Abstract

Peptides are emerging as a new class of biomaterials due to their unique chemical, physical, and biological properties. The development of peptide-based biomaterials is driven by the convergence of protein engineering and macromolecular self-assembly. This review covers the basic principles, applications, and prospects of peptide-based biomaterials. We focus on both chemically synthesized and genetically encoded peptides, including poly-amino acids, elastin-like polypeptides, silk-like polymers and other biopolymers based on repetitive peptide motifs. Applications of these engineered biomolecules in protein purification, controlled drug delivery, tissue engineering, and biosurface engineering are discussed.

Keywords: biomaterials, elastin-like polypeptides, drug delivery, protein purification, tissue engineering, surface engineering

1 Introduction

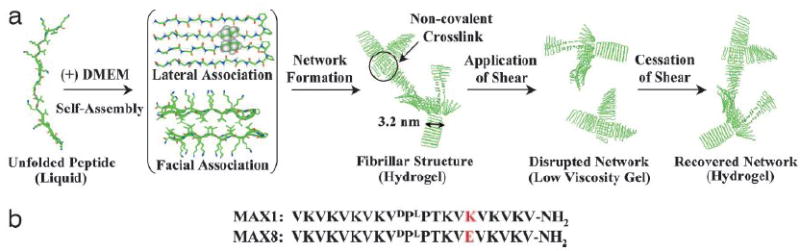

Synthetic and natural biopolymers are finding their way into a variety of applications in materials science and biointerface engineering, such as tissue engineering scaffolds, drug delivery matrices, and as detectors and transducers in biosensors. Commonly used natural biopolymers include cellulose, collagen, hyaluronic acid, and fibrin gels. In contrast to these naturally occurring biopolymers, “engineered” peptide-based biopolymers have recently attracted much attention as a new class of materials. Prototypical examples of engineered peptide-based biomaterials include poly-amino acids, elastin-like polypeptides, silk-like proteins, coiled-coil domains, tropoelastin-based peptides, leucine zipper based peptides, peptide amphiphiles, beta-sheet forming ionic oligopeptides, and beta-hairpin peptides.

This explosion of new peptide-based materials is driven by two scientific developments. The first is our increasingly sophisticated understanding of protein structure-function, which provides peptide motifs that are useful for the design of repetitive, polypeptide based materials. The second is the maturation of recombinant DNA technologies, which allows these materials to be synthesized in large yields with precise control over the chain length, stereochemistry, and monodispersity.

This article aims to provide the materials science community a primer on the design principles, synthesis techniques, and characterization methodologies of biopolymers, as well as an overview of current trends in the field of peptide-based biomaterials. The current limitations, challenges, and prospects of peptide-based biopolymers are compared to their synthetic counterparts. This review also summarizes the current applications of peptide-based biopolymers as protein purification tags, targeted drug delivery carriers and controlled release depots, self-assembled and chemically crosslinked tissue engineering scaffolds, and as components for biosensing and bioanalytical devices.

2 Peptide-based biopolymers

2.1 Overview

2.1.1 Structural description

Our basic understanding of amino acids, peptides, and proteins forms the foundation for the current development of peptide-based biomaterials. A discussion of the properties and applications of peptide-based biomaterials would be incomplete without an understanding of how their structure influences their physical, chemical, and biological properties. The primary amino acid sequence, the secondary structure (e.g., alpha-helix or beta-sheet motifs), and the tertiary structure (i.e., the actual three dimensional structure of the peptide) determine the functionality of these materials. Furthermore, for peptides that undergo self-assembly, the interactions between individual molecules also affects the structure and thus the function of peptide-based materials. For more details, readers are referred to other reviews on the structure-function relationship of peptide-based materials [1-5].

2.1.2 Physical, chemical, and biological properties

Peptide-based biomaterials are “soft” and “wet”, while most other materials used in biomedical sciences and biointerface engineering, such as metals, ceramics, and polymers (with the exception of hydrogel polymers), are regarded as “hard” and “dry”. Hence, hydration is particularly important in maintaining the structural and functional integrity of peptide-based biomaterials. The constraint of hydration is both a blessing and curse: it makes these materials unsuitable for applications that cannot tolerate water, but in applications that necessitate bringing these materials into contact with an aqueous environment, the requirement of hydration can be profitably exploited in materials design.

Polypeptide-based materials have other important advantages and disadvantages as compared to synthetic polymers that determine their applications. The primary disadvantage of peptide-based polymers is the limited number of building blocks; compared to synthetic polymers, which can be synthesized via an ever-expanding set of monomers, peptide based polymers are largely restricted to the 20 natural amino acids (though we note that this limit is expanding through new synthetic and biological methods to incorporate unnatural amino acids into peptides and proteins [6, 7]). Despite this important limitation, peptide based materials offer many potential advantages over synthetic materials. First, short peptide motifs such as RGD, KNEED, and IKVAV that are ubiquitous ligands for cell receptors and mediate various cell behaviors such as attachment and spreading [8-12] can be appended to or embedded within repetitive polypeptide materials with greater ease than in synthetic materials. Second, self-assembly and directed-assembly of peptides have recently gained research interest as viable ways to generate functional biomaterials. Leucine zipper-based materials, peptide amphiphiles, beta-sheet forming ionic oligopeptides, and beta-hairpin peptides are a few examples of self-assembling biomaterials that can be generated from peptides. Third, many peptide-based biomaterials are easily degraded by the body, thus making them desirable as drug delivery vehicles and tissue engineering scaffolds. Fourth, biology is replete with peptide sequences that exhibit structural transitions in response to the binding of metal ions and other biological ligands [13-26]; these sequences offer enormous possibilities in the design of biologically responsive materials.

In this discussion, it is important to note that peptide-based materials are often touted as biocompatible. This statement, in the absence of hard experimental evidence, must be greeted with some skepticism. There is no intrinsic reason for peptide based materials to be biocompatible other than the somewhat naïve notion that they must be, simply because they are composed of building blocks that are native to all organisms. As an important counter-example, it should be noted that many peptides and protein drugs are immunogenic, so the potential immunogenicity of all peptide based materials must be considered, especially peptides that are “non-self”.

2.2 Materials design and synthesis

There are two general approaches to designing polypeptides. In the synthetic approach, standard polymerization techniques are employed using amino acids or their derivatives as monomers, such as the solid-phase polypeptide synthesis [27, 28] or synthesis by NCA polymerization [29, 30]. This approach is especially useful if the goal is to design hybrid materials that combine peptide motifs within a non-peptidic macromolecular architecture (e.g., peptide side chains on a synthetic polymer backbone). On the other hand, the chain length and stereochemistry of these polymers are often difficult to control. In contrast, recombinant DNA techniques offer an alternative, genetically encoded approach for the synthesis of polypeptides. This approach offers the advantage of high specificity in sequence, stereochemistry, and molecular weight. However, not all polypeptides can be expressed well in a heterologous host, nor can the polypeptide, during expression, be combined with non-peptidic moieties, other than by post-expression modification of the polypeptide.

In this review, we refer to polypeptides made via chemical methods as synthetic polypeptides, and we refer to polypeptides made by recombinant DNA methodologies as genetically encoded polypeptides. With this distinction clarified, we next summarize two examples of peptide-based materials that have been synthesized either by chemical methods or genetically encoded synthesis: elastin-like polypeptides and silk-like polymers.

2.2.1 Elastin-like polypeptides

Elastin is one of the most abundant extracellular matrix proteins, along with glycosaminoglycans (GAGs) and collagens, and it has the unique mechanical property of allowing repeated extensibility followed by elastic recoil. It is commonly found in large arteries, lung parenchyma, and elastic ligaments [31-35]. Elastin is an insoluble protein, and it is synthesized as the soluble precursor tropoelastin (MW 70 kDa), which is composed of alternating hydrophobic and hydrophilic domains containing lysine crosslinking sites. Tropoelastin is secreted from cells during elastogenesis, and then forms fibrils that are enzymatically crosslinked [31].

Elastin-like polypeptides are derived from a repeating motif within a hydrophobic domain of mammalian tropoelastin: the most common motif has the sequence (VPGXG)m, where X can be any amino acid other than proline, and m is the number of repeats [36]. There are many other variants of ELPs that range from other pentapeptides with the repeat sequences KGGVG [37] or LGGVG [38] to heptapeptides with the sequence LGAGGAG and nonapeptides with the sequence LGAGGAGVL [39]. All of these elastin analogues appear to exhibit elastin-like properties. Here, we largely confine our discussion to the most widely studied pentapeptide motifs.

ELPs composed of the (VPGXG)m repeat are thermally responsive polypeptides that undergo a reversible, inverse temperature phase transition [40]. ELPs are highly soluble in an aqueous solution below their transition temperature (Tt), but aggregate rapidly above their Tt. In applications where control of the Tt of ELPs is important, there are several design constraints, as follows: first, thermally responsive ELPs must retain the Val-Pro-Gly-Xaa-Gly repeat unit, where Xaa is a guest residue; a variant that contravenes this rule is IPGVG [41]. Second, proline at the guest residue position must be avoided, as its presence at the fourth position prevents helix formation. Third, the guest residue composition strongly affects the transition temperature, making its selection the primary focus in ELP design. Fourth, the transition temperature shows a 1/L dependence on the chain length (L) of an ELP. In addition to ELPs solely consisting of pentapeptide repeats, side groups capable of adding functionality to the ELP can be added without disrupting the transition. For example, Cys has been added to the 3’-terminus of some ELPs to allow for conjugation, while lysine residues have been added to allow for crosslinking.

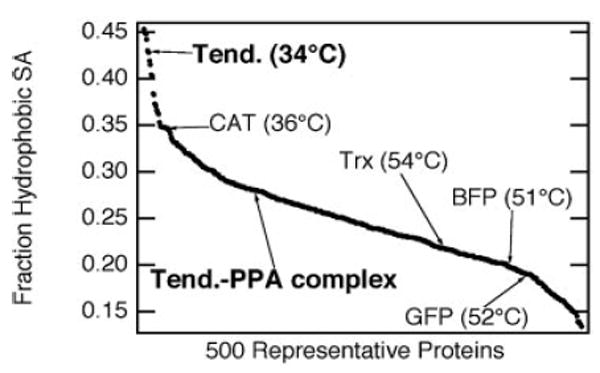

The strict amino acid sequence requirements make it attractive to design ELPs at the genetic level. A good starting point for the design of ELPs comes from the studies of Urry and co-workers, who quantified the effects of each of the guest residues on transition temperature by determining the free energy change involved in the transition of ELPs containing a single guest residue [36, 42] (Table 1). These studies clearly illustrated the effects of hydrophobicity on the Tt of an ELP. A similar approach has been used to successfully predict the Tt of ELP fusion proteins y quantifying the effect that the solvent accessible residues on a protein have on the Tt of the fused ELP. Trabbic-Carlson et al. calculated the solvent accessible hydrophobic surface area of proteins with known crystal structures using PROBE [43], and showed that the change in Tt of an ELP fusion protein inversely scales with this parameter [44] (Figure 2). This modeling approach allows the Tt of an ELP fusion protein to be predicted from that of the ELP that is appended to.

Table 1.

The effects of guest residue composition on the Tt of ELP homopolymers. The Tt’s reported in this table are a useful starting point for choosing which guest residues to include in the ELP gene in order to achieve a desired LCST, but are only approximate as they do not take into account the effect of MW on the Tt of the ELP [36].

| Residue | R Group | Abbreviation | Letter | Tta | ΔHt kcal/mold ± 0.05 | ΔSt kcal/mold ± 0.05 |

|---|---|---|---|---|---|---|

| Tryptophan |

|

Trp | W | −90°C | 2.10 | 7.37 |

| Tyrosine |

|

Tyr | Y | -55°C | 1.87 | 6.32 |

| Phenylalanine |

|

Phe | F | −30°C | 1.93 | 6.61 |

| Histidine |

|

His | H | −10°C | ||

| Proline(calc.)b | −CH2CH2CH2− | Pro | P | (−8°C) | ||

| Leucine | −CH2CH(CH3)2 | Leu | L | 5°C | 1.51 | 5.03 |

| Isoleusine | −CH(CH3)CH2CH3 | Ile | I | 10°C | 1.43 | 4.60 |

| Methionine | −CH2CH2SCH3 | Met | M | 20°C | 1.00 | 3.29 |

| Valine | −CH(CH3)2 | Val | V | 24°C | 1.20 | 3.90 |

| Histidine |

|

His+ | H+ | 30°C | ||

| Glutamic Acid | −CH2CH2COOH | Glu | E | 30°C | 0.96 | 3.14 |

| Cysteine | −CH2SH | Cys | C | 30°C | ||

| Lysine | −CH2CH2CH2CH2NH2 | Lys+ | K+ | 35°C | 0.71 | 2.26 |

| Proline(exptl)c | −CH2CH2CH2− | Pro | P | 40°C | 0.92 | 2.98 |

| Alanine | −CH3 | Ala | A | 45°C | 0.85 | 2.64 |

| Aspartic Acid | − CH2COOH | Asp | D | 45°C | 0.78 | 2.57 |

| Threonine | −CH(OH)CH3 | Thr | T | 50°C | 0.82 | 2.60 |

| Asparagine | −CH2CONH2 | Asn | N | 50°C | 0.71 | 2.29 |

| Serine | −CH2OH | Ser | S | 50°C | 0.59 | 1.86 |

| Glycine | −H | Gly | G | 55°C | 0.70 | 2.25 |

| Arginine | −CH2CH2CH2NHC(NH)NH2 | Arg | R | 60°C | ||

| Glutamine | −CH2CH2CONH2 | Gln | Q | 60°C | 0.55 | 1.76 |

| Lysine | −CH2CH2CH2CH2NH3+ | Lys | K | 120°C | ||

| Tyrosinate |

|

Tyr- | Y- | 120°C | 0.31 | 0.94 |

| Asporate | −CH2COO- | Asp- | D+ | 120°C | ||

| Glutamate | −CH2CH2COO- | Glu- | E- | 250°C |

Figure 2.

Effect of the hydrophobic fraction of solvent-accessible surface area (SAShydrophobic/SAStotal) on the Tt of ELP fusion proteins. Hydrophobic fractions of solvent-accessible surface for 500 proteins (having > 40 amino acids) selected from the protein database (PDB) are shown. The positions of five specific proteins are plotted along with their corresponding ELP fusion protein transition temperatures (at 25 μM in PBS) to show the inverse relationship between SAShydrophobic/SAStotal and Tt. Green fluorescent protein (GFP), blue fluorescent protein (BFP), thioredoxin (Trx), chloramphenicol acetyltransferase (CAT), and tendamistat (Tend) are shown. This plot also predicts that when a Tend-ELP fusion protein binds its protein partner, porcine pancreatic α-amylase (PPA), the transition temperature will increase due to the increase in hydrophobic surface area of the bound protein complex [44].

2.2.2 Silk-like polypeptides

Silk is a natural protein fiber that is produced by spiders of the class Arachnida as well as several worms of the order Lepidoptera. Spider silk is a remarkable biomaterial that is lightweight, extremely strong and elastic, and has excellent impact resistance. Silks from the silkworm Bombyx mori and the orb-weaving spider Nephila clavipes have been investigated to understand their structure and processing mechanisms and to exploit the properties of these proteins for use as biomaterials [45, 46]. These native silk proteins contain highly repetitive crystalline domains periodically interrupted by less crystalline or amorphous regions. The crystalline region from B. mori fibroin is a 59 amino acid repeat [GAGAGSGAAG[SGAGAG]8Y], with a 3:2:1 ratio of glycine, alanine, and serine [47]. Repeated motifs from N. clavipes dragline silk are less conserved, but a 13 amino acid repeat [YGGLGSQGAGRGG] has been identified [48, 49]. Many synthetic genes encoding B. mori silk-like sequences have been cloned and expressed in E. coli. A six amino acid repeat [GAGAGS] controls crystallinity in films and fibers [50], and repeats such as [(AG)3PEG] [51] and [(AG)3EG] [52] have been used in efforts to control crystalline order in protein-based materials.

Capello et al. demonstrated that silk-like proteins (SLPs) based on the repeating motif [GAGAGS] produce crystalline structures similar to the β-sheet structures of native silk proteins. Their degree of crystallinity can be controlled by periodically including blocks of amino acids such as GAAGY. They also showed that the addition of elastin-like blocks within the SLPs to make silk-elastin-like proteins (SELPs) further disrupts the crystalline structure. While SLPs are generally insoluble in aqueous solution, the ELP blocks influence the molecular chain properties of the protein so that the SELPs are water soluble [50]. This is an important property, as water solubility is essential for the manufacturing, purifying, and processing of silk-like biopolymers. A second method for increasing the water solubility of SLPs is the addition of sterical crystallization triggers. Winkler et al. added methionine residues flanking the β-sheet forming polyalanine sequences of a recombinant silk protein. The oxidized methionine residues sterically hinder β-sheet formation and increase the protein’s hydrophilicity, while in the reduced state, the added residues have no effect on crystallization [53]. They also modified a recombinant silk protein to include a phosphorylation site for cyclic AMP-dependent protein kinase (cAPK). By introducing charged phosphate groups, the hydrophobic interactions required for β-sheet formation were interrupted, also preventing insolubility [53].

One of the greatest hurdles in producing silk in large quantities is the level of expression. The highly repeating gene sequence that codes for silk is not efficiently translated in E. coli, the most extensively used expression host. Some alternative expression hosts have proven more successful, although they still present challenges of their own. Insect cells show lower-than-desired levels of expression. Transgenic species such as tobacco and potato have shown high levels of expression (2% of all soluble protein) [54], and yeast cells have shown high levels of expression, but the resultant protein has lower purity. Partial gene sequences cloned into mammalian epithelial cells have produced proteins with mechanical properties close to that of native silk fibers [55].

2.3 Synthesis

2.3.1 Synthetic polymers

Given the time and effort required for the synthesis of genetially encoded polypeptides and the restriction on the use of natural amino acids, there is great interest in developing synthetic procedures that rival genetically encoded synthesis to produce polypeptides with similar control of size and uniformity [56]. Although the genetic polymerization methods may offer greater control of sequence, synthetic methods do allow for the incorporation of artificial amino acids, stereochemically unique amino acids, and β-amino acids, all of which can prevent protease degradation. Conventional polymerization methods are also ideal for combining polypeptides with other synthetic polymers such as poly(ethylene glycol). Although progress has been made in the site specific incorporation of unnatural amino acids into proteins during recombinant synthesis [6, 7], these approaches are still difficult to use and do not, in general, lend themselves to the large scale production of polypeptides with unnatural amino acids.

2.3.2 Genetically encoded polymers

Conceptually, genetically encoded synthesis has three steps: creation of a recombinant gene segment that codes for the protein of interest, insertion of this segment into a DNA vector, which is typically a plasmid to create a recombinant DNA molecule, and transformation of this recombinant DNA molecule into a host cell (Figure 1). Cells that are successfully transformed or transfected with the recombinant DNA molecule are grown in culture, and the polypeptide produced by the cell is purified from the cell. The rate-limiting step in genetically encoded synthesis lies mostly in assembly of the gene to insert into the desired vector, especially if the desired polypeptide product (and consequently the gene that encodes it) is comprised of a large number of repeats. Short DNA sequences of up to 100 nucleotides can be directly synthesized chemically on an automated solid phase DNA synthesizer. These short single stranded, chemically synthesized DNA sequences must be assembled into larger pieces that encode for repetitive polypeptides of the desired MW (typically several tens of thousands or larger MW). These methods include concatenation of oligonucleotides, recursive directional ligation (RDL), and mutagenesis or amplification of existing gene segments using polymerase chain reaction (PCR). In this section, we focus on concatenation of oligonucleotides and RDL.

Figure 1.

Schematics of concatemerization (A) and RDL (B). During concatemerization, a statistical distribution of genes encoding a monomer is ligated together, the gene inserts are sorted based on size, and desired insert is ligated into a vector. RDL incorporates the insert produced during a given step as the insert for the next step to ensure a given size. Figure reproduced from [62] with permission from Elsevier.

The concatemerization method and RDL are both designed to generate repetitive DNA sequences [50]. Both ELP and silk genes are candidates for these methods of gene design, as they consist of pentamer repeat units [57, 58]. Even with variation of the guest residue within pentamers, the distribution of guest residues can typically be captured within one synthetic insert. In the concatemerization method, a library of these oligonucleotide inserts is built, and the vectors are cut at specific sites with different restriction enzymes. The inserts of various discrete sizes are then ligated into vectors at a specific site to recircularize the vector-insert combinations. The ligation products are sorted according to their size by gel electrophoresis and transformed into cells for polypeptide expression. The advantage of using this method is that different sizes of the repetitive gene are obtained in a single experiment. The disadvantage is that concatemerization is a statistical process, so it is difficult to, a priori, design a polypeptide of a certain size, and it is difficult to synthesize genes that encode for large polypeptides (> 100 kDa). This method is useful when a library of genes of different sizes is desired, but not for the creation of a gene of a specific size or for very large genes.

RDL is an alternative method that provides a greater level of control over the size of the insert [59]. In this method, a single double stranded oligonucleotide is inserted into a vector to create a circular, recombinant DNA molecule with two different restriction sites flanking the insert. After in vivo amplification of the recombinant DNA molecules within a host cell by replication to obtain sufficient quantities for the next step, one population of this recombinant DNA molecule is cut at both sites and the insert is extracted. A second population is cut at a single site (linearized) so that the resultant ends are compatible with the extracted insert. The single oligonucleotide insert is then ligated to the linearized parent molecule to create a recombinant DNA molecule that now contains a dimerized insert in a head-to-tail orientation; by choice of the two restriction sites, this process seamlessly joins the 2 monomeric inserts and also eliminates the restriction site at the junction between the two monomeric inserts, so that the two unique restriction sites are now on either end of the dimerized gene. This process is then repeated to double the size of the gene, though we note that at the second iteration of RDL, the monomer can be combined with the dimer to create a trimer. In the iterative ligation process, any two oligomers from previous rounds can be combined, so that a library of genes can be obtained wherein each recombinant molecule contains a unique gene, and the library can contain genes ranging from the monomer to n-mer oligomer.

This deterministic method of synthesis has several advantages over chemical synthesis. First, polypeptides synthesized by this method have a defined sequence, stereochemistry, and molecular weight based on the genetic template. Second, transformed cells can provide a perpetual supply of the polypeptide. Third, in the event that the polypeptide has secondary or tertiary structural elements, the in vivo folding machinery of the cell can assist in forming the correct secondary and tertiary structure.

Recombinant synthesis techniques have several disadvantages as well. Genetically encoded polymers have a significant lead-time, mainly due to the work involved in the molecular biology necessary to assemble the gene in the desired vector and to optimize expression levels in the host cell. Second, typically only the 20 proteinogenic L-amino acids can be incorporated using standard cellular components, thus limiting the monomers that can be incorporated through genetically encoded synthesis, though as we have pointed out, these restrictions are slowly being relaxed due to advances in the incorporation of unnatural amino acids in genetically encoded synthesis [6, 60, 61].

2.4 Characterization techniques

Many techniques, originally developed to characterize the solution properties opf peptides and proteins and the mechanical properties of hydrogels, can be used to determine the biophysical, structural, and rheological properties of peptide-based materials. The techniques highlighted below are a partial compendium of useful techniques, and are by no means comprehensive. Additional techniques may be necessary for individual applications in order to fully determine the functionality of the biomaterials; these will be discussed separately for each application.

2.4.1 Biophysical properties

Many characterization techniques originally developed for the characterization of proteins are useful for the characterization of repetitive peptides as well [63]. Protein concentrations of peptide-based biomaterials can be rapidly determined spectrophotometrically or colorimetrically or by using a Coomassie brilliant blue or bicinchonic acid assay. Molecular weights of these materials can be measured by electrophoresis-based methods such as SDS-PAGE, mass spectrometry (MS) methods such as matrix-assisted laser desorption ionisation (MALDI-MS) and electrospray MS, or analytical ultracentrifugation based on sediment coefficients.

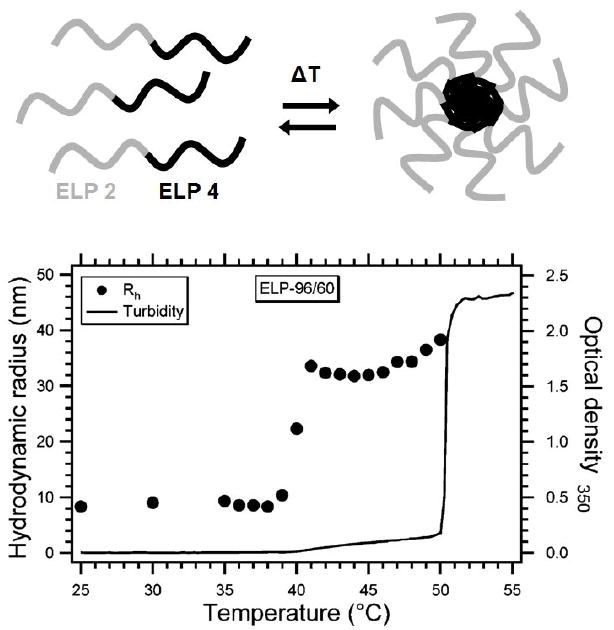

For ELPs, the inverse temperature transition behavior is usually represented by the lower critical solution temperature (LCST) or transition temperature (Tt) (the two terms are used interchangeably), which is often determined by the turbidity (optical density at 350 nm) as a function of temperature (Figure 3) [64, 65].

Figure 3.

(A) Relative turbidity measurements for free ELP and ELP fusion proteins of various size. (B) The relationship between transition temperature and length of thioredoxin-ELP fusion proteins. (C) The relationship between transition temperature and NaCl concentration for the thioredoxin/60-mer ELP fusion protein (25 μM) in 50 mM phosphate buffer, pH 8.0. [69]

Surface plasmon resonance spectroscopy (SPR) provides a quick and convenient way to determine the binding behavior of peptide-based biomaterials. Peptides can be easily immobilized on a gold coated glass chip using a common conjugation chemistry such as 11-mercaptohexadecanoic acid (MHA). Binding constants such as ka, kd, and Kd are easily calculated based on the binding curves of the peptides [66]. Isothermal titration calorimetry (ITC) can also be used to study the binding thermodynamics of peptides with their binding partner. Thermodynamic parameters such as the binding enthalpy, entropy, free energy, and binding constant can be calculated from calorimetric data.

2.4.2 Structural properties

Structural properties such as particle size and proper folding play an important role in protein purification, tissue engineering, and drug delivery applications. Nuclear magnetic resonance (NMR) and X-ray crystallography are the methods of choice to obtain comprehensive structural information for proteins. In addition, protein folding can be studied using circular dichroism (CD) spectrometry, which identifies the unfolding and folding transitions of peptides. In particular, CD measures the absorption of left- and right-handed circularly polarized light to determine the fraction of alpha-helices and beta sheets in a polypeptide. Protein folding is an important determinant in the functionality of peptide-based biomaterials, especially those with enzymatic and biological functions. Differential scanning microcalorimetry (DSC) can be used to elucidate the folding and refolding properties of peptides during cooling and heating. In principle, DSC measures the amount of heat required to increase the temperature of the peptide during a physical transformation such as a phase transition, from which the state of protein folding can be determined [66].

Dynamic light scattering (DLS), also known as photon correlation spectroscopy, can be used to determine the hydrodynamic radius (Rh) of polypeptides in aqueous solution. In DLS, a beam of light is passed through the aqueous sample, and the particles scatter some of the light in all directions. Because the particles are small enough to undergo random thermal (Brownian) motion, the distance between them is constantly varying, and constructive and destructive interference of the light scattered by neighboring particles causes the measured scattered intensity to fluctuate with time. Analysis of the intensity time correlation function can yield the diffusion coefficient of the particles and, via the Stokes Einstein equation, Rh [67]. DLS is especially useful for examining the formation of self-assembled polypeptide micelles.

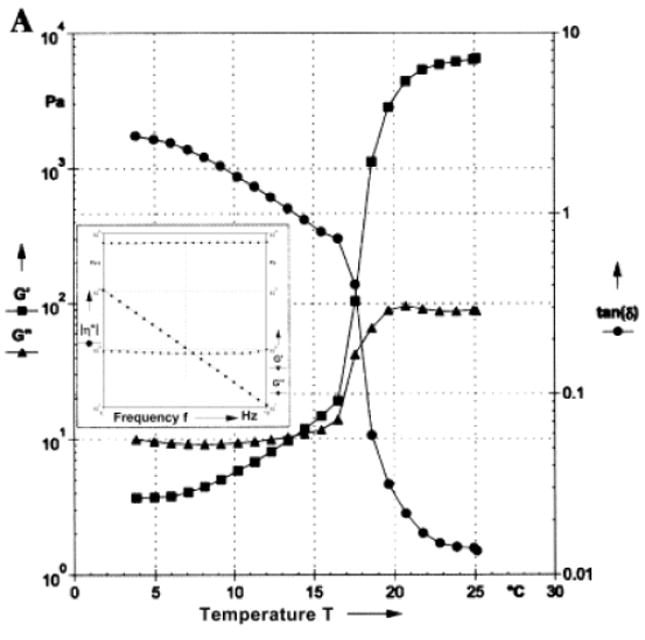

2.4.3 Rheological properties

Rheological properties of peptide-based biomaterials are particularly important in tissue engineering scaffolds, because their primary role is as a structural component to support cell growth. The load supporting ability of crosslinked or self-assembled polypeptides can be determined by oscillatory rheological characterization in a solution state (Figure 4). The rheological properties can be estimated by measuring G′ (elastic (storage) modulus), G″ (viscous (loss) modulus), G* (dynamic (complex) shear modulus), η* (dynamic (complex) viscosity), and tan δ (loss angle) as a function of strain, frequency, temperature, time, and other parameters in order to elucidate a relationship between the molecular structure of a polypeptide and its rheological properties. From basic rheological principles, the elastic modulus G′ represents the solid-like component of a viscoelastic hydrogel, and the viscous modulus G″ represents the liquid-like component. If G″ is much larger than G′, the liquid-like behavior of the solution predominates. On the other hand, if G′ is larger than G″, solid-like behavior prevails. The gelation point is defined as the crossover between G′ and G″. The loss angle, δ, is a measure of the dissipation of energy inherent in the material (δ = 90 ° for an elastic solid; δ = 90 ° for a Newtonian viscous fluid), and is a useful parameter for quantifying the viscoelasticity of a material.

Figure 4.

Dynamic rheological data describing the variation of the storage (G′) and loss (G″) moduli and loss angle (tan(δ)) as a function of temperature for a concentrated aqueous (25 wt.%) solution of an elastin-mimetic triblock polypeptide. The inset within the figure depicts the frequency sweep for the solution at 25 °C at a strain amplitude of 1 %. The gelation point is defined as the point where G′ and G″ cross. Below the gelation point, this polypeptide is a viscoelastic liquid (G′ < G″), and above the gelation point, it is a viscoelastic solid (G′ > G″). A loss angle approaching zero also indicates solid-like behavior. Reproduced from [70].

For elastin-like polypeptides, gel swelling is another important rheological parameter that can be quantitatively described by the swelling ratio. A swelling ratio of greater than one indicates that the gel undergoes swelling, and a ratio of less than one indicates that the gel undergoes contraction. By simply weighing the peptide-based gels before and after incubation with buffer, the swelling ratio can be easily calculated by normalizing the measured weight to the original weight [68].

3 Applications

In this section, we discuss a variety of applications of peptide-based polymers in protein purification, drug delivery, tissue engineering, and biointerface science.

3.1 Protein purification

3.1.1 Introduction

The ready availability of recombinant proteins is essential for their many biomedical applications as therapeutics and diagnostics, and in regenerative medicine and biosensing. Proteins are also important reagents for drug discovery, lead identification and validation, and high-throughput screening. Although many proteins can be produced in large quantities by recombinant expression, the cost of the final product, most of which (~70%) is due to purification, can sometimes be prohibitive for routine use. In addition, the production of many other proteins in quantities relevant for biopharmaceutical applications remains difficult, mainly due to problems in protein expression and purification. To a great extent, these constraints also apply to peptide-based polymers.

Many strategies have been developed to improve protein expression and have been thoroughly discussed in other reviews [71, 72]. Different expression hosts such as bacteria, mammalian cells, and insect cells are commonly used, and their selection is largely based on the properties of the proteins to be expressed. The choice is also dictated by the requirement of proper folding and post-translational modifications, which determine the bioactivity of the purified protein [71]. Once the expression host has been selected, the yield of the protein must be maximized by the optimization of expression conditions such as medium formulation, feeding schedule, and metabolic waste removal [72].

3.1.2 Protein purification methods

Most protein purification techniques are based on the intrinsic differences in the physico-chemical properties of proteins, such as solubility, size, charge, hydrophobicity, and shape. Commonly used methods that take advantage of these properties include precipitation, dialysis, electrophoresis, and chromatography.

3.1.2.1 Chromatography

Among all available methods, chromatography is by far the most widely used for purifying proteins. Chromatography encompasses a family of techniques that use columns to separate proteins based on size [73], charge [74], hydrophobicity [75], or shape [76]. A single chromatographic separation based on a single physical parameter of a protein can be applied to all proteins, but will usually only provide a modest gain in purity. Multiple chromatographic steps, each using an orthogonal separation property (e.g., separation based on charge followed by size) are needed to attain the desired purity. These methods, when used either individually or in combination, provide a means to isolate and enrich proteins of interest in a quantity relevant for biopharmaceutical and biomedical uses.

As an alternative to conventional chromatography methods that exploit differences in the physico-chemical properties of proteins, recombinant proteins can be purified through the combination of genetic engineering and affinity chromatography. An affinity tag, typically a short peptide, is tagged on a target protein at the N- or C-terminus using genetic engineering methods. The tag serves as a binding partner to capture molecules anchored on chromatography beads. Over the years, many affinity tags such as short peptide sequences and binding proteins have been developed and are now routinely used in protein purification (Table 2). Although affinity chromatography can produce proteins of high purity, the use of affinity tags is limited to recombinant proteins (with the notable exception of using protein A chromatography to purify antibodies). In addition, the presence of the affinity tag can change the structure and bioactivity of the isolated protein. In some cases, affinity tags can adversely influence crystallization (e.g. His-tag) [72] or make proteins hard to solubilize (e.g. polyarginine) [72]. The tags are also susceptible to proteolytic cleavage (e.g. CBD) [77]. Removal of the affinity tag from the purified protein by site-specific proteolysis requires an additional round of protein purification and may leave behind extraneous residues.

Table 2.

Affinity tags used in recombinant protein expression and purification [91].

| Tag | Size | Binding partner | Ref. |

|---|---|---|---|

| Short peptide sequences | |||

| FLAG™ peptide (DYKDDDDK) | 8 aa | Antibody with Ca2+ | [92] |

| HA tag (YPYDVPDYA, influenza virus hemagglutinin) | 9 aa | Antibody | |

| Myc/c-myc (EQKLISEED) | 10 aa | Antibody | |

| Poly-arginine | 5-15 aa | S-sepharose (cationic) | |

| Poly-aspartic acid | 5-16 aa | Anionic | |

| Poly-cysteine | 4 aa | Thiopropyl-sepharose | |

| Poly-histidine (His-tag) | 6/8/10 aa | Nickel | [93, 94] |

| Poly-phenyalanine | 11 aa | Phenyl-superose (hydrophobic) | |

| S-tag | 15 aa | S-protein (modified ribonuclease A) | |

| Strep-tag (AWRHPQFGG) | 9 aa | Streptavidin | [95, 96] |

| Strep-tag II (WSHPQFEK) | 8 aa | Strep•Tactin (modified streptavidin) | [97] |

| T7-tag | 11/16 aa | Antibody | |

| V5 tag (GKPIPNPLLGLDST, SV5 virus) | 14 aa | Antibody | |

| VSV tag (YTDIEMNRLGK, vesicular stomatitis virus) | 11 aa | Antibody | |

| Binding proteins | |||

| Calmodulin binding protein (CBP) | 4 kDa | Calmodulin/Ca2+ | |

| Cellulose binding domains (CBD) | 156/114/107 aa | Cellulose | [98-100] |

| Dihydrofolate reductase (DHFR) | 25 kDa | Methotrexate | |

| Galactose-binding protein (GBP) | 33.5 kDa | Galactose-sepharose | |

| Glutathione-S-transferase (GST) | 26 kDa | Glutathione/ GST antibody | |

| Maltose binding protein (MBP) | 40 kDa | Amylose | |

| Thioredoxin | 11.7 kDa | Phenylarsine oxide (ThioBond) | [101] |

| Streptavidin/avidin | 60/ 68 kDa | Biotin | |

| Staphylococcal protein A | 14/ 31 kDa | IgG antibody | [102] |

| Streptococcal protein G | 28 kDa | Albumin | |

Overall, although chromatography-based protein purification methods have been successfully applied to the production of many recombinant proteins and peptide-based polymers, challenges remain in several important areas: 1) Chromatography packing materials can be quite costly, especially those for affinity chromatography when biological ligands are used. Although column packing materials can be reused after regeneration, the chromatography column may suffer from a deterioration in performance and require regular replacement to ensure high recovery. 2) The sample throughput of chromatography is volume-limited, because the loading capability is governed by the amount of packing materials used, which in turn is limited by the physical size of the column. 3) Products isolated by chromatography are usually diluted by elution buffer. A concentration step is frequently necessary after chromatography and may cause a loss in yield. Because of these issues, especially cost, affinity chromatography is largely a bench top laboratory tool, and its use in industry is confined to the use of protein A chromatography for the purification of antibodies.

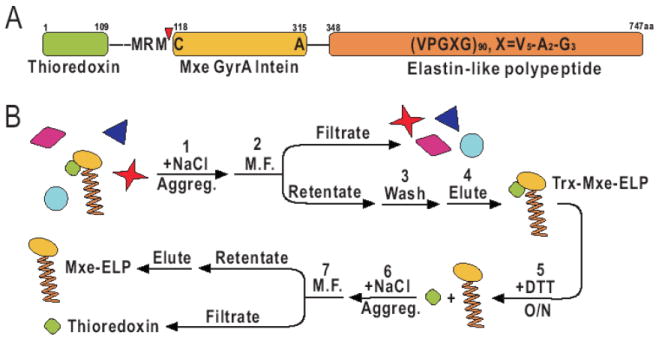

3.1.2.2 ELP-based protein purification

Research and development efforts have been made to alleviate purification problems through incremental improvements in the design of equipment and chromatography column packing material. In our view, new approaches are needed to overcome all of these difficulties. Protein purification using environmentally responsive polypeptides such as thermally sensitive elastin-like polypeptides (ELPs) circumvents many of the problems associated with chromatography based methods. Similar to an affinity tag, an ELP tag can be genetically engineered into recombinant proteins, and it imparts its phase transition behavior to the fusion protein. Because ELP fusion proteins are soluble at temperatures lower than their transition temperature Tt and insoluble at temperatures above the Tt, ELP fusion proteins can be purified in solution without chromatography using a technique termed inverse thermal cycling (ITC). In ITC, the soluble proteins are suspended in buffer, and the solution is centrifuged at a temperature below Tt to remove insoluble cellular proteins. The supernatant is then heated and centrifuged at a temperature above Tt in order to capture the insoluble ELP fusion protein. The pellet can then be resuspended in buffer and subjected to several more centrifugation cycles to obtain recombinant fusion protein at a high yield and purity. To recover the target protein, the ELP tag can be cleaved by an enzyme or by a change in acidity, depending on the cleavage site used [78] (Figure 5).

Figure 5.

Purification of self-cleaving ELP. (A) The target protein, thioredoxin, is fused to an intein-ELP construct. (B) Purification scheme utilizing microfiltration (M.F.) The intein-ELP tag is removed from the target protein at the self-cleavage site (red arrow) by the addition of dithiothreitol (DTT). Figure reprinted from [103].

Protein purification using an ELP tag has several advantages over conventional chromatography: 1) Although the choice of ELP tag depends on the characteristics of the fusion partners and the desired transition temperature, purification of proteins with ELP tags by ITC appears to be universal for soluble recombinant proteins. 2) The ELP tag that is co-expressed as a fusion partner with the target protein acts as a capture mechanism, so no chromatography beads are needed. This reduces the expenses associated with protein purification. 3) The ELP-based purification method does not require a concentration step to recover the final product. Because the recombinant protein is precipitated and concentrated during each step of the purification process, loss of the final product is lower than in chromatography.

3.1.3 Applications of ELP-based protein purification

As the principle of ITC purification is quite simple, many proteins have been successfully expressed as ELP fusions and isolated using ITC for a variety of biotechnology and biomedical applications. Most applications of ELP-based protein purification can be categorized into two major groups: direct ELP tagging and ELP-mediated affinity capture (Table 3). In direct ELP tagging, an ELP is fused to the protein of interest and expressed in host cells. This method offers simplicity of purification without multiple binding and desorption steps, high yield and high recovery, and superior purity. Fusion proteins with ELP tags of different sizes and compositions have also been synthesized and used for applications other than protein purification, such as tissue engineering and drug delivery [69]. ELP-tagged green fluorescence protein (GFP), blue fluorescence protein (BFP), thioredoxin, chloramphenicol acetyl transferase (CAT), and calmodulin (CaM) are a few examples of proteins that have been purified by ITC [44, 79, 80].

Table 3.

Applications of ELP-based purification.

| Examples | Ref. | |

|---|---|---|

| Direct ELP tagging | ||

|

|

[44] |

|

[69] | |

|

|

[82] |

|

|

[78, 103] |

| ELP-mediated affinity capture | ||

|

HIV antigen | [104] |

|

Antibodies | [83] |

|

His-tagged protein | [84] |

|

DNA | [85] |

|

Sugar group | [86] |

|

Mercury, arsenic, and cadmium | [87-90] |

Direct ELP tagging suffers from several drawbacks: 1) The ELP must be cleaved from the fusion protein if the ELP is not necessary in subsequent applications. 2) Enzymatic cleavage of the ELP tag can be expensive in large-scale production and the enzyme used must be removed from the final product. 3) The design of ELP must be tailored to the protein of interest and the transition temperature must be fine-tuned for each protein. 4) The recovery of the target protein is not satisfactory when its concentration is very low. However, new techniques and methodologies in direct ELP tagging have been developed to overcome some of these hurdles. For example, the requirement of an enzyme such as thrombin to remove the ELP tag can be eliminated with the use of a pH-dependent self-cleavage sequence (intein) [78, 81] (Figure 5). As the efficiency of ELP-based protein purification largely depends on the concentration of the fusion protein itself, those expressed at very low concentrations may present difficulties in protein purification. To circumvent this problem, it has been demonstrated that the addition of excess ELP to the cell lysate is sufficient to isolate target proteins of concentrations as low as 1 – 10 nM, which is equivalent to a few fusion protein molecules per E. coli cell [82]. Some of these techniques can also be performed together with microfiltration to increase the recovery of fusion proteins [81] (Figure 6).

Figure 6.

Different configurations for microfiltration purification of ELP fusion proteins by ITC. A) Syringe with a microfilter. B) AKTA system (Amersham Biosciences, Piscataway, NJ) with a microfilter. C) AKTA system with a stirred cell module. [81]

In ELP-mediated affinity capture, ELP is either recombinantly expressed or chemically attached to a capture partner that binds specifically to the target protein in solution. After binding, ITC may be used to purify the protein. This strategy circumvents the need to individually produce the target protein together with an ELP tag, thus shortening the development and optimization cycle. Furthermore, ELP-mediated affinity capture also opens the possibility of recycling the capture molecule, which further reduces the cost of producing the target protein. Also, ELP-mediated affinity capture does not require enzymatic or chemical cleavage of the ELP tag.

Representative examples of capture ligands that could used for purification by ITC are listed in Table 3. ELP-tagged proteins A, G, and L provide a general platform to capture antibody molecules of different subclasses [83] and allow complex multiplexing of protein purification and detection schemes. ELP-nickel conjugates can be used successfully to isolate proteins tagged with a short histidine sequence [84]. To purify unmodified proteins, ELP-tagged single-chain antibodies can be selectively bound to their protein partners. The underlying principle of this method is very similar to immuno-precipitation; however, it is more efficient due to the ELP-tag that facilitates the isolation and enrichment of the target protein. Recently, Kostal et al reported the successful purification of plasmid DNA using an ELP-tagged bacterial metalloregulatory protein MerR [85] (Figure 7). Biomolecules other than protein and DNA can also be isolated by this technique. It is possible to isolate glyco-polypeptides using the interaction between the capture molecule and the sugar group [86] (Figure 8). It has also been shown that ELPs fused to an appropriate fusion partner can bind to heavy metals such as mercury [87], arsenic [88] or cadmium [89, 90], and facilitate the rapid isolation of these toxic metal contaminants.

Figure 7.

Affinity purification of plasmid DNA using thermally triggered precipitation of ELP-tagged bacterial metalloregulatory protein MerR [85].

Figure 8.

Protein purification by glyco-affinity precipitation [86].

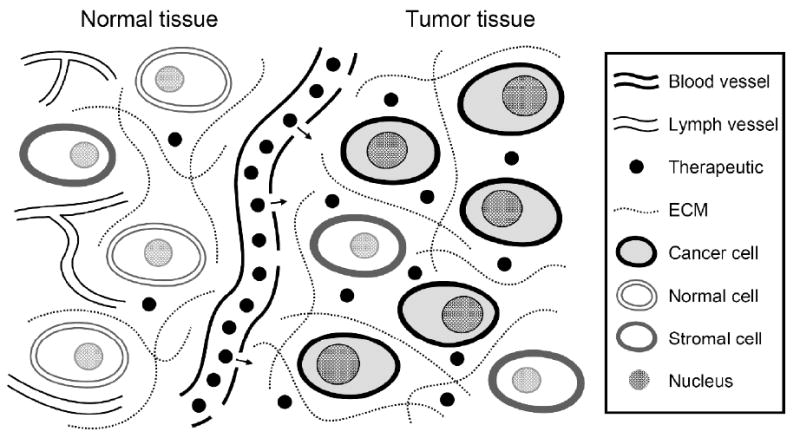

3.2 Controlled drug delivery

3.2.1 Introduction

Many experimental therapeutics have shown activity in vitro, but do not have significant in vivo efficacy. This discrepancy in performance can usually be attributed to problems in transport; many therapeutics have limited efficacy due to sub-optimal pharmacokinetics or systemic toxicity. Advances in drug delivery are hence needed to improve the pharmacokinetics of promising drugs for many diseases, and peptide-based biomaterials have great potential for in vivo delivery of pharmaceuticals [105]. In this section, we focus on methods for the delivery of cancer therapeutics to solid tumors.

In 1906, Paul Ehrlich proposed the use of a carrier capable of delivering “therapeutically active groups to the organ in question,” thus effectively starting the field of targeted drug delivery. In this approach, drug carriers are designed to enhance availability of the drug at a specific location, while minimizing systemic non-specific exposure of a drug. This method offers improvement over delivery of free drug by targeting the drug to a specific site. The efficacy of the drug is increased, and the accumulation at off-target sites is lowered, which lowers the toxicity of the compound. [106].

Targeted drug delivery, however, must overcome the transport barriers in the body, which are quite complex. Systemic delivery of compounds can be divided into three transport phases: from injection to tissue site, from vasculature to interstitium, and from interstitium to molecular site of action [107] (Figure 9). Furthermore, those drugs that have subcellular targets (i.e. nucleus or lysosome) will require a fourth transport phase depending on the site of action [108, 109]. When a drug is administered systemically, the compound will accumulate at the site of action, but will also accumulate in healthy tissue, and may concurrently be cleared through the reticuloendothelial system (RES). Low MW drugs will readily diffuse from the bloodstream into healthy tissues, as suggested by studies that reveal uniform distribution throughout the body [110]. This homogeneous localization of the drug leads to low concentrations of the drug at the tumor site and causes most of the negative side effects associated with systemic therapy. Furthermore, small molecules are rapidly cleared from the bloodstream, requiring multiple administrations to achieve therapeutic effects [106].

Figure 9.

Diagram illustrating systemic drug delivery for therapy of solid tumors using the enhanced permeability and retention (EPR) effect. The drug will extravasate from the permeable tumor vasculature and diffuse across the interstitium to reach the target cells. A small portion of the drug is lost due to clearance in the bloodstream and the interstitium and due to uptake by normal tissue, but retention is enhanced within the tumor due to the lack of functional lymphatics. The goal of drug delivery is to maximize the drug concentration in the target cells while minimizing uptake by healthy cells.

One property of tumors that can be exploited in drug delivery is that the physiology of tumor vasculature is different from normal vasculature. While normal blood vessels have low permeability, the irregularity of tumor vasculature leads to leaky sections, which increases the overall permeability. There is also a lack of functional lymphatics within the tumor interstitium. These two properties of tumors combine to create the enhanced permeability and retention (EPR) effect, which causes an increase in the uptake of blood-borne molecules into the tumor [111, 112].

Despite the EPR effect, there are many factors opposing the delivery of drugs to tumors. The pressure in the interstitium is high relative to the vasculature, creating a barrier for diffusion into the tumor. Also, blood vessels within the tumor are heterogeneously distributed [113]. While the evenly-spaced vessels of healthy tissue allow for perfusion to all tissues, not all regions of a large tumor can be reached via simple diffusion [114]. The lack of lymphatics does reduce transport of the drug away from the tumor, but it also reduces any convection-based transport within the tumor. Yet another barrier is the multi-drug resistance effect that allows cells to actively pump a wide variety of hydrophobic drugs out of the cytoplasm via membrane-bound efflux pump proteins [115]. This leads to low intracellular concentrations as well as the prevention of subcellular trafficking. All of these barriers combine to create a challenge for successful administration of anticancer drugs.

Two distinct methods have been used to meet this challenge. First, soluble macromolecular carriers can be used for systemic delivery of antitumor agents. Soluble polymer carriers have a long plasma half-life, which allows them more time to accumulate in tumors by diffusing through their permeable vasculature. Knowledge of the exact location of the tumor is not necessary for administration; ideally the carriers can reach any vascularized tumors, provided that the compound is not quickly cleared from circulation. The limit of this approach is that the carriers must overcome the multiple transport barriers to reach the target cells.

The second method, local delivery, sidesteps transport issues by sustaining delivery of low MW compounds from a controlled release depot at the site of action. By releasing the drug directly at the tumor, delivery does not need to rely on the limited vasculature. Also, the composition of the matrices used for sustained release can be tailored for a wide variety of compounds. The limitation of local delivery is that the exact tumor site must be known and accessible via direct injection for minimally invasive administration. In this section we will discuss the use of peptide-based polymers as both soluble carriers and local depots.

3.2.2 Soluble carriers

Polymers have recently gained attention as macromolecular carriers that are capable of overcoming transport barriers that limit drug delivery to tumors [106, 110, 116, 117]. Polymer conjugates for drug delivery are typically large hydrophilic molecules linked to a therapeutic agent. These conjugates can target tumors either “passively” through the EPR effect or “actively” through a triggered stimulus or affinity towards the site of therapy [116, 118, 119]. These macromolecular carriers have a longer plasma half-life, show reduced systemic toxicity, retain activity against multiple drug resistant cell lines, and increase the solubility of poorly-soluble drugs. All of these attributes have led to higher anticancer efficiency for passively-targeted polymer conjugates compared to free drug [116, 120-127].

Recent advances in peptide-based polymer design have led to the use of polypeptides as polymeric carriers for anticancer therapeutics. There are several inherent advantages to using polypeptides as opposed to synthetic polymers. First, polypeptides comprised of natural amino acids are likely to maintain biocompatibility throughout the degradation process, breaking down into metabolites excreted through normal metabolic pathways [128]. Second, genetically encoded peptides exhibit molecular weight and sequence uniformity, which are properties that will control pharmacokinetics, transport, biodistribution, and degradation [120, 129]. Third, targeting moieties such as short peptide segments can be incorporated at the genetic level at predetermined locations on the protein. Furthermore, amphiphilic polypeptides can be used to encapsulate drugs in self-assembling structures such as micelles and vesicles similar to those made from synthetic polymers.

3.2.2.1 Elastin-like polypeptides

The thermosensitive properties of ELPs make them an interesting class of polypeptides for use in drug delivery. Because ELPs are macromolecules, they are useful as carriers for passive targeting. More importantly, certain ELPs have been shown to undergo the inverse solubility transition in vivo at temperatures between 37 °C, body temperature, and 42°C [64, 130, 131], the clinically permitted temperature used in hyperthermia treatment [132].

Over the past decade, much work has been done to develop ELPs as soluble carriers that can be thermally targeted to tumors. In an effort to identify ELPs with desired transition characteristics in vivo, a series of ELPs of different MWs and guest residues were synthesized based on the LCSTs of ELPs containing a single guest residue [36]. ELP genes designed for thermally targeted drug delivery were cloned using the RDL method followed by expression and characterization of the resulting proteins [133]. Two ELPs were chosen for these studies: ELP1, which has a guest residue distribution of Val, Ala, and Gly in a 5:2:3 ratio, and ELP2, which has a distribution of Val, Ala, and Gly in a 1:8:7 ratio. ELP1 with a MW of 50-60 kDa was shown to have an LCST slightly above body temperature at concentrations between 5-50 μM. ELP2, a more hydrophilic protein, has an LCST outside the hyperthermia range at the same conditions.

ELP1 and ELP2 were monitored in vivo using intravital microscopy, a technique that allows for monitoring the kinetics of the accumulation of flouorophore labels within the tumor and determination of the 3D spatial distribution with micron resolution [134]. The ELPs were conjugated to different fluorophores and injected into nude mice implanted with human tumor xenografts. ELP1 formed micron-sized aggregates in the vasculature while ELP2 did not, showing for the first time that a thermosensitive polymer could transition at a specific temperature inside tumor vasculature. The ELP was also compared to pNIPAAM, a synthetic polymer that also exhibits an LCST [64]. Both ELP and pNIPAAM showed a two-fold concentration increase within the tumor at temperatures above the Tt. However, the biocompatibility, monodispersity, and sequence control of the ELP make it more useful than pNIPAAM as a thermally targeted carrier.

More recently, studies have been performed to further develp ELPs as a drug carriers. One example is the development of an acid-labile ELP1-doxorubicin conjugate for lysosomal release [130]. Doxorubicin, a hydrophobic anticancer drug, acts at the nucleus by inhibiting topoisomerase, thus killing the tumor cell. Its intranuclear mode of action requires that it be released from the carrier upon cellular uptake to allow entry into the nucleus. ELP1-150 (~60 kDa) was conjugated via a pH-sensitive hydrazone bond to a modified doxorubicin that contains a maleimide linker. In vivo studies showed similar levels of cytotoxicity during administration of free doxorubicin and ELP-doxorubicin despite varied distribution within the cell, suggesting that the ELP-doxorubicin conjugate likely has a different mode of action. Further optimization studies of the ELP-Dox maleimide linker showed that the spacer length affects the LCST and aggregate size without significantly changing pH-sensitive drug release, leading to the selection of B-Dox, which has an 8.1 Å spacer [135]. This linker minimally affected the LCST and will be used for future investigation of ELP-doxorubicin conjugates.

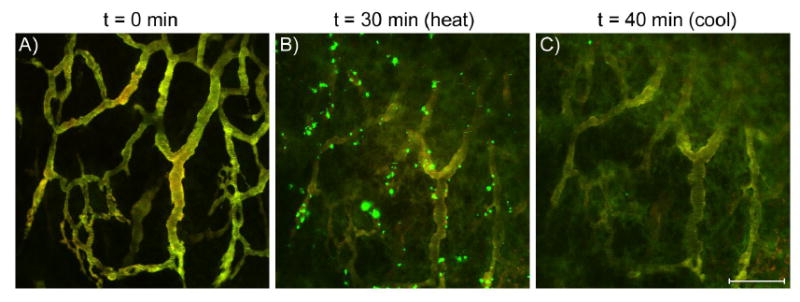

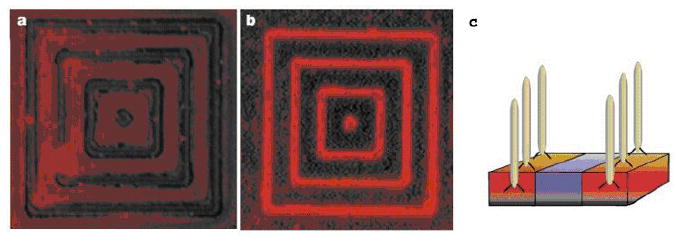

Other studies were performed to evaluate the pharmacokinetics and biodistribution of ELP within the tumor. Dreher et al. used confocal fluorescence microscopy to quantify the effects of the ELP phase transition in vivo. ELP1 (green) and ELP2 (red) were co-injected into nude mice, creating a yellow color within the lumen of the vasculature (Figure 10) [134, 136]. Upon introduction of hyperthermia, bright green ELP1 aggregates formed along the epithelium of the vessel as well as along branch points in the vasculature. These aggregates disappeared after cooling, demonstrating the reversibility of the process over several cycles.

Figure 10.

Images of ELP1 (green) and ELP2 (red) in a solid tumor before, during, and after hyperthermia treatment. These images are maximum projections along the z-axis of about 50 μm of tumor tissue, and imaging parameters were selected such that the vascular intensities of ELP1 and ELP2 were balanced to produce a yellow color. A) 0 min, no heat; B) tumor heated to 41.5 °C. The green particles indicate accumulation of ELP1; C) tumor cooled to 37 °C. The bar corresponds to 100 μm for all images. [136]

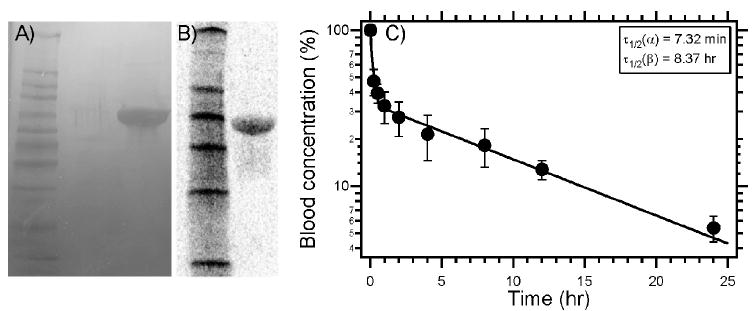

Biodistribution studies were performed on nude mice implanted with FaDu flank tumors using an ELP1/carbon-14 conjugate. This conjugate, formed at the expression level, was used to detect the amount of tumor uptake as well as the spatial distribution of the ELP upon hyperthermia [137]. The conjugate proved especially useful, as it allows for facile monitoring of the localization and degradation of ELP1 in vivo. Since the protein is covalently labeled with the radioactive nuclide, it also limits the potential for artifacts resulting from free radiolabel. Autoradiography of ELP1 shows that the product is homogenous and highly pure [138] (Figure 11). In two complementary, separate sets of experiments, 14C-ELP was used to monitor the plasma half-life of ELP1 in vivo as well as image the distribution of ELP within the tumor. The plasma half-life of ELP1-150 was 8.4 hr as determined in nude mice (Figure 11), and autoradiographs of tumor cross-sections showed that heated ELP1 accumulated 2-fold more and penetrated further into the tumor than non-heated and thermally-insensitive controls (Figure 12). Both of these recent studies suggest the potential of targeted drug delivery using thermosensitive ELP as a drug carrier.

Figure 11.

SDS-PAGE analysis of (A) C-ELP1 visualized by copper staining. (B) Radiolabeled ELP autoradiography after SDS-PAGE. (C) Pharmacokinetic analysis of radiolabeled ELP in mice (Balb/c nu/nu) exhibits a characteristic distribution and elimination response with a terminal half-life of 8.4 hr. Reprinted from [138] with permission from Elsevier.

Figure 12.

(A) Autoradiography images of 14C-ELP1 (ELPactive) with and without heat and 14C-ELP2 (ELPpassive)with heat from 20 μm tumor sections after 1 h of hyperthermia. (B) Scintillation analysis of tumor accumulation of the 14C-ELPs. ELP1 accumulates to a greater extent in heated tumors than unheated ELP1 or heated ELP2 controls. Data are shown as mean±SEM, n=5. *Significant difference compared with both controls (Fischer’s PLSD). Reprinted from [137] with permission from Elsevier.

ELP derivatives have also been used as soluble protein carriers by other investigators. Silk elastin-like polypeptides (SELPs) are polypeptides that contain repeating motifs from both silk and elastin proteins. SELPs with a minimal silk component do not form crosslinked networks and display the stimuli-sensitive behavior seen in ELPs, making them good candidates for use as soluble carriers. Nagresekar et al. observed a decrease in Tt when hydrophobic residues were added to an otherwise hydrophilic SELP. When glutamic acid residues were added, SELPs also exhibited pronounced pH and ionic transition temperature sensitivity [139]. The ability to adjust the sensitivity to ionic effects makes non-crosslinking SELPs good vehicles for systemic gene delivery.

Genetic templating allows for the incorporation of other peptide units with great precision at the gene level. This has led to the development of ELP-fusion peptides not only for protein purification, but also for therapeutic applications. These fusion proteins, unlike those designed for protein purification, do not necessarily require the eventual detachment of the bound peptide. For example, peptides that will enhance accumulation at the tumor site can be attached to the carrier. Raucher et al. attached the cell penetrating peptides (CPP) penetratin (AntP), MTS, and Tat to the 5′ end of an ELP [140]. The addition of a CPP to the ELP increased uptake in both SKOV-3 ovarian cancer cells and HeLa cervical cancer cells. The CPP AntP showed the greatest in vitro increase in uptake in the unimer phase. An AntP-ELP fusion protein was also conjugated to the H1 peptide that is used to disrupt transcriptional activation of cells by inhibiting the c-Myc oncogene [141]. AntP-ELP-H1 caused a 2-fold decrease in cell proliferation when administered in hyperthermic versus normothermic conditions.

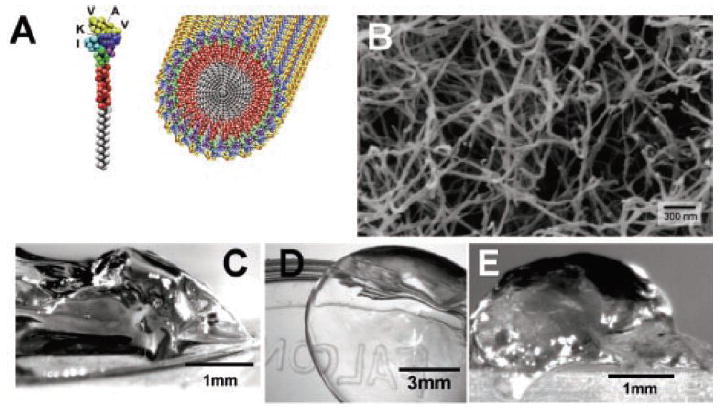

3.2.2.2 Polymeric micelles

Polymeric micelles have recently received great attention as potential carriers for hydrophobic drugs or genes [142-146]. These self-assembling nanostructures are made from amphiphilic block copolymers (BCPs) that consist of two blocks with differing polarity. This difference drives the formation of micellar structures in aqueous solution with the hydrophobic block of each unimer partitioning into the core and the hydrophilic block forming the corona. Other physical differences between the blocks, most notably charge, can influence the formation or destruction of nanoparticles (Figure 13). The hydrophobic core can be used to encapsulate hydrophobic compounds and increase their solubility in an aqueous environment. Polymeric micelles typically have a critical micelle concentration that is lower than for surfactant micelles, allowing for self-assembly at concentrations relevant for drug delivery [147]. Micelles also retain the positive aspects of polymeric delivery, such as prolonged plasma half-life, because the size of a typical micelle allows it to evade the reticuloendothelial system (Rh< 100 nm). Furthermore, the predictable self-assembly behavior allows for the incorporation of functional groups in the corona that range from passive components such as PEG to active groups such as targeting ligands or CPPs.

Figure 13.

Formation of thermosensitive ELP block copolymer micelles. At temperatures below the transition temperature of the ELP4 block (< 37 °C), the copolymer remains in unimer form. At temperatures between the transition temperatures of the ELP2 and ELP4 blocks, the block copolymers self assemble into spherical nanoparticles, possibly micelles. At temperatures above the transition temperature of the ELP2 block (> 37 °C), the corona of the micelle undergoes its phase transition, and micron-sized aggregates form. The turbidity (line) and DLS (points) data show the progression of the ELP from monomer to aggregate. [182]

The use of biopolymers has created a new class of “smart” micelles capable of triggered response to outside stimuli. For example, pH-sensitive micelles have been created using synthetic methods to create poly(histidine)-PEG and poly(histidine co-phenylalanine) block copolymers [133, 148, 149]. These micelles have a PEG corona and a hydrophobic core formed by the poly(histidine) block (pKa ~ 6.0). At low pH, the histidine becomes protonated, making the core more hydrophilic and thus disrupting the micelle. The addition of hydrophobic amino acids such as phenylalanine can be used to tune the pH sensitivity. Early studies have shown that these micelles, when coated with folate, can reduce the multi drug resistance effect by destabilizing endosomes within MCF-7 tumor cells[150, 151].

Both bio- and synthetic polymers have been used to produce thermosensitive self-assembling block copolymer micelles [133, 152-154]. The use of biopolymers provides the ability to design block copolymers that have specific LCSTs and precise MWs. Thermosensitive ELPs can be used to make block copolymers by seamlessly fusing multiple ELP genes at the genetic level. If the two blocks have different transition temperatures, each block will transition independently, and amphiphilic structures will form in the temperature range lying between the two transitions. Multiple groups have successfully created ELP BCPs using standard cloning techniques. Lee et al. concatemerized ELP oligonucleotides for hydrophilic and hydrophobic blocks and sorted them via gel electrophoresis to obtain a variety of block sizes [152]. Thermally induced formation of micelles was verified by dynamic light scattering (DLS) and differential scanning calorimetry (DSC). TEM images showed the formation of spherical and cylindrical micelles with core diameters of 54±9 nm and 50±10 nm, respectively. Chilkoti et al. expanded this idea by applying RDL to form blocks of precise size and composition [133] (Figure 13). ELP2 (guest residues: V1A8G7) and ELP4 (guest residue: V) blocks of varying molecular weight were characterized by turbidity and DLS measurements. The DLS data suggest that ELP2-ELP4 block copolymers exist in four distinct phases: unimer at T < Tt1, micelle at Tt1 < T < Tt2, larger nanoparticle at T ~ Tt2, and aggregate at T > Tt2. ELP BCP micelles with transitions Tt1 < 37 °C and Tt2 > 37 °C show potential as carriers for triggered and targeted delivery.

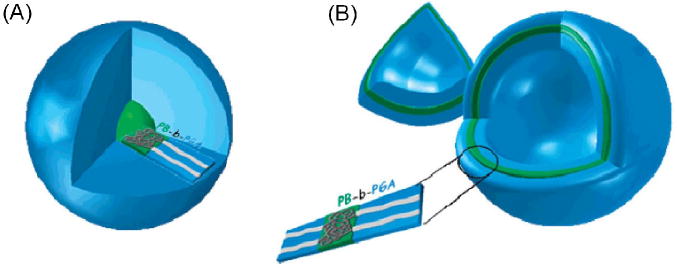

Checot and coworkers designed and characterized a series of polypeptide-polymer hybrids for drug delivery using poly(butadiene-b) (hydrophobic block) and poly(l-glutamic acid) (hydrophilic block) (Figure 14). These diblock copolymers self-assemble into micelles at hydrophilic to hydrophobic ratios of 3:1 [155]. The hydrodynamic radius of the micelles depends on both pH and salt concentration, because the poly(l-glutamic acid) in the corona transitions from a helix to an extended coil structure. These block copolymers contain a synthetic polymer but show greater stimulus sensitivity than other supramolecular assemblies due to their protein component.

Figure 14.

Diagram of pH-sensitive (A) micelles and (B) vesicles formed from poly(butadiene-b)-poly(glutamic acid) diblock copolymers. The hydrophilic to hydrophobic ratio of the blocks determines whether a micelle or vesicle will form. Deprotonation of glutamic acid residues in the hydrophilic corona imparts pH sensitivity to these structures. Reproduced from [155].

3.2.2.3 Vesicles

Polymer vesicles are another type of self-assembled nanoscale carrier for hydrophobic drugs. Vesicles maintain the geometry and flexibility of naturally-occurring lipid bilayer cellular membranes, but can include a wider variety of amphiphiles [156]. They are typically larger than micelles, and vesicles can fully encapsulate the compound of interest, protecting it from the outer environment. For example, “stealth” lipid-based vesicles, or liposomes, have been successfully used for systemic doxorubicin delivery [157].

Bellomo et al. produced synthetic diblock copolymers consisting of one lysine block and one leucine/lysine block using an existing synthetic peptide formation process [158]. Fluorescence emission measurements indicated no release of particles for several days at pH 10.6, but the measurements show near instantaneous degradation of the vesicles at pH 3.0. Checot et al. developed a series of pH-responsive poly(butadiene)-poly(glutamic acid) block copolymer vesicles intended for nano-encapsulation (Figure 14) [159]. They found that the copolymers form vesicles at near 1:1 hydrophilic to hydrophobic ratios and micelles at a 3:1 ratio. The vesicles are stimuli-responsive, and their size depends on both the pH and ionic strength of the solution [160]. Vesicles designed from these copolymers that degrade at pH 4 are physiologically relevant for lysosomal-triggered drug release [155].

3.2.3 Local Delivery

The second major class of controlled drug delivery methods is local delivery. In local delivery, the local drug concentration is increased by implanting a drug reservoir near the site of interest. This enhances diffusion into the desired site, mitigating the negative effects seen in systemic delivery. However, this method has some limitations. For example, not all tumor sites can easily be identified or are accessible within the body. Also, many implantable polymer structures require invasive implantation. Self-assembling injectable hydrogels are an alternative to rigid polymer structures and do not require an invasive surgical implantation. These hydrogels spontaneously crosslink and quickly form a gel in vivo following injection at the site. Self-assembling hydrogels can also incorporate a number of stimuli such as temperature or pH to control the matrix assembly [139, 161].

Injectable hydrogels must posess a unique set of properties. Gelation kinetics, geometry, swelling, density, stability, charge, and release rates are all important characteristics to consider when designing a matrix that will appropriately release therapeutic compounds [162]. Fortunately, these are all properties that can be controlled through the rational design of peptide-based biopolymers. In addition, most peptide-based hydrogels are biocompatible and resorbable upon degradation. Furthermore, control over polypeptide folding and organization can be exploited to create unique crosslinking systems that do not require chemical modification. It has been demonstrated that self-assembling protein hydrogels can be used to deliver both hydrophobic drugs as well as plasmid DNA for gene therapy applications.

3.2.3.1 Peptide-ELP fusion proteins

Many protein drugs have been developed to treat the degenerative joint disease osteoarthritis. While these drugs have the potential to modify progression of the disease upon intra-articular injection, their administration is limited by very short half lives [163, 164]. The Setton group has proposed a solution where the protein drug interleukin-1 receptor antagonist (IL1Ra) is fused to an elastin-like polypeptide (ELP). The ELPs aggregate and form a ‘drug depot’ upon injection at physiological temperatures, which prolongs the release time of the drug. In a study by Betre et al., an aggregating ELP was shown to have a 25-fold longer half-life in the injected joint than an equivalent molecular weight protein that remains soluble and does not aggregate [165]. In an accompanying study by Shamji et al., an ELP-IL1Ra fusion displayed a complete recovery of IL1Ra activity, matching that of the commercial antagonist [166]. They also demonstrated the facile collagenase degradation of the ELP domain, which may further promote the therapeutic efficacy of this drug delivery system. The results of these two studies show that an ELP-IL1Ra fusion injected within the intra-articular joint space will prolong the delivery of the active IL1Ra drug and improve the quality of treatment for osteoarthritis.

3.2.3.2 Silk-ELP hybrids

Silk is a useful biomaterial due to its high mechanical strength and biocompatibility. However, silk undergoes strong intramolecular hydrogen bonding that leads to rapid crystallization and can complicate its use for injection-based applications [53, 167]. One route to increasing its solubility is the incorporation of peptide sequences from other proteins, such as elastin, that disrupt β-sheet formation [50]. Silk elastin-like polypeptides (SELPs) are chimeric proteins designed to retain the mechanical properties of silk, while incorporating the high solubility and environmental sensitivity of ELPs [139, 161, 168]. Some SELPs can be injected through hypodermic needles, and they then form insoluble hydrogels at the injection site without chemical assistance [162, 169-171].

The main parameters of interest for SELP hydrogels are the rate of gelation, release rate of encapsulated compounds, swelling capability, stability, and biocompatibility of the hydrogel. Initial SELPs capable of self-gelation were identified by Cappello et al. They have the general composition (SmEn)o, where S is the silk-like block, GAGAGS, and E is the elastin-like block, GVGVP. The parameter m varies from 2 to 8, n from 1 to 16, and o from 2 to 100, so that the MW is between 60 and 85 kDa [171].

A series of SELP characterization studies support the use of these hydrogels for drug delivery. DSC was initially used to determine the gelation kinetics, and it showed that decreasing the number of silk blocks leads to a delay in the gelation rate at room temperature. Conversely, hydration studies showed the addition of silk blocks also reduces the swelling ratio [172, 173]. Encapsulation studies have shown that the presence of either charged or uncharged solutes disrupts the formation of the gel. Release studies were performed using fluorescent dextran, various proteins, and DNA [171, 174]. While an increase in polymer concentration greatly reduced the release rate, the MW of the released compound had no effect on the release rate. For charged molecules such as DNA, the ionic strength of the hydrogel affects the release rate, but encapsulation does not reduce the bioactivity of the encapsulated compounds [174]. Furthermore, degradation of SELPs does not appear to produce cytotoxic intermediates, as shown by histological data [175].

3.2.3.3 Coiled coil domains

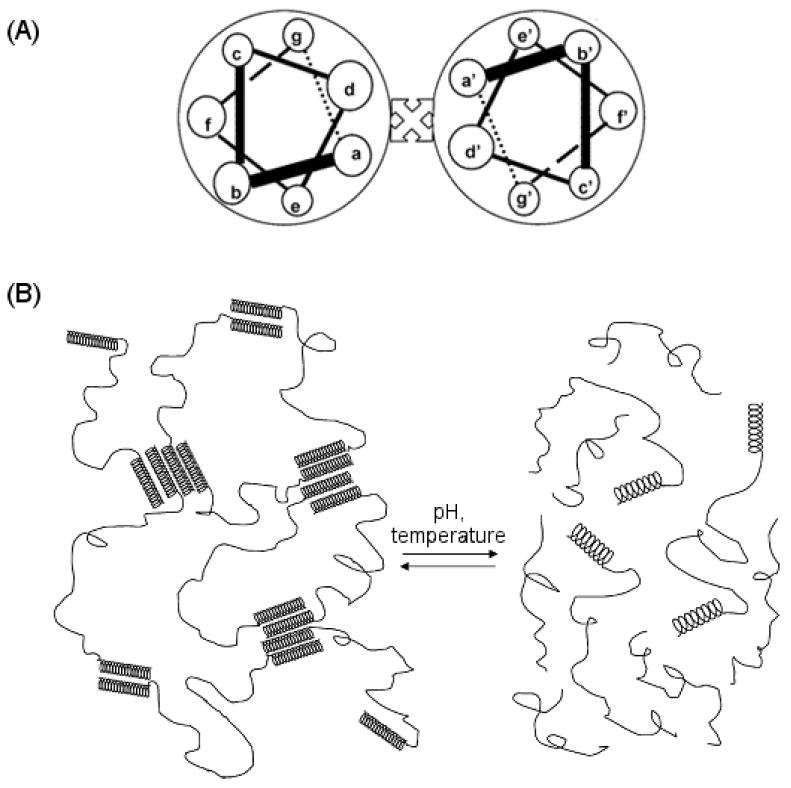

The coiled coil is one of the basic folding patterns of native proteins, consisting of two or more right-handed amphiphilic α-helices wound together non-covalently to form a slightly left-handed superhelix (Figure 15) [176-178]. The coiled coil domain is based on a heptad repeat unit abcdefg, where a and d are typically hydrophobic amino acids (leucine), and e and g are charged (glutamic acid) [179]. Helical stability is maintained by electrostatic interactions between e and g [180]. Coiled coil motifs intended for drug delivery utilize the reversible hydrophobic association of α-helices within the core as well as the electrostatic interaction from the outer charged residues. These interactions determine the stability of the bundles upon changes in pH and temperature. The peptide sequence in the heptad unit of the coiled coil can be tailored so that the electrostatic interactions are disrupted and protein collapse is induced under the influence of stimuli such as pH, temperature, light, and binding of ligands. This behavior has been exploited to create pH-sensitive and temperature-sensitive hydrogels [176, 181]. These genetically encoded hydrogels demonstrated tunable diffusion, which is controlled by the residues composing the heptad sequence as well as the state of the hydrogel (soluble versus collapsed) [178, 181].

Figure 15.

Schematic showing the design of coiled-coil polypeptide hydrogels. (A) The α-helices are formed from heptamer repeats. The helix bundles are formed by interhelical hydrophobic interaction between residues a and d and stabilized by interhelical electrostatic interactions between residues g and e. (B) Variations in pH and temperature can disrupt these interactions and cause reversible dissolution of the hydrogel. Reprinted with permission from [176]. Copyright 2005 American Chemical Society.

3.3 Tissue engineering