lag time in swelling would be beneficial in healing the traumatized damaged tissue.

Further, SPHs with environmentally sensitive swelling characteristics have also been synthesized [33]. Poly(acrylamide–co–acrylic acid) (p(AM–AA)) SPHs have been found to exhibit pH–sensitivity as well as fast swelling properties. Repeated swelling and de–swelling was observed when these SPHs were exposed to alkaline and acidic conditions respectively, due to alternating ionization and deionization of the carboxyl functionalities. Temperature–sensitive swelling was observed in poly(N–isopropylacrylamide–co–acrylamide) (poly(NIPAM–AM)) SPHs. The lower critical solution temperature (LCST) of the poly(NIPAM–AM) SPHs can be hydrophobically modulated by altering the polymer composition, as explained in Section 3.2.

2.2 Shape–Memory Gels

Responses actuated by shape–memory and stimuli–responsiveness are interrelated. In fact, stimuli–responsiveness can be considered to be an archetypal example of the shape–memory property in materials. Materials are said to exhibit a shape–memory effect if they can be deformed and fixed into a temporary shape, and have the ability to recover the original, permanent shape only on exposure to an external stimulus. The first shape–memory materials to be discovered were shape–memory alloys (SMAs). The concept of a “metal with a memory” was first discovered in the shape–retaining alloy Nitinol (Nickel Titanium Naval Ordnance Laboratory), discovered in 1959 by William J. Buehler of the U.S. Naval Ordnance Laboratory, and was subsequently developed by Buehler and Frederick E. Wang. This discovery paved the way to its diverse set of applications, ranging from “shrink–to–fit” pipe couplers for aircrafts, solid state heat engines and toys, to biomedical applications in orthopedics, orthodontics, and cardiovascular surgery. Raychem Corporation's Cryofit “shrink–to–fit” pipe couplers, introduced in 1969, was the first successful Nitinol product on the market [41]. Today SMAs, such as Nitinol®, have been instrumental in significantly improving the quality of diagnostics, treatments, and surgeries [42]. However, the mechanical properties of SMAs can only be varied to a limited extent. The deformation between the temporary and permanent shape is limited to a maximum of 8%. Further, SMAs are non–degradable and the programming of these materials is time–consuming and demands temperatures of several hundred degrees Celsius. Therefore, degradable polymer implant materials with shape–memory have been developed for biomedical applications [43-45]. Though the specific mechanism and applications of shape–memory in metals is outside the scope of this review, the recapitulation of this discovery in metals highlights the far–reaching effects of the shape–memory property in a materials' world.

Shape–memory polymers show stimuli–responsive alterations in structure. Upon exposure to external stimuli, such as an increase in temperature, these materials have the ability of changing their shape. The shape–memory effect is not a specific material property of single polymers. The effect results from the structure and morphology of the polymer coupled with the processing and programming technology. The deformation, and thus, strain energy, is captured in the shape–memory material by a reversible morphology change induced by the deformation, e.g., martensitic transformation for SMAs and thermal or strain–induced crystallization for SMPs. The higher the shape fixity imparted by strain–induced crystallization, the greater the potential of the shape–memory material to exert a force and enable mechanical work on demand. An example of this would be the deployment of a shape–memory stent after proper placement in the vascular graft. In fact, the main applications of SMPs revolve around the ability to use the entropically stored energy to exert force, enabling the transduction of the stored latent energy to mechanical work [46].

Alteration in the shape of a shape–memory material by a thermal stimulus will result in what is termed “thermally induced shape–memory effect.” By exceeding the switching temperature, Ttrans, the polymer switches from its temporary shape to its memorized, permanent shape. The netpoints, that can be chemical or physical in nature, determine the permanent shape. The net chains show a thermal transition either at a glass transition point (Tg) or a melting point (Tm) in the temperature range in which the shape–memory effect is supposed to be triggered. For biomedical applications a thermal transition of the switching segments from the room temperature to the body temperature range is of great interest [43, 47].

Osada and Matsuda demonstrated the shape–memory effect in poly(N,N′– methylenebisacrylamide) [48] in 1995. Since then, biodegradable SMPs have been synthesized, including network polymers formed by crosslinking oligo(ε–caprolactone) dimethyacrylate and N–butylacrylate [45], a multiblock copolymer of oligo(ε–caprolactone) and 2,2(4),4–trimethylhexanediisocyante [44], a composite of poly(D,L–lactide) and hydroxyapatite [49], and polyurethane derivatives containing polyesters [50, 51]. In addition to biodegradability, other criteria attractive for SMP–based biomedical implants include reversibility in the on–off signal transition with minimal hysteresis and reinforced mechanical properties to act as mechanical actuators without buckling under stress. Dramatic improvement in the stiffness and recovery force of SMPs can be achieved by the synthesis of fiber–reinforced SMP composites. Liu et al. studied the thermomechanics of a shape–memory polymer and its composites made by adding nanoscale SiC reinforcements [52]. SMP nanocomposites were demonstrated to have a higher elastic modulus and were capable of generating higher recovery forces as compared to SMP alone. Constitutive models are critical for predicting the deformation and recovery of SMPs under varying thermomechanical conditions. In view of this, Liu et al. constitutively modeled SMPs, quantifying the storage and release of entropic deformation during thermomechanical processing. Modeling of strain and stress recovery responses under various flexible external constraints in SMPs can prove to be valuable for engineering SMP–based actuators and other biomedical devices [53].

Vaia et al. tested the thermomechanical behavior of shape–memory nanocomposites incorporating anisotropic carbon nanotubes in traditionally monolithic SMPs. These polymer carbon nanotube nanocomposites (PCNs) demonstrated enhanced mechanical characteristics and novel actuation properties. Non–radiative decay of infrared photons absorbed by nanotubes raises the internal temperature; melting strain–induced polymer crystallites and remotely actuating the release of the entropic strain energy [46]. In fact, carbon nanotubes impart unique electrical, optical, and thermal properties to polymer matrices at very low concentrations, in addition to substantial mechanical enhancements [54].

Many new robotic and teleoperated applications require a high degree of mobility or dexterity that is difficult to achieve with current actuator technology. Reinforcement of SMPs can in fact play a major role in their use in novel actuators. Natural muscle is an actuator that has many features, including high energy density, fast speed of response, and large stroke, that are desirable for such applications. Gall et al. have characterized the shape–memory mechanics of electrostrictive polymer artificial muscle (EPAM) actuators that can produce strains of up to 30% and pressures of up to 1.9 MPa. A rotary motor using EPAM actuator elements has been shown to produce a specific torque of 19 mNm/g and a specific power of 0.1 W/g, demonstrating the potential toward greater specific power and specific torque than conventional electric motors [55].

Fast–responsive shape–memory hydrogels have been largely useful in the fabrication of microfluidic devices. Several microvalves utilizing shape–memory hydrogels have been developed [56-59]. In–channel polymerization of hydrogel–based flow modulators greatly simplifies device construction, assembly, and operation. Hydrogel–based microvalves have a number of advantages over conventional microvalves, including relatively simple fabrication, no external power requirement, no integrated electronics, and large displacement force generation. However, electronically controllable hydrogel microvalves, based on temperature sensitive hydrogels, offer greater precision in flow modulation and signal actuation, stemming from the integrated electronic circuitry. Richter et al. devised smart microvalves with short switching times in the range of 0.3 sec to 10 sec [58]. Microfluidic applications of polymeric gels have been described in greater detail in Section 4 of this article.

Smart, biodegradable implant materials also demonstrate promising potentials toward minimally invasive surgery. For example, the mechanical characteristics and degradability of shape–memory, multiblock copolymers can be used for the preparation of smart surgical sutures. By increasing the temperature higher than the Ttrans, shape–memory fibers, programmed to apply the optimum force, shrink and tighten suture knots [43]. Other relatively bulky biodegradable implants can be inserted into the body in a compressed, temporary shape through a small incision via laparoscopy. Their shape–memory ability enables such implants to perform complex mechanical deformations automatically. The additional advantage of designing biodegradable SMPs would be to prevent the discomfort of a follow–on surgery. New polymers have been synthesized with this concept in mind, including phase segregated multiblock copolymers whose starting materials are proven biocompatible monomers, such as ε–caprolactone and p–dioxanone [44, 45, 60]. Generally, these materials have at least two separated phases, each with thermal transition (glass or melting) temperatures. The phase with the higher transition temperature is responsible for the permanent shape, whereas the second phase acts as a molecular switch, enabling the fixation of the temporary shape.

Another, opportunity afforded by SMPs is the ability to inject drug loaded SMPs into the body through a laparoscopic hole and retaining the ability to form an implant via thermally induced shape alterations. Interestingly, a thermally induced shape–memory effect that can be activated by an increase in temperature can potentially be induced by heating on exposure to an electrical current or by photoinduction. For one, significant advances have recently been made in the development of SMPs that “move in response to light” [61]. The main challenge in the development of such polymer systems is the conversion of photoinduced effects at the molecular level to macroscopic scales of movement. Examples include the contraction and bending of azobenzene–containing liquid–crystal elastomers and volume alterations in gels. Using light as a trigger for the shape–memory effect will extend the applications of shape–memory polymers, especially in the field of medical devices where triggers other than heat are highly desirable [62].

The concept underlying the responsiveness of shape–memory materials has been very deftly described by Russell, exemplifying the responsive energy stored in a stretched rubber band [26]. If this latent energy of recoil, or the generated elastic retractive force, can be stored in the rubber band for a finite time period, the stored force can be utilized to do useful “work”. In semi–crystalline or glassy polymers, in which crystals act as crosslinking points, a frozen–in strain can produce a similar response. The melting of the strain–induced polymer crystallites (which are responsible for temporarily securing the deformed shape) remotely triggers the release of the stored energy. In fact, shape–memory polymers possess the capacity to recover large strains of the order of 50–400% by the application of heat. This ability of shape–memory polymers to spontaneously recover inelastic strain energy in restricted environments span diverse applications, including heat–shrink tubing, deployable aerospace structures, microsystems, and biomedical devices. Further, the stiffness and stress recovery parameters of shape–memory polymers can be enhanced manifold by the inclusion of ceramic fillers or, more recently investigated, inclusion of anisotropic carbon nanotubes. This unique optimization of properties unfolds promising potentials for developing shape–memory systems as a powerful class of stimuli responsive materials [46, 63-66].

2.3 Artificial protein hydrogels

Limitations of hydrogels fabricated by traditional methods, such as crosslinking copolymerizaton, include the absence of precise control of structural morphology and the hysteresis associated with “on” and “off” transitions. Protein engineering [Figure 4] offers powerful solutions to overcome these limitations via the formation of well–defined, supramolecular structures. For example, self–assembling structural domains found in native proteins, e.g., β–sheets and α–helices, can be outfitted with integrin binding domains (e.g., Arginine–Glycine–Aspartic Acid or, RGD) or with enzymatic domains [67]. Further, the possibility of going beyond the domain of the natural amino acids and incorporating unnatural amino acids in protein or peptide structures instill greater versatility in genetically engineered motifs [68-76]. Prompted by protein engineering as well as self–assembling strategies for nanofabrication, two new models for engineering smart hydrogels are evolving—first, the synthesis of hydrogels or their associative building blocks by genetic engineering methods, and second, the approach of spontaneous association of the building blocks by molecular self–assembly. The combination of these two techniques affords a promising strategy for the design of hydrogels with a rapid on–off transition [26].

Figure 4.

Overview of the protein engineering methodology (Modified from Reference [321]).

Molecular self–assembly is a powerful approach for creating novel supramolecular architectures. Formation of such supramolecular structures is ubiquitous in the natural world, ranging from the formation of lipid domain structures in plasma membranes, the spontaneous self–assembly of two α and β chains in hemoglobin forming a quaternary structure, or even the very basic example of formation of oil globules in water. The unique three–dimensional shape of proteins, culminating in protein folding, arises from non–covalent interactions between regions in the linear sequence of amino acids. In fact, only when a protein is in its correct three–dimensional structure, or conformation, is it able to function efficiently [77].

Along the lines of self–assembly of associative blocks, Deming et al. have fabricated novel copolypeptide hydrogels with smart, tunable properties [78-80]. Specifically, the properties of these copolypetide–based hydrogels can be tuned by varying the secondary structure and the charge character of the associative blocks via alteration of the incorporated amino acid building blocks. The facile assembly of hydrogels using amino acid building blocks closely mimics the supramolecular assembly of living matter and affords the advantage of tuning the secondary conformation of the constituting blocks, akin to the self–assembly of proteins in living systems. Thus, gelation depends not only on the overall amphiphilic nature of the fabricated polypeptides, but also on the secondary structure of the individual amino acid monomers (α–helix, β–strand, or random coil). Further, contrary to most protein gels, which generally dissolve at temperatures greater than 60 °C, transition–metal mediated polypeptide gels, fabricated by Deming et al., did not demonstrate visible thinning up to temperatures as high as 90 °C. Also, the dynamics of the gelation process were investigated by subjecting the polymer gels to large amplitude oscillations and observing the recovery process as a function of time. The hydrogels recovered 80–90 % of their strength within relatively short time intervals, followed by a slower recovery to finally attain the initial storage modulus. Such bottom–up, supramolecular approaches toward fabricating smart materials for various biomedical and pharmaceutical applications are discussed in greater detail in Section 5 of this article.

Recombinant DNA methods have also been used to create artificial proteins that undergo reversible gelation in response to alterations in pH or temperature. The architecture of such proteins emulates those of naturally occurring protein multimeric structures, mostly based on a class of protein motifs called coiled–coil motifs. Kopecek et al. have synthesized hybrid hydrogel systems using coiled–coil domains to drive the self–assembly of polymer chains [81-83]. Coiled–coil induced self–assembly has been shown to be strongly dependent on environmental stimuli such as concentration, temperature, pH, and properties of the solvent. To understand the marvels of innovative research, emulating the self–assembling potential of such coiled–coil motifs, it is important to understand the architecture of such motifs. A coiled coil is comprised of a bundle of α–helices wound into a superhelix [84]. It is a common and important structural motif that mediates protein–protein interactions, and is formed by approximately 3–5% of all amino acids in native proteins. It was first described in 1953 by Crick [85] and Pauling and Corey [86, 87] as the main structural element of a large class of fibrous proteins, including keratin, myosin, and fibrinogen. The most commonly observed coiled–coil motif is left–handed; here each helix has a periodicity of seven (a heptad repeat), usually denoted as (a–b–c–d–e–f–g)n in one helix and (a′–b′–c′–d′–e′–f′–g′)n in the other. In this model, a and d are typically non–polar core residues found at the interface of the two helices, juxtaposed in such a manner that they can hydrophobically interact; whereas e and g are solvent–exposed polar residues that confer specificity to the interaction between the two helices via electrostatic interactions. Consequently, two α helices with these hydrophobic “stripes” spanning the surface can wrap around each other with the non–polar side chains of one α helix interacting with the non–polar side chains of the other. Typically, in gene regulation the portion of the protein responsible for dimerization is distinct from the portion that is responsible for DNA binding; gene regulatory proteins normally being homodimeric. Notably, however, leucine zipper motifs efficiently combine these two discrete functions into one. These motifs are so named because of the way the two α helices, one from each helical monomer, dimerize to form a short coiled–coil. The hydrophobic force of interaction mostly arises from leucine residues interacting with one another. Just beyond the dimerization interface the two α helices separate from each other to form a Y–shaped structure, allowing their side chains to bind to the major groove of DNA [5, 88-91].

Many native and de novo designed coiled–coils undergo conformational transitions, such as folding or oligomerization, in response to temperature, pH, ionic strength, and other stimuli. In fact, dramatic alterations in coiled–coil stability, conformation, and responsiveness can result from minor alterations in the primary structure. By incorporating coiled coil motifs as crosslinks in polymeric hydrogels, Kopecek et al. conferred predetermined sensitivity to the fabricated hybrid hydrogels [92]. Specifically, they prepared a linear hydrophilic copolymer of N–(2–hydroxypropyl)–methylacrylamide (HPMA), and a metal–chelating monomer N–(N′,N′–dicarboxymethylaminopropyl)–methacrylamide (DAMA). Complex formation between iminodiacetate (IDA)–Ni2+ pendant chains and the terminal histidine tags of the coiled coil motifs anchored the peptide motifs to the primary hydrogels chains [Figure 5]. Temperature induced collapse of the coiled–coil conformation resulted from the transition from the elongated coiled–coil conformation to random–coiled conformation. This occurred at a temperature close to the melting temperature of the native coiled–coil protein (Tm = 35 °C) and structurally altered the gels. Further, with the same copolymer precursor and similarly charged, two different coiled–coil motifs, different swelling profiles were obtained. This difference was possibly due to considerable difference in the size of the motifs, resulting in different crosslinking densities and/or difference in the polymer–solvent interaction parameter, χ. Also, increase in the swelling of the gels was observed when imidazole was added to the system, since imidazole, in moderate concentrations, competes with the histidine–tagged coiled–coils to bind to Ni2+. In effect, this method of crosslinking brilliantly combines the features of the synthetic polymer and peptide world and indicates huge promise in the tailoring of coiled–coil domains and obtaining different structural transition temperatures. Other transition metal ions, such as Zn2+ and Ga2+, can replace Ni2+ in order to stabilize tagged proteins or to track hydrogels in vivo using magnetic resonance imaging (MRI).

Figure 5.

Schematic of a hybrid hydrogel assembled from histidine–tagged coiled–coil proteins and the synthetic polymer, poly(HPMA–co–DAMA). The pendant iminodiacetate groups from DAMA complex with Ni2+, to which the terminal histidines of the coiled–coil tetramer (not drawn to scale) are attached. The tetrameric, self–assembling coiled–coil motif, crosslinking the primary hydrogel chains, consist of two parallel dimers associating in an antiparallel fashion, and constitute only one of the several possible conformations of coiled–coil proteins (Modified from Reference [92]).

Further, coiled–coil stem loop (CCSL) peptides, immobilized on a solid substrate, were also demonstrated to enable biorecognition by forming a rigid brush–like structure with the loop regions exposed to the environment [Figure 6]. Specifically, the designed epitope–display model system consisted of two main components: epitope–containing histidine–tagged peptide, and a synthetic polymer with two types of functionalities, one for covalent attachment to the substrate and the other for peptide immobilization [82].

Figure 6.

Biorecognition of target via the displayed epitope on a coiled–coil stem loop (CCSL) peptide (Modified from Reference [82]).

In a recent article, Kopecek et al. documented the synthesis of coiled–coil grafted HPMA hydrogels, where, in contrast to metal–induced complexation, grafting of coiled–coil motifs to the HPMA backbone was done. The coiled–coil motifs flanked with cysteine residues (at the C terminus) were attached to the HPMA backbone via thioether linkages with side chain maleimide groups. It was found that at least four coiled–coil heptads were needed to enable the association of graft copolymers into hybrid hydrogels. The properties and environmental sensitivity of these advanced hydrogels were largely modulated by the structure of the coiled–coil domain [81].

Another interesting example of an artificially engineered motif, inspired by the natural coiled–coil architecture, has been reported by Tirrell et al. [93]. In their report they discuss the formation of a multidomain (“triblock”) artificial protein in which the two apparently contradictory properties of hydrogels, namely, polymer chain crosslinking and solvent retention have been captured in a discrete modular manner. Specifically, the topology of the protein is comprised of relatively short “leucine zipper” end blocks flanking a central, hydrophilic, polyelectrolyte domain, namely (PEG)x; (PEG = polyethylene glycol). The hydrogel formed by the coiled–coil interaction of the terminal leucine zipper domains gradually turned into a viscous solution with increasing temperature and when the pH was increased above 8.0. The mild conditions under which gel formation can be tuned (near–neutral pH and near–ambient temperature) and the reversible gel–sol transformation demonstrate promising potential in bioengineering applications. Further, aggregation number and kinetics, dimerization specificity, and aggregate structure can be manipulated broadly by simply changing the number and type of amino acid residues constituting the modules. Thus, the architecture of protein motifs employed in gene regulation have been deftly mimicked to confer switchable “on–off” transition abilities to these “smart” hydrogels. The elegant modular design allows independent regulation of the structure of the polyelectrolyte domain and the flanking, hydrophobic end blocks; thereby fine–tuning the properties of the hydrogel to perform specific functions.

In a recently reported attribute of protein hydrogels, Harden et al. indicated the promise of ECM–mimetic protein hydrogels with modular integrin binding domains in tissue engineering applications [94]. The integrin–binding activity of natural adhesion proteins can be partially mimicked by oligopepetide sequences [95, 96], such as the ubiquitous RGD (i.e., arginine–glycine–aspartic acid) [97-100], RGD and PHSRN (i.e., proline–histidine–serine– arginine–asparagine) (in synergy) [101, 102], IKVAV (i.e., isoleucine–lysine–valine–alanine–valine) [103-105], YIGSR (tyrosine–isoleucine–glycine–serine–arginine) [106, 107], PHSRN , and so on. Harden et al. went a step further from the triblock architecture initially proposed by Tirrell et al. by conjugating RGD to the central block of the modular triblock protein architecture. So, the modified architecture now contained three distributed repeats of the RGD sequence. The terminal leucine repeats of the original telechelic triblock motif engineered by Tirrell et al. [93], is retained in this modular structure with the addition of three RGD sequences.

Responsive gels have also been formed by the molecular self–assembly of β strands to form polymeric β–sheet tapes [108, 109]. Aggeli et al. designed long, semi–flexible β–sheet tapes that became entangled even at low volume fractions to form gels [108]. The viscoelastic properties of this gel system can be modulated by chemical (pH) or physical (shear) influences. The rheological properties of this β–aggregated system indicated characteristics such as response to small–strain oscillatory shear, reminiscent of highly entangled polymer gels. Interestingly, this follows the same type of molecular self–assembling dynamics as in the fibrillization of the amyloid β peptides—Aβ40 and Aβ42, a defining pathological feature of the Alzheimer's disease [110].

On a slightly different note, the far–reaching potentials of molecular self–assembly help us appreciate the huge promise in this emerging field. Recent research in the field of nanometer–scale electronics is probing into the “bottom–up” approach for fabricating nanostructured materials. This is in contrast to the conventionally adopted miniaturization strategies, i.e., the established “top–down” fabrication techniques. Biological macromolecules, especially proteins, provide many valuable properties, but poor physical stability and poor electrical characteristics have prevented their direct use in electrical circuits. Linquist et al. have described the use of self–assembling amyloid protein fibers to construct nanowire elements [111]. These fibers were placed across gold electrodes, and additional metal was deposited by highly specific chemical enhancement of the colloidal gold by reductive deposition of metallic silver and gold from salts. The resulting silver and gold wires were 100 nm wide and demonstrated the conductive properties of a solid metal wire, such as low resistance and ohmic behavior. Thus, exploiting the far–reaching potentials of molecular self–assembly, it is possible to harness the extraordinary diversity and specificity of protein functions for nanoscale fabrication.

3 CLASSIFICATION OF SMART POLYMERIC GELS ON THE BASIS OF STIMULI

This section describes pH, temperature, and an array of biochemical analytes as representative stimuli modulating volume transitions in smart polymeric gels. In the context of analyte sensitivity, the applications of the molecular imprinting technology in enabling molecular recognition in smart gels are also described. The analyte to be “sensed” by such “imprinted gels” is used as the template to actuate selective recognition behavior in the gels. For example, for molecularly imprinted glucose sensitive gels, where glucose serves as the analyte; glucose would be used as the template to enable the smart polymer to memorize glucose's three dimensional structure. Further, it may be appropriate to reiterate here that there is a host of other stimuli that can actuate smart responses in gels; a small subset of these have been alluded to in Section 2.2, on shape–memory polymers, and in Section 4, illustrating microfluidic applications.

3.1 pH–sensitive gels

Polymers containing acidic or alkaline functional groups that respond to changes in pH are called pH–sensitive polymers. A pH change around the pKa value of the functional groups results in the ionization of the groups and the generated electrostatic repulsive force leads to an increase in the hydrodynamic volume of the polymeric hydrogel (i.e., swelling). For pH–sensitive hydrogels, the difference in concentration of mobile ions in the hydrogel interior relative to external solution (osmotic pressure), with changes in solvent pH, drives the volume change [112]. The volume change, and hence the degree of swelling of these hydrogels, with acidic or alkaline functionalities would depend on the degree of ionization of the functional groups. Poly(acrylic acid) [113, 114], poly(methacrylic acid) [115-117], poly(ethylene imine) [118], poly(propylene imine) [119], chitosan [120-123], poly(L–lysine) [124, 125], and poly(L–histidine) [126-129] are typical examples of pH sensitive polymeric hydrogels.

Since ionization (protonation or deprotonation) mostly governs the swelling of pH–sensitive gels, it is important to understand the factors affecting the swelling equilibriums in ionic gels. These factors include: (i) free energy of mixing of the network chains with the solvent; (ii) ion osmotic pressure; and (iii) elastic retractile response of the expanding gel network. The volume transition in stimuli–sensitive ionic gels based on vinyl polymers with side–chain dissociative groups (e.g., poly(acrylic acid)) is driven by the persistence length transition. The concept of electrostatic persistence length was first suggested and elaborated by Odijk [130-132]. Konak and Bansil extended the idea of electrostatic persistence length to conformational changes of polymer chains and derived equations for the swelling equilibriums of polyelectrolyte gels. The swelling behavior of ionized poly(methacrylic acid) hydrogels in the absence of salts was described reasonably well by these persistence length relations [133]. At the swelling equilibrium, the osmotic pressure is balanced by the elastic pressure generated by the stretching of the polymer network [134].

Several methods have been used to develop pH–sensitive polymers with a pKa in the range of 5–8. By incorporating hydrophobic moieties, such as side chain alkyl groups, into poly(acrylic acid), the pH at which there is a conformational change in the polymer increases. This is because hydrophobic modification of the polymeric structure would translate to greater values of electrostatic repulsion to separate the increasing force of hydrophobic polymer–polymer interaction [135]. Khokklov et al. were able to demonstrate this phenomenon by hydrophobically modifying poly(acrylic acid), forming alkyl acrylates. It was shown that the swelling transition shifts to alkaline pH values with increasing hydrophobicity of the gel. The higher pH required for the behavioral transitions in these pH–sensitive anionic gels was due to the stabilization of the collapsed state of the gel by the increasing extent of hydrophobic aggregation with greater side chain alkylation [136]. Along similar lines, Tirrell et al. extended the versatility of the polyelectrolyte poly(2–ethylacrylic acid) (PEAA) system by modifying the critical pH for the onset of the targeted membrane solubilization. This was achieved by copolymerizing 2–ethyl acrylic acid (EM) with methacrylic acid (MAA) to obtain copolymers of varying composition. Increasing MAA mole fractions led to progressive reduction in the critical pH for membrane solubilization, which was observed turbidometrically. This method of hydrophobically modifying the polymeric structure thus affords the ability to “tune” the critical pH of a pH sensitive system; specifically in this case, hydrophobic modification altered the critical pH value from 5.7 to 6.5. This kind of modulation is especially useful in biological applications that require targeting to different intracellular destinations, which may typically maintain different degrees of acidity or alkalinity [137]. Notably, the pH variation in the gastrointestinal tract (GIT) is pronounced. The stomach has an acidic environment with a pH of 1–2 in a fasting condition and a pH of 4 during digestion. The intestine has an alkaline pH with a pH of 5.5 at the duodenum, this being the pH at which the acidic chyme mixes with the bicarbonate secreted from the pancreatic juices. Also, the extracellular or intracellular pH values in most cancers are more acidic than in normal tissues or cells [138, 139].

Cancer drug targeting is a challenging area, especially due to problems like multi–drug resistance (MDR). MDR confers on cancer cells the ability to pump out toxic anticancer agents before they can kill the cells. There are two general classes of resistance to anticancer drugs: those that impair delivery of anticancer drugs to tumor cells, and those that arise in the cancer cell itself due to genetic and epigenetic alterations that affect drug sensitivity. Impaired drug delivery can result from poor absorption of orally administered drugs, increased drug metabolism or increased excretion, resulting in lower levels of drug in the blood and reduced diffusion of drugs from the blood into the tumor mass [140]. Further, the metabolic profile of cancer cells is different due to poor oxygen perfusion, resulting in elevated levels of lactic acid production and a reduction in pH from 7.4 to about 6.0 [141, 142]. This property has been exploited by drug researchers by employing pH–sensitive polymers to target actively metastizing cancer cells. For one, Haag et al. generated dendritic core–shell nanocarriers based on hyperbranched poly(ethylene imine) cores and different shells containing aliphatic chains and poly(ethylene glycol) chains, respectively [143]. pH–triggered release of polar drugs was studied. Fast pH–sensitive cleavage of the imine bond occurred at pH 5–7 while relatively high stability of the imine bond was observed at a pH of 8. This pH shift corresponds to the pH shift observed in malignant tissues from that of normal tissues and hence is a valuable trigger for releasing encapsulated drugs at the target site. Further, the effect of enhanced permeability and retention (EPR) and the mechanism of receptor–mediated endocytosis (RME) are thought to be useful mechanisms for targeting macromolecular drugs specifically to tumor tissues on a vasculolymphatic level [144].

Another important application of pH sensitive controlled delivery is in the realm of gene delivery. Polyelectrolyte complexes (PECs) formed between DNA and cationic pH sensitive polymers are attracting increasing attention as novel synthetic vectors for delivery of genes [118, 126, 145]. Transport of naked DNA is difficult because of the large size and the negatively charged phosphate backbone of DNA. Cationic polymers, such as poly(L–lysine) (PLL), poly(ethylene imine), amine containing dendrimers, and amine containing fractured dendrimers have been investigated for this purpose. Schacht et al. went a step further from the formation of pristine DNA–cationic polymer complexes. They successfully grafted the cationic polymer, PLL, with a range of hydrophilic polymer blocks, including poly(ethylene glycol) (PEG), dextran and poly(N–(2–hydroxypropyl)methacrylamide) (PHPMA) to form cationic–hydrophilic block copolymers. Discrete complexes were formed, typically about 100 nm in diameter, and with surface charges slightly shielded by the presence of the hydrophilic polymer. The complexes generally show decreased cytotoxicity compared with simple PLL/DNA complexes. Further, PEG–containing complexes showed increased transfection activity using cells in vitro [125].

In fact, pH–sensitive ionization of constituting macromers is a ubiquitous property of several PECs. For example, the stability of a PEC formed using chitosan and alginate would depend on the ionization of the carboxylate groups of the alginate macromer and of the amino groups of the chitosan macromer, forming the PEC [146-150]. Since alginate–chitosan matrices exhibit pH–dependent swelling, the reversible ionization/deionization of the amino groups in chitosan and the carboxylate groups of alginate would essentially determine the stability of the PEC structure. Chitosan, a biopolymer widely used in nature, is also known to be complexed by citrate in the range of 4.3–7.6 [151]. Thus, chitosan, being a pH–sensitive natural polymer can be used to deliver drugs in a controlled manner by exploiting the pH–sensitive formation and disintegration of chitosan containing PECs.

Research efforts along the direction of cellular membrane mimicking strategies have drawn increasing attention toward the self–assembling properties of phospholipid–like molecules. These naturally occurring compounds usually comprise of double hydrophobic tails and a polar head group [5], which in many cases contains the phosphorylcholine (PC) motif. This has led to a class of biomaterials synthesized by either grafting PC–based macromolecules of clinically proven biocompatibility or by polymerizing PC–containing vinyl monomers [152]. One of the most fascinating properties of amphiphilic block copolymers is the micellization tendency of the block polymer when dissolved in a selective solvent, i.e., a solvent that would selectively solubilize one of the blocks but not the other and hence thermodynamically favor the formation of micelles. Giacomelli et al. synthesized biocompatible block copolymers consisting of a poly(2–methacryloyloxyethyl phosphorylcholine) (PMPC) corona–forming block and a pH–sensitive poly(2– (diisopropylamino)ethyl methacrylate) (PDPA) core–forming block (PMPC–b–PDPA) [152]. When PMPC–b–PDPA copolymers were molecularly dissolved in dilute acid solution, the DPA block was protonated and hydrophilic. However, when the pH was elevated to 6–7, the DPA block got deprotonated. This triggered hydrophobicity led to the micellization of the block copolymer, with the dehydrated PDPA forming the core and the hydrated PMPC forming the corona. There are several advantages of block copolymer micelles for drug delivery applications. First, the block copolymer micelles can be designed biocompatible and/or biodegradable by the proper selection of blocks. Second, they are nanosized and have a narrow size distribution, which allows intravenous injection. Third, they are able to encapsulate and release (in response to appropriate stimuli) their contents, which could be relatively insoluble or highly toxic compounds for delivery at specific sites (e.g., site of metastases). Fifth, they increase the bioavailability of the drug by minimizing drug degradation and loss.

Exploring the wide diversity in the behavior of polymer gels, Nagasaki et al. stumbled upon an interesting property in silicone–based polysilamine gels. The chemistry of this novel class of hydrogels comprises of alternating diamine and organosilyl units. These gels, surprisingly, hardened on swelling based on a reversible rod–globule transition [153]. This is in contrast to most hydrogels in which modulus decreases with increasing swelling degree at comparatively low values of solvent content. Further, in aqueous media, polysilamine hydrogels exhibit reproducible swelling/syneresis behavior in response to the protonation degree (α) of the network. The gel network chains expand and rigidify their conformation on protonation and anion binding, which induce the gel swelling consistently. Since a drawback in the use of most conventional hydrogels as biomedical devices is the decrease in mechanical properties on swelling, the unique property of this class of silicone based hydrogels makes them attractive for use in controlled drug delivery, especially as pump systems in pulsatile drug delivery.

3.2 Temperature–sensitive or thermo–responsive gels

The study of thermo–responsive gels started in 1978. Tanaka reported the thermodynamics underlying the collapse of the polymer network in polyacrylamide gels [154]. Poly(N–isopropylacrylamide) (poly(NIPAM)) in water demonstrated remarkable hydration–dehydration changes in response to changes in temperature, resulting in a lower critical solution temperature (LCST). Temperature is a commonly used triggering signal for modulating drug release [155, 156]. Thermal stimuli are physiologically very relevant, a common example being elevation of body temperature under the influence of pyrogens in fever. This is mediated by elevated concentrations of prostaglandin E2 (PGE2) within certain areas of the brain altering the firing rate of neurons that control thermoregulation in the hypothalamus [157].

In general, the solubility of most polymers increases with increase in temperature. However, in the case of polymers exhibiting LCST, increase in temperature decreases the polymer's water solubility due to predominating hydrophobic interactions. Thus, LCST is a characteristic facet of “inversely” thermo–responsive polymers. It is defined as the temperature at which the polymer solution undergoes a phase transition from a soluble state (i.e., random coil form) to an insoluble state (i.e., collapsed or globule form) on elevating the temperature. In fact this coil–to–globule transition of poly(NIPAM) has been clearly seen on a nanometer scale using atomic force microscopy (AFM) [158]. Using laser scanning confocal microscopy (LSCM), the mesoscopic internal structures of network polymers, including those of poly(NIPAM), were shown to be composed of continuous two–domain structures with dense and sparse regions in the polymer network demonstrating “fixed concentration fluctuations” [159].

A wide range of poly(N–substituted acrylamide)s, such as poly(N–isopropylacrylamide) and poly(N,N′–diethylacrylamide) [Figure 7], have been investigated. Intermolecular forces originating from the hydrophobic groups in the polymer result in changes in the orientation of the polymer in its solvent. Such interactive forces primarily include hydrogen bonding resulting in association/dissociation and hydrophobic interactions resulting in gel shrinkage in crosslinked polymers [160]. In general, the temperature sensitivity of swelling can be attributed to the delicate hydrophilic–lipophilic balance (HLB) of polymer chains and is affected by the size, configuration, and mobility of alkyl side groups. A sharp swelling transition occurs at LCST, when an optimum HLB value is attained in networks demonstrating sharp thermo–responsive properties; such as poly(NIPAM) networks [161, 162].

Figure 7.

Chemical structures of thermally responsive poly(N–substituted acrylamides). (a) poly(N–isopropylacrylamide); (b) poly(N,N′–diethylacrylamide). These polymers exhibit LCST phase transition. Notably, a common characteristic of most LCST polymers is the presence of hydrophobic alkyl groups.

Increasing the temperature increases the hydrophobic interaction, causing association of hydrophobic polymer chains. Moreover, the hydrogen bonding between polymer and water becomes unstable with increase in temperature, further favoring hydrophobic association. Due to the positive or negative dependence of polymer chain relaxation with temperature alteration, diffusion kinetics modulated by the polymer matrix also varies with alterations in temperature [163]. This unique property of thermally responsive polymers, demonstrating reversible phase transitions with thermal alterations, has made them especially attractive in the realm of modulated drug delivery.

Poly(NIPAM), like other LCST polymers, is fully hydrated with an extended chain conformation below 32 °C and gets extremely dehydrated and compact above 32 °C. The huge promise in the thermo–responsive property of poly(NIPAM), however, lies in the fact that its LCST phase transition occurs close to the body temperature [164]. In general, the LCST of thermo–responsive polymers can also be tuned to such useful values, by simply adjusting the ratio of hydrophilic and hydrophobic segment of the polymer [165-168]. Modification of LCST polymers (e.g., poly(NIPAM)) with more hydrophilic monomers (e.g., acrylic acid) will favor hydrogen bonding in preference to hydrophobic interactions and will increase the LCST of the copolymer [169-171]. Interestingly, co–polymerizing poly(NIPAM) with more hydrophobic monomers (e.g., N–butyl methacrylate) resulted in the formation of a dense skin during the de–swelling process (i.e., when the temperature was raised above LCST) [172-174]. This dense skin formed at high temperatures blocked release of drugs loaded in the matrix, resulting in the abrupt tapering off of drug release, modulated by temperature.

Further, engineering dual stimuli–responsive polymers, such as poly(NIPAM–co–methacrylic acid), has resulted in the pulsatile delivery of drugs by simultaneous pH and temperature alterations. The pulsatile delivery of the thrombolytic agent, streptokinase, by such a mechanism was found to be useful in its application at the site of blood clotting [175]. This kind of alternating on–off drug release pattern was obtained via interpenetrating polymer networks (IPN) of poly(acrylamide–co–butylmethacrylate) and poly(acrylic acid) [176] and poly(N,N–dimethylacrylamide) and poly(acrylic acid) [177], among others. Thermo–responsive polymers also afford a smart strategy to combat restenosis in vascular myopathies. Kavanagh et al. studied the release of colchicine from copolymer films such as N–isopropylacrylamide and N–tert– butylacrylamide (NIPAM/NtBAM). The copolymer collapsed above LCST, releasing colchicine, an anti proliferative agent to prevent restenosis [178].

Interestingly, the temperature–dependent switching characteristic of LCST polymers can afford a smart strategy to control the affinity of an enzyme for its ligand. Hoffman et al. used genetically engineered streptavidin (mutant form) to control the affinity kinetics of the mutated protein with immobilized biotin [179]. Cassette mutagenesis was carried out to introduce a cysteine residue in streptavidin and allow conjugation of the protein to poly(NIPAM). The conjugation of poly(NIPAM) to streptavidin resulted in the temperature modulated molecular “gating” of streptavidin's active site [Figure 8].

Figure 8.

Schematic of molecular gating using an LCST polymer. The polymer switches from its hydrated, random coil state to its collapsed state on increasing the temperature above LCST and blocks ligand binding to the substrate. This specific example describes the blocking of the interaction between a mutant streptavidin–poly(NIPAM) conjugate and biotin (ligand molecule), induced by the phase transition of poly(NIPAM). For poly(NIPAM), this phase transition induced molecular gating occurs around 37 °C (Modified from Reference [179]).

Thus, the site–specific conjugation of such phase reversible polymers to genetically modified protein affords an attractive tool to control biomolecular recognition processes, allowing “gating” of on–off rates as well as “switching” of on–off signals. Combinatorial libraries of thermo–responsive polymers, both compositionally and on the basis of molecular mass, can be created and utilized for the fine–tuning of such recognition processes. Further, triggered release of bound ligands can also be actuated using phase transition of polymers, this strategy being useful both in controlled drug delivery modalities and in size exclusion chromatographic methods.

Another widely researched area of exploring the potentials of thermo–responsive polymers is in the realm of cell manipulation techniques. The temperature dependent switching characteristic of poly(NIPAM) surface coatings, or more specifically, the switch from being hydrophilic at low temperature to hydrophobic at high temperature has been useful in both in vitro cell culturing and in fabricating layered constructs for engineering novel tissues. Thermo–responsive artificial extracellular matrices (ECMs), such as poly(NIPAM)–grafted gelatin (poly(NIPAM)–gelatin) have been researched to investigate the phenomenon of thermo–responsive adhesion and detachment of cells from the polymer surface [180]. The methods currently used to detach cells by enzymes, such as trypsin–induced cell peeling from the surface, have the potential to damage cells [181, 182]. For example, a decrease in cell culture temperature below LCST resulted in the release of cardiac myocyte sheets without the aid of enzymes [183]. Recovered cell sheets can potentially be transferred to other surfaces; this strategy represents a novel method for fabricating organ–mimicking layered constructs in tissue engineering [165]. Along similar lines, Okano et al. detached neonatal rat cardiomyocyte sheets from NIPAM–grafted surfaces and overlaid the cell sheets to construct cardiac grafts [184]. Layered cell sheets began to pulse simultaneously and morphological communication via connexin 43 was established between the sheets. Promising results were achieved with electrically communicative pulsatile 3–D cardiac layered constructs both in vitro and in vivo. This strategy of layering cell sheets thus appears to afford a sizeable step jump toward engineering cardiac tissue and thus enabling cardiovascular tissue repair.

Several researchers have investigated the thermal switching phenomenon using different compositions of NIPA–grafted polymers and have attempted to characterize and control the properties of these temperature sensitive coatings [185-190]. Matsuda et al. determined the adhesive strength of cell monolayers on thermo–responsive poly(NIPAM)–grafted gelatin [191]. The adhesive strength of monolayered tissue on a non–coated dish was reported to be approximately 560 Pa or 230 nN/cell at 37 °C. For dishes coated with thermo–responsive gelatin, the adhesive strength was reported to be 1050 Pa or 584 nN/cell at 37 °C, and 26 Pa or 14 nN/cell at room temperature. This technique affords a promising tool for determining the adhesive strength of interaction between a tissue monolayer and its substrate. Determination of tissue–substrate adhesive strength can potentially provide critical indications toward the performance of implant devices. Proteolytically sensitive thermoresponsive hydrogels have also been engineered and may well be considered doubly intelligent. Specifically, MMP–13 (collagenase–3)–sensitive peptide crosslinkers have been used to fabricate semi–interpenetrating networks (SIPN), as a synthetic equivalent of the ECM [192]. The idea of a modular EC–mimetic hydrogel with cell–adhesive signals and proteolytically sensitive peptides offers a robust rationale toward parametric modeling. This would enable analysis of the effects of individual, modular properties of the hydrogel on cell adhesion, proliferation, and differentiation.

Another area of extensive research has been in the use of thermally responsive polymers in anti–tumor treatment modalities, specifically targeting polymer–drug conjugates to solid tumors while limiting systemic exposure [193-196]. Elastin–like polypeptides (ELP), which are biopolymers of the pentapeptide repeat (VPGXG; i.e., valine–proline–glycine–X–glycine), where the “guest residue” X can be any of the natural amino acids except proline. ELPs exhibit LCST or inverse temperature transition and have been researched in novel tumor treatment modalities [197, 198]. Thermal targeting, resulting in the collapse of the ELP structure with phase transition, synergistically combines the benefits of polymer carriers (e.g., increased plasma half–life, high loading capacity) with the thermally induced actuation of a favorable response at the target site [198]. Recently, a thermally responsive ELP–based intra–articular drug delivery system was devised that could spontaneously aggregate upon injection into the knee joint, forming a drug–depot [199]. Biodistribution studies of these radiolabeled ELP aggregates revealed a 25–fold longer half–life in the locally injected form than in non–aggregating (soluble) similar molecular weight proteins. This strategy points toward the potential use of ELP–based fusion proteins in therapeutic modalities to treat osteoarthritis and other arthritides. Further, the conformational phase transition demonstrated by these responsive polymers can potentially be harnessed for force generation in actuation devices on nano and micro–scales. Chilkoti et al. probed the force–extension and conformational behavior of ELPs, below and above their transition temperature [200]. The results indicated a collapsed, potentially entangled, hydrophobic state of ELP with large, unspecific adhesion forces, above LCST. However, the extension behavior below the phase transition temperature closely followed conformational changes in the random polymer coil, without any significant unspecific adhesion forces. The excellent fit of a simple extended freely jointed chain model to the data at intermediate and large extension suggested that the ELP below LCST was in a random conformational state without significant secondary structure. Forces associated with polymer phase transition associated with a hydrophobic collapse can potentially be harnessed for reproducible recognition and actuation.

A large number of poly(ethylene oxide) (PEO) and poly(propylene oxide) (PPO) block copolymers have been found to possess an inverse temperature–sensitive micellization and gelation potential, and are commercially available under the names of Pluronics® (or, Poloxamers®) and Tetronics® [201]. Specifically, Pluronics (e.g., commercially available PF127 which is a PEO–b–PPO–b–PEO triblock copolymer) have distinct amphiphilic properties and the ability to from thermally reversible non–crosslinked gels. At appropriate concentration levels and thermal conditions, aqueous Pluronic solutions form micellar systems consisting of dehydrated, hydrophobic, PPO cores and solvated, hydrophilic, PEO coronas. Recently, Kabanov et al. synthesized nano–sized block ionomer complexes (BICs) composed of graft–comb copolymers of Pluronic and polyacrylic acid (Pluronic–PAA) and a model cationic surfactant hexadecyltrimethylammonium bromide (HTAB) [202]. The fabricated BICs were of a spherical morphology and responded to changes in environmental parameters such as ionic strength, pH, and temperature. The stability of the BICs was found to be dependent on the structure of Pluronic (the lengths of the PEO and PPO chains) and the charge ratio of polyacrylic acid and the cationic surfactant, HTAB. These environmentally sensitive BICs can thus be used as nano–containers for in vivo drug delivery. By using cationic surfactants such as Lipofectamine™, they can potentially be evaluated as DNA delivery vehicles. The hydrophobic PPO group of Pluronics, can be replaced with other hydrophobic groups, such as poly(1,2–butylene oxide) (PBO) [203, 204], poly(L–lactic acid) (PLLA), and poly(DL–lactic acid–co–glycolic acid) (PLGA) [203-207]. Further, Cohn et al. have developed new family of “reverse thermoresponsive gels” (RTGs) consisting of alternating [A—B]n block copolymers, with PEO and PPO as the blocks, using phosgene as a novel coupling agent [208]. The gels exhibited superior rheological properties, when compared with existing RTG displaying PEO–PPO–PEO triblocks. In fact, the relatively low viscosity of conventionally crosslinked RTG polymers, such as PEO–PPO–PEO triblocks, on phase transition, has been a disabling factor in their applications, especially due to the limited stability and short residence times.

Degradable composite Pluronic hydrogels, conjugated with hyaluronic acid (HA) have also been synthesized to combine the thermo–responsive property of Pluronic, specifically, PF127, with the biocompatibility and biodegradability of HA [209].

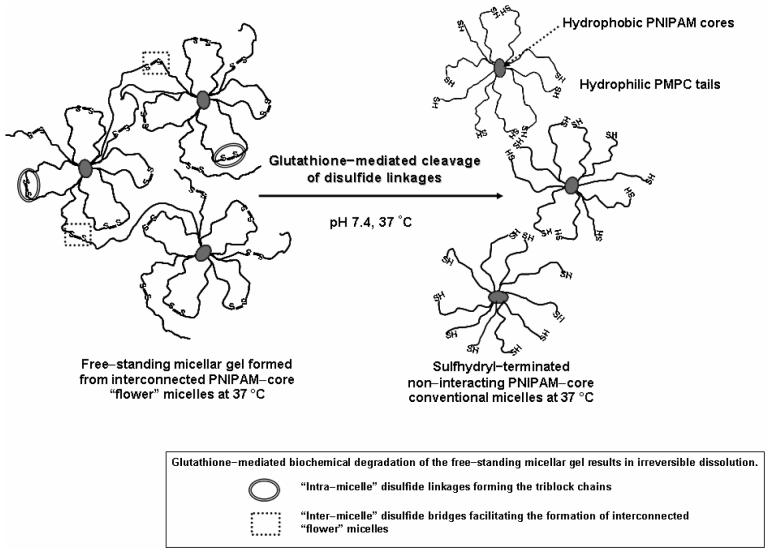

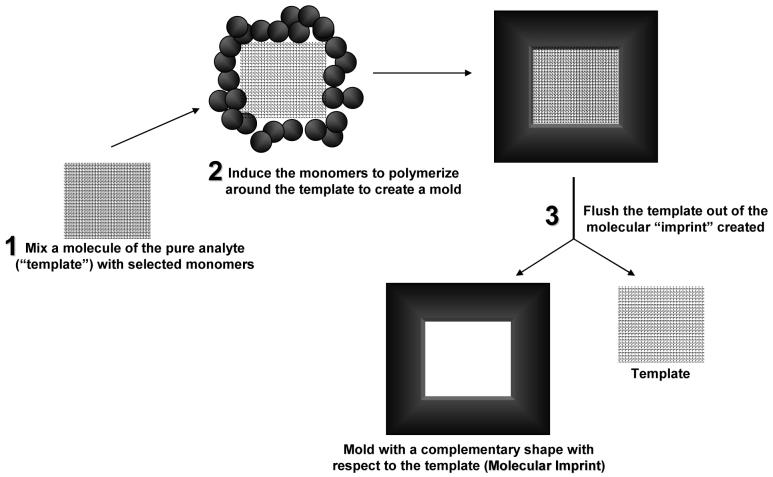

Further, multiblock copolymers based on Pluronic, that combine amphiphilic, thermo–responsive Pluronic triblocks, with associative blocks responsive to other stimuli have also been researched. The ability to tune the stimuli responsive properties of block copolymers by modifying the architecture of the individual blocks as well as by incorporating blocks supplementing the properties of the parent block(s), have made the evolution process of novel block copolymers increasingly exciting. Along these lines, Mallapragada et al. have conferred pH–sensitivity to Pluronic–based triblock copolymers by flanking on either side of the PF127 triblock, cationic moieties consisting of poly(diethylaminoethyl methacrylate) (PDEAM), a methyl ether of poly(ethylene glycol) with pendant amines [210]. At physiological temperature and pH values, aqueous solutions of this novel block copolymer coalesced to form phase–separated hydrogels, stemming from the increasing hydrophobicity of the cationic PDEAM blocks at higher pH values (pKa value of the pendant amines of PDEAM = 7.6). The continual increase in the size of the spherical micelles with further increase in pH finally resulted in macroscopic phase separation, above pH values of 11, with the formation of a turbid solution. This occurred due to the precipitation of the copolymer micelles with increasing hydrophobicity of the cationic PDEAM blocks. Further heating of the precipitate above 70 °C resulted in the spontaneous formation of an elastic hydrogel with only 25–35 wt % water. Interestingly, this novel material exhibited reversible pH sensitive phase transitions, while retaining the thermo–reversible property inherent of Pluronic–based gels. In effect, even the structures of the phase–separated hydrogels could be reversibly tuned from nanoscale to microscale dimensions, via stimuli sensitive alterations in micellar morphology [211]. In addition, when these block polymers were complexed with reporter genes, the resultant polyplexes appeared to be promising candidates for controlled, localized, non–viral gene delivery [212]. Deming et al. also fabricated novel diblock copolymers consisting of a PEG block conjugated with a polycationic block. The polycationic block comprised of polylysine or, alternately, an amine substituted methacrylate ester, and demonstrated similar pH sensitivity [202]. The effects of total cationic charge, type of cationic anchor for the PEG block, and the PEG molecular weight were investigated in relation to pH–sensitivity.