Introduction

Failure analysis includes examination of a fractured component in order to investigate the circumstances surrounding a failure event with the expectation of eventually elucidating the cause of failure, whether it was a result of design deficiency, material deficiency (fabrication process) or in situ stress-induced conditions.

Fractography includes the examination of fracture surfaces that contain features resulting from the interaction of the advancing crack with the microstructure of the material and the stress fields. The description and interpretation of fracture markings used to understand failure events of brittle materials are summarized in a comprehensive, new book currently available, a NIST recommended practice guide for Fractography of Ceramics and Glasses 1 (free download at http://www.ceramics.nist.gov/pubs/practice.htm) as well as by the ASTM C1322-05a, Standard practice for fractography and characterization of fracture origins in advanced ceramics 2.

The key tools for performing fractography on failed parts are the binocular stereomicroscope and the scanning electron microscope (SEM). The stereomicroscope is often used to carry out the preliminary inspection of the fractured ceramic piece. Its separate optical paths with two eyepieces provide slightly different viewing angles to the left and right eyes. In this way the stereomicroscope produces a 3-D visualization of the sample being examined allowing better understanding of the spatial relationships of the observed fracture features which are best viewed by varying the angle of the illumination. In addition, it retains all color, surface roughness and reflectivity information of the fractured compound. The SEM, on the other hand, is an excellent complementary tool to the stereomicroscope analysis allowing for high-resolution close-ups of predetermined regions of interest. In many instances, an optical stereomicroscope examination is enough for an interpretation.

Very few papers in the dental literature have been published using a standardized approach of crack feature recognition to failure analysis of fractured ceramic restorations 3–10. Hence, the purposes of this paper are 1) to present a methodological approach using stereo and scanning electron microscope examination for failure analysis of an alumina all-ceramic premolar crown (Procera AllCeram)a that fractured in situ after 4 years of intra oral function and 2) to promote such analysis as a routine method for failure analysis of fractured ceramic restorations within the dental community.

Technical Nomenclature

Definitions of the most common fracture surface features visible in dental ceramics such as compression curl, hackle, wake hackle, twist hackle, corner hackle and arrest lines are summarized below for better understanding of this paper and have been lengthily described in the NIST guide textbook 1 as well as in several dental literature references 4,5,7–10. These will be used and illustrated in the present analysis of a broken Procera AllCeram crown.

Compression curl is the curved lip just before total fracture of a body loaded in bending. The existence of a compression curl is an important sign that the specimen either was loaded primarily in bending or had a strong bending component 1.

Hackle are lines on the surface running in the local direction of cracking, separating parallel, but noncoplanar portions of the crack surface 1. Hackle lines are commonly formed when the crack moves rapidly.

Other common features such as velocity hackle and shear hackle which are subsets of hackle have not been observed in this case but are described in the NIST recommended practice guide1.

Wake hackle is a hackle mark extending from a singularity at the crack front in the direction of cracking. It is created by the crack front advancing along the sides of the singularity (e.g. pore) before continuing on slightly different planes 1. Thus, wake hackle markings are excellent indicators of the direction of crack propagation.

Twist hackle markings are hackle that separate portions of the crack surface, each of which has rotated from the original crack plane in response to a lateral rotation or twist in the axis of principal tension. The roughly parallel segments point in the direction of local crack propagation. Twist hackle can be generated by the primary crack as it travels directly through the body, especially as it goes around corners or geometric irregularities, or as the stress conditions changed 1.

Corner hackle is a fan-like array of hackle lines created when a crack goes around a corner of a component 1 (e.g., the corner on a ceramic core material between the axial tooth wall and the occusal side).

An arrest line is a sharp line on the fracture surface defining the crack front shape of an arrested or momentarily hesitated crack prior to resumption of crack propagation under a more or less altered stress configuration 1. Arrest lines are also indicators of the direction of propagation as the beginning of a crack event is always located on the concave side of the first arrest line.

Materials and Methods

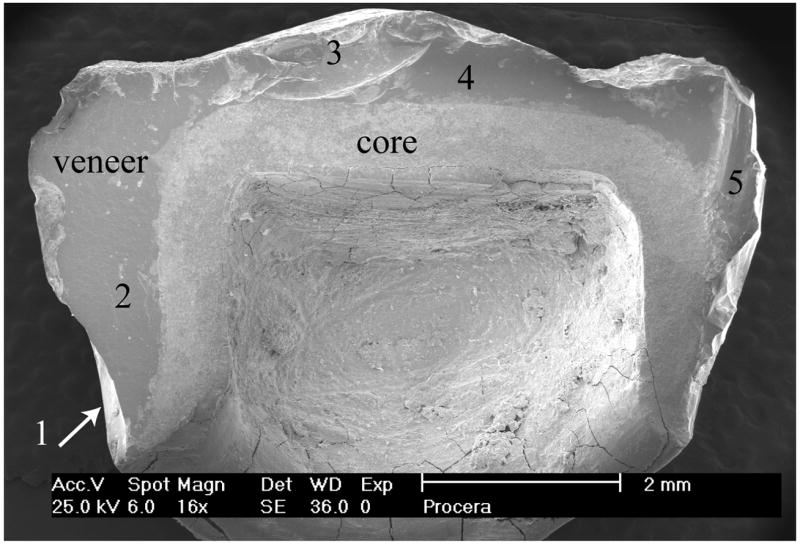

A Procera®AllCeram (Nobel Biocare, Sweden) upper premolar crown fractured through its full-thickness after 4 years of intra-oral function (Fig. 1a). The patient remembered biting on something hard and recovered the broken half of the crown (Fig. 1b) which was used for documentation and analysis. The Procera®AllCeram uses a computer aided system for the core design and manufacturing which is made of 99.9 vol % of alumina and veneered with an alumina based porcelain. The first examination of the broken Procera AllCeram crown piece was performed using a stereomicroscope (Wild M3Z, Heerbrugg, Switzerland). The analysis started at one margin of the crown piece, moving upwards towards the occlusal section and finishing at the other end of the crown, photographing all recognizable features within the traveling path. Magnifications of the stereomicroscope ranged from 10 to 200× depending on the size of the characteristic marks detected while constantly changing the illumination angle for better viewing of crack features. A preliminary mapping of the observed features was then sketched out indicating areas of interest for further examination under the SEM. After securing the “as received” initial microscopic state of the fractured crown part with digital photographs, the broken crown piece was cleaned in an ultrasonic alcohol bath for 10 minutes. The specimen was then gold coated for the SEM and the same sequence of analysis was performed as for the stereomicroscope but using magnifications up to 4000× for higher definition of specific key crack features in the selected areas of interest marked from 1 to 5 in Fig. 1c. Based on the microscope findings a final map was then created on an overall view of the failed component indicating the general crack propagation direction, the area where the crack originated and the sequence of crack events allowing for further discussion about the possible reasons for failure.

Fig. 1.

Fig. 1a. Procera AllCeram upper right second premolar crown fracture exposing part of tooth structure and amalgam restoration (Photo: courtesy of Dr. U. Brodbeck, Zurich, Switzerland).

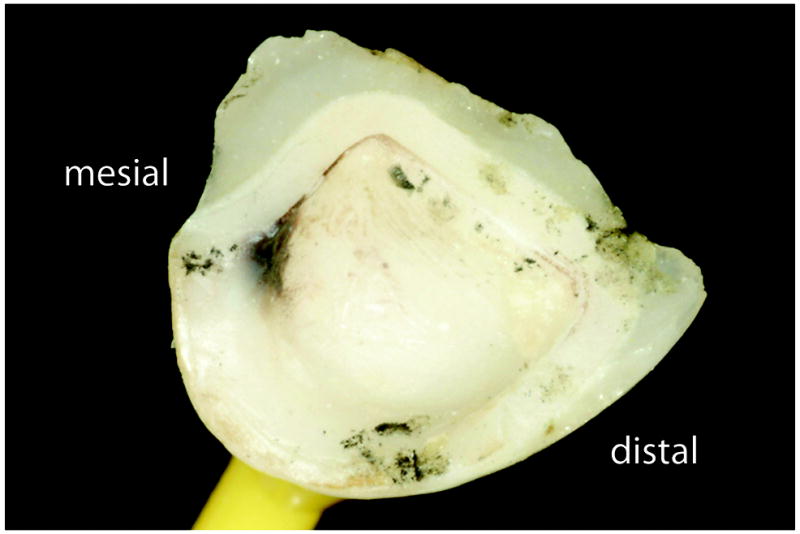

Fig. 1b. Recovered part by the patient of the broken Procera AllCeram premolar crown.

Fig. 1c. Recovered fractured Procera AllCeram crown part viewed at 16× under the SEM. Zones of interest for detailed fractographic analysis are numbered 1 to 5 starting at the mesial (left) margin to the other side of the crown.

Results

Fractographic stereomicroscope and SEM analysis

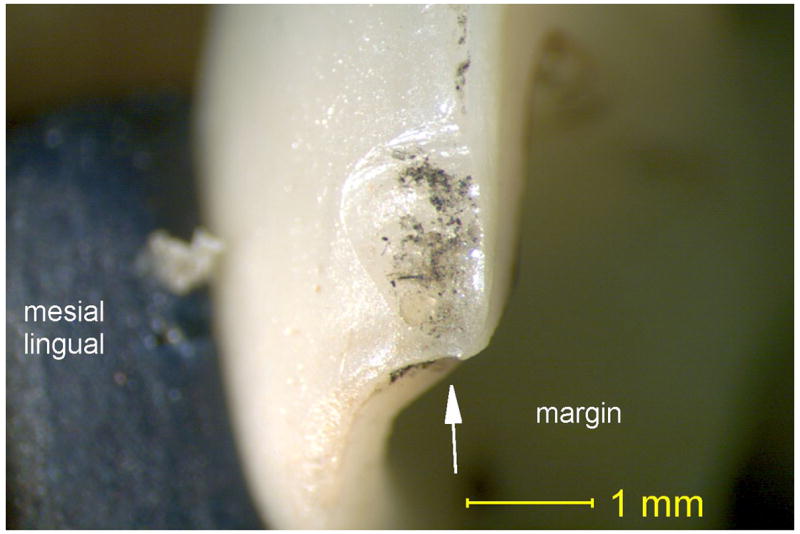

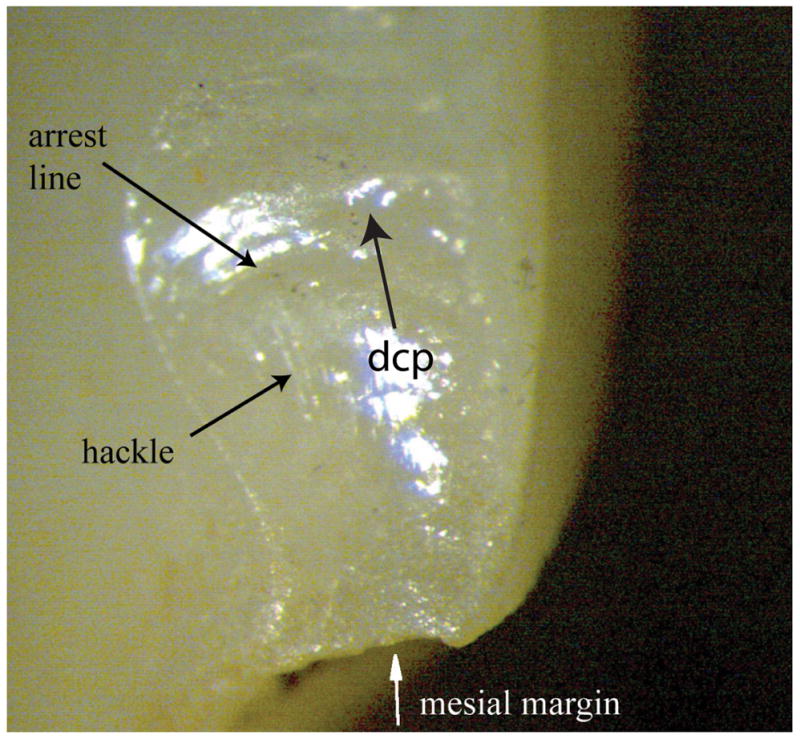

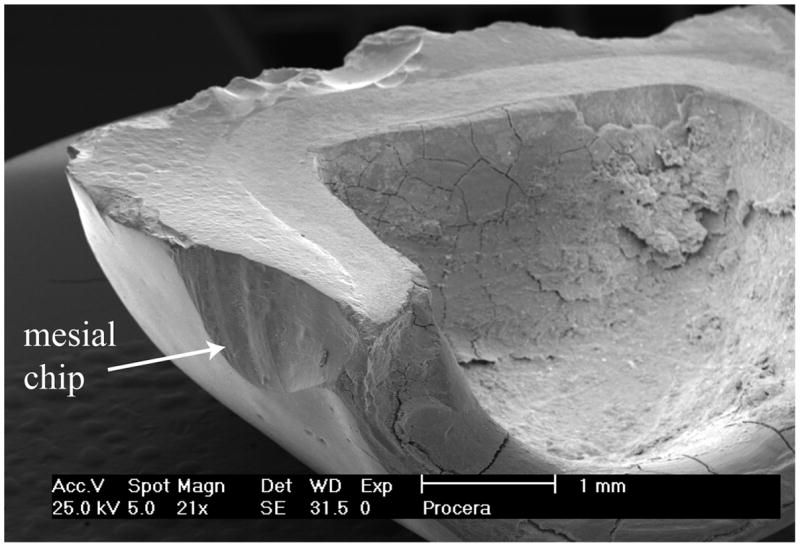

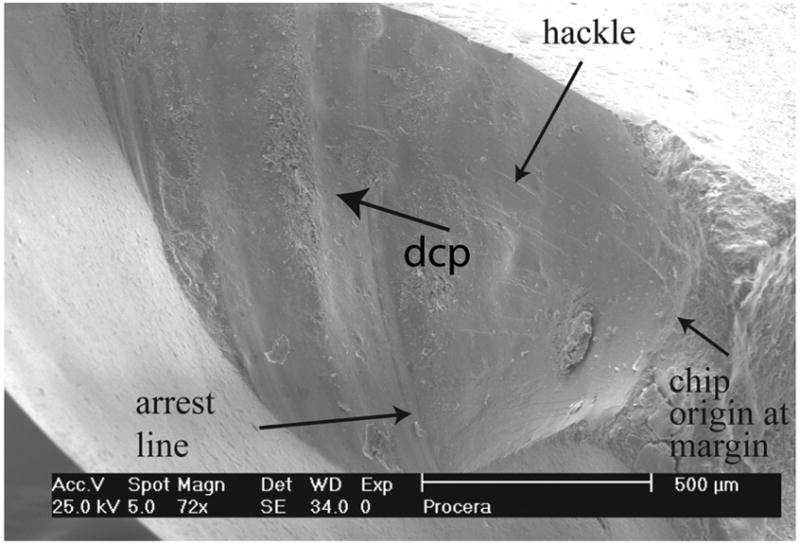

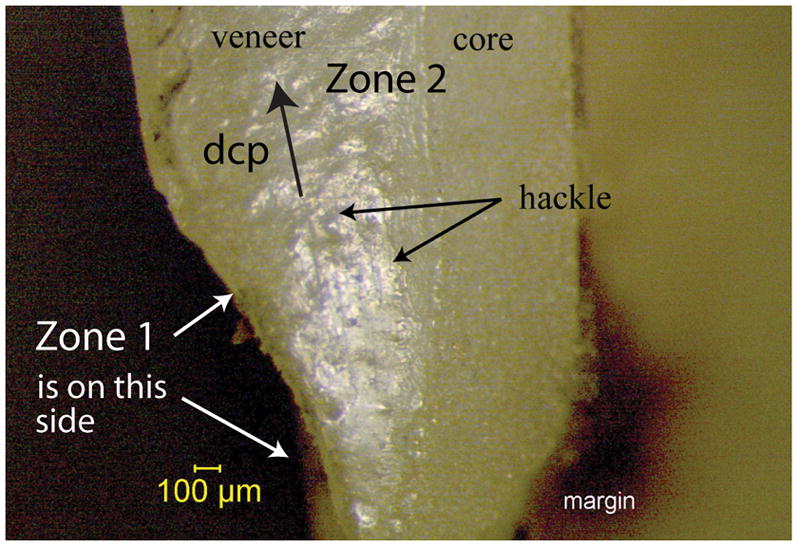

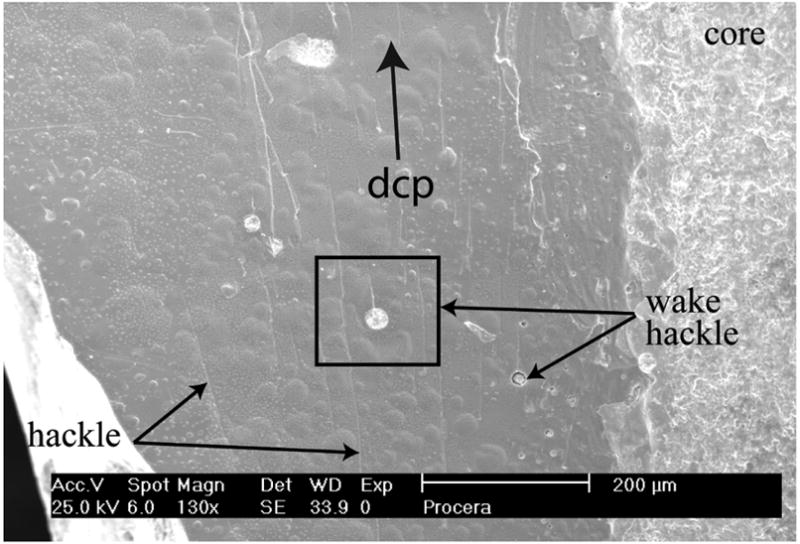

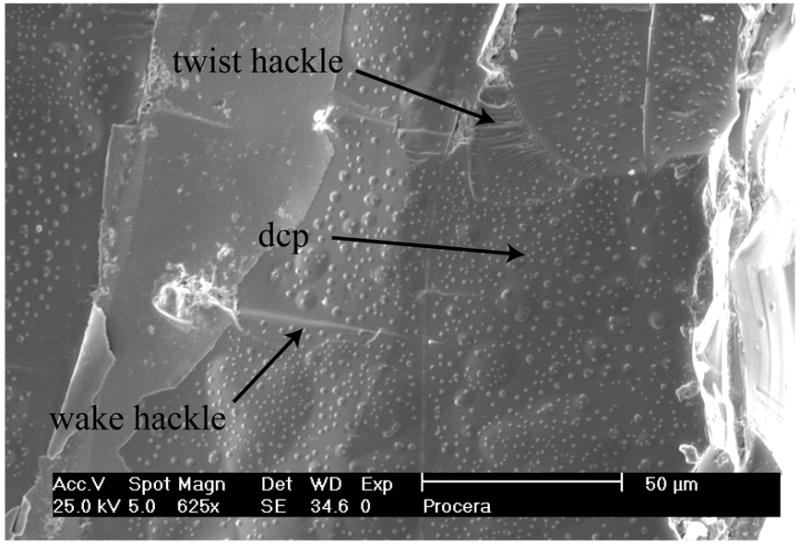

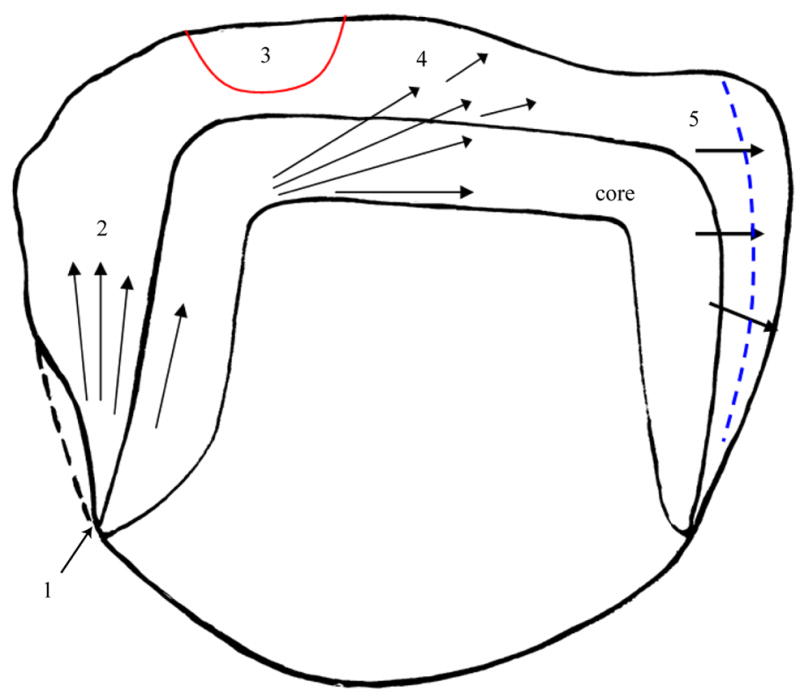

The initial stereo analysis starting at the mesial margin (zone of interest 1 in Fig. 1c) showed a porcelain veneer chip (1.5 mm × 2 mm) before (Fig. 2a) and after cleaning with ethanol (Fig. 2b). The fact that the chipped surface had considerable staining before it was cleaned with ethanol indicated that the fracture of the chip must have occurred early in the clinical age of the crown. Adjusting the light at different angles, several arrest lines and hackle became clearly visible on the chip. Greater magnifications under the SEM confirmed the presence of these features including wake hackle (Figs 3a–c) which are good indicators of the direction of crack propagation (dcp). Thus, this chip started at the mesial margin and propagated 2 mm upwards within the veneering ceramic before fracture. The recovered part of the fractured Procera crown was then examined on its rather flat fractured surface in the vicinity of the marginal mesial axial wall (zone 2). The stereo image of zone 2 (Fig. 4a) showed hackle and wake hackle easily seen on the veneering ceramic, as well as by using the SEM at greater magnifications (Figs. 4b,c). The direction of crack propagation (dcp) is again confirmed by the presence of wake hackle indicating that the crack moved from the mesial margin along the axial wall upwards towards the occlusal wall. On the occlusal side of the recovered crown part (zone 3) the veneering ceramic showed chip damage (Fig. 5a) as viewed under the stereomicroscope. Using the SEM, the concave orientation of the arrest lines (Fig. 5b) of the chipped veneering ceramic as well as the presence of many fine twist hackle (Fig. 5c) emanating from the arrest lines indicated that the chip damage started on the occlusal biting surface of the crown. The crack features of this occlusal chip however remained confined within the veneering ceramic thickness without penetrating into the alumina core. The inspection of zone 4 with the stereomicroscope nicely revealed arrays of hackle moving around the mesial axial corner (corner hackle) emanating from the alumina core towards the veneering ceramic (Fig. 6a). Higher magnifications with the stereomicroscope and fine tuning of the illumination angle revealed wake hackle within the veneering ceramic (Fig. 6b) indicating the crack front moved from mesial to distal and towards the occlusal surface. The last area of interest (zone 5) showed at low magnification the presence of a compression curl (Figs. 1b,7a) in form of a curved lip of approximately 2 mm in vertical length. Greater magnification under the SEM within the compression curl (Fig. 7b) revealed the presence of twist and wake hackle confirming the crack path moved outwards exiting at the axial distal wall. The key findings obtained after stereo analysis are sketched out as shown in Fig. 8a and confirmed by a summary SEM image (Fig. 8b) on which arrows have been drawn indicating the general direction of crack propagation based on the presence of identified crack features.

Fig. 2.

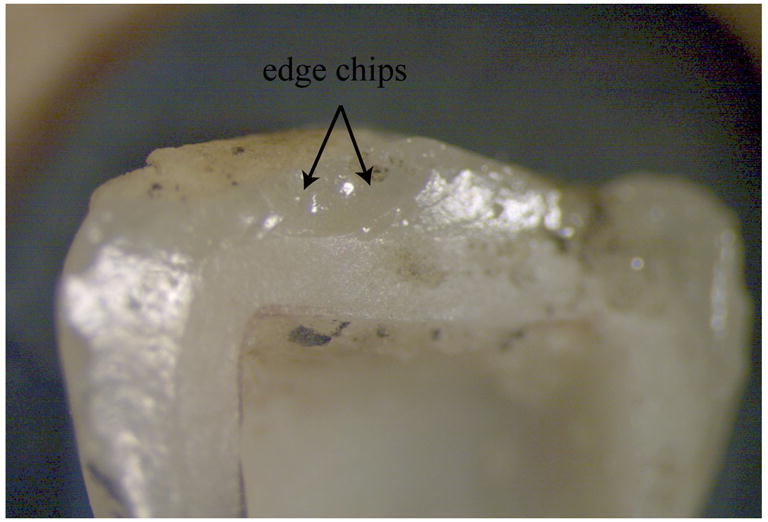

Fig. 2a. Stereomicroscope image of a mesial marginal edge chip within the veneering ceramic in zone 1 before cleaning the specimen. Note the localized staining covering the chipped ceramic surface.

Fig. 2b. Stereomicroscope image of the same chipped zone 1 after cleaning the crown part 10 minutes in an ultrasonic ethanol bath removing the stain. The arrow labeled “dcp” shows the direction of crack propagation.

Fig. 3.

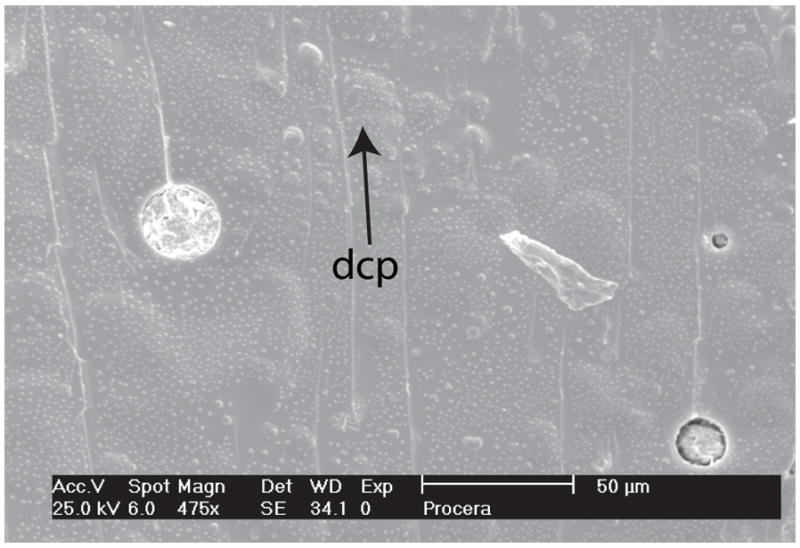

Figs. 3a-c. SEM images of the chip in zone 1 at different magnifications. Arrest lines, hackle and wake hackle are recognizable and provide the direction of crack propagation (dcp) as marked by a black arrow from the margin upwards.

Fig. 4.

Fig. 4a. Stereomicroscope image of zone 2 of interest. Parallel running hackle lines are concentrated in the veneering ceramic. These indicate the direction of crack propagation is from the bottom to top in this view.

Figs. 4b,c. Same area as in Fig. 4a viewed under the SEM at higher magnification. Hackle and wake hackle (emanating from pores and inclusions) are easily distinguished and used to indicating the crack was running upwards towards the occlusal side.

Fig. 5.

Fig. 5a. Stereomicroscope image focusing on zone 3 showing occlusal surface chip damage.

Figs. 5b,c. SEM images at higher magnifications of zone 3. The veneering ceramic surface has occlusal edge chip damage delimited by arrest lines from which emanate fine twist hackle. The concavity of the arrest lines as well as the river pattern of the twist hackle indicate that the direction of crack propagation (dcp) within the edge chip is running from top to bottom (black arrow).

Fig. 6.

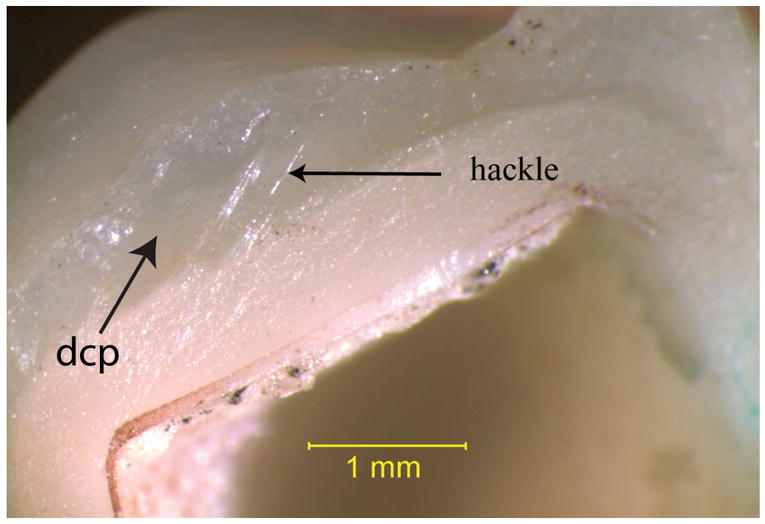

Figs. 6a,b. Stereomicroscope images of zone 4 showing an array of corner hackle radiating from the core towards the veneer confirmed by wake hackle in the veneer. This radiating fan-like pattern is generated when a crack goes around a corner of a structure. The direction of crack propagation (dcp) is marked by a black arrow.

Fig. 7.

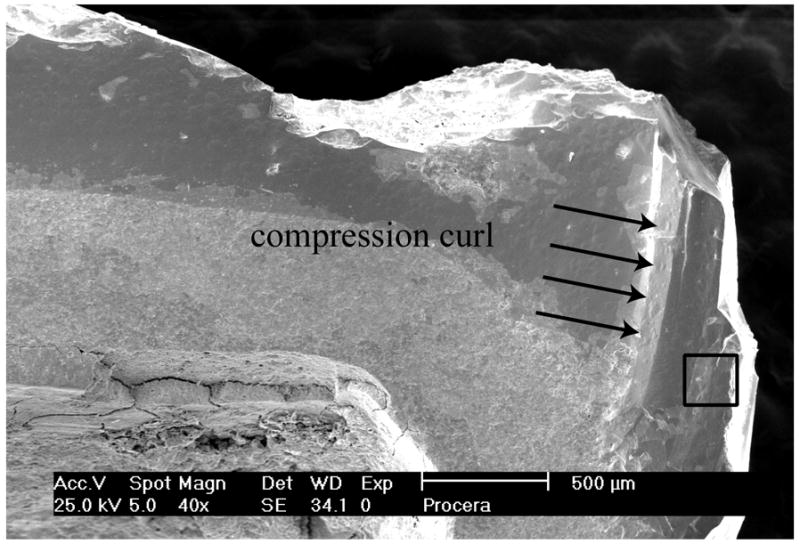

Figs. 7a,b. SEM images of zone 5 (distal portion of the crown part) showing a 2 mm in length compression curl in which wake hackle and twist hackle confirm the final breakthrough of the fracture crack.

Fig. 8.

Figs. 8a,b. Sketched illustration of the stereo findings as well as a summary image of SEM mapping the general direction of crack propagation of the recovered broken Procera AllCeram crown part.

Discussion

The combined use of stereo and SEM analysis for the fractographic failure analysis of a recovered Procera AllCeram crown part allowed for clear identification of key crack features providing evidence as to the crack propagation direction and sequence of the crack travel history. Chip shapes indicate the force application location and direction. In the case of the marginal chip, the direction of the chip force is parallel to the photographed surface, in the same direction as the white arrows labelled "margin" in Figs. 2(a) and 2(b). A force in this direction, applied on the veneer seated surface, is unlikely to arise from hard food, unless such a food particle has become wedged beneath the margin. Also, the force location and direction is unlikely to arise from a dental instrument once the crown is cemented in place. The force direction has been confirmed by fractographic markings such as hackle and wake hackle. The presence of staining and the growth of the gingiva into the space as seen in Fig 1a indicate that this mesial margin veneer chip must have occurred early in the lifespan of the crown. This chip may have occurred during the cementation procedure when finger pressure was exercised vertically to seat the crown on the tooth shoulder preparation generating a predominant local contact stress on a slightly overhanging veneering ceramic causing it to chip off. The veneer ceramic is a rather weak material (bending strength ≈100 MPa, Young’s modulus ≈70 GPa, KIc ≈ 1 MPa√m). Hence, any overhanging build-up of this ceramic over the high-strength, high-density alumina core margin will be at risk for early failure during cementation or initial chewing cycles and should be avoided during fabrication of the crown. Another possibility may be that the marginal chip occurred during fabrication in the dental laboratory without being noticed and the crown cemented as received with a predamaged zone (i.e. the chip) in an area of stress concentration (i.e. the crown margin).

The other chip damaged area located at the occlusal side of the crown definitely occurred as a secondary event since the twist hackle emanating from several arrest lines remained confined within the ceramic veneer, not reaching the alumina core material. In addition to this observation, the general direction of crack propagation as evidenced by wake hackle seen within the zones of interest clearly moved from mesial to distal. The exact origin could not be located but must have been in the vicinity of the mesial edge chip which acted as a predamaged site on which hoop stresses (generated during mastication) concentrated and from which a critical crack started and propagated along the axial and occlusal walls until fracturing the whole crown into two parts, one remaining on the tooth (Fig. 1a), the other recovered by the patient (Fig. 1b) and used for the fractographic analysis.

The optical examination is a crucial step for setting the fractographic foundation for the SEM analysis. Tilting the specimen under the optical microscope while playing with the illumination from the side revealed most fracture features and provided a 3D vision of the fractured surface. It’s important to emphasize that most cases are solved just from the stereomicroscope screening. The SEM however will provide more easily the high power images of fine details such as wake hackle and twist hackle.

The systematic approach to failure analysis using fractography as described in this paper will help interpreting failure data for all categories of ceramic restorations available today. At the current state, dentists and scientist should work together helping to collect the available clinical evidence. There is a learning curve when starting to use fractographic failure analysis which is strongly associated with time commitment in front of a microscope. In this particular case, the initial stereoptical microscope examination and interpretation that the margin chip was the origin of fracture was accomplished within an hour. The total time invested in preparing the specimen, documenting and analyzing the crown, as well as composing a summary report approached 40 hours. Much less time would be needed to interpret and analyze another case like this. Nevertheless, it’s worth the effort as similar failure trends may occur for other ceramic materials and restorations.

Acknowledgments

The authors are grateful to Dr. Urs Brodbeck (private practice, Zurich, Switzerland) for providing the fractured crown part as well as the in-situ initial photo (Fig. 1a).

This work is supported in part by NIH Grant, DE-17983.

Footnotes

Commercial products and equipment are identified in this report only to specify adequately experimental procedures and does not imply endorsement by the authors, institutions or organizations supporting this work.

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Quinn GD. A NIST recommended practice guide; Special Publication 960–16; National Institute of Standards and Technology; Washington, DC: [May 2007]. Fractography of Ceramics and Glasses. http://www.ceramics.nist.gov/pubs/practice.htm. [Google Scholar]

- 2.ASTM C1322-05a. Annual Book of Standards, Volume 15.01. ASTM International; West Conshohoken, PA: 2005. Standard practice for fractography and characterization of fracture origins in advanced ceramics. [Google Scholar]

- 3.Fischer H, Gröbel J, Marx R. Fraktographische Schadensanalyse an Dentalkeramik. Dtsch Zahnärztl Z. 2000;55:667–70. [Google Scholar]

- 4.Quinn JB, Quinn GD, Kelly JR, Scherrer SS. Fractographic analyses of three ceramic whole crown restoration failures. Dent Mater. 2005;21(10):920–9. doi: 10.1016/j.dental.2005.01.006. [DOI] [PubMed] [Google Scholar]

- 5.Scherrer SS, Quinn JB, Quinn GD, Kelly JR. Failure analysis of ceramic clinical cases using qualitative fractography. Int J Prosthodont. 2006;19(2):185–192. [PubMed] [Google Scholar]

- 6.Taskonak B, Mecholsky JJ, Jr, Anusavice KJ. Fracture surface analysis of clinically failed fixed partial dentures. J Dent Res. 2006;85:277–81. doi: 10.1177/154405910608500314. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Scherrer SS, Quinn JB, Quinn GD, Wiskott HWA. Fractographic ceramic failure analysis using the replica technique. Dent Mater. 2007;23(11):1397–1404. doi: 10.1016/j.dental.2006.12.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Scherrer SS, Quinn JB, Quinn GD, Wiskott HWA. Descriptive Fractography on All Ceramic Dental Crown Failures. In: Varner James R, Quinn George D, Wightman Marlene., editors. Fractography of Glasses and Ceramic V, Ceramic Transaction. Vol. 199. The American Ceramic Society, John Wiley & Sons; Hoboken, New Jersey: 2007. pp. 339–350. [Google Scholar]

- 9.Quinn JB, Scherrer SS, Quinn GD. The Increasing Role of Fractography in the Dental Community. In: Varner James R, Quinn George D, Wightman Marlene., editors. Fractography of Glasses and Ceramic V, Ceramic Transaction. Vol. 199. The American Ceramic Society, John Wiley & Sons; Hoboken, New Jersey: 2007. pp. 253–270. [Google Scholar]

- 10.Taskonak B, Yan J, Mecholsky JJ., Jr . Fracture Surface Analysis of Dental Ceramics. In: Varner James R, Quinn George D, Wightman Marlene., editors. Fractography of Glasses and Ceramic V, Ceramic Transaction. Vol. 199. The American Ceramic Society, John Wiley & Sons; Hoboken, New Jersey: 2007. pp. 271–279. [Google Scholar]