Abstract

The objective of this study was to evaluate the performance of handheld XRF analyzers on wood that has been treated with a preservative containing arsenic. Experiments were designed to evaluate precision, detection limit, effective depth of analysis, and accuracy of the XRF arsenic readings. Results showed that the precision of the XRF improved with increased sample concentration and longer analysis times. Reported detection limits decreased with longer analysis times to values of less than 1 mg/kg or 18 mg/kg, depending on the model used. The effective depth of analysis was within the top 1.2 cm and 2.0 cm of sample for wood containing natural gradients of chemical preservative and concentration extremes, respectively. XRF results were found to be 1.5-2.3 times higher than measurements from traditional laboratory analysis. Equations can be developed to convert XRF values to results which are consistent with traditional laboratory testing.

Keywords: XRF, Treated wood, Arsenic, Handheld

1. Introduction

The recent development of a handheld unit that employs XRF (X-ray fluorescence) technology to rapidly identify elements has allowed for multiple field applications. These applications include the analysis of metals in soil (Vanhoof et al., 2004) and sediment (Hou et al., 2004; Stallard et al., 1995), the analysis of metals in aerosols collected on a filter (Kuznetsova et al., 2004), lead dust wipe analysis (Sterling et al., 2000), analysis of artifacts and art (Hou et al., 2004; Szökefalvi-Nagy et al., 2004) and the classification of hazardous wastes (Kalnicky and Singhvi, 2001; Rossini and Bernardes, 2005; Wolksa, 2005). XRF has also been used traditionally for the analysis of preservatives within pressure-treated wood (AWPA, 2005, Method A9-01). These traditional analyses require the use of large non-portable desktop systems and a considerable amount of sample pre-processing including grinding and compaction of wood samples. The advent of handheld XRF units has increased their portability and has decreased the need for pre-processing making the units ideal for analysis of wood in the field.

Wood may be pressure-treated with a variety of chemicals to protect it from rotting. One of the most popular wood preservatives has been CCA (chromated copper arsenate), which contains high levels of arsenic (2000-20 000 mg/kg). Although this preservative was phased out effective December 31, 2003 for most residential and consumer uses (US EPA, 2002), an abundance of treated wood containing arsenic can be found in outdoor structures and, as these structures age, they will ultimately enter wood recycling facilities and land-fills (Solo-Gabriele and Townsend, 1999). Treated wood containing arsenic is of environmental concern because some chemical may migrate from treated wood into the surrounding soil (Stilwell and Gorny, 1997; Townsend et al., 2003b) and groundwater (Khan et al., 2004; Townsend et al., 2003a, 2004). Arsenic may also be dislodged from the treated wood surface upon contact with skin (Hemond and Solo-Gabriele, 2004; Shibata, 2006; Stilwell et al., 2003; US CPSC, 2003; US EPA, 2005). The amounts of dislodged arsenic and potential impacts to the environment are a function of the amount of arsenic within the treated wood product. In these cases, quantification of the arsenic within the wood is necessary for evaluating impacts.

Recycling options are limited for treated wood containing arsenic and efforts focus on removal of this material from the recycling stream (Solo-Gabriele and Townsend, 1999; Townsend et al., 2003a), in particular for applications which require an uncontaminated source of wood. Typically, sorting at recycling facilities requires detection of preservative treatment rather than quantification. The identification of CCA-treated wood within the disposal sector is difficult, as it has the same appearance as other copper treated wood types that do not contain arsenic. To further complicate matters, once in the outdoor environment, CCA-treated wood may weather to the same silver-gray color of untreated wood making it very difficult to identify CCA-treated wood from appearances alone. As a result, there is a need for technologies which can properly identify treated wood containing arsenic during inservice use and during disposal.

XRF technology has the capacity to fulfill this need through rapid, non-destructive identification and quantification of the concentration of metal or metalloid preservative that has been added to wood. XRF technology has the advantage over other existing identification methods, such as visual identification based upon the green hue that is observed when the wood is new, indicator stains like the PAN (1-(2-pyridylazo)-2-naphthol) stain (Blassino et al., 2002), and traditional laboratory analysis. Although visual sorting is the quickest method, it is unreliable, in particular for weathered wood because treated and untreated wood can appear the same. The PAN stain, while more accurate than visual sorting, is difficult to use on dirty or wet wood (Blassino et al., 2002; Sawyer and Irle, 2005). Both visual sorting and the PAN stain rely on identifying copper, which may be present in preservatives with and without arsenic. Therefore, neither of these methods definitively identifies arsenic. Conventional laboratory-based technologies for detecting arsenic in wood and other solid samples are accurate, but require a considerable amount of time for preparation and analysis of samples. An arsenic-specific stain has been developed for consumer use (Omae et al., 2006) but the stain requires a 45 min reaction time. A faster quantitative method for identifying arsenic is needed for assessing structures in service. Quantitation is also helpful for assessing the amount of arsenic in wood that is sorted at recycling facilities. Handheld XRF units are portable, weighing less than 2 kg, and analyze for many elements in seconds, representing a possible technology for rapid detection and quantification of wood treated with arsenic-based preservative.

XRF has previously been used in conveyor-mounted (Solo-Gabriele et al., 2004) and handheld (Jacobi et al., in press) configurations at wood recycling facilities. The conveyor-mounted configuration was shown to be a promising technology for online sorting of wood. However, due to the need for an air gap between the XRF unit and the wood surface (for a conveyor based system), the online system serves as a detection technology (treated versus untreated) rather than as a quantitative tool. The handheld configuration allows more freedom in the location where sorting or spot-checking would occur and may also be placed directly on the sample, for increased accuracy allowing for quantification.

XRF works at the atomic level to identify elements by the characteristic wavelength that they emit when subjected to radiation. A primary X-ray sent by the XRF induces the emission of a secondary X-ray by the target atoms in the test material, which is read by the detector in the XRF unit. The emission of this secondary X-ray is called fluorescence. The wavelength of the secondary X-ray is characteristic of the element from which it was emitted, enabling the detector to identify the element (Kalnicky and Singhvi, 2001).

XRF technology is fairly new to field applications and uncertainties concerning its use for quantitative measurements still exist. First, the depth of the target atom within the wood (analysis depth) has not yet been quantified. Detection limits, which are a function of analysis time, sample matrix, and presence of interfering elements (Kalnicky and Singhvi, 2001), have been reported between 10 and 100 ppm for a soil matrix (Innov-X Systems Inc., 2006; US EPA, 2004). The detection limits for arsenic in wood are yet to be evaluated, although XRF instruments have been used for the identification of treated wood containing arsenic in the field (Blassino et al., 2002; Solo-Gabriele et al., 2004; Jacobi et al., in press). The XRF units commercially available are calibrated to soil standards using the Compton Normalization method as described in Method 6200 (US EPA, 1994). Using portable XRF technology for lead dust wipe analysis (Sterling et al., 2000) indicated that XRF precision improved with increasing concentration and accuracy was comparable to traditional laboratory measurements. Limited information exists about the accuracy and precision of the instrument’s concentration readings when used for analysis in other matrices, like wood. Matrix effects on XRF analysis are mainly due to differences in density and uniformity of samples. Although precision and accuracy testing for the XRF in a soil matrix has been conducted, tests in a wood matrix would increase confidence in quantitative results obtained for treated wood samples, as calibration should be matrix-specific (Kalnicky and Singhvi, 2001). XRF technology has already been established as a valuable tool for detecting arsenic in wood (Jacobi et al., in press; Solo-Gabriele et al., 2004). The objectives of this study focus on the quantitative performance of the XRF handheld units. Specifically, this study evaluated precision, detection limits, effective depth of analysis, and accuracy.

2. Methods

Four sets of experiments were designed to evaluate each of the parameters of interest (precision, detection limits, effective depth of analysis, and accuracy). Tests designed to measure precision and detection limits focused on evaluating the effects of concentration and analysis time, while the effective depth of analysis corresponds to the depth at which the XRF takes concentration readings. Depth of analysis experiments were based upon evaluating wood containing natural gradients of chemical preservative and by also evaluating extremes in preservative treatment by testing untreated wood with an underlying sample of treated wood. Accuracy of the XRF analyzers was evaluated by comparing concentration readings from the XRF to concentration readings from a traditional laboratory-based method. This comparison was intended to establish a relationship that could be used to more accurately estimate the quantity of arsenic contained within preservative-treated wood from XRF readings. Statistical analyses included mean, standard deviation, correlation, and paired two-tail t-tests.

Two models of handheld XRF analyzers were used in this study. Both models were manufactured by Innov-X Systems, Inc., Woburn, MA. The Alpha Analyzer (α-2000s) and Inspector (I-3000c) models were used for the precision and detection limit tests, while the alpha model, exclusively, was used to evaluate the effective depth of analysis and for experiments focusing on accuracy. Both models weighed 1.6 kg and contained an X-ray tube excitation source. The alpha model analyzed for more elements than the inspector model, although both analyzed for chromium, copper, and arsenic, the active ingredients in the CCA wood treatment. The current study focuses on the results for arsenic.

Two types of wood samples were used for experimentation; weathered wood and un-weathered CCA-treated wood. Weathered wood samples were collected from in-service structures (playgrounds from Miami-Dade County, Florida USA) in the form of sawdust from drilling to a 1.5 cm depth in the wood. XRF analyses of the weathered wood samples were made through the plastic sample bags containing the sawdust. The plastic bag was necessary to minimize cross-contamination of samples. The presence of the plastic bag did not affect the results. For un-weathered wood samples, both whole wood and sawdust were analyzed. The un-weathered wood samples chosen for experimentation represented the range of possible CCA treatment. These samples included untreated wood (Southern Yellow Pine, SYP) and SYP treated to CCA concentration extremes (4 and 40 kg of CCA chemical on an oxide basis per cubic meter of wood) as standardized by the industry (AWPA, 2005). The un-weathered wood sample blocks were cut from boards that had been kept in the laboratory since the time (about 2 years) of their purchase from a local retail establishment. The degree of treatment throughout the boards was relatively uniform, as evidenced by the uniform green color observed throughout the wood. Areas containing knots or non-uniform treatments were avoided. As all samples were kept in the laboratory during experimentation, they were assumed to have similar moisture contents. Each block was created by cutting an 8 cm length from the original board (cross-section 3.5 × 8 cm), and then the resulting portion was cut in half, lengthwise. In total, 20 wood blocks were cut (four untreated blocks, eight 4 kg/m3 blocks, and eight 40 kg/m3 blocks). Further preparation of sample blocks depended on the experiment and is described in the following sections.

2.1. Precision

The primary parameters considered during the precision experiments were concentration and analysis time. The effects of concentration on precision (as measured by statistical error) were evaluated using both XRF models by taking measurements on the weathered wood sawdust samples in triplicate (three readings per location) to obtain an average value (μ). Statistical error as reported by the XRF corresponds to three times the standard deviation, σ (Kalnicky and Singhvi, 2001).

The effects of analysis time on precision were evaluated using two (one treated at 4 kg/m3 and one treated at 40 kg/m3) of the original 20 un-weathered wood sample blocks. Readings on each block were taken at two locations on the sapwood (outermost layer of the tree’s growth rings) side of the block. Analysis times consisted of 2, 6, 15, 30, 60, 120, 300, 600, and 900 s.

2.2. Detection limit

Detection limits as output by the instrument were reported for one untreated wood sample block. Detection limits are computed internally by the instrument at 3σ of the signal value. The values reported herein corresponded to the average of the detection limits output from the analysis taken at two locations on the block. The data were evaluated to determine the effects of analysis time and concentration on the reported detection limit.

2.3. Effective depth of analysis

Of the remaining 17 un-weathered samples, 14 (two untreated blocks, six 4 kg/m3 blocks, and six 40 kg/m3 blocks) were used to evaluate the effective depth of analysis. The XRF analysis was performed at two locations on the sapwood side of each block to obtain an initial reading. The analysis time utilized was 6 s and the concentration readings were recorded in triplicate for each sample location. After collecting the initial readings, each wood block was cut horizontally into three layers using a band saw, with a thickness of 1.2 cm each of top, middle, and bottom layers. The top, middle, and bottom layers of each sample were analyzed separately using the XRF. In analyzing the layers, readings were taken two per layer, in triplicate. These XRF readings were then compared to the initial readings obtained from the same locations to determine in which layer or zone, within the sample of wood, the XRF was receiving a signal.

To further evaluate the effective depth of analysis, layers of wood characterized by concentration extremes were evaluated using three un-weathered sample blocks (untreated, 4 kg/m3, and 40 kg/m3). The testing surface (Innov-X Systems XRF stand) was cleaned and analyzed with the XRF, confirming that no arsenic was detected. Untreated, 4 kg/m3, and 40 kg/m3 samples were next measured with the XRF, to determine their direct-measurement arsenic concentrations. Laboratory tissue paper (Kimwipes®) were used to prevent cross-contamination and were found to have no effect on the concentration readings. The untreated wood block was cut into seven layers with average thickness of 0.43 cm. The layers were placed on top of a treated (4 kg/m3 or 40 kg/m3) wood sample and held together using a plastic cinch tie to approximate the original solid sample. The untreated wood (initially 3.0 cm thick) was analyzed with the XRF and identified as “untreated.” To determine the maximum thickness of untreated wood at which the effect of the underlying material was recognized, the depth of untreated wood cover was decreased incrementally by removing layers, until the treated wood sample was detected by the XRF unit. XRF readings were thus taken approximately every 0.43 cm of depth and the depth at which the XRF detected arsenic was noted.

2.4. Accuracy

Accuracy experiments used the weathered wood samples and the same un-weathered samples as those used for experiments focusing on the effective depth of analysis based upon natural gradients of wood preservative. After the effective depth experiments were completed, sawdust was collected using a drill from the entire 1.2 cm layer in the corresponding analysis zone from each of the 84 XRF sampling points. Each collected sawdust sample was placed in a plastic bag, mixed thoroughly, and analyzed in triplicate through the sample bag using XRF. A pre-weighed aliquot of sawdust (1 g) was then digested using Method 3050B (US EPA, 1994) and subsequently analyzed by atomic absorption (AA) with flame atomization (Perkin-Elmer Instruments AAnalyst 800) using Method 7000A (US EPA, 1994). The detection limit of the atomic absorption analysis was 0.1 mg/kg for arsenic in wood and the standard deviation of the results were within 10%.

3. Results

3.1. Precision

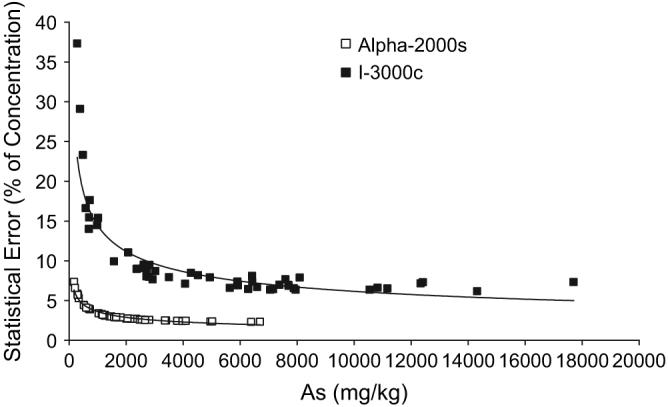

The statistical error, relative to the measured concentration (3σ/μ), decreased as a power function of the arsenic concentration in the samples. This relationship was similar between both I-3000c and α-2000s XRF models, although the statistical error in the α-2000s model was consistently lower than that of the I-3000c model, by 7.1 times on average (Fig. 1). Although the concentration readings between the two models were correlated, the concentrations between the two models for the same samples were statistically different from each other (p < 0.001 in a paired t-test).

Fig. 1.

Statistical error (% of concentration, 3σ/μ) versus As concentration (mg/kg) for two XRF models as measured on weathered wood sawdust samples.

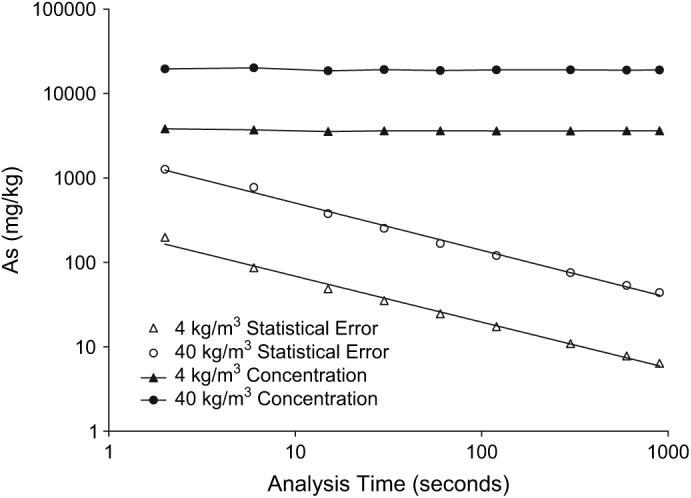

Statistical error for the 4 kg/m3 and 40 kg/m3 treated samples decreased to values of 6.4 and 44 mg/kg, respectively, after a 15 min analysis time (Fig. 2). Although it was confirmed that the statistical error continued to decrease with additional analysis time, analysis times in excess of 10 min were not considered necessary as the standard error was well below the typical concentrations of arsenic within treated wood. In addition, the concentration reading output by the XRF remained essentially constant after 2 s (Fig. 2), regardless of the decrease in statistical error over time, making additional analysis time unnecessary. The manufacturer-recommended analysis time of 6 s was used for the remainder of the experiments.

Fig. 2.

Statistical error (3σ) and concentration readings (mg/kg) versus analysis time (up to 15 min) for 4 and 40 kg/m3 samples. Results correspond to the α-2000s model.

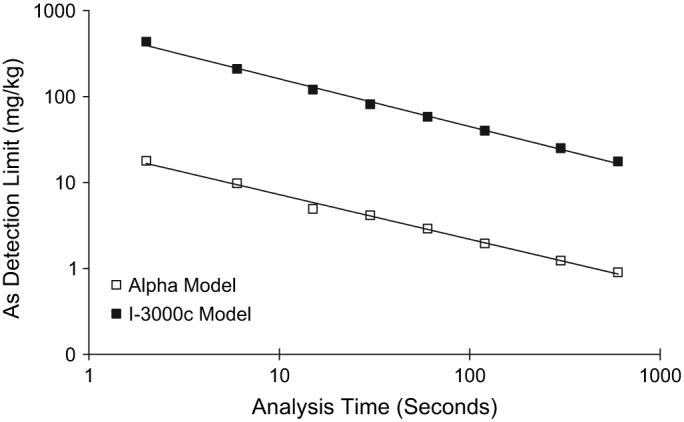

3.2. Detection limits

The reported detection limits of the XRF units as defined as 3σ (and as provided as the instrument output) were observed to be a function of concentration and analysis time (Fig. 3). The detection limit for the untreated sample was reported as 9.8 mg/kg for a 6-s analysis time and improved with a longer analysis time (to less than 1 mg/kg for a 10-min analysis time using the model α-2000s). The XRF model I-3000c showed a similar trend, the only difference being that the reported detection limits were higher overall, for all concentrations and analysis times. For this model, the detection limit of the untreated sample was reported as 210 mg/kg for a 6-s analysis time and reached a value of 18 mg/kg at a 10-min analysis time (Fig. 3). Results thus emphasize the need to increase the analysis times for samples characterized by low arsenic concentrations, in particular extremely weathered samples of wood for which a large fraction of the initial preservative treatment may have been lost.

Fig. 3.

Reported detection limit (mg/kg) versus analysis time (up to 10 min) for untreated, un-weathered wood.

3.3. Effective depth of analysis

Prior to cutting the wood blocks into three layers, the average initial arsenic concentration observed from the 4 kg/m3 wood blocks was 2870 mg/kg arsenic. Once cut into layers, the top, middle, and bottom layers measured at 2890 mg/kg, 2160 mg/kg, and 2620 mg/kg, respectively, with an average of 2560 mg/kg. For the 40 kg/m3 sample the initial arsenic reading prior to cutting into layers was 18 500 mg/kg. The top, middle, and bottom layers measured at 18 500 mg/kg, 14 300 mg/kg, and 14 200 mg/kg, respectively with an average of 15 700 mg/kg. For both the 4 kg/m3 and 40 kg/m3 wood samples, results showed that the initial sapwood concentration readings before cutting were statistically the same as the top layer readings, while significantly different (p < 0.001) from the middle and bottom layers and the average of the three layers (Table 1). These results indicate that the XRF concentration readings correspond to a 1.2 cm depth or less.

Table 1.

XRF reading versus layers

| Layer | Arsenic reading (mg/kg) | p-value (compared to initial) | |

|---|---|---|---|

| 4 kg/m3 | 40 kg/m3 | ||

| Initial | 2870 | 18 500 | 1.000 |

| Top | 2890 | 18 500 | 0.892 |

| Middle | 2160 | 14 300 | <0.001 |

| Bottom | 2620 | 14 200 | <0.001 |

| Average | 2560 | 15 700 | <0.001 |

The initial value corresponds to the reading prior to cutting the block. Each block was cut into three layers 1.2 cm thick. XRF instrument utilized corresponded to the Innov-X, Model Alpha-2000s.

When evaluating concentration extremes, the 4 kg/m3 wood sample was detected below the untreated wood at a depth of 1.3 cm and less, which was consistent with the observations above conducted with treated wood containing natural concentration gradients. The 40 kg/m3 sample was detected below the untreated wood at depths of 1.6 cm or less (Table 2).

Table 2.

Effects of extreme concentration gradients on XRF readings (6-s analysis time)

| Depth of untreated sample (cm) | As concentration (mg/kg) | % of direct-measurement reading | ||

|---|---|---|---|---|

| Preservative loading of treated wood block underlying untreated wood | ||||

| 4 kg/m3 | 40 kg/m3 | 4 kg/m3 | 40 kg/m3 | |

| 3.0 | BDLa | BDL | NDb | ND |

| 2.3 | BDL | BDL | ND | ND |

| 2.0 | BDL | BDL | ND | ND |

| 1.6 | BDL | 26.1 | ND | 0.15 |

| 1.3 | 32.8 | 120. | 1.06 | 0.70 |

| 0.8 | 308 | 1460 | 9.96 | 8.48 |

| 0.4 | 724 | 3670 | 23.5 | 21.3 |

| 0.0 | 3090 | 17 200 | 100. | 100. |

In these experiments the untreated wood of various thicknesses was underlain by either 4 kg/m3 or 40 kg/m3 wood blocks. XRF instrument utilized corresponded to the Innov-X, Model Alpha-2000s.

BDL indicates that the XRF reading was below the reported detection limit for arsenic (<9.8 mg/kg).

ND, Not detected.

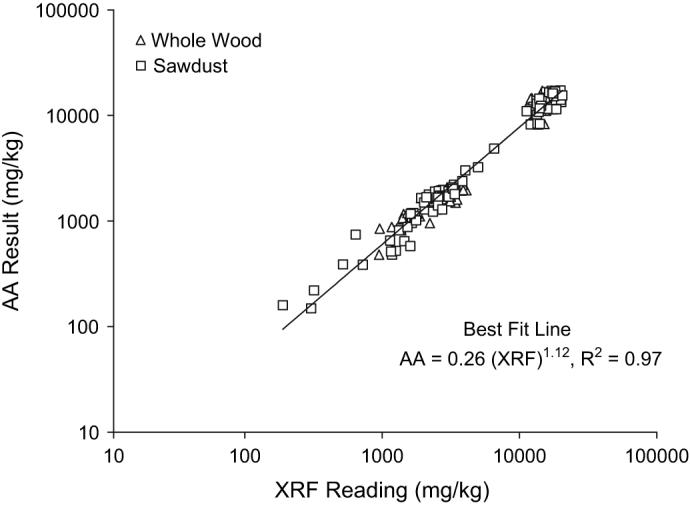

3.4. Accuracy

The results for the XRF and AA were correlated (R2 = 0.97) but significantly different (p < 0.001), with XRF readings at an average of 1440 mg/kg greater than AA results. Overall for all samples, the averages from XRF and AA analyses were 8130 and 6690 mg/kg arsenic, respectively. Conversion equations using data for the entire concentration range evaluated were created to estimate AA results from XRF readings through linear regression (Fig. 4). The XRF readings for the sawdust samples were statistically the same as those for the whole wood samples, thus different conversion equations were not necessary for sawdust versus whole wood. The XRF readings, regardless if obtained from whole wood or sawdust, were statistically different from the AA results. When the applicable conversion equation was applied to all samples, the AA results and the converted XRF readings were not statistically different (p = 0.08). The converted XRF readings were, on average, 3% lower than the corresponding AA results for arsenic. Since calibration of the XRF is accomplished by the manufacturer using soil standards, conversion equations can be developed through laboratory analysis of wood samples without altering the instrument’s calibration. These equations can provide higher quantitative accuracy in the XRF measurements, which may or may not be required, depending on the application.

Fig. 4.

Comparison of XRF arsenic readings against traditional laboratory methods (AA, atomic absorption) for whole wood and sawdust samples. Results correspond to model Alpha-2000s.

4. Discussion and recommendations

From the precision tests, the results show that model α-2000s is more precise than model I-3000c based on reported statistical error. The concentration results from the two models were correlated, but statistically different from each other, indicating that concentration readings for the same sample from each model would not necessarily be comparable. Also, in the precision tests, the concentration readings output by the I-3000c model were higher than those output by the α-2000s model, and thus further from results from traditional laboratory analysis used as a baseline for comparison. It is important to note that, when used for detection only, both models performed adequately. The difference between the two models when measuring arsenic treatment in wood was only apparent when quantitative results were required. Although results supported the idea that precision is improved for longer analysis times (Hou et al., 2004; Solo-Gabriele et al., 2004), the results obtained from precision tests in this study showed that when the concentrations of arsenic in a sample are high (at levels typically found in treated wood containing arsenic), increased analysis time has little effect on the concentration reading, and a short analysis time of 6 s is sufficient. These results are similar to those obtained during a study using XRF for identification of CCA-treated wood (Blassino et al., 2002). The positive correlation between precision and concentration was also noted by Sterling et al. (2000).

When the XRF was used to analyze a sample, the reading represented the concentration of arsenic in the top 1.2 cm of the sample. This concentration reading was not representative of the average sample arsenic concentration or the concentration of any of the lower layers. However, when the layers of a sample were extremely different in treatment level, results indicate that the XRF reading may represent the concentration at a deeper depth, from 1.2 cm up to 2 cm, depending on the treatment levels of the sample layers. Blassino et al. (2002) and Solo-Gabriele et al. (2004) noted the effect of separation distance between the sample and the XRF detector, and determined that arsenic can be detected at a maximum separation distance of 2.5 cm away (through air), and that arsenic concentration readings decreased with increased separation distance. The results from evaluating air gaps were consistent with the results observed in this study utilizing preservative concentration extremes. Further effects of separation distance were not investigated in Blassino et al. (2002) and Solo-Gabriele et al. (2004), although the effect of paint layers, which decreased concentration readings (Kalnicky and Singhvi, 2001; Solo-Gabriele et al., 2004), was a preliminary indication of the effect of layers with concentration extremes.

The results of the accuracy experiment showed that raw XRF readings were not comparable to AA results, but that they were correlated. This observation was similar to those stated by Vanhoof et al. (2004) and Hou et al. (2004), but contradictory to those stated by Sterling et al. (2000). Different results for accuracy of the XRF may result from differences in calibration methods (Kalnicky and Singhvi, 2001). The high correlation observed in the current study permitted for the development of conversion equations to express XRF readings as estimated AA results. Such applications would save time and make accurate field analysis possible. However, the precision of the model chosen and concentration extremes in the field must be carefully considered, as they may affect the quantification of treated wood containing arsenic. Applications focusing only on detection of arsenic would not necessarily benefit from this increased accuracy. However, it would be useful for studies which require a mass balance assessment of arsenic from the wood. Mass balance approaches are needed to evaluate the fate of arsenic from preservative-treated wood and resulting concentrations in various environmental media. These results show that XRF could be used to provide a rapid measurement of arsenic concentration comparable to the conventional AA method, through the use of simple conversion equations.

The XRF analyzer has shown promise for field use for the identification and quantification of arsenic in CCA-treated wood with loadings between 4 kg/m3 and 40 kg/m3. Precision of the XRF depends on analysis time and the concentration of the sample. The depth of the XRF reading depends on the treatment level of each sample layer. Also, while XRF readings do not directly correspond to AA results, they are correlated and can be converted to reasonable estimates of AA results. The objectives for these experiments were met, but factors affecting the XRF’s effective depth of reading, such as concentration extremes, should be more closely examined. It has also been suggested that moisture content may affect the results of the analysis (US EPA, 2004; Hou et al., 2004), although the results of some studies which focused on detection of elements and not quantification have shown otherwise (Solo-Gabriele et al., 2004; Stallard et al., 1995). The importance of using matrix-specific calibration standards is highlighted in recent studies (Hou et al., 2004; Kalnicky and Singhvi, 2001), indicating that the use of XRF for quantitative identification of treated wood containing arsenic will eventually require precise calibration using treated wood standards. Experiments for this study were conducted in a laboratory setting. However, as the targeted application of XRF analyzers is in the field, future research should focus on testing of weathered wood in various field conditions, as well as developing calibration standards for XRF analyzers specifically for the analysis of treated wood samples.

Acknowledgements

Funding for this project was received from the Florida Center for Solid and Hazardous Waste Management and the Florida Center for Environmental Solutions (NSF BES0126172). The NSF-REU program (OCE0432368) provided partial support for the first author of this paper. The authors also gratefully acknowledge Joseph Koch and others at Innov-X Systems, Inc., who offered information concerning the use and calibration of the handheld XRF units.

References

- American Wood Preservers’ Association . Standards. American Wood Preservers’ Association; Selma, Alabama: 2005. [Google Scholar]

- Blassino M, Solo-Gabriele H, Townsend T. Pilot scale evaluation of sorting technologies for CCA treated wood waste. Waste Management & Research. 2002;20:290–301. doi: 10.1177/0734242X0202000310. [DOI] [PubMed]

- Hemond HF, Solo-Gabriele HM. Children’s exposure to arsenic from CCA-treated wooden decks and playground structures. Risk Analysis. 2004;24(1):51–64. doi: 10.1111/j.0272-4332.2004.00411.x. [DOI] [PubMed] [Google Scholar]

- Hou X, He Y, Jones BT. Recent advances in portable X-ray fluorescence spectrometry. Applied Spectroscopy Reviews. 2004;39(1):1–25. [Google Scholar]

- Jacobi G, Solo-Gabriele H, Townsend T, Dubey B. Evaluation of methods for sorting CCA-treated wood. Waste Management. 2006 Sep 014; doi: 10.1016/j.wasman.2006.09.014. doi:10.1016/jlwasman. in press. [DOI] [PubMed] [Google Scholar]

- Kalnicky D, Singhvi R. Field portable XRF analysis of environmental samples. Journal of Hazardous Materials. 2001;83:93–122. doi: 10.1016/s0304-3894(00)00330-7. [DOI] [PubMed] [Google Scholar]

- Khan BI, Solo-Gabriele HM, Dubey BK, Townsend TG, Cai Y. Arsenic speciation of solvent-extracted leachate from new and weathered CCA-treated wood. Environmental Science & Technology. 2004;38:4527–4534. doi: 10.1021/es049598r. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kuznetsova OV, Korzhova EN, Smagunova AN, Mukhetdinova AV, Tomilova OA, Sizykh YI. Comparison of the results of atomic absorption and X-ray fluorescence analysis of metals in atmospheric aerosols. Journal of Analytical Chemistry. 2004;59(1):46–51. [Google Scholar]

- Omae A, Solo-Gabriele H, Townsend T. A Chemical Stain for Identifying Arsenic-Treated Wood. Florida Center for Solid and Hazardous Waste Management; Gainesville, Florida: 2006. Report No. 05-0432025. Available from: < http://www.ccaresearch.org/publications.htm>. [Google Scholar]

- Rossini G, Bernardes AM. Galvanic sludge metals recovery by pyrometallurgical and hydrometallurgical treatment. Journal of Hazardous Materials. 2005;131(13):210–216. doi: 10.1016/j.jhazmat.2005.09.035. [DOI] [PubMed] [Google Scholar]

- Sawyer G, Irle M. In: Gallis CT, editor. Development of colour indicator techniques to detect chemical contamination in wood waste for recycling; Proceedings of the 2nd European COST E31 Conference on the Management of Recovered Wood; University Studio Press, Thessaloniki, Greece. 2005.pp. 215–229. [Google Scholar]

- Shibata T. Dislodgeable arsenic from in-service CCA-treated wood. In: Townsend T, Solo-Gabriele H, editors. Environmental Impacts of Preservative Treated Wood. CRC Press; Boca Raton, FL: 2006. pp. 237–256. [Google Scholar]

- Solo-Gabriele HM, Townsend T. Disposal practices and management alternatives for CCA-treated wood waste. Waste Management & Research. 1999;17:378–389. [Google Scholar]

- Solo-Gabriele HM, Townsend TG, Hahn DW, Moskal TM, Hosein N, Jambeck J, Jacobi G. Evaluation of XRF and LIBS technologies for on-line sorting of CCA-treated wood waste. Waste Management. 2004;24:413–424. doi: 10.1016/j.wasman.2003.09.006. [DOI] [PubMed] [Google Scholar]

- Stallard MO, Apitz SE, Dooley CA. X-ray fluorescence spectrometry for field analysis of metals in marine sediments. Marine Pollution Bulletin. 1995;31(412):297–305. [Google Scholar]

- Sterling DA, Lewis RD, Luke DA, Shadel BN. A portable X-ray fluorescence instrument for analyzing dust wipe samples for lead: evaluation with field samples. Environmental Research. 2000;83:174–179. doi: 10.1006/enrs.2000.4058. [DOI] [PubMed] [Google Scholar]

- Stilwell D, Toner M, Sawhney B. Dislodgeable copper, chromium and arsenic from CCA-treated wood surfaces. Science of the Total Environment. 2003;312:123–131. doi: 10.1016/S0048-9697(03)00195-5. [DOI] [PubMed] [Google Scholar]

- Stilwell DE, Gorny KD. Contamination of soil with copper, chromium, and arsenic under decks built from pressure treated wood. Bulletin of Environmental Contamination and Toxicology. 1997;58:22–29. doi: 10.1007/s001289900295. [DOI] [PubMed] [Google Scholar]

- Szökefalvi-Nagy Z, Demeter I, Kocsonya A, Kovács I. Non-destructive XRF analysis of paintings. Nuclear Instruments and Methods in Physics Research Section B, Beam Interactions with Materials and Atoms. 2004;226:53–59. [Google Scholar]

- Townsend TG, Solo-Gabriele HM, Tolaymat T, Stook K. Impact of chromated copper arsenate (CCA) in wood mulch. Science of the Total Environment. 2003a;309:173–185. doi: 10.1016/S0048-9697(03)00047-0. [DOI] [PubMed] [Google Scholar]

- Townsend T, Solo-Gabriele H, Tolaymat T, Stook K. Chromium, copper, and arsenic concentrations in soil underneath CCA-treated wood structures. Soil and Sediment Contamination. 2003b;12:1–20. [Google Scholar]

- Townsend T, Tolaymat T, Solo-Gabriele H, Dubey B, Stook K, Wadanambi L. Leaching of CCA-treated wood: implications for waste disposal. Journal of Hazardous Materials. 2004;B114:75–91. doi: 10.1016/j.jhazmat.2004.06.025. [DOI] [PubMed] [Google Scholar]

- US Consumer Products Safety Commission (CPSC) Briefing Package, Petition to Ban Chromated Copper Arsenate (CCA)-Treated Wood in Playground Equipment. Petition HP 01-3. U.S. CPSC; Washington, DC: 2003. [Google Scholar]

- US EPA . Test Methods for Evaluating Solid Waste, Physical/Chemical Methods (SW-846), third ed. Method 3050B: Acid Digestion of Sediments, Sludges, and Solids. Method 6200: Field Portable X-Ray Fluorescence Spectrometry for Determination of Elemental Concentrations in Soil and Sediment. Method 7000A: Atomic Absorption Methods. Environmental Protection Agency, Office of Solid Waste and Emergency Response; Washington DC: 1994. [Google Scholar]

- US EPA . Notice of Receipt of Requests to Cancel Certain Chromated Copper Arsenate (CCA) Wood Preservative Products and Amend to Terminate Certain Uses of CCA Products. FRL-6826-8. U.S. Environmental Protection Agency; Washington, DC: 2002. [Google Scholar]

- US EPA . Summary of Detection Limits for Selected Field-based Methods: X-ray Fluorescence (Based on SW-846 Method 6200) Environmental Protection Agency, Office of Solid Waste and Emergency Response; Washington, DC: 2004. [accessed December 2005]. Available from: < www.epa.gov/superfund/programs/dfa/download/meth_xrf.pdf>. [Google Scholar]

- US EPA . A Probabilistic Exposure Assessment for Children Who Contact CCA-Treated Playsets and Decks Using the Stochastic Human Exposure and Dose Simulation Model for the Wood Preservative Exposure Scenario (SHEDS-Wood) Office of Research and Development, National Exposure Research Laboratory, Office of Pesticide Programs, Antimicrobials Division G; Washington, DC: 2005. [Google Scholar]

- Vanhoof C, Corthouts V, Tirez K. Energy-dispersive X-ray fluorescence systems as analytical tool for assessment of contaminated soils. Journal of Environmental Monitoring. 2004;6(4):344–350. doi: 10.1039/b312781h. [DOI] [PubMed] [Google Scholar]

- Wolksa J. Safeguarding the environment - XRF analysis of heavy metals in polyethylene. Plastics, Additives and Compounding. 2005;7(1):36–39. [Google Scholar]