Abstract

Although brittle material behavior is often considered undesirable, a quantitative measure of “brittleness” is currently not used in assessing the clinical merits of dental materials.

Objective

To quantify and compare the brittleness of human enamel and common dental restorative materials used for crown replacement.

Methods

Specimens of human enamel were prepared from the 3rd molars of “young” (18≤age≤25) and “old” (50≤age) patients. The hardness, elastic modulus and apparent fracture toughness were characterized as a function of distance from the DEJ using indentation approaches. These properties were then used in estimating the brittleness according to a model that accounts for the competing dissipative processes of deformation and fracture. The brittleness of selected porcelain, ceramic and Micaceous Glass Ceramic (MGC) dental materials was estimated and compared with that of the enamel.

Results

The average brittleness of the young and old enamel increased with distance from the DEJ. For the old enamel the average brittleness increased from approximately 300 µm−1 at the DEJ to nearly 900 µm−1 at the occlusal surface. While there was no significant difference between the two age groups at the DEJ, the brittleness of the old enamel was significantly greater (and up to 4 times higher) than that of the young enamel near the occlusal surface. The brittleness numbers for the restorative materials were up to 90% lower than that of young occlusal enamel.

Significance

The brittleness index could serve as a useful scale in the design of materials used for crown replacement, as well as a quantitative tool for characterizing degradation in the mechanical behavior of enamel.

Keywords: brittleness, elastic modulus, enamel, fracture toughness, hardness

INTRODUCTION

The physical properties of human enamel have been studied for many decades. In describing the mechanical behavior of this hard tissue, the hardness, elastic modulus and fracture toughness have both physical significance and direct clinical relevance. Hardness represents a measure of a materials resistance to permanent deformation or “penetration” under contact loads. According to selected published studies, the hardness of human enamel ranges from approximately 3 to 5 GPa [1–5]. The elastic modulus describes a materials resistance to deform elastically and quantifies the ratio of the magnitude of stress responsible for a corresponding degree of deformation. Based on studies conducted within the last decade, the elastic modulus of enamel ranges from roughly 70 to 100 GPa [1–7]. Fracture toughness is a property that describes a material’s ability to resist propagation of an existing crack under a particular state of stress. The indentation approach has been adopted in evaluating the apparent fracture toughness of enamel, and average values from 0.6 to 1.5 MPa•m0.5 have been reported [3, 8–11]. There is a relatively large range in these properties, which is at least partly attributed to anisotropy posed by the prisms (e.g. [4]) and the interprismatic organic matrix (e.g. [12]), and spatial variations in the enamel chemistry [13] and mineral content [14].

While the aforementioned properties describe fundamental aspects of mechanical behavior, they do not convey whether a material is brittle or not. Specifically, they do not address the propensity for inception of flaws and cracks under contact loads, or characterize a material’s ability to resist the initiation of fracture processes through either elastic or inelastic deformation. Brittleness can be interpreted using different parameters. For instance, resistance to crack growth (i.e. fracture toughness) is sometimes used to infer the brittleness of a material, but technical definitions of brittleness generally include the material stiffness and hardness as well. A quantitative measure of brittleness (B) has recently been defined according to

| (1) |

where Hc is the “transition point hardness” or constant hardness of the material and E and KIc are the elastic modulus and fracture toughness, respectively. Many materials exhibit indentation size effects (ISE) and load-dependent hardness. Brittle materials often exhibit a distinct transition point in the hardness vs. load curve at which the hardness becomes load independent or a constant value [15]. The definition of B in Eqn. 1 has a theoretical basis and is dependent on an energy ratio that compares deformation and fracture processes. The brittleness index has been used as a practical measure for characterizing the brittle behavior of engineering ceramics [15,16]. Materials with high B value are more prone to fracture than undergo elastic or inelastic deformation, whereas materials with low B would be more likely to deform elastically or dissipate energy through inelastic deformation. Despite the relevance of this physical description to the performance of dental materials, a measure of brittleness has not been adopted for characterizing their mechanical behavior. Therefore, the primary objectives of this study were to quantify the brittleness of human enamel from two patient age groups and to compare results with the brittleness of common dental restorative materials used for its replacement.

MATERIALS AND METHODS

Human third molars (N=34) of selected patients within 18≤age≤78 were obtained from participating clinics in the state of Maryland according to an approved protocol issued by the Institutional Review Board of the University of Maryland Baltimore County. All of the molars were caries free and had not been restored. Immediately following extraction the teeth were maintained in Hank’s balanced salt solution (HBSS) at 2°C to maintain hydration [17] and divided into young (18 ≤ age ≤ 25) and old (50 ≤ age) groups according to the patient age. Third molars were used to minimize the influence of cuspal wear on the enamel thickness and the potential for accumulated damage at the cusps in first and second molars due to cyclic contact. While all of the 3rd molars were at least partially erupted at extraction, it is unknown whether they were in occlusion. None of the occlusal surfaces had signs of cuspal wear.

The restorative dental materials selected for the evaluation were comprised of materials generally used for crown replacement and included groups of feldspathic porcelains, Micaceous Glass Ceramics (MGCs), and selected dental ceramics (Table 1). The MGCs were comprised of a range of mica platelet sizes that were achieved through heat treatment and have been shown to exhibit a relatively wide range in both hardness and fracture toughness. While only the fine to medium fine MGCs might technically be considered dental restoratives (similar to Dicor), the entire MGC series has been effectively used as model materials in the dental literature, especially in determining mechanical property correlations with microstructure [18–20]. Details pertaining to the chemistry and microstructure of the dental materials, as well of the methods of specimen preparation and testing have been presented elsewhere [18].

Table 1.

Mechanical properties of the enamel and selected restorative materials obtained from the indentation analyses. Values presented represent the mean.

| Material | HVc (GPa) | E (GPa) | Kc (Mpa*m0.5)b | B (µm−1) |

|---|---|---|---|---|

| Human Enamel (young) | ||||

| Inner | 3.1 | 75 | 0.88 | 305 |

| Middle | 3.5 | 82 | 0.88 | 375 |

| Outer | 4.1 | 87 | 0.95 | 393 |

| Human Enamel (old) | ||||

| Inner | 3.0 | 79 | 0.88 | 313 |

| Middle | 3.4 | 90 | 0.73 | 582 |

| Outer | 4.0 | 100 | 0.67 | 897 |

| Micaceous Glass Ceramicsa | ||||

| Fine (d=1.1 µm) | 4.2 | 71 | 1.04 | 271 |

| Medium-fine (d=1.8 µm) | 3.6 | 70 | 1.18 | 180 |

| Medium (d=3.7 µm) | 3.4 | 68 | 1.31 | 135 |

| Coarse (d=10 µm) | 2.7 | 50 | 1.65 | 49 |

| Cmacor glass (d=15 µm) | 1.8 | 64 | 1.50 | 51 |

| Feldspathic Porcelainsa | ||||

| Leucite Body | 5.6 | 67 | 1.14 | 288 |

| Leucite Incisal | 5.3 | 65 | 1.26 | 216 |

| Leucite Finesse | 5.6 | 70 | 0.99 | 402 |

| Leucite Empress | 5.6 | 67 | 1.03 | 353 |

| Nepheline syenite | 6.3 | 70 | 1.19 | 310 |

| Dissimilarsa | ||||

| Zirconia | 13.9 | 210 | 4.90 | 122 |

| Glass-infused alumina | 11.7 | 250 | 3.10 | 304 |

| Glass-ceramic | 5.5 | 104 | 2.80 | 73 |

from Quinn et al, [18]

values obtained using indentation and represent apparent toughness (Kc(app))

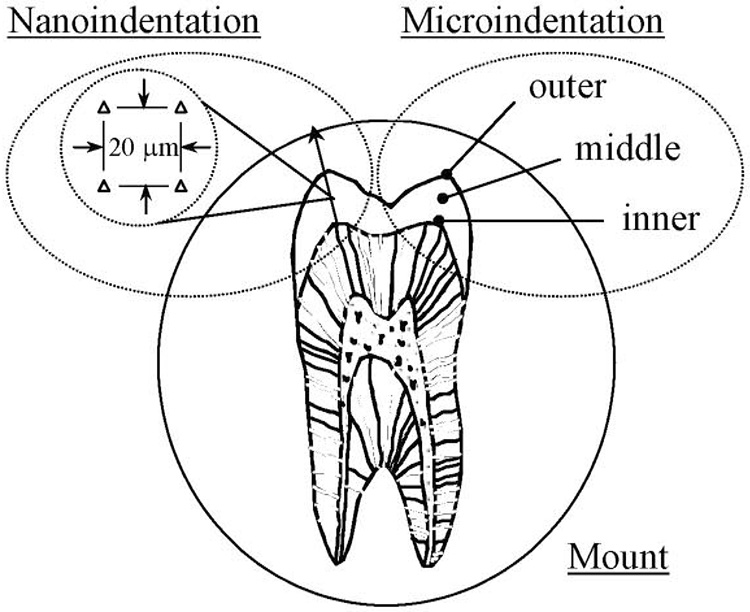

The teeth were sectioned using a programmable slicer/grinder (K.O. Lee Model S3818EL, Aberdeen, SD) with diamond impregnated slicing wheels (#320 mesh abrasives) and then mounted in a cold-cured epoxy resin. The enamel surfaces were polished using silicon carbide abrasive paper with successively smaller particle sizes and finished using diamond particle suspensions (Buehler) of sizes 9, 3, and 0.04 µm. The sections were subjected to either nanoindentation or microindentation testing. Those teeth examined using nanoindentation (N=14) were sectioned bucco-lingually (Fig. 1(a)), equidistant from the buccal and lingual aspects. Microindentation testing was performed on the remaining teeth (N=20); ten of these teeth were sectioned bucco-lingually as described earlier. For the remaining ten teeth, secondary sections were made from initial bucco-lingual sections to extract beams from beneath the cusps (Fig. 1(b)). The beams were mounted in the epoxy resin with the prisms oriented nominally perpendicular to the polished surface.

Figure 1. Schematic diagrams of the specimen configurations and regions of evaluation.

a) a molar sectioned bucco-lingually and the regions of evaluation for the nanoindentation and microindentation testing. Nanoindentation was performed along paths defined parallel to the prism orientation in the cuspal region as defined by the line with arrow (left side). Indentations were made from the DEJ to the occlusal surface at 9 equidistant sites along this line.

Microindentation was performed in the inner, middle and outer enamel to evaluate indentation load dependence on the hardness (right side).

b) specimens used for estimating the apparent fracture toughness using the microindentation approach. The cuspal beams were mounted in cold-cure epoxy such that the occlusal surface faced outward and the enamel prisms were oriented perpendicular to the potting surface.

Nanoindentation was performed using an automated test system (*Triboindenter, Hysitron Inc., Mineapolis, MN) with a Berkovich diamond indenter and 50 nm tip radius. A load/hold/unload procedure was used with a rate of loading and unloading of 1 mN/sec, and a maximum applied load of 5 mN for 5 seconds. The surfaces were hydrated with HBSS during testing. By virtue of the sectioning process, the indentations were nominally perpendicular to the enamel prism axes. The hardness and elastic modulus were evaluated as a function of distance from the DEJ beneath the buccal and lingual cusps. Each path of evaluation (Fig. 1(a)) was defined parallel to the nominal prism orientation from the DEJ to the occlusal surface. Indents were introduced at 9 different equidistant sites along these paths with the first site located approximately 20 µm from the DEJ, and the last site within 50 µm of the occlusal surface. At each of the 9 sites, four indents were introduced on a square array and 20 µm center-to-center distance, resulting in a total of 72 indents in each tooth (2 paths × 9 sites × 4 indents/site). Both properties were evaluated using the traditional approaches [21]. Briefly, the hardness (H) was determined from the ratio of applied load and indentation surface area, and the “reduced” elastic modulus (E) was calculated using the stiffness of the unloading portion of the indent routine.

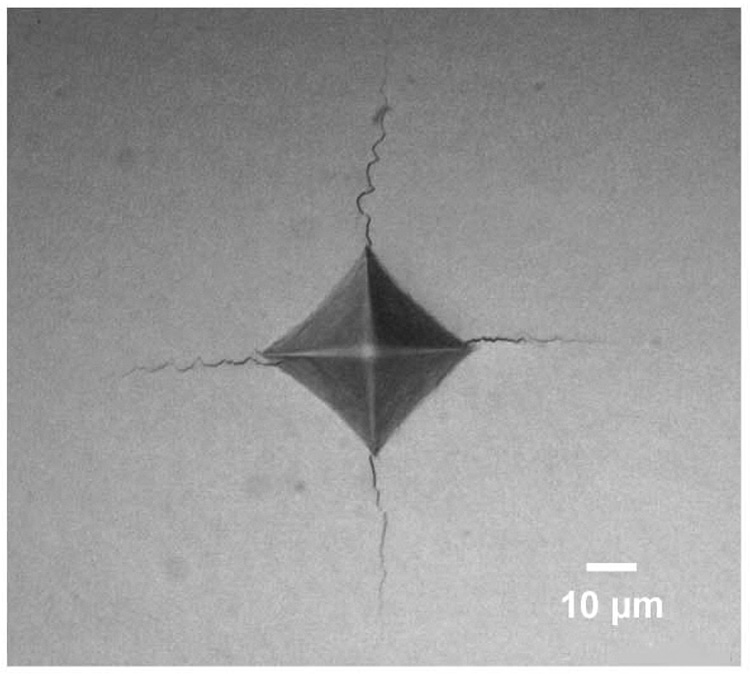

Microindentation was performed using a semi-automated test system (*Leitz Miniload II Microhardness Tester, Ernst Leitz, Wetzlar, Germany) with Vickers diamond indenter. The specimens were hydrated routinely with HBSS during testing. In the 10 teeth sectioned bucco-lingually, indentations were made at a distance no more than 100 µm from the DEJ (inner enamel), midway between the DEJ and occlusal surface (middle enamel) and at a distance no more than 100 µm from the occlusal surface (outer enamel) as shown in Figure 1(a). Within each region 10 indents were made at each load of 0.1, 0.25, 0.5, 1.0, 2.0, 3.0 and 5.0 N. The Vicker’s hardness (HV) was estimated from the indent diagonals in accordance with the ASTM standard C1327 [22] by the indent load divided by the contact area. The hardness distribution was plotted in terms of indentation load to identify the transition point hardness (HVc).

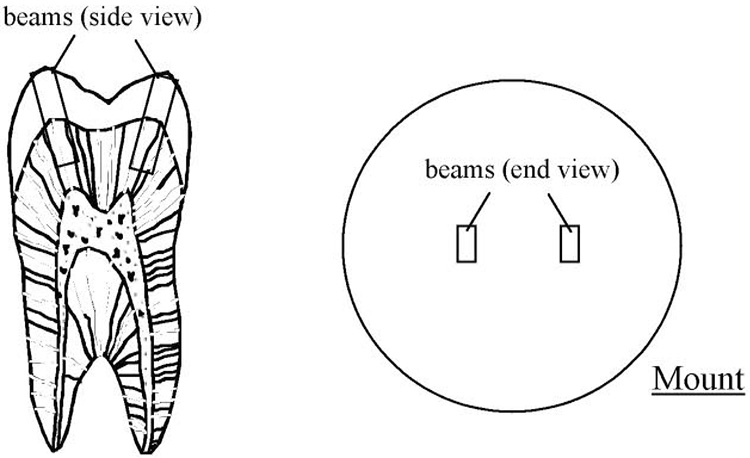

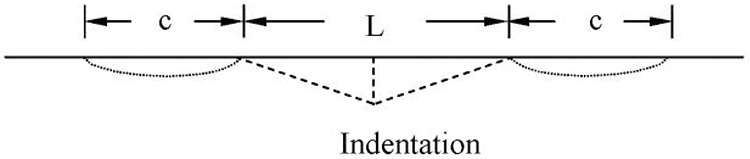

The excised beams of enamel mounted in epoxy (Fig. 1(b)) were used in evaluating the apparent fracture toughness (Kc(app)) using the indentation crack length approach. Briefly, 5 indents were made on the polished surface using a 3 N load, which exceeded the critical load corresponding to the transition point hardness. The diagonal lengths and average crack lengths emanating from the indentation corners (Fig. 2(a)) were measured for each indentation. Then, the surface was polished to remove approximately 200 µm of material and the indentation process was repeated. Sequential polishing and measurement was continued until reaching the DEJ. A complementary subsurface evaluation of the crack configuration beneath the indented surface distinguished that the cracks exhibited a Palmqvist configuration (Fig. 2(b)). Therefore, the apparent fracture toughness (Kc(app)) was estimated for each indentation according to [23]

| (2) |

where E and HVc are the elastic modulus and the transition point hardness, respectively, and P, L and c are the indentation load (kg), average diagonal length (m) and crack length (m), respectively. The crack length was measured from the tip of the indentation diagonal to the end of the crack tip (Fig. 2(b)). Note that Eqn. 2 is for Palmqvist cracks [11, 23], with ratio of crack length to indent diagonal of 0.125≤c/L≤1.25 [23], which were consistent with the crack system and sizes examined. The values computed using Eqn. 2 are regarded herein as the “apparent” fracture toughness in recognition of concerns raised in using indentation methods to estimate the fracture toughness of materials [24]. Indentation tests are occasionally used for estimating the fracture toughness of materials, particularly when the volume of material available precludes the use of standardized methods of evaluation. There are concerns associated with this approach for estimating fracture toughness and as such the results are often termed the indentation fracture resistance (IFR) rather than fracture toughness. Details pertaining to indentation fracture testing and the corresponding complications are summarized in Reference 24.

Figure 2. Indentation of enamel and the development of cracks at the indentation corners.

a) a typical indentation in young enamel. The enamel is from a 21 year old female patient and the indentation in this figure was obtained midway between the DEJ and occlusal surface.

b) the Palmqvist crack configuration from a side view of a Vickers indentation. The indentation diagonal (L) and crack lengths emanating from the indentation corners (c) are highlighted for clarity.

The aforementioned properties (E, HVc, and Kc(app)) were used to estimate the brittleness of the enamel from the DEJ to the occlusal surface according to Eqn. 1. Brittleness numbers for the dental materials were also estimated according to Eqn. 1 and the properties required for these estimates were obtained in a previous investigation [18]. Mechanical properties of the enamel (E, H, Kc(app) and the brittleness) were evaluated as a function of normalized distance from the DEJ. Normalization was achieved by dividing the distance from the DEJ by the total distance from the DEJ to the enamel surface along that path of evaluation [25]. The normalization allowed the property distributions to be described over a distance from 0 to 1, regardless of differences in the enamel thickness. Comparisons of the mechanical properties were conducted using a t-test with unpaired samples or an analysis of variance and significance was defined as p≤0.05.

RESULTS

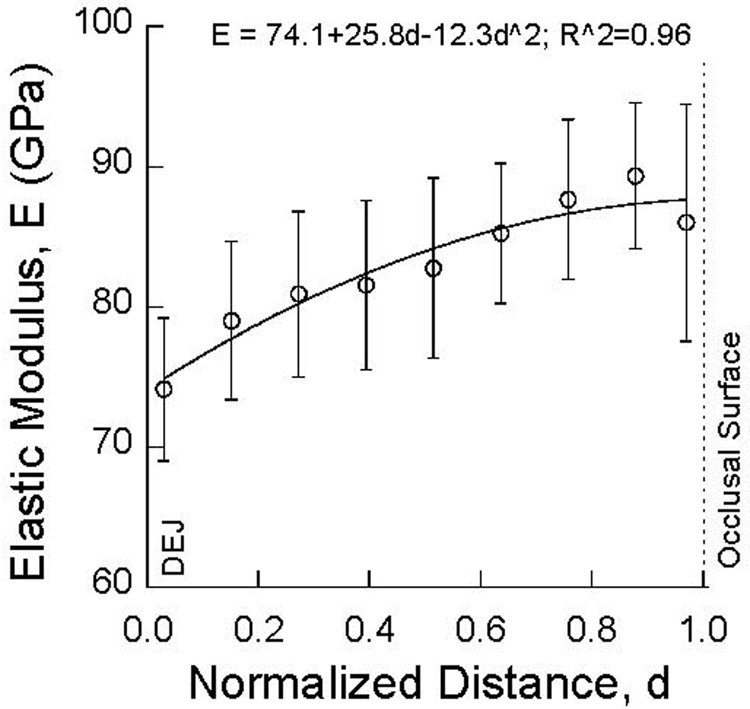

The distribution in hardness and elastic modulus of the young enamel is shown in terms of the normalized distance from the DEJ in Figure 3(a) and Figure 3(b), respectively. There is an increase in both properties with distance from the DEJ, except at the occlusal surface. Average values for the elastic modulus within the inner, middle and outer regions (Fig. 1(a)) are listed in Table 1. For the old enamel, both the hardness and elastic modulus increased continuously with distance from the DEJ to the occlusal surface. The average elastic modulus increased from approximately 80 GPa at the DEJ to 100 GPa at the occlusal surface. Similarly, the hardness increased from 3.5 GPa to 4.8 GPa. Results obtained for the elastic modulus of the old enamel within the three distinct regions of evaluation are listed in Table 1. At the occlusal surface, both the elastic modulus (p<0.001) and hardness (p<0.01) of the old enamel were significantly greater than the corresponding properties of the young enamel.

Figure 3. Property distributions of the young cuspal enamel determined using nanoindentation. The normalized distance ranges from 0 (at the DEJ) to 1 (at the occlusal surface).

a) elastic modulus

b) hardness

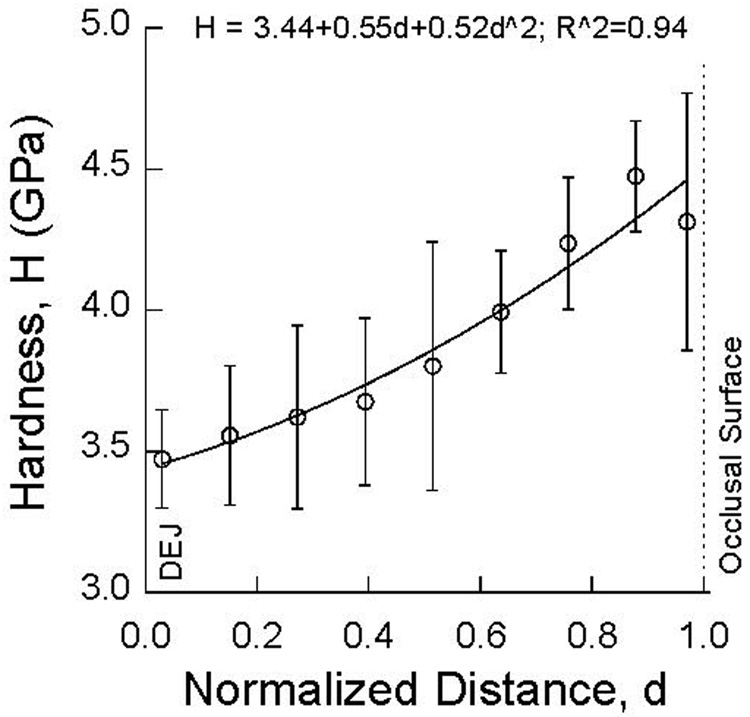

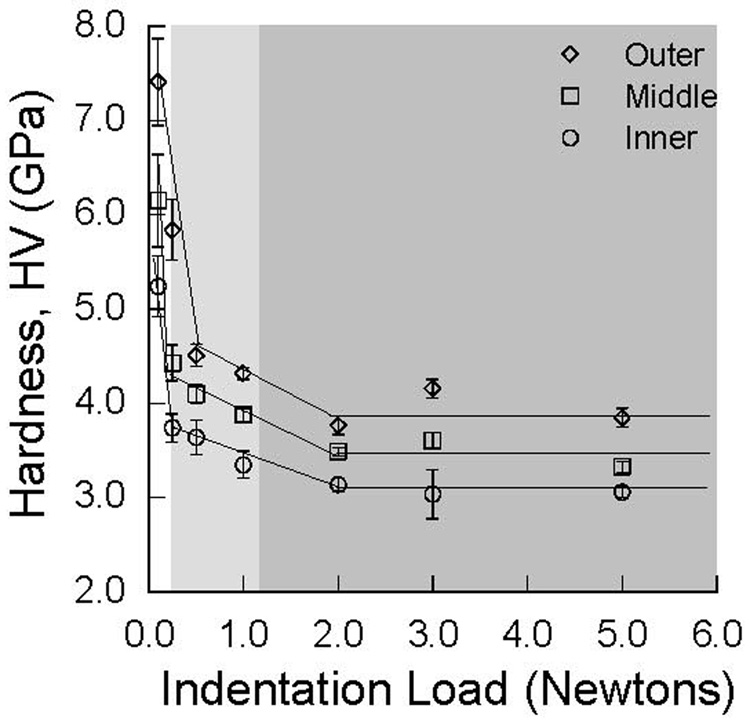

The Vickers hardness of the inner, middle and outer enamel of a selected molar are plotted in terms of the indentation load in Figure 4(a). Consistent with results of nanoindentation testing, the hardness increased from the inner to the middle enamel, and then to the occlusal surface. There is a 50% reduction in the hardness from loads of 0.1 to 5 N and a prominent indentation size effect in the responses. All three regions exhibited a transition in hardness to a constant value (HVc) that was essentially load independent beyond an indentation load of approximately 2 N. Microcracks were evident along the indentation periphery for loads between 0.25 and 1 N, whereas distinct cracks developed at the indentation corners at loads greater than 1 N. While difficult to compare objectively, the degree of microcracking appeared to be most extensive in the occlusal region of both age groups, and particularly in the old enamel. The indentation damage findings are overlaid with the measured hardness in Figure 4(a) and convey that the reduction in hardness is associated with the development of microcracking. The transition point hardness was accompanied by peripheral cracks concentrated at the indentation corners. Regardless of age, the inner and outer enamel possessed the smallest and largest transition point hardness, respectively (Fig. 4(a)). Though the HVc of the inner, middle and outer regions were significantly different (p<0.01), there was no significant difference in the values from corresponding regions between the young and old enamel. An equivalent hardness distribution for a fined grained incisal Leucite porcelain veneer is plotted in Figure 4(b). This material also exhibited indentation size effects with higher hardness at low loads and transition hardness (HVc) beyond a load of 2 N. An overlay of the damage analysis revealed that the transition point hardness is associated with the development of cracks at the indentation corners; microcracking was not observed at lower loads. The transition point hardness of the enamel and dental materials are listed in Table 1.

Figure 4. Indentation size effect diagrams for enamel and a selected crown material.

a) human enamel (patient age = 23). The highlighted region indicates the load range in which microcracks (light grey) were evident at the indentation periphery and well-defined cracks (grey) were evident at the indentation corners.

b) porcelain veneer on an alumina foundation. The highlighted region indicates the load range in which well-defined cracks were evident at the indentation corners. There was no evidence of microcracking at smaller loads.

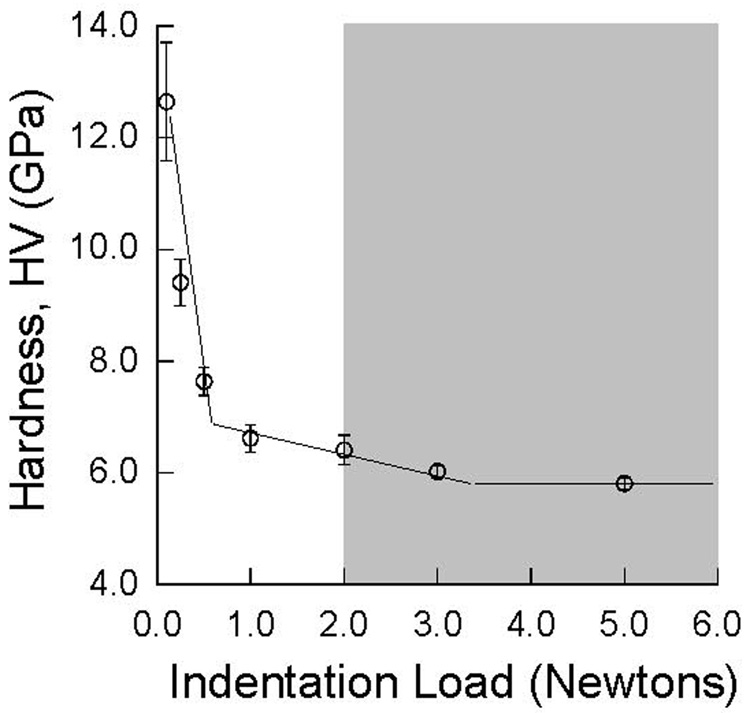

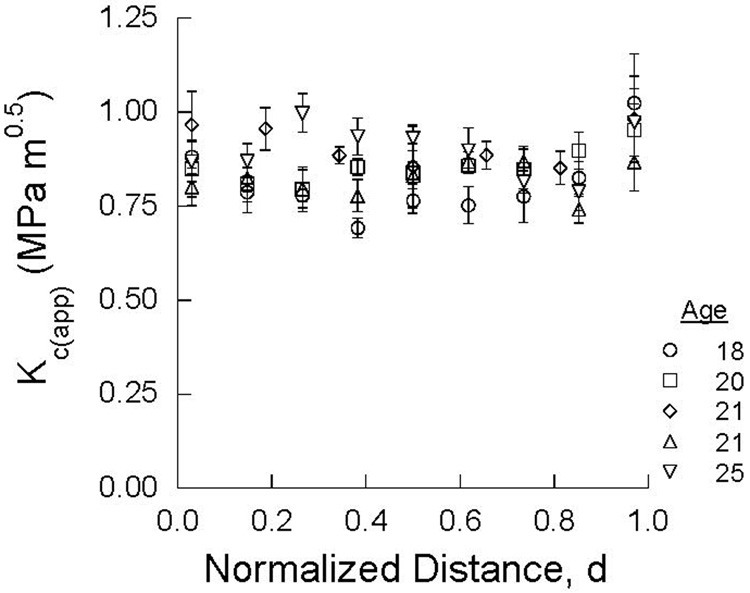

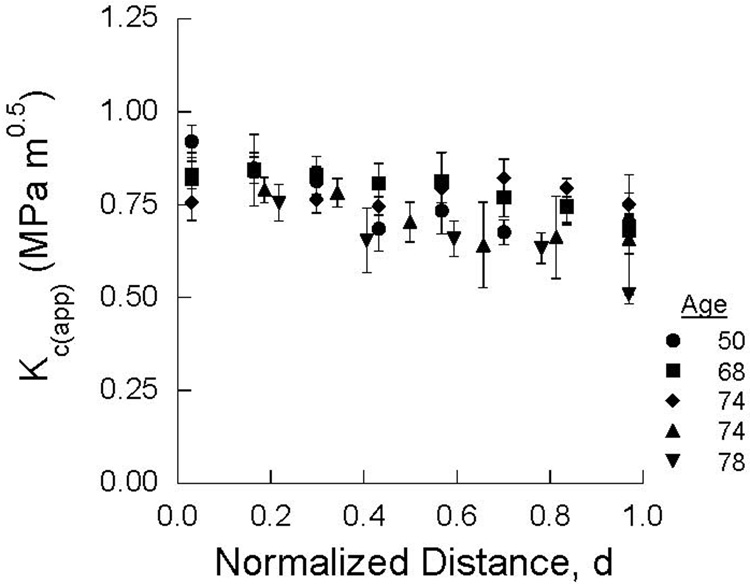

The distribution in apparent fracture toughness of the young and old cuspal enamel are plotted in terms of normalized distance from the DEJ in Figure 5(a) and Figure 5(b), respectively. There was no distinct trend in Kc(app) of the young enamel with distance from the DEJ (Fig. 5(a)); the average Kc(app) was 0.83 ±0.09 MPa•m0.5. In contrast, there was a decrease in the average Kc(app) of the old enamel from the DEJ (0.88 MPa•m0.5) to the occlusal surface (0.67 MPa•m0.5) as evident in Figure 5(b). Average results obtained for the young and old enamel within the three distinct regions of comparison are listed in Table 1. The difference in Kc(app) between the two age groups was significant at the occlusal surface (p< 0.001), but not in the other two regions

Figure 5. The apparent fracture toughness distribution of the enamel obtained using microindentations.

a) young

b) old

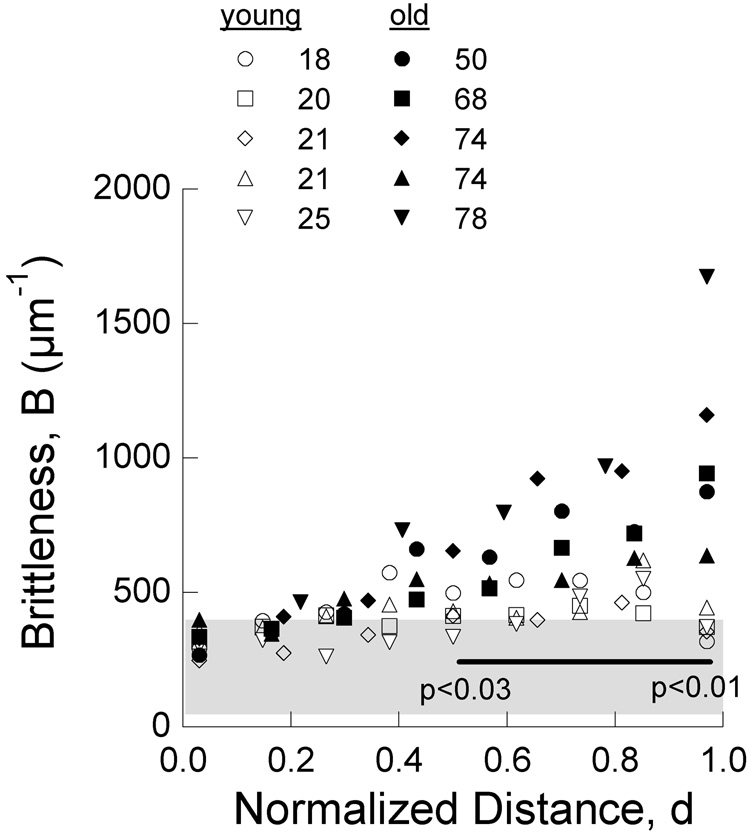

The brittleness of the enamel was estimated according to Eqn. 1 using the elastic modulus from nanoindentation testing (Fig. 3(a) and Table 1) and the HVc and Kc(app) estimated using results from the Vicker’s testing (Table 1). Average values for the young and old enamel within the three regions of evaluation are listed in Table 1 along with brittleness numbers for the dental materials. There is an increase in the brittleness from the DEJ towards the occlusal surface irrespective of patient age. However, the average brittleness of the old enamel is over 100 % greater than that of the young enamel at the occlusal surface; this difference is significant (p<0.02). In general, the brittleness of the dental materials was lower than that of the young enamel, except for the Leucite Empress and Finesse and the glass-infused alumina. The feldspathic porcelains exhibited the highest brittleness of the dental materials with values ranging from approximately 200 to 400 µm−1. According to the brittleness index, enamel is the most brittle material of those studied and the disparity in brittleness between the enamel and restorative materials increases with patient age.

Though the brittleness of enamel is dependent on age and location (Table 1), the values obtained within the inner, middle and outer regions do not clearly describe the spatial dependence. A more cohesive description of brittleness over the enamel thickness can be achieved by using the spatial hardness distributions of the enamel obtained using nanoindentation (Fig. 3(b)). But nanoindentation and microindentation measures of hardness are not the same. Hardness obtained using nanoindentation is determined by the indentation load divided by the contact area under load, thereby accounting for both elastic and inelastic deformation. Hardness obtained using microindentation is determined by the indentation load divided by the contact area after load removal, which accounts for inelastic deformation only due to elastic recovery of the indent. Nanoindentation and microindentation hardness measurements would be expected to exhibit close agreement in conditions where elastic recovery is small (and specifically when the elastic energy is dissipated by fracture in measures of HVc). Note that within the 3 specific regions the hardness (H) obtained using nanoindentation (Fig. 3(b)) and the HVc obtained using Vickers indentations are within 10% of each other. Therefore, replacing the transition point hardness (HVc) with the hardness distribution obtained from nanoindentation, the brittleness distribution was estimated using Eqn. 1 for both the young and old enamel; the distribution is shown as a function of normalized distance from the DEJ in Figure 6. When compared to the young enamel, there is a marked increase in brittleness of the old enamel with distance from the DEJ, as well as a larger degree of variation in the brittleness numbers. The old enamel is significantly more brittle than the young tissue and particularly near the occlusal surface.

Figure 6. Brittleness distribution for the young and old enamel.

The brittleness numbers in this figure were calculated according to Eqn. 1 using the H and E distributions obtained using nanoindentation (Fig. 3) and the Kc(app) distribution obtained using microindentation (Fig. 5). The region highlighted in gray represents the range in brittleness numbers obtained for the dental materials listed in Table 1. *The line denotes significant difference over the range in normalized distance covered. The p-value increases from left to right.

DISCUSSION

Hardness is commonly used to assess the physical behavior of enamel, particularly in studies aimed at quantifying the effects of clinical treatments on its mechanical behavior (e.g. [26–30]). Evaluations conducted using microindentation tests generally employ a single load of between 0.25 and 10 N. Only a single investigation has considered the potential for load dependence in the tissue’s response [31]. Furthermore, no prior study has distinguished the indentation size effects in enamel and the mechanistic contributions to the mechanical behavior of this tissue. Results from the microindentation testing of enamel showed that the Vickers hardness was dependent on the indentation load and that the material response was load dependent. Indents made with loads of 0.5 N and larger had microcracks that developed along the periphery. Those indents made with loads larger than 2 N were accompanied by the development of well-defined cracks at the indentation corners (e.g. Fig. 2(a)). Therefore, the reduction in hardness of enamel with increasing load (Fig. 4(a)) distinguishes that there is a change in the mechanistic response to concentrated contact loads. These results emphasize that human enamel does not exhibit a single hardness (for loads less than 2 N) and that reported measurements can reflect contributions from two different components of material behavior. Specifically, at indentation loads less than 0.5 N, the measurement reflects enamel’s ability to resist permanent deformation in the classical sense (i.e. through quasi-ductile dissipative mechanisms). At indentation loads equal to 2 N and larger, hardness measurements largely represent the tissue’s resistance to indentation damage through the generation of new surface area (i.e. brittle fracture). Hardness measures conducted between the aforementioned load range (0.5<P<2 N) are influenced by a combination of dissipative processes comprising deformation and fracture. Therefore, it is essential to choose an indentation load in examining the hardness of enamel such that the measured values reflect the component of physical response of greatest interest.

Substantial efforts have been invested in the development of dental restorative materials for replacement of enamel. Though hardness measurements are used to interpret the resistance to contact damage and/or wear, they have limitations in describing the mechanical behavior of dental materials if not examined correctly. For example, the measured hardness is subject to indentation size effects as shown for the feldspathic porcelain (Fig. 4(b)). There is some obvious merit to the brittleness index in application to dental materials. Brittleness numbers for the dissimilar ceramics (Table 1) underscore the qualitative differences between the brittle alumina and the tough zirconia that has been observed in Hertzian contact studies [19]. For the MGCs, the brittleness numbers range from approximately 50 to 300 and increase with a reduction in mica platelet (grain) size. Previous studies on the contact damage resistance of MGCs [20] have shown that coarse grain structures undergo substantial quasi-plastic deformation under Hertzian contact and thereby suppress the development of detrimental cone-cracks. Finer grain MGCs undergo a much greater degree of brittle contact damage [20] and the traditional properties (E, HV or Kc(app)) do not clearly delineate this behavior on an individual basis. The brittleness numbers for the MGCs in Table 1 clearly distinguish the increase in brittleness with decreasing grain size. However, despite their low brittleness, MGCs with coarse grains have lower damage resistance under dynamic fatigue [32]. Thus, the brittleness index should be useful in future evaluations of dental restorative materials, but the clinical performance may not necessarily be optimized by microstructures with minimum brittleness numbers.

In comparing properties of the materials in Table 1, the high brittleness numbers of old enamel result from its comparatively low fracture toughness. Results for Kc(app) (Fig. 5(a)) fall well within the range of values reported in the literature. The Kc(app) for young enamel in Table 1 is within 20% of that reported by Xu et al. [3] (for 3rd molars) and Caputo et al. [8] (for a manidibular molar). Both of the aforementioned groups reported values that were lower than those determined in the present study, which would result in higher brittleness estimates than those presented in Table 1 and Figure 6. The latter group found that the apparent fracture toughness of enamel was dependent on the tooth type and the specific location evaluated. Also, differences in Kc(app) between these studies are not unexpected due to the experimental difficulties and limitations of the indentation fracture test [24]. Despite the minor differences in Kc(app) reported, enamel is the most brittle material of those evaluated in this investigation. And as the disparity in brittleness between enamel and the dental materials increases with patient age, the enamel of seniors is potentially the most brittle material in the oral environment. The comparatively high brittleness numbers of the old enamel indicates that it becomes more likely to dissipate strain energy via fracture. These results forecast the potential problems that may arise in cyclic contact between enamel and dental materials in the teeth of senior patients. Studies have not been performed to determine whether the brittleness index correlates with a materials scratch and/or wear resistance. As such, the higher brittleness numbers for the old enamel cannot necessarily be used to indicate that it is more likely to fail through any one of the aforementioned modes without additional evidence. Further study should address these relationships.

Brittleness numbers for the old enamel were significantly greater than those of the young enamel near the occlusal surface. There are two relevant age-related processes that may contribute to the observed differences. Specifically, there is a reduction in the proteinaceous matrix residing along the prism boundaries as a result of natural maturation and oral conditions that lower the oral pH [33]. In turn, prolonged exposure to mineral ions and fluoride within the oral environment can promote replacement of the organic material with fluoro-apatities [34]. White et al [9] postulated that the enamel possesses larger fracture toughness than hydroxyapatite due to the unique mechanisms of toughening enabled by the organic matrix. Indeed, the apparent fracture toughness of the old enamel was found to be significantly lower than that of the young enamel at the occlusal surface (Table 1). Therefore, the larger brittleness of the old enamel is expected to result from a reduction in the interprismatic organic matrix and an increase in mineral content, both of which would reduce the resistance to cracking and brittle fracture. In contrast to old enamel, the brittleness of young enamel exhibited an acute decrease at the occlusal surface (Fig. 6). The response is attributed in part to a reduction in both the elastic modulus and hardness (Fig. 3) and an increase in apparent fracture toughness at the occlusal surface (Fig. 5(a)). This response was unexpected and may be associated with differences between the near-occlusal chemistry and that of deeper enamel that results from mechanisms of diffusion. An evaluation of the structural and chemical factors that are responsible for the observed trends in mechanical behavior is currently underway.

Importance of the interprismatic organic matrix on the mechanical behavior of enamel has received recent attention. In evaluations of the stress-strain characteristics and creep responses it was reported that the enamel behaved more like a metal than a ceramic [35] and that the protein content of the organic interprismatic enamel is the essential medium bestowing enamel with damage tolerance. A related study [36] showed that the time-dependent behavior of enamel is lost when heated to temperatures that cause irreversible damage to the organic matrix. Even under the small contact forces associated with nanoindentation, enamel undergoes irreversible deformation and the energy absorbed is largely a function of the interprismatic contributions [37, 38]. In light of these studies, the brittleness of the old enamel is believed to be greater than that of the young enamel due to changes in the material’s capacity to undergo deformation and propensity for fracture. Specifically, the microstructural changes cause a reduction in the energy dissipation by inelastic deformation and an increase in that via cracking and fracture. Overall these results highlight that the interprismatic protein matrix may be more important to the initiation of cracks and brittle fracture of enamel than its contribution to elastic or inelastic deformation.

CONCLUSIONS

The brittleness of human enamel and common crown replacement materials was estimated. According to results of the evaluation the following conclusions were drawn:

The hardness of enamel is a function of the indentation load and exhibits indentation size effects. There is a decrease in hardness of enamel with increasing load, which results from an increase in energy dissipation through the development of cracks and brittle fracture

The average brittleness of the young enamel increased from 300 µm−1 at the DEJ to 400 µm−1 at the occlusal surface. The average brittleness of the old enamel increased from 310 µm−1 at the DEJ to nearly 900 µm−1 at the occlusal surface. At the DEJ there was no significant difference in brittleness between the young and old enamel. However, at the occlusal surface the brittleness of the old enamel was significantly greater (p<0.02) and between 2 to 4 times larger than that of young enamel.

The porcelain, ceramic and micaceous glass ceramic restorative materials exhibited a brittleness of between 50 and 400 µm−1. Their comparatively low brittleness suggests that contact loading of the restoratives is more likely to promote either elastic or inelastic deformation than fracture, in comparison to enamel.

The enamel was the most brittle material of all those evaluated in this investigation and its brittleness increased with patient age. The brittleness index could serve as a useful scale in the design of materials used for crown replacement, as well as a quantitative tool for characterizing degradation in the mechanical behavior of enamel.

ACKNOWLEDGEMENTS

The authors acknowledge support for the investigation was received from the National Science Foundation (BES 0521467) and the National Institutes of Health (R01-DE17983). The authors are grateful to George D. Quinn at the Ceramics Division of NIST for many valuable discussions.

Support for the following investigation was provided by the National Science Foundation (Award #: BES0521467) and the NIH (R01-DE17983)

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

Commercial products and equipment are identified only to specify adequately experimental procedures and does not imply endorsement by the authors, institutions or organizations supporting this work.

REFERENCES

- 1.Willems G, Celis JP, Lambrechts P, Braem M, Vanherle G. Hardness and Young's modulus determined by nanoindentation technique of filler particles of dental restorative materials compared with human enamel. J Biomed Mater Res. 1993;27(6):747–755. doi: 10.1002/jbm.820270607. [DOI] [PubMed] [Google Scholar]

- 2.Meredith N, Sherriff M, Setchell DJ, Swanson SA. Measurement of the microhardness and Young's modulus of human enamel and dentine using an indentation technique. Arch Oral Biol. 1996;41(6):539–545. doi: 10.1016/0003-9969(96)00020-9. [DOI] [PubMed] [Google Scholar]

- 3.Xu HH, Smith DT, Jahanmir S, Romberg E, Kelly JR, Thompson VP, Rekow ED. Indentation damage and mechanical properties of human enamel and dentin. J Dent Res. 1998;77(3):472–480. doi: 10.1177/00220345980770030601. [DOI] [PubMed] [Google Scholar]

- 4.Habelitz S, Marshall SJ, Marshall GW, Jr, Balooch M. Mechanical properties of human dental enamel on the nanometre scale. Arch Oral Biol. 2001;46(2):173–183. doi: 10.1016/s0003-9969(00)00089-3. [DOI] [PubMed] [Google Scholar]

- 5.Mann AB, Dickinson ME. Nanomechanics, chemistry and structure at the enamel surface. Monogr Oral Sci. 2006;19:105–131. doi: 10.1159/000090588. [DOI] [PubMed] [Google Scholar]

- 6.Staines M, Robinson WH, Hood JAA. Spherical indentation of tooth enamel. J Mat Sci. 1981;16(9):2551–2556. [Google Scholar]

- 7.Balooch G, Marshall GW, Marshall SJ, Warren OL, Asif SA, Balooch M. Evaluation of a new modulus mapping technique to investigate microstructural features of human teeth. J Biomech. 2004;37(8):1223–1232. doi: 10.1016/j.jbiomech.2003.12.012. [DOI] [PubMed] [Google Scholar]

- 8.Hassan R, Caputo AA, Bunshah RF. Fracture toughness of human enamel. J Dent Res. 1981;60(4):820–827. doi: 10.1177/00220345810600040901. [DOI] [PubMed] [Google Scholar]

- 9.White SN, Luo W, Paine ML, Fong H, Sarikaya M, Snead ML. Biological organization of hydroxyapatite crystallites into a fibrous continuum toughens and controls anisotropy in human enamel. J Dent Res. 2001;80(1):321–326. doi: 10.1177/00220345010800010501. [DOI] [PubMed] [Google Scholar]

- 10.Rizkalla AS, Jones DW. Indentation fracture toughness and dynamic elastic moduli for commercial feldspathic dental porcelain materials. Dent Mat. 2004;20(2):198–206. doi: 10.1016/s0109-5641(03)00092-7. [DOI] [PubMed] [Google Scholar]

- 11.Sakar-Deliormanli A, Guden M. Microhardness and fracture toughness of dental materials by indentation method. J Biomed Mater Res: Appl Biomat. 2006;76(2):257–264. doi: 10.1002/jbm.b.30371. [DOI] [PubMed] [Google Scholar]

- 12.Ge J, Cui FZ, Wang XM, Feng HL. Property variations in the prism and the organic sheath within enamel by nanoindentation. Biomaterials. 2005;26(16):3333–3339. doi: 10.1016/j.biomaterials.2004.07.059. [DOI] [PubMed] [Google Scholar]

- 13.Cuy JL, Mann AB, Livi KJ, Teaford MF, Weihs TP. Nanoindentation mapping of the mechanical properties of human molar tooth enamel. Arch Oral Biol. 2002;47(4):281–291. doi: 10.1016/s0003-9969(02)00006-7. [DOI] [PubMed] [Google Scholar]

- 14.Kodaka T, Debari K, Yamada M, Kuroiwa M. Correlation between microhardness and mineral content in sound human enamel (short communication) Caries Res. 1992;26(2):139–141. doi: 10.1159/000261498. [DOI] [PubMed] [Google Scholar]

- 15.Quinn JB, Quinn GD. Indentation brittleness of ceramics: a fresh approach. J Mat Sci. 1997;32(16):4331–4346. [Google Scholar]

- 16.Quinn JB, Quinn GD. On the hardness and brittleness of ceramics. Key Engr. Mat. 1997:132–136. 460–463. [Google Scholar]

- 17.Habelitz S, Marshall GW, Jr, Balooch M, Marshall SJ. Nanoindentation and storage of teeth. J Biomech. 2002;35(7):995–998. doi: 10.1016/s0021-9290(02)00039-8. [DOI] [PubMed] [Google Scholar]

- 18.Quinn JB, Sundar V, Lloyd IK. Influence of microstructure and chemistry on the fracture toughness of dental ceramics. Dent Mat. 2003;19:603–611. doi: 10.1016/s0109-5641(03)00002-2. [DOI] [PubMed] [Google Scholar]

- 19.Peterson IM, Pajares A, Lawn BR, Thompson VP, Rekow ED. Mechanical characterization of dental ceramics by hertzian contacts. J Dent Res. 1998;77(4):589–602. doi: 10.1177/00220345980770041201. [DOI] [PubMed] [Google Scholar]

- 20.Peterson IM, Wuttiphan S, Lawn BR, Chyung K. Role of microstructure on contact damage and strength degradation of micaceous glass-ceramics. Dent Mat. 1998;14(1):80–89. doi: 10.1016/s0109-5641(98)00013-x. [DOI] [PubMed] [Google Scholar]

- 21.Oliver WC, Pharr GM. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res. 1992;7(6):1564–1583. [Google Scholar]

- 22.Standard Test Method for Vickers Indentation Hardness of Advanced Ceramics. ASTM C 1327-96a. West Conshohocken, Pennsylvania: ASTM; [Google Scholar]

- 23.Niihara K, Morena R, Hasselman DPH. Evaluation of KIC of brittle solids by the indentation method with low crack to indent ratios. J Mater Sci Lett. 1982;1:13–16. [Google Scholar]

- 24.Quinn GD, Bradt RC. On the Vickers indentation fracture toughness test. J Am Ceram Soc. 2007;90(3):673–680. [Google Scholar]

- 25.Park S, Wang DH, Zhang D, Romberg E, Arola D. J. Mat Sci: Mater Med. Mechanical properties of human enamel as a function of age and location in the tooth. (in press) [DOI] [PubMed] [Google Scholar]

- 26.Seghi RR, Denry I. Effects of external bleaching on indentation and abrasion characteristics of human enamel in vitro. J Dent Res. 1992;71(6):1340–1344. doi: 10.1177/00220345920710061201. [DOI] [PubMed] [Google Scholar]

- 27.Attin T, Müller T, Patyk A, Lennon AM. Influence of different bleaching systems on fracture toughness and hardness of enamel. Oper Dent. 2004;29(2):188–195. [PubMed] [Google Scholar]

- 28.Rodrigues JA, Marchi GM, Ambrosano GM, Heymann HO, Pimenta LA. Microhardness evaluation of in situ vital bleaching on human dental enamel using a novel study design. Dent Mat. 2005;21(11):1059–1067. doi: 10.1016/j.dental.2005.03.011. [DOI] [PubMed] [Google Scholar]

- 29.Zantner C, Beheim-Schwarzbach N, Neumann K, Kielbassa AM. Surface microhardness of enamel after different home bleaching procedures. Dent Mat. 2007;23(2):243–250. doi: 10.1016/j.dental.2006.06.044. [DOI] [PubMed] [Google Scholar]

- 30.Maia E, Baratieri LN, Andrada MA, Monteiro S, Jr, Vieira LC. The influence of two home-applied bleaching agents on enamel microhardness: An in situ study. J Dent. 2007 doi: 10.1016/j.jdent.2007.09.011. (in press) [DOI] [PubMed] [Google Scholar]

- 31.Collys K, Slop D, Cleymaet R, Coomans D, Michotte Y. Load dependency and reliability of microhardness measurements on acid-etched enamel surfaces. Dent Mat. 1992;8(5):332–335. doi: 10.1016/0109-5641(92)90110-x. [DOI] [PubMed] [Google Scholar]

- 32.Yio J-G, Lee KS, Lawn BR. Role of microstructure in dynamic fatigue of glass-ceramics after contact with spheres. J Am Ceram Soc. 2000;83(6):1545–1547. [Google Scholar]

- 33.Ten Cate AR. “Oral Histology: Development, Structure, and Function. 5th ed. Saint Louis: Mosby-Year Book; 1998. [Google Scholar]

- 34.Robinson C, Kirkham J, Brookes SJ, Shore RC. Chemistry of mature enamel. In: Robinson C, Kirkham J, Shore R, editors. Dental Enamel: Formation to Destruction. CRC Press; 1995. pp. 167–191. [Google Scholar]

- 35.He LH, Swain MV. Enamel - a "metallic-like" deformable biocomposite. J Dent. 2007;35(5):431–437. doi: 10.1016/j.jdent.2006.12.002. [DOI] [PubMed] [Google Scholar]

- 36.He LH, Swain MV. Influence of environment on the mechanical behaviour of mature human enamel. Biomaterials. 2007;28(30):4512–4520. doi: 10.1016/j.biomaterials.2007.06.020. [DOI] [PubMed] [Google Scholar]

- 37.He LH, Swain MV. Energy absorption characterization of human enamel using nanoindentation. J Biomed Mater Res A. 2007;81(2):484–492. doi: 10.1002/jbm.a.31051. [DOI] [PubMed] [Google Scholar]

- 38.He LH, Swain MV. Understanding the mechanical behavior of humand enamel from its structural and compositional characteristics. J Mech. Beh of Biomed Mater. 2008;1(1):18–29. doi: 10.1016/j.jmbbm.2007.05.001. [DOI] [PubMed] [Google Scholar]