Abstract

Vitamin E-stabilized, highly cross-linked ultrahigh molecular weight polyethylene (UHMWPE) is a promising oxidation and wear resistant UHMWPE with improved mechanical strength in comparison with the first generation, irradiated and melted UHMWPE. One approach of incorporating vitamin E in UHMWPE is through blending of vitamin E in UHMWPE powder followed by consolidation and radiation crosslinking. However radiation crosslinking efficiency of UHMWPE decreases in the presence of vitamin E. Therefore an optimum vitamin E concentration and radiation dose level needs to be determined to achieve a cross-link density comparable to 100-kGy irradiated and melted UHMWPE, which has shown excellent wear properties in vivo. We investigated the cross-link density and mechanical properties of vitamin E-blended UHMWPEs as a function of vitamin E concentration in the blend and gamma irradiation doses up to 200 kGy. We found that 0.3 wt% vitamin E-blended UHMWPE could not be cross-linked above a cross-link density achieved at a radiation dose of 65 kGy for virgin UHMWPE and 1.0 wt% vitamin E-blended UHMWPE could not be cross-linked above a cross-link density achieved at a radiation dose of 25 kGy for virgin UHMWPE even when the former were irradiated to a radiation dose of 200 kGy. In addition, higher plasticity at vitamin E concentrations at and above 0.3 wt% indicated that increased chain scissioning may be prevalent. Since the wear resistance of this irradiated UHMWPE would be expected to be low, vitamin E concentrations equal to or above 0.3 wt% are not recommended for subsequent irradiation to achieve a wear resistant cross-linked UHMWPE. The long–term oxidative stability of irradiated blends with low vitamin E concentrations has yet to be studied to determine an optimum between cross-link density and long-term oxidative stability.

Introduction

Ultra-high molecular weight polyethylene (UHMWPE) is the material of choice for total joint arthroplasty bearings. Wear of UHMWPE bearing surfaces contributes to the particulate debris burden that eventually leads to peri-prosthetic osteolysis in total joints. Radiation cross-linking of UHMWPE has been used to decrease wear successfully in vitro [1, 2] and in vivo [3]. In addition, oxidation of cross-linked UHMWPE can decrease the mechanical properties and wear resistance substantially. Oxidation is primarily caused by trapped residual free radicals in the crystalline regions of UHMWPE after irradiation. Currently, thermal annealing below the melting point or melting of the cross-linked material are used to stabilize cross-linked UHMWPE; however, thermally annealed cross-linked UHMWPE has shown oxidation in vivo, presumably, due to the lack of elimination of all free radicals [4]. In contrast, melting subsequent to radiation cross-linking decreases the concentration of residual free radicals to undetectable levels and prevents long-term oxidation. However, melting also reduces crystallinity and mechanical properties of the irradiated polymer [5].

A second generation of cross-linked UHMWPE has been developed by stabilizing irradiated UHMWPE by the incorporation of vitamin E, an antioxidant, without melting the irradiated polymer, thus avoiding the reduction of mechanical properties [6, 7]. Vitamin E hinders the cascading oxidation reactions in UHMWPE [8] by donating a hydrogen to the primary alkyl free radicals on polyethylene chains and the peroxy free radicals caused by reactions with oxygen. One approach is to diffuse the antioxidant into virgin UHMWPE after consolidation and radiation cross-linking. Another is to blend the vitamin E into UHMWPE powder and consolidate the blend. This blend subsequently can be irradiated to achieve a desired cross-link density. In addition to cross-linking, main chain scissioning is a mechanism that occurs when polymers are irradiated. These mechanisms are characterized by their respective yields, which are defined as the number of newly formed intermolecular linkages; G(x), and the number of main chain bonds broken; G(s), per 100eV of absorbed energy. Chain scission in polyethylene is very low with G(s)/G(x) values of 0.3-0.6 [9], where cross-linking dominates below a ratio of 4.0 [10]. The free radical scavenging ability of vitamin E interferes with cross-linking in UHMWPE [9, 11], therefore, vitamin E concentration and radiation dose have to be optimized to achieve a desired cross-link density, comparable to 100-kGy irradiated and melted UHMWPE, which has shown very high wear resistance in vivo [12].

Another concern when considering the vitamin E concentration in blended UHMWPE is long-term oxidative stability. The advantage of vitamin E-stabilized cross-linked UHMWPE is improved mechanical properties over irradiated and melted UHMWPE while maintaining wear and oxidation resistance. However, some of the vitamin E is exhausted during radiation crosslinking of the blend [13]. Although not the topic of this paper, another optimum has to be considered between the cross-link density in the presence of vitamin E and the vitamin E concentration which will be enough to protect irradiated UHMWPE against oxidation in the long term.

The aim of this study was to investigate the effect of vitamin E concentration and radiation dose on cross-linking and mechanical properties. We further aimed to determine the vitamin E concentrations and subsequent radiation doses that could be used to achieve a cross-link density and mechanical properties equivalent to that of 100-kGy irradiated virgin UHMWPE. Since cross-link density has been shown to be directly related to wear [14], it is used as an indicator of wear resistance.

Materials and Methods

Sample preparation

Blocks of UHMWPE (5.5×10×12 cm, GUR1050) containing vitamin E (D,L-α-tocopherol, >98%, Alfa Aesar, Ward Hill, MA) were prepared by mixing UHMWPE powder with vitamin E and consolidating the mixture. The UHMWPE powder was first mixed with vitamin E to obtain a 5 wt/wt% mixture for consistency after which the mixture was adjusted to 0.1, 0.3, and 1.0 wt% vitamin E by diluting with virgin UHMWPE powder (Orthoplastics Ltd, Lancashire, UK). Virgin UHMWPE consolidated without vitamin E was used as control. Samples were irradiated by gamma irradiation to 25, 65, 100, 150 and 200 kGy (Steris Isomedix, Northborough, MA) in air. Thin sections (3.2 mm) were machined from samples for further testing.

Determination of cross-link density

Crosslink density measurements were performed by thermal mechanical analysis (DMA 7e, Perkin Elmer, Wellesley, MA). Thin sections (thickness 3.2 mm) were melted at 170°C under nitrogen purge to remove any stresses residual from the consolidation process that might result in additional swelling during cross-link density measurements. Small sections were cut out by razor blade from these thin sections to be analyzed (approximately 3 mm by 3 mm). These pieces were placed under the quartz probe of the DMA (10 mN) and the initial height of the sample was recorded after about 10 minutes when the creep deformation equilibrated. Then, the probe was immersed in xylene, which was subsequently heated to 130°C and held for at least 100 minutes. The UHMWPE samples swelled in hot xylene until equilibrium was reached. The final height was recorded. The cross-link density of the samples was calculated as described previously [14] and are reported as mol/m3.

Mechanical testing

Dogbone specimens (n=5 each) were stamped from 3.2 mm-thick sections in accordance with ASTM D638, standard test method for tensile properties of plastics. These samples were then tested in accordance with ASTM D-638 using a MTS II machine (Eden Prarie, MN) at a crosshead speed of 10 mm/min. The engineering ultimate tensile strength (UTS) and work-to-failure (WF), calculated as the area under the engineering stress-strain curve are reported here. In addition, the elongation at break (EAB) was determined using an extensometer.

In all studies in which there were at least three samples, statistical analysis was performed using a Student's t-test for two-tailed distributions with unequal variance. Significance was reported if p<0.05.

Results

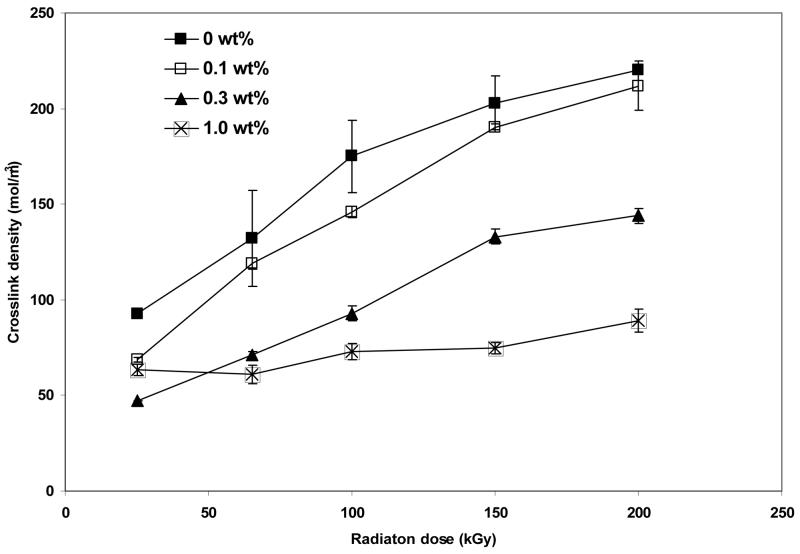

The cross-link density of virgin UHMWPE increased from about 90 mol/m3 at a radiation dose of 25 kGy to about 210 mol/m3 at 200 kGy (Fig 1). The cross-link density did not change significantly above 150kGy as previously shown for electron beam irradiated UHMWPE [14]. Except for 65-kGy irradiated 0.1 wt% vitamin E blend, the cross-link density of vitamin E-blended and irradiated UHMWPE was less than virgin UHMWPE at all radiation doses and decreased with increasing vitamin E concentration (Fig 1).

Fig 1.

Cross-link density of vitamin E-blended and subsequently irradiated UHMWPE as a function of vitamin E concentration.

Although the gel content increased with increasing radiation dose, except for 0.1 wt% vitamin E-blended UHMWPE, it decreased with increasing vitamin E concentration compared to virgin irradiated UHMWPE; this decrease was significant with the 0.3 wt% blend that was irradiated at a radiation dose of 65 kGy and 1 wt% blend at all radiation doses (Table 1).

Table 1.

Gel content of vitamin E-blended and irradiated UHMWPEs.

| Radiation Dose (kGy) | |||||

|---|---|---|---|---|---|

| Vitamin E concentration (wt%) |

25 | 65 | 100 | 150 | 200 |

| 0 | NT | 97.6±0.3 | 99.0±0.5 | 98.2±0.3 | 97.4±0.1 |

| 0.1 | NT | 98.3±0.8 | 98.4±0.1 | 98.6±0.1 | 98.2±0.1 |

| 0.3 | NT | 95.1±0.5 | 97.4±1.4 | 97.4±1.0 | 97.2±0.4 |

| 1.0 | NT | 92.3±0.4 | 93.7±0.9 | 92.8±0.1 | 93.5±0.1 |

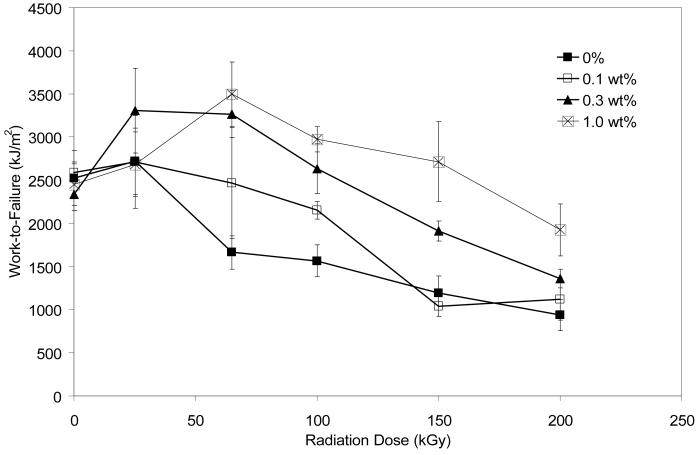

The UTS and WF of irradiated virgin UHMWPE did not change significantly at 25 kGy and decreased gradually over the radiation dose range from 25 to 200 kGy compared to virgin, unirradiated UHMWPE (Figs 2 and 4). The EAB decreased significantly at all doses (Fig 3). The UTS, EAB and WF of 0.1 wt% vitamin E-blended UHMWPE stayed constant up to 100, 65 and 25 kGy, respectively, after which they decreased significantly (Figs 2, 3 and 4).

Fig 2.

Ultimate tensile strength (UTS) of vitamin E-blended and subsequently irradiated UHMWPE.

Fig 4.

Work to failure (WF) of vitamin E-blended and subsequently irradiated UHMWPE.

Fig 3.

Elongation at break (EAB) of vitamin E-blended and subsequently irradiated UHMWPE.

The UTS for 0.3 and 1 wt% vitamin E-blended UHMWPEs did not change at 25 kGy and increased significantly at 65 kGy compared to their unirradiated counterparts, then decreased significantly at 200 kGy (Fig 2). The EAB and WF for 0.3 wt% vitamin E-blended UHMWPE increased significantly at 25 and 65 kGy, was similar to unirradiated 0.3 wt% blended UHMWPE at 100 kGy and decreased significantly at 150 and 200 kGy. The EAB and WF of 1.0 wt% vitamin E-blended UHMWPE was similar to unirradiated 1.0 wt% blended UHMWPE at 25 kGy, increased significantly at 65 and 100 kGy, was similar to unirradiated 1.0 wt% blended UHMWPE at 150 kGy and decreased significantly at 200 kGy (Figs 3 and 4).

Discussion

The goal in irradiating Vitamin E/UHMWPE blends is to obtain a cross-linked UHMWPE with enough cross-link density to achieve (1) wear properties equivalent to that of 100-kGy irradiated and melted UHMWPE, (2) improved strength to resist cyclic stresses even under adverse conditions and (3) long-term oxidative stability such that the wear and mechanical properties can be maintained in the long term. One disadvantage of blending vitamin E with UHMWPE prior to irradiation is decreasing the potency of vitamin E during irradiation. Since vitamin E is a free radical scavenger, it interacts with the free radicals formed on polyethylene chains during irradiation and sacrifices some of its activity. In addition, we [11] and others [9] have shown that cross-linking efficiency in UHMWPE is decreased with increasing vitamin E concentration due to its activity during irradiation. Therefore, it is proposed that high radiation dose with low vitamin E concentration is required to obtain a desired cross-link density. Although not the topic of this paper, it has to be noted that the vitamin E concentration has to be kept high enough to protect irradiated UHMWPE against oxidation in the long-term.

In light of these general goals, the specific aim of this paper was to investigate the effects of vitamin E concentration and radiation dose on the cross-link density and mechanical properties of irradiated blends. The dependence of cross-linking of virgin UHMWPE on radiation dose (Fig 1) was previously reported [14] and relates directly to increased wear resistance. Similar to the cross-link density of radiation cross-linked virgin UHMWPE, the cross-link density for vitamin E blends reached an equilibrium value above 150 kGy. In contrast, the maximum value of cross-link density reached at 200 kGy was lower than virgin UHMWPE and decreased with increasing vitamin E concentration. Of the vitamin E-blended samples used in this study, 0.3 and 1.0 wt% vitamin E-blended UHMWPEs reached an equilibrium cross-link density of 144 and 89 mol/m3, respectively at 200 kGy; this value was lower than that of 100-kGy irradiated virgin UHMWPE (175 mol/m3; Fig 1). UHMWPE bearing surfaces cross-linked to approximately 65-100 kGy have been successful in reducing the wear rate of UHMWPE substantially. Ideally, an optimized vitamin E-blended UHMWPE would have a cross-link density and thus a wear rate comparable to or better than 100-kGy irradiated, virgin UHMWPE. Looking at the minimal incremental change in cross-link density of 1 wt% vitamin E-blended UHMWPE over the 25-200 kGy dose range, it appeared that it was not even possible to obtain a substantially cross-linked UHMWPE from stock containing 1 wt% vitamin E (Fig 1). Moreover, the gel content of 0.3 and 1.0 wt% blends are substantially lower than that of virgin and 0.1 wt% blended UHMWPE, even at the highest radiation dose (Table 1). These results suggest that vitamin E concentrations equal to or above 0.3 wt% prevent achieving desirable cross-link density in UHMWPE for improved wear resistance.

Cross-links introduced into the amorphous phase by radiation decrease the mobility of the chains and the overall plasticity of the polymer. While this phenomenon results in a decrease in wear, it also leads to a decrease in mechanical properties of virgin irradiated UHMWPE ([5], Figs 2-4). The decrease in plasticity is manifested as a dose-dependent decrease in elongation to break (EAB) and work-to-failure (WF). If the mechanical properties were dependent solely on the cross-link density, then we would have expected that EAB, WF and UTS of vitamin E-blended, irradiated UHMWPE to be similar to those of virgin UHMWPE of similar cross-link density and gradually decrease as a function of radiation dose as observed in virgin irradiated UHMWPE. However, the increase and eventual decrease in UTS, EAB and WF of 0.3 and 1.0 wt% blends over the studied radiation dose range suggested that there may be increased chain scissioning affecting the properties despite increasing crosslinking.

We propose that because vitamin E could hinder cross-linking, that chain scissioning became more prominent. Consider that a vitamin E molecule is in the vicinity of a C-C bond, which has been broken and has created two C free radicals due to radiolytic cleavage. It is possible that the recombination probability of these two free radicals is decreased because the vitamin E can donate a proton to at least one these free radicals. This would result in increased incidence of chain scission and a decrease in effective molecular weight by an increase in the number of chain ends. This mechanism would also compete with the effect of cross-linking in terms of mechanical properties. While cross-linking creates a less mobile network, chain scissioning would increase local mobility of the chains. We discuss the possibility of increased chain scission through mechanical properties because it was not possible to calculate reliable GS and GX values for such highly cross-linked samples, whose gel content did not change substantially with increasing radiation dose within the studied range (Table 1). These values are reliably calculated for irradiated UHMWPEs below or around gelation [15].

Similar to virgin UHMWPE, 0.1 wt% vitamin E-blended UHMWPE showed gradually decreasing mechanical properties as a function of increasing radiation dose. This suggested that cross-linking was the dominating mechanism in this irradiated UHMWPE. In contrast, in 0.3 wt% up to 100 kGy and in 1.0 wt% vitamin E-blended UHMWPE up to 150 kGy, plasticity (as quantified by EAB and WF) increased, suggesting that the effect of chain scissioning may have dominated, despite increasing cross-linking density. We postulate that at radiation doses higher than 150 kGy for 0.3 and 1.0 wt% vitamin E-blended UHMWPE, the activity of vitamin E was substantially decreased and therefore crosslinking became more prominent; as a result, the UTS, EAB and WF decreased.

We determined that not only is the cross-link density at a given radiation dose lower for increasing vitamin E concentration blended into UHMWPE, but also that the limit of cross-link density is lower at higher concentrations of vitamin E, making it impossible to achieve high cross-link density despite high radiation doses for some vitamin E concentrations. In addition, we found that at high vitamin E concentrations and low irradiation doses, chain scissioning in UHMWPE may become prevalent. This study suggests that there is a maximum concentration of vitamin E below 0.3 wt% feasible for use in radiation cross-linking of vitamin E blends as alternative total joint replacement bearing surfaces.

Another concern in considering what vitamin E concentration should be used in highly cross-linked UHMWPE is long-term oxidative stability. Since vitamin E is used up during irradiation, there should also be a lower limit of vitamin E that can be used such that irradiated UHMWPE is protected against oxidation. Our current studies focus on accelerated and real-time aging of vitamin E-blended UHMWPEs of different concentrations irradiated up to 200 kGy to determine this yet unknown limit.

Conclusions

The cross-linking density of 100-kGy irradiated virgin UHMWPE could not be achieved by increasing radiation dose for 0.3 and 1.0 wt% vitamin E-blended UHMWPE due to the free radical scavenging activity of vitamin E. Irradiation at this concentration of vitamin E also resulted in higher plasticity over 65-150 kGy irradiation range, suggesting increased chain scissioning in addition to decreased cross-linking compared to virgin, irradiated UHMWPE. Since these will lead to decreased wear resistance, vitamin E concentrations equal to or above 0.3 wt% are not recommended for subsequent irradiation to achieve a wear and oxidation resistant cross-linked UHMWPE.

Acknowledgements

This work was funded by a research grant from the National Institutes of Health (AR051142) and a research grant from Zimmer, Inc..

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errorsmaybe discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Muratoglu OK, Merrill EW, Bragdon CR, O'Connor DO, Hoeffel D, Burroughs B, et al. Effect of radiation, heat, and aging on in vitro wear resistance of polyethylene. Clinical Orthopaedics & Related Research. 2003;417:253–62. doi: 10.1097/01.blo.0000093004.90435.d1. [DOI] [PubMed] [Google Scholar]

- 2.McKellop H, Shen F-W, Lu B, Campbell P, Salovey R. Development of an extremely wear resistant ultra-high molecular weight polyethylene for total hip replacements. J Orthop Res. 1999;17(2):157–67. doi: 10.1002/jor.1100170203. [DOI] [PubMed] [Google Scholar]

- 3.Digas G, Karrholm J, Thanner J, Herberts P. 5-year experience of highly crosslinked polyethylene in cemented and uncemented sockets - Two randomized studies using radiostereometric analysis. Acta Orthopaedica. 2007;78(6):746–54. doi: 10.1080/17453670710014518. [DOI] [PubMed] [Google Scholar]

- 4.Wannomae K, Bhattacharyya S, Freiberg A, Estok D, Harris W, Muratoglu O. In vivo oxidation of retrieved crosslinked UHMWPE acetabular components with residual free fadicals. Journal of Arthroplasty. 2006;21(7):1005–11. doi: 10.1016/j.arth.2005.07.019. [DOI] [PubMed] [Google Scholar]

- 5.Oral E, Malhi A, Muratoglu O. Mechanisms of decrease in fatigue crack propagation resistance in irradiated and melted UHMWPE. Biomaterials. 2006;27:917–25. doi: 10.1016/j.biomaterials.2005.06.025. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Oral E, Wannomae KK, Hawkins NE, Harris WH, Muratoglu OK. α-Tocopherol doped irradiated UHMWPE for high fatigue resistance and low wear. Biomaterials. 2004;25(24):5515–22. doi: 10.1016/j.biomaterials.2003.12.048. [DOI] [PubMed] [Google Scholar]

- 7.Oral E, Christensen S, Malhi A, Wannomae K, Muratoglu O. Wear resistance and mechanical properties of highly crosslinked UHMWPE doped with vitamin E. Journal of Arthroplasty. 2006;21(4):580–91. doi: 10.1016/j.arth.2005.07.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Oral E, Rowell S, Muratoglu O. The effect of alpha-tocopherol on the oxidation and free radical decay in irradiated UHMWPE. Biomaterials. 2006;27:5580–87. doi: 10.1016/j.biomaterials.2006.07.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Parth M, Aust N, Lederer K. Studies on the effect of electron beam radiation on the molecular structure of ultra-high molecular weight polyethylene under the influence of alpha-tocopherol with respect to its application in medical implants. J Mater Sci-Mater Med. 2002;13(10):917–21. doi: 10.1023/a:1019892004830. [DOI] [PubMed] [Google Scholar]

- 10.Charlesby A, Pinner SH. Analysis of the solubility behaviour of irradiated polyethylene and other polymers. Proc. Rot. Soc. Lond. 1958;269A:367–86. [Google Scholar]

- 11.Oral E, Greenbaum E, Malhi A, Muratoglu O. Characterization of blends of α-Tocopherol with UHMWPE. Biomaterials. 2005;26:6657–63. doi: 10.1016/j.biomaterials.2005.04.026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Digas G, Karrholm J, Thanner J, Malchau H, Herberts P. Highly cross-linked polyethylene in total hip arthroplasty: randomized evaluation of penetration rate in cemented and uncemented sockets using radiostereometric analysis. Clin Orthop. 2004;(429):16. [PubMed] [Google Scholar]

- 13.Bracco P, Brunella V, Zanetti M, Luda MP, Costa L. Stabilisation of ultra-high molecular weight polyethylene with vitamin E. Polymer Degradation and Stability. 2007;92:2155–62. [Google Scholar]

- 14.Muratoglu OK, Bragdon CR, O'Connor DO, Jasty M, Harris WH, Gul R, et al. Unified Wear Model for Highly Crosslinked Ultra-high Molecular Weight Polyethylenes (UHMWPE) Biomaterials. 1999;20(16):1463–70. doi: 10.1016/s0142-9612(99)00039-3. [DOI] [PubMed] [Google Scholar]

- 15.Janik I, Kasprzak E, Al-Zier A, Rosiak J. Radiation cross-linking and scission parameters for poly(vinyl methyl ether) in aqueous solution. Nuclear Instruments and Methods in Physics Research B. 2003;208:374–79. [Google Scholar]