Sample-exchange robots with a double-tongs system that could exchange samples within 10 s have been developed.

Keywords: sample-exchange robot, protein crystallography, automated system, diffraction experiment

Abstract

Sample-exchange robots that can exchange cryo-pins bearing protein crystals out of experimental hutches according to user instructions have been developed. The robots were designed based on the SAM (Stanford Synchrotron Research Laboratory automated mounting) system. In order to reduce the time required for the sample exchange, the single tongs of the SAM system were modified and a double-tongs system that can hold two cryo-pins at the same time was developed. Robots with double tongs can move to the goniometer head holding the next cryo-pin with one set of tongs, dismount the experimented cryo-pin with the other set, and then mount the next pin onto the goniometer head without leaving the diffractometer area. Two different types of tongs have been installed: single tongs at beamlines BL-5A and AR-NW12A, and a double-tongs system at beamline BL-17A of the Photon Factory. The same graphical user interface software for operation of the sample-exchange robots is used at all beamlines, however, so that users do not need to consider differences between the systems. In a trial, the robot with double tongs could exchange samples within 10 s.

1. Introduction

Protein crystallography involves many steps: overexpression, purification, crystallization, data collection, data processing and structure determination. In order to facilitate high-throughput structural analyses of a large number of proteins, we are pursuing several projects aimed towards a fully automated system at the Structural Biology Research Center of the Photon Factory. For example, we have already developed a high-throughput protein crystallization system (Hiraki et al., 2006 ▶), used this system to produce a large number of protein crystals, and determined their structures. We are also developing an automated crystal harvesting system consisting of a micromanipulator and a six-axis industrial robot for holding cryo-loops (Ohara et al., 2004 ▶). In preliminary trials, we have succeeded in using this system to harvest protein crystals from crystallization drops.

X-ray protein crystallographic experiments at synchrotron beamlines are often carried out with loop-mounted crystals under cryogenic conditions. The advantages in insertion devices, beamline optics and fast-readout CCD detectors have substantially reduced the time required for X-ray experiments, and consequently a major proportion of beam time is spent on sample manipulation in experimental hutches. Before each diffraction experiment, users need to enter the hutch, dismount a previous sample, mount a cryo-pin with a new crystal, and center it on the rotation axis of the goniometer. Sample-exchange robots can substantially reduce the time required for these procedures. Therefore, various automated sample-exchange systems have been developed, and are currently in use at many synchrotron facilities (Cohen et al., 2002 ▶; Cipriani et al., 2006 ▶; Karain et al., 2002 ▶; Obana et al., 2004 ▶; Pohl et al., 2004 ▶; Snell et al., 2004 ▶; Ueno et al., 2004 ▶). Several robots are commercially available, such as ACTOR from Rigaku, easymount from Marresearch GmbH, and BRUNO from Bruker AXS.

In this paper we describe sample-exchange robots installed in our beamlines and the double-tongs system that we have developed for high-throughput operation.

2. Sample-exchange robots

We considered the following three factors for choosing sample-exchange robots at our insertion-device beamlines BL-5A, BL-17A (Igarashi et al., 2007 ▶) and AR-NW12A. First, although special screw pins adopted from the SPACE (SPring-8 precise automatic cryo-sample exchanger; Ueno et al., 2004 ▶) improve the reproducibility of the sample position, our exchange robots should be able to handle widely used and/or commercially available cryo-pins such as the CrystalCap Copper Magnetic manufactured by Hampton Research Co. Second, the capacity of the robots must be large enough for continuous data collection from several hundred samples. This is a particularly important factor for fragment-based drug design. Third, the devices should leave ample space for manual mounting of cryo-pins by the beamline users, for times when the robots are unavailable or their use is not desired.

The sample-exchange robots developed by ESRF (Cipriani et al., 2006 ▶), DORIS (Karain et al., 2002 ▶), ALS (Snell et al., 2004 ▶) and SPring-8 do not provide sufficient space for manipulations by beamline users because these robots stay near the goniometer head. Even if five- or six-axis robots are adopted by ESRF (Ohana et al., 2003 ▶), EMBL (Pohl et al., 2004 ▶), Rigaku and Bruker AXS, manual mounting still might not be easy. The SAM (Stanford Synchrotron Research Laboratory automated mounting) system (Cohen et al., 2002 ▶) developed by the macromolecular crystallography group at the SSRL (Stanford Synchrotron Radiation Laboratory) fulfils these requirements, and we decided to implement their system (with generous help from the SSRL group) in the structural biology beamlines at the Photon Factory. The SAM system can handle the CrystalCap Copper Magnetic cryo-pins, can mount 288 cryo-pins sequentially, and has a wide working space that leaves ample area around the goniometer head.

2.1. System overview

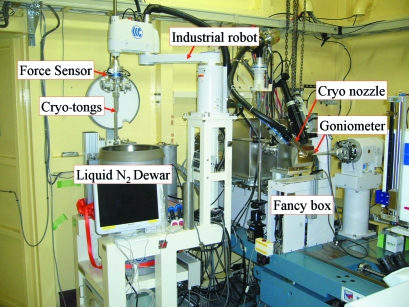

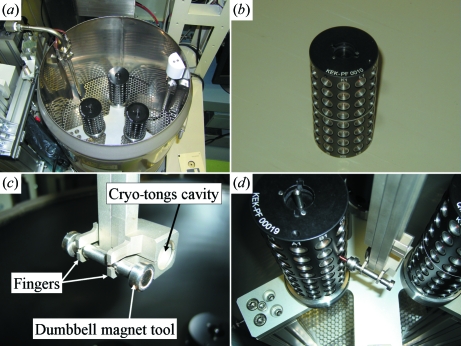

For sample manipulation, we selected an industrial four-axis robot of the same series as the SAM system; the longer arm of this robot allows sufficient space for manual mounting. Fig. 1 ▶ gives an overview of the robot installed at BL-17A. This industrial robot is fixed on the top of a robot base that has been redesigned to fit our beamlines. Ninety-six cryo-pins containing protein crystals are stored in each sample cassette (Fig. 2b ▶), developed by the SSRL group, and three cassettes can be placed in each liquid-nitrogen Dewar (Fig. 2a ▶). Cryo-tongs hang down from the robot arm and are controlled by a pneumatic actuator. Fig. 2(c) ▶ shows the cryo-tongs at the ends of the rods, which grasp a dumbbell magnet tool with fingers. In this paper, cryo-tongs similar to that of the SAM system are referred to as ‘single tongs’.

Figure 1.

Sample-exchange robot installed at the micro-focus beamline BL-17A.

Figure 2.

(a) Liquid-nitrogen Dewar of the robot installed at BL-5A. Three cassettes can be set in the Dewar. The designs of the components inside the Dewar are almost the same as the SAM system. (b) Sample cassette developed by the SSRL group. (c) Cryo-tongs with the dumbbell magnet tool. (d) Placing the cryo-pin to the sample cassette using the weak end of the dumbbell magnet tool.

To detect collision of the robot arm, a six-axis force sensor is inserted between the robot arm and the pneumatic actuator. In addition, this force sensor is used to calibrate the position and direction of the components inside the Dewar, i.e. the cassettes, the dumbbell magnet tool and dumbbell cradle, under the liquid nitrogen.

Because all components (robot, robot controller, liquid-nitrogen Dewar, dryer unit and electrical devices) are implemented on the robot base, the system can easily be temporarily detached from the beamline, for instance, during maintenance.

2.2. Sequence of operation with the single tongs

The sequence of operations for our system with the single tongs is the same as that for the SAM system. The procedure for mounting and dismounting a cryo-pin is as follows: the robot cools the tongs in the liquid nitrogen, picks up the dumbbell magnet tool with fingers (Fig. 2c ▶) and pulls the required cryo-pin from the cassette using the strong end of the dumbbell. The robot then holds the cryo-pin with the tongs, moves the tongs towards the goniometer and mounts the pin on the goniometer. The tongs are then opened and moved away from the goniometer. After an X-ray diffraction experiment, the robot dismounts the cryo-pin from the goniometer using pre-cooled tongs, returns to the Dewar and puts the used cryo-pin on the weak end of the dumbbell. Then the robot grasps the dumbbell and restores the used cryo-pin into the cassette (Fig. 2d ▶).

3. Reduction of sample-exchange time

3.1. Single tongs

The sample-exchange time can be reduced by changing the sequence of handling the cryo-pins (Hiraki et al., 2007 ▶). If the next cryo-pin is already prepared on the strong end of the dumbbell magnet tool before dismounting the pin, the robot can grasp the next pin and move towards the goniometer immediately after putting the dismounted pin on the weak end of the dumbbell. With this proposed sequence, the time required for exchanging the cryo-pins could be decreased from 90 s to 30 s, because the robot can prepare the next pin and can restore the dismounted pin to the cassette in parallel with the process of loop centering and data collection.

In this sequence, however, the next pin is on the strong end until the robot returns to the Dewar after dismounting the pin. The dismounted pin also remains on the weak end until the robot returns after mounting the next pin. These situations increase the probability that small ice formations will accumulate on the cryo-loops in the Dewar.

3.2. Double tongs

The reduction of the sample-exchange time is more effective in the case of a short data collection period, as may be the case when taking several diffraction images for evaluation of the crystals, or when using a faster detector such as the X-ray HARP detector (High Energy Accelerator Research Organization, 2004 ▶).

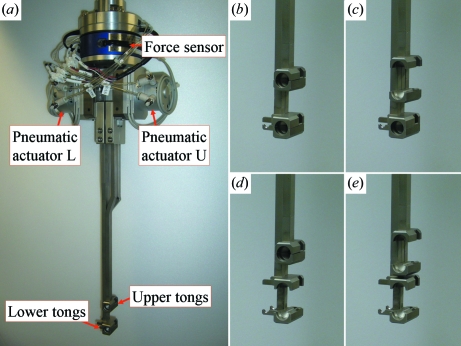

In order to reduce by a factor of two the number of trips between the Dewar and the goniometer, we combined two single tongs into a tongs system named ‘double tongs’, which can hold two cryo-pins simultaneously (Fig. 3 ▶). Upper and a lower tongs are independently controlled by pneumatic actuators U and L, respectively (Figs. 3b–3e ▶). The fingers are fixed only on the lower tongs. A robot with the double tongs can move to the goniometer holding the next cryo-pin, dismount the previous cryo-pin with the other tongs and mount the next cryo-pin onto the goniometer without leaving the diffractometer area. Furthermore, while the robot is waiting for the ‘mount’ command, the next pin can be protected against small ice formations by the cryo-tongs.

Figure 3.

Double tongs combining two single tongs. (a) Overview of the double tongs. (b)–(e) The upper and lower tongs can be opened and closed separately.

4. Sample exchange with double tongs

For a preliminary trial of the double tongs that we developed, we attached the double tongs to the BL-5A robot and tried to exchange the cryo-pins.

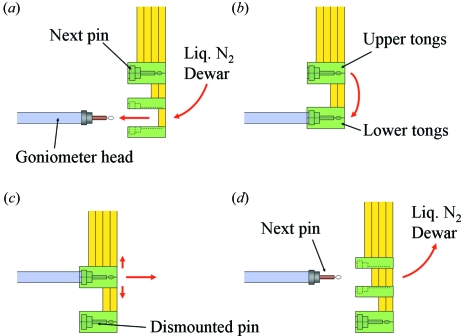

Fig. 4 ▶ shows sequential images taken while the robot exchanged two cryo-pins. After the diffraction experiment, components such as the beam stopper are housed in the fancy box (Fig. 1 ▶) to prepare for sample exchange. For high-throughput operation, the robot must then hold the next pin with the upper tongs until the end of the diffraction experiment. The robot moves towards the goniometer head, opens the lower tongs (Fig. 4a ▶) and holds the previous pin on the goniometer head (Fig. 4b ▶). The robot leaves the goniometer, moves down until the height of the upper tongs becomes equal to the height of the goniometer and mounts the next cryo-pin (Fig. 4c ▶). The robot releases the mounted pin from the upper tongs (Fig. 4d ▶) and takes the dismounted pin to the Dewar with the lower tongs. Finally, the robot stores the dismounted pin to its original position in the sample cassette in parallel with crystal centering and the diffraction experiment.

Figure 4.

Sequential movements during sample exchange by the double-tongs system. (a) The robot comes to the side of the sample pin and opens the lower tongs. (b) The robot picks the previous pin on the goniometer head with the lower tongs. (c) The sample pin, which has been grasped by the upper tongs, is mounted on the goniometer head. (d) The robot releases the mounted sample pin from the upper tongs and carries the dismounted pin to the liquid-nitrogen Dewar.

In our sample-exchange test with the double tongs, the exchange time was successfully reduced to 10 s.

5. Communication network

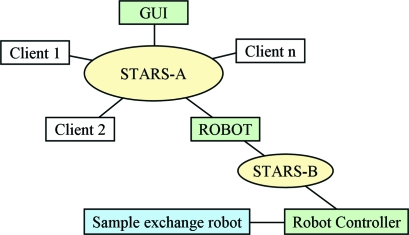

We have installed two different types of tongs, i.e. the single and double tongs, in the beamlines. The same GUI (graphical user interface) software for the operation of the sample-exchange robots is used at all beamlines, however, so that the users do not need to consider the differences between the systems. To this end, an intermediate computer named ‘ROBOT’ is placed between the GUI software and the robot controller (Fig. 5 ▶).

Figure 5.

Beamline control network including ROBOT client. The communication between clients is carried out via the STARS server. The ROBOT client receives commands from the GUI and sends commands to the robot controller to control the sample-exchange robot.

When a user wants to exchange cryo-pins, they select the next pin and push the button ‘Exchange’ on the GUI. Then the GUI software sends only the command exchange, regardless of the type of tongs, to the ROBOT via the STARS (simple transmission and retrieval system) communication server (Kosuge et al., 2002 ▶). The ROBOT is one of the clients of the STARS-A server for beamline control and also belongs to the STARS-B server for the sample-exchange robot. After receiving the command exchange, the ROBOT client sends a set of commands suitable for the type of tongs to the robot controller, which is also one of the clients of the STARS-B server. The ROBOT client knows whether the tongs are of the single or double type. In the case of the single tongs, the ROBOT client sends the commands dismount, putloop (putting the pin on the weak end of the dumbbell), placeloop (restoring the pin to the cassette), pickloop (picking up the pin from the cassette), getloop (grasping the pin on the strong end of the dumbbell) and mount single in that order. On the other hand, in the case of the robot having the double tongs, the commands pickloop, getloop, mount double, putloop and placeloop are sent by the ROBOT client.

As mentioned above, because of the intermediate ROBOT client, the GUI developers only need to implement one command, exchange, regardless of the type of tongs. Moreover, the development of the software becomes easier because the simple commands only need to be prepared at the robot controller.

6. Calibration and continuous test

Because the components shrink under liquid nitrogen, we must calibrate the position and orientation of the cassettes and cradle for the dumbbell magnet tools inside the Dewar. The six-axis force and torque sensor inserted between the robot arm and the cryo-tongs can detect contact, and is used for this calibration. First, the robot starts searching the cradle from the initial position given by the operator and measures the position and the orientation of the cradle without the dumbbell. Since the robot can grasp the dumbbell based on the results of the cradle calibration, the robot calibrates both the tongs and the dumbbell. Then the robot calibrates the cassettes and the goniometer head.

After the calibration we investigated the error rate during the sample exchanges. The result of the continuous sample-exchange test is shown in Table 1(a) ▶. The robot exchanged 634 cryo-pins without protein crystals and stopped 47 times after having detected collision with the cassette. In this trial we considered that the cassettes stood vertically and the inclination of the cassette could be disregarded.

Table 1. Error rates during sample exchanges (a) without consideration of the inclination of the cassette, (b) with consideration of the inclination of the cassette, (c) after the modification based on the height difference between the strong end and the weak end of the dumbbell magnet tool.

| Trials | Errors | Error rate (%) | |

|---|---|---|---|

| (a) | 634 | 47 | 7.4 |

| (b) | 4234 | 114 | 2.7 |

| (c) | 3840 | 1 | 0.026 |

To calculate the inclination of the cassettes, we measured the centers of each cassette at two different heights. The results of the measurements showed that the cassettes had inclined. Therefore we added the measurement and calculation procedure of the inclination of the cassette to the calibration software and carried out the sample-exchange trial again, this time considering the inclination of the cassette. The error rate decreased from 7.4% to 2.7% (Table 1b ▶).

Furthermore, we measured the height difference between the strong end and the weak end of the dumbbell magnet tool precisely. The robot could exchange the cryo-pins almost completely after the modification of the movement based on the measured height difference (Table 1c ▶).

7. Conclusions

We have developed automated sample-exchange robots based on the SSRL automated mounting system and have already installed them on our insertion device beamlines: BL-5A, BL-17A and AR-NW12A. To reduce the time required for exchanging samples during high-throughput operation, we developed double tongs that can hold two cryo-pins at the same time. The robot with the double tongs moves to the goniometer holding the next cryo-pin, dismounts the previous cryo-pin with the other tongs and mounts the next cryo-pin onto the goniometer without leaving the diffractometer area. The intermediate client software makes the commands simpler because it translates the commands based on the type of tongs.

In a sample-exchange trial, the double-tongs robot could exchange the cryo-pins within 10 s. Optimization allowed us to decrease the error rate to 0.026% after precise calibration, including the measurement of cassette inclination and the height difference between both ends of the dumbbell magnet tool.

We are currently modifying the calibration and the robot control software in order to improve the stability of the system. Moreover, we are aiming at a fully automated and high-throughput protein structural analysis system by combining the sample-exchange robot with the double tongs with automated crystal centering software that is currently being developed.

Acknowledgments

The authors would like to thank Mike Soltis, Mitchell Miller, Scott McPhillips, Jinhu Song and Aina Cohen, of the Macromolecular Crystallography Group at SSRL for their great help with the mechanical design and the software. We thank Masanori Kobayashi, Structural Biology Research Center, KEK-PF, for his support of the experiments for data collection at the beamlines. The development of the sample-exchange robots was supported by the Protein 3000 project of the Ministry of Education, Culture, Sports, Science and Technology (MEXT) of Japan, and also supported by the programs of the Strategic International Cooperative Program and the Development of Systems and Technology for Advanced Measurement and Analysis from the Japan Science and Technology Agency (JST). The research of the calibration was supported by a Grant-in-Aid for Young Scientists (B) 18760204 of the MEXT of Japan. Experiments with the sample-exchange robots have been performed under the approval of the Photon Factory Program Advisory Committee (Proposal No. 2007G193).

References

- Cipriani, F. et al. (2006). Acta Cryst. D62, 1251–1259. [DOI] [PubMed]

- Cohen, A. E., Ellis, P. J., Miller, M. D., Deacon, A. M. & Phizackerley, R. P. (2002). J. Appl. Cryst.35, 720–726. [DOI] [PMC free article] [PubMed]

- High Energy Accelerator Research Organization (2004). Annual Report 2004, pp. 69–73. High Energy Accelerator Research Organization, Japan.

- Hiraki, M. et al. (2006). Acta Cryst. D62, 1058–1065. [DOI] [PubMed]

- Hiraki, M., Watanabe, S., Yamada, Y., Matsugaki, N., Igarashi, N., Gaponov, Y. A. & Wakatsuki, S. (2007). AIP Conf. Proc.879, 1924–1927.

- Igarashi, N., Matsugaki, N., Yamada, Y., Hiraki, M., Koyama, A., Hirano, K., Miyoshi, T. & Wakatsuki, S. (2007). AIP Conf. Proc.879, 812–815.

- Karain, W. I., Bourenkov, G. P., Blume, H. & Bartunik, H. D. (2002). Acta Cryst. D58, 1519–1522. [DOI] [PubMed]

- Kosuge, T., Saito, Y., Nigorikawa, K., Katagiri, H., Shirakawa, A., Nakajima, H., Ito, K., Abe, I., Kishiro, J. & Kurokawa, S. (2002). PCaPAC2002: Proceedings of the 4th International Workshop on Personal Computers and Particle Accelerator Controls.

- Ohana, J., Jacquamet, L., Joly, J., Bertoni, A., Taunier, P., Michel, L., Charrault, P., Pirocchi, M., Carpentier, P., Borel, F., Kahn, R. & Ferrer, J.-L. (2004). J. Appl. Cryst.37, 72–77.

- Ohara, K., Ohba, K., Tanikawa, T., Hiraki, M., Wakatsuki, S., Mizusawa, M. & Tanie, K. (2004). Proceedings of the International Conference on Micro/Nanomechatronics and Human Science, pp. 301–306.

- Pohl, E., Ristau, U., Gehrmann, T., Jahn, D., Robrahn, B., Malthan, D., Dobler, H. & Hermes, C. (2004). J. Synchrotron Rad.11, 372–377. [DOI] [PubMed]

- Snell, G., Cork, C., Nordmeyer, R., Cornell, E., Meigs, G., Yegian, D., Jaklevic, J., Jin, J., Stevens, R. C. & Earnest, T. (2004). Structure, 12, 537–545. [DOI] [PubMed]

- Ueno, G., Hirose, R., Ida, K., Kumasaka, T. & Yamamoto, M. (2004). J. Appl. Cryst.37, 867–873.