1 Introduction and Scope

In an age when organic chemists have shown that even the most complex natural and unnatural products can be synthesized,1-3 the emphasis of synthetic chemistry is shifting to how they can be assembled in a truly practical fashion.4-6 A pressing challenge facing organic chemists, therefore, is to advance new processes that are not only efficient, selective, and high yielding, but that are also environmentally friendly.7,8 Historically, the metric of reaction success has been the yield. Although yields will remain imperative, alternative measures are the ‘greenness’ of a reaction, or E factor,9 and the volume productivity.10 The E factor, introduced by Sheldon,9 is defined as the ratio of weight waste to weight product while the volume productivity is the grams product per liter of reaction medium. The E factor for many pharmaceuticals has been estimated to exceed 100.11,12 The largest contributors to the magnitude of E factor are organic solvents, many of which are ecologically harmful and require expensive remediation.

As global environmental legislation becomes stricter, consideration of environmental concerns must be addressed at early stages of product development. By doing so, project cost reduction of 50% or more have been realized.13 Although steps toward sustainability can be made by reusing solvents, rarely is recycling accomplished with complete efficiency. An alternative strategy to reduce the E factor of reactions and their impact on the environment is to conduct them under solvent-free conditions.11,14-16 Among the benefits of solvent-free processes are cost savings, decreased energy consumption, reduced reaction times, and a large reduction in reactor size and capital investment. As a result, introduction of solvent-free reactions, including solvent-free polymerizations,14,17-20 radical additions,14,21-24 ionic reactions,25-31 solid state reactions15,32-34 and photochemical reactions15,35-37 has increased steadily in recent years. Solvent-free catalytic enantioselective reactions, however, have received much less attention.

The paucity of catalytic asymmetric solvent-free reactions is not unexpected. Catalyst efficiency and enantioselectivity is frequently highly sensitive to the nature of the solvent.38 Examples in which a catalyst can generate enantiomeric products with high levels of enantioselectivity in different solvents have been reported.39 Moreover, enantioselectivities are often dependent on catalyst concentrations. Consequently, two of the most important variables for catalyst optimization, solvent properties and concentration, are eliminated under solvent-free conditions. Furthermore, under solvent-free conditions the reaction medium will change as reagents and substrates are converted to products. The impact of such changes is currently unpredictable, complicating reaction development. We believe that these limitations have dissuaded many investigators from considering solvent-free catalytic asymmetric reactions. The potential environmental benefits and the economic incentive, however, have created significant demand for such processes.

In response to these challenges, an increasing number of research groups are developing asymmetric catalysts for use under solvent-free or highly concentrated reaction conditions. The results of these studies have been mixed. In some cases, catalysts that demonstrate excellent enantioselectivity and activity under standard solvent conditions exhibit lower selectivity in the absence of solvent. In contrast, other catalysts react with excellent levels of enantioselectivity and greatly increased activity, enabling significant reductions in catalyst loading under solvent-free conditions.

The potential advantages of asymmetric catalysis under solvent-free and highly concentrated reaction conditions have inspired this review. In turn, it is hoped that a comprehensive compilation of reports in this area will stimulate further investigations into solvent-free catalytic asymmetric reactions.

A significant body of research has been published concerning solvent-free organic synthesis and the subject has been reviewed.10,11,14,15,40 Solvent-free asymmetric catalysis, however, is a relatively new area and we are not aware of reviews devoted to this topic. This review will cover small molecule catalyzed enantioselective reactions under solvent-free or highly concentrated reaction conditions up to the end of 2006. Additionally, we will include reactions of enantioenriched substrates with enantioselective catalysts in which the diastereoselectivity is catalyst controlled (not substrate controlled). We define solvent-free reactions as those employing less than five equivalents of one reagent with respect to the substrate. The definition of highly concentrated reaction conditions used herein is those that utilize less than 5 equivalents of solvent with respect to the substrate.

Despite amazing advances in chemistry database coverage, technology, and search engines, there are no straightforward ways to search the literature for ‘highly concentrated catalytic asymmetric reactions’. Even reactions performed in the absence of solvent do not always contain the key words ‘solvent-free.’ The citations included herein come from extensive literature searches, scouring experimental sections and supporting information, and personal knowledge. Nonetheless, our apologies are extended to those who have made contributions in this area but whose work we missed.

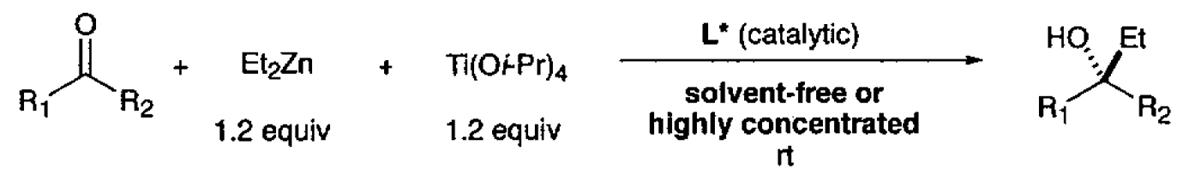

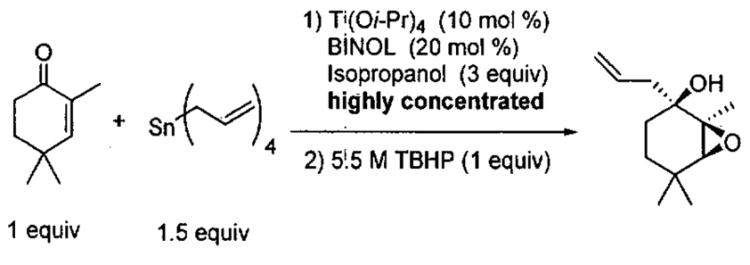

2 Solvent-Free and Highly Concentrated Reactions in Asymmetric Catalysis

2.1 Epoxide Opening Reactions

The catalytic asymmetric ring opening (ARO) of epoxides by nucleophiles can provide access to a variety of functionalized chiral building blocks that are of enormous utility in enantioselective organic synthesis.41-45 In several cases, epoxide opening reactions are also exemplary environmentally friendly processes in which all or nearly all of the atoms in the starting materials are present in the products, therefore, little or no waste is generated. Such processes have been classified as highly atom economical.46,47

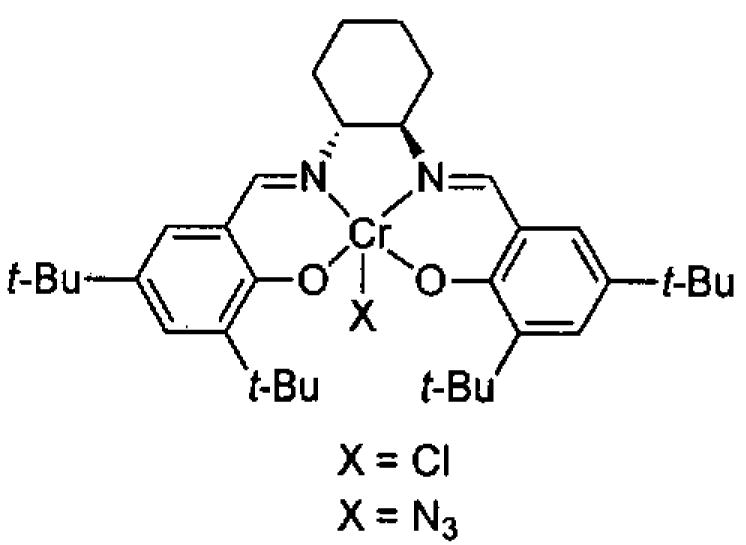

The Jacobsen group has been actively investigating transition metal (salen)M(III)-based catalysts for the desymmetrization of meso epoxides and the kinetic resolution of racemic epoxides via ARO reactions.42 An important feature of (salen)M(III) catalysts is that a wide variety of complexes with diverse substitution patterns are easily synthesized, facilitating catalyst screening and reaction optimization.

The mechanisms of (salen)M catalyzed epoxide opening reactions have also been studied in detail and have provided significant insight into the operation of these highly efficient and enantioselective catalysts. The mechanistic understanding garnered by the Jacobsen group has allowed expedient optimization of both catalyst activity and enantioselectivity in epoxide opening reactions. Most of the mechanistic studies have been conducted in common solvents, and it is assumed that the reaction mechanisms do not change significantly under solvent-free conditions.42,48-53

2.1.1 Desymmetrization of meso-Epoxides

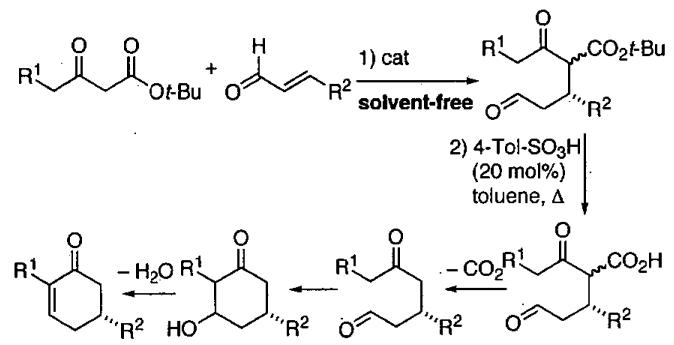

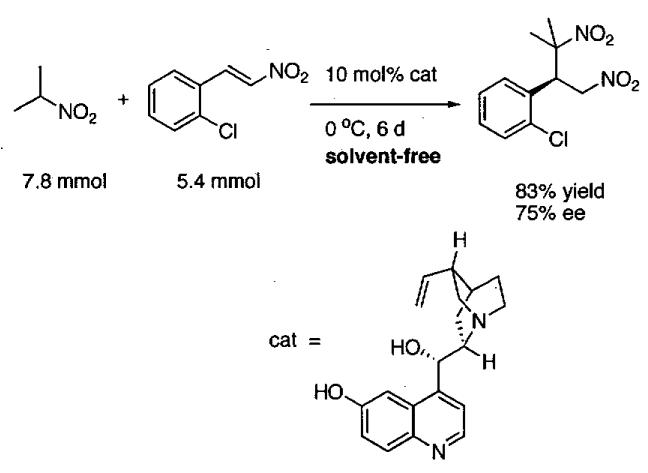

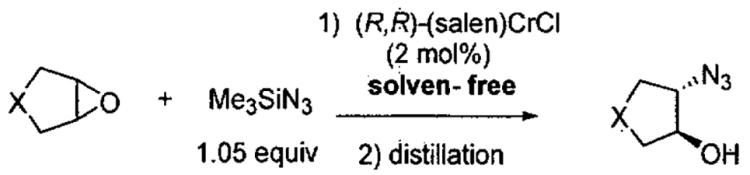

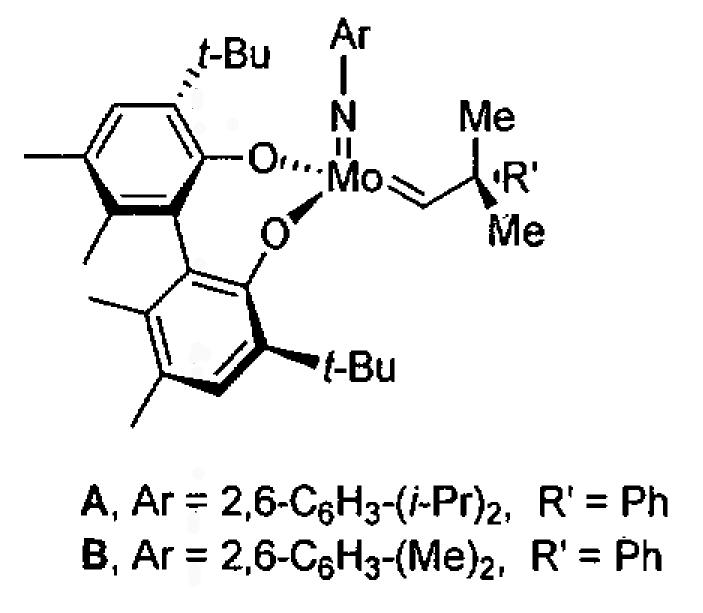

In pioneering studies, Jacobsen and coworkers reported the (salen)Cr(III) catalyzed opening of meso epoxides and the kinetic resolution of racemic terminal epoxides with trimethylsilyl azide.49,51,54-67 The tetra-tert-Bu derived (salen)M complexes with the ligand illustrated in Figure 1 have proven so useful in solvent-free asymmetric catalysis68 that (salen)M will refer to this ligand structure throughout this review unless otherwise mentioned.

Figure 1.

Jacobsen's (salen)CrCl precatalyst and (salen)CrN3 catalyst for epoxide opening with trimethylsilyl azide. In this review, (salen)M will refer to a metal bound to this salen ligand unless otherwise stated.

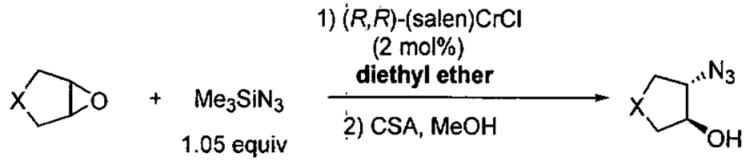

Initial studies of ARO of meso epoxides with (salen)CrCl precatalyst (Figure 1) were conducted in diethyl ether solvent.54 A few representative examples are shown in Table 1 that demonstrate both the enantioselectivity and overall efficiency of this process. It was also reported that reactions could be conducted in the absence of solvent (Table 2).54 Under solvent-free conditions, cyclic 5 and 6-membered epoxides underwent ring opening with 2 mol% (salen)CrCl and only a slight excess of Me3SiN3. After complete consumption of the epoxide, the reaction mixture was distilled under reduced pressure providing the ring opened product in high purity. The catalyst can be easily recovered and reused for several cycles without loss of activity. For example, Table 2 illustrates the use of a single catalyst dose in three cycles with cyclohexene oxide (cycles 1-3). In cycles four and five, cyclopentene oxide and 4,5-epoxycyclohexene were employed as substrates. In each case, isolated yields were ≥ 75% and enantioselectivities rivaled those outlined in reactions conducted with diethyl ether as solvent (Table 1).

Table 1.

ARO of meso epoxides in diethyl ether with (R,R)-(salen)CrCl (Figure 1) as precatalyst.

| ||||

|---|---|---|---|---|

| entry | X | time(h) | isolated yield (%) |

ee(%) |

| 1 | CH2CH2 | 18 | 80 | 88 |

| 2 | CH2 | 18 | 80 | 94 |

| 3 | CH=CH | 46 | 72 | 81 |

Table 2.

ARO of meso epoxides under solvent-free conditions with (salen)CrCl (Figure 1) as precatalyst illustrating catalyst recyclability.

| ||||

|---|---|---|---|---|

| cycle | X | time(h) | isolated yield (%) |

ee(%) |

| 1 | CH2CH2 | 18 | 86 | 84 |

| 2 | CH2CH2 | 21 | 88 | 87 |

| 3 | CH2CH2 | 20 | 91 | 88 |

| 4 | CH2 | 4 | 81 | 94 |

| 5 | CH=CH | 18 | 75 | 83 |

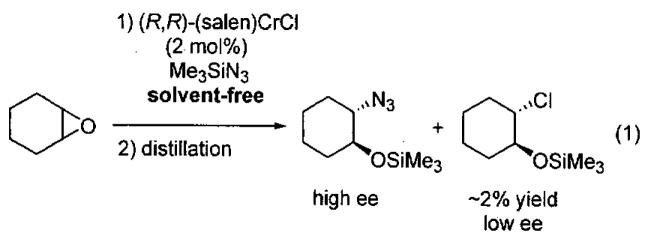

2.1.2 Mechanistic Investigations and Implications for Solvent-Free Epoxide Opening

Insight into the mechanism of ARO with (salen)CrCl was first gained through product analysis,54 where it was found that a chlorohydrin byproduct was generated in the initial stages of the reaction from epoxide opening by the chromium-bound chloride (Eq 1). Elemental analysis of the recovered catalyst after completion of the reaction indicated the absence of chloride and a ratio of Cr : N of 1 : 5. The IR spectrum of the recovered catalyst contained a strong stretch at 2058 cm−1, consistent with the formation a chromium azide, Cr-N3. In support of this proposal, (salen)Cr(N3)(THF) has been isolated and characterized crystallographically.51 Spectroscopic data support (salen)Cr(N3)(epoxide) as the resting state of the active catalyst in the ARO, hinting that the catalyst activates the epoxide as well as the azide. Also of note, the reaction does not proceed in the absence of trace water, which is necessary to generate HN3 from hydrolysis of Me3SiN3.

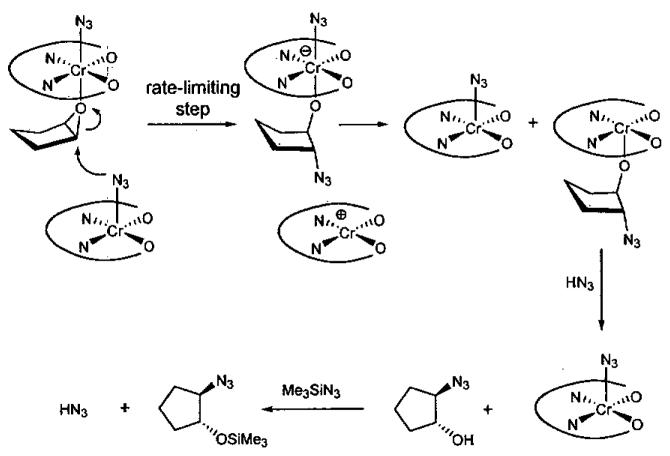

The dual role of the catalyst was confirmed by kinetic analysis, which indicated a second order catalyst dependency, inverse order in epoxide, and zero order in azide. The key steps of the proposed mechanism are illustrated in Figure 2.

Figure 2.

Key steps in the proposed mechanism of the ARO illustrating the bifunctional nature of the (salen)CrN3 catalyst.

The second order dependence on (salen)CrN3 concentration has important practical implications. For example, decreasing the catalyst loading by 10-fold is predicted to result in a 100-fold decrease in the rate of the reaction. This drawback can be partially offset under solvent-free conditions, where the concentrations of the reagents and catalysts are maximized.

Guided by the results of the mechanistic studies, Jacobsen and coworkers proceeded to optimize the ARO reaction. To eliminate the chlorohydrin byproduct (Eq 1) formed in conversion of the precatalyst (salen)CrCl to the catalyst (salen)CrN3, (salen)CrN3 was prepared synthetically.55 A comparison of product ee from (salen)CrCl and (salen)CrN3 was conducted under solvent-free conditions.69 Direct application of (salen)CrN3 resulted in slightly higher product ee's and yields than use of the precatalyst (salen)CrCl (Table 3). Also noteworthy is that these reactions were performed using 25–50 mmol of epoxide, and generated important synthetic intermediates.

Table 3.

Comparison of (salen)CrCl and (salen)CrN3 in the solvent-free asymmetric opening of meso epoxides.

| |||

|---|---|---|---|

| % ee (% yield)a |

|||

| entry | Y | (salen)CrCl | (salen)CrN3 |

| 1 | CH2 | 93 (97) | 94 (99) |

| 2 | (CH2)2 | 85(96) | 88 (99) |

| 3 | O | 97 (96) | 97 (99) |

| 4 | NCOCF3 | 95 (87) | 95 (96) |

Scale: 25 - 50 mmol epoxide.

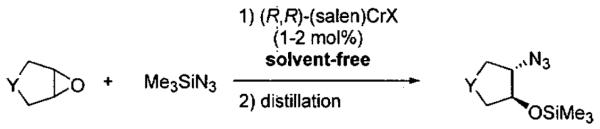

To overcome the second order catalyst dependency of the ARO, tethered dimeric catalysts were used in diethyl ether to enforce the cooperative catalyst behavior (Table 4).48 A kinetic study was performed and analysis of the rate data indicated that both intra-and intermolecular epoxide opening pathways were in operation, and their ratio was dependent on the tether length. Dimers with n = 2 and 4 proceeded largely through intermolecular pathways, while catalyst with n = 5 exhibited the greatest intramolecular rate (Table 4). As the tether length is further increased, the ratio of intramolecular to intermolecular pathway decreases, presumably due to the increase in entropic cost with longer tethers.48

Table 4.

Dimeric catalysts with tether lengths between n = 2 to 10 used in the ARO of cyclopentene oxide. The rate constant kintra is for the cooperative intramolecular pathway.

| |||

|---|---|---|---|

| n | ee (%) | kintra (min−1 × 10−2) | kintra (M−1 min−1) |

| 2 | 90 | 4.4 | 15.7 |

| 4 | 90 | 5.4 | 15.1 |

| 5 | 93 | 42.9 | 27.4 |

| 6 | 93 | 31.7 | 15.8 |

| 7 | 93 | 20.9 | 7.9 |

| 8 | 94 | 14.7 | 10.5 |

| 10 | 92 | 3.8 | 4.4 |

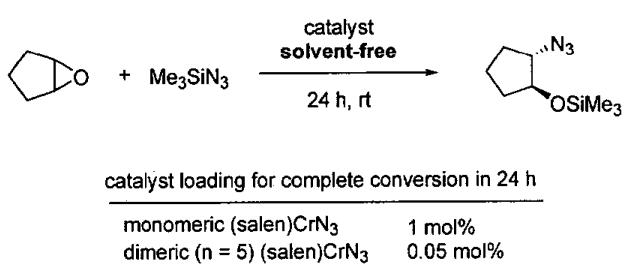

Based on these results, dimeric catalyst with n = 5 was compared to monomeric analogs in the solvent-free ARO (Figure 3). At 0.05 mol%, the dimeric catalyst promoted the ARO of cyclopentene oxide with Me3SiN3 in 24 h at room temperature, whereas the monomeric catalyst required a loading of 1 mol% to effect complete conversion under the same conditions.

Figure 3.

Comparison of catalyst loading with monomeric (salen)CrN3 and dimeric (n = 5) (salen)CrN3 (from Table 4).

The ARO of meso epoxides with trimethylsilyl azide is an important example of the design of environmentally friendly catalysts and reaction conditions. Not only can the reactions be conducted under solvent-free conditions, the catalyst can be recycled and the products isolated by distillation. Furthermore, the highly enantioenriched products are very useful in the synthesis of biologically active molecules.44,55,70-72

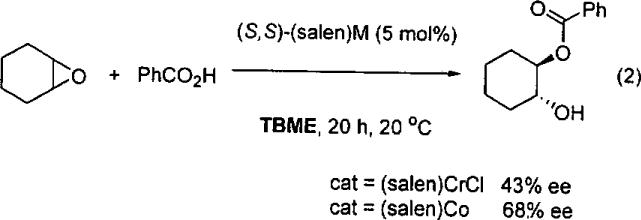

2.1.3 ARO of meso Epoxides with Benzoic Acid

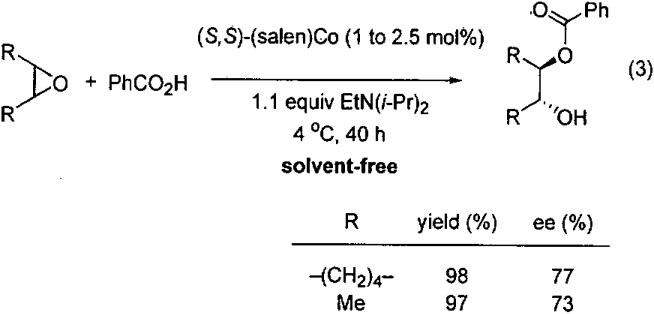

In search of catalysts to promote the ARO of meso epoxides with different nucleophiles, the Jacobsen group screened first row (salen)M complexes in the presence of benzoic acid.58 It was found that the (salen)CrCl complex (5 mol%) promoted the ARO with 43% ee. In contrast, the cobalt analog, (salen)Co(II), promoted the ARO to give the ester product in 68% ee (Eq 2). When the reaction was conducted in the presence of EtN(i-Pr)2 the product ee increased, most likely due to the greater solubility of the benzoic acid in the tert-butyl methyl ether (TBME) in the presence of the amine.

The (salen)Co(II) complex was then employed in the solvent-free ARO with benzoic acid (Eq 3). ARO with cyclohexene oxide was conducted on multigram scale in the presence of 1 mol% catalyst, providing the product with 77% ee and 98% yield. While the product ee was moderate, a single recrystallization afforded the product with 98% ee in 75% isolated yield. Use of cis-2-butene oxide as substrate under solvent-free conditions furnished the product with 73% ee in 97% yield.

The products of the ARO of meso epoxides with benzoic acid can be readily hydrolyzed to chiral diols, which are useful ligands in asymmetric catalysis and valuable building blocks in synthesis. The active catalyst in this reaction, as well as others introduced in the next sections, is generated by oxidation of the (salen)Co(II) to (salen)Co(III) by oxygen.

While the ARO of meso epoxides represents elegant research that formed the basis of several other synthetically important reactions, it is limited to meso epoxides. These substrates form a relatively small subset of epoxides. As will be outlined in the next sections, the kinetic resolution of epoxides enables the isolation of a broader range of chiral building blocks with high ee.

2.2 Reactions with Racemic Epoxides

2.2.1 Kinetic Resolution of Epoxides with Me3SiN3

The stereospecific nucleophilic ring opening of enantioenriched epoxides allows access to a wealth of chiral building blocks. As such, much effort has been invested in the direct enantioselective synthesis of epoxides and considerable progress has been made.73-78 Nonetheless, certain classes of epoxides remain difficult to prepare enantioselectively. Highly enantioenriched terminal epoxides, which are probably the most synthetically challenging, are also among the most useful due to the high stereoselectivity with which they undergo nucleophilic ring opening.

Difficulties with direct enantioselective methods for the synthesis of epoxides have led researchers to examine methods for kinetic resolution of these substrates. The well-known drawback of resolution is that the maximum yield is 50%. This disadvantage, however, can be relatively minor when compared to the benefits of kinetic resolutions.79-81 If the desired compound is the resolved starting material, it is relatively easy to control its ee simply by allowing reaction conversion to exceed 50%. Even in cases where the catalyst is only moderately enantioselective, starting material of high enantiopurity can be obtained. For example, if the relative rate of the fast to slow reacting substrate (krel = kfast/kslow) is 10, the slower reacting starting material can be recovered in 95% ee and up to 34% yield. Of course, if krel is higher, the reaction can be quenched at lower conversion, providing greater yield of the recovered starting material.

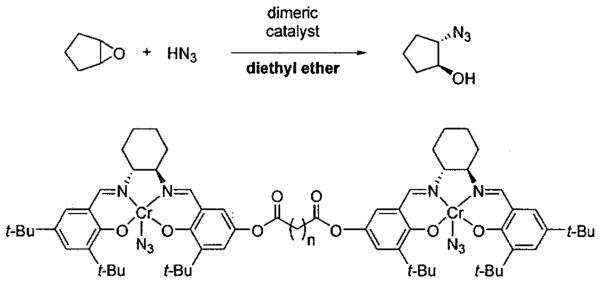

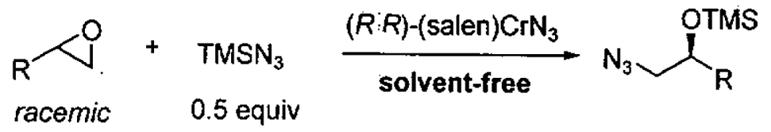

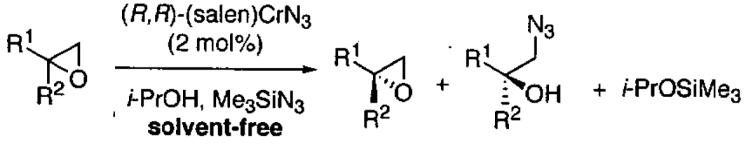

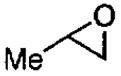

Initial studies by the Jacobsen group in the kinetic resolution of terminal epoxides employed (salen)CrN3.54 Thus, reaction of racemic propylene oxide with 0.5 equivalents of Me3SiN3 in the presence of 1 mol% (R,R)-(salen)CrN3 at 0 °C in the absence of solvent gave a mixture of the azide product and propylene oxide. Removal of the volatile epoxide and distillation of the product furnished the azidoalcohol in near quantitative yield with 97% ee (Table 5, entry 1). The relative rate of the fast reacting enantiomer to the slow reacting enantiomer (krel) for the resolution of propylene oxide was determined to be > 200. As outlined in Table 5, other substrates also exhibited very high krel values (44 - 280) and the ring opened products could be isolated with excellent ee's.56

Table 5.

Kinetic resolution of racemic terminal epoxides with Me3SiN3 catalyzed by (R,R)-(salen)CrN3 under solvent-free conditions.

| |||||

|---|---|---|---|---|---|

| entry | R | cat. mol% | yield (%)b | ee (%) | krel |

| 1 | CH3 | 1.0 | 98 | 97 | 230 |

| 2 | CH2CH3 | 2.0 | 83 | 97 | 140 |

| 3 | (CH2)3CH3 | 2.0 | 89 | 97 | 160 |

| 4 | CH2OTBDMS | 3.0 | 96 | 96 | 150 |

| 5 | CH2O(1-naphthyl) | 5.0 | 74 | 93 | 48 |

| 6 | CH2C6H5 | 2.0 | 94 | 93 | 71 |

| 7 | c-C6H11 | 2.0 | 84c | 97 | 140 |

| 8 | (CH2)2CH=CH2 | 2.0 | 94 | 98 | 280 |

| 9 | CH(OEt)2 | 2.0 | 96 | 89 | 44 |

| 10 | CH2CN | 2.0 | 80 | 92 | 45 |

Reactions were run without solvent for 18-50 h at 0-2 °C.

Isolated yield of the azido sily ether based on TMSN3.

Isolated yield of the azido alcohol.

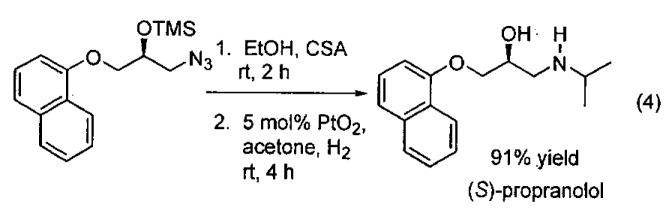

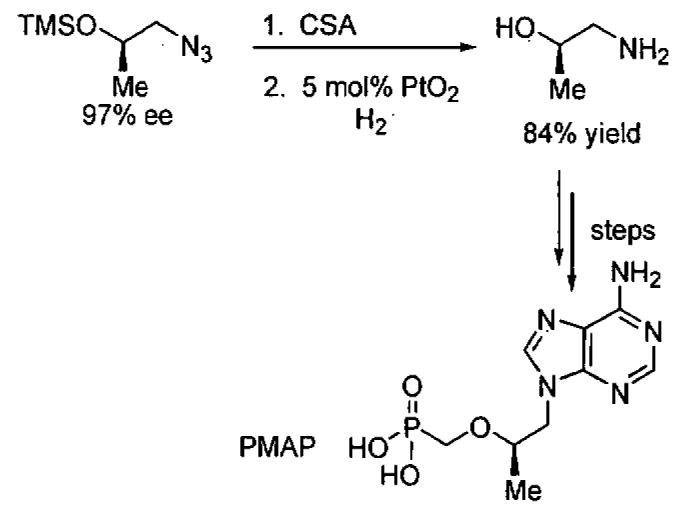

The azidoalcohols synthesized in the KR reaction are very useful chiral building blocks for the synthesis of biologically important molecules, as exemplified by the synthesis of (S)-propranolol, a widely used anti-hypertensive agent (Eq 4), and the synthesis of an enantioenriched amino alcohol used in the synthesis of (R)-9-[2-(phosphonomethoxy)propyl]adenine (PMPA), which displays prophylactic activity against SIV infections (Figure 4).56

Figure 4.

Application of enantioenriched azidoalcohol to the synthesis of (R)-9-[2-(phosphonomethoxy) propyl]adenine (PMPA).

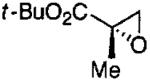

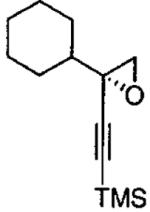

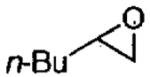

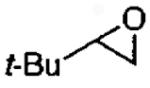

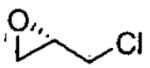

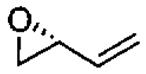

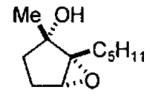

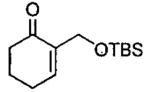

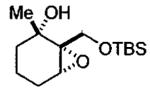

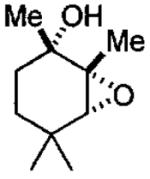

Terminal epoxides are excellent substrates for kinetic resolution reactions employing (salen)M-based catalysts. In contrast, chiral 2,2-disubstituted epoxides are less reactive and fail to undergo ARO with (salen)Co-based catalysts. These more sterically hindered epoxides do react with azide in the presence of (salen)CrN3. Most of the substrates examined exhibited excellent relative rates and afforded product in ≥ 97% ee and ≥ 42% yield when TBME was employed as solvent (not shown).82 Certain substrates, however, gave better results when ARO was conducted under solvent-free conditions (Table 6).

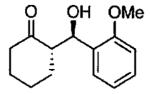

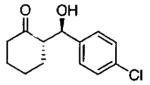

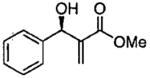

Table 6.

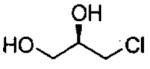

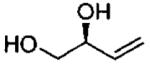

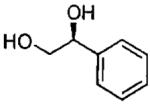

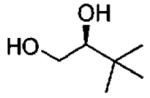

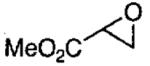

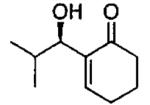

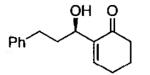

Kinetic resolution of racemic 2,2-disubstituted epoxides under solvent-free conditions.

| ||||

|---|---|---|---|---|

| Me3SIN3 (equiv) |

i-PrOH (equiv) |

yield (%) | ee (%) | epoxide product |

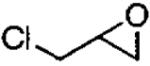

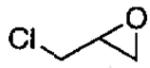

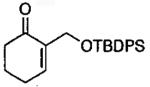

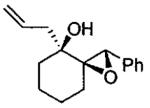

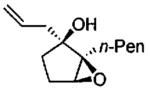

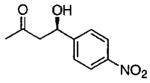

| 0.55 | 0.55 | 46 | 85 |  |

| 0.70 | 0.70 | 48 | 80 |  |

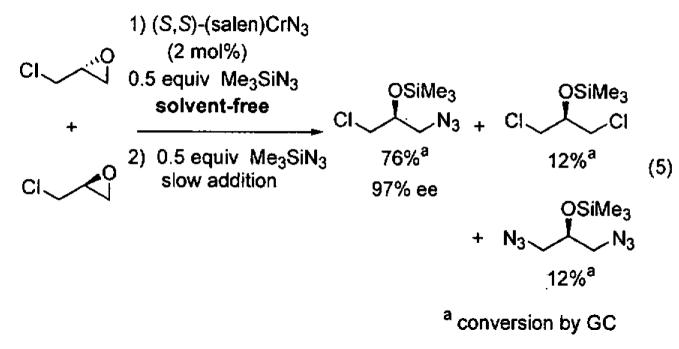

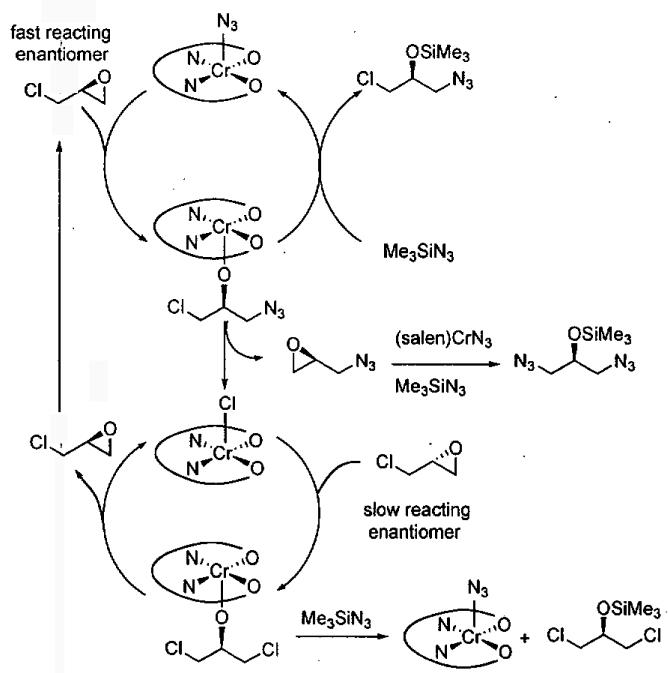

2.2.2 Dynamic Kinetic Resolution of Epichlorohydrin

Kinetic resolutions, such as those outlined above, can be very effective for the preparation of organic compounds, particularly if the starting materials are readily available, krel is high, and the resolved starting material and product are easily separated.79 Dynamic kinetic resolutions (DKR)83,84 are more desirable, however, because it is possible to obtain highly enantioenriched product in significantly greater than the maximum yield in a kinetic resolution (50%). A rare example of a solvent-free DKR is the ARO of racemic epichlorohydrin, which provided the densely functionalized azidoalcohol in 76% yield and 97% ee after optimization (Eq 5).57 In the initial investigations of this reaction, full conversion to the azidoalcohol was observed, but the ee was low (40%). It was hypothesized that ARO of the slow reacting epichlorohydrin enantiomer was competitive with its racemization. To increase the rate of racemization relative to ARO, the Me3SiN3 was added in two portions. The first 0.5 equivalents was combined with the epichlorohydrin to initiate the ARO. After the first 0.5 equivalents of Me3SiN3 had reacted, most of the slow reacting epoxide remained. The second dose of Me3SiN3 was added slowly over 16 h to reduce the rate of the ARO with respect to the racemization.

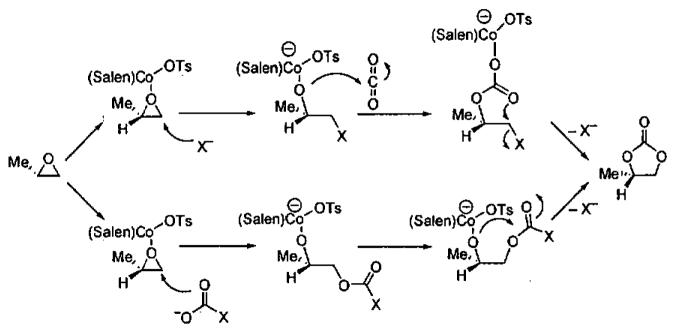

Analysis of the reaction products provided insight into the DKR (Eq 5). A mechanism that accounts for the formation of the 1,3-dichloro and 1,3-diazido byproducts is illustrated in Figure 5. It has been shown that the ARO with (salen)CrN3 results in the formation of an alkoxide intermediate (upper cycle).48 This unsymmetrical alkoxide can react with Me3SiN3 to produce the desired azidoalcohol and regenerate the catalyst via the upper cycle. It can also undergo ring closure to generate the azidoepoxide and (salen)CrCl. Ring opening of the azidoepoxide by (salen)CrN3 leads to the 1,3-diazide byproduct. The (salen)CrCl initiates the racemization of epichlorohydrin in the lower cycle. Ring opening of epichlorohydrin by (salen)CrCl generates a 1,3-dichloro alkoxide intermediate that can close to give either enantiomer of epichlorohydrin or undergo reaction with Me3SiN3 to regenerate (salen)CrN3 and the 1,3-dichloro product. As outlined in the proposed mechanism, the formation of the byproducts is intimately tied to the DKR process and has been difficult to suppress while maintaining high ee.57

Figure 5.

Proposed mechanism for the dynamic kinetic resolution of epichlorohydrin.

The densely functionalized product of the DKR is a useful chiral building block for the synthesis of enantioenriched biologically active compounds, such as U-100592, a promising antibacterial.57

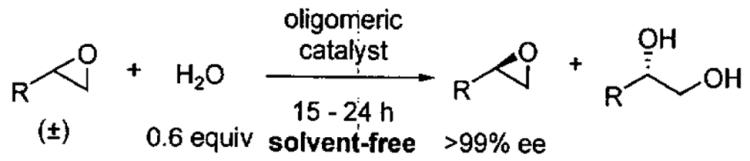

2.2.3 Hydrolytic Kinetic Resolution of Epoxides

The kinetic resolution of terminal epoxides with (salen)CrN3 and Me3SiN3 is an excellent method to prepare useful enantioenriched 1-azido-2-alcohols, however, it has several drawbacks. One disadvantage is that it is difficult to prepare resolved epoxides with this method. Also, Me3SiN3 is too costly to make the epoxide resolution economically feasible for all but high value epoxides. Finally, there is some concern about the thermal stability of the azidoalcohol byproduct, especially on large-scale resolutions. For these reasons, the search for more practical methods for the solvent-free and highly concentrated kinetic resolution of epoxides was undertaken.

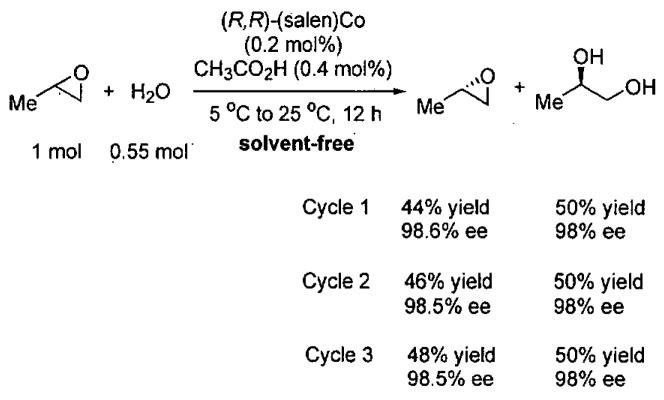

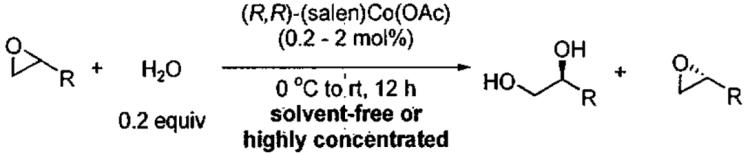

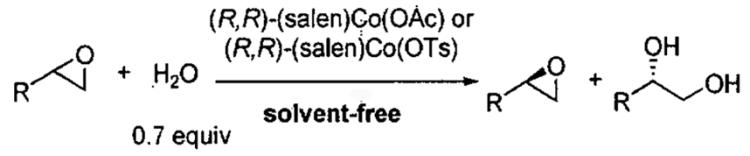

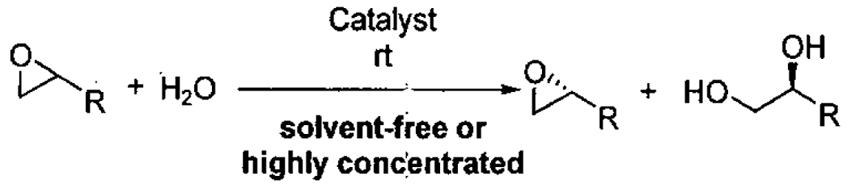

In 1997, Jacobsen and co-workers reported a major break through in the isolation of terminal epoxides with high enantioselectivity. It was found that water could serve as a nucleophile in the presence of catalytic (salen)Co(OAc) to open epoxides (Figure 6), giving rise to the hydrolytic kinetic resolution (HKR).59

Figure 6.

HKR of propylene oxide illustrating catalyst recycling.

The HKR provides direct access to both unreacted epoxide and 1,2-diol products in high enantiomeric excess and yield. Many HKR processes are conducted under solvent-free conditions by combining the catalyst with slightly more than 0.5 equivalents of water if the epoxide is the desired product. If the diol is desired, just under 0.5 equivalents of water is needed. Due to the low water solubility of epoxides with hydrophobic substituents, many reactions are conducted by combining the epoxide with a suitable solvent (1 : 1 v/v) for the HKR. Under these conditions, a minimal amount of solvent is employed and the reaction mixture is highly concentrated.

As an example of the HKR, the resolution of propylene oxide is outlined in Figure 6.59 Preformed (salen)Co(OAc) (0.2 mol%) and propylene oxide were combined, cooled to 0 °C and water added. The reaction was stirred for 14 h at room temperature, and then the reaction mixture was distilled. The volatile epoxide was distilled at atmospheric pressure and the diol at 65 °C and 0.25 torr, allowing facile separation of the mixture. The HKR of propylene oxide represents a special case, because both the epoxide and diol product are relatively volatile and can be distilled from the catalyst. The remaining catalyst residue is reactivated by addition of acetic acid and can be recycled without loss of activity or enantioselectivity for three cycles (Figure 6). It is also noteworthy that the HKR of propylene oxide has been performed on large scale (> 200 kg).42

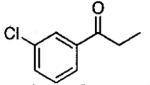

Many terminal epoxides have been tested in HKR and the reaction has been found to be incredibly general and tolerant of functionality. The results of extensive studies will be succinctly summarized here. Table 7 contains krel values. Recovered resolved epoxide ee's and yields are given in the text. Aliphatic epoxides with small to sterically demanding substituents (Me to t-Bu) are excellent substrates for HKR (Table 7, enties 1 - 7). The resolved epoxides could be isolated in 82–92% of the theoretical yield (41–46% yield based on racemic epoxide) in ≥ 99% ee. While some substrates underwent HKR under solvent-free conditions, lipophilic epoxides with low solubility in water gave better results with a small amount of solvent (highly concentrated conditions).66

Table 7.

Measured krel values for a series of epoxides under solvent-free and highly concentrated reaction conditions.

| ||||

|---|---|---|---|---|

| entry | epoxide substituent | conv. (%)c | diol ee (%) | krel |

| Aliphatic Epoxides | ||||

| 1a | CH3 | 19 | 99.5 | 500 |

| 2a | (CH2)3CH3 | 19 | 99.2 | 310 |

| 3b | (CH2)11CH3 | 18 | 99.5 | 490 |

| 4b | (CH2)2CH=CH2 | 20 | 99.4 | 420 |

| 5b | CH2Ph | 20 | 97.4 | 96 |

| 6b | c-C6H11 | 19 | 99.6 | 630 |

| 7b | t-C4H9 | 16 | 97.0 | 79 |

| Halogenated Epoxides | ||||

| 8b | CH2Cl | 20 | 98.7 | 190 |

| 9b | CH2Br | 20 | 96 | 49 |

| 10a | CH2F | 17 | 98 | 120 |

| 11a | CF3 | 18 | 99.6 | 620 |

| Epoxides Bearing Ether and Carbonyl Functionality | ||||

| 12b | CH2OBn | 20 | 97 | 83 |

| 13b | CH2OTBS | 18 | 99 | 250 |

| 14b | CH2OPh | 18 | 98 | 120 |

| 15b | CH2O(1-naphthyl) | 20 | 99 | 250 |

| 16b | CH2CH2OBn | 19 | 97 | 82 |

| 17b | oxiranyld | 20 | 98 | 130 |

| 18b | CH2OCOn-C3H7 | 54 | 99.4 | 68 |

| 19b | CH2CO2Et | 20 | 98 | 130 |

| 20b | CH2NHBoc | 18 | 74 | 7.8 |

| 21b | CO2CH3 | 19 | 98 | 120 |

| 22b | COCH3 | 18 | 97 | 81 |

| 23b | COCH2CH3 | 18 | 96 | 60 |

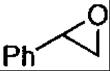

| Aryl, Vinyl, and Alkynyl Epoxides | ||||

| 24b | C6H5 | 20 | 98 | 130 |

| 25b | 4-ClC6H4 | 18 | 97 | 81 |

| 26b | 3-ClC6H4 | 17 | 98 | 120 |

| 27b | 3-(CH3O)C6H4 | 19 | 98 | 120 |

| 28b | 3-(NO2)C6H4 | 19 | 99 | 280 |

| 29b | 2-ClC6H4 | 18 | 98 | 120 |

| 30b | CH=CH2 | 18 | 98 | 120 |

| 31b | CCTBS | 19 | 99.4 | 420 |

Solvent-free.

Highly concentrated with epoxide : THF = 1 : 1 v/v ratio.

Isolated yield of 1,2-diol.

The substrate was d,l-butadiene diepoxide.

Halogenated epoxides (Table 7, entries 8 - 11), ether containing epoxides (Table 7, entries 12 - 16), and carbonyl containing epoxides (bearing esters, ketones, and carbamates) (Table 7, entries 17 - 23) were all excellent substrates for HKR. Terminal epoxides bearing unsaturated C-C bonds, such as styryl, vinyl and alkynyl derivatives (Table 7, entries 24 - 31) proved to be useful substrates in HKR, affording valuable epoxides with ≥ 99% ee in 36 – 44% yield (based on racemic epoxide).

Isolation of the product of a kinetic resolution, however, is more complicated because the product ee decreases with increasing reaction conversion. Nonetheless, with high krel values, products of very high ee can be isolated at yields approaching 50%. As outlined above, with krel of 10, starting material of 95% ee can be obtained in up to 34% yield. To obtain product with identical ee and yield, a krel value of 63 is necessary!66

The krel values of a variety of epoxides were determined in the HKR as outlined in Table 7. In a kinetic resolution, the ee's of both the starting material and the product change with conversion. Thus, to describe a kinetic resolution with product ee's is not as informative as characterization by krel values. In the determination of krel values in Table 7, 0.2 equivalents of water were employed.

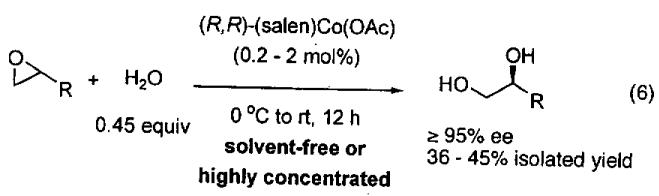

The use of the HKR under solvent-free and highly concentrated conditions to isolate enantioenriched diols is illustrated in Eq 6. In almost all cases, diol ee's exceeded 95% and isolated yields ranged from 36 – 45% (based on racemic epoxide).

Detailed investigations into the mechanism of the HKR by Nielsen, Stevenson, Blackmond, and Jacobsen50 have not only provided insight into cooperative interactions between (salen)Co(III) complexes, but have lead to an improved catalyst for the solvent-free process. When (salen)CoCl is employed, it rapidly reacts with epoxide and water to generate (salen)Co(OH), which also serves as a Lewis acid to activate the epoxide. In contrast, with less nucleophilic counterions, such as acetate and tosylate, the reaction of the counterion with the epoxide is slower (Figure 7). The more Lewis acidic complexes (salen)Co(OAc) and (salen)Co(OTs) not only activate the epoxide more strongly, increasing its reactivity, but also exhibit greater binding constants for epoxide coordination. Thus, while the catalyst does play a dual role in the epoxide ring-opening reactions, the optimal characteristics of each (salen)Co(III) component are not identical. By way of comparison, when the precatalyst has been converted entirely to Co-OH, the HKR is up to 30 times slower than when (salen)Co-OH and Co-OTs are both present. Under ideal conditions, the ratio of (salen)Co(OH) to (salen)Co(OTs) is 1 : 1. Comparison of the improved catalyst (salen)Co(OTs) to (salen)Co(OAc) in the HKR of several epoxides is illustrated in Table 8.

Figure 7.

Mechanism of the HKR illustrating the dual roles of the (salen)Co(III) centers.

Table 8.

Comparison of the HKR with (salen)Co(OAc) and (salen)Co(OTs) with various epoxides.

| ||||

|---|---|---|---|---|

| epoxide | catalyst | catalyst (mol%)a |

time (h) |

yield (%)b |

|

(salen)Co(OAc) | 0.5 | 16 | 43 |

| (salen)Co(OTs) | 0.15 | 3 | 44 | |

| (saten)Co(OTs) | 0.05 | 16 | 45 | |

|

(salen)Co(OAc)c | 2.0 | 48 | 40 |

| (salen)Co(OTs)c | 1.2 | 48 | 39 | |

|

(salen)Co(OAc) | 0.5 | 16 | 43 |

| (salen)Co(OTs) | 0.2 | 16 | 42 | |

|

(salen)Co(OAc) | 2.0 | 24 | 43 |

| (salen)Co(OTs) | 0.5 | 16 | 42 | |

|

(salen)Co(OAc) | 0.5 | 16 | 47 |

| (salen)Co(OTs) | 0.06 | 16 | 45 | |

Catalyst loading based on racemic epoxide.

Isolated yield of >99% ee epoxide based on racemate (theoretical maximum 50%).

Reaction at 0-4 °C.

In summary, HKR with (salen)Co(III) displays an extraordinary scope, as a wide assortment of sterically and electronically varied epoxides can be resolved to 99% ee. The HKR has several appealing features from a practical standpoint, including the use of H2O as a reagent, low loadings of a recyclable and commercially available catalyst, high yield and selectivity, low reagent cost, and low reagent toxicity. The ability to conduct reactions under solvent-free and highly concentrated reaction conditions results in high volumetric productivity and low waste generation. These characteristics make HKR attractive for large-scale applications.

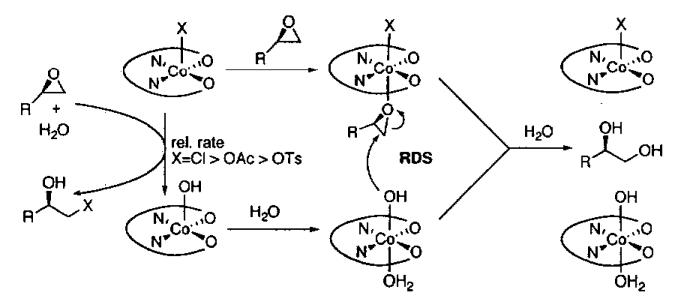

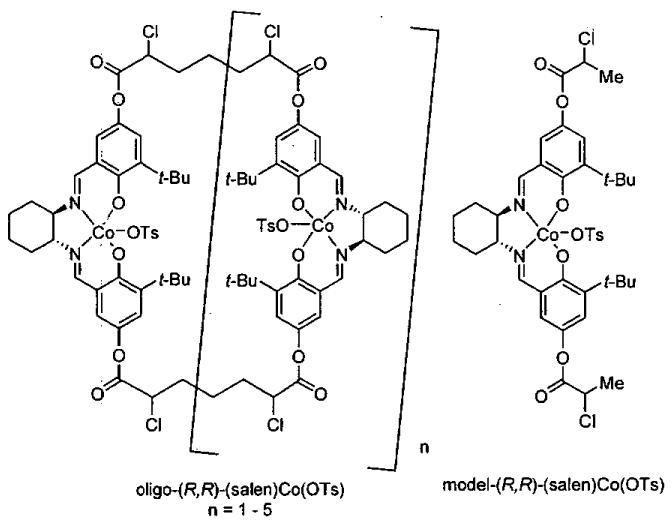

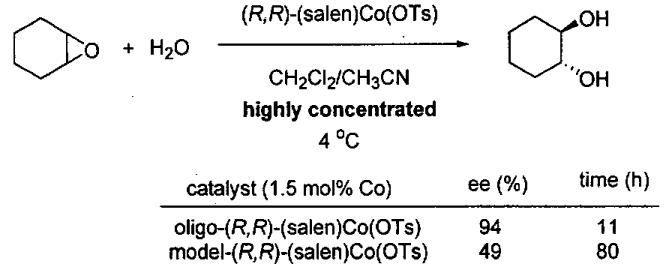

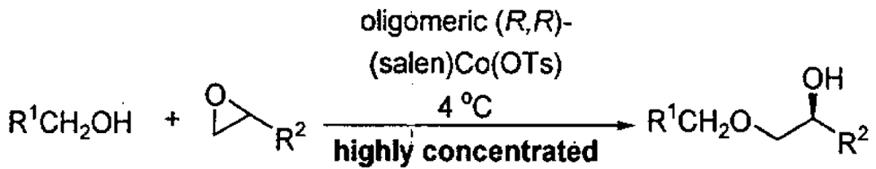

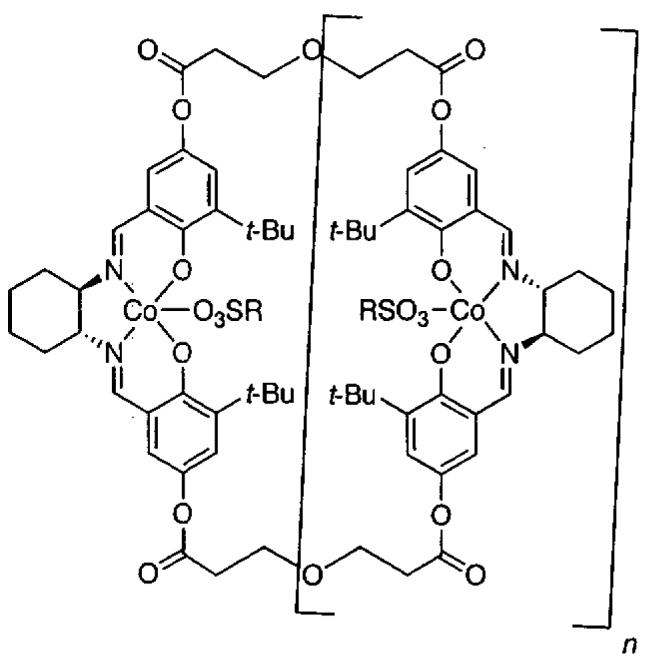

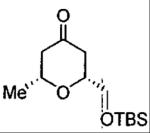

2.2.4 Oligomeric (salen)Co(III) Catalysts for the HKR

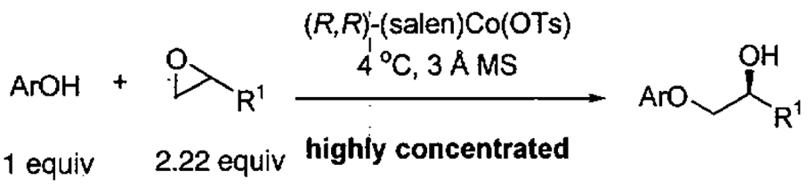

Like the ARO of meso epoxides by (salen)CrN3 catalysts, the HKR with (salen)Co(III) catalysts proceeds by a cooperative bimetallic mechanism wherein one molecule of catalysts activates the epoxide and the second activates the water in the form of a (salen)Co(OH). As outlined previously, such second order behavior in catalyst concentration results in dramatically increased reaction times as the catalyst loading is reduced. The catalyst loading of monomeric (salen)Co(III) used in the HKR of terminal epoxides, while relatively low (0.2 – 2 mol%), remains the primary cost determinant in the HKR. To circumvent this limitation, several cyclic oligomeric catalysts were prepared and examined in the HKR of racemic epoxides under solvent-free and highly concentrated conditions.

Initial cyclic oligomeric catalyst structures are illustrated in Figure 8 along with a monomeric model system prepared for the purpose of comparison. The stereocenters on the tethers are random and give rise to diastereomeric catalyst mixtures. The reactivity of the oligomeric catalyst mixture was compared to the monomeric model system from Figure 8 in the challenging ARO of cyclohexene oxide under highly concentrated reaction conditions (Figure 9).85 With 1.5 mol% loading of cobalt metal centers, the oligomeric catalyst reached completion in 11 h while the monomeric model system required 80 h. The enhanced reactivity of the oligomeric catalyst was attributed to the increase in effective molarity of the cobalt centers due to the tethering of the (salen)Co(III) units. Surprisingly, the oligomeric catalyst also exhibited much higher enantioselectivity (94%) than the monomeric model catalyst (49% ee). The remarkable increase in enantioselectivity of the oligomeric catalyst is likely due to the constrained orientation of the two reacting cobalt centers in the oligomeric catalyst system.

Figure 8.

Structures of oligomeric Co(III) catalysts and a monomeric model system for the ARO of epoxides.

Figure 9.

Comparison of the ARO of cyclohexene oxide with oligomeric and monomeric model catalysts from Figure 8.

The positive effects of tethering on enantioselectivity and reactivity were encouraging with cyclohexene oxide, leading to examination of four racemic substrates in the HKR under solvent-free or highly concentrated conditions (Table 9).85 The practicality of the oligomeric catalyst in Figure 8 is highlighted in entry 1. With 0.5 mol of epichlorohydrin and 0.3 mol of water, the HKR was performed at room temperature with only 50 mg of the oligomeric catalyst. After 11 h, the epoxide was vacuum transferred from the reaction mixture and filtered through a pad of MgSO4 to remove the excess water, furnishing 23 g of epoxide (45% yield, >99% ee). As outlined in Table 9, use of the oligomeric catalyst allowed a 10- to 50-fold decrease in the cobalt loading with a simultaneous reduction of up to a factor of 16 in reaction time.

Table 9.

Catalyst comparison in the HKR of terminal epoxides with the oligomeric catalyst (Figure 8) and the standard (R,R)-(salen)Co(OAc).

| |||||

|---|---|---|---|---|---|

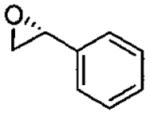

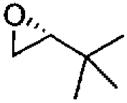

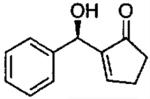

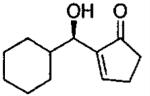

| entry | isolated product | catalyst | Co (mol%)a | time (h)% | yieldf (% ee) |

| epoxidesg | |||||

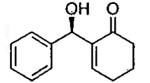

| 1b |  |

monomer oligomer |

0.5 0.01 |

18 11 |

42(99) 45(99) |

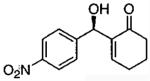

| 2c |  |

monomer oligomer |

0.85 0.05 |

68 24 |

26(99) 36 (99) |

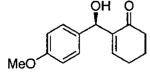

| 3d |  |

monomer oligomer |

0.8 0.08 |

72 24 |

44(99) 37(99) |

| 4e |  |

monomer oligomer |

2.0 0.1 |

48 24 |

41(99) 41(99) |

| diolsg | |||||

| 5d |  |

monomer oligomer |

2.0 0.01 |

24 1.5 |

50(96) 40(97) |

| 6d |  |

monomer oligomer |

0.64 0.03 |

20 4 |

49(94) 46(97) |

| 7d |  |

monomer oligomer |

0.8 0.08 |

12 4 |

41(98) 43(96) |

| 8d |  |

monomer oligomer |

2.0 0.05 |

20 18 |

40(95) 49(95) |

Loading on a Co basis relative to racemic epoxide.

Solvent-free.

Highly concentrated reaction using butyronitrile as solvent.

Highly concentrated reaction using 1:1 CH2Cl2: CH3CN as solvent.

Highly concentrated reaction using 1,2-hexanediol as solvent.

Isolated yield based on racemic epoxide.

For reactions in which resolved epoxide was targeted, 0.55-0.60 equiv H2O was used for the resolution. For recovery of diol, 0.45 equiv H2O was employed.

The oligomeric catalyst was also employed in the kinetic resolution of epoxides, using alcohols as the reacting partner (Table 10). Under highly concentrated conditions, a variety of primary alcohols participated in epoxide opening reactions to afford monoprotected alcohols with high levels of regio- and enantioselectivity (94–99% ee). In most cases, yields were high, catalyst loading was low, and reaction times were 3 – 24 h. These results represented the first kinetic resolution of epoxides using alcohols as nucleophiles.85

Table 10.

Kinetic resolution of epoxides with alcohols using the oligomeric catalyst from Figure 8.

| |||||

|---|---|---|---|---|---|

| entrya | R1 | R2 | Co (mol%)b | yield (%)c,d | ee (%) |

| 1 | Ph | (CH2)3CH3 | 2.0 | 87 | 98 |

| 2 | CH2TMS | (CH2)3CH3 | 0.2 | 97 | 99 |

| 3 | H | (CH2)3CH3 | 0.1 | 96 | 94 |

| 4 | 2-C6H4-Br | (CH2)3CH3 | 0.1 | 99 | 99 |

| 5 | 4-C6H4-OMe | (CH2)3CH3 | 2.0 | 62 | 94 |

| 6 | 2-C6H4-NO2 | (CH2)3CH3 | 0.5 | 98 | 99 |

| 7 | CH=CH2 | (CH2)3CH3 | 0.5 | 87 | 97 |

| 8 | Ph | CH2Cl | 2.0 | 91 | 98 |

| 9 | Ph | CH2O(allyl) | 2.0 | 95 | 98 |

Reactions were carried out with 5M substrates in CH3CN.

Catalyst loading on a per Co bases relative to alcohol.

Isolated yields based on RCH2OH.

Reaction times 3 - 24 h.

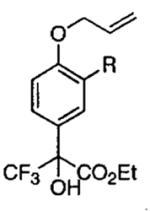

Kinetic resolution of terminal epoxides using phenol derivatives as nucleophiles provides α-aryloxy alcohols with high ee's. A comparison of the reactivity and enantioselectivity of the oligomeric (salen)Co(OTs) catalyst with the parent (salen)Co(OTs) was performed and is outlined in Table 11.85 The oligomeric catalyst is significantly more reactive, as judged by entries 2 and 3, and in some cases is also more enantioselective.

Table 11.

Comparison of the oligomeric catalyst from Figure 8 and the (salen)Co(OTs) in the kinetic resolution of epoxides with phenol derivatives.

| ||||||

|---|---|---|---|---|---|---|

| entry | Ar | R1 | (R,R)-cat. | Co (mol%)c | yield (%)d,e | ee (%) |

| 1 | Ph | CH2Cl | (salen)Co(OTs)a | 4.0 | 96 | 99 |

| oligomerb | 0.25 | 99 | 99 | |||

| 2 | 2-C6H4-(Oallyl) | CH2Cl | (salen)Co(OTs)a | 4.4 | 48 | 84 |

| oligomerb | 0.25 | 99 | 98 | |||

| 3 | Ph | Ph | (salen)Co(OTs)a | 4.0 | f | n.d. |

| oligomerb | 1.0 | 60 | 97 | |||

| 4 | Ph | c-hexyl | (salen)Co(OTs)a | 8.0 | 89 | 94 |

| oligomerb | 0.5 | 99 | 98 | |||

| 5 | 2-C6H4-Cl | n-Bu | (salen)Co(OTs)a | 4.0 | 80g | 68 |

| oligomerb | 0.8 | 98 | 99 | |||

5M substrates in TBME.

5M substrates in CH3CN.

Catalyst loading on a per Co basis relative to ArOH.

Isolated yields based on ArOH.

Reaction times 4 - 24 h unless otherwise noted.

After 10 days 63% conversion, 2:3 mixture favoring internal attack.

72 h reaction time.

Kinetic experiments with racemic 1,2-epoxyhexane, 2-chlorophenol, and the oligomeric catalyst indicated that the ring-opening was first order in cobalt catalyst, consistent with an intramolecular ring-opening. Such behavior can be contrasted with the second order dependence observed for the monomeric (salen)Co(OTs). These results indicate that the epoxide opening with the oligomeric catalyst occurs in an intramolecular fashion via a cooperative mechanism involving at least two cobalt centers.

The primary drawback of the oligomeric catalyst system in Figure 8 is its hydrophobic character, which resulted in limited solubility in the epoxide-water mixtures of the HKR. The solubility properties of the chlorinated oligomer required solvent to solubilize the catalyst, complicating the otherwise simple isolation of the volatile epoxide. This difficulty inspired continued investigation into oligomeric catalysts with greater solubility in the HKR reaction medium.

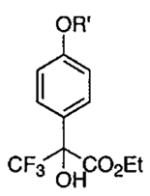

In designing the next generation of oligomeric catalysts, the Jacobsen group focused on the tether to modulate the solubility and the counterion to increase reactivity.86,87 By using tethers containing ether linkages and void of chloro groups, oligomeric catalyst with increased solubility in the epoxide/water mixture of the HKR were identified (Figure 10). To evaluate the reactivity of the new tethered catalyst, the HKR of methyl glycidate was studied (Table 12, entry 1). Under solvent-free conditions with 0.03 mol% catalyst, the reaction reached completion in 8 h. Resolved methyl glycidate with > 99% ee was isolated. In contrast, under identical conditions with the monomeric (salen)Co(OAc) the epoxide ee was 8% after 8 h.

Figure 10.

Next generation soluble oligomeric catalyst for the HKR of terminal epoxides (R = CF3, 3-NO2-C6H4).

Table 12.

HKR of terminal epoxides catalyzed by oligomeric (salen)Co(O3SR) from Figure 10.

| ||||

|---|---|---|---|---|

| entry | epoxide | (salen)Co(O3SR) R = |

catalyst loading (mol%) |

yielda (%) |

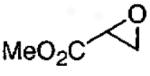

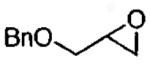

| 1 |  |

CF3 | 0.015 | 44 |

| 2 | CF3 | 0:0025 | 43 | |

| 3 |  |

CF3 | 0.001 | 44 |

| 4 |  |

CF3 | 0.0003 | 40 |

| 5 |  |

3-NO2-C6H4 | 0.04 | 40 |

Isolated yields based on racemic epoxides (theoretical maximum = 50%).

The HKR of propylene oxide, an important substrate, was also extremely efficient and easily scalable (Table 12, entry 4). Under solvent-free conditions, 1.5 mol of epoxide was resolved with 3.6 mg catalyst (41 ppm by mass, 3 ppm on a molar basis) furnishing 35 g of isolated epoxide with > 99% ee.86

The mixture of oligomers (Figure 10, n = 1 – 3) was separated to determine their individual reactivity. Surprisingly, a substantial difference in reactivity was observed with n = 3, which was significantly more reactive and enantioselective than the dimer or tetramer.87

The use of oligomeric catalysts has allowed circumvention of many of the pitfalls associated with systems that are second order in catalyst. By tethering (salen)Co(III) units, high effective concentrations of cobalt centers are achieved at low cobalt loading.

2.2.5 Supported (salen)Co(III) Catalyst for the HKR

The homogenization of (salen)Co(III) complexes has been examined to facilitate separation of the catalyst from the reaction mixture and as a method to maintain a high effective molar concentration of cobalt centers to promote the cooperative bimetallic mechanism.49,88 The resulting supported catalysts have been employed under highly concentrated conditions and have exhibited high values of krel. While the catalyst has been recycled several times, or even used in continuous flow systems,49 their application has been limited to small scale kinetic resolutions and do not present advantages over the oligomeric systems outlined above. They are not covered further here.

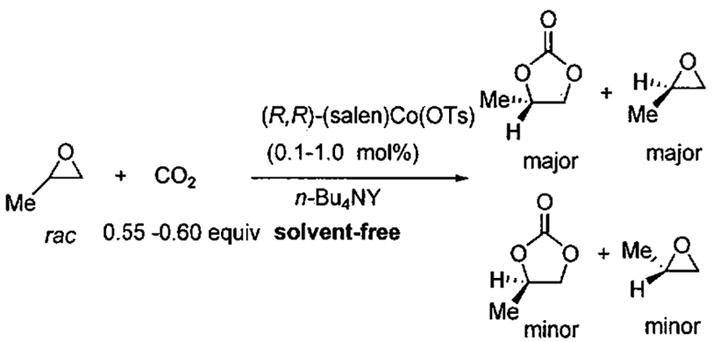

2.2.6 Asymmetric Ring-Opening of Epoxides Using Carbon Dioxide

In the nucleophilic ring opening of epoxides promoted by (salen)M complexes, there is ample evidence that the epoxide is activated by coordinating to the Lewis acidic (salen)M complex. In the systems that have been studied, the nucleophile is also activated by the (salen)M complex in the form of (salen)M-Nu. As illustrated below, however, this is not always the case.

An interesting partner for the asymmetric epoxide opening is carbon dioxide. This handy C1 building block does not readily react with epoxides in the presence of Lewis acids. It was discovered that, in the presence of certain nucleophiles, epoxide opening does occur, ultimately generating cyclic carbonates. The synthesis of five-membered cyclic carbonates via the coupling of CO2 and epoxides is an environmentally benign process and CO2 is a safe and plentiful C1 building block.89

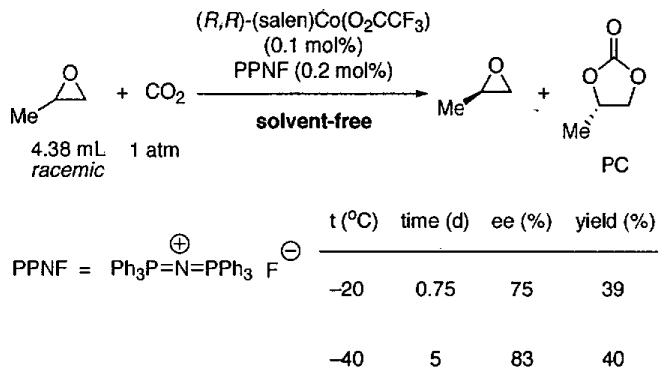

Based on the possible mechanisms of epoxide opening catalyzed by Lewis acids and nucleophilic cocatalysts (Figure 11), Lu et al. designed a system for generating optically active cyclic carbonates from racemic epoxides.90 Using Jacobsen's chiral (salen)Co(III) catalysts42 in combination with catalytic tetrabutylammonium halides (n-Bu4NX), these researchers devised a convenient solvent-free kinetic resolution of propylene oxide to provide enantioenriched propylene carbonate (PC). Chiral (salen)CoX complexes with a sterically bulky axial X-group, such as p-toluene sulfonate, were essential for maximizing enantioselectivity in the kinetic resolution. Additionally, the anion of the quaternary ammonium co-catalyst has a significant impact on propylene carbonate enantiomeric purity.

Figure 11.

Two possible mechanisms for epoxide opening with carbon dioxide.

In the absence of the halide cocatalyst, no reaction was observed (Table 13, entry 1). Lu et al found that reaction of neat rac-propylene oxide (0.5 mol) with 0.55 – 0.60 equiv of CO2 in the presence of 0.1 mol% of (salen)Co(OTs) complex and 0.1 mol % of n-Bu4NBr as nucleophile produced optically active propylene carbonate (PC) of moderate ee in the kinetic resolution (Table 13, entry 2).90 The relative rate of the fast vs. slow reacting epoxide was just over 5. The best results were obtained with n-Bu4NCl (Table 13, entries 3 – 8).

Table 13.

Catalytic kinetic resolution of rac-propylene oxide by CO2 coupling.

| |||||||

|---|---|---|---|---|---|---|---|

| entry | cocatalyst n-Bu4NY (equiv) |

T (°C) | time (h) | conv (%) | krel | TOF (h−1) | PC ee (%) |

| 1 | none | 25 | 10.0 | 0 | - | 0 | - |

| 2 | n-Bu4NBr (1) | 25 | 2.5 | 50.8 | 5.2 | 203 | 51.6 |

| 3 | n-Bu4NCl (1) | 25 | 4.0 | 50.5 | 6.4 | 126 | 56.7 |

| 4 | n-Bu4NCl (2) | 25 | 2.5 | 46.8 | 6.0 | 187 | 57.2 |

| 5 | n-Bu4NCl (10) | 25 | 2.0 | 48.1 | 5.8 | 240 | 55.9 |

| 6 | n-Bu4NCl (2) | 45 | 1.5 | 47.4 | 2.8 | 316 | 35.2 |

| 7 | n-Bu4NCl (2) | 15 | 6.0 | 43.9 | 7.2 | 73 | 63.5 |

| 8 | n-Bu4NCl (2) | 0 | 15.0 | 40.0 | 9.0 | 27 | 70.2 |

While the krel values measured in the epoxide resolution with carbon dioxide are below what is generally considered useful, these investigations are important because they address a long-standing challenge in organic chemistry: the feasibility of using CO2 as a C1 source in asymmetric catalysis. The (salen)Co(OTs)/n-Bu4NCl based catalyst system is highly efficient at catalyzing this reaction. The low relative rates of the fast and slow reacting enantiomers have inspired the search for better catalysts. Using the same (salen)CoX, Berkessel and Brandenburg91 examined the use of different counterions X and cocatalysts under solvent-free conditions. They observed that the counterion X had a large impact on catalyst activity, but not enantioselectivity and that the counterion of the cocatalyst influenced the activity and selectivity. After extensive screening, a catalyst system was found that operated under much lower pressure of carbon dioxide (Figure 12). Under optimal conditions, the selectivity factor was 18.7.

Figure 12.

Kinetic resolution of propylene oxide with formation of enantioenriched propylene carbonate (PC)

The results outlined in Section 2.2 illustrate how a series of (salen)M-based catalysts have been applied to the ARO and kinetic resolution of epoxides. In general, these transformations work well under standard solvent conditions. Under solvent-free and highly concentrated reaction conditions, little or no loss in enantioselectivity is observed with respect to those reactions conducted in solvent. It is found that the (salen)M-based catalysts are more active under solvent-free and highly concentrated reaction conditions. Given the breadth of the reactions outlined above, one must wonder if the (salen)M-based catalysts are unique in their ability to exhibit high levels of enantioselectivity under standard solvent conditions, highly concentrated conditions, and solvent-free conditions; or if these results are due primarily to the efforts of a few researchers interested in conducting reactions in a non-traditional fashion to develop more practical asymmetric processes. We believe that the latter rational is more likely and that many other catalysts may display similar levels of enantioselectivity and activity under highly concentrated and solvent-free conditions.

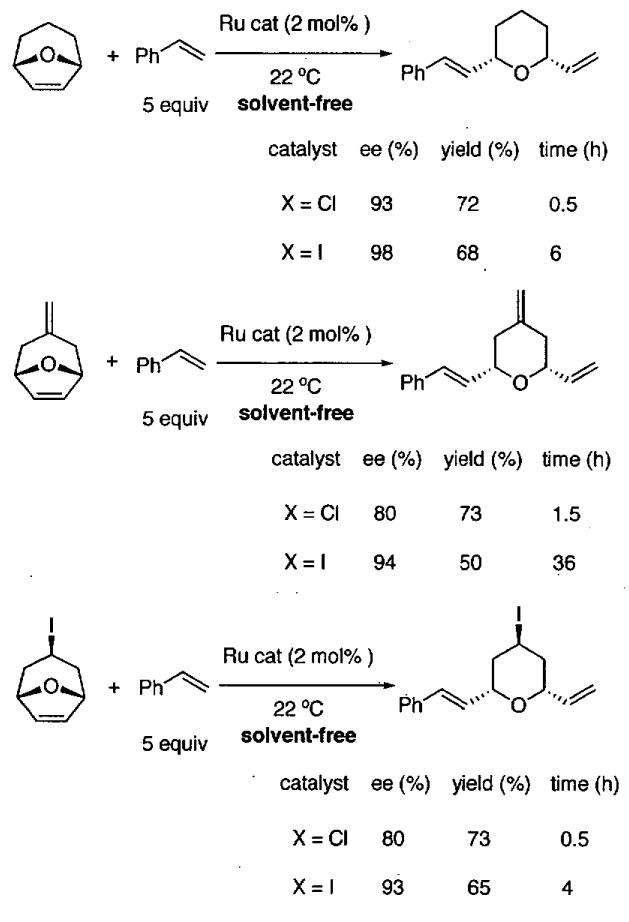

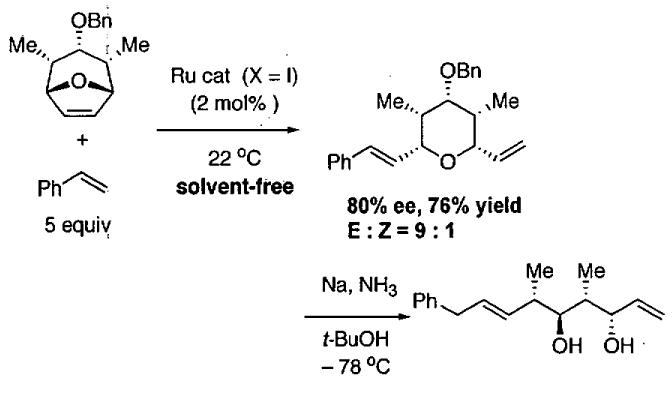

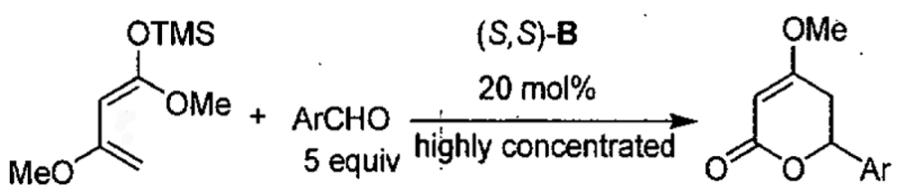

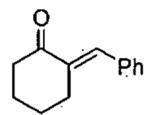

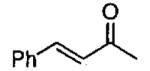

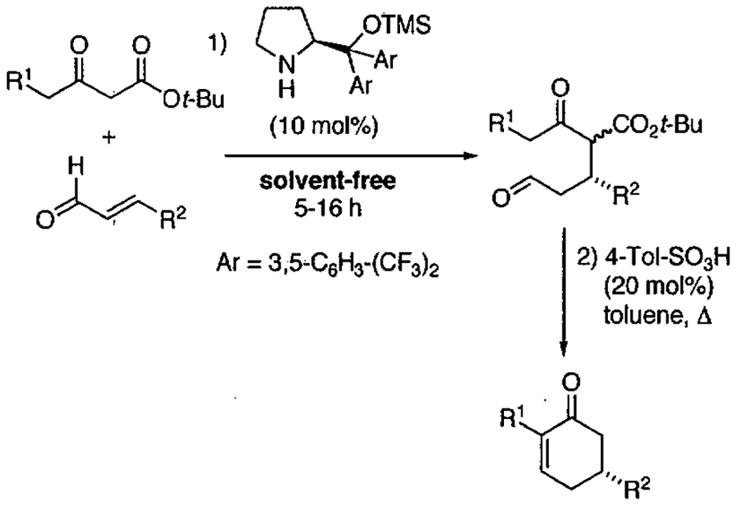

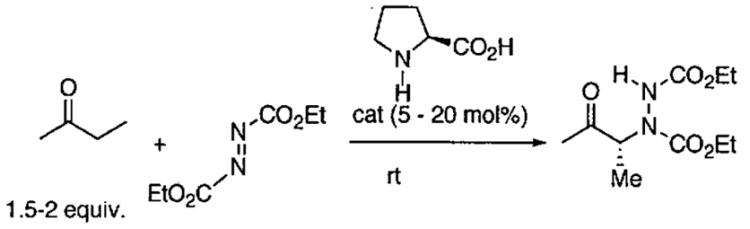

2.3 Asymmetric Hetero-Diels-Alder Reaction

The catalytic asymmetric hetero-Diels–Alder (HDA) reaction is one of the most important asymmetric C–C bond-forming processes in heterocyclic chemistry.92-94 It provides a highly effective method for preparing optically active six-membered ring compounds such as dihydropyrans and dihydropyranones, and has been extensively utilized in the synthesis of natural products. Many main-group, transition metal, lanthanide, and even organocatalysts have been developed that promote the enantioselective HDA reaction.95,96 The asymmetric HDA reaction has been frequently and successfully examined under solvent-free and highly concentrated reaction conditions. The successful adaptation of the HDA from solvent to solvent-free reaction conditions likely stems from the concerted nature of the cycloaddition transition state, which exhibits only minimal dependency on the reaction medium.

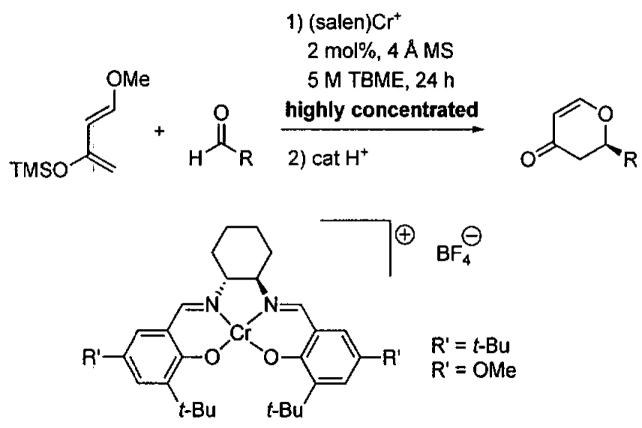

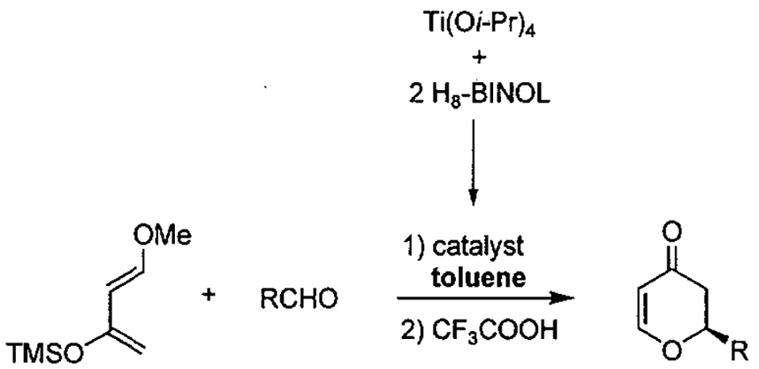

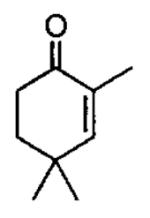

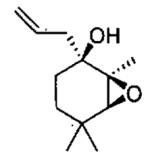

2.3.1 Asymmetric Hetero-Diels-Alder Reaction of Danishefsky's Diene and Aldehydes

The formal HDA reaction between 1-methoxy-3-(trimethylsilyloxy)buta-1,3-diene (Danishefsky's diene)97 and aldehydes provides a powerful method to access dihydropyranones, a class of heterocycles with broad utility in organic synthesis. A number of chiral catalysts have been reported for HDA reactions under standard solvent conditions. For example, Keck and co-workers reported that a catalyst generated from (R)- or (S)-BINOL and Ti(O-iPr)4 in a 2:1 ratio in the presence of 4 Å molecular sieves and 3-4 equiv of CF3COOH in Et2O was able to promote the reaction of Danishefsky's diene with aldehydes to yield dihydropyranones with good to excellent ee's (55-97%).98

In 2000, Jiang and co-workers99 also reported that asymmetric HDA reactions of Danishefsky's diene with aldehydes gave high enantioselectivity using chiral H8-BINOL-Ti(O-iPr)4 complexes as catalysts and toluene as the solvent (Table 14). The yield and enantioselectivity were found to be dependent on the catalyst loading. When the amount of catalyst was reduced from 20 mol% to 10 mol%, the enantioselectivity and yield of the reaction decreased considerably (Table 14, entries 1 vs. 2, 97% ee to 73% ee, yield 92% to 75%).

Table 14.

Asymmetric HDA reactions of Danishefsky's diene and aldehydes with toluene solvent.

| |||||

|---|---|---|---|---|---|

| entrya | R | temp(°C) | time (h) | yield (%) | ee (%) |

| 1 | Ph | 0 | 24 | 92 | 97 |

| 2b | Ph | 0 | 12 | 75 | 73 |

| 3 | Ph | 23-25 | 6 | 92 | 93 |

| 4 | 4-C6H4-OMe | 0 | 24 | 52 | >99 |

| 5 | 4-C6H4-Me | 0 | 24 | 60 | 99 |

| 6 | 4-C6H4-F | 0 | 24 | 54 | 99 |

All reactions were carried out using 20 mol% of catalyst in toluene.

10 mol% catalyst used.

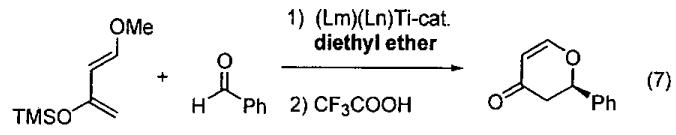

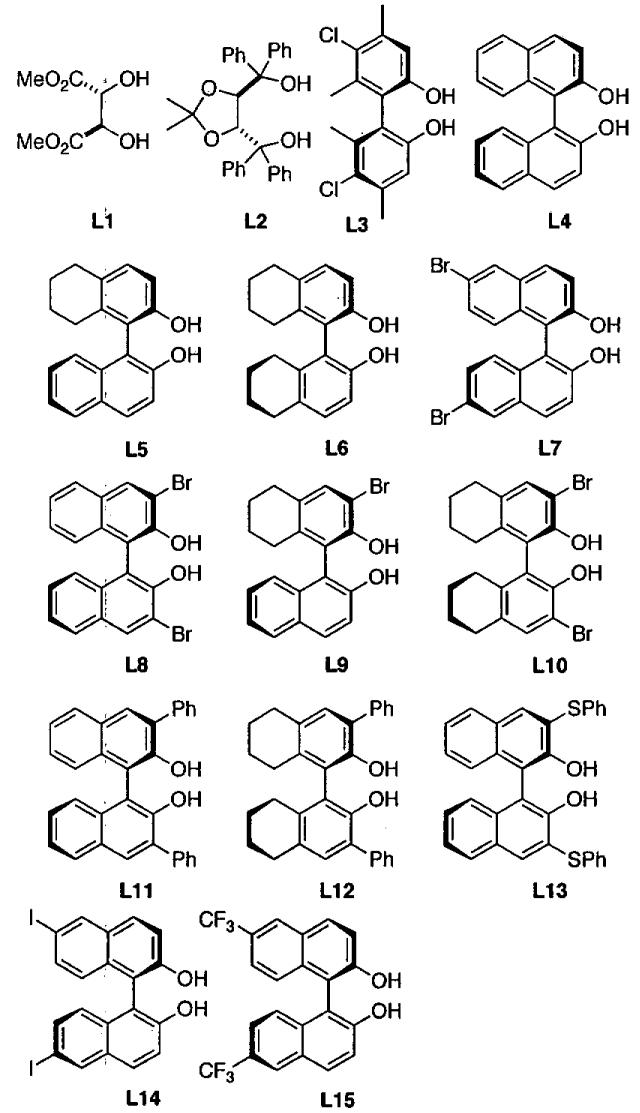

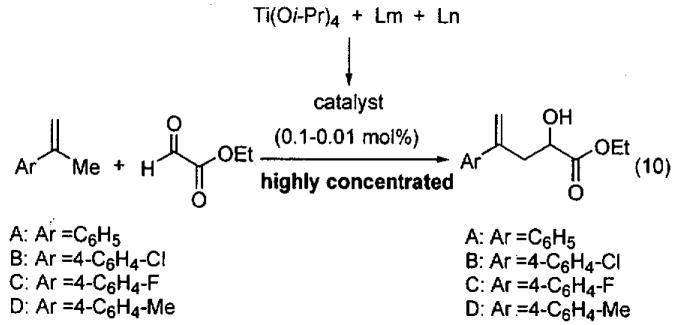

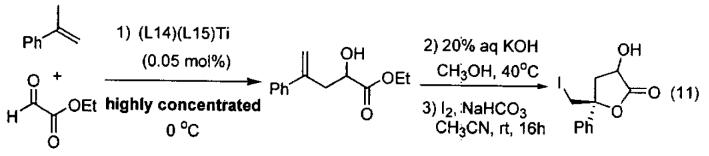

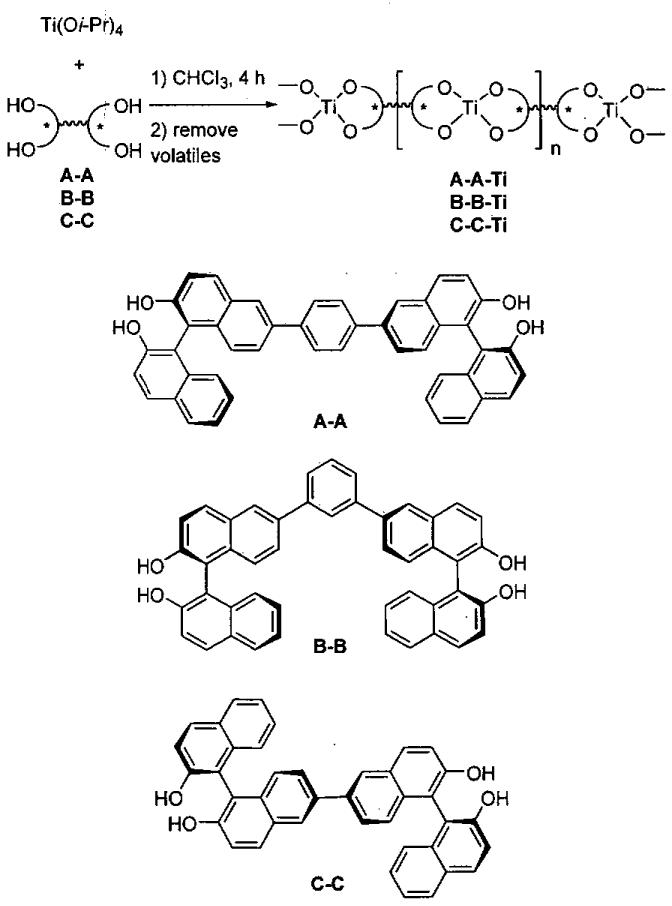

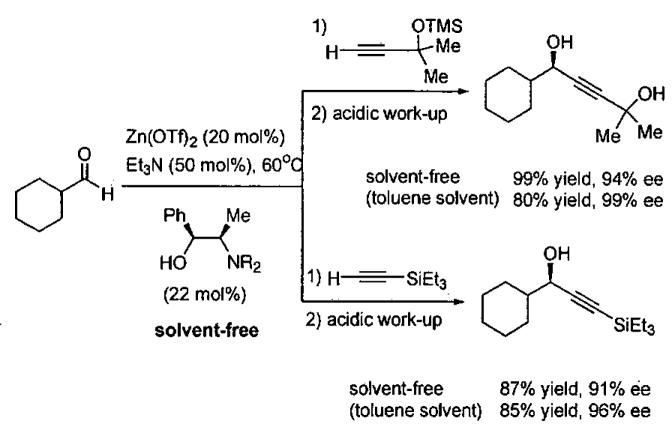

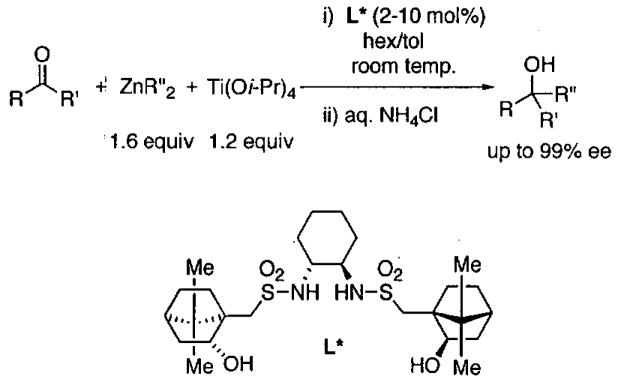

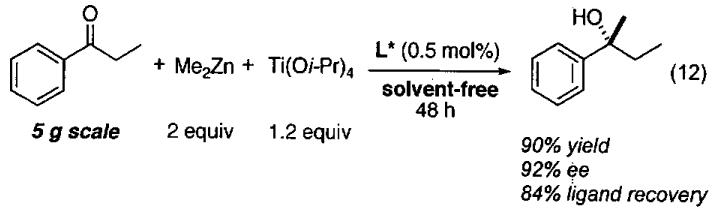

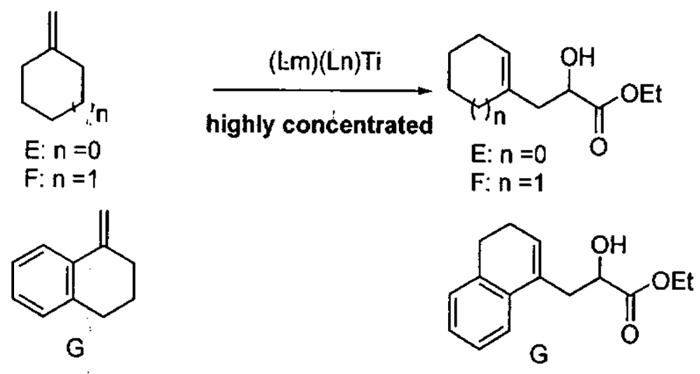

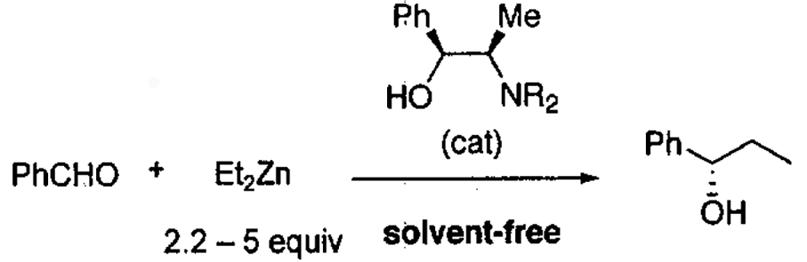

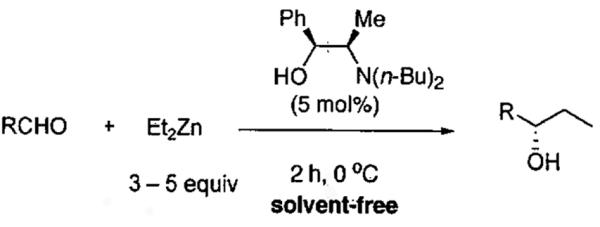

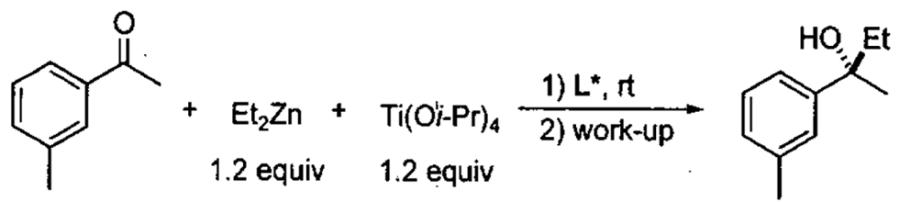

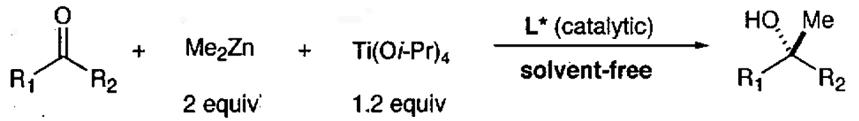

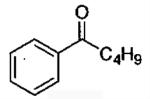

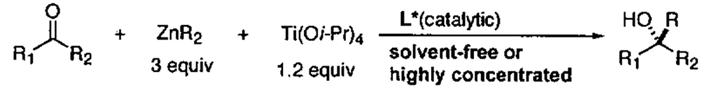

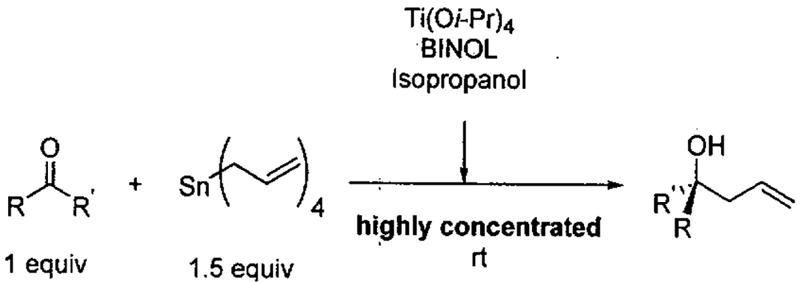

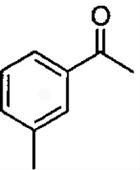

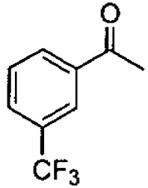

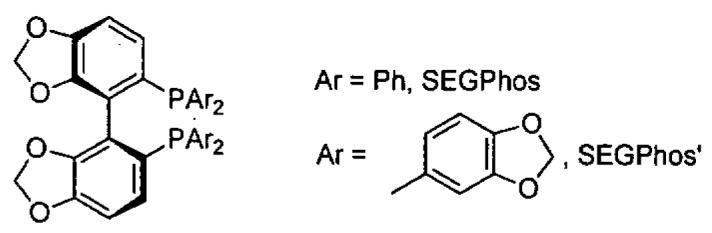

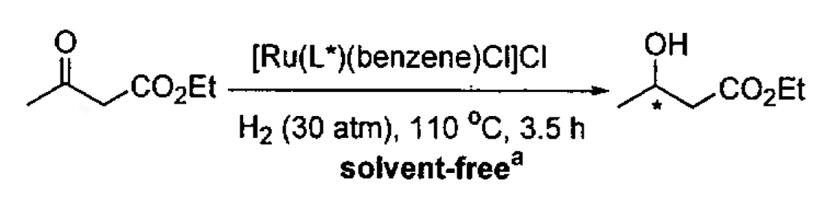

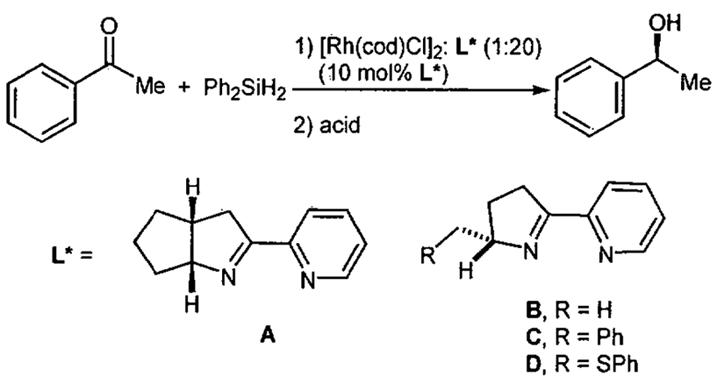

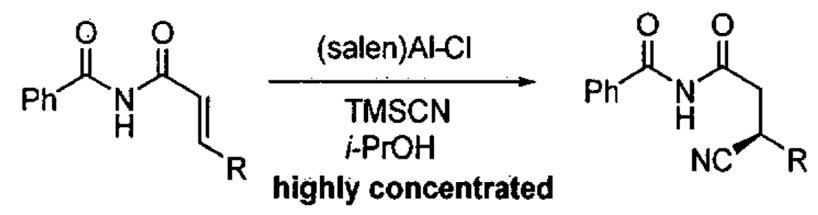

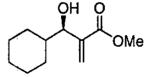

In related chemistry, Ding and co-workers discovered highly efficient catalysts for solvent-free enantioselective HDA reaction by high-throughput screening of a combinatorial library of chiral ligands attached to titanium (Eq 7).100,101

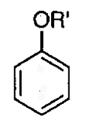

Using titanium tetraisopropoxide and two ligands from the collection in Figure 13 in a Lm : Ln : Ti ratio of 1 : 1 : 1, a series of (Lm)(Ln)Ti-based catalysts were generated. In mixing all possible combinations with L1-L13, a library of 104 catalysts can be generated. Most of the ligand combinations above will result in a mixture of titanium compounds under thermodynamic control. It is anticipated that the titanium centers will bind identical ligands giving (Lm)2Ti- and (Ln)2Ti-based catalysts or two different ligands as in (Lm)(Ln)Ti-derivatives. Furthermore, the resulting complexes may exhibit monomer-dimer-oligomer equilibria, complicating analysis of the enantioselective reactions.

Figure 13.

Ligands used to prepare (Lm)(Ln)Ti-based catalysts and (Lm)Zn-based catalysts for the solvent-free HDA.

Initial screening of in situ prepared (Lm)(Ln)Ti-based complexes in the HDA reaction with Danishesky's diene and benzaldehyde (Eq 7) in diethyl ether indicated ligands L4 - L7 generated catalysts that exhibited > 75% ee. The most promising ligand combinations were then examined under solvent-free conditions at lower catalyst loadings (Eq 8). The combinations (L5)2Ti and (L5)(L6)Ti each exhibited 99% ee and then were both used with a series of aldehydes to define the scope of the catalysts, as outlined in Table 15.

Table 15.

Solvent-free asymmetric HDA reaction of aldehyde with Danishefsky's diene as illustrated in Eq 8.

| aldehydes | (L5)2Ti |

(L5)(L6)Ti |

||||||

|---|---|---|---|---|---|---|---|---|

| loading (%) | time (h) | yield (%) | ee (%) | loading (%) | time (h) | yield (%) | ee (%) | |

| benzaldehyde | 0.05 | 24 | >99 | 99.3 | 0.05 | 24 | 82 | 99.4 |

| p-anisaldehyde | 0.05 | 48 | >99 | 90.8 | 0.05 | 48 | >99 | 98.0 |

| m-anisaldehyde | 0.05 | 48 | 81 | 96.6 | 0.05 | 48 | 82.6 | 99.8 |

| o-anisaldehyde | 0.05 | 48 | 95 | 75.1 | 0.05 | 48 | >99 | 95.1 |

| 3-phenylpropionaldehyde | 0.05 | 96 | >99 | 97.9 | 0.05 | 96 | >99 | 98.3 |

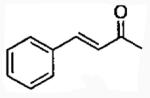

| trans-cinnamaldehyde | 0.1 | 96 | 82 | 98.4 | 0.05 | 96 | 56.6 | 96.6 |

| furfural | 0.05 | 48 | >99 | 99.2 | 0.05 | 48 | >99 | 99.7 |

| furfural | 0.01 | 96 | 37 | 94.7 | 0.01 | 96 | >99 | 97.7 |

| furfural | - | - | - | - | 0.005 | 144 | 63 | 96.2 |

| m-tolualdehyde | 0.1 | 48 | 95 | 98.5 | 0.05 | 48 | 92 | 99.5 |

| 1-naphthaldehyde | 0.05 | 48 | 55 | 85.6 | 0.05 | 48 | 65 | 98.5 |

| p-cyanobenzaldehyde | 0.1 | 48 | >99 | 92.9 | 0.05 | 48 | 98.4 | 97.9 |

| m-bromobenzaldehyde | 0.1 | 48 | >99 | 97.4 | 0.05 | 48 | 98.3 | 97.6 |

| p-bromobenzaldehyde | 0.05 | 48 | >99 | 98.0 | 0.05 | 48 | >99 | 98.4 |

| p-chlorobenzaldehyde | 0.05 | 48 | >99 | 91.2 | 0.05 | 48 | >99 | 99.1 |

| p-nitrobenzaldehyde | 0.05 | 48 | >99 | 97.3 | 0.05 | 24 | >99 | 99.4 |

Inspection of the results in Table 15 indicates that the reaction is particularly successful with aromatic aldehydes. It is noteworthy that in the cycloaddition with furfural, only 0.005 mol% of the (L5)(L6)Ti-based catalyst was needed to promote the reaction smoothly and furnish the product in 63% yield with 96.3% ee. This is one of the lowest catalyst loadings reported in early transition metal Lewis acid catalyzed processes! Comparison of the results in Table 14 and Table 15 obtained with two very similar catalysts, indicate the potential benefits of solvent-free and highly concentrated reaction conditions.

The dihydropyranones generated in this HDA reaction are very useful building blocks that have been employed in numerous syntheses. This study is particularly impressive given the unprecedented low catalyst loadings (0.1 – 0.005 mol%) and high enantioselectivities observed under solvent-free reaction conditions.

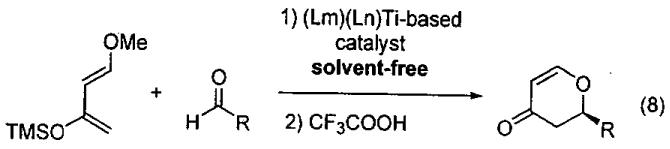

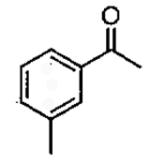

In a related study, the Ding group reported a highly enantioselective HDA reaction of Danishefsky's diene with aldehydes catalyzed by zinc-based chiral Lewis acids using toluene solvent.102 Most of the chiral ligands examined in this chemistry are shown in Figure 13. The catalyst was generated in situ by combining 10 mol% of diethylzinc with an equal amount of one of the chiral ligands in Figure 13. The catalyst prepared from 3,3'-dibromo-1,1'-bi-2-naphthol (L8) exhibited the highest enantioselectivity (Figure 14). When the reactions were carried out under solvent-free conditions, however, the product ee dropped from 97% to 10%, even though the yield was 99%. This result illustrates the dramatic role played by the solvent in this example, especially when compared with the titanium system in Eq 8 and Table 15.100

Figure 14.

Comparison of toluene and the solvent-free HDA reaction with ligand L8 from Figure 13.

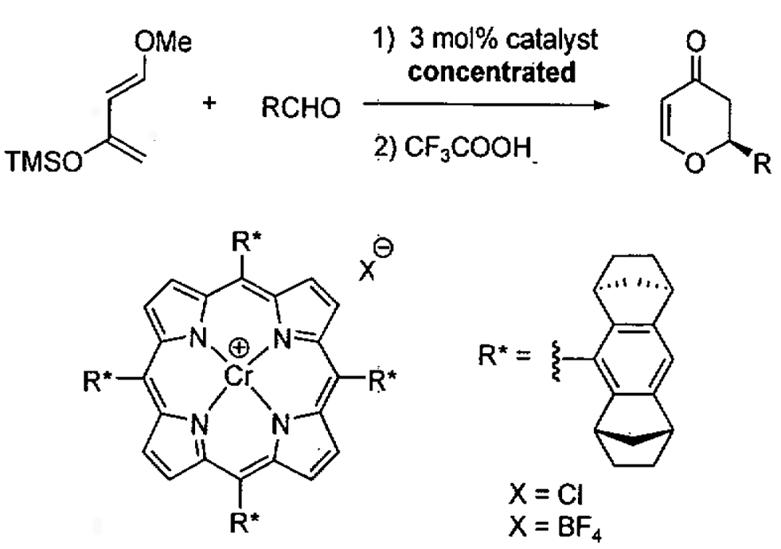

Many porphyrin complexes are unsaturated and can promote Lewis acid catalyzed processes such as the HDA reaction. Using Halterman's chiral porphyrin,103,104 Berkessel and co-workers reported that chiral Cr(III) porphyrins complexes are efficient and highly enantioselective catalysts for HDA between aldehydes and Danishefsky's diene under highly concentrated conditions (Table 16).105

Table 16.

Asymmetric HDA catalyzed by chiral porphyrin complexes.

| |||||

|---|---|---|---|---|---|

| entrya | R | catalyst counterion (X−) |

temp (°C) | yield (%) | ee (%) |

| 1 | Ph | Cl− | −18 | 85 | 95 |

| 2 | Ph | BF4− | −18 | 92 | 88 |

| 3 | c-hexyl | Cl− | −18 | 76 | 88 |

| 4 | n-hexyl | Cl− | −18 | 75 | 92 |

| 5 | 2-furyl | Cl− | −18 | 70 | 97 |

| 6 | (E)-CH=CHPh | Cl− | 0 | 55 | 74 |

| 7 | 2-pyridyl | Cl− | −18 | 70 | 78 |

The reactions were performed at 2.0M substrate concentration in MTBE.

As illustrated, high enantioselectivities were observed with a variety of aldehydes. Interestingly, cinnamaldehyde underwent reaction at the carbonyl rather than the C-C double bond. Heterosubstituted aldehydes proved to be excellent substrates for this system as shown with furfural and 2-pyridinecarboxaldehyde (Table 16, entries 5 and 7). It is surprising that the pyridyl group does not interfere with the activation of the carbonyl group in 2-pyridinecarboxaldehyde. It is hypothesized that sever steric hindrance about the metal center does not allow tight binding of the pyridine nitrogen.

The porphyrin-based catalysts will also promote the HDA reaction with monooxygenated dienes with moderate enantioselectivities.105 The results of the HDA reaction above are impressive, given that porphyrin complexes have not been widely embraced by scientists working in asymmetric catalysis. This is because many consider the chirality to be overly distant from the Lewis acidic metal center.

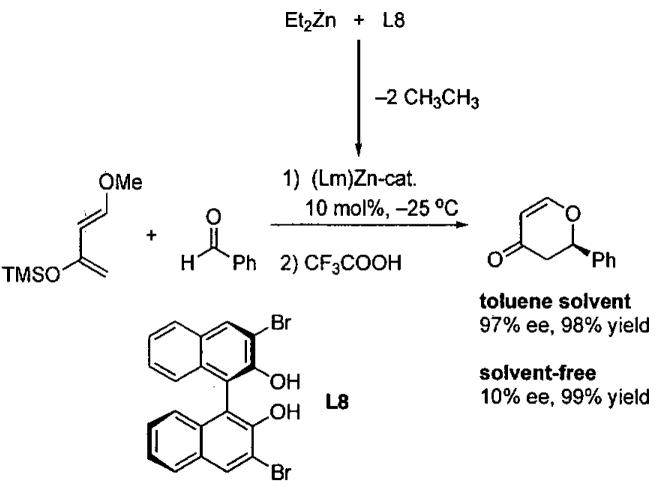

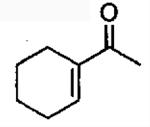

2.3.2 Hetero-Diels-Alder Reaction Catalyzed by (salen)Cr(X) Complexes

Schaus, Brånalt, and Jacobsen optimized the asymmetric HDA reaction catalyzed by (salen)Cr-based catalysts under highly concentrated conditions and provided insight into the reaction mechanism.106 Beginning with an initial substrate concentration of 1.0 M, the reaction achieved just over 90% conversion in 8 h with (salen)CrCl. Under highly concentrated conditions (5.0 M), complete conversion was attained after only 4 h with slightly higher ee (60%). The catalyst enantioselectivity was found to be highly dependent on the nature of the counterion, with the non-coordinating BF4− derivatives proving to be the most effective (Figure 15). Similar levels of enantioselectivity were observed with ligands R' = t-Bu and OMe (Table 17). In two cases, reactions were successfully conducted on a 10 mmol scale under highly concentrated reaction conditions.

Figure 15.

Enantioselective HDA reaction with cationic (salen)Cr(III) catalysts under highly concentrated conditions.

Table 17.

Results of the asymmetric HDA reaction catalyzed by (salen)Cr+ BF4 complexes.

| (salen)Cr+ R1 = t-Bu |

(salen)Cr+ R1 = OMe |

|||||

|---|---|---|---|---|---|---|

| entry | R | temp (°C) |

ee (%) | yield (%) | yield (%) | ee (%) |

| 1 | Ph | −30 | 87 | 85 | 98 | 65 |

| 2 | c-C6H11 | −20 | 93 | 71 | 76 | 85 |

| 3 | n-C5H11 | −40 | 83 | 86 | 85 | 62 |

| 4 | 2-furyl | −10 | 76 | 89 | 80 | 68 |

| 5 | (E)-CH=CHPh | 0 | 70 | 65 | 96 | 73 |

| 6 | CH2OCH2(4-C6H4-Br) | −30 | 79 | 67 | 94a | 84 |

| 7 | CH2O2C(2-C6H4-Cl) | −20 | 83a | 92 | 86 | 72 |

Reactions were run on 10.0 mmol scale

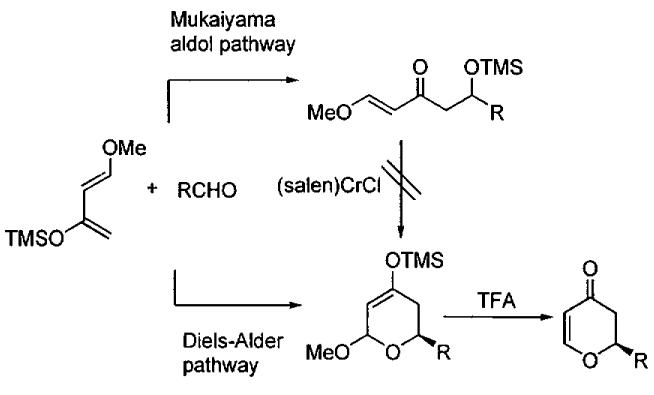

Lewis acid catalyzed HDA typically proceed through either a Mukaiyama aldol mechanism (stepwise mechanism) or a [4+2] Diels–Alder cycloaddition (concerted mechanism). Examination of the 1H NMR spectrum of the crude product indicated exclusive formation of cycloaddition product, a sign that the reaction likely proceeds through a concerted cycloaddition pathway. To test the possible intermediacy of a Mukaiyama aldol condensation adduct, the silyl ether product was independently synthesized and subjected to the conditions of the Cr(salen)-catalyzed HDA reaction (Figure 16). No detectable cyclization product was observed after 6 h at room temperature, suggesting that product formation proceeds via a concerted [4+2] mechanism.106

Figure 16.

Addition of (salen)CrCl to the independently prepared Mukaiyama aldol product did not lead to cyclization, suggesting that the reaction proceeds through a concerted [4+2] cycloaddition pathway.

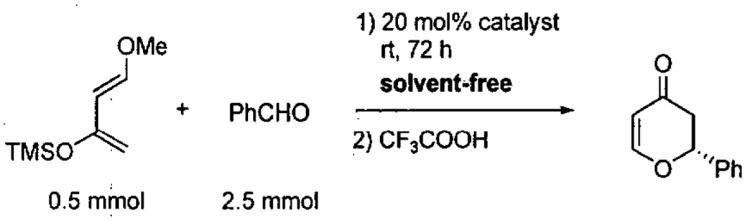

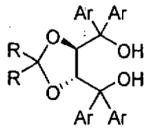

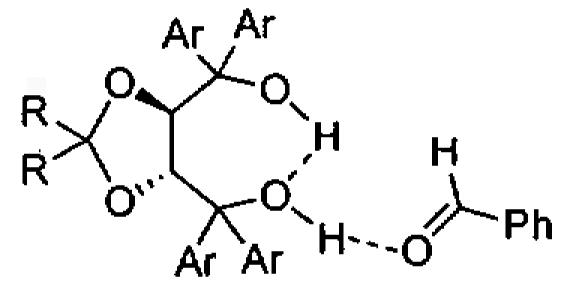

2.3.3 Organocatalytic Hetero-Diels-Alder Reaction Catalyzed by TADDOL-Derivatives

In 2003, Rawal and coworkers reported a seminal work involving the asymmetric HDA reaction catalyzed by chiral Brønsted acids, such as the chiral diol TADDOL (TADDOL = α,α,α',α'-tetraaryl-1,3-dioxolan-4,5-dimethanol).107 This work has served as the inspiration for numerous related asymmetric reactions promoted by chiral organocatalysts.108-113 In one such example, Wu, Ding, and coworkers conducted experimental and theoretical studies on the asymmetric HDA promoted by TADDOL derivatives under solvent-free conditions.114 As outlined in Table 18, reactions were typically conducted with 20 mol% TADDOL for 72 h at room temperature before treatment with TFA (trifluoroacetic acid). The ee and yield of the HDA product was found to be highly dependent on the structure of the TADDOL derivative employed.

Table 18.

HDA reaction catalyzed by chiral TADDOL derivatives.

| ||||

|---|---|---|---|---|

| yield (%) | ee (%) | |||

|

a: Ar = Ph | R = CH3 | 18 | 12.1 |

| b: Ar = 1-naphthyl | R = CH3 | 77 | 76.3 | |

| c: Ar = 2-naphthyl | R = CH3 | 36 | 18.7 | |

| d: Ar = 1-naphthyl | R-R = (CH2)4 | 50 | 69.1 | |

| e: Ar = 2-naphthyl | R-R = (CH2)4 | 60 | 4.0 | |

| f: Ar = 1-naphthyl | R-R = (CH2)5 | 58 | 77.0 | |

| g: Ar = 2-naphthyl | R-R = (CH2)5 | 58 | 21.2 | |

To differentiate between the two common mechanisms for the HDA reaction (Figure 16), a 1H NMR spectrum of the crude product was examined before treatment with acid. The absence of the Mukaiyama aldol product suggested that the reaction proceeded through the concerted [4+2] cycloaddition pathway.114 To further investigate the mechanism of the asymmetric HDA reaction catalyzed by TADDOL derivatives, calculations were performed using the ONIOM (our own N-layered integrated molecular orbital + molecular mechanics) (B3LYP/6-31G* : PM3) method. These studies are consistent with an intramolecular hydrogen bond between the two hydroxyl groups of the TADDOL and activation of the benzaldehyde via a single hydrogen bond (Figure 17).

Figure 17.

Proposed model for activation of benzaldehyde by TADDOL in the organocatalytic HDA reaction.

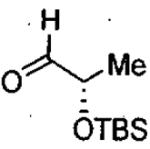

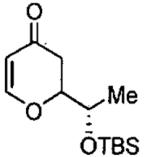

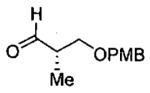

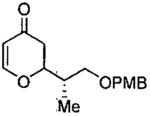

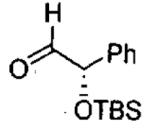

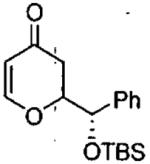

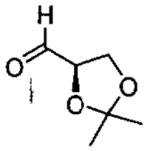

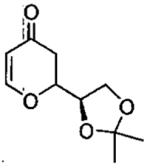

2.3.4 Diastereoselective Hetero-Diels-Alder Reaction

Typically, enantioselective syntheses of natural products begin with simple chiral building blocks that are elaborated in a diastereoselective fashion to construct the molecular skeleton and to install additional stereogenic centers. Unfortunately, diastereoselective reactions under substrate control can be problematic if they lead to significant amounts of the undesired stereoisomer. An underappreciated approach to controlling formation of new stereocenters in chiral substrates is to employ enantioselective catalysts to enhance or even override the inherent diastereoselectivity of the substrate. Such an approach has been employed in the doubly diastereoselective HDA reaction under highly concentrated conditions (Figure 18).

Figure 18.

HDA of enantioenriched aldehydes with achiral and chiral Cr(III) Schiff base complexes (see Table 19).

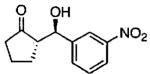

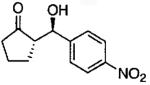

Using achiral and enantiomeric Cr(III)-Schiff base catalysts under concentrated reaction conditions, the HDA between Danishefsky's diene and enantioenriched aldehydes was examined (Figure 18).115 While the achiral catalyst gave poor diastereoselectivity, the chiral catalysts exhibited high levels of stereocontrol with unhindered chiral aldehydes. For example, with the (S)-lactaldehyde derivative, the achiral catalyst promoted the cycloaddition reaction with modest diastereoselectivity (Table 19, entry 1, 1 : 2 dr). In contrast, use of the resolved catalysts provided the products with dr between 1 : 12 and 15 : 1. Similar results were obtained with other unhindered chiral aldehydes (entries 2 and 3). In general, bulkier substrates gave lower dr with the chiral catalysts (Table 19). Importantly, the ee of several of the products was determined to be ≥ 97%, indicating that no epimerization of the aldehyde occurred under the Lewis acid catalyzed HDA reaction conditions.

Table 19.

Results of HDA of enantioenriched aldehydes with achiral and chiral Cr(III) Schiff base complexes from Figure 18.

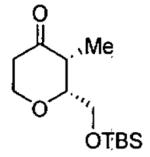

| entry | aldehyde | product | cat. | yield (%) | dr |

|---|---|---|---|---|---|

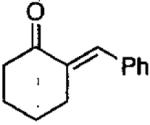

| 1 |  |

|

achiral (1R,2S) (1S,2R) |

81 96 97 |

1 : 2.0 1 : 12 15 : 1 |

| 2 |  |

|

achiral (1R,2S) (1S,2R) |

50 90 86 |

1 : 1.1 1: 11 9.3 : 1 |

| 3 |  |

|

achiral (1R,2S) (1S,2R) |

85 98 99 |

1:1.3 16 : 1 1 : 11 |

| 4 |  |

|

achiral (1R,2S) (1S,2R) |

58 58 54 |

1.7 : 1 3.6 : 1 1 : 2.6 |

| 5 |  |

|

achiral (1R,2S) (1S,2R) |

68 76 84 |

1 : 4.5 1 : 1.2 1 : 33 |

The challenging aldehydes in entries 4 and 5 of Table 19 underwent cycloaddition reactions with slightly higher diastereoselectivities with enantioenriched (salen)Cr+BF4− catalysts.115

These catalyst-controlled doubly diastereoselective HDA reactions selectively provide each of the four possible stereoisomers of the dihydropyranone products with good to excellent dr by judicious choice of aldehydes and catalyst enantiomers.115

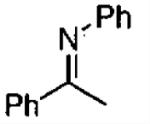

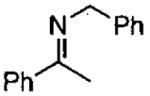

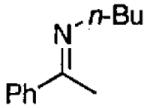

2.3.5 Asymmetric Hetero-Diels-Alder Reaction of Danishefsky's Diene with N-Aryl Imines

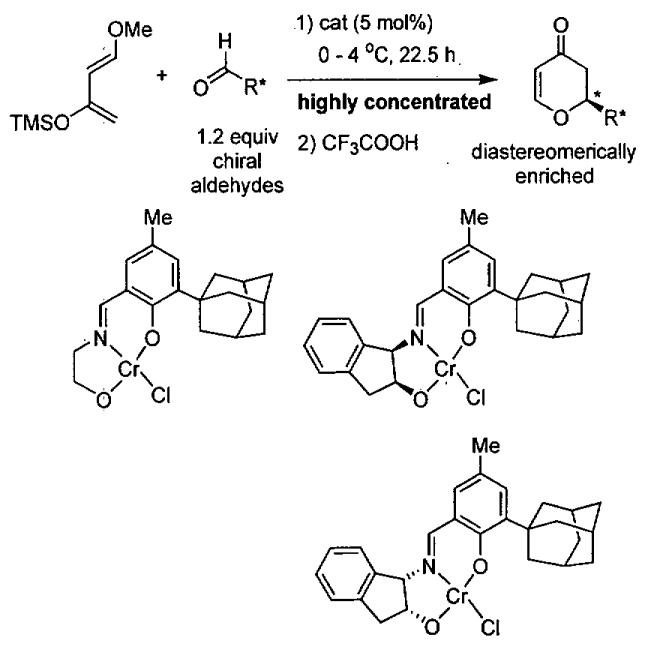

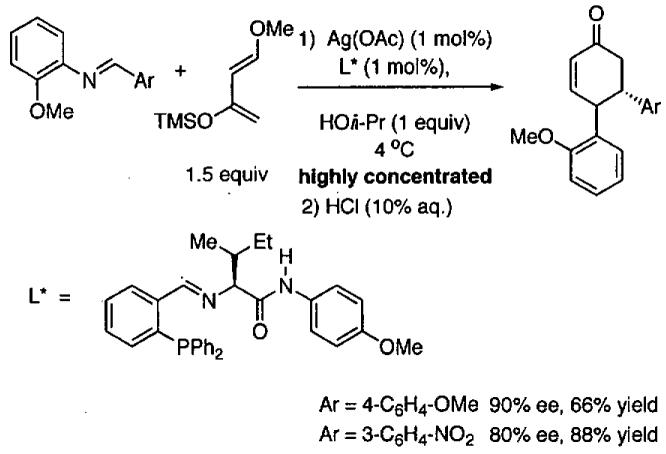

The HDA of Danishefsky's diene with imines provides access to chiral nitrogen-containing heterocycles, which are useful intermediates in the synthesis of functionalized enantioenriched piperidones.116-118 To develop catalysts prepared from readily available starting materials and used at low catalyst loading, Josephsohn, Snapper, and Hoveyda developed a highly enantioselective silver catalyst.119 After screening a parallel library of amino acid-based ligands, metals, and additives the system in Figure 19 was discovered. Use of 1 mol% each of Ag(OAc) and L* in the presence of 1 equiv of 2-propanol under highly concentrated conditions resulted in formation of the HDA in 80-90% yield after workup with acid. For comparison, reactions under standard solvent conditions in THF gave higher yields (86-92%) with these substrates and both were formed with 91% enantioselectivity. While the role of the 2-propanol is not understood, it is necessary for high TOF and enantioselectivity. Presumably a variety of other aryl imines would give similar results under the highly concentrated conditions in Figure 19.

Figure 19.

Asymmetric HDA reaction with a silver catalyst under highly concentrated conditions.

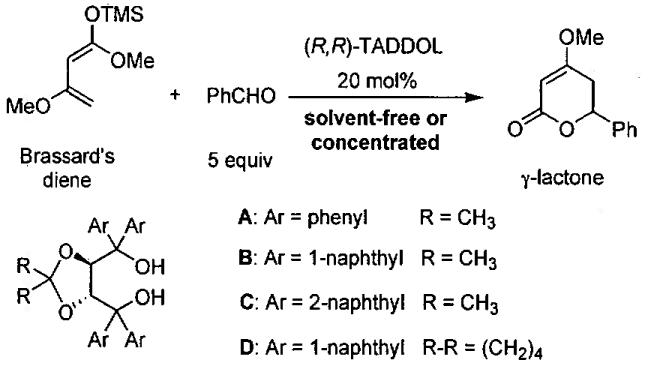

2.3.6 Asymmetric Hetero-Diels-Alder Reaction of Brassard's Diene and Aldehydes

The asymmetric HDA reaction of electron-rich 1,3-dimethoxy-1-(trimethylsiloxy)butadiene (Brassard's diene)120 with aldehydes provides a useful route to synthetically important enantioenriched γ-lactones. Based on Rawal's discovery that TADDOL derivatives catalyze the asymmetric HDA between aldehydes and Danishefsky's diene,107 Ding and coworkers extended their earlier work to include asymmetric HDA with Brassard's diene.121 As outlined in Figure 20, four TADDOL derivatives (A – D) were examined in the hydrogen-bond promoted HDA reaction. The results of screening these catalysts with benzaldehyde and Brassard's diene are illustrated in Table 20. Initially, the reaction was carried out at room temperature with 0.5 mmol of diene, 2.5 mmol of benzaldehyde, and 20 mol% of catalyst (R,R)-A (Figure 20) under solvent-free conditions (entry 1). The reaction proceeded enantioselectively forming the cycloaddition product in 30% yield and 7% ee. Employing TADDOL derivative B at −30 °C, the ee improved to 71% with 70% yield. When the catalyst loading was reduced to 10 mol%, the product ee was unchanged although the yield decreased to 50% (entry 4). In contrast to the results with A and B, the use of TADDOL derivative C gave racemic product (entry 5), emphasizing the important role of the TADDOL aryl groups in the asymmetric induction. Changes in the ketal backbone were found to result in small differences in the product ee (compare entries 4 and 6).

Figure 20.

Enantioselective HDA reaction between Brassard's diene and benzaldehyde catalyzed by TADDOL derivatives.

Table 20.

Results from the enantioselective HDA reaction between Brassard's diene and benzaldehyde (0.5 mmol) catalyzed by TADDOL derivatives A - D (Figure 20).

| entry | catalyst | solvent (mL)a | temp (°C) | time (h) | yield (%) | ee (%) |

|---|---|---|---|---|---|---|

| 1 | A | none | rt | 12 | 30 | 7 |

| 2 | B | none | rt | 12 | 40 | 50 |

| 3 | B | none | −30 | 24 | 70 | 71 |

| 4b | B | none | −30 | 24 | 50 | 72 |

| 5b | C | none | −30 | 24 | 40 | 0 |

| 6b | D | none | −30 | 24 | 37 | 74 |

| 7 | B | toluene (0.05) | −30 | 24 | 70 | 75 |

| 8 | B | toluene (0.1) | −30 | 24 | 68 | 76 |

| 9 | B | toluene (0.2) | −60 | 48 | 67 | 83 |

| 10 | B | toluene (0.4) | −60 | 48 | 50 | 86 |

| 11 | B | toluene (0.2) | −78 | 48 | 26 | 89 |

All the reactions were carried out with 2.5 mmol of benzaldehyde and 0.5 mmoll of diene.

10 mol% catalyst was used.

In their work, Ding and co-workers experienced one of the limitations of solvent-free chemistry; the sharp increase in reaction medium viscosity with decreasing temperature. To circumvent this obstacle, small amounts of a low melting solvent, toluene in this case, were added to the reaction vessel to reduce the solution viscosity. Under these concentrated conditions, the reaction temperature could be reduced to −60 °C, which afforded the product in 83–86% ee without a significant reduction in yield. At −78 °C a slight increase in ee was observed, but the yield dropped sharply.

The TADDOL derivative B was effective for the reactions of a variety of aromatic aldehydes to give the corresponding 6-substituted 4-methoxy-5,6-dihydropyran-2-ones in 45–85% yield with 68–91% ee (Table 21). With solid aldehyde substrates, additional toluene was added to ensure that the reaction mixtures were homogeneous.

Table 21.

Reaction of Brassard's diene with various aldehydes catalyzed by TADDOL B (Figure 20).

| |||||

|---|---|---|---|---|---|

| entry | Ar | toluene (mL)a | temp. (°C) | yield (%) | ee (%) |

| 1b | Ph | 0.2 | −60 | 67 | 83 (S) |

| 2b | furyl | 0.2 | −60 | 80 | 87 (S) |

| 3 | 2-C6H4-Me | 0.2 | −30 | 54 | 68 (R) |

| 4 | 4-C6H4-Cl | 0.2 | −30 | 85 | 76 (R) |

| 5 | 4-C6H4-Br | 0.2 | −30 | 72 | 78 (R) |

| 6 | 3-C6H4-Br | 0.2 | −60 | 67 | 89 (R) |

| 7 | 2-C6H4-Br | 0.2 | −60 | 75 | 82 (R) |

| 8 | 3-C6H4-OMe | 0.2 | −60 | 45 | 91 (n.d.) |

All the reactions were carried out with 2.5 mmol of benzaldehyde and 0.5 mmol of diene.

The catalyst employed in this case was (R,R)-B.

A comparison between the titanium- and zinc-based catalysts in Eq 8 and Figure 14, respectively, which were successfully used in the HDA with Danishefsky's diene, and the TADDOL derived organocatalyst B was made using Brassard's diene. In this case, the organocatalyst proved significantly more enantioselective and higher yielding than the metal containing catalysts under the reaction conditions outlined above.121

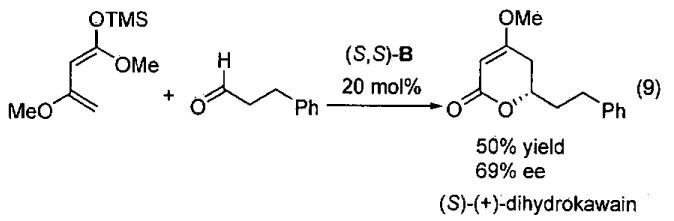

The TADDOL derivative B was also employed in the synthesis of (S)-(+)-dihydrokawain. Thus, reaction of 3-phenylpropionaldehyde with Brassard's diene in the presence of the chiral diol led to formation of the natural product in one step in 50% yield with 69% ee (Eq.9).

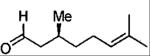

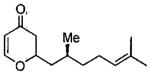

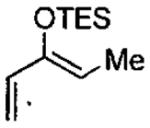

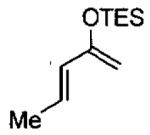

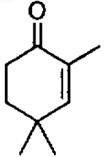

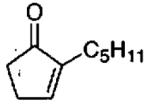

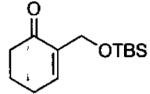

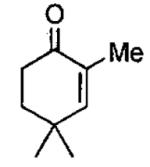

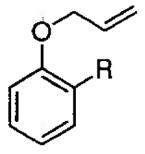

2.3.7 Asymmetric Hetero-Diels-Alder Reaction of Mono-Oxygenated Dienes and Aldehydes

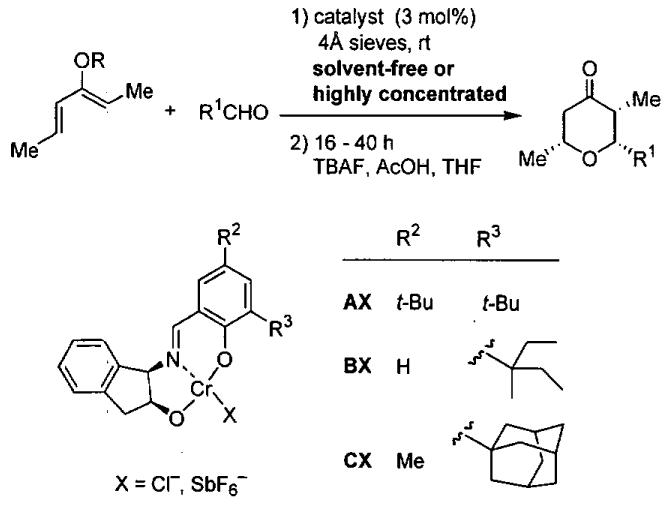

In contrast to the HDA reactions outlined above, which employ the electron rich Danishefsky and Brassard dienes, asymmetric HDA reactions with less electron-rich dienes were not explored until 1999 when Dossetter, Jamison, and Jacobsen studied HDA reactions with monooxygenated dienes catalyzed by Cr(III) species.122 Employing tridentate complexes A•Cl and A•SbF6 in the HDA with (2Z,4E)-triethylsilyloxy-2,4-hexadiene and two aldehydes (R1 = Ph, CH2OTBS) generated tetrahydropyranones after desilylation (Figure 21). While the ee's were moderate (80 and 57% ee, respectively) only the endo product was formed, leading to the all-cis stereochemistry of the tetrahydropyranone product (Table 22, entries 1 and 2). Increasing the size of the catalyst's R3 substituent from t-Bu to 1-ethyl-1-methylpropyl, and 1-adamantyl increased the product ee's to 98% (compare entries 2-5, Table 22). A similar increase in ee with benzaldehyde was not possible under solvent-free conditions (entries 6 and 7), inspiring the investigators to examine solvent additives.122

Figure 21.

Asymmetric HDA with chiral tridentate Schiff base complexes of Cr(III) and monooxygenated dienes.

Table 22.

Results from HDA reaction in Figure 21.

| entry | diene OR |

aldehyde R1 |

solvent | catalyst | yield (%) | ee (%) |

|---|---|---|---|---|---|---|

| 1 | OTES | Ph | none | A•SbF6 | 50 | 80 |

| 2 | OTES | CH2OTBS | none | A•SbF6 | n.d. | 57 |

| 3 | OTES | CH2OTBS | none | B•SbF6 | n.d. | 85 |

| 4 | OTES | CH2OTBS | none | C•Cl | 88 | 98 |

| 5 | OTES | CH2OTBS | none | C•SbF6 | 93 | 98 |

| 6 | OTES | Ph | none | C•Cl | n.d. | 65 |

| 7 | OTES | Ph | none | C•SbF6 | n.d. | 81 |

| 8 | OTES | Ph | conc. | C•SbF6 | 72 (80)a | 90 |

| 9 | OTES | CH2OTBS | conc. | C•Cl | 90 | 99 |

| 10 | OTES | CH2OTBS | conc. | C•SbF6 | 97 | >99 |

| 11 | OTES | CH2OBn | conc. | C•SbF6 | 89 | 94 |

| 12 | OTES | n-C5H11 | none | C•SbF6 | 85 | 98 |

| 13 | OTES | (CH2)4CH=CH2 | none | C•SbF6 | 78 | 98 |

| 14 | OTES | CH2CH2Ph | conc. | C•SbF6 | 78 (84)a | 98 |

| 15 | OTES | CH2CH2NHBoc | conc. | C•SbF6 | 28 (31)a | 96 |

| 16 | OTES | 2-furyl | conc. | C•SbF6 | 77 (86)a | 95 |

| 17 | OTMS | n-C5H11 | none | C•SbF6 | 81 | 98 |

| 18 | OTBS | n-C5H11 | none | C•SbF6 | 93 | 96 |

| 19 | OTIPS | n-C5H11 | none | C•SbF6 | 77 | 94 |

Reaction conversion after 40 h in parenthesis.

Screening various solvents under highly concentrated conditions led to the discovery that addition of acetone resulted in a significant increase in the product ee to 90% (entry 8). Addition of a small amount of acetone to the reactions was found to be general, as illustrated in Table 22; however, with some substrates (entries 12, 13, 17 – 19), the solvent-free conditions resulted in excellent enantioselectivities. It was also noted that the nature of the trialkylsilyl substituent had little impact on the ee or yield of the cycloaddition products (entries 12 and 17 – 19).

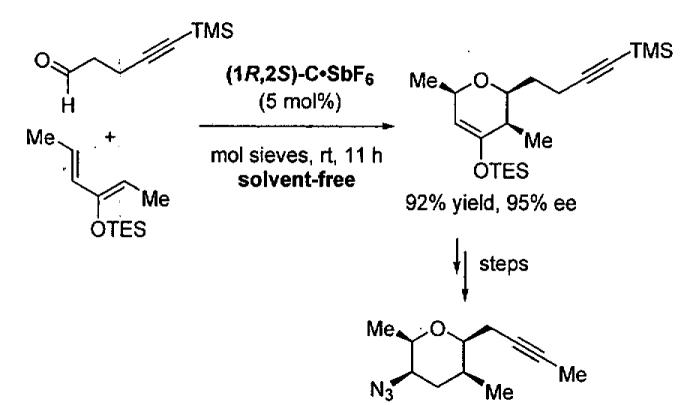

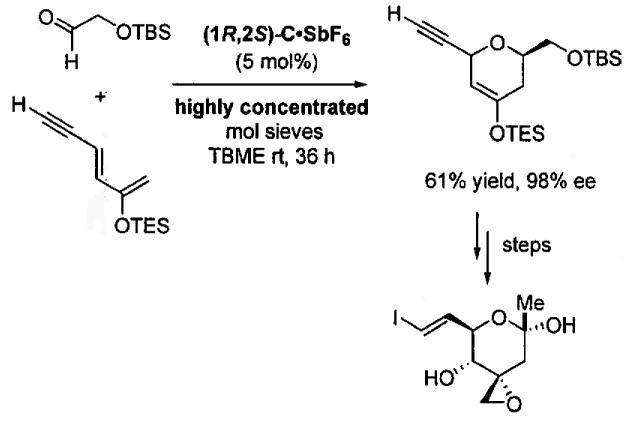

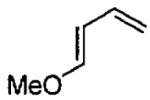

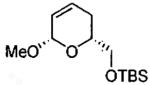

Given the successful HDA reactions between (2Z,4E)-triethylsilyloxy-2,4-hexadiene and various aldehydes catalyzed by C•SbF6 (Table 22), the authors examined the ability of C•C1 to promote HDA reactions with other dienes. As shown in Table 23, reaction of (2E)-2-triethylsilyloxy-l,3-pentadiene resulted in formation of the product in 78% yield with 98% ee (entry 1). Similar results were obtained with the isomeric pentadiene (entry 2). Use of 1-methoxybutadiene proceeded smoothly to furnish the product with >99% ee (91% yield, entry 3).

Table 23.

Catalytic asymmetric HDA reaction with dienes and aldehydes catalyzed by 3 mol% C•Cl from Figure 21.

| entry | diene | product | conditionsa,b | yield (%) | ee (%) | config. |

|---|---|---|---|---|---|---|

| 1 |  |

|

200 μL acetone highly concentrated |

78 | 98 | (2R,6R) |

| 2 |  |

|

sovent-free | 50 | 91 | (2R,3R) |

| 3 |  |

|

sovent-free | 91 | >99 | (2S,6R) |

Reactions were carried out with 1:1 diene : aldehyde on a 1.0 mmol scale with 3 mol% catalyst (1R,2S)-C•Cl and powdered 4 Å molecular sieves.

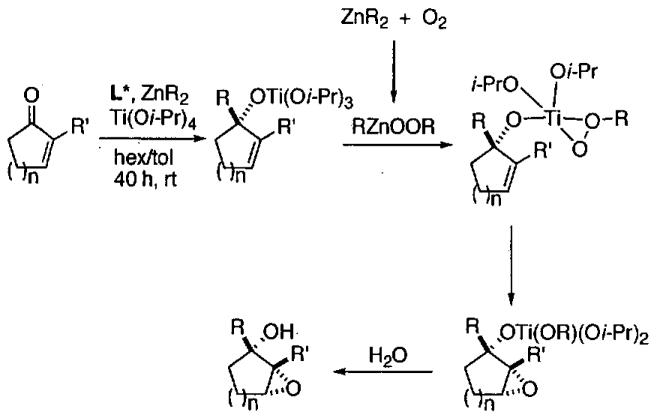

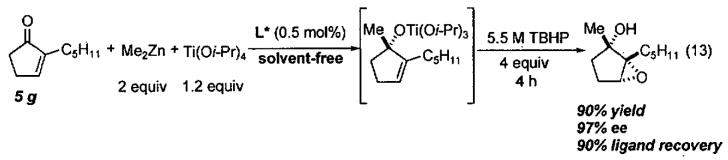

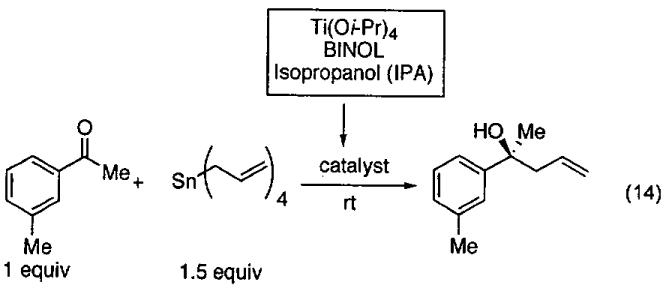

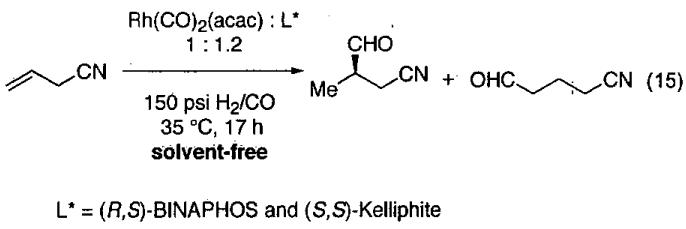

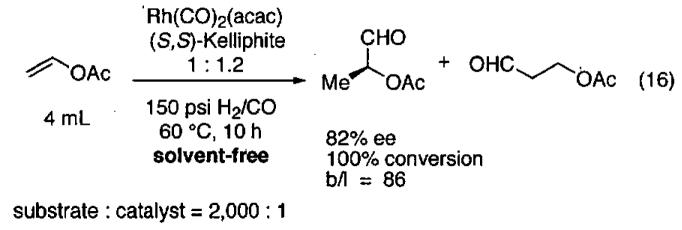

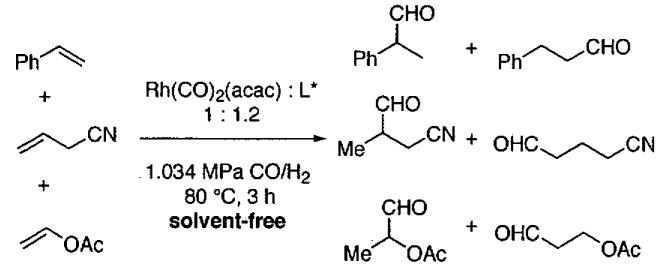

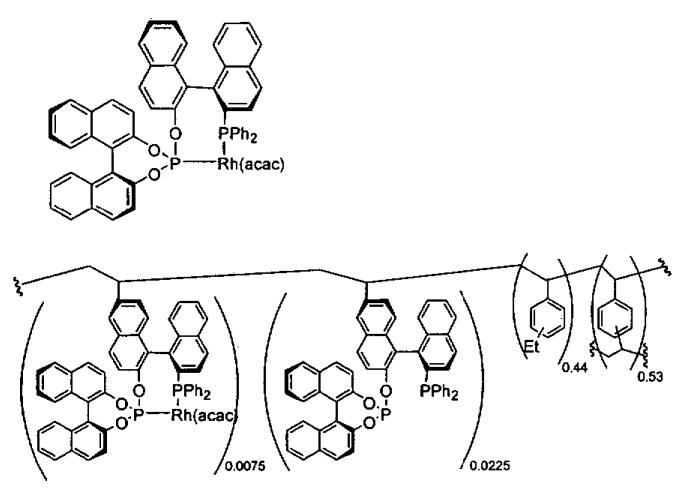

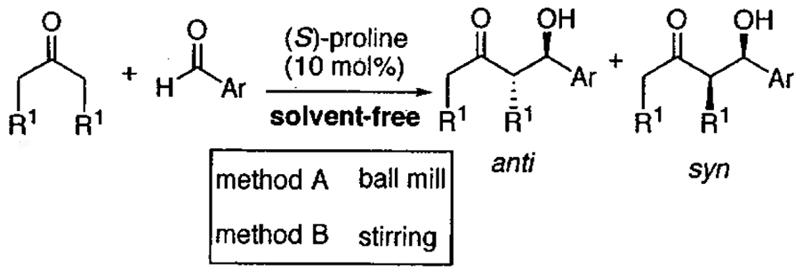

The products were isolated by treatment with either TFA in CH2Cl2 at 0 °C or with TBAF, AcOH, THF at 0°C.