Abstract

Objectives: This paper investigates determinants of wood dust exposure and trends in dust level in the furniture industry of Viborg County, Denmark, using data from two cross-sectional studies 6 years apart.

Methods: During the winter 1997/1998, 54 factories were visited (hereafter study 1). In the winter 2003/2004, 27 factories were revisited, and personal dust measurements were repeated. In addition, 14 new factories were included (hereafter study 2). A total of 2303 woodworkers participated in study 1, and 2358 measurements from 1702 workers were available. From study 2, 1581 woodworkers participated and 1355 measurements from 1044 workers were available. Information on occupational variables describing potential determinants of exposures like work task, exhaust ventilation, enclosure and cleaning procedures were collected. A total of 2627 measurements and 1907 persons were included in the final mixed model in order to explore determinants of exposure and trends in dust level.

Results: The overall inhalable wood dust concentration (geometric means (geometric standard deviation)) has decreased from 0.95 mg/m3 (2.05) in study 1 to 0.60 mg/m3 (1.63) in study 2, representing a 7% annual decrease in dust concentration, which was confirmed in the mixed model. From study 1 to study 2 there has been a change towards less manual work and more efficient cleaning methods, but on the contrary also more inadequate exhaust ventilation systems. The following determinants were found to ‘increase’ dust concentration: sanding; use of compressed air; use of full-automatic machines; manual work; cleaning of work pieces with compressed air; kitchen producing factories and small factories (<20 employees). The following determinants of exposure were found to ‘decrease’ dust concentration: manual assembling/packing; sanding with adequate exhaust ventilation; adequate exhaust ventilation; vacuum cleaning of machines and special cleaning staff.

Conclusions: Despite a substantial drop in the dust concentration during the last 6 years in the furniture industry in Viborg County, further improvements are possible. There should be more focus on improved exhaust ventilation, professional cleaning methods and avoiding use of compressed air.

Keywords: exposure assessment, furniture industry, hygiene assessment, inhalable dust, mixed effect models, wood dust

INTRODUCTION

Approximately 3.6 million workers in the European Union are exposed to wood dust (Kauppinen et al., 2006). The International Agency for Research on Cancer (IARC) classifies wood dust as a human carcinogen (IARC, 1995). The predicate ‘wood dust’ covers a heterogeneous collection of substances, and the impact on health depends, among others, on wood type and concurrent exposures to other substances used in the wood industry. Though, across different wood types and wood industries, a large number of epidemiological studies have identified wood dust as a risk factor for asthma or asthma symptoms (Ishizaki et al., 1973; Chan-Yeung et al., 1978; Shamssain, 1992; Åhman et al., 1995; Bohadana et al., 2000; Mandryk et al., 2000; Douwes et al., 2001; Fransman et al., 2003), nasal impairment (Holness et al., 1985; Pisaniello et al., 1991; Norrish et al., 1992; Shamssain, 1992; Åhman et al., 1995), acute or chronic impairment of lung function (Al-Zuhair et al., 1981; Whitehead et al., 1981; Holness et al., 1985; Carosso et al., 1987; Shamssain, 1992; Noertjojo et al., 1996; Mandryk et al., 1999), and dermal effects, mainly dermatitis (Hausen, 1986; Gan et al., 1987; Meding et al., 1996).

A 6-year follow-up study in the Danish furniture industry investigated the relation between wood dust exposure and respiratory diseases. At the same time, a new cross-sectional study was performed, including 14 new factories apart from the 27 follow-up factories. This was done in order to investigate the trend in wood dust exposure and respiratory impairment among woodworkers employed in the furniture industry in a well-defined geographical area. The exposure was mostly softwood (pine, spruce) and wooden boards (particle boards, medium density fibreboards).

In the baseline study (study 1), we revealed dose–response relationships between inhalable wood dust concentration and respiratory symptoms (Schlünssen et al., 2002b), acute nasal mucosal swelling (Schlünssen et al., 2002a), increased bronchial hyper reactivity (Schlünssen et al., 2004a) and an acute decline in lung function (Schlünssen et al., 2004b).

The relation between exposure to wood dust and variables describing potential determinants of exposures in the furniture industry and related industries have earlier been investigated in Europe (Scheeper et al., 1995; Alwis et al., 1999), Canada (Hall et al., 2002; Friesen et al., 2005) and Africa (Rongo et al., 2004). In summary, work task, job title, ventilation, encapsulation and cleaning procedures seem to be important determinants of wood dust exposure. In study 1, a broad spectrum of variables, all related to one of the levels—worker, machine, department, and factory—were investigated in hierarchic structured mixed models (Mikkelsen et al., 2002). Work task, use of compressed air, degree of automation, cleaning procedures, ventilation procedures and safety representative elected within the last 2 years were significant determinants of wood dust exposure.

The purpose of this paper is to update the model introduced by Mikkelsen et al. (2002) in order to estimate the determinants of wood dust exposure in the Danish furniture industry. Furthermore, the present data set enables us to explore the time trend from 1997/1998 to 2003/2004 in wood dust level and in determinants of exposure. The overall purpose of the study is to generate knowledge in order to create an updated evidence-based platform for prevention of occupational respiratory diseases in the furniture industry.

MATERIALS AND METHODS

Study design

The baseline study population was identified in a cross-sectional study (hereafter study 1) performed in the winter 1997–1998 described by Schlünssen et al. (2002b). In brief, 86 factories with more than four employees situated in Viborg County were identified. All factories with >20 employees were asked to participate (45 of 48 accepted), and an additional random sample of factories with 5–20 employees (9 of 38) was drawn. A total of 54 factories participated in the study. The study population was workers employed in woodworking departments, assembling departments and stock departments in these factories. Dust measurements were performed on all 54 factories.

Study 2 took place from 2003 to 2004. Furniture factories with more than four employees in Viborg County were identified and invited to participate (52 of 59 accepted, where 38 factories also participated at baseline). Dust measurements were performed on a random sample of factories of study 1 stratified by factory size and type of factory (n = 27) and on all new included factories (n = 14), all together 41 factories.

All participants gave informed consent and the protocol has been approved by the Ethics Committee for Viborg County, Denmark.

Dust measurements

Personal dust sampling was carried out with passive dust monitors as described by Vinzents (1996). The method is based on measuring light extinction before and after sampling of transparent foils. The light extinction increase was reported as dust covered foil area converted into equivalent inhalable dust concentration by linear regression models. A blind foil was mounted at the monitor protected from dust deposition. The standard deviation (SD) of the distribution of blind foil measurements was used as the limit of detection for the passive dust measurements. The validity of the sampler has been tested in a number of studies, and details of performance and comparisons to active filter sampling of inhalable dust using the Institute of Occupational Medicine (IOM) sampler (Mark and Vincent, 1986) have been reported (Vinzents, 1996; Schlünssen et al., 2001b). The validity of the passive sampler for sampling of size fractions involving large particles has been demonstrated by image analysis (Schneider et al., 2002).

In study 1, a model was developed based on calibration measurements from study 1 as well as earlier calibration measurements (Schlünssen et al., 2001b). In study 2, an updated model including new calibration measurements were developed (Jacobsen, 2007). The log-transformed dust concentration (active sampling) was treated as the dependent variable, while the independent variables were the log-transformed dust covered foil area per hour of sampling from the foils. Table 1 shows coefficients and statistics for the model used in study 1 and study 2. The main differences between the two models were (i) the exclusion of the downward foil in model 2 (it did not contribute significantly to the model) and (ii) inclusion of study-specific slopes and intercepts.

Table 1.

Coefficients and statistics for the inhalable dust concentration models

| Model used in study 1 (Schlünssen et al., 2001b) | Model used in study 2 | |

| Coefficient (95% CI), intercept | −0.03 (−0.15; 0.09) | −0.04 (−0.12; 0.04) |

| Coefficient (95% CI), upward foil | 0.64 (0.50; 0.78) | 0.50 (0.40; 0.60) |

| Coefficient (95% CI), forward foil | −0.001 (−0.10; 0.09) | 0.02 (−0.05; 0.10) |

| Coefficient (95% CI), downward foil | −0.02 (−0.12; 0.08) | — |

| Coefficient (95% CI), study-specific intercept, upward foil | — | −0.16 (−0.24; −0.08) |

| Adjusted R2 | 0.62 | 0.62 |

| Number of calibration measurements | 109 | 236 |

CI, confidence interval.

A total of 2303 woodworkers participated in study 1. For 1682 persons, dust samples were available from first measuring round. From 38 factories with >20 employees, workers were randomly drawn for repeated measurements (Vinzents et al., 2001), resulting in 351 measurements in the second round and 325 measurements in the third round, altogether 2358 measurements from 1702 workers. The time interval between each sampling round was 5–9 days. The mean (SD) duration of sampling was 254 (51) min.

In total, 42% of woodworkers used mainly pinewood, 16% particle board or fibreboard and 5% different kinds of hardwood, mainly beech. The last 37% used a mixture of different wood species.

A total of 1581 woodworkers participated in study 2. For 1042 persons, dust samples were available from first measuring round. Woodworkers from 24 factories with >20 employees were randomly drawn for repeated measurements, resulting in 160 measurements in the second round and 153 measurements in the third round, altogether 1355 measurements from 1044 workers. The time interval between each sampling round was 5–9 days. The mean (SD) duration of sampling was 396 (75) min. In total, 36% of woodworkers mainly used pinewood, 28% particle board or fibreboard and 3% different kinds of hardwood, mainly beech. The last 33% used a mixture of different wood species.

The 234 measurements from study 1 and study 2 (6%) below detection limit were given half the limit of detection. According to Hass and Scheff (1990), this method produces a bias on the mean value of the true distribution <2%.

Occupational hygiene data documentation

Each of the occupational variables describing potential determinants of exposures could be assigned to one of four hierarchic ordered levels: worker, machine, department and, as the highest level, factory. Data were recorded during the first measuring round on the data record forms 1–4, one form for each level.

The ‘personal measuring form’ 1 was filled in by the worker who was asked to identify the machines he had used for >1 h during the measuring period. To fill in the ‘machine form’ one or more walk through were carried out by the project group. Machines to be used during the measuring period were recorded with the assistance of the foreman or workers and supplied with an identification number. ‘Department and factory forms’ were filled in by interviews with the foreman of the department and the management, respectively. In study 1, workers were assumed to have identical job tasks and determinants of exposure in all three measuring rounds. In study 2, job task and determinants of exposure were separately recorded for rounds 1, 2 and 3. An overview of the variables describing potential determinants of exposures recorded can be found in Table 2.

Table 2.

Variables describing potential determinants of exposure

| Personal level | |

| Use of compressed air | No, yes |

| Work shift | Day, evening, night |

| Machine level | |

| Work task | Sanding, sanding and cutting, cutting, handling and assembling (includes gluing shops for laminated board and veneer), truck driver, foreman, store man) |

| Level of automation | Fully automatic, semi-automatic, manual |

| Exhaust ventilation | No, yes, not relevant |

| Exhaust ventilation, adequate | No, yes, not relevant |

| Enclosure, partial or full | No, yes, not relevant |

| Wood dust on the work piece | No, yes, not relevant |

| Type of wood | Pine, hardwood, composite, medium density fibreboard, mixed wood types |

| Department level | |

| Natural logarithm of the room volume | |

| Supplementary fresh air intake | No, yes |

| Heating of supplementary air | No, yes |

| Cleaning method, rooms | Vacuum cleaning, wet cleaning, compressed air |

| Daily cleaning of the room | No, yes |

| Cleaning method, work pieces | Vacuum cleaning, brush, compressed air |

| Cleaning method, machines | Vacuum cleaning, compressed air |

| Factory level | |

| Type of factory | Pine furniture, chair factory, kitchen/shop furniture, particle board/medium density fibreboard furniture |

| Number of employees | <20, 20–199, 200+ employees |

| Election of a safety representative | |

| Within the last 2 years | No, yes |

| Re-circulation of air to working rooms | No, yes |

| Supplementary fresh air intake | No, yes |

| Re-circulation of air to enclosed machines | No, yes |

| Plan for regular check of central exhaust ventilation system | No, yes |

| Plan for cleaning of rooms | No, yes |

| Special cleaning staff | No, yes |

Data analysis

In order to estimate the true proportion of employees in the furniture industry in Viborg County exposed to potential determinants of exposures, we used inverse probability weighting for each of 13 strata (based on factory size and type of factory) to adjust for the different subsets of factories in the two studies. The strata-specific probabilities were equal to the proportion of sampled factories in the strata. For each variable, a confidence interval on the absolute difference between the proportions in the two studies was obtained using bootstrap sampling (N = 200) of the factories in each strata and study.

The strategy for identifying determinants of exposure was inspired by the model used in (Mikkelsen et al., 2002). Only measurements where the worker had the same job during the measuring day were included in the model, leaving 2627 measurements and 1907 persons for further analysis.

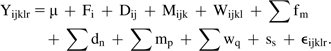

In order to account for unbalanced data and random variation of the hierarchic ordered variables—worker–machine–department–factory, a mixed effects model was adopted (Brown and Prescott, 1999):

|

(1) |

The dependent variable Yijklr is the natural log-transformed inhalable dust concentration measured on the r'th measuring round at the l'th worker at the k'th machine of the j'th department at the i'th factory. The log transformation is used because of the approximate lognormal distribution of the exposure data. μ is the intercept and Fi, Dij, Mijk and Wijkl are the random effects corresponding to factory, department, machine or worker, respectively. fm, dn, mp and wq are the fixed effects related to the same four levels, and ss is the fixed effect related to study. The summations of equation (1) are over the indices m, n, p and q, respectively, and lead to the inclusion of the fixed variables of each of the four levels. εijklr is the residual term. This term and the random effects Fi, Dij, Mijk and Wijkl are assumed to be statistically independent and approximately normally distributed with mean value zero. Equal variance of the worker random effect across machines, departments and factories is assumed. Corresponding assumptions are done for the machine and department random effects. All four random effects were kept in the model, irrespective of their level of significance.

The strategy for model making takes into account the hierarchical structure of the random effects. It reflects the assumption that variables describing potential determinants of exposures of a lower level are more likely to determine exposure than those of a higher one, the first ones describing an environment closer to the source of the contaminant and to the exposed person.

The process of model making went through four phases. In phase 1, all random effects, fixed effects of worker and machine level and study as fixed effect were included. In phases 2 and 3, fixed effects of department and factory level were included. In phase 4, interaction between variables were included. Within each of the first three phases, fixed effects were excluded step by step with variables with the highest P-values excluded first, until only significant effects (P < 0.05) for the respective phase were kept in the model. Relevant interaction terms (n = 27) were tested in phase 4 one by one, and significant interactions were included in the model (n = 2). Insignificant determinants of exposure were kept in the model if they were part of an interaction term or were significant after one of each of the four modelling phases.

Model diagnostics included probability plots of residuals and scatter plots of residuals against predicted values.

The calculations were carried out using Proc Mixed with restricted maximum likelihood (REML) using the SAS System 9.1.3. for Windows (SAS Institute Inc., 2004).

The percent change in dust level caused by each determinant b was calculated as

RESULTS

In Table 3, geometric means (GMs) and geometric standard deviations (GSDs) for dust levels for all workers and stratified by work task are given together with results from persons only doing one job during the day. GM and GSD for inhalable wood dust concentrations were 0.95 mg/m3 (2.05) for study 1 and 0.60 mg/m3 (1.63) for study 2.

Table 3.

Wood dust exposure as GM and GSD of inhalable dust concentration (mg/m3) for all workers and during specific work tasks in study 1 (1997/98) and study 2 (2003/2004)a

| Group, (n/N) | Study 1, GM (GSD), n/N | Study 2, GM (GSD), n/N |

| All workers,b 2746/3713 | 0.95 (2.05), 1702/2358 | 0.60 (1.63), 1044/1355 |

| Sanding, 150/208 | 1.55 (1.87), 111/163 | 0.68 (1.67), 39/45 |

| Cutting, 773/1043 | 1.13 (1.95), 504/694 | 0.67 (1.55), 269/349 |

| Cutting and sanding, 264/362 | 1.38 (1.76), 139/178 | 0.78 (1.66), 125/184 |

| Handling and assembling, 830/1144 | 0.71 (1.98), 539/750 | 0.55 (1.42), 291/394 |

| Truck driver, 116/166 | 0.78 (2.01), 49/70 | 0.45 (1.50), 67/96 |

| Foreman, 123/151 | 0.56 (2.04), 82/107 | 0.38 (1.62), 41/44 |

| Store man, 59/87 | 0.79 (1.79), 40/59 | 0.36 (1.66), 19/28 |

| Mixed task, 251/393 | 1.10 (1.78), 151/215 | 0.63 (1.57), 100/120 |

| Other tasks, 133/176 | 0.92 (2.10), 72/100 | 0.58 (2.02), 61/76 |

| Unknown task, 19/41 | 1.20 (2.37), 15/22 | 0.51 (1.69), 4/19 |

| Workers only doing one job during the day, 1907/2627 | 0.94 (2.10), 1239/1721 | 0.58 (1.65), 668/906 |

Every persons' measurements were averaged, the distribution was log-transformed and the log-transformed mean and SDs were exponentiated in order to get GM and GSM. N = number of measurements, n = number of persons.

The total number of workers exceeds the sum of workers in each work task as workers with different tasks in three repeated measurements (n = 28) were excluded.

A trend towards lower dust levels in study 2 was seen for all work tasks. The highest exposure was found for sanding (study 1) and sanding and cutting (study 2). The lowest exposure was found for foremen (study 1) and store men (study 2). Overall, the yearly average percent decline was ∼7%, most pronounced for sanding.

Only small differences in overall GM and GSD were seen between workers doing more jobs during the day compared to those doing only one job.

Table 4 shows the frequency of potential determinants of exposures in studies 1 and 2. There were only minor differences between the observed and the adjusted differences in frequencies of determinants between the two studies.

Table 4.

Frequency of potential determinants of exposure among persons participating in study 1 and study 2

| Possible determinants of exposure | Study 1, % (number of persons)a | Study 2, %, (number of persons)a | Adjusted absolute % difference (study 2–study 1), (95% CI)b |

| Personal and machine level | |||

| Use of compressed air | 45 (725) | 42 (432) | −2 (−9; 4) |

| Fully automatic | 10 (160) | 8 (87) | −2 (−5; 5) |

| Semi-automatic | 36 (590) | 38 (394) | 5 (12; −2) |

| Manual | 40 (657) | 28 (288) | −12 (−23; −3) |

| Exhaust ventilation, adequate | 48 (206) | 33 (101) | −12 (−24; 0) |

| Enclosure | 56 (435) | 45 (226) | −7 (−18; 5) |

| Wood dust on the work piece | 9 (100) | 6 (44) | −3 (−8; 1) |

| Department level | |||

| Supplementary fresh air intake | 37 (437) | 49 (453) | 16 (3; 35) |

| Vacuum cleaning of rooms | 81 (999) | 90 (828) | 9 (−3; 22) |

| Cleaning of rooms with compressed air | 8 (98) | 2 (17) | −6 (−15; 3) |

| Vacuum cleaning of work pieces | 21 (184) | 6 (51) | −15 (−29; 0) |

| Cleaning of work pieces with compressed air | 55 (486) | 17 (161) | −39 (−57; −21) |

| Factory level | |||

| Pine factory | 66 (1121) | 49 (516) | −11 (−29; 7) |

| Chair factory | 5 (83) | 3 (34) | −6 (−12; 1) |

| Kitchen/shop factory | 11 (189) | 21 (218) | 9 (−5; 22) |

| Particle board/medium density fibreboard furniture | 18 (298) | 24 (250) | 7 (−12; 26) |

| Election of a safety representative within the last 2 years | 84 (1352) | 99 (656) | 17 (1; 32) |

| Re-circulation of air to working rooms | 56 (954) | 26 (249) | −27 (−49; −5) |

| Re-circulation of air to enclosed machines | 67 (1131) | 86 (888) | 26 (8; 43) |

| Plan for cleaning of rooms | 52 (877) | 58 (556) | 10 (−14; 35) |

| Plan for regularly check of central exhaust ventilation system | 67 (1137) | 62 (642) | 0 (−17; 18) |

| Special cleaning staff | 58 (981) | 70 (690) | 12 (−10; 35) |

The number of valid cases is highly variable. For example, enclosure is of relevance for some work tasks only.

In order to estimate the true proportion of employees in the furniture industry in Viborg County exposed to potential determinants of exposures, we used inverse probability weighting for each of 13 strata (based on factory size and type of factory) to adjust for the different subsets of factories in the two studies,. The strata-specific probabilities were equal to the proportion of sampled factories in the strata. For each variable, a confidence interval (CI) on the absolute difference between the proportions in the two studies was obtained using bootstrap sampling (N = 200) of the factories in each strata and study.

From study 1 to study 2, there was a change towards (i) less manual work. (ii) Less pine furniture, and more furniture and cabinets made of particle board or medium density fibreboard. (iii) A ‘decrease’ in adequate exhaust ventilation systems, enclosure, cleaning of rooms with compressed air, cleaning of work pieces with vacuum cleaning and with compressed air and re-circulation of air to working rooms. (iv) An ‘increase’ in supplementary fresh air intake, vacuum cleaning of rooms, re-circulation of air to enclosed machines, special cleaning staff and election of a safety representative within the last 2 years.

Multivariate model

Using the strategy of model making, we ended up with a model including four random terms, study as fixed effect, fixed effects from all the four levels and two interaction terms, namely manual × assembling/packing and sanding × adequate exhaust ventilation. Insignificant determinants of exposure kept in the model were handling/assembling and sanding (part of an interaction term), and day shift, use of hardwood and encapsulation (significant after one of each of the four modelling phases). A plot of predicted values versus residuals shows no trends apart from two straight lines caused by the 6% of observations below the limit of detection.

In Table 5, coefficients, standard error, P-value and percent change in dust level for determinants of exposure are given for fixed effect included in the final model. In addition, a model only including the 27 factories which participated in both study 1 and 2 is provided.

Table 5.

Variables describing potential determinants of exposure. Coefficients, standard error (SE) and P-value for fixed effect included in a mixed effect model for all factories, and for factories included in both studies 1 and 2

| Determinants of exposure | All 68 factories | 27 Factories included in both studies 1 and 2 | |||||

| Coefficient | SE | P-value | % Change (95% CI)a | Coefficient | SE | P-value | |

| Intercept | 0.03 | 0.08 | — | −0.003 | 0.10 | — | |

| Study (ref. study 1) | −0.54 | 0.04 | <0.0001 | −41 (−36; −46) | −0.52 | 0.05 | — |

| Personal level | |||||||

| Use of compressed air | 0.13 | 0.03 | <0.0001 | 14 (8; 20) | 0.11 | 0.04 | <0.01 |

| Day shift | 0.06 | 0.03 | 0.06 | NS | 0.06 | 0.04 | 0.16 |

| Machine level | |||||||

| Handling/assembling | −0.03 | 0.06 | 0.60 | NS | −0.02 | 0.07 | 0.16 |

| Manual task | 0.17 | 0.05 | <0.001 | 17 (8; 30) | 0.22 | 0.06 | 0.01 |

| Sanding | 0.42 | 0.10 | <0.001 | 53 (36; 86) | 0.44 | 0.13 | <0.001 |

| Fully automatic task | 0.15 | 0.05 | <0.01 | 16 (5; 27) | 0.19 | 0.06 | <0.01 |

| Adequate exhaust ventilation | −0.10 | 0.05 | 0.04 | −10 (−0; −18) | −0.09 | 0.06 | 0.06 |

| Encapsulation | −0.03 | 0.04 | 0.48 | NS | −0.07 | 0.06 | 0.20 |

| Use of hardwood | 0.09 | 0.08 | 0.27 | NS | −0.08 | 0.09 | 0.38 |

| Department level | |||||||

| Cleaning of work pieces with compressed air | 0.14 | 0.06 | 0.01 | 15 (3; 28) | 0.12 | 0.07 | 0.09 |

| Vacuum cleaning machines | −0.13 | 0.05 | 0.02 | −12 (−2; −21) | −0.13 | 0.07 | 0.06 |

| Kitchen production | 0.17 | 0.09 | 0.04 | 19 (0; 41) | 0.25 | 0.12 | 0.05 |

| Factory level | |||||||

| Factories <20 employees | 0.24 | 0.10 | 0.02 | 27 (4; 55) | 0.25 | 0.18 | 0.17 |

| Special cleaning staff | −0.12 | 0.05 | 0.01 | −12 (−3; −19) | −0.18 | 0.06 | <0.01 |

| Handling/assembling × manual | −0.28 | 0.07 | <0.001 | −25 (−13; −35) | −0.35 | 0.10 | <0.001 |

| Sanding × adequate exhaust ventilation | −0.35 | 0.14 | 0.01 | −29 (−7; −46) | −0.35 | 0.18 | 0.06 |

The dependent variable was the loge-transformed dust concentration.

The percent change in dust level caused by each determinant b was calculated as (1 – exp(bcoefficient)) × 100. NS: non-significant.

Determinants found in the model based on the 27 factories which participated in both the studies were similar to determinants found in the model that included all 68 factories.

No significant interactions between determinants of exposure and study were found.

The following significant determinants ‘increased’ the dust concentration: use of compressed air (14%), fully automatic tasks (16%), sanding (53%), manual tasks (17%), cleaning of work pieces with compressed air (15%), kitchen production (19%) and small factories (27%).

Significant determinants for ‘decrease’ in dust concentration were study 2 (41%), adequate exhaust ventilation (10%), vacuum cleaning of machines (12%), special cleaning staff (12%), handling/assembling × manual (25%) and sanding × adequate exhaust ventilation (29%).

The final model was repeated on the subgroup of 183 workers (540 measurements) surveyed in both studies 1 and 2. The intercept and coefficients were largely in the same range as the model based on all participants from the 68 factories (data not shown).

In order to explore the impact of the different exposure documentation in the two studies, we repeated the analyses and restricted the population to subjects who had the same job during the three repeated measuring rounds, and it did not significantly changed the coefficients for determinants of exposure given in Table 5.

In order to explore possible differences in mean dust level between factories participating in only one of the studies compared to factories participating in both studies, we included participation status in the mixed model described above, and repeated the analyses for study I and study 2 separately. We found no significant differences between factories participating one time versus factories participating two times, that is, they shared the same mean.

Trends in dust level

GM (GSD) for inhalable wood dust concentrations were 0.95 mg/m3 (2.05) for study 1 and 0.60 mg/m3 (1.63) for study 2, representing a 7.2% annual decrease in dust concentration. The decrease was even more pronounced in the multivariate model (coefficient for study = −0.54, equalling an 8.6% annual decrease). We repeated the analysis without any fixed effect but study, and this did not change the result (coefficient for study = −0.55, equalling an 8.8% annual decrease). The same multivariate model with all fixed effects was performed for the 27 factories which participated in both studies, and it did not change the results markedly (coefficient for study = −0.52, equalling an 8.3% annual decrease).

Variance components

Table 6 shows estimated variance components of random terms for the total study. The residual variance component is termed the within-worker variance components, but may include (smaller) contributions from, for example, measurement error.

Table 6.

Estimates of variance components for the total model (number of factories = 68)

| Variance components in model excluding fixed effects (%) | Variance components in model including fixed effects (%) | |

| Total between-worker variance | 0.31 (58) | 0.18 (34) |

| Between-factories variance | 0.05 (9) | 0.03 (5) |

| Between-department variance | 0.07 (14) | 0.02 (4) |

| Between-machines variance | 0.07 (13) | 0.04 (7) |

| Between-workers variance | 0.12 (22) | 0.09 (18) |

| Within-workers variance | 0.22 (42) | 0.20 (38) |

| Sum of variance explained by random effects | 0.53 (100) | 0.38 (72) |

| Total variance | 0.53 (100) | 0.53 (100) |

| Variance explained by fixed effects (%) | — | 0.15 (28) |

The proportion of variance explained by the fixed terms was 28%. The proportion of the total between-worker variance explained by the fixed terms was 42%, calculated as: ((sum of variance explained by random effects – within-worker varianceexcl fixed effects) − (sum of variance explained by random effects – within-worker varianceincl fixed effects))/(sum of variance explained by random effects – within-worker varianceexcl fixed effects) × 100%.

DISCUSSION

Study design

There were some differences in the inclusion of factories in study 1 and study 2. For practical reasons, measurements were only performed on two-third of the ‘old’ factories in study 2. They were randomly chosen, stratified by factory size and factory type, and we consider the participating factories to be representative for the old factories. In fact, we did not find any difference in the overall mean between factories participating in only one of the studies compared to factories participating in both studies.

In study 1, only a random sample of small factories (<20 employees) was invited, whereas study 2 included all factories with more than four employees in Viborg County. Based on the results from study 1, it was estimated that the mean exposure of all furniture workers in Denmark was ∼7% larger than the value found for Viborg County (Schlünssen, 2001a), partly caused by the under-representation of small factories and partly because the furniture factories in Viborg county were larger than those of Denmark in general. By inviting all small factories with more than four employees in study 2, the part of subjects employed at small factories increased from 3% to 10%, making study 2 more representative for Denmark in general. In this study, working at small factories determined increased dust level (Table 5), which supported our earlier findings (Schlünssen et al., 2001b) and also those reported by others (Vinzents and Laursen, 1993).

One of our aims was to estimate differences in wood dust exposure level and in determinants of exposure between 1997/1998 and 2003/2004 on furniture industries situated in a well-characterized geographical area in Denmark. A priory we did not expect factories which participated in both studies to be representative for the furniture industry. This was the main argument for including all factories of both surveys in the analysis. Another argument was to keep as much information as possible in the model. One main advantage by using mixed modelling is the possibility to merge information from paired and unpaired data in the same analysis. A posteriori analysis on the 27 factories which participated in both studies revealed basically the same determinants for wood dust exposure, pointing towards the 27 factories to be quite representative for the furniture industry in Viborg County. The final model applied on the subgroup of 183 workers surveyed both in studies 1 and 2 also showed coefficients largely in the same range as the model based on all participants.

The differences in sampling strategy in 1997/1998 and 2003/2004 were taken into account in the analysis, that is, by using inverse probability weighting for factory size and type of industry (Table 4), and by including study, factory size and type of industry in the mixed model (Table 5).

In order to simplify the model, we decided only to include the 70% workers who had the same job during the day. The overall difference in GM and GSD between workers with one job and workers with more than one job was negligible, so were the differences after stratifying for work task. We therefore truly believe our results to be representative also for workers with more jobs during the day.

Comments on the model

When analysing unbalanced, correlated data with repeated measurements, mixed effect models are valid tools (Brown and Prescott, 1999). In order to adjust the fixed terms and to generalize the model—worker–machine–department–factory were included as random effects.

Equal variance of the worker random effect across machines, departments and factories was assumed, and corresponding assumptions were done for the machine and department random effects. The homogeneity of variances across various strata was not explored in great details. There were several reasons for this: homogeneity of variances was a part of the specification of the random effects, since we assume that random effects at the same hierarchical level were described by a single normal distribution. To our knowledge, there are no satisfactory statistical methods for checking this. Simulation studies have shown that the estimates of the fixed effects are rather robust to miss-specified random effects. We have considered stratifying the analysis by factories, but this method has several drawbacks: the fixed effects are estimated within each factory and some factories have sparse data for which the variances on the random components cannot be estimated or are estimated with poor precision. However, if we restrict the analysis to the factories with sufficient data, we find no evidence against homogeneity of the variances judged by a deviance test comparing the two maximized likelihood functions.

Hence, the assumption of equal variances was possibly a minor statistical problem.

In the strategy of model making, potential determinants of exposures were included in a hierarchical way with worker/machine as the lowest level. The assumption that a lower level means greater influence on the dust exposure seems partly proved by the fact that all of the significant fixed effects at lower levels (except use of hardwood and day shift) remain so after the inclusion of variables of the higher levels before inclusion of interaction terms. By including two significant interaction terms, handling/assembling and encapsulation became insignificant. This suggests that the impact of handling/assembling and encapsulation on the dust level is dependent on other determinants, that is, the degree of automation, work task and quality of exhaust ventilation.

The explainable part of the variation was lower than stated in the majority of previous studies modelling wood dust exposure using conventional linear regression models (Scheeper et al., 1995; Alwis et al., 1999; Hall et al., 2002) or mixed models including within-worker variation (Teschke et al., 1999a). Personal exposure to wood dust contains contributions from many sources in the production facilities, for example, the machine present, other machines in the vicinity, dust carried by re-circulated air or dust re-suspended by compressed air or by sweeping. The relatively low overall GM and GSD in this study, especially for study 2, suggest that the highest values of the distribution were not present in study 2. This could indicate that the working environment efforts in the industry during the last 6 years have been directed against the highest exposures, and that low-level indirect exposure sources are important for exposure. Only few determinants for indirect exposure were included in our model, for instance, dust on work pieces. Scheeper et al. (1995) documented differences between background exposures and near-source exposures to decrease with decreasing levels of exposure.

Determinants of exposure

‘Exhaust ventilation’ has earlier been shown to reduce wood dust exposure (Alwis et al., 1999). In our study, the presence of exhaust ventilation was not a determinant of exposure, although difficult to investigate, as nearly 90% of all woodworking machines in fact have exhaust ventilation. ‘Adequate exhaust ventilation’ decreases dust exposure in our study. Thus, it seems valuable to include the quality aspect of exhaust ventilation. In this study, the evaluation of exhaust ventilations was performed by the study crew. Inadequate exhaust ventilation was defined if the exhaust hood was not present with reasonable distance from all of the important sources of chips and dust at the machine or the hoods were clearly unable to remove chips and dust formed during use.

As seen in earlier studies ‘sanding’ (Jones and Smith, 1986; Vinzents and Laursen, 1993; Scheeper et al., 1995; Alwis et al., 1999; Teschke et al., 1999b) separates out as a woodworking process of high exposure.

Interestingly, the multivariate analysis uncovered that sanding performed with ‘adequate exhaust ventilation’ in fact decreased the dust level. This underlines the importance of a continuous focus on exhaust ventilation in the preventive work at the factories.

The tendency to higher exposures for ‘day shift’ compared to night and evening shifts might be related to the greatly reduced workforce on most factories, resulting in a lower background concentration of wood dust.

‘Handling/assembling’ only had decreased dust level when manually performed. When handling/assembling was performed with automatic machines, the task resulted in a dust level very close to the overall mean dust level, after controlling for other variables in the multivariate model. This is in accordance with the results in Mikkelsen et al. (2002), where automation increased exposure in a separate model for handling and assembling. It is possible that handling/assembling will move towards more automation in the years to come. This emphasizes the importance of focusing on handling/assembling departments, which has been done only sparsely until now (Scheeper et al., 1995).

Overall, ‘manual work’ and ‘fully automatic tasks’ were determinants for increased dust level. Much manual work in woodworking departments is characterized by being close to the dust source, where dust control is difficult due to irregular shapes. On the contrary, fully automatic tasks are often characterized by large machines with long distances between the workers breathing zone and the dust source. But fully automatic machines in general work with higher speed and therefore possibly generate more dust.

As found in this study, use of compressed air has earlier proved to increase dust concentration (Pisaniello et al., 1991; Alwis et al., 1999). In general, the use of compressed air has not changed from study 1 to study 2, but cleaning of rooms and work pieces with compressed air have decreased substantially from 1997 to 2003.

‘Encapsulation’ did not remain significant in the model after including interaction terms. Encapsulation is regarded as an effective dust-reducing variable although not documented in earlier studies. However, Teschke et al. (1999a) found that enclosure of the workers in a booth or a cab decreased dust levels in the Canadian lumber industry significantly.

‘Cleaning methods’ were important for the dust level, that is, ‘vacuum cleaning of machines’ and ‘special cleaning staff’ decreased the dust level. Special cleaning staff was defined as professional cleaning personal. On the other hand, cleaning of work pieces with compressed air increased the dust level. Clearly, compressed air re-suspends the dust, whereas an effective vacuum cleaning more efficiently removes the dust from the air. Use of special cleaning staff may be a proxy for a higher quality of room cleaning and, consequently, less re-suspension of wood dust.

‘Kitchen production’ was found to increase dust level compared to other types of furniture industry. Kitchen production is, among others, characterized by many manual tasks, especially manual sanding of solid wood pieces lining, for example, table tops. Manual work and sanding were included in the multivariate analyses, which might suggest other characteristics of kitchen production to be of importance for the dust level. The Danish kitchen production is mostly not a standardized production but characterized by large, unique pieces with specific dimensions and irregular shapes involving work close to the dust producing interface of tool and wood.

Comparisons between the original and the updated model

In general, the updated model confirmed the results from Mikkelsen et al. (2002), which is not surprising since most of the data were used in both analyses. Though, there were some differences. In Mikkelsen et al. (2002), ‘safety representative elected within the last 2 years’ significantly decreased the dust level among woodworkers, which was not the case in the present model, probably because very few workers were employed at factories where election of safety representatives did not take place. The number of workers employed at factories where election of a safety representative within the last 2 years had taken place was increased from 84% to 99%, which possibly reflects more awareness of the work environment.

On the other hand, small factories, kitchen production and sanding performed with adequate exhaust ventilation were significant determinants in the update model, but not in Mikkelsen et al. (2002), which is probably a matter of power, since the same tendencies were seen in 2002, but without reaching the level of significance.

Trends in dust level and determinants of exposure

The GMs for inhalable wood dust were 0.95 mg/m3 for study 1 and 0.60 mg/m3 for study 2, equalling a 7.2% annual decrease in dust concentration. In the multivariate model, the decrease was even more pronounced, namely an 8.8% annual decrease. In the mixed model approach, the time trend can be thought of as a weighted average of the time trend estimated from factories participating in both studies (similar to a paired design) and from the mean difference between factories participating in study 1 and in study 2 (similar to an unpaired design).

This point towards a low and decreasing exposure level in the Danish furniture industry compared to furniture industries in other countries (Scheeper et al., 1995; Alwis et al., 1999; Brosseau et al., 2002; Kauppinen et al., 2006), though different measuring strategies and measuring principles make direct comparisons complicated. It has recently been estimated that 87 000 furniture industry workers in the European Union (12%) may be exposed to a level exceeding 5 mg/m3, and that the concentration of 2 mg/m3 may be exceeded by 225 000 workers (32%) (Kauppinen et al., 2006). In the present investigation, the numbers were six workers (0.2%) >5 mg/m3 and 225 workers (8%) >2 mg/m3, suggesting the furniture industry in Viborg County to be in the very low end of the wood dust exposure distribution in European furniture industry. As reported in an earlier paper by Schlünssen et al. (2001b), the exposure level in woodworking departments of the Danish furniture industry has been reduced by ∼50% during the period 1988–1998, equalling a 6% annual decrease. A 7% annual decline has been reported from 1978 to 1997 for the US wood industry as well (Teschke et al., 1999b), and an 8% median yearly decrease has been seen for particulate contaminant in a range of industries (Symanski et al., 1998; Kromhout and Vermeulen, 2000).

In order to adjust for the different subsets of factories in the two studies, we used inverse probability weighting to adjust the observed changes in frequency of determinants between study 1 and 2. There were only minor differences between the observed and the adjusted changes, indicating the observed frequencies to reflect real temporal changes in determinants.

There were positive changes in most variables related to a decreased dust concentration, that is, less manual work, less use of compressed air, less re-circulation of air to working rooms and more use of special cleaning staff. Furthermore, sanding was more prevalent in study 1 (7%) compared to study 2 (4%), and sanding seems to have the most pronounced yearly decline in dust concentration, 13% resulting in mean dust concentrations for sanding in the same range as cutting in study 2.

With respect to negative changes, only more inadequate exhaust ventilations were documented.

Study was included as a fixed effect in the multivariate model partly to explore whether a change in determinants of exposure could explain the decrease in dust concentration between the two studies. Study remained highly significant representing a 41% (36–46) decline from study 1 to study 2, indicating the significant fall in dust concentration to be caused by other factors. The same result was seen when the analysis was restricted to the 27 factories participating in both studies. Determinants of exposures demanding closer technical examination, such as type, dimension and speed of machine tools and wind velocity in chip extraction systems, were outside the scope of the present study, but they may have changed between study 1 and study 2. Furthermore, from 1997 to 2003, the industry has changed towards larger factories and larger, more complicated machines resulting in longer distances from the dust source to the worker, parameters which are only partly included in our model.

Preventive measures

Even though there has been a substantial drop in the dust concentration during the last 6 years in the furniture industry in Viborg County, our results indicate that further improvements are possible. Study design and analyses were performed in a way to make our results of relevance to furniture industries outside Viborg County, Denmark.

In order to decrease the wood dust exposure level, focus should be on exhaust ventilation and cleaning methods. It is crucial to ensure effective local exhaust ventilation at all woodworking machines, to professionalize cleaning, to avoid use of compressed air and to increase the use of vacuum cleaning.

Acknowledgments

This work has been supported by the Danish Work Environment Foundation, Viborg County, the Danish Medical Research Council, the Wood Industry and Building Workers Union in Denmark, the Danish Lung Association, the Asthma and Allergy Association in Denmark and the Health Insurance Fond.

References

- Åhman M, Söderman E, Cynkier I, et al. Work-related respiratory problems in industrial arts teachers. Int Arch Occup Environ Health. 1995;67:111–8. doi: 10.1007/BF00572234. [DOI] [PubMed] [Google Scholar]

- Al-Zuhair YS, Whitaker CJ, Cinkotai FF. Ventilatory function in workers exposed to tea and wood dust. Br J Ind Med. 1981;38:339–45. doi: 10.1136/oem.38.4.339. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alwis U, Mandryk J, Hocking AD, et al. Dust exposures in the wood processing industry. Am Ind Hyg Assoc J. 1999;60:641–6. doi: 10.1080/00028899908984485. [DOI] [PubMed] [Google Scholar]

- Bohadana AB, Massin N, Wild P, et al. Symptoms, airway responsiveness, and exposure to dust in beech and oak wood workers. Occup Environ Med. 2000;57:268–73. doi: 10.1136/oem.57.4.268. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Brosseau LM, Parker DL, Lazovich D, et al. Designing intervention effectiveness studies for occupational health and safety: the Minnesota wood dust study. Am J Ind Med. 2002;41:54–61. doi: 10.1002/ajim.10029. [DOI] [PubMed] [Google Scholar]

- Brown H, Prescott R. Applied mixed models in medicine. Chichester, UK: John Wiley & Sons; 1999. [Google Scholar]

- Carosso A, Ruffino C, Bugiani M. Respiratory diseases in wood workers. Br J Ind Med. 1987;44:53–6. doi: 10.1136/oem.44.1.53. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chan-Yeung M, Ashley MJ, Corey P, et al. A respiratory survey of cedar mill workers. I. Prevalence of symptoms and pulmonary function abnormalities. J Occup Med. 1978;20:323–7. [PubMed] [Google Scholar]

- Douwes J, McLean D, Slater T, et al. Asthma and other respiratory symptoms in New Zealand pine processing sawmill workers. Am J Ind Med. 2001;38:608–15. doi: 10.1002/ajim.1060. [DOI] [PubMed] [Google Scholar]

- Fransman W, McLean D, Douwes J, et al. Respiratory symptoms and occupational exposures in New Zealand plywood mill workers. Ann Occup Hyg. 2003;47:287–95. doi: 10.1093/annhyg/meg046. [DOI] [PubMed] [Google Scholar]

- Friesen MC, Davies HW, Teschke K, et al. Predicting historical dust and wood dust exposure in sawmills: model development and validation. J Occup Environ Hyg. 2005;2:650–8. doi: 10.1080/15459620500391676. [DOI] [PubMed] [Google Scholar]

- Gan SL, Goh CL, Lee CS, et al. Occupational dermatosis among sanders in the furniture industry. Contact Derm. 1987;17:237–40. doi: 10.1111/j.1600-0536.1987.tb02720.x. [DOI] [PubMed] [Google Scholar]

- Hall AH, Teschke K, Davies H, et al. Exposure levels and determinants of softwood dust exposures in BC lumber mills, 1981–1997. Am Ind Hyg Assoc J. 2002;63:709–14. doi: 10.1080/15428110208984759. [DOI] [PubMed] [Google Scholar]

- Hass CN, Scheff PA. Estimation of averages in truncated samples. Environ Sci Technol. 1990;24:912–9. [Google Scholar]

- Hausen BM. Contact allergy to woods. Clin Dermatol. 1986;4:65–76. doi: 10.1016/0738-081x(86)90065-9. [DOI] [PubMed] [Google Scholar]

- Holness DL, Sass-Kortsak AM, Pilger CW, et al. Respiratory function and exposure-effect relationships in wood dust-exposed and control workers. J Occup Med. 1985;27:501–6. [PubMed] [Google Scholar]

- International Agency for Research on Cancer (IARC) Volume 62: IARC monographs on the evaluation of carcinogenic risks to humans. Wood dust and formaldehyde. Lyon: International Agency for Research on Cancer; 1995. [Google Scholar]

- Ishizaki T, Shida T, Miyamoto T, et al. Occupational asthma from western red cedar dust (Thuja plicata) in furniture factory workers. J Occup Med. 1973;15:580–5. [PubMed] [Google Scholar]

- Jacobsen G. Denmark: Aarhus University, Department of Environmental and Occupational Medicine; 2007. Asthma and other respiratory diseases among workers in the Danish furniture industry occupationally exposed to wood dust. Thesis. [Google Scholar]

- Jones PA, Smith LC. Personal exposures to wood dust of woodworkers in the furniture industry in the high Wycombe area: a statistical comparison of 1983 and 1976/77 survey results. Ann Occup Hyg. 1986;30:171–84. doi: 10.1093/annhyg/30.2.171. [DOI] [PubMed] [Google Scholar]

- Kauppinen T, Vincent R, Liukkonen T, et al. Occupational exposure to inhalable wood dust in the member states of the European Union. Ann Occup Hyg. 2006;50:549–61. doi: 10.1093/annhyg/mel013. [DOI] [PubMed] [Google Scholar]

- Kromhout H, Vermeulen R. Long-term trends in occupational exposure: Are they real? What causes them? What shall we do with them? Ann Occup Hyg. 2000;44:325–7. doi: 10.1093/annhyg/44.5.325. [DOI] [PubMed] [Google Scholar]

- Mandryk J, Alwis KU, Hocking AD. Work-related symptoms and dose-response relationships for personal exposures and pulmonary function among woodworkers. Am J Ind Med. 1999;35:481–90. doi: 10.1002/(sici)1097-0274(199905)35:5<481::aid-ajim5>3.0.co;2-n. [DOI] [PubMed] [Google Scholar]

- Mandryk J, Alwis U, Hocking AD. Effects of personal exposures on pulmonary function and work-related symptoms among sawmill workers. Ann Occup Hyg. 2000;44:281–9. [PubMed] [Google Scholar]

- Mark D, Vincent JH. A new personal sampler for airborne total dust in workplaces. Ann Occup Hyg. 1986;30:89–102. doi: 10.1093/annhyg/30.1.89. [DOI] [PubMed] [Google Scholar]

- Meding B, Åhman M, Karlberg AT. Skin symptoms and contact allergy in woodwork teachers. Contact Derm. 1996;34:185–90. doi: 10.1111/j.1600-0536.1996.tb02171.x. [DOI] [PubMed] [Google Scholar]

- Mikkelsen AB, Schlünssen V, Sigsgaard T, et al. Determinants of wood dust exposure in the Danish furniture industry. Ann Occup Hyg. 2002;46:673–85. doi: 10.1093/annhyg/mef082. [DOI] [PubMed] [Google Scholar]

- Noertjojo HK, Dimich-Ward H, Peelen S, et al. Western red cedar dust exposure and lung function: a dose-response relationship. Am J Respir Crit Care Med. 1996;154:968–73. doi: 10.1164/ajrccm.154.4.8887593. [DOI] [PubMed] [Google Scholar]

- Norrish AE, Beasley R, Hodgkinson EJ, et al. A study of New Zealand wood workers: exposure to wood dust, respiratory symptoms, and suspected cases of occupational asthma. N Z Med J. 1992;105:185–7. [PubMed] [Google Scholar]

- Pisaniello DL, Connell KE, Muriale L. Wood dust exposure during furniture manufacture—results from an Australian survey and considerations for threshold limit value development. Am Ind Hyg Assoc J. 1991;52:485–92. doi: 10.1080/15298669191365090. [DOI] [PubMed] [Google Scholar]

- Rongo LM, Msamanga GI, Burstyn I, et al. Exposure to wood dust and endotoxin in small-scale wood industries in Tanzania. J Expo Anal Environ Epidemiol. 2004;14:544–50. doi: 10.1038/sj.jea.7500375. [DOI] [PubMed] [Google Scholar]

- SAS Institute Inc. SAS/STAT 9.1 users guide. Cary, NZ: SAS Institute Inc; 2004. [Google Scholar]

- Scheeper B, Kromhout H, Boleij JS. Wood-dust exposure during wood-working processes. Ann Occup Hyg. 1995;39:141–54. [PubMed] [Google Scholar]

- Schlünssen V. Asthma and other respiratory diseases among woodworkers in the furniture industry occupational exposed to wood dust. Denmark: Aarhus University, Department of Environmental and Occupational Medicine; 2001a. Thesis. [Google Scholar]

- Schlünssen V, Schaumburg I, Andersen NT, Sigsgaard T, Pedersen OF. Nasal patency is related to dust exposure in woodworkers. Occup Environ Med. 2002a;59:23–9. doi: 10.1136/oem.59.1.23. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schlünssen V, Schaumburg I, Heederik D, et al. Indices of asthma among atopic and non-atopic woodworkers. Occup Environ Med. 2004a;61:504–11. doi: 10.1136/oem.2003.007815. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schlünssen V, Schaumburg I, Taudorf E, et al. Respiratory symptoms and lung function among Danish woodworkers. J Occup Environ Med. 2002b;44:82–98. doi: 10.1097/00043764-200201000-00013. [DOI] [PubMed] [Google Scholar]

- Schlünssen V, Sigsgaard T, Schaumburg I, et al. Cross-shift changes in FEV1 in relation to wood dust exposure: the implications of different exposure assessment methods. Occup Environ Med. 2004b;61:824–30. doi: 10.1136/oem.2003.011601. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schlünssen V, Vinzents PS, Mikkelsen AB, et al. Wood dust exposure in the Danish furniture industry using conventional and passive monitors. Ann Occup Hyg. 2001b;45:157–64. doi: 10.1016/s0003-4878(00)00055-7. [DOI] [PubMed] [Google Scholar]

- Schneider T, Schlünssen V, Vinzents PS, et al. Passive sampler used for simultaneous measurement of breathing zone size distribution, inhalable dust concentration and other size fractions involving large particles. Ann Occup Hyg. 2002;46:187–95. doi: 10.1093/annhyg/mef029. [DOI] [PubMed] [Google Scholar]

- Shamssain MH. Pulmonary function and symptoms in workers exposed to wood dust. Thorax. 1992;47:84–7. doi: 10.1136/thx.47.2.84. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Symanski E, Kupper LL, Rappaport SM. Comprehensive evaluation of long-term trends in occupational exposure: Part 1. Description of the database. Occup Environ Med. 1998;55:300–9. doi: 10.1136/oem.55.5.300. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Teschke K, Demers PA, Davies HW, et al. Determinants of exposure to inhalable particulate, wood dust, resin acids, and monoterpenes in a lumber mill environment. Ann Occup Hyg. 1999a;43:247–55. [PubMed] [Google Scholar]

- Teschke K, Marion SA, Vaughan TL. Exposures to wood dust in U.S. industries and occupations, 1979 to 1997. Am J Ind Med. 1999b;35:581–9. doi: 10.1002/(sici)1097-0274(199906)35:6<581::aid-ajim5>3.0.co;2-i. [DOI] [PubMed] [Google Scholar]

- Vinzents PS. A passive personal dust monitor. Ann Occup Hyg. 1996;40:261–80. [Google Scholar]

- Vinzents PS, Laursen B. A national cross-sectional study of the working environment in the Danish wood and furniture industry—air pollution and noise. Ann Occup Hyg. 1993;37:25–34. doi: 10.1093/annhyg/37.1.25. [DOI] [PubMed] [Google Scholar]

- Vinzents PS, Schlünssen V, Feveile H, et al. Variation in exposure to inhalable wood dust in the Danish furniture industry. Within- and between-workers and factory components estimated from passive dust sampling. Ann Occup Hyg. 2001;45:603–8. [PubMed] [Google Scholar]

- Whitehead LW, Ashikaga T, Vacek P. Pulmonary function status of workers exposed to hardwood or pine dust. Am Ind Hyg Assoc J. 1981;42:178–86. doi: 10.1080/15298668191419541. [DOI] [PubMed] [Google Scholar]