Abstract

Objective: To study the optimal medium composition for xylanase production by Aspergillus niger XY-1 in solid-state fermentation (SSF). Methods: Statistical methodology including the Plackett-Burman design (PBD) and the central composite design (CCD) was employed to investigate the individual crucial component of the medium that significantly affected the enzyme yield. Results: Firstly, NaNO3, yeast extract, urea, Na2CO3, MgSO4, peptone and (NH4)2SO4 were screened as the significant factors positively affecting the xylanase production by PBD. Secondly, by valuating the nitrogen sources effect, urea was proved to be the most effective and economic nitrogen source for xylanase production and used for further optimization. Finally, the CCD and response surface methodology (RSM) were applied to determine the optimal concentration of each significant variable, which included urea, Na2CO3 and MgSO4. Subsequently a second-order polynomial was determined by multiple regression analysis. The optimum values of the critical components for maximum xylanase production were obtained as follows: x 1 (urea)=0.163 (41.63 g/L), x 2 (Na2CO3)=−1.68 (2.64 g/L), x 3 (MgSO4)=1.338 (10.68 g/L) and the predicted xylanase value was 14374.6 U/g dry substrate. Using the optimized condition, xylanase production by Aspergillus niger XY-1 after 48 h fermentation reached 14637 U/g dry substrate with wheat bran in the shake flask. Conclusion: By using PBD and CCD, we obtained the optimal composition for xylanase production by Aspergillus niger XY-1 in SSF, and the results of no additional expensive medium and shortened fermentation time for higher xylanase production show the potential for industrial utilization.

Keywords: Xylanase, Optimization of medium composition, Plackett-Burman design (PBD), Central composite design (CCD), Response surface methodology (RSM), Aspergillus niger XY-1

INTRODUCTION

Xylan, the major hemicellulose polysaccharide, is widely distributed in agricultural by-products including corncob, rice husk, wheat straw and wheat bran. In China billions of tons of those by-products have been produced every year and some of them have been used in animal feed as feed ingredients for economic reasons. However, due to the high content of arabinoxylans, which might reduce animal digestibility of dietary protein and the absorption of amino acids, the utilization of those by-products in feed is limited and impractical (Slominski et al., 2004; Barrera et al., 2004). Hence the removal of arabinoxylans from agricultural by-products becomes highly desirable.

To degrade arabinoxylans completely, a number of enzymes are required including xylanases, β-xylosidase, α-arabinofuranosidase, acetyl and feruloyl esterases and α-D-glucuronosidases (Courtin et al., 2006). Among them xylanase (EC 3.2.1.8), which can catalyze the hydrolysis of the xylopyranosyl linkages of β-1,4-xylan and randomly cut the arabinoxylan backbone to produce a wide range of arabinoxylan fragments, plays the most important role. Supplementation of xylanase into the feed has thus been reported as an efficient method to increase the apparent faecal digestibility coefficients of crude protein, crude fat, crude fibre and organic matter, and improved energy absorption (Lindberg et al., 2007; Tapingkae et al., 2008; Sterk et al., 2007; Nortey et al., 2007). So far commercial xylanase products have already appeared on the market and most of them are produced by Bacillus (Heck et al., 2006; Gessesse and Mamo, 1999), Aspergillus (Wu et al., 2005; Senthilkumar et al., 2005; Botella et al., 2007), Penicillium oxalicum (Li et al., 2007a; 2007b), Paecilomyces themophila (Yang et al., 2006) and Thermomyces lanuginosus (Sonia et al., 2005).

Production of xylanase by solid-state fermentation (SSF) using various lignocellulosic substrates has been reported previously (Ghanem et al., 2000; Li et al., 2007c) and was found to have several advantages, such as higher productivity as well as lower operational and capital costs. Because the cost of the enzyme is the major factor for broad application, approaches that either decrease the medium cost or increase production efficiency should be investigated. Since SSF can be performed on a variety of lignocellulosic materials, such as wheat straw, wheat bran and corncob, the cost of xylanase production can be reduced greatly. On the another hand, high yield xylanase production strains have been screened by Yang et al.(2006), but the fermentation time was 4~12 d and that was not adequate in meeting industrial needs (Narang et al., 2001; Park et al., 2002; Bakri et al., 2003; Wu et al., 2005; Yang et al., 2006). Recently an Aspergillus niger strain XY-1 was isolated for high-level xylanase production in our lab and its fermentation time was shortened to 2 d. It provided great expectations for use as an industrial strain.

The aim of this work was to apply statistical methods to optimize the fermentation medium compositions for the improvement of xylanase production by A. niger XY-1. A Placket-Burman design (PBD) (Plackett and Burman, 1946) was firstly used to identify the medium components which had significant effects on xylanase production. A central composite design (CCD) (Box and Wilson, 1951) was then employed to optimize the factors that had a significant influence on xylanase production.

MATERIALS AND METHODS

Microorganism and chemicals

The organism used in the current study was A. niger XY-1, identified by the China General Microbiological Culture Collection Center. The strain was grown on potato dextrose agar (PDA) slants at 28 °C for 5 d and then stored at 4 °C. Inoculum was prepared by suspending the spores from a PDA slant by adding sterile distilled water to give a final spore count of 1×106 spores/ml. Unless indicated otherwise, all chemicals and reagents were purchased from Huadong Medicine Co., Ltd. Equipment Chemical Reagent Branch (Hangzhou, China).

SSF for xylanase production

Wheat bran was purchased from a local market and used as the solid substrate in the experiments. The fermentation medium was made by adding 10 g of wheat bran to a 300-ml Erlenmeyer flask, then mixed with 10 ml of additive nutrient solution (changed according to experimental needs) to give the final moisture ratio of 1:1 (w/v). After sterilization by autoclaving at 121 °C for 30 min, the medium in the flask was cooled down and inoculated with 1 ml spores suspension, then incubated at 28 °C for 48 h. To assess the effects of medium ingredients on the production of xylanase by using PBD and CCD, the composition of the nutrient solution varied according to the experimental designs.

PBD for valuating the factors effect

There are a range of factors that need to be tested for their importance in xylanase production. PBD is a useful tool to screen ‘n’ variables (‘n−3’ actual factors and ‘3’ invented variables for estimating errors) in just ‘n+1’ experiments (Plackett and Burman, 1946), which will reduce the enormous total number of experiments in comparison with full factorial designs which require 2N (N denotes the number of factors) experiments. The factors investigated in the current study included eight easily metabolized sugars (glucose, xylose, maltose, galactose, lactose, sucrose, mannose and raffinose), seven nitrogen sources (yeast extract, peptone, beef extract, (NH4)2SO4, NaNO2, NaNO3 and urea) and five salt additives (CaCl2, FeSO4, Na2CO3, MgSO4 and KH2PO4). Each variable was tested at two levels. The high level was 5 g/L (+) and the low level was 0 g/L (−). The impact of each variable on xylanase activity was estimated based on comparison of the difference in the mean between the high level (+) and the low level (−).

CCD for ingredient optimization

Based on the results from PBD experiments, three factors that significantly affected the xylanase production were identified and optimized further using the response surface methodology (RSM). The CCD with three factors and five levels including six replicates at the centre point was used to fit the second order response surface. Table 1 shows the factors and values. This methodology allows the modeling of a second-order equation that describes the process. Xylanase production was analyzed by multiple regressions through the least squares method to fit the following equation:

, ,

|

where Y represents response variable, a 0 is the interception coefficient, ai is the coefficient of the linear effect, aii is the coefficient of quadratic effect and aij is the coefficient of interaction effect. xi and xj denote the coded levels of variable Xi and Xj in experiments. The variable Xi was coded as xi according to the following transformation equation:

| xi=(Xi−X0)/ΔXi, |

where xi is the dimensionless coded value of the variable Xi, X 0 is the value of Xi at the center point, and ΔXi is the step change.

Table 1.

Coded values of variables used in CCD

| Coded value xi | Independent variables Xi (g/L) |

||

| Urea (i=1) | Na2CO3 (i=2) | MgSO4 (i=3) | |

| −1.68 | 23.18 | 2.64 | 4.64 |

| −1 | 30.00 | 4.00 | 6.00 |

| 0 | 40.00 | 6.00 | 8.00 |

| 1 | 50.00 | 8.00 | 10.00 |

| 1.68 | 56.82 | 9.36 | 11.36 |

Crude enzyme extraction

After 48 h incubation the sample was transferred into the drier at 40 °C until its moisture content of the medium was below 10%, then pulverized through a 0.25-mm sieve. A 1 g sample was soaked with 160 ml distilled water and kept in 40 °C water bath for 30 min. The enzyme extract was filtered by a Whatman #1 analytical filter and the suitable dilution was stored at 4 °C for further analysis.

Xylanase assay

The xylanase activity was determined using Oat spelts xylan (Sigma Co., USA) as substrate. The reducing sugars produced were quantified by the dinitrosalicylic acid method using D-xylose as standard. In brief, the reaction containing 0.5 ml of appropriate enzyme solution and 0.5 ml of 1% (w/v) oat spelts xylan (pH 5.0 acetate buffer) was incubated in a water bath at 40 °C for 15 min, then determinated by adding 1.5 ml of dinitrosalicylic acid solution. After incubation in a boiling bath for 5 min, the liberated reducing sugars were measured at 540 nm wavelength with spectrophotometer (VIS-7220). One unit (U) of xylanase activity was defined as the amount of enzyme that released 1 μmol of xylose per minute under the assay conditions. Xylanase production of fermentation was expressed as U/g dry substrate.

Statistical analysis

Quantification of enzyme activity was carried out in duplicate experiments and the mean values were given. The significance of each variable in the PBD experiment was determined by applying the Student’s t-test using MINITAB statistical software (6sigma, Mb13). For the CCD experiment the working parameters were calculated and generated response surface graphs using MINITAB statistical software. The accuracy and general ability of the above polynomial model could be evaluated by the determination coefficient (R 2).

RESULTS AND DISCUSSION

PBD and response values

PBD for 20 factors made a total of 24 experimental treatments. The PBD factors and response values are listed in Table 2. From the listed data, treatment 11 with A−B−C+D−E+F−G−H+J+K−L−M+N+O−P+Q−R+S+T+U+ gave a better value than the others.

Table 2.

The PBD and the experimental results

| Trial | Coded value xi |

Y (U/g dry substrate) | |||||||||||||||||||

| A | B | C | D | E | F | G | H | J | K | L | M | N | O | P | Q | R | S | T | U | ||

| 1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | 6048 |

| 2 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 6628 |

| 3 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | 7344 |

| 4 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | 5466 |

| 5 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | 6932 |

| 6 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 5934 |

| 7 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 5722 |

| 8 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | 7164 |

| 9 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | 6242 |

| 10 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 6068 |

| 11 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 7626 |

| 12 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | 6118 |

| 13 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 6162 |

| 14 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 6454 |

| 15 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | 5798 |

| 16 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | 6014 |

| 17 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | 6682 |

| 18 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | 5950 |

| 19 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | 5630 |

| 20 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 6270 |

| 21 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 5342 |

| 22 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 6350 |

| 23 | −1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 5408 |

| 24 | −1 | −1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | 6600 |

A: Glucose; B: Xylose; C: Maltose; D: Lactose; E: Sucrose; F: Mannose; G: Galactose; H: Yeast extract; J: Peptone; K: Raffinose; L: Beef extract; M: (NH4)2SO4; N: KH2PO4; O: MgSO4; P: FeSO4; Q: CaCl2; R: Na2CO3; S: NaNO2; T: NaNO3; U: Urea

Table 3 shows test factors and the rank of significance. Among them the reliability of NaNO3, yeast extract, urea, Na2CO3, MgSO4, CaCl2, peptone, xylose, (NH4)2SO4, sucrose and raffinose reached 90%, suggesting a significant effect on xylanase production. When the concentrations of CaCl2, xylose, sucrose and raffinose were increased, xylanase production declined. In contrast, positive effects on xylanase production were observed when the levels of NaNO3, yeast extract, urea, Na2CO3, MgSO4, peptone and (NH4)2SO4 were increased. The factors resulting in a negative effect on xylanase production were no longer taken into account, while the positive factors were included in the next CCD optimization.

Table 3.

The factors included in the PBD and the importance ranking

| Variable | Coefficient | t-test | P>|t| | Ranking |

| Interception | 6248 | 272.46 | 0 | |

| A | −1.84 | −0.08 | 0.943 | 20 |

| B | −122.34 | −5.34 | 0.013 | 7 |

| C | 12.34 | 0.53 | 0.631 | 19 |

| D | −24.00 | −1.05 | 0.372 | 16 |

| E | −84.84 | −3.71 | 0.034 | 10 |

| F | −42.34 | −1.85 | 0.161 | 15 |

| G | −42.66 | −1.87 | 0.158 | 14 |

| H | 226.00 | 9.85 | 0.002 | 2 |

| J | 122.84 | 5.36 | 0.013 | 7 |

| K | −61.00 | −2.66 | 0.076 | 11 |

| L | 17.00 | 0.75 | 0.508 | 17 |

| M | 97.16 | 4.24 | 0.024 | 9 |

| N | 13.16 | 888.90 | 0.570 | 18 |

| O | 138.34 | 6.03 | 0.009 | 5 |

| P | −52.84 | −2.30 | 0.105 | 12 |

| Q | −131.00 | −5.71 | 0.011 | 6 |

| R | 180.16 | 7.84 | 0.004 | 4 |

| S | 51.00 | 2.23 | 0.112 | 13 |

| T | 349.00 | 15.21 | 0.001 | 1 |

| U | 200.34 | 8.73 | 0.003 | 3 |

A: Glucose; B: Xylose; C: Maltose; D: Lactose; E: Sucrose; F: Mannose; G: Galactose; H: Yeast extract; J: Peptone; K: Raffinose; L: Beef extract; M: (NH4)2SO4; N: KH2PO4; O: MgSO4; P: FeSO4; Q: CaCl2; R: Na2CO3; S: NaNO2; T: NaNO3; U: Urea

It was postulated that the positive effects of NaNO3, yeast extract, urea, peptone and (NH4)2SO4 on xylanase production could be attributed to the requirement for nitrogen sources during fermentation, whereas beef extract and NaNO2 had little effect. The optimal nitrogen source for xylanase production was diversified depending on the microorganisms tested. It was reported that Aspergillus fischeri Fxn 1, Thermomyces lanuginosus D2W3, Aspergillus terreus and Aspergillus sp. Zh-26 can use (NH4)2SO4 and NaNO2 as the best optimal nitrogen sources (Ghanem et al., 2000; Senthilkumar et al., 2005; Sonia et al., 2005; Li et al., 2007c), while Paecilomyces themophila J18 used yeast extract as the best nitrogen source (Yang et al., 2006). Based on our knowledge it was the first report showing that NaNO3, yeast extract and urea have the most significant effect on xylanase production. For inorganic nitrogen sources like NaNO2, it was reported that this could reduce sporulation by decreasing the conidiation level (Sanchez and Pilosof, 2000). Senthilkumar et al.(2005) found that NaNO2 has a significant effect on xylanase production by Aspergillus fischeri Fxn 1, and that the reduced level of protease activity was directly responsible for the retention of xylanase activity in the optimized medium. In current study NaNO2 had no significant effect on xylanase production. A fermentation medium lacking an exogenous supply of nitrogen yielded relatively high enzyme activity, indicating that the substrate already supplied the organism with an adequate amount of nitrogen.

Metabolizable sugars such as glucose, xylose, sucrose, lactose, maltose, raffinose, galactose and mannose demonstrated different influences on xylanase production for different microorganisms. Glucose, maltose and xylose acted as the induction materials for a few strains but showed repression for other strains (Gessesse and Mamo, 1999). In contrast, galactose acted as the repression material for most strains (Sun et al., 2007). Wheat bran systems were resistant to catabolic repression even at high concentrations of glucose (Gessesse and Mamo, 1999; de Souza et al., 2001). In the current experiment, only maltose had a positive but not statistically significant effect on xylanase production by A. niger XY-1. Other sugars such as xylose, sucrose and raffinose showed a significantly negative effect. A slight repression effect was observed with galactose, mannose and lactose, while, due to its wheat bran buffering capacity, glucose showed little effect on xylanase production.

Ca2+ was found to be the essential element for xylanase productivity and stability by Aspergillus terreus and Chainia sp. (Bandivadekar and Deshpande, 1994; Ghanem et al., 2000). However, in the current study a negative effect was detected on xylanase production. All these results indicated the need for a nutrients experiment for xylanase production using different strains.

Optimal nitrogen source for A. niger XY-1

From PBD, NaNO3, yeast extract and urea were recognized as the suitable nitrogen sources for A. niger XY-1 xylanase production. To compare those three nitrogen sources, different concentrations of NaNO3, yeast extract and urea were tested for xylanase production. The fermentation medium was composed of 10 g of wheat bran and different concentrations of the nitrogen sources. As indicated in Table 4, the maximal xylanase enzyme activity reached 9543, 9432 and 9531 U/g dry substrate when 40 g/L of NaNO3, 300 g/L of yeast extract and 30 g/L of urea were added respectively. It was interesting to note that the maximal enzyme activity achieved by the three nitrogen sources was similar, while the concentration of yeast extract in the medium was much higher than those of NaNO3 and urea. For future cost concerns, urea was chosen as the best nitrogen source. Li et al.(2007d) reported that Alternaria mali ND-16 used NH4Cl and urea as nitrogen sources for xylanase production, but NH4Cl acted as the primary nitrogen source and urea acted as the secondary nitrogen source.

Table 4.

Effect of nitrogen concentration on xylanase production

| Nitrogen source | Concentration (g/L) | Xylanase activity (U/g dry substrate) |

| NaNO3 | 10 | 6512±110 |

| 20 | 6934±92 | |

| 30 | 7746±118 | |

| 40 | 9543±59 | |

| 50 |

7464±68 |

|

| Yeast extract | 50 | 5502±95 |

| 100 | 7109±62 | |

| 200 | 7642±130 | |

| 300 | 9432±200 | |

| 400 |

4579±64 |

|

| Urea | 10 | 6620±122 |

| 20 | 7987±31 | |

| 30 | 9531±189 | |

| 40 | 7970±128 | |

| 50 | 4776±105 |

Outcome of CCD experiment

CCD is a very useful tool for determining the optimal level of medium constituents and their interaction. Based on the results from PBD and nitrogen optimal experiments, urea, Na2CO3 and MgSO4 were selected for the further evaluation of their effects on xylanase production by CCD. Table 1 shows the maximum and minimum levels of variables chosen in the CCD. For RSM analysis based on the CCD, 20 experiments were carried out and their response values with different combinations of three factors are demonstrated in Table 5.

Table 5.

Experimental design and results of the CCD

| Run No. | Coded variables |

Response (U/g dry substrate) |

|||

| x1 (urea) | x2 (Na2CO3) | x3 (MgSO4) | Actual | Predicted | |

| 1 | −1 | 1 | 1 | 13110 | 12842.1 |

| 2 | 0 | 0 | 0 | 14158 | 13958.2 |

| 3 | 0 | 0 | −1.68 | 13110 | 13328.6 |

| 4 | −1 | −1 | 1 | 13022 | 12759.0 |

| 5 | −1 | −1 | −1 | 12948 | 12274.7 |

| 6 | 0 | 0 | 0 | 13922 | 13958.2 |

| 7 | 1 | 1 | −1 | 10900 | 10753.4 |

| 8 | −1 | 1 | −1 | 12936 | 13198.8 |

| 9 | 0 | 0 | 0 | 13684 | 13958.2 |

| 10 | 0 | 0 | 0 | 14084 | 13958.2 |

| 11 | 0 | −1.68 | 0 | 13048 | 13892.4 |

| 12 | 0 | 0 | 0 | 13860 | 13958.2 |

| 13 | 1 | −1 | −1 | 12774 | 12632.4 |

| 14 | 1 | −1 | 1 | 14158 | 13485.7 |

| 15 | 0 | 0 | 0 | 14144 | 13958.2 |

| 16 | −1.68 | 0 | 0 | 10988 | 11351.0 |

| 17 | 1.68 | 0 | 0 | 9690 | 9907.4 |

| 18 | 0 | 1.68 | 0 | 12648 | 12383.9 |

| 19 | 0 | 0 | 1.68 | 13384 | 13745.8 |

| 20 | 1 | 1 | 1 | 10502 | 10765.8 |

From Table 5 it can be seen that the centre points were set up at runs of 2, 6, 9, 10, 12, 15 and the maximum xylanase production was achieved at the centre points. The minimum xylanase production (9690 U/g dry substrate) was detected in run No. 17.

From multiple regression analysis, we found that the second-order polynomial equation can explain xylanase production regardless of the significance of coefficients:

, ,

|

where Y is the response value. In current experiment, Y value is the level of xylanase production (U/g dry substrate). x 1, x 2 and x 3 represent the coded levels of urea, Na2CO3 and MgSO4, respectively.

The statistical significance of the regression model was checked by F-test, and the analysis of variance for the response surface quadratic model is shown in Table 6. The model was highly significant, as manifested by the F-value and the probability value [(P total model>F)=0.000]. The linear terms, quadratic terms and cross terms were all statistically significant based on the F-value. The data from the analysis of variance showed that the second-order model was well fitted to the experimental data. The goodness of fit was manifested by the determination coefficient (R 2). In this case the R 2 value of 92.2% indicated that the response model can explain 92.2% of the total variations. In general, a regression model having an R 2 value higher than 0.9 is considered to have a very high correlation (Haaland, 1989). The value of the adjusted determination coefficient (R Adj 2=85.3%) was also high enough to indicate the significance of the model.

Table 6.

Analysis of variance for the response of xylanase production

| Source | df | ∑x2 (×106) | F-value | P>F |

| Linear product | 3 | 5.47 | 7.18 | 0.007 |

| Quadratic product | 3 | 20.43 | 26.78 | 0.000 |

| Cross product | 3 | 4.35 | 5.70 | 0.015 |

| Total model | 9 | 30.26 | 13.22 | 0.000 |

| Total error | 10 | 2.54 |

The Student’s t-distribution and the corresponding P-value, along with the parameter, are given in Table 7. The P-values are used as a tool to check the significance of each coefficient, which will help to explain the pattern of mutual interactions between the best variables. The parameter coefficient and the corresponding P-value suggested that, among the independent variables, x 1 (urea) and x 2 (Na2CO3) have a significant effect on xylanase production.

Table 7.

Results of the regression analysis of the CCD

| Source | Coefficient | SE | t-test | P>|t| |

| Interception | 13958 | 205.7 | 67.868 | 0.000 |

| x1 | −430 | 136.5 | −3.147 | 0.010 |

| x2 | −449 | 136.5 | −3.288 | 0.008 |

| x3 | 124 | 136.5 | 0.910 | 0.384 |

| x12 | −1179 | 133.1 | −8.864 | 0.000 |

| x22 | −291 | 133.1 | −2.183 | 0.054 |

| x32 | −149 | 133.1 | −1.121 | 0.288 |

| x1x2 | −701 | 178.3 | −3.930 | 0.003 |

| x1x3 | 92 | 178.3 | 0.517 | 0.616 |

| x2x3 | −210 | 178.3 | −1.179 | 0.266 |

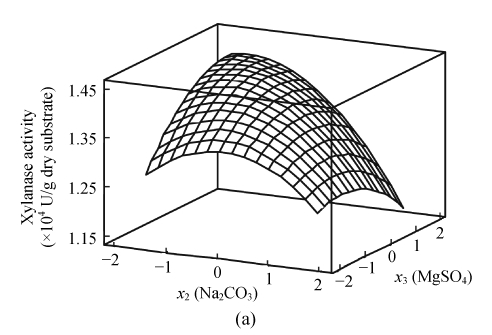

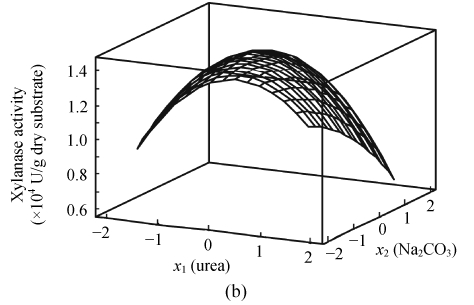

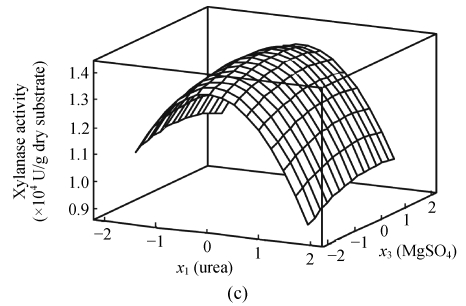

The 3D response surfaces plots were employed to determine the interaction of the basal medium components and the optimum levels that have the most significant effect on xylanase production. Fig.1 illustrated the relationship between the response and the experimental data. Fig.1a describes the effects of Na2CO3 and MgSO4 on xylanase production, when urea was fixed at its middle level (40 g/L). From Fig.1a it can be seen that the yield of xylanase production decreased gradually while the Na2CO3 concentration increased at a high level of MgSO4. With the increase in the concentration of MgSO4, the xylanase production steadily increased at a low concentration of Na2CO3. This observation was consistent with the results demonstrated in Table 7, which suggest a negative interaction of Na2CO3 and MgSO4. Fig.1b demonstrates the effects of urea and Na2CO3 on xylanase production when the MgSO4 concentration was fixed at its middle level (8 g/L). The xylanase production was predominantly affected by the urea concentration and the interaction between urea and Na2CO3 was significantly negative for xylanase production. Similarly Fig.1c shows the effects of urea and MgSO4 on the xylanase production when the concentration of Na2CO3 was set at the middle level (6 g/L).

Fig. 1.

Response surface for xylanase production by A. niger. The interaction between Na2CO3 and MgSO4 (a), urea and Na2CO3 (b) and urea and MgSO4 (c)

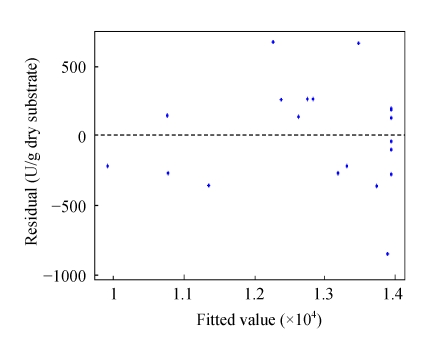

In general it is necessary to compare the fitted model with the real system and confirm that the fitted model provides an adequate approximation. Unless the model shows an adequate fit, proceeding further with a fitted response surface may end in misleading results. The residuals from the least squares fit play an important role in judging the model adequacy. Fig.2 presents a plot of residuals versus the predicted response. The plot shows the residuals scattered randomly on the display, suggesting that the variance of the original observation was constant for all values of xylanase enzyme activity (Y). Because the plot of xylanase production was satisfactory, the conclusion can be drawn that the empirical model was adequate to describe the xylanase activity by response surface.

Fig. 2.

Plot of residuals versus fitted value of xylanase production

The prediction from response optimizer analysis gives a maximum level of xylanase as 14374.6 U/g dry substrate in the medium containing x 1 (urea)=0.163 (41.63 g/L), x 2 (Na2CO3)=−1.68 (2.64 g/L), x 3 (MgSO4)=1.338 (10.68 g/L). Verification of the predicted values was conducted by using optimal conditions in fermentation. The practical corresponding response was 14637 U/g dry substrate, which corroborated the validity and the effectiveness of the current model.

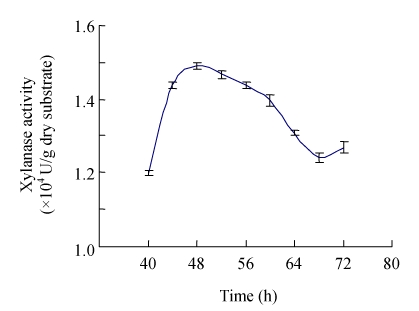

Time course curve

To evaluate the effect of the optimized medium on xylanase production, the time course of enzyme activities was conducted for 72 h. Maximum production was observed at 48 h (Fig.3). Further incubation beyond this time point did not show any improvement in any aspect of enzyme production.

Fig. 3.

Time course of xylanase production by A. niger XY-1

In comparison with other xylanase production strains (Table 8), A. niger XY-1 showed a shortened fermentation time and a relatively high enzyme yield.

Table 8.

Comparison of xylanase production by different strains in SSF

| Strains | Xylanase activity (U/g dry substrate) | Fermentation time (h) | References |

| Aspergillus XY-1 | 14637 | 48 | This work |

| Aspergillus fischeri Fxn1 | 1024 | 72 | Senthilkumar et al., 2005 |

| Thermomyces lanuginosus D2W3 | 48000 | 144 | Sonia et al., 2005 |

| Bacillus sp. | 720 | 72 | Gessesse and Mamo, 1999 |

| Aspergillus niger N218 | 6320 | 64 | Wu et al., 2005 |

CONCLUSION

Xylanase production by A. niger XY-1 was optimized using response analysis, which was found to be an efficient tool. From PBD and nitrogen screening experiments, urea, Na2CO3 and MgSO4 were shown to be critical components for xylanase production by A. niger XY-1. The CCD experiment estimated the optimum values of the critical components for maximum xylanase production. Under the following conditions: x 1 (urea)=0.163 (41.63 g/L), x 2 (Na2CO3)=−1.68 (2.64 g/L), x 3 (MgSO4)=1.338 (10.68 g/L) and with a substrate of wheat bran, the predicted xylanase activity was 14374.6 U/g dry substrate. In the current experiment, xylanase production reached 14637 U/g dry substrate after 48 h of fermentation in the shake flask experiment, which accorded with the predicted value. In summary, the facts that no additional expensive medium was required and that there was a shortened fermentation time for higher xylanase production by A. niger XY-1 show the potential for industrial utilization.

Footnotes

Project (No. 2004C32049) supported by the Science and Technology Department of Zhejiang Province, China

References

- 1.Bakri Y, Jacques P, Thonart P. Xylanase production by Penicillium canescens 10-10c in solid-state fermentation. Appl Biochem Biotechnol. 2003;108(1-3):737–774. doi: 10.1385/ABAB:108:1-3:737. [DOI] [PubMed] [Google Scholar]

- 2.Bandivadekar KR, Deshpande VV. Enhanced stability of cellulase free xylanase from Chainia sp. (NCL. 82.5.1) Biotechnol Lett. 1994;16(2):179–182. doi: 10.1007/BF01021667. [DOI] [Google Scholar]

- 3.Barrera M, Cervantes M, Sauer WC, Araiza AB, Torrentera N, Cervantes M. Ileal amino acid digestibility and performance of growing pigs fed wheat-based diets supplemented with xylanase. J Anim Sci. 2004;82(7):1997–2003. doi: 10.2527/2004.8271997x. [DOI] [PubMed] [Google Scholar]

- 4.Botella C, Diaz A, de Ory I, Webb C, Blandino A. Xylanase and pectinase production by Aspergillus awamori on grape pomace in solid state fermentation. Process Biochemistry. 2007;42(1):98–101. doi: 10.1016/j.procbio.2006.06.025. [DOI] [Google Scholar]

- 5.Box G, Wilson KB. On the experimental attainment of optimum conditions. J Roy Stat. 1951;13(1):1–45. [Google Scholar]

- 6.Courtin CM, Gys W, Delcour JA. Arabinoxylans and endoxylanases in refrigerated dough syruping. J Sci Food Agric. 2006;86(11):1587–1595. doi: 10.1002/jsfa.2500. [DOI] [Google Scholar]

- 7.de Souza DF, de Souza CGM, Peralta RM. Effect of easily metabolizable sugars in the production of xylanase by Aspergillus tamari in solid-state fermentation. Proc Biochem. 2001;36(8-9):835–838. doi: 10.1016/S0032-9592(00)00295-8. [DOI] [Google Scholar]

- 8.Gessesse A, Mamo G. High-level xylanase production by an alkaliphilic Bacillus sp. by using solid-state fermentation. Enzyme and Microbial Technology. 1999;25(1-2):68–72. doi: 10.1016/S0141-0229(99)00006-X. [DOI] [Google Scholar]

- 9.Ghanem NB, Yusef HH, Mahrouse HK. Production of Aspergillus terreus xylanase in solid-state cultures: application of the Plackett-Burman experimental design to evaluate nutritional requirement. Bioresource Technology. 2000;73(2):113–121. doi: 10.1016/S0960-8524(99)00155-8. [DOI] [Google Scholar]

- 10.Haaland PD, editor. Experimental Design in Biotechnology. New York: Marcel Dekker; 1989. Separating Signals from the Noise; pp. 61–83. [Google Scholar]

- 11.Heck JX, Flores SH, Hertz PF, Ayub MAZ. Statistical optimization of thermo-tolerant xylanase activity from Amazon isolated Bacillus circulans on solid-state cultivation. Bioresource Technology. 2006;97(15):1902–1906. doi: 10.1016/j.biortech.2005.08.013. [DOI] [PubMed] [Google Scholar]

- 12.Li Y, Cui FJ, Liu ZQ, Xu YY, Zhao H. Improvement of xylanase production by Penicillium oxalicum ZH-30 using response surface methodology. Enzyme and Microbial Technology. 2007;40(5):1381–1388. doi: 10.1016/j.enzmictec.2006.10.015. [DOI] [Google Scholar]

- 13.Li Y, Liu ZQ, Zhao H, Xu YY, Cui FJ. Statistical optimization of xylanase production from new isolated Penicillium oxalicum ZH-30 in submerged fermentation. Biochemical Engineering Journal. 2007;34(1):82–86. doi: 10.1016/j.bej.2006.11.011. [DOI] [Google Scholar]

- 14.Li Y, Liu ZQ, Cui FJ, Xu YY, Zhao H. Application of experimental design to optimize culture requirements of Aspergillus sp. Zh-26 producing xylanase for degradation of arabinoxylans in mashing. Journal of Food Science. 2007;72(5):E320–E329. doi: 10.1111/j.1750-3841.2007.00389.x. [DOI] [PubMed] [Google Scholar]

- 15.Li Y, Liu ZQ, Cui FJ, Xu YY, Zhao H. Application of Plackett-Burman experimental design and Doehlert design to evaluate nutritional requirements for xylanase production by Alternaria mali ND-16. Appl Microbiol Biotechnol. 2007;77(2):285–291. doi: 10.1007/s00253-007-1167-6. [DOI] [PubMed] [Google Scholar]

- 16.Lindberg JE, Lyberg K, Sands J. Influence of phytase and xylanase supplementation of a wheat-based diet on ileal and total tract digestibility in growing pigs. Livestock Science. 2007;109(1-3):268–270. doi: 10.1016/j.livsci.2007.01.114. [DOI] [Google Scholar]

- 17.Narang S, Sahai V, Bisaria VS. Optimization of xylanase production by Melanocarpus albomyces IIS-68 in solid state fermentation using response surface methodology. J Biosci Bioeng. 2001;91(4):425–427. doi: 10.1263/jbb.91.425. [DOI] [PubMed] [Google Scholar]

- 18.Nortey TN, Patience JF, Sands JS, Zijlstra RT. Xylanase supplementation improves energy digestibility of wheat by-products in grower pigs. Livestock Science. 2007;109(1-3):96–99. doi: 10.1016/j.livsci.2007.01.092. [DOI] [Google Scholar]

- 19.Park YS, Kang SW, Lee JS, Hong SI, Kim SW. Xylanase production in solid state fermentation by Aspergillus niger mutant using statistical experimental designs. Appl Microbiol Biotechnol. 2002;58(6):761–766. doi: 10.1007/s00253-002-0965-0. [DOI] [PubMed] [Google Scholar]

- 20.Plackett RL, Burman JP. The design of optimum multifactorial experiments. Biometrika. 1946;33(4):305–325. doi: 10.1093/biomet/33.4.305. [DOI] [Google Scholar]

- 21.Sanchez VE, Pilosof AMR. Protease-conidia relationships of Aspergillus niger grown in solid state fermentation. Biotechnol Lett. 2000;22(20):1629–1633. doi: 10.1023/A:1005606309334. [DOI] [Google Scholar]

- 22.Senthilkumar SR, Ashokkumar B, Chandra Raj K, Gunasekaran P. Optimization of medium composition for alkali-stable xylanase production by Aspergillus fischeri Fxn 1 in solid-state fermentation using central composite rotary design. Bioresource Technology. 2005;96(12):1380–1386. doi: 10.1016/j.biortech.2004.11.005. [DOI] [PubMed] [Google Scholar]

- 23.Slominski BA, Boros D, Campbell LD, Guenter W, Jones O. Wheat by-products in poultry nutrition. Part I. Chemical and nutritive composition of wheat screenings, bakery by-products and wheat mill run. Can J Anim Sci. 2004;84:421–428. [Google Scholar]

- 24.Sonia KG, Chadha BS, Saini HS. Sorghum straw for xylanase hyper-production by Thermomyces lanuginosus (D2W3) under solid-state fermentation. Bioresource Technology. 2005;96(14):1561–1569. doi: 10.1016/j.biortech.2004.12.037. [DOI] [PubMed] [Google Scholar]

- 25.Sterk A, Verdonk JMAJ, Mul AJ, Soenen B, Bezençon ML, Frehner M, Losa R. Effect of xylanase supplementation to a cereal-based diet on the apparent faecal digestibility in weanling piglets. Livestock Science. 2007;108(1-3):269–271. doi: 10.1016/j.livsci.2007.01.077. [DOI] [Google Scholar]

- 26.Sun ZT, Zhao XY, Liu JJ, Du JH. Microbial xylanases and their industrial applications. Biotechnology. 2007;17(2):93–97. [Google Scholar]

- 27.Tapingkae W, Yachai M, Visessanguan W, Pongtanya P, Pongpiachan P. Influence of crude xylanase from Aspergillus niger FAS128 on the in vitro digestibility and production performance of piglets. Anim Feed Sci, Technol. 2008;140(1-2):125–138. doi: 10.1016/j.anifeedsci.2007.02.001. [DOI] [Google Scholar]

- 28.Wu M, Li SC, Yao JM, Pan RR, Yu ZL. Mutant of a xylanase-producing strain of Aspergillus niger in solid state fermentation by low energy ion implantation. World Journal of Microbiology Biotechnology. 2005;21(6-7):1045–1049. doi: 10.1007/s11274-004-7870-x. [DOI] [Google Scholar]

- 29.Yang SQ, Yan QJ, Jiang ZQ, Li LT, Tian HM, Wang YZ. High-level of xylanase production by the thermophilic Paecilomyces themophila J18 on wheat straw in solid-state fermentation. Bioresource Technology. 2006;97(15):1794–1800. doi: 10.1016/j.biortech.2005.09.007. [DOI] [PubMed] [Google Scholar]