Abstract

During polymerization, dental composites develop residual stresses that may compromise the marginal integrity and properties of the restorative. The objective of this study was to use the thin-walled ring-slitting method to measure and compare residual stresses. The hypotheses to be tested were that composites would generate different levels of residual stress based on their specific formulations and slitting times. Rings made from composites (Z100, Herculite, and Heliomolar) were cut at different times (10 min, 1 and 24 hrs) after being light-cured, and stress was measured. Residual stress was higher at the earlier cutting times, except for Heliomolar (α < 0.05). For the 10-minute and one-hour cutting groups, stress followed this order: Z100 > Herculite > Heliomolar. Early slitting was better to capture residual stress, and the thin-walled rings showed higher values than thick-walled rings and were better able to discriminate residual stress in composites.

Keywords: residual stress, ring-slitting method, dental composite, elastic modulus

Introduction

Polymerization shrinkage of dental composite may generate stresses within the material that can be transferred to the bonded tooth interface (Versluis et al., 2004a,b) and can negatively affect the mechanical and physical properties of the composite (Whittle et al., 2000; Toschi et al., 2003; Choi et al., 2004). Inadequate adaptation to the cavity preparation, loss of marginal seal accompanied by leakage, post-operative sensitivity, secondary caries, and the production of internal defects such as microcracks—all have been suggested as possible effects attributable to contraction stresses (Davidson et al., 1984; Eick and Welch, 1986; Ferracane and Mitchem, 2003). Surface residual stress has been shown to be important in ceramic restorative materials, because flaws or cracks may nucleate in service, resulting in sudden fractures at stresses well below the yield stress (Alkhiary et al., 2003; Taskonak et al., 2005). The same may be applied to composites, which may also contain surface flaws from finishing or marginal debonding. Many studies have been performed to reduce or control the polymerization stress of dental composites (Kemp-Scholte and Davidson, 1990; Uno and Asmussen, 1991; Condon and Ferracane, 1998; Yoshikawa et al., 2001; Braga et al., 2003; Ferracane, 2005; Witzel et al., 2005).

After polymerization, stresses remain “locked” in the composite, and are considered as residual stresses (Lu, 1996). When external force is applied to the composite, the total force may surpass the limitations of the material itself, causing failure (Nairn, 2004). Therefore, a study of the production and effect of residual stress in dental composites may be helpful in improving our understanding of their clinical performance.

Several techniques—such as direct strain gauge application, layer removal, and ring-slitting—have been used for the determination of residual stress in thick-walled (Seif et al., 1997) and thin-walled plastic pipes (Seif and Short, 2002). Most recently, the ring-slitting technique was used for the measurement of the residual stress of dental composite (Park and Ferracane, 2005). In this study, the residual stress produced in 3 different composites ranged between 0.5 and 2.9 MPa when the ring was cut within 1 hr or 24 hrs after being cured. Though this technique may not be directly correlated with the clinical situation, it was useful for the evaluation and comparison of residual stresses in different dental composites. While the technique was capable of discriminating the materials under certain conditions, the stress magnitudes may have been underestimated, due to relaxation events occurring between the curing and slitting times, since most of the contraction stress in dental composite is generated during the first few minutes after light-activation (Ilie et al., 2005). Furthermore, the study was conducted on rings considered to be thick-walled (r/t = 5), rather than on the thin-walled type (r/t = 10) for which the technique was initially developed.

In this study, we aimed to improve the discriminating ability of the ring-slitting method for measuring residual stresses in dental composite by using thin-walled rings, and by attempting to capture more of the generated stresses by comparing the results obtained by cutting the rings at 10 min, 1 hr, and 24 hrs after being cured.

Materials & Methods

Materials

Two minifill-type hybrid composites, Z100 (3M ESPE, St. Paul, MN, USA) and Herculite (Kerr, Orange, CA, USA), and one microfill composite, Heliomolar (Ivoclar/Vivadent, Schaan, Liechtenstein), were evaluated. These composites were used in our previous study and have been shown to have different volumetric shrinkages and elastic moduli, and to produce various levels of contraction stress (Ferracane and Mitchem, 2003).

Sample Preparation

We used a brass mold consisting of 2 concentric cylinders with a rectangular groove at one end of the inner cylinder to produce the ring-shaped specimens (inner diameter = 16.50 mm, outer diameter = 17.83 mm, height = 0.9 mm, radius/thickness, r/t = 12.9) (Fig. 1). The composites were packed into the mold, and excess material was removed. The composite was light-activated within the mold for 80 sec (Triad II, Dentsply, Milford, DE, USA), removed with a surgical blade, and cured for 40 sec more from both the top and bottom (total, 160 sec of light-curing) to maximize cure and also minimize the effect of polymerization shrinkage after ring-cutting. Though it is difficult to provide an exact irradiance for the curing unit, an estimate of 100-110 mW/cm2 has been determined in a previous study in which the degrees of conversion for specimens cured in this unit were shown to be equivalent to those from specimens cured with a hand-held halogen light (Ferracane et al., 2003). Ten specimens were made for each material for each condition.

Figure 1.

Geometry of composite ring before (left) and after (right) slitting. a = inner radius of composite ring, b = outer radius of composite ring, r = radius measured at a point of the ring thickness, t = thickness of the ring, P1 and P2 = reference point for measurement of distance change, αo = angle between the 2 points before cutting, αf = angle between the 2 points after cutting, δo = distance between the 2 points before cutting, and δf = distance between the 2 points after cutting.

Two points were marked with a blade 3 (± 0.5) mm apart at the middle of the flat surface of the rings. The rings were stabilized between glass slides by means of double-sided adhesive tape while being slit with a low-speed diamond saw (0.5 mm thick; Isomet, Buehler, Lake Bluff, IL, USA) between the points. One group of rings was cut at 10 (± 1) min after final curing, one group was cut 1 (± 0.2) hr after final curing, and the last group was cut 24 (± 1) hrs after final curing.

Residual Stress Measurement

The magnified image of the 2 marked points was captured with a stereomicroscope (SMZ-10, Nikon, Tokyo, Japan) and digital camera (Coolpix 990, Nikon, Tokyo, Japan) before ring-cutting and 1 hr and 24 hrs after cutting. For the 10-minute and 24-hour cutting times, measurements were made at multiple time periods up to 24 hrs, for a better description of the time-dependence of the measurement. The change in distance between the points was measured with an image analyzer program (Scion Image Beta 4.02, Scion Co., Frederick, MA, USA). From the change of distance (average, 25-75 μm), the circumferential (σθ) residual stress was calculated by the following equations (Seif and Short, 2002):

| (1) |

| (2) |

| (3) |

| (4) |

where a = inner radius of composite ring, b = outer radius of composite ring, r = radius measured at a point of the ring thickness, Mr = residual moment, α = change in angle between the 2 points, E = elastic modulus of the composite (from our previous study: Z100 = 15.1 GPa, Herculite = 10.4 GPa, Heliomolar = 5.4 GPa), δo = distance between the 2 points before cutting, and δf = distance between the 2 points after cutting.

We used Eq. (5) to calculate the average circumferential residual stress, σave:

| (5) |

The other component of residual stress was not considered, because its value was minimal compared with the circumferential stress.

We analyzed the residual stress values with two-way ANOVA and Tukey's test (α < 0.05) for each measuring time, to compare the effects of cutting time and composite, and for each composite to compare the effects of measuring time and cutting time.

Results

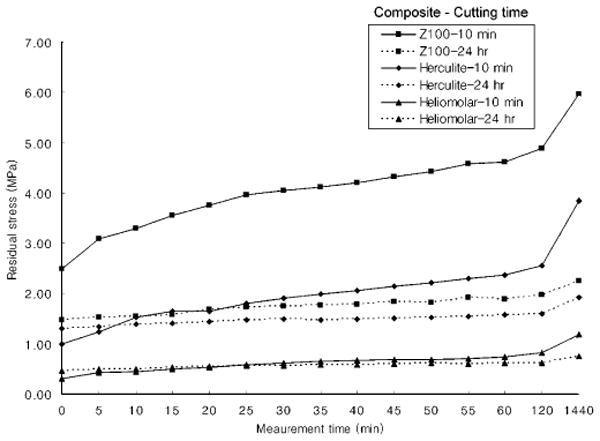

The residual stress measured at each time period for Z100 and Herculite was generally higher for the specimens cut 10 min after final light-curing compared with those cut after 24 hrs (Fig. 2).

Figure 2.

The change in the circumferential residual stress (σθave) for Z100, Herculite, and Heliomolar. The ring was cut at 10 min (solid line) and 24 hrs (dotted line) after final curing. Stress was measured at five-minute intervals until 60 min and then at 2 hrs and 24 hrs.

When the materials were compared at both measurement times, the residual stress for Z100 was higher than that for Herculite, which was higher than that for Heliomolar, except when the cut was made at 24 hrs, where there was no difference between Z100 and Herculite (Table). When the cutting times were compared at both measurement times, the stress for Z100 was higher at 10 min than at 1 hr, and the stress at 1 hr was higher than that at 24 hrs. For Herculite, the stress at 10 min was greater than that at the one-hour cutting time for both measuring times. In addition, the stress at the one-hour cutting time was greater than that for the 24-hour cutting time, but only when measured at 24 hrs. There was no difference in stress levels for Heliomolar for any of the cutting times at either measurement time.

Table.

Comparison of Circumferential Residual Stress (σθ, Mean ± SD in MPa) for the 3 Composites Measured 1 hr and 24 hrs after Cutting (n = 10)

| Cutting Time | ||||

|---|---|---|---|---|

| Measurement Time* = 1 hr | 10 min | 1 hr | 24 hrs | |

| Z100 | Stress | 4.61 ± 0.74a1 | 2.98 ± 0.52b1 | 1.89 ± 0.32c1 |

| Herculite | Stress | 2.36 ± 0.49a2 | 1.88 ± 0.22b2 | 1.58 ± 0.27b1 |

| Heliomolar | Stress | 0.73 ± 0.29a3 | 0.68 ± 0.17a3 | 0.62 ± 0.13a2 |

|

| ||||

| Measurement Time = 24 hrs | ||||

|

| ||||

| Z100 | Stress | 5.96 ± 0.54a1 | 3.94 ± 0.98b1 | 2.25 ± 0.48c1 |

| Herculite | Stress | 3.84 ± 0.64a2 | 2.82 ± 0.59b2 | 1.92 ± 0.34c1 |

| Heliomolar | Stress | 1.18 ± 0.31a3 | 1.02 ± 0.22a3 | 0.75 ± 0.13a2 |

For each measurement time, residual stress means in the same row with the same letter superscript were not significantly different, and residual stress means in the same column with the same number superscript were not significantly different.

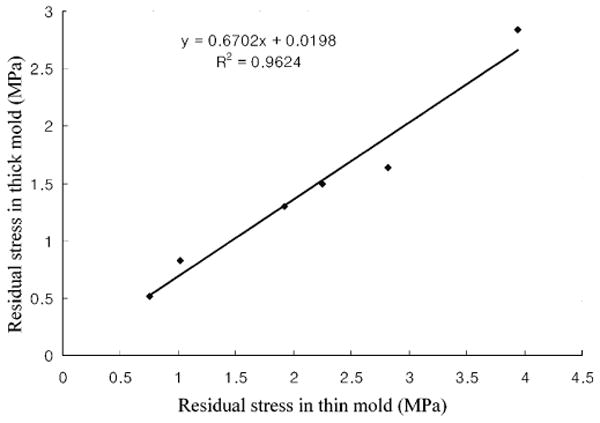

The results of the 24-hour measurement of the current thin-walled ring experiment are in good agreement with those of the previous thick-walled ring study (Fig. 3).

Figure 3.

Correlation of the circumferential residual stress between the thick- (n = 14) and thin-walled (n = 10) composite rings. The ring of each composite material (Z100, Herculite, Heliomolar) was cut at 1 hr and 24 hrs and measured 24 hrs later.

Discussion

Previously, we used the ring-slitting technique to measure the residual stresses of these same dental composites, but the specimens qualified as thick-walled (r/t = 5) rather than thin-walled rings (r/t = 10) (Park and Ferracane, 2005). Thick-walled rings were easier to produce and less delicate. However, because the experimental technique was originally designed for thin-walled rings, the applicability of the data was brought into question. The comparison showed that approximately 60% higher residual stress was measured with the thin-walled composite ring, but that there was an excellent correlation between the two sets of data. This suggests that the results from the thick-walled ring were reasonable in terms of providing good relative comparisons of materials or conditions, but that the thin-walled ring is capable of measuring higher residual stresses and is probably the more valid and more discriminating testing mode.

The factors affecting the measured residual stress in this study were the type of composite, the time after light-activation when ring-slitting occurred, and the measurement time. Because post-cure polymerization continues after irradiation, the residual stress of the ring might be affected by both the measurement and cutting times. For example, in the 10-minute-cutting group, the residual stress differences between the one-hour and the 24-hour measurements were 1.35 (Z100), 1.48 (Herculite), and 0.45 (Heliomolar). In the 24-hour-cutting group, the differences were lower, i.e., 0.36 (Z100), 0.34 (Herculite), and 0.13 (Heliomolar), likely because the post-curing was almost finished. It was not possible to eliminate the post-curing effect with the technique used in this experiment. But it is desirable to capture the maximum residual stresses generated during the composite polymerization to better distinguish the materials, and this was obtained when the measurement time was extended to 24 hrs. It is possible that waiting even longer to measure would result in slightly higher calculated stresses.

The importance of the measuring time becomes clearer when one calculates the ratio of stress measured at 1 hr and compares it with that measured at 24 hrs (1 hr/24 hrs measurement). For Herculite and Heliomolar, the ratio increased from 0.62 at 10 minutes' cutting to 0.67 at 1 hr and to 0.83 at 24 hrs. Similar results were seen for Z100, but the ratios for the 10-minute, one-hour and 24-hour cutting times were 0.77, 0.76, and 0.84, respectively. Analysis of the data suggests that the continued polymerization of the composite after light-activation leads to further deformation of the ring (Leung et al., 1983; Pilo and Cardash, 1992; Tarumi et al., 1999). The ring deformation was restricted when the ring was whole, but was allowed to occur once the ring was cut. Therefore, higher residual stresses for each cutting time will be calculated if the measurement period is delayed to capture this change.

As shown in the previous study, the residual stress produced in Z100 was generally greater than that produced in Herculite, which in turn was greater than that produced in Heliomolar (Park and Ferracane, 2005). This is likely due to differences in the curing rate and elastic moduli of these composites, both of which result from the differences in their filler and catalyst compositions.

Due to the continued polymerization shrinkage after light-activation, the effect of cutting time would be expected to be very important in this experiment. Analysis of the data showed higher residual stresses for Z100 and Herculite when the rings were cut at 10 min after light-activation, as compared with 1 hr or 24 hrs. This can be explained by the release of the residual stress through relaxation phenomena, likely within the polymer matrix and perhaps at the filler/matrix interface.

The composition of the material should affect stress reduction (e.g., the stress reduction of Z100 and Herculite). For the 10-minute- and one-hour-cutting groups, Z100 showed higher stress than Herculite. However, the two did not have significantly different residual stresses at the 24-hour cutting. This may perhaps be explained by the molecular make-up of their respective matrices. While both composites are based on Bis-GMA and TEGDMA monomers, there is a higher concentration of the more flexible and less rigid TEGDMA monomer in Z100. This may result in the higher initial contraction and residual stress, but ultimately produces a polymer network with greater capacity for relaxing stresses (Feilzer and Dauvillier, 2003). Another factor may be the shape of the filler and the filler/matrix interfacial adhesion. The filler shape of Herculite is irregular, and that of Z100 is mostly spherical (Kim et al., 2002). In general, bonding of the resin matrix to irregular fillers is expected to be better than that to spherical fillers, due to the greater surface area. Perhaps there is stronger filler/matrix bonding for Herculite due to the irregularly shaped fillers, which make it more difficult to release the residual stress between the filler and matrix.

In Heliomolar, the effect of cutting time was not significant. The residual stress of Heliomolar was 15-20% of Z100 for the 10-minute cutting time. Heliomolar is not based on Bis-GMA, and actually undergoes less stress-relieving than either Z100 or Herculite, possibly due to enhanced matrix rigidity. Heliomolar also incorporates pre-polymerized resin filler (PPRF) particles into its matrix. The difference between the thermal expansion coefficients of the filler and the matrix is another factor that can exert an effect on the residual stress of composites (Lee et al., 2000). During polymerization, heat from the curing unit and the polymerization reaction will increase the temperature of the material. As the material cools after being cured, residual stresses will be generated between the filler and matrix. It is possible that the bond between the resin matrix and the PPRF makes the material less likely to relax residual stresses compared with a composite containing individual glass fillers. It is also possible that Heliomolar may actually develop less residual stress during polymerization, because of its comparatively lower filler content and slower polymerization reaction, which allow it to relieve more stresses during their generation.

In summary, this experiment showed that ring-slitting is a useful means for measuring residual stress in dental composites. Because residual stress measurements are time-dependent, early ring-slitting allows less time for stress relaxation and better captures all of the initial residual stress produced in the constrained composite during curing. The thin ring is a more valid test vehicle than the thick ring, and results in higher residual stress values, but the results for the 2 specimen sizes correlate well. Finally, the measurement of the residual stress at 24 hrs allows for near-total polymerization shrinkage and results in the maximum discriminating ability for materials when coupled with early ring-slitting (i.e., 10 min).

Acknowledgments

This work was supported by NIH/NIDCR grant DE07079.

References

- Alkhiary YM, Morgano SM, Giordano RA. Effect of acid hydrolysis and mechanical polishing on surface residual stresses of low-fusing dental ceramics. J Prosthet Dent. 2003;90:133–142. doi: 10.1016/s0022-3913(03)00277-4. [DOI] [PubMed] [Google Scholar]

- Braga RR, Hilton TJ, Ferracane JL. Contraction stress of flowable composite materials and their efficacy as stress-relieving layers. J Am Dent Assoc. 2003;134:721–728. doi: 10.14219/jada.archive.2003.0258. [DOI] [PubMed] [Google Scholar]

- Choi KK, Ryu GJ, Choi SM, Lee MJ, Park SJ, Ferracane JL. Effects of cavity configuration on composite restoration. Oper Dent. 2004;29:462–469. [PubMed] [Google Scholar]

- Condon JR, Ferracane JL. Reduction of composite contraction stress through non-bonded microfiller particles. Dent Mater. 1998;14:256–260. doi: 10.1016/s0109-5641(98)00036-0. [DOI] [PubMed] [Google Scholar]

- Davidson CL, de Gee AJ, Feilzer A. The competition between the composite-dentin bond strength and the polymerization contraction stress. J Dent Res. 1984;63:1396–1399. doi: 10.1177/00220345840630121101. [DOI] [PubMed] [Google Scholar]

- Eick JD, Welch FH. Polymerization shrinkage of posterior composite resins and its possible influence on postoperative sensitivity. Quintessence Int. 1986;17:103–111. [PubMed] [Google Scholar]

- Feilzer AJ, Dauvillier BS. Effect of TEGDMA/BisGMA ratio on stress development and viscoelastic properties of experimental two-paste composites. J Dent Res. 2003;82:824–828. doi: 10.1177/154405910308201012. [DOI] [PubMed] [Google Scholar]

- Ferracane JL. Developing a more complete understanding of stresses produced in dental composites during polymerization. Dent Mater. 2005;21:36–42. doi: 10.1016/j.dental.2004.10.004. [DOI] [PubMed] [Google Scholar]

- Ferracane JL, Mitchem JC. Relationship between composite contraction stress and leakage in Class V cavities. Am J Dent. 2003;16:239–243. [PubMed] [Google Scholar]

- Ferracane JL, Ferracane LL, Musanje L. Effect of light activation method on flexural properties of dental composites. Am J Dent. 2003;16:318–322. [PubMed] [Google Scholar]

- Ilie N, Felten K, Trixner K, Hickel R, Kunzelmann KH. Shrinkage behavior of a resin-based composite irradiated with modern curing units. Dent Mater. 2005;21:483–489. doi: 10.1016/j.dental.2004.08.007. [DOI] [PubMed] [Google Scholar]

- Kemp-Scholte CK, Davidson CL. Complete marginal seal of Class V resin composite restorations effected by increased flexibility. J Dent Res. 1990;69:1240–1243. doi: 10.1177/00220345900690060301. [DOI] [PubMed] [Google Scholar]

- Kim KH, Ong JL, Okuno O. The effect of filler loading and morphology on the mechanical properties of contemporary composites. J Prosthet Dent. 2002;87:642–649. doi: 10.1067/mpr.2002.125179. [DOI] [PubMed] [Google Scholar]

- Lee SY, Chiang HC, Lin CT, Huang HM, Dong DR. Finite element analysis of thermo-debonding mechanism in dental composites. Biomaterials. 2000;21:1315–1326. doi: 10.1016/s0142-9612(99)00217-3. [DOI] [PubMed] [Google Scholar]

- Leung RL, Fan PL, Johnston WM. Post-irradiation polymerization of visible light-activated composite resin. J Dent Res. 1983;62(Spec Iss):363–365. [Google Scholar]

- Lu J. Introduction. In: Lu J, editor. Handbook of measurement of residual stress. Lilburn, GA: The Fairmont Press Inc.; 1996. pp. 1–4. [Google Scholar]

- Nairn JA. Residual stress effects in fracture of composites and adhesives. In: Moore DR, editor. The application of fracture mechanics to polymers, adhesives and composites. Kidlington: Elsevier; 2004. pp. 193–200. [Google Scholar]

- Park JW, Ferracane JL. Measuring the residual stress in dental composites using a ring slitting method. Dent Mater. 2005;21:882–889. doi: 10.1016/j.dental.2005.03.006. [DOI] [PubMed] [Google Scholar]

- Pilo R, Cardash HS. Post-irradiation polymerization of different anterior and posterior visible light-activated resin composites. Dent Mater. 1992;8:299–304. doi: 10.1016/0109-5641(92)90104-k. [DOI] [PubMed] [Google Scholar]

- Seif MA, Short SR. Determination of residual stresses in thin-walled composite cylinders. Exp Techniques. 2002;26:43–46. [Google Scholar]

- Seif MA, Kishawy HA, Hassan MA. Residual stresses in plastic pipes by laser speckle technique. J Test Eval. 1997;25:465–470. http://journalsip.astm.org/JOURNALS/TESTEVAL/PAGES/336.htm.

- Tarumi H, Imazato S, Ehara A, Kato S, Ebi N, Ebisu S. Post-irradiation polymerization of composites containing bis-GMA and TEGDMA. Dent Mater. 1999;15:238–242. doi: 10.1016/s0109-5641(99)00040-8. [DOI] [PubMed] [Google Scholar]

- Taskonak B, Mecholsky JJ, Jr, Anusavice KJ. Residual stresses in bilayer dental ceramics. Biomaterials. 2005;26:3235–3241. doi: 10.1016/j.biomaterials.2004.08.025. [DOI] [PubMed] [Google Scholar]

- Toschi F, Melandri C, Pinasco P, Roncari E, Guicciardi S, de Portu G. Influence of residual stresses on the wear behavior of alumina/alumina-zirconia laminated composites. J Am Ceram Soc. 2003;86:1547–1553. [Google Scholar]

- Uno S, Asmussen E. Marginal adaptation of a restorative resin polymerized at reduced rate. Scand J Dent Res. 1991;99:440–444. doi: 10.1111/j.1600-0722.1991.tb01052.x. [DOI] [PubMed] [Google Scholar]

- Versluis A, Tantbirojn D, Douglas WH. Distribution of transient properties during polymerization of a light-initiated restorative composite. Dent Mater. 2004a;20:543–553. doi: 10.1016/j.dental.2003.05.006. [DOI] [PubMed] [Google Scholar]

- Versluis A, Tantbirojn D, Pintado MR, DeLong R, Douglas WH. Residual shrinkage stress distributions in molars after composite restoration. Dent Mater. 2004b;20:554–564. doi: 10.1016/j.dental.2003.05.007. [DOI] [PubMed] [Google Scholar]

- Whittle AJ, Burford RP, Hoffman MJ. Influence of residual stress on the relationship between pipe pressure and C-ring tests. Polym Eng Sci. 2000;40:2311–2316. [Google Scholar]

- Witzel MF, Calheiros FC, Goncalves F, Kawano Y, Braga RR. Influence of photoactivation method on conversion, mechanical properties, degradation in ethanol and contraction stress of resin-based materials. J Dent. 2005;33:773–779. doi: 10.1016/j.jdent.2005.02.005. [DOI] [PubMed] [Google Scholar]

- Yoshikawa T, Burrow MF, Tagami J. The effects of bonding system and light curing method on reducing stress of different C-factor cavities. J Adhes Dent. 2001;3:177–183. [PubMed] [Google Scholar]