Abstract

We assessed the clinical and radiographic results of 40 porous-coated acetabular cups with an Acetabular Cup System polyethylene liner over a minimum 14-year follow-up. Femoral head penetration was estimated using a software package. Fifteen cups were revised, 11 due to polyethylene liner rupture. All cups but two were radiographically stable, and 11 hips showed acetabular osteolysis. The overall femoral head penetration rate in hips without liner fracture with reference to the early penetration point was 0.1188±0.070 mm per year. Polyethylene liner fractures were associated with higher early femoral head penetration (P<0.0001) and a vertical cup position (P=0.0016). The 14-year survival without cup revision for any reason was 63.9%, 71.8% with no ACS polyethylene liner fracture and 65.3% with no acetabular osteolysis. Most cups showed a good clinical outcome in general, but major Acetabular Cup System liner failure and osteolysis were frequent. Patients with the ACS cups still in place should be monitored closely.

Résumé

Nous présentons les résultats de 40 cupules acétabulaires à revêtement poreux avec un noyau en polyéthylène « Acetabular Cup System » (ACS), à un recul minimum de 14 ans. La pénétration de la tête fémorale était estimée par un logiciel particulier. Quinze cupules étaient révisées dont 11 à cause d’une rupture du polyéthylène. Toutes les cupules sauf 2 étaient radiologiquement stable et 11 hanches montraient une ostéolyse acétabulaire. La vitesse de pénétration de la tête dans les cupules sans rupture était de 0,1188±0,070 mm par an. Les ruptures du polyéthylène étaient en rapport avec une importante pénétration précoce (P<0,0001) et une position verticale de la cupule (P=0,0016). La survie sans révision à 14 ans était de 63,9%, sans rupture du PE de 71,8% et sans ostéolyse de 65,3%. La plupart des cupules avaient une bonne évolution clinique mais la faillite du noyau en polyéthylène et l’ostéolyse étaient fréquentes. Les patients porteurs de cupule ACS doivent être suivis minutieusement.

Introduction

Most hemispheric porous-coated titanium cups show radiographically stable fixation, but the most frequent causes of total hip prosthesis failure are polyethylene wear and osteolysis [13].

The early cementless modular cups offered the possibility of exchanging the inserts without disturbing the metal shell. However, when the locking mechanism is inadequate, movement between the liner and the metal shell can also generate debris and favour polyethylene failure, especially in thin liners [1], and can even produce a catastrophic failure of the acetabular component [3, 4, 12]. The design features of the Acetabular Cup System (ACS) liner, which may have increased the risk of this complication, included the thin polyethylene rim and incongruity between the liner and the metal shell [3, 12]. The early acetabular cups have all now been withdrawn from the market and redesigned by the manufacturers. As catastrophic failures of the acetabular components with an ACS liner have been well documented after short-term follow-up [3, 4, 12], no long-term results of more than 14 years follow-up for the uncomplicated cups have been reported. This led us to assess a series of acetabular cups with an ACS polyethylene liner after 14–16 years of follow-up.

Patients and methods

Between November 1988 and April 1991, 43 consecutive cementless acetabular components with an ACS (Acetabular Cup System, DePuy, Warsaw, IN) liner were implanted by the senior author (EGC). (Three patients were lost during the follow-up period). The study group, therefore, consisted of 40 hips in 37 patients (25 women) followed for a minimum of 14 years or until cup revision or liner exchange. Their mean age at the time of the operation was 57.5±9.6 years. The activity level according to Devane et al. [8] was grade 2 in five hips, grade 3 in nine, grade 4 in 15 and grade 5 in 11.

The primary diagnosis was primary osteoarthrosis in 23 hips, avascular necrosis in 8, rheumatoid arthritis in 4, arthritis secondary to developmental dysplasia in 2, arthritis secondary to Legg-Calvé-Perthes disease in 2 and acetabular protrusion in 1. The mean average follow-up period was 11.5±4.1 (range, 3–16.5) years for the whole series, and 14.0±1.4 (range, 12–16.5) for hips without liner fracture.

The ACS polyethylene liner is cylindrical and thicker at the dome than at the cup face, with thinner polyethylene at the rim of the liner and a thickness ranging from 4.7 to 6.9 mm. ACS polyethylene liners were associated with two hemispherical cementless porous-coated acetabular cups made of titanium: the Tri-Lock Plus (DePuy, Warsaw, IN), which used two or three screws (16 cups), or the Profile (DePuy, Warsaw, IN), which used two antirotatory pegs to improve bone fixation (24 hips). The porous coating (Porocoat, DePuy, Warsaw, IN) of both cups is composed of pure titanium beads sintered to a solid substrate with pore size ranging from 200 to 300 μm. The diameter of the femoral heads was 28 mm in 29 hips and 32 mm in 11 hips. All the polyethylene liners were the same and were sterilized by gamma irradiation in air. All cups with an ACS liner were paired with a Profile femoral stem (DePuy, Warsaw, IN).

All operations were performed using a posterolateral approach. The acetabular cup was implanted after underreaming the acetabulum by 2 mm. Median acetabular cup size was 52 mm (range, 48 to 64 mm).

All patients were followed prospectively. Clinical results were assessed using the Merle D’Aubigné-Postel scale [20]. Standard anteroposterior radiographs of the pelvis and lateral radiographs of the hip were made immediately after the operation, at 6 weeks, at 3, 6 and 12 months, and annually thereafter for at least 14 years following the same protocol. The patient was placed in a supine position. The X-ray tube was positioned over the symphysis pubis 1 m from and perpendicular to the table, with symmetrical obturator foramena, and visible lesser trochanter and iliac crest [17]. To reduce interobserver error, measurements were made by a single author (EGR), who had not been involved in the surgery.

Cup position was assessed according to Johnston et al. [15]. The distribution of any radiolucent lines or osteolysis was recorded in the zones described by DeLee and Charnley [6] for the acetabulum and in the zones described by Gruen et al. [11] for the femur. A cup was considered to have migrated according to the Massin et al. criteria [19]. Femoral osteolysis was defined and classified according to Goetz et al. [10].

Penetration of the prosthetic head into the polyethylene liner was measured retrospectively by a computer system with software specially designed to measure femoral head penetration into polyethylene (AutoCAD Release 14, AutoDesk Inc, Sausalito, Calif.). Anteroposterior pelvic radiographs were digitised using a scanner (Epson Expression 1680, Seiko Epson Corp., Nagano, Japan). Supine radiographs were aligned on the digitiser tablet so that the interteardrop line was parallel to the edge of the tablet. The operator then digitised three points around the circumferences of the femoral head and the acetabular shell. The computer software fitted circles to these points and determined their centres. The distance between these centers was used to calculate the amount of penetration of the femoral head into the polyethylene liner in the plane of the radiograph [18, 23]. The femoral head size was used as the internal reference. The amount of penetration on the postoperative radiograph at 6 weeks was designated as the “zero” position and was the reference for subsequent measurements [23]. Although we have not validated the method used in the current series ourselves, digitised methods have previously been validated [14, 18, 23], and good radiographic quality is necessary to obtain accurate measurements [14, 25]. Sychterz et al. [25] reported a mean error ranging around 0.14±0.09 mm when measuring optimal radiographs, and 0.23±0.22 mm in suboptimal radiographs with a similar digitised measurement method. Despite all the radiographs being taken according to the same protocol, they were still screened for quality before inclusion in the analysis of this study. As a result of this, 128 of the 810 radiographs (15.8%) were excluded from the evaluation due to the poor radiographic quality of their images. Head penetration into the polyethylene liner was determined at annual intervals.

Statistical analysis

Kaplan-Meier survivorship analysis [16] with 95% confidence intervals was used to estimate the cumulative probability of not having cup revision for any cause, fracture of the ACS polyethylene liner, acetabular osteolysis or femoral osteolysis.

Qualitative data were compared with the use of the chi-square test or Fisher’s exact test, and quantitative data were compared with using of the Student’s test, the Mann-Whitney test, analysis of variance or the Kruskal-Wallis test, depending on the distribution of the data. Cox multivariate regression analysis was used to assess the influence of various factors on survival time until some event. The level of significance was P<0.05.

Results

Postoperative complications included early dislocation in two hips; all of these hips were treated successfully closed and were included in the follow-up study. To date, there have been no infections in any of the hips.

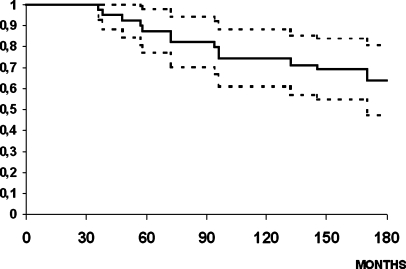

There were 15 cup revisions: 11 hips had polyethylene liner fracture (8 ACS-Tri-Lock Plus cups and three ACS-Profile cups); 1 hip in a patient with rheumatoid arthritis showed cup loosening and pelvic discontinuity; 1 cup had stable fixation, but extensive acetabular osteolysis associated with a worn liner. All of the hips had level 4 (or less) pain in the groin and buttock before revision. There was no thigh pain in any hip. At revision surgery all cups with a liner fracture were well-fixed despite metallosis. Another two cups presented with late dislocation associated with severe wear of the 28-mm liner and required liner exchange. The Kaplan-Meier [16] cumulative probability of not having a cup revision for any reason (exchange of the cup or the polyethylene liner) was 63.9% at 14 years (95% confidence interval, 47.2%–80.6%) (Fig. 1).

Fig. 1.

Kaplan-Meier cumulative probability of not having a revision of the metal cup shell for any cause in the patients included in the follow-up study. The upper and lower curves represent the 95% confidence limits

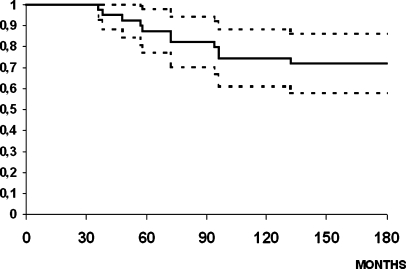

The average interval from operation to the appearance of liner fracture was 71.5±29.6 months. The cumulative probability of not having fracture of the ACS polyethylene liner at 14 years was 71.8 (57.7%-86.1%) for the whole ACS liner group, 46.9% (20.6% to 73.2) for the ACS-Tri-Lock Plus cups and 86.1% (71.4–100%) for the ACS-Profile cups (Mantel-Cox test, P=0.0002) (Fig. 2).

Fig. 2.

Kaplan-Meier cumulative probability of not having a polyethylene liner fracture in the patients included in the follow-up study. The upper and lower curves represent the 95% confidence limits

Of the 40 hips that were included in the follow-up study, 3 had transitory level 4 pain in the thigh during the first 2 years after operation. The mean preoperative pain rating was 3.2 and had improved to 5.7 at the latest follow-up examination. The walking function rating increased from 3.0 to 5.6. The sum for the arc of motion improved from 3.0 (61° to 100°) to 5.1 (161° to 210°).

Except for the two cups in the same rheumatoid arthritis patient, all cups had stable fixation. Radiographic evaluation of the polyethylene liner fractures revealed a well-fixed cup and an eccentrically placed femoral head within the acetabular component. All femoral stems also had stable fixation.

There were 22 neutral cups (55%), 12 vertical cups (30%) and 6 horizontal cups (15%). The mean acetabular angle was 47.9±9.4° for the cups with an ACS polyethylene liner (52.1±10.7° for the Tri-Lock Plus and 45.0±7.3 for Profile cups) (Kruskal-Wallis test, P=0.032), the mean height of the center of the hip was 23.7±6.9 mm and the mean horizontal distance of the cup was 33.3±5.3 mm.

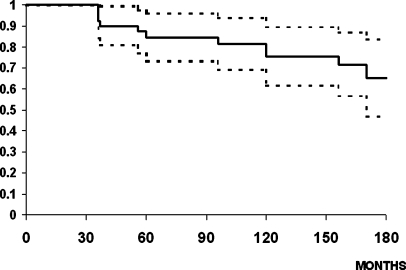

There were 11 hips with acetabular osteolysis. Two hips had osteolysis in only one DeLee and Charnley zone (no PE liner fractures), five in two zones (four PE liner fractures) and four in the three zones (two PE liner fractures). Osteolysis was found in six hips with a liner fracture and was a related risk factor (P=0.042, Fisher’s test), with stable fixation in three hips, and with cup loosening in both hips of the same patient. The cumulative probability of not having acetabular osteolysis at 14 years was 65.3% (46.9–83.6%) (Fig. 3).

Fig. 3.

Kaplan-Meier cumulative probability of not having acetabular osteolysis in the patients included in the follow-up study. The upper and lower curves represent the 95% confidence limits

There were seven hips with proximal femoral osteolysis. Osteolysis was found in five hips with a liner fracture, while two patients with a good clinical result at the end of the follow-up evaluation also showed mild osteolysis in their hips (P=0.0108, Fisher’s test). The cumulative probability of not having femoral osteolysis at 14 years was 81.3% (68.8 to 93.8%).

Polyethylene liner fractures were associated with a higher zero position (P<0.0001), the use of the Tri-Lock Plus cup (P=0.0128) and a vertical cup position (P=0.0016). Although a liner fractures were more frequently associated with smaller outer cup diameter and a 32-mm femoral head diameter, no significant differences could be found between the two groups with the number of hips available. The risk of the appearance of liner fracture (Cox multivariate regression analysis) increased with a vertical cup position (hazard risk =1.13, 95% confidence interval, 1.05–1.21; P=0.001) and a higher zero position (hazard risk =18.8, 4.24–83.3; P<0.001). Information on associated risk factors can be found in Table 1.

Table 1.

Risk factors related with the ACS polyethylene liner fracture

| No fracture | Fracture | Total | P values | |

|---|---|---|---|---|

| N=29 | N=11 | N=40 | ||

| Gender (male/female) (no. of hips) | 11/18 | 4/7 | 15/25 | P=0.1194 |

| Mean age (years) | 57.7±10.09 | 54.7±8.28 | 57.5±9.67 | P=0.7195 |

| Mean weight (kgs) | 70.8±11.72 | 71.0±13.01 | 70.8±11.95 | P=0.6974 |

| Mean activity level (7) | 3.8+0.77 | 4.1+0.79 | 2.9+0.78 | P=0.8598 |

| Mean acetabular cup size | 53.2±3.70 | 51.3±4.29 | 52.6±3.93 | P=0.1303 |

| Median acetabular cup size (range) | 53 (48–64) | 50 (48–62) | 52 (48–64) | |

| Mean femoral head diameter (mm) | 28.1±2.63 | 30.0±2.08 | 28.6±2.61 | P=0.1438 |

| Mean acetabular angle (degrees) | 45.3±7.06 | 53.8±11.61 | 47.9±9.39 | P=0.0016 |

| Median acetabular angle (range) | 45 (30–60) | 57 (40–70) | 45 (30–70) | |

| Mean horizontal distance (mm) | 33.7±5.36 | 32.4±5.35 | 33.3±5.32 | P=0.4535 |

| Vertical distance (mm) | 23.6±7.60 | 24.2±5.27 | 23.8±6.93 | P=0.8417 |

| ACS cup | ||||

| Tri-Lock Plus | 8 | 8 | 16 | P=0.0128 |

| Profile | 21 | 3 | 24 | |

| Mean zero position (mm) | 0.234±0.15 | 0.602±0.57 | 0.335±0.36 | P=0.009 |

| Acetabular osteolysis | 5 | 6 | 11 | P=0.042 |

| Femoral osteolysis | 2 | 5 | 7 | P=0.0108 |

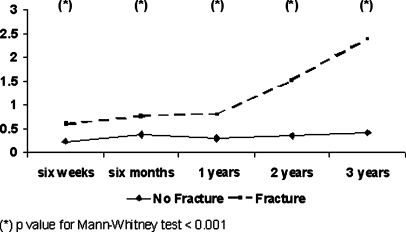

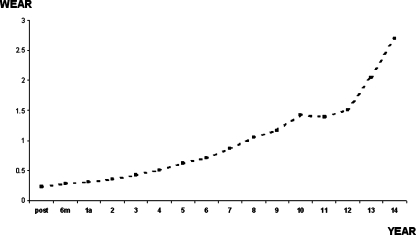

The zero position was 0.6018±0.575 mm in patients with an ACS liner fracture and 0.2338±0.158 mm in patients with an unfractured ACS liner (Mann-Whitney test, P=0.009). An analysis of the mean femoral head penetration until the appearance of the first liner fracture (3 years) shows that femoral head penetration was significantly higher in the group with eventual liner fracture from as early as 6 weeks post-implant. This difference in the mean femoral head penetration became extremely marked after 1 year (P<0.0001). The mean penetration rate was higher during the first 3 years after the operation in all cups with eventual liner fracture, and the first case of liner fracture appeared (P<0.0001) (Fig. 4). The overall penetration rate referring to zero position was 0.1188±0.070 mm per year for the hips with an unfractured ACS liner, and their mean linear femoral head penetration at the end of the follow-up evaluation was 1.13±0.44 mm (Fig. 5).

Fig. 4.

Graph showing the mean femoral head penetration during the 1st 3 years after the operation in cups with and without liner fracture before the 1st event was diagnosed (3 years)

Fig. 5.

Graph showing the mean amount of femoral head penetration over time in cups without polyethylene liner fracture

Discussion

Although radiographically stable fixation was found in most cups and in all femoral stems, polyethylene wear and osteolysis were the most frequent causes of total hip prosthesis failure [13].

Manual radiographic methods for measuring polyethylene femoral head penetration are associated with substantial errors [7, 18]. Computer-assisted radiographic techniques have improved the accuracy of femoral head penetration measurements [18, 24]. These methods make it possible to determine polyethylene femoral head penetration, as long as the radiographic image clearly defines the respective borders of the cup and the femoral head. Although we have not personally validated the digitised method used in the current series, Sychterz et al. [25] reported a mean error ranging around 0.14±0.09 mm when measuring optimal radiographs, and 0.23±0.22 mm in suboptimal radiographs using a similar digitised measurement method. Different authors [9, 14, 24] have suggested that the two-dimensional measurements are sufficient to determine the major wear vector.

As in other series [3, 4, 12], ACS polyethylene liner failure and fracture were frequent in the current study, and they were associated with good cup bone fixation. Hamadouche et al. [12] reported three catastrophic failures of the polyethylene liner in a series of 50 hips using a Trilock cup with a mean follow-up of 8.7 years. In all three hips, the minimum thickness of the liner was less than 5 mm. In our series, the long-term result after 10 years in the cases without liner fracture was good, and only two cups in the rheumatoid arthritis patient became loosened. In the other two cases, with a high wear rate and late dislocation, the liners were exchanged with a good clinical result. In hips without liner failure, the liner femoral head penetration rate was similar to that reported with other designs [5, 26].

The main predisposing factor for ACS polyethylene liner fracture appears to be a thin polyethylene rim width of less than 5 mm [3, 4, 12]. In our series, polyethylene liner fractures were associated with a higher zero position and a vertical cup position. The mean femoral head penetration until the appearance of the first liner fracture (3 years) was analysed. Femoral head penetration was found to be significantly higher in the group in which the liner eventually fractured from as early as 6 weeks and was particularly marked after 1 year. Given the geometry and lip of the liner, when the liner did not sit properly within the metal shell, there was a small gap between the bottom of the liner and the shell [4]. This gap would increase stress upon and eventually deform the liner and lead to the fractures, which have been reported frequently with this design [4]. A vertical position of the cup was more frequent with the ACS-Tri-Lock Plus cups. Accelerated femoral head penetration in cups with an acetabular angle greater than 50° has been reported in cementless prostheses [3]. Vertical cups tend to be less well-covered by the polyethylene liner; the rim of the liner is closer to the line of action of the resultant force, and this may increase the resulting polyethylene stress [3, 4]. Patil et al. [22], using finite-element analysis, predicted increased peak contact stressess with increased acetabular angles.

Although liner fracture was more frequent in patients with a 32-mm femoral head diameter than in patients with a 28-mm femoral head diameter, with the number of available hips, femoral head size was not a risk factor for liner failure in our study. Berry et al. [3] reported only one hip with a 32-mm femoral head diameter in a series of seven ACS polyethylene liner fractures. The 32-mm femoral head is known to give worse results than 28-mm femoral heads, and is usually considered to be a risk factor for liner fracture [4]. Different series [2, 7] have reported that polyethylene failure is not directly related to head size, and they have related failure to polyethylene thickness.

Osteolysis was more frequent in hips with a liner fracture. Orishimo et al. [21] have quantified the relationship between the prevalence of osteolysis and polyethylene femoral head penetration, and recommended more frequent follow-up visits once a patient’s femoral head penetration rate exceeds 0.2 mm per year in order to better assess osteolysis.

We can conclude that, although major ACS liner failure and osteolysis are frequent and are related to a greater femoral head penetration at 6 weeks and a vertical cup position, most cementless porous hemispheric cups show stable fixation, and more than two-thirds of the hips have a good clinical result 14 years after surgery with reasonable polyethylene linear wear figures. Although the acetabular cups have now all been withdrawn from the market by the manufacturers and have been redesigned, these patients should be carefully followed up to enable an easy exchange of the worn liner, if it becomes necessary, with a minimum delay in order to avoid the negative effects of particulate debris formation and osteolysis.

References

- 1.Astion DJ, Saluan P, Stulberg BN, Rimnac CM, Li S (1996) The porous-coated anatomic total hip prosthesis: Failure of the metal-backed acetabular component. J Bone Joint Surg Am 78:755–766 [DOI] [PubMed]

- 2.Bartel DL, Bicknell VL, Wright TM (1986) The effect of conformity, thickness and material on stresses in ultra-high molecular weight components for total joint replacement. J Bone Joint Surg Am 68:1041–1051 [PubMed]

- 3.Berry DJ, Barnes CL, Scott RD, Cabanela ME, Poss R (1994) Catastrophic failure of the polyethyhlene liner of uncemented acetabular components. J Bone Joint Surg Br 76:575–578 [PubMed]

- 4.Bono JV, Sanford L, Toussaint JT (1994) Severe polyethylene wear in total hip arthroplasty. Observations from retrieved AML Plus hip implants with an ACS polyethylene liner. J Arthroplasty 9:119–125 [DOI] [PubMed]

- 5.Cruz-Pardos A, García-Cimbrelo E (2001) The Harris-Galante total hip arthroplasty. A minimum 8-year follow-up. J Arthroplasty 16:586–597 [DOI] [PubMed]

- 6.DeLee JG, Charnley J (1976) Radiological demarcation of cemented sockets in total hip replacement. Clin Orthop 121:20–32 [PubMed]

- 7.Devane PA, Bourne RB, Rorabeck CH, Hardie RM, Horne JG (1995) Measurement of polyethylene wear in metal backed cups: Three dimensional technique. Clin Orthop 319:303–316 [PubMed]

- 8.Devane PA, Horne JG, Martin K, Coldham G, Krause B (1997) Three-dimensional polyethylene wear of a press-fit titanium prosthesis. Factors influencing generation of polyethylene debris. J Arthroplasty 12:256–266 [DOI] [PubMed]

- 9.Dowd JE, Sychterz CJ, Young AM, Engh CA (2000) Characterization of long-term femoral-head penetration rates. Association with and prediction of osteolysis. J Bone Joint Surg Am 82:1102–1107 [DOI] [PubMed]

- 10.Goetz DD, Smith JJ, Harris WH (1994) The prevalence of femoral osteolysis associated with components inserted with or without cement in total hip replacements. J Bone Joint Surg Am 76:1121–1128 [DOI] [PubMed]

- 11.Gruen TA, McNeice GM, Amstutz HC (1979) “Modes of failure” of cemented stem-type femoral components. Clin Orthop 171:17–27 [PubMed]

- 12.Hamadouche M, Witvoet J, Porcher R, Meunier A, Sedel L, Nizard R (2001) Hydroxyapatite-coated versus grit blasted femoral stems. A prospective, randomised study using EBRA-FCA. J Bone Joint Surg Br 83:979–987 [DOI] [PubMed]

- 13.Harris WH (1995) The problem is osteolysis. Clin Orthop 311:46–53 [PubMed]

- 14.Hui AJ, McCalden RW, Martell JM, MacDonald SJ, Bourne RB, Rorabeck CH (2003) Validation of two- and three-dimensional radiographic techniques for measuring polyethylene wear after total hip arthroplasty. J Bone Joint Surg Am 85:505–511 [DOI] [PubMed]

- 15.Johnston RC, Fitzgerald RH, Harris WH, Poss R, Müller ME, Sledge CB (1990) Clinical and radiographic evaluation of total hip arthroplasty. A standard system of terminology for reporting results. J Bone Joint Surg Am 72:161–168 [PubMed]

- 16.Kaplan EL, Meier P (1958) Nonparametric estimation from incomplete observations. J Am Statistc Assn 53:457–481 [DOI]

- 17.Manning DW, Chiang PP, Martell JM, Galante JO, Harris WH (2005) In vivo comparative wear study of traditional and highly cross-linked polyethylene in total hip arthroplasty. J Arthroplasty 20:880–886 [DOI] [PubMed]

- 18.Martell JM, Berdia S (1997) Determination of polyethylene wear in total hip replacements with use of digital radiographs. J Bone Joint Surg Am 79:1635–1641 [DOI] [PubMed]

- 19.Massin P, Schmidt L, Engh CA (1989) Evaluation of cementless acetabular component migration. An experimental study. J Arthroplasty 4:245–251 [DOI] [PubMed]

- 20.Merle D’Aubigné R, Postel M (1954) Functional results of hip arthroplasty with acrylic prosthesis. J Bone Joint Surg Am 36:451–475 [PubMed]

- 21.Orishimo KF, Claus AM, Sychterz CJ, Engh CA (2003) Relationship between polyethylene wear and osteolysis in hips with a second-generation porous-costed cementless cup after seven years of follow-up. J Bone Joint Surg Am 85:1095–1099 [DOI] [PubMed]

- 22.Patil S, Bergula A, Chen PC, Colwell CW Jr, D’Lima DD (2003) Polyethylene wear acetabular component orientation. J Bone Joint Surg Am 85(Suppl 4):56–63 [DOI] [PubMed]

- 23.Sychterz CJ, Engh CA Jr, Shah N, Engh CA Sr (1997). Radiographic evaluation of penetration by the femoral head into the polyethylene liner over time. J Bone Joint Surg Am 79A:1040–1046 [DOI] [PubMed]

- 24.Sychterz CJ, Yang AM, McAuley JP, Engh CA (1999) Two-dimensional versus three-dimensional radiographic measurements of polyethylene wear. Clin Orthop 365:117–123 [DOI] [PubMed]

- 25.Sychterz CJ, Young AM, Engh CA (2001) Effect of radiographic quality on computer-assisted head penetration measurements. Clin Orthop 386:150–158 [DOI] [PubMed]

- 26.Thanner J, Kärrholm J, Herberts P, Malchau H (1999) Poor outcome of the PCA and Harris-Galante hip prostheses. Randomized study of 171 arthroplasties with 9-year follow-up. Acta Orthop Scand 70:155–162 [DOI] [PubMed]