Abstract

Background

Scratches on the metal bearing surface of metal-on-polyethylene total joint replacements have been found to appreciably accelerate abrasive/adhesive wear of polyethylene, and constitute a source of the considerable variability of wear rate seen within clinical cohorts. Scratch orientation with respect to the local direction of relative surface sliding is presumably a factor affecting instantaneous debris liberation during articulation.

Method of Approach

A three-dimensional local finite element model was developed of orientation-specific polyethylene articulation with a scratched metal counterface, to explore continuum-level stress/strain parameters potentially correlating with the orientation dependence of scratch wear in a corresponding physical experiment.

Results

Computed maximum stress values exceeded the yield strength of ultra-high molecular weight polyethylene (UHMWPE) for all scratch orientations, but did not vary appreciably among scratch orientations. Two continuum-level parameters judged most consistent overall with the direction dependence of experimental wear were: (1) cumulative compressive total normal strain in the direction of loading, and (2) maximum instantaneous compressive total normal strain transverse to the sliding direction.

Conclusions

Such stress/strain metrics could be useful in global computational models of wear acceleration, as surrogates to incorporate anisotropy of local metal surface roughening.

Keywords: wear, wear surrogate, scratch wear, scratch orientation, finite element analysis, arthroplasty, THA, TKA, polyethylene, UHMWPE

INTRODUCTION

Roughening of the metal counterface is responsible for substantial increase of wear rate in metal-on-polyethylene total joint replacements 1–4. This arguably is the cause of much of the variability in wear rates and wear directions seen among individual patients within study cohorts 5–7. Retrieved femoral heads often show scratch damage (burnishing) involving substantial fractions of the head surface area. Determination of a consistent and direct relationship between conventional tribologic mean surface roughness parameters (Ra, Rp, etc.) and ensuing implant wear has proven elusive 8–10. This has prompted several groups to study scratch patterns, toward a more definitive determinant of wear acceleration propensity 1,9,11. Scratches are widely regarded as resulting from 3rd body ingress into the bearing surface, the debris responsible being in forms such as bone mineral crystals, bone cement particles, radio-opacifier particles, porous coating particles, or metal frettings 8,9,12–14. It has been argued that even some 3rd body particles that are (moderately) softer than the counterface are capable of causing scratching 14.

Scratch-induced wear of polyethylene (conventional or crosslinked) in total hip arthroplasty (THA) is due to local material failure. It seems reasonable that the direction of scratches on the metal counterface, relative to the direction of local sliding of the opposing polyethylene, would have an effect on the amount of wear produced during articulation. Past research involving scratch wear has presumed that the greatest wear occurs with scratches oriented perpendicular (90º) to the direction of motion 15–22. Plausibly, however, more wear debris might well be liberated at a more acute attack angle, for example, from shearing-off of polyethylene by scratch lip asperities.

Recent developments in whole-joint computational wear simulation have proven helpful for understanding individual prosthesis design parameters 23, and for understanding the relative criticality of specific roughened regions in terms of accelerating wear 24. To date, however, such models have not addressed scratch directionality. Such anisotropic influence might be implemented at the global analysis level using appropriate continuum surrogates, given formal mappings of scratch topography. Toward that end, a local computational model was developed to phenomenologically survey which stress/strain tensorial component(s), or which metric(s) involving several such components, might show orientation dependence resembling that observed experimentally. Such surrogate(s) could be useful to account for scratch-direction-dependent wear acceleration in global computational models incorporating anisotropic surface damage.

MATERIALS AND METHODS

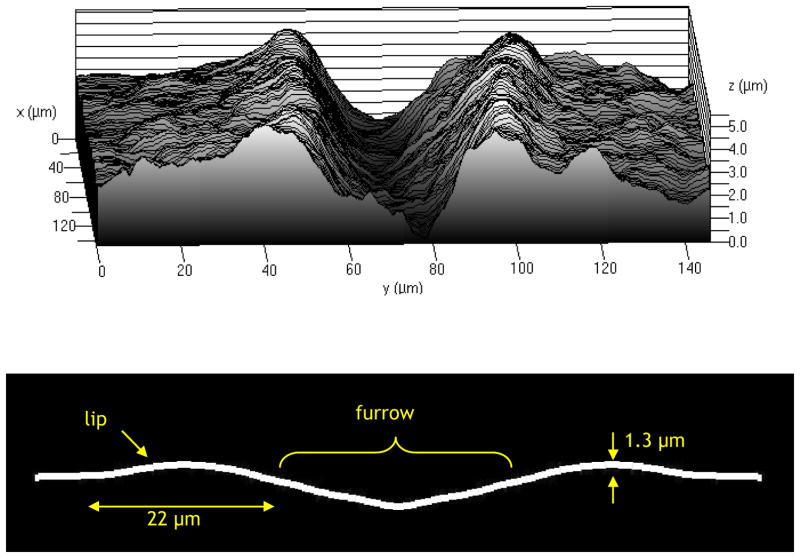

The physical experiment to which the (below-described) finite element model was matched involved reciprocal motions of arrays of 550 parallel scratches, diamond-scribed at 150-μm intervals on lapped (Ra < 100 nm) 316L stainless steel plates. These scratches had nominal lip heights, lip widths and furrow widths of 1.3, 22 and 23 μm, respectively (Figure 1). The width of inter-scratch spacing and the dimensions of the individual scratches (which resemble typical large scratches found on retrievals 15) were such as to produce a substantial volume of wear in a relatively short time. This severe degree of damage was not intended to directly replicate an in situ articular environment, but rather to generate sufficient wear to facilitate discrimination of the effect of scratch directionality.

Figure 1.

(Top) Laser scanning microscopy image of custom scratch profile created on 316L stainless steel. (Note the scale differences, which accentuate the scratch for visual emphasis.) (Bottom) Scratch profile (cross-section) employed as the counterface surface in the FE model.

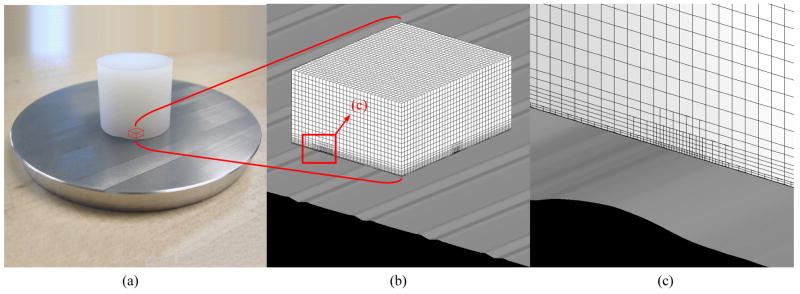

Using a Scotch yoke pin-on-plate fixture installed on a biaxial load frame, the scratched counterface plate was driven reciprocally against a simple flat-ended cylindrical 25.4 mm diameter polyethylene pin1 (Figure 2), while loaded axially by 1269 N (nominal stress = 2.5 MPa). Parametric tests were conducted, in which the plate was moved across the polyethylene pin at angles of 0, 2.5, 5, 10, 15, 20, 30, 45, 60, and 90º relative to the scratch orientation. This was done both for both conventional polyethylene (CPE, HSS Reference, 4150HP, Poly Hi Solidur, Ft. Wayne, IN 25) and for highly crosslinked polyethylene (HXPE, DePuy Marathon®2, Warsaw, IN). The contact surface was kept immersed in 100% fetal bovine serum (treated with 10 mM EDTA and 0.01% sodium azide to prevent microbial growth), with wear periodically assessed gravimetrically. Tests were run to 90,000 cycles at an average (sinusoidal) sliding speed of 72 mm/s, with steady-state behavior typically ensuing at about 60,000 cycles.

Figure 2.

(A) Pin-plate articulating couple used in polyethylene-stainless steel reciprocating wear tester. The parallel scratches on surface of the metal platen are spaced 150 μm apart. (B) The corresponding polyethylene continuum mesh (white) and analytical scratched stainless steel surface (gray) utilized in the finite element model. (C) Enlarged view illustrating the spatial refinement of the polyethylene mesh in the region used for data registry.

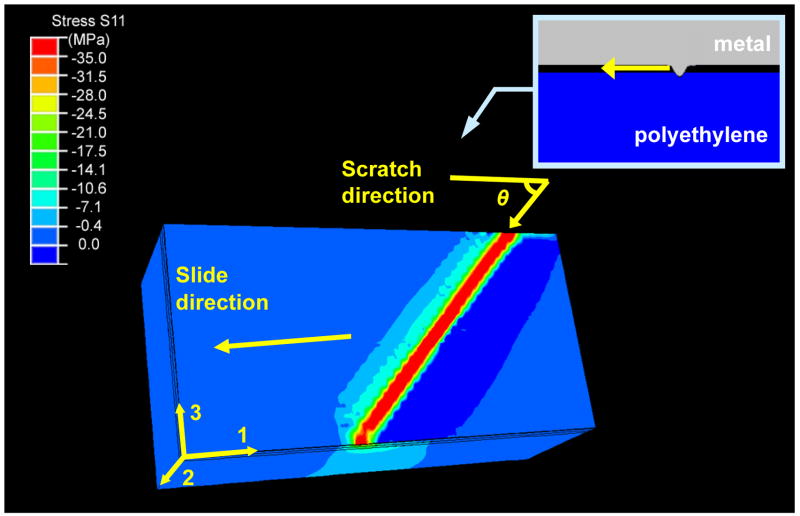

A three-dimensional local finite element model (Figures 2,3) of this experiment was developed, to explore continuum-level stress/strain parameters potentially correlating with the direction-dependent interaction observed experimentally. Scratch-angle-specific meshes were generated to replicate the orientations of scratch traverse in the physical wear experiment. A loaded scratch was driven under displacement control across the polyethylene surface (Figure 3), with stress/strain data being registered at fiducial elements on the surface throughout course of scratch approach, over-passage and recession.

Figure 3.

Contour plot of instantaneous longitudinal normal stress during passage of a scratch oriented at 45°. Note the edge effect near the sides of the block. Fiducial nodes for stress registry were therefore located along the block centerline.

Finite element geometries were defined and meshed using PATRAN (r3, MSC.Software Corporation, Santa Ana, CA). These were input to the ABAQUS solver (v 6.4-2, ABAQUS, Inc., Pawtucket, RI), and were post-processed using ABAQUS/Viewer. Additional post-processing was performed using scripts custom-written in MATLAB 6.5.1 (The Mathworks, Inc., Natick, MA).

Although a suitably refined local finite element model for the entire testing interface would have been intractable, the physical system’s periodicity allowed isolating a single scratch. This assumed, effectively, that the same local instantaneous stress-strain history would recur over and over at a given point on the polyethylene surface, due to large numbers of over-passages of identical scratches. A provisional assumption was made (subsequently verified computationally) that the inter-scratch-lip distance, scratch lip height, polyethylene material properties, and loading were such that contact occurred only on scratch lips, rather than also on the (flat) inter-scratch regions of the metal surface. Accordingly, the corresponding load per unit scratch lip length (185 N/m for the 1269 N loads used experimentally) was employed in the computational model. Since the polyethylene pin remained entirely within the scratched region of the plate, the total length of scratch lip “line contact” (6.8 m) remained constant throughout the duty cycle. A rectangular polyethylene solid of finite size and appropriate aspect ratio 26 was generated for each specific scratch orientation.

Topographic data from a representative scratch lip profile were captured using a laser scanning microscope (0.01 μm depth accuracy, 0.3 μm sampling resolution), and directly transferred to the finite element model (Figure 1). Both the polyethylene surface and inter-scratch areas of the metal plate were modeled as flat.

Constitutively, UHMWPE was modeled using a fourth-order relationship for tangent modulus E as a function of von Mises stress, as reported by Cripton 27. An h-convergence series run for a nominally corresponding Hertzian contact problem 26 established that 0.3334 μm was an appropriate dimension for the polyethylene elements. A rigid-on-deformable local contact condition was invoked, with a Coulombic friction coefficient of 0.038 28. The analysis was quasi-static and modeled nonlinear contact geometry. Boundary conditions specified for the respective faces of the polyethylene block were configured so as to have the block approximate an infinite half-space 26.

The provisionally assumed simplification of the counterface topography to a single scratch lip was justified using a 2-D plane strain finite element simulation of sliding contact 26, executed for nonlinear UHMWPE, under the full prescribed service load of 185 N/m. Under these conditions, stress field “disturbances” from neighboring scratches were effectively isolated from each other, as indeed even were those from the two scratch lips on opposing sides of a given scratch furrow. A reference node representing the rigid Bezier surface of the scratch lip was utilized to prescribe the kinematics of the scratch lip.

A metric was formulated to reflect cumulative mechanical stimulus to the polyethylene during an event of scratch approach, over-passage, and recession. Full tensorial stress and strain data were output for five fiducial elements located centrally on the polyethylene, at serial instants (typically, 50) throughout the slide event. The overall putative stimulus Φ delivered to a given site on the polyethylene during a scratch encounter was indexed as follows. Consider a plausibly physically consequential instantaneous surrogate wear parameter φ. For example, φ might be an individual component of stress or an individual component of strain, or a function derived from some combination thereof (e.g., strain energy density). For a quasi-static sliding event, the cumulative stimulus Φ (Equation 1) can be characterized in terms of the history integral of the instantaneous value of the candidate stimulus parameter, i.e.,

| (1) |

In the context of finite element analysis, where solutions are reported only at discrete times, and where (for tractability) the analysis is restricted only to the immediate “time neighborhood” of appreciable stress disturbance due to scratch encounter, the corresponding discretized expression (Equation (2)) is

| (2) |

Here, i0 is the first finite element solution increment for which supra-background stress ensues with oncoming scratch approach, imax is the last solution increment for which supra-background stress persists as the scratch recedes after over-passage, and Δti is the time increment between successive FEA solution reports.

The dimensional units of the kernel (φ) and the integrand (Φ ) varied, according to the specific composition of the candidate mechanical stimulus. To facilitate commonality of subsequent correlation comparisons of potential surrogates with experimentally observed volumetric wear rates (units of mm3/million cycles per mm2 of platen area, A, engaged), a dimensional compensation term γ was included in the surrogate computational volumetric wear (V̂) prediction expression, Equation (3).

| (3) |

For example, if the candidate kernel parameter φ was compressive normal stress σ22, the units of A *Φ would be mm2 (for A)* (for Φ), i.e. N ·sec, in which case γ would need to take units of . Thus, the units for each term in Equation (3) would be .

Four separate registry treatments were considered to implement the Φ summation. The first of these involved summing all incremental kernel values, without segregating by algebraic sense; that is, negative values were combined with positive values, thus admitting the possibility of partial cancellation. In the second treatment, absolute values of each incremental φ were summed. The third and fourth treatments involved summing only the positive and only the negative φ values, respectively. Additionally, four non-summation-based metrics of mechanical stimulus were considered: the maximum peak-to-valley excursion for each kernel parameter φ, and that kernel parameter’s algebraic maximum, algebraic minimum, and absolute maximum throughout the scratch passage event.

Wear correlations with plastic strains areas were also considered, prompted by the localized scratch finite element model reported by McNie et al. 29. For each scratch orientation, a predetermined set of centrally-located surface/subsurface fiducial elements were interrogated for plastic strains occurring above specific thresholds. The total cross-sectional area (in the plane of the axes of loading and motion) was summed for those elements experiencing supra-threshold strains at any instant during the scratch encounter. The maximum instantaneous area of plastic strain above these specific thresholds was registered, as were the areas for principal plastic strain and maximum plastic shear strain. Again, plastic strain area results were segregated by maximum positive and negative values of strain, respectively, maximum absolute magnitudes of strain, and by residual plastic strain. These plastic strain areas were tabulated for 20 different plastic strain thresholds, spanning two orders of magnitude (0, 0.0005, 0.001–0.01 by increments of 0.001, and 0.01–0.09 by increments of 0.01). Additionally, the scratch angle dependence of the product of maximum instantaneous area of plastic strain times magnitude of plastic strain was investigated, for all four of the above-segregated areas and all 20 plastic strain thresholds. In total, 1,027 different stimulus variants were considered as possible surrogate metrics of wear, both for conventional and for highly crosslinked polyethylene (2,054 comparisons overall).

For both polyethylene variants, correspondence of the candidate metrics with the experimentally observed scratch direction-dependence of wear was evaluated both by objective measures of goodness-of-fit, and visually for specific qualitative criteria. All candidate metrics were formally ranked according to the average of three goodness-of-fit measures. The first of these measures was the cross-correlation coefficient r, defined 30 as follows:

| (4) |

Here, Φ and V̂ represent values of the surrogate metric and the experimental wear for a set of nθ scratch angles, with mΦ and mV denoting the respective means. The second goodness-of-fit measure was the area fraction  shared by two respective wear-vs-direction curves, after normalization to ensure equal areas. The third measure of fit was an R2 correlative statistic emerging from a random-fixed effects regression model. Briefly (details in Appendix A), analysis of variance (ANOVA) was performed both including and not including the computational dataset as a predictor of the experimental dataset. The improvement in variance achieved by adding the computational dataset as a predictor yielded an R2 statistic for that computational dataset. For visual assessments, plots of each φ parameter were reviewed manually throughout the individual scratch passage event, as were (normalized) plots of the corresponding Φ values versus angle-dependent experimental wear.

RESULTS

Experimentally, for conventional UHMWPE, a scratch oriented at 15º with respect to the sliding direction produced the greatest wear. The direction of greatest wear for crosslinked UHMWPE was 5º. In the finite element model, maximum stress values did not vary appreciably with scratch orientation. Rather, UHMWPE stresses achieved similarly supra-yield magnitudes for all scratch orientations. Peak normal stresses and principal stresses typically approached 60 MPa during scratch over-passage, while peak shear stresses were typically on the order of 10 MPa.

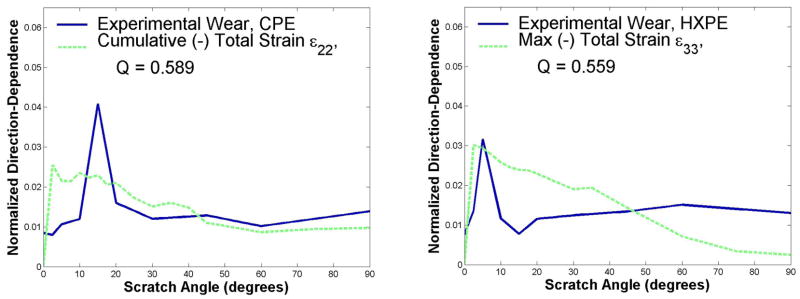

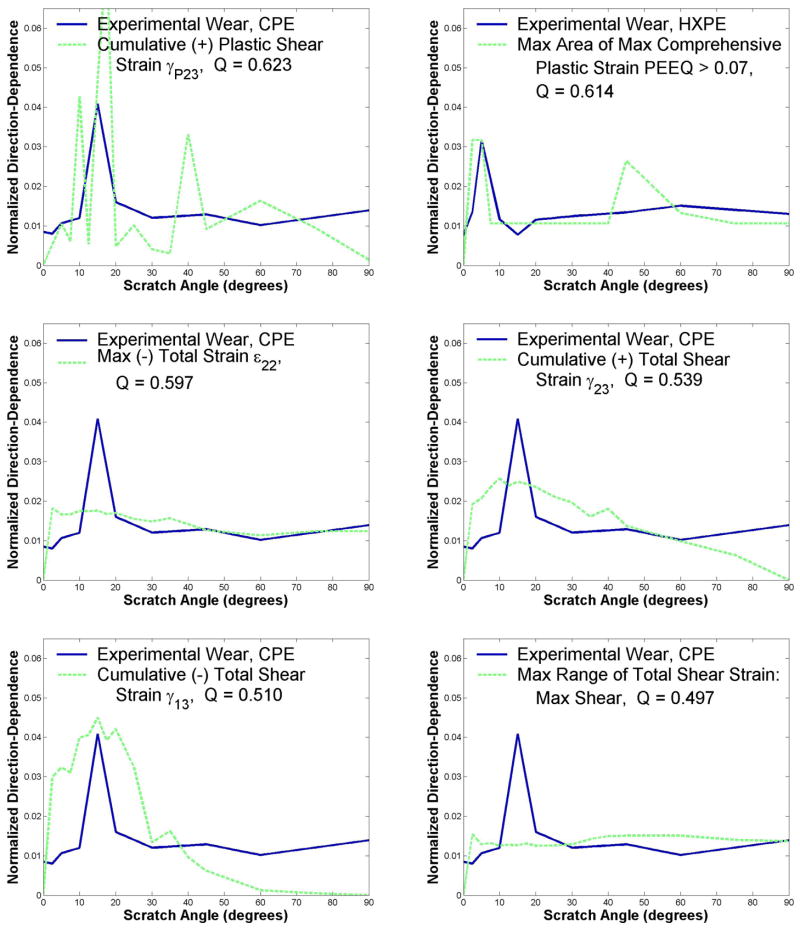

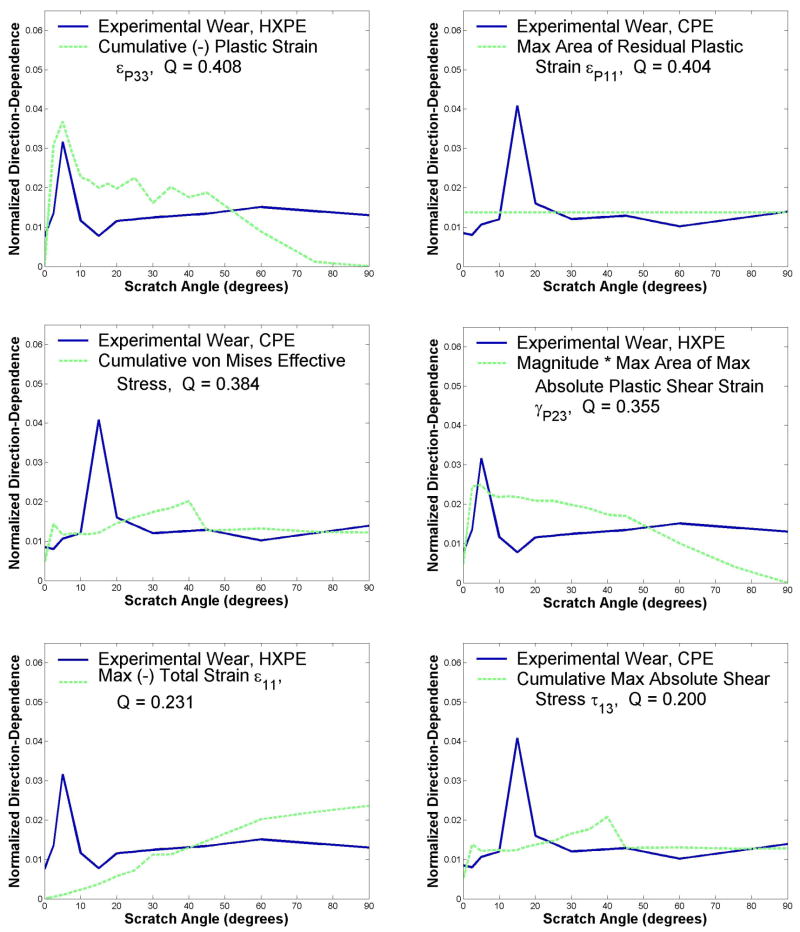

Two continuum wear surrogates were judged to most reasonably resemble the scratch lip direction-dependence observed experimentally. These two best-performing surrogates were (1) the cumulative compressive total normal strain in the direction of loading, and (2) the maximum instantaneous compressive total normal strain in the direction transverse to sliding (Figure 4). “Total strain” in this context denotes the sum of elastic plus plastic logarithmic strain.

Figure 4.

The two surrogate mechanical stimuli judged to best resemble the scratch lip direction-dependence of experimental wear. “Total strain” refers to the sum of elastic and plastic strain in the specified component direction.

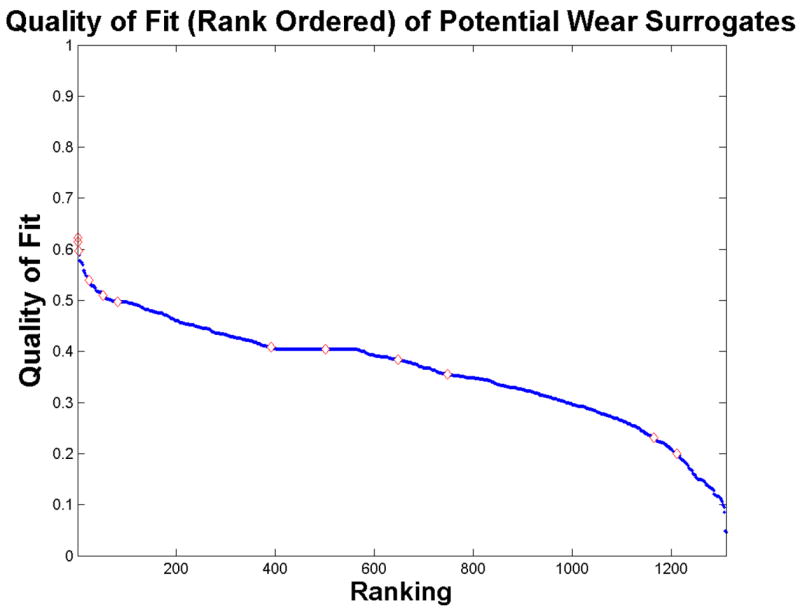

A truncated list of candidate surrogates demonstrating the best quality of fit to scratch-direction-dependent experimental wear is presented in Table 1. Overall, the various surrogates computed in the finite element simulation did not show an ability to better fit the angle-dependence of one polyethylene material variant as opposed to the other. The entire quality-of-fit distribution is presented in Figure 5. Illustrative angle-dependencies of fits of candidate metrics are displayed in Figure 6, demonstrating the spectrum of predictive capability. The relative performance of these particular parameters (with respect to the complete set of available candidates) can be appreciated from Figure 5.

Table 1.

Best-performing 2.5% of the fits for the 2,054 mechanical stimulus candidates to experimentally observed UHMWPE wear (1,027 each for conventional and crosslinked UHMWPE). The tabulated quality of fit Q is the average of three measures: (1) 2-D correlation coefficient r, (2) fraction of shared area  in normalized plots of the two given datasets, and (3) correlative statistic R2 from a fixed/random effects ANOVA statistical model (See Appendix A). The complete rank list is provided in Appendix B (page 30). Please refer to the key following table for abbreviations.

| Rank | Q | Stm | TD | Cmp | Rgy | Thrsh | Mtl | Rank | Q | Stm | TD | Cmp | Rgy | Thrsh | Mtl |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.623 | PS | H | 23 | (+) | V | 36 | 0.525 | APS | I | 22 | Mx+ | 0.002 | X | |

| 2 | 0.614 | APS | I | “E” | 0.07 | X | 37 | 0.525 | TS | I | 23 | Mx+ | V | ||

| 3 | 0.597 | TS | I | 22 | Mx− | V | 38 | 0.519 | APS | I | MnP | |M| | 0.005 | X | |

| 4 | 0.589 | TS | H | 22 | (−) | V | 39 | 0.519 | APS | I | MnP | Mx− | 0.005 | X | |

| 5 | 0.578 | APS | I | MnP | |M| | 0.009 | X | 40 | 0.518 | TS | I | MxP | |M| | X | |

| 6 | 0.578 | APS | I | MnP | Mx− | 0.009 | X | 41 | 0.518 | TS | I | MxP | Mx+ | X | |

| 7 | 0.576 | TS | I | 22 | PV | V | 42 | 0.518 | APS | I | “M” | 0.006 | X | ||

| 8 | 0.575 | APS | I | MxS | 0.009 | X | 43 | 0.517 | APS | I | MxP | |M| | 0.005 | X | |

| 9 | 0.573 | APS | I | MxP | |M| | 0.009 | X | 44 | 0.517 | APS | I | MxP | Mx+ | 0.005 | X |

| 10 | 0.573 | APS | I | MxP | Mx+ | 0.009 | X | 45 | 0.517 | PSE | I | Gnl | X | ||

| 11 | 0.569 | APS | I | MnP | |M| | 0.01 | X | 46 | 0.516 | APS | I | MxP | Mx− | 0.0005 | V |

| 12 | 0.569 | APS | I | MnP | Mx− | 0.01 | X | 47 | 0.516 | APS | I | MnP | Mx+ | 0.0005 | V |

| 13 | 0.559 | TS | I | 33 | |M| | X | 48 | 0.516 | APS | I | MnP | Mx+ | 0.005 | V | |

| 14 | 0.559 | TS | I | 33 | Mx− | X | 49 | 0.516 | M*A | I | MnP | |M| | 0 | X | |

| 15 | 0.556 | APS | I | “E” | 0.05 | X | 50 | 0.516 | M*A | I | MnP | Mx− | 0 | X | |

| 16 | 0.553 | APS | I | MxS | 0.02 | X | 51 | 0.514 | APS | I | MxS | 0.005 | X | ||

| 17 | 0.549 | APS | I | 11 | Mx+ | 0.0005 | V | 52 | 0.511 | TS | I | 13 | Mx− | V | |

| 18 | 0.548 | TS | I | MnP | |M| | X | 53 | 0.510 | TS | H | 13 | (−) | V | ||

| 19 | 0.548 | TS | I | MnP | Mx− | X | 54 | 0.508 | APS | I | 22 | Mx− | 0.006 | V | |

| 20 | 0.546 | M*A | I | “E” | 0 | X | 55 | 0.506 | APS | I | MxP | Mx− | 0.001 | V | |

| 21 | 0.546 | TS | I | 23 | |M| | X | 56 | 0.505 | APS | I | MxP | Mx− | 0.002 | V | |

| 22 | 0.541 | APS | I | MxP | |M| | 0.03 | X | 57 | 0.504 | APS | I | “M” | 0.02 | X | |

| 23 | 0.541 | APS | I | MxP | Mx+ | 0.03 | X | 58 | 0.504 | APS | I | MnP | Mx+ | 0.002 | V |

| 24 | 0.539 | TS | H | 23 | (+) | V | 59 | 0.504 | APS | I | MxS | 0.03 | X | ||

| 25 | 0.537 | TS | I | MxS | X | 60 | 0.503 | M*A | I | MxS | 0 | X | |||

| 26 | 0.535 | APS | I | MxS | 0.006 | X | 61 | 0.503 | APS | I | “E” | 0.007 | X | ||

| 27 | 0.531 | PS | I | 23 | Mx+ | V | 62 | 0.503 | APS | I | MnP | |M| | 0.02 | X | |

| 28 | 0.531 | APS | I | “M” | 0.007 | X | 63 | 0.503 | APS | I | MnP | Mx− | 0.02 | X | |

| 29 | 0.529 | APS | I | MnP | |M| | 0.006 | X | 64 | 0.503 | APS | I | “E” | 0.006 | X | |

| 30 | 0.529 | APS | I | MnP | Mx− | 0.006 | X | 65 | 0.502 | S | H | 22 | (−) | X | |

| 31 | 0.529 | S | I | 22 | Mx+ | X | 66 | 0.502 | S | I | 23 | |M| | X | ||

| 32 | 0.528 | APS | I | 12 | Mx− | 0.002 | V | 67 | 0.502 | S | I | 23 | Mx+ | X | |

| 33 | 0.528 | APS | I | 22 | Mx+ | 0.001 | V | 68 | 0.502 | APS | I | “M” | 0.03 | X | |

| 34 | 0.528 | APS | I | MnP | Mx+ | 0.001 | V | 69 | 0.500 | APS | I | “E” | 0.03 | X | |

| 35 | 0.526 | APS | I | 12 | Mx− | 0.001 | V | 70 | 0.500 | S | H | 3rd | (−) | X |

NOTE: The following key provides abbreviations used for the above column headings and corresponding variants: Q = Quality of fit (= 1/3(r + Â + R2) ); Stm = Stimulus; APS = Area of Plastic Strain; MA = Magnitude of Area of plastic strain; PS = Plastic Strain; PSE = Plastic Strain Energy; TS = Total Strain; TSE = Total Strain Energy; TD = Temporal Designation; I = Instantaneous; H = (Cumulative) History; Cmp = Component; 11 = stimulus in the 1-plane, and in the 1-direction; 3rd = 3rd Invariant of stress (determinant of the stress tensor); “E” = “Equivalent” (ABAQUS effective value for consolidated tensorial components); Gnl = General state (normal state plus shear state); “M” = “Magnitude” (ABAQUS effective magnitude for consolidated tensorial components); MnP = Min Principal; MxP = Max Principal; Nml = Normal state; prs = equivalent pressure; Shr = Shear state; Tca = Tresca effective stress; vM = von Mises effective stress; Rgy = Registry; (+) = Positive values; (−) = Negative values; Mx+ = Max positive; Mx− = Max negative; |M| = Max (instantaneous) absolute magnitude; |m| = max (cumulative) absolute magnitude; PV = max cyclic Peak-to-Valley swing (suggestive of a fatigue measure for failure); Res = Residual (plastic strain); Thrsh = Threshold (of plastic strain, used in computing an area of plastic strain); Mtl = Material; V = conventional UHMWPE; X = highly crosslinked UHMWPE.

Figure 5.

Statistical fit distribution for all 2,054 comparisons of surrogate candidates to experimental wear. Selected cases (red dots) are illustrated in Figure 6, in order of decreasing quality of fit. Note: after the worst-fitting candidate listed above (#1310, quality of fit = 0.046), for administrative/procedural reasons, all remaining candidates involved incomplete datasets, and were assigned a quality of fit = 0.

Figure 6.

Selected plots of computational surrogate candidates representing a variety of mechanical stimuli and a range of statistical fit quality. These twelve plots correspond to the respective symbols on the distribution curve in Figure 5.

Once the complete list of candidate mechanical stimulus parameters was ranked according to quality-of-fit Q, the highest-ranking candidates (those with Q ≥ 0.5) were further screened visually, to ensure that they met four qualitative criteria. First, because desirable surrogate candidates needed to have a direction-dependent relationship that tended toward a single maximum, candidates presenting multiple discrete maxima of similar magnitude were eliminated from consideration. Similarly, candidates showing a relatively uniform distribution were excluded, as were those that had a global maximum at a scratch angle inconsistent with the experimental relationship. Fourth, since both positive-valued and negative-valued variants were evaluated for most potential surrogates, it seemed reasonable not to place credence in a given candidate (e.g., positive stress in the 2-direction) if its complement (negative stress in the 2-direction) was of far greater magnitude. Therefore, candidate surrogates involving normal stress were eliminated if their complement (reflecting physically distinct behavior in tension versus compression) was two or more orders of magnitude greater. Shear stress/strain components were eliminated if their complements were even nominally greater, since shear is physically similar for positive and negative values. Distribution choppiness (Fig 6a), per se, was not a basis for exclusion, provided that the Q value was high and that none of the above four exclusion criteria were applicable.

Two surrogates emerged as being overall most appropriate. These were (1) cumulative total (elastic + plastic) compressive normal strain in the direction of loading, and (2) maximum instantaneous total compressive normal strain transverse to the sliding direction. Secondary parametric influences (e.g., leading lip versus trailing lip passage, repeated lip passage residual strains) and variants of data normalization and interpolation are reported in detail elsewhere 26.

DISCUSSION

A reciprocal, unidirectional duty cycle was adopted experimentally in the interest of preserving consistent orientation between scratch direction and counterface motion, thereby allowing isolation of the specific effect - scratch directionality - under study. For wear of UHMWPE against polished counterfaces, it is well recognized that such a duty cycle fails to incorporate the crossing-path motions responsible for shearing off striations of polyethylene produced by asperity adhesion/abrasion, and thus tends to underestimate the wear occurring in the actual (in vivo) service environment 31,32. In the present experimental embodiment, however, besides achieving the desired effect of isolating the variable of primary interest (scratch directionality), there is a potent (indeed, arguably dominant) crossing-path effect, owing to scratch obliquity.

Computationally, the vast majority of the candidate mechanical parameters that were considered as potential wear surrogates turned out to correlate unremarkably (i.e., 1,984 of the 2,054 considered had Q < 0.5), or indeed even poorly (1,063 had Q < 0.3) with the experimentally observed scratch direction-dependence of polyethylene wear (Figure 6). The dominant shortcoming in that regard arose from failure to replicate the pronounced wear rate maximum consistently observed experimentally for scratches oriented at low angles (5–15°) relative to the sliding direction. The local FEA model did not incorporate a formal material failure criterion to directly model abrasive/adhesive wear, but many of the potential wear surrogates considered were parameters that are strongly associated with continuum-level material failure processes (e.g., first principal stress with tensile failure, von Mises stress with shear failure). Thus, one might reasonably infer that, had the local FEA model formally implemented a material failure mode, the scratch angle-dependence of such a failure process (e.g., tensile failure) would have been very highly correlated with the scratch angle-dependence of the failure-associated surrogate measure (i.e., first principal stress).

Given the observed insensitivity of the local stress and strain fields to scratch angle, one would not expect these simple metrics to be good predictors of angle-dependent wear rate. However, for metrics which implicitly incorporate a kinematic effect (e.g., stress or strain components transverse to the sliding direction), or those which explicitly incorporate a cumulative stimulus during scratch overpassage, the opportunities for correlation with physical wear mechanisms would seemingly be better. Although none of the individual surrogate mechanical parameters that were evaluated showed highly precise (Q > 0.9) or strong (Q > 0.7) replication of the experimentally observed relationship between scratch angle and wear rate, a small subset of them showed modest correlation (70 had Q > 0.5). Such surrogates therefore might plausibly be useful for phenomenological prediction of wear in FEA models of local asperities, and/or for making adjustments to global-level FEA wear predictions to possibly account for anisotropic roughening effects. Also, given these best-correlating parameters’ associations with specific physical failure mechanisms, one might also reasonably infer the failure mechanism(s) associated with polyethylene wear rate acceleration in the presence of 3rd body-induced scratch damage of a metal counterface. In that regard, a “slicing” paradigm suggests itself quite compellingly, rather than the sort of a “plowing” mechanism intuitively associated with scratches oriented nearly perpendicular to the direction of relative surface motion.

Obviously, the stress distributions computed in the present local finite element model were predicated on the numbers, spacing, and lip height of scratches being such that the global contact load was supported entirely by “line contact” with scratch lips, rather than being supported substantially by unscratched surface regions. While this local FEA model was a realistic replication of the corresponding physical testing set-up, the latter had been deliberately designed to generate very large amounts of debris in short periods of time, in order to accentuate possible directional differences. The particular scratch profile utilized experimentally and computationally was representative of typical in vivo 3rd body damage, but the numbers/spacing of such scratches in the model corresponded to a situation far more abusive than would conceivably be tolerable in vivo. (As a point of reference, the absolute wear factor for the present 15° scratch angle experiments for conventional polyethylene averaged 5x10−6 mm3/N-m, whereas typical wear factors for borderline-wear-problematic THA implants are on the order of 1.2–1.9x10−6 mm3/N-m 39,108.) Nevertheless, even though the great majority of load in clinical THA constructs is presumably supported by polished/ undamaged surface regions rather than by scratch lips, the present data arguably isolate the direction-dependence of wear rate acceleration due to whatever population of scratches happens to be physically present.

The maximum instantaneous area of plastic strain during scratch engagement was found to correlate fairly well with the experimental scratch-direction-dependence of wear, supporting the results of McNie et al.’s 2-D FEA work on scratch asperity damage to UHMWPE 15,29. The results of the present study are also consistent with that group’s observation that the area (or volume, in the case of the present 3-D formulation) of polyethylene undergoing plastic strain may more reliably relate to wear volume than does the magnitude of maximum plastic strain per se.

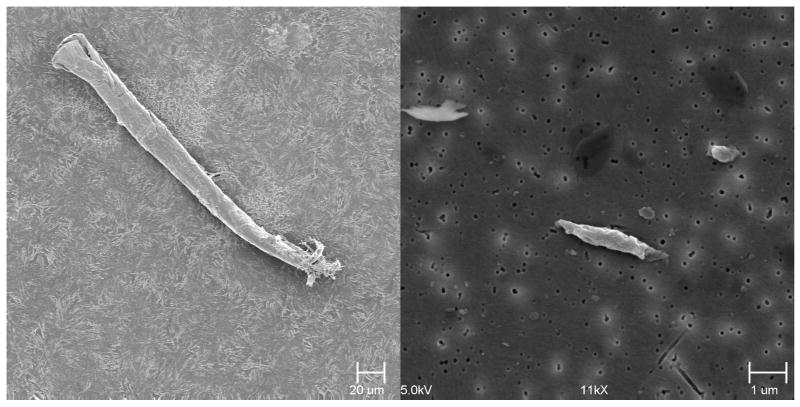

High surface and subsurface plastic strains have been associated with the initiation of both surface ripples 33 and with fatigue micro-cracks on or below the surface 29. The migration of such micro-cracks to the surface is believed to promote formation of polyethylene debris, potentially encouraging liberation of fibers or ridges tens of microns in length 34. In the present study, such large fibers were ubiquitous in particle populations harvested from the lubricant (Figure 7) when a scratched counterface was involved. As a negative control, an otherwise similar non-roughened metal plate (Ra< 100 nm) reciprocating against polyethylene produced particles of submicron or micron size (Figure 7), resembling the predominant volumetric fraction of particles observed to surround total joints in vivo.

Figure 7.

UHMWPE debris particles collected from the experimental apparatus following articulation. (a) Particles generated by a scratched surface were typically orders larger than the most biologically reactive submicron debris. Here, a particle of crosslinked UHMWPE is presented, produced by a scratch orientation of 5°. (b) A smooth articulation couple produced debris that were of submicron- or micron-order size, similar to the overwhelming volumetric fraction of particles found in tissues surrounding an implanted total joint in vivo. Further details regarding the relationships between local stress fields and sliding parameters are reported elsewhere26.

In summary, a finite element model was used to investigate the sliding articulation of polyethylene with parametrically-oriented scratch lips, surveying field variable histories in an attempt to identify continuum parameters empirically associated with corresponding experimentally-determined wear dependence. All candidate parameters were graphically reviewed manually, and were formally ranked statistically. The best correlating of these surrogates - two variants of compressive total strain - potentially provide a basis by which to account for anisotropic scratch damage in global FEA models of accelerated wear due to articulation against roughened femoral heads.

Appendix B.

Complete listing of all ranked candidate surrogates for scratch angle-dependent wear. Please refer to Table 1 key for abbreviations.

| Rank | Stm | TD | Cmp | Rgy | Thrsh | Mtl | Q | Rank | Stm | TD | Cmp | Rgy | Thrsh | Mtl | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | PS | H | 23 | (+) | V | 0.623 | 36 | APS | I | 22 | Mx+ | 0.002 | X | 0.525 | |

| 2 | APS | I | “E” | 0.07 | X | 0.614 | 37 | TS | I | 23 | Mx+ | V | 0.525 | ||

| 3 | TS | I | 22 | Mx− | V | 0.597 | 38 | APS | I | MnP | |M| | 0.005 | X | 0.519 | |

| 4 | TS | H | 22 | (−) | V | 0.589 | 39 | APS | I | MnP | Mx− | 0.005 | X | 0.519 | |

| 5 | APS | I | MnP | |M| | 0.009 | X | 0.578 | 40 | TS | I | MxP | |M| | X | 0.518 | |

| 6 | APS | I | MnP | Mx− | 0.009 | X | 0.578 | 41 | TS | I | MxP | Mx+ | X | 0.518 | |

| 7 | TS | I | 22 | PV | V | 0.576 | 42 | APS | I | “M” | 0.006 | X | 0.518 | ||

| 8 | APS | I | MxS | 0.009 | X | 0.575 | 43 | APS | I | MxP | |M| | 0.005 | X | 0.517 | |

| 9 | APS | I | MxP | |M| | 0.009 | X | 0.573 | 44 | APS | I | MxP | Mx+ | 0.005 | X | 0.517 |

| 10 | APS | I | MxP | Mx+ | 0.009 | X | 0.573 | 45 | PSE | I | Gnl | X | 0.517 | ||

| 11 | APS | I | MnP | |M| | 0.01 | X | 0.569 | 46 | APS | I | MxP | Mx− | 0.0005 | V | 0.516 |

| 12 | APS | I | MnP | Mx− | 0.01 | X | 0.569 | 47 | APS | I | MnP | Mx+ | 0.0005 | V | 0.516 |

| 13 | TS | I | 33 | |M| | X | 0.559 | 48 | APS | I | MnP | Mx+ | 0.005 | V | 0.516 | |

| 14 | TS | I | 33 | Mx− | X | 0.559 | 49 | M*A | I | MnP | |M| | 0 | X | 0.516 | |

| 15 | APS | I | “E” | 0.05 | X | 0.556 | 50 | M*A | I | MnP | Mx− | 0 | X | 0.516 | |

| 16 | APS | I | MxS | 0.02 | X | 0.553 | 51 | APS | I | MxS | 0.005 | X | 0.514 | ||

| 17 | APS | I | 11 | Mx+ | 0.0005 | V | 0.549 | 52 | TS | I | 13 | Mx− | V | 0.511 | |

| 18 | TS | I | MnP | |M| | X | 0.548 | 53 | TS | H | 13 | (−) | V | 0.510 | ||

| 19 | TS | I | MnP | Mx− | X | 0.548 | 54 | APS | I | 22 | Mx− | 0.006 | V | 0.508 | |

| 20 | M*A | I | “E” | 0 | X | 0.546 | 55 | APS | I | MxP | Mx− | 0.001 | V | 0.506 | |

| 21 | TS | I | 23 | |M| | X | 0.546 | 56 | APS | I | MxP | Mx− | 0.002 | V | 0.505 | |

| 22 | APS | I | MxP | |M| | 0.03 | X | 0.541 | 57 | APS | I | “M” | 0.02 | X | 0.504 | |

| 23 | APS | I | MxP | Mx+ | 0.03 | X | 0.541 | 58 | APS | I | MnP | Mx+ | 0.002 | V | 0.504 |

| 24 | TS | H | 23 | (+) | V | 0.539 | 59 | APS | I | MxS | 0.03 | X | 0.504 | ||

| 25 | TS | I | MxS | X | 0.537 | 60 | M*A | I | MxS | 0 | X | 0.503 | |||

| 26 | APS | I | MxS | 0.006 | X | 0.535 | 61 | APS | I | “E” | 0.007 | X | 0.503 | ||

| 27 | PS | I | 23 | Mx+ | V | 0.531 | 62 | APS | I | MnP | |M| | 0.02 | X | 0.503 | |

| 28 | APS | I | “M” | 0.007 | X | 0.531 | 63 | APS | I | MnP | Mx− | 0.02 | X | 0.503 | |

| 29 | APS | I | MnP | |M| | 0.006 | X | 0.529 | 64 | APS | I | “E” | 0.006 | X | 0.503 | |

| 30 | APS | I | MnP | Mx− | 0.006 | X | 0.529 | 65 | S | H | 22 | (−) | X | 0.502 | |

| 31 | S | I | 22 | Mx+ | X | 0.529 | 66 | S | I | 23 | |M| | X | 0.502 | ||

| 32 | APS | I | 12 | Mx− | 0.002 | V | 0.528 | 67 | S | I | 23 | Mx+ | X | 0.502 | |

| 33 | APS | I | 22 | Mx+ | 0.001 | V | 0.528 | 68 | APS | I | “M” | 0.03 | X | 0.502 | |

| 34 | APS | I | MnP | Mx+ | 0.001 | V | 0.528 | 69 | APS | I | “E” | 0.03 | X | 0.500 | |

| 35 | APS | I | 12 | Mx− | 0.001 | V | 0.526 | 70 | S | H | 3rd | (−) | X | 0.500 | |

| 71 | M*A | I | “M” | 0 | X | 0.499 | 121 | S | I | prs | PV | X | 0.491 | ||

| 72 | S | I | 3rd | |M| | X | 0.499 | 122 | S | I | 11 | PV | X | 0.490 | ||

| 73 | S | I | 3rd | Mx− | X | 0.499 | 123 | S | I | 33 | |M| | X | 0.490 | ||

| 74 | APS | I | 12 | Mx− | 0.0005 | X | 0.499 | 124 | S | I | 33 | Mx− | X | 0.490 | |

| 75 | S | H | 33 | (+) | V | 0.498 | 125 | TSE | I | Shr | X | 0.489 | |||

| 76 | APS | I | “E” | 0.04 | X | 0.498 | 126 | APS | I | 11 | Res | 0.0005 | V | 0.489 | |

| 77 | TS | I | 33 | PV | X | 0.498 | 127 | S | I | MxP | PV | X | 0.489 | ||

| 78 | APS | I | MnP | |M| | 0.03 | X | 0.497 | 128 | S | I | MxP | |M| | X | 0.488 | |

| 79 | APS | I | MnP | Mx− | 0.03 | X | 0.497 | 129 | S | I | MxP | Mx− | X | 0.488 | |

| 80 | APS | I | “E” | 0.06 | X | 0.497 | 130 | M*A | I | 22 | Mx− | 0 | V | 0.486 | |

| 81 | PSE | I | Shr | PV | X | 0.497 | 131 | S | H | prs | (+) | X | 0.486 | ||

| 82 | TS | I | MxS | PV | X | 0.497 | 132 | S | I | 22 | PV | X | 0.486 | ||

| 83 | APS | I | 12 | |M| | 0.0005 | X | 0.497 | 133 | APS | I | MxP | Mx− | 0.003 | V | 0.485 |

| 84 | APS | I | 12 | Mx+ | 0.0005 | X | 0.497 | 134 | APS | I | MnP | Mx+ | 0.003 | V | 0.485 |

| 85 | TSE | I | Shr | PV | X | 0.497 | 135 | APS | I | 22 | Mx− | 0.01 | V | 0.483 | |

| 86 | TS | I | 23 | PV | X | 0.497 | 136 | TS | I | 22 | |M| | X | 0.483 | ||

| 87 | TS | I | MnP | PV | X | 0.497 | 137 | PS | I | MnP | PV | X | 0.482 | ||

| 88 | S | I | Tca | PV | X | 0.497 | 138 | APS | I | “M” | 0.04 | X | 0.482 | ||

| 89 | S | I | vM | PV | X | 0.497 | 139 | APS | I | 11 | |M| | 0.0005 | V | 0.482 | |

| 90 | S | I | 3rd | PV | X | 0.497 | 140 | S | I | MxS | X | 0.482 | |||

| 91 | S | I | MxS | PV | X | 0.497 | 141 | S | I | Tca | X | 0.482 | |||

| 92 | S | I | 23 | PV | X | 0.497 | 142 | S | I | vM | X | 0.482 | |||

| 93 | TSE | I | Nml | X | 0.497 | 143 | TS | I | 22 | Mx+ | X | 0.482 | |||

| 94 | APS | I | 22 | |M| | 0.004 | V | 0.497 | 144 | S | H | prs | (−) | X | 0.482 | |

| 95 | TSE | I | Gnl | X | 0.497 | 145 | TS | I | 22 | Mx− | X | 0.481 | |||

| 96 | PSE | I | Gnl | PV | X | 0.497 | 146 | APS | I | MxP | Mx− | 0.004 | V | 0.480 | |

| 97 | TS | H | 33 | (−) | V | 0.497 | 147 | S | H | 3rd | (+) | V | 0.480 | ||

| 98 | S | I | MnP | |M| | X | 0.497 | 148 | APS | I | 12 | |M| | 0.002 | V | 0.480 | |

| 99 | S | I | MnP | Mx− | X | 0.497 | 149 | APS | I | 12 | Mx+ | 0.002 | V | 0.480 | |

| 100 | APS | I | 12 | Mx− | 0.0005 | V | 0.497 | 150 | APS | I | MnP | Mx+ | 0.004 | V | 0.480 |

| 101 | APS | I | 22 | Mx− | 0.004 | V | 0.496 | 151 | PS | I | “M” | PV | X | 0.479 | |

| 102 | S | I | MnP | PV | X | 0.496 | 152 | TS | I | 23 | Mx+ | X | 0.479 | ||

| 103 | S | I | 3rd | Mx+ | X | 0.496 | 153 | APS | I | MxP | Mx− | 0.005 | V | 0.478 | |

| 104 | S | I | 22 | |M| | X | 0.495 | 154 | S | H | 33 | (−) | X | 0.478 | ||

| 105 | S | I | 22 | Mx− | X | 0.495 | 155 | APS | I | 12 | |M| | 0.001 | X | 0.478 | |

| 106 | S | I | 33 | Mx+ | X | 0.495 | 156 | APS | I | 12 | Mx+ | 0.001 | X | 0.478 | |

| 107 | TSE | I | Nml | PV | X | 0.495 | 157 | PSE | I | Nml | X | 0.477 | |||

| 108 | TS | I | MxP | PV | X | 0.494 | 158 | APS | I | MxP | |M| | 0.004 | X | 0.477 | |

| 109 | TSE | I | Gnl | PV | X | 0.494 | 159 | APS | I | “M” | 0.005 | X | 0.477 | ||

| 110 | S | I | 33 | PV | X | 0.494 | 160 | APS | I | MxS | 0.004 | X | 0.477 | ||

| 111 | TS | I | 22 | PV | X | 0.494 | 161 | APS | I | MxP | Mx+ | 0.004 | X | 0.477 | |

| 112 | APS | I | 22 | Mx− | 0.009 | V | 0.493 | 162 | APS | I | MxP | |M| | 0.006 | X | 0.476 |

| 113 | S | I | 11 | |M| | X | 0.493 | 163 | APS | I | MxP | Mx+ | 0.006 | X | 0.476 | |

| 114 | S | I | 11 | Mx− | X | 0.493 | 164 | PS | I | MxS | PV | X | 0.476 | ||

| 115 | S | H | 23 | (−) | V | 0.493 | 165 | APS | I | 22 | Mx+ | 0.0005 | V | 0.476 | |

| 116 | S | H | 3rd | (+) | X | 0.492 | 166 | S | H | 12 | X | 0.476 | |||

| 117 | S | I | prs | |M| | X | 0.492 | 167 | S | I | MxP | Mx+ | V | 0.475 | ||

| 118 | S | I | prs | Mx+ | X | 0.492 | 168 | TS | I | 23 | PV | V | 0.475 | ||

| 119 | M*A | I | MxP | |M| | 0 | X | 0.492 | 169 | PSE | I | Nml | PV | X | 0.475 | |

| 120 | M*A | I | MxP | Mx+ | 0 | X | 0.492 | 170 | TS | I | 33 | |M| | V | 0.475 | |

| 171 | TS | I | 33 | Mx− | V | 0.475 | 221 | APS | I | “E” | 0.03 | V | 0.454 | ||

| 172 | S | H | 11 | (−) | X | 0.475 | 222 | APS | I | MxP | |M| | 0.02 | X | 0.454 | |

| 173 | TS | I | 23 | Mx− | X | 0.474 | 223 | APS | I | MxP | Mx+ | 0.02 | X | 0.454 | |

| 174 | PS | I | MxP | PV | X | 0.473 | 224 | APS | I | 22 | |M| | 0.01 | V | 0.454 | |

| 175 | TS | I | 33 | PV | V | 0.473 | 225 | PS | I | 33 | |M| | X | 0.453 | ||

| 176 | APS | I | “E” | 0.008 | X | 0.472 | 226 | APS | I | “E” | 0.04 | V | 0.452 | ||

| 177 | S | I | 23 | |M| | V | 0.471 | 227 | TS | I | 23 | |M| | V | 0.452 | ||

| 178 | S | I | 23 | Mx+ | V | 0.471 | 228 | TS | I | 23 | Mx− | V | 0.452 | ||

| 179 | S | I | prs | Mx− | V | 0.471 | 229 | APS | I | MnP | |M| | 0.03 | V | 0.452 | |

| 180 | S | I | 33 | Mx+ | V | 0.471 | 230 | APS | I | 12 | |M| | 0.0005 | V | 0.452 | |

| 181 | TS | H | 12 | (+) | X | 0.471 | 231 | APS | I | MnP | Mx− | 0.03 | V | 0.452 | |

| 182 | S | I | 3rd | |M| | V | 0.470 | 232 | APS | I | “E” | 0.06 | V | 0.452 | ||

| 183 | S | I | 3rd | Mx− | V | 0.470 | 233 | APS | I | 12 | Mx+ | 0.0005 | V | 0.452 | |

| 184 | APS | I | 12 | |M| | 0.003 | V | 0.469 | 234 | S | I | 13 | Mx− | V | 0.452 | |

| 185 | APS | I | 12 | Mx+ | 0.003 | V | 0.469 | 235 | S | I | 23 | Mx− | X | 0.452 | |

| 186 | APS | I | 12 | |M| | 0.001 | V | 0.467 | 236 | S | I | 33 | PV | V | 0.451 | |

| 187 | APS | I | 12 | Mx+ | 0.001 | V | 0.467 | 237 | S | I | 23 | Mx− | V | 0.451 | |

| 188 | PS | I | 12 | PV | X | 0.466 | 238 | S | I | 12 | PV | X | 0.450 | ||

| 189 | S | H | 23 | (+) | V | 0.465 | 239 | APS | I | 23 | |M| | 0.008 | V | 0.450 | |

| 190 | APS | I | 22 | |M| | 0.009 | V | 0.465 | 240 | APS | I | 23 | Mx− | 0.008 | V | 0.450 |

| 191 | S | I | MxP | Mx+ | X | 0.465 | 241 | APS | I | MxS | 0.03 | V | 0.449 | ||

| 192 | APS | I | MnP | Mx+ | 0.006 | V | 0.464 | 242 | APS | I | 23 | |M| | 0.01 | V | 0.448 |

| 193 | APS | I | 22 | |M| | 0.006 | V | 0.464 | 243 | APS | I | 23 | Mx− | 0.01 | V | 0.448 |

| 194 | S | I | 3rd | PV | V | 0.463 | 244 | APS | I | 23 | |M| | 0.007 | V | 0.448 | |

| 195 | APS | I | 12 | Mx− | 0.001 | X | 0.463 | 245 | APS | I | 23 | Mx− | 0.007 | V | 0.448 |

| 196 | APS | I | MxS | 0.01 | X | 0.463 | 246 | APS | I | 22 | Mx− | 0.008 | V | 0.448 | |

| 197 | S | I | 23 | PV | V | 0.462 | 247 | APS | I | 33 | Mx− | 0.001 | V | 0.448 | |

| 198 | PS | I | “E” | PV | X | 0.461 | 248 | APS | I | 33 | |M| | 0.002 | V | 0.447 | |

| 199 | APS | I | MxP | |M| | 0.01 | X | 0.461 | 249 | APS | I | 33 | Mx+ | 0.002 | V | 0.447 |

| 200 | APS | I | MxP | Mx+ | 0.01 | X | 0.461 | 250 | APS | I | 33 | |M| | 0.003 | V | 0.447 |

| 201 | APS | I | 22 | Mx− | 0.005 | V | 0.460 | 251 | APS | I | 33 | Mx+ | 0.003 | V | 0.447 |

| 202 | APS | I | 33 | Mx− | 0.0005 | V | 0.460 | 252 | S | I | Tca | PV | V | 0.445 | |

| 203 | S | H | 12 | (+) | X | 0.460 | 253 | S | I | MxS | PV | V | 0.445 | ||

| 204 | M*A | I | 23 | |M| | 0 | V | 0.460 | 254 | TS | I | 12 | PV | X | 0.445 | |

| 205 | M*A | I | 23 | Mx− | 0 | V | 0.460 | 255 | APS | I | MxP | |M| | 0.006 | V | 0.445 |

| 206 | PS | H | 22 | (+) | X | 0.458 | 256 | APS | I | MxP | Mx+ | 0.006 | V | 0.445 | |

| 207 | TS | H | 33 | V | 0.457 | 257 | S | I | vM | PV | V | 0.445 | |||

| 208 | APS | I | “E” | 0.007 | V | 0.457 | 258 | PS | I | 11 | PV | X | 0.445 | ||

| 209 | APS | I | MnP | |M| | 0.02 | V | 0.457 | 259 | S | H | 13 | (−) | V | 0.445 | |

| 210 | APS | I | MnP | Mx− | 0.02 | V | 0.457 | 260 | APS | I | 23 | |M| | 0.009 | V | 0.445 |

| 211 | APS | I | “E” | 0.006 | V | 0.457 | 261 | APS | I | 23 | Mx− | 0.009 | V | 0.445 | |

| 212 | APS | I | 33 | Mx+ | 0.001 | V | 0.456 | 262 | TS | I | 33 | Mx+ | V | 0.445 | |

| 213 | APS | I | “M” | 0.03 | V | 0.456 | 263 | TSE | H | Shr | V | 0.444 | |||

| 214 | S | H | 33 | (+) | X | 0.455 | 264 | TSE | I | Gnl | V | 0.444 | |||

| 215 | S | I | 3rd | Mx+ | V | 0.455 | 265 | PS | I | 13 | |M| | V | 0.444 | ||

| 216 | APS | I | MxP | Mx− | 0.006 | V | 0.455 | 266 | PS | I | 13 | Mx+ | V | 0.444 | |

| 217 | APS | I | 33 | |M| | 0.001 | V | 0.455 | 267 | PS | I | MxP | |M| | X | 0.444 | |

| 218 | TS | I | 33 | Mx+ | X | 0.454 | 268 | PS | I | MxP | Mx+ | X | 0.444 | ||

| 219 | S | H | 33 | (−) | V | 0.454 | 269 | APS | I | 22 | |M| | 0.02 | X | 0.442 | |

| 220 | S | H | 12 | V | 0.454 | 270 | APS | I | MxS | 0.005 | V | 0.442 | |||

| 271 | APS | I | 23 | Mx+ | 0.0005 | V | 0.440 | 321 | S | H | 22 | (−) | V | 0.427 | |

| 272 | M*A | I | 22 | |M| | 0 | V | 0.439 | 322 | PS | I | MnP | |M| | V | 0.427 | |

| 273 | APS | I | 23 | Mx+ | 0.002 | V | 0.439 | 323 | PS | I | MnP | Mx− | V | 0.427 | |

| 274 | APS | I | 23 | Mx+ | 0.001 | V | 0.438 | 324 | S | I | prs | |M| | V | 0.426 | |

| 275 | PS | I | 22 | PV | X | 0.438 | 325 | S | I | prs | Mx+ | V | 0.426 | ||

| 276 | APS | I | “M” | 0.008 | V | 0.437 | 326 | APS | I | 13 | |M| | 0.0005 | V | 0.426 | |

| 277 | S | H | 22 | (+) | X | 0.437 | 327 | APS | I | 22 | |M| | 0.003 | X | 0.426 | |

| 278 | S | I | 11 | Mx+ | V | 0.437 | 328 | M*A | I | 33 | Mx+ | 0 | V | 0.426 | |

| 279 | APS | I | 13 | Mx− | 0.001 | V | 0.436 | 329 | APS | I | 33 | |M| | 0.0005 | V | 0.426 |

| 280 | APS | I | 13 | |M| | 0.001 | V | 0.436 | 330 | TS | I | 13 | Mx− | X | 0.426 | |

| 281 | TSE | I | Nml | V | 0.436 | 331 | APS | I | 33 | Mx+ | 0.0005 | V | 0.425 | ||

| 282 | PS | I | 33 | PV | V | 0.436 | 332 | APS | I | “E” | 0.02 | X | 0.425 | ||

| 283 | APS | I | “E” | 0.008 | V | 0.436 | 333 | APS | I | 22 | |M| | 0.005 | X | 0.425 | |

| 284 | APS | I | 23 | |M| | 0.03 | V | 0.436 | 334 | TSE | I | Shr | PV | V | 0.424 | |

| 285 | APS | I | 23 | Mx− | 0.03 | V | 0.436 | 335 | S | I | 13 | PV | V | 0.424 | |

| 286 | PS | I | 33 | |M| | V | 0.436 | 336 | APS | I | 33 | Mx+ | 0.005 | V | 0.423 | |

| 287 | PS | I | 22 | Mx+ | X | 0.436 | 337 | S | I | prs | Mx− | X | 0.423 | ||

| 288 | TSE | I | Gnl | PV | V | 0.435 | 338 | S | H | prs | (+) | V | 0.423 | ||

| 289 | APS | I | MnP | |M| | 0.007 | V | 0.435 | 339 | S | I | 12 | Mx+ | X | 0.423 | |

| 290 | APS | I | MnP | Mx− | 0.007 | V | 0.435 | 340 | M*A | I | 33 | |M| | 0 | V | 0.422 |

| 291 | APS | I | MxP | |M| | 0.005 | V | 0.435 | 341 | TS | H | 33 | (+) | V | 0.422 | |

| 292 | APS | I | MxP | Mx+ | 0.005 | V | 0.435 | 342 | APS | I | MxP | Mx− | 0.0005 | X | 0.422 |

| 293 | S | I | MxP | PV | V | 0.434 | 343 | APS | I | MnP | Mx+ | 0.0005 | X | 0.422 | |

| 294 | S | I | vM | V | 0.434 | 344 | TS | I | 12 | |M| | X | 0.422 | |||

| 295 | S | I | MxS | V | 0.434 | 345 | TS | I | 12 | Mx+ | X | 0.422 | |||

| 296 | S | I | Tca | V | 0.434 | 346 | APS | I | 22 | Mx+ | 0.006 | X | 0.422 | ||

| 297 | S | I | prs | PV | V | 0.433 | 347 | APS | I | 23 | Mx+ | 0.004 | V | 0.422 | |

| 298 | APS | I | MxS | 0.007 | V | 0.433 | 348 | S | I | MxP | |M| | V | 0.421 | ||

| 299 | APS | I | 13 | Mx− | 0.0005 | V | 0.433 | 349 | S | I | MxP | Mx− | V | 0.421 | |

| 300 | S | I | MnP | |M| | V | 0.433 | 350 | APS | I | 23 | |M| | 0.05 | V | 0.421 | |

| 301 | S | I | MnP | Mx− | V | 0.433 | 351 | APS | I | 23 | Mx− | 0.05 | V | 0.421 | |

| 302 | TS | H | 23 | (−) | V | 0.432 | 352 | PSE | I | Shr | PV | V | 0.421 | ||

| 303 | PS | I | MxS | X | 0.432 | 353 | PS | I | 33 | Mx− | X | 0.421 | |||

| 304 | APS | I | “M” | 0.006 | V | 0.432 | 354 | S | I | 11 | PV | V | 0.420 | ||

| 305 | S | I | MnP | PV | V | 0.432 | 355 | APS | I | 12 | Mx− | 0.003 | V | 0.419 | |

| 306 | S | I | 22 | Mx+ | V | 0.430 | 356 | TS | I | 13 | PV | X | 0.419 | ||

| 307 | APS | I | 23 | Mx+ | 0.008 | V | 0.430 | 357 | APS | I | 22 | Mx− | 0.003 | V | 0.418 |

| 308 | TSE | I | Nml | PV | V | 0.430 | 358 | PS | I | 12 | |M| | V | 0.418 | ||

| 309 | APS | I | 13 | Mx+ | 0.001 | X | 0.429 | 359 | PS | I | 12 | Mx+ | V | 0.418 | |

| 310 | S | I | 22 | PV | V | 0.429 | 360 | APS | I | MnP | |M| | 0.006 | V | 0.418 | |

| 311 | S | I | 22 | |M| | V | 0.429 | 361 | APS | I | MnP | Mx− | 0.006 | V | 0.418 | |

| 312 | S | I | 22 | Mx− | V | 0.429 | 362 | PS | I | “M” | X | 0.418 | |||

| 313 | S | I | 33 | |M| | V | 0.429 | 363 | PS | I | MnP | PV | V | 0.416 | ||

| 314 | S | I | 33 | Mx− | V | 0.429 | 364 | TS | I | 11 | PV | X | 0.416 | ||

| 315 | PS | I | 13 | PV | V | 0.429 | 365 | PS | H | 22 | X | 0.416 | |||

| 316 | TS | H | 22 | (+) | X | 0.428 | 366 | APS | I | “M” | 0.007 | V | 0.415 | ||

| 317 | PS | I | 33 | Mx− | V | 0.428 | 367 | APS | I | 22 | |M| | 0.005 | V | 0.415 | |

| 318 | APS | I | “E” | 0.05 | V | 0.428 | 368 | TS | I | 13 | PV | V | 0.415 | ||

| 319 | TS | H | 12 | X | 0.428 | 369 | APS | I | 33 | |M| | 0.005 | V | 0.415 | ||

| 320 | APS | I | 13 | Mx+ | 0.0005 | V | 0.428 | 370 | APS | I | “E” | 0.009 | V | 0.414 | |

| 371 | TS | H | 23 | |m| | X | 0.413 | 421 | APS | I | 13 | Res | 0 | X | 0.404 | |

| 372 | APS | I | 23 | Mx+ | 0.006 | V | 0.413 | 422 | APS | I | 12 | Res | 0 | X | 0.404 |

| 373 | S | I | 13 | PV | X | 0.413 | 423 | APS | I | MnP | Res | 0 | X | 0.404 | |

| 374 | APS | I | 23 | |M| | 0.006 | V | 0.412 | 424 | APS | I | MxP | Res | 0 | X | 0.404 |

| 375 | APS | I | 23 | Mx− | 0.006 | V | 0.412 | 425 | APS | I | 33 | Res | 0 | X | 0.404 |

| 376 | APS | I | 22 | Mx− | 0.003 | X | 0.412 | 426 | APS | I | 22 | Res | 0 | X | 0.404 |

| 377 | APS | I | 23 | Mx+ | 0.003 | V | 0.412 | 427 | APS | I | 11 | Res | 0 | X | 0.404 |

| 378 | APS | I | MnP | Mx+ | 0.001 | X | 0.412 | 428 | APS | I | MnP | |M| | 0.004 | X | 0.404 |

| 379 | APS | I | 23 | Mx+ | 0.007 | V | 0.412 | 429 | APS | I | MnP | |M| | 0.003 | X | 0.404 |

| 380 | APS | I | 22 | |M| | 0.008 | X | 0.411 | 430 | APS | I | MxP | |M| | 0.003 | X | 0.404 |

| 381 | M*A | I | 23 | Mx+ | 0 | V | 0.411 | 431 | APS | I | MnP | |M| | 0.002 | X | 0.404 |

| 382 | S | I | 11 | |M| | V | 0.410 | 432 | APS | I | MxP | |M| | 0.002 | X | 0.404 | |

| 383 | S | I | 11 | Mx− | V | 0.410 | 433 | APS | I | 22 | |M| | 0.002 | X | 0.404 | |

| 384 | APS | I | “M” | 0.01 | X | 0.410 | 434 | APS | I | MnP | |M| | 0.001 | X | 0.404 | |

| 385 | PS | I | 33 | PV | X | 0.410 | 435 | APS | I | MxP | |M| | 0.001 | X | 0.404 | |

| 386 | TS | H | 13 | |m| | X | 0.409 | 436 | APS | I | 22 | |M| | 0.001 | X | 0.404 | |

| 387 | PS | I | MxS | V | 0.409 | 437 | APS | I | MnP | |M| | 0.0005 | X | 0.404 | ||

| 388 | PS | I | “M” | V | 0.409 | 438 | APS | I | MxP | |M| | 0.0005 | X | 0.404 | ||

| 389 | PS | I | 23 | |M| | V | 0.408 | 439 | APS | I | 22 | |M| | 0.0005 | X | 0.404 | |

| 390 | PS | I | 23 | Mx− | V | 0.408 | 440 | APS | I | 23 | |M| | 0 | X | 0.404 | |

| 391 | PS | H | 33 | (−) | X | 0.408 | 441 | APS | I | 13 | |M| | 0 | X | 0.404 | |

| 392 | APS | I | 22 | |M| | 0.003 | V | 0.407 | 442 | APS | I | 12 | |M| | 0 | X | 0.404 |

| 393 | APS | I | MxS | 0.006 | V | 0.407 | 443 | APS | I | MnP | |M| | 0 | X | 0.404 | |

| 394 | PS | I | “E” | V | 0.407 | 444 | APS | I | MxP | |M| | 0 | X | 0.404 | ||

| 395 | APS | I | 23 | |M| | 0.005 | V | 0.407 | 445 | APS | I | 33 | |M| | 0 | X | 0.404 |

| 396 | APS | I | 23 | Mx− | 0.005 | V | 0.407 | 446 | APS | I | 22 | |M| | 0 | X | 0.404 |

| 397 | PS | I | “E” | PV | V | 0.406 | 447 | APS | I | 11 | |M| | 0 | X | 0.404 | |

| 398 | PS | I | 23 | PV | X | 0.406 | 448 | APS | I | MnP | Mx− | 0.004 | X | 0.404 | |

| 399 | APS | I | MxS | 0.007 | X | 0.406 | 449 | APS | I | MnP | Mx− | 0.003 | X | 0.404 | |

| 400 | APS | I | MnP | |M| | 0.007 | X | 0.406 | 450 | APS | I | MnP | Mx− | 0.002 | X | 0.404 |

| 401 | APS | I | MnP | Mx− | 0.007 | X | 0.406 | 451 | APS | I | MnP | Mx− | 0.001 | X | 0.404 |

| 402 | APS | I | 11 | Mx+ | 0.001 | X | 0.405 | 452 | APS | I | MnP | Mx− | 0.0005 | X | 0.404 |

| 403 | APS | I | 23 | |M| | 0.003 | X | 0.405 | 453 | APS | I | 23 | Mx− | 0 | X | 0.404 |

| 404 | APS | I | 23 | Mx− | 0.003 | X | 0.405 | 454 | APS | I | 13 | Mx− | 0 | X | 0.404 |

| 405 | APS | I | 23 | |M| | 0.002 | X | 0.405 | 455 | APS | I | 12 | Mx− | 0 | X | 0.404 |

| 406 | APS | I | 23 | Mx− | 0.002 | X | 0.405 | 456 | APS | I | MnP | Mx− | 0 | X | 0.404 |

| 407 | APS | I | “M” | 0.008 | X | 0.405 | 457 | APS | I | MxP | Mx− | 0 | X | 0.404 | |

| 408 | APS | I | 23 | Mx+ | 0.009 | V | 0.405 | 458 | APS | I | 33 | Mx− | 0 | X | 0.404 |

| 409 | APS | I | 23 | Mx− | 0.001 | X | 0.405 | 459 | APS | I | 22 | Mx− | 0 | X | 0.404 |

| 410 | APS | I | MxP | Mx− | 0.001 | X | 0.405 | 460 | APS | I | 11 | Mx− | 0 | X | 0.404 |

| 411 | APS | I | 23 | |M| | 0.02 | V | 0.405 | 461 | APS | I | “E” | 0.005 | X | 0.404 | |

| 412 | APS | I | 23 | Mx− | 0.02 | V | 0.405 | 462 | APS | I | “M” | 0.004 | X | 0.404 | |

| 413 | APS | I | 23 | Mx+ | 0.005 | V | 0.404 | 463 | APS | I | “E” | 0.004 | X | 0.404 | |

| 414 | APS | I | 23 | |M| | 0.0005 | X | 0.404 | 464 | APS | I | “M” | 0.003 | X | 0.404 | |

| 415 | APS | I | 23 | Mx− | 0.0005 | X | 0.404 | 465 | APS | I | “E” | 0.003 | X | 0.404 | |

| 416 | APS | I | 11 | |M| | 0.001 | X | 0.404 | 466 | APS | I | MxS | 0.003 | X | 0.404 | |

| 417 | APS | I | “M” | Res | 0 | X | 0.404 | 467 | APS | I | MxP | Mx+ | 0.003 | X | 0.404 |

| 418 | APS | I | “E” | Res | 0 | X | 0.404 | 468 | APS | I | “M” | 0.002 | X | 0.404 | |

| 419 | APS | I | MxS | Res | 0 | X | 0.404 | 469 | APS | I | “E” | 0.002 | X | 0.404 | |

| 420 | APS | I | 23 | Res | 0 | X | 0.404 | 470 | APS | I | MxS | 0.002 | X | 0.404 | |

| 471 | APS | I | MxP | Mx+ | 0.002 | X | 0.404 | 521 | APS | I | 11 | |M| | 0 | V | 0.404 |

| 472 | APS | I | “M” | 0.001 | X | 0.404 | 522 | APS | I | MnP | Mx− | 0.004 | V | 0.404 | |

| 473 | APS | I | “E” | 0.001 | X | 0.404 | 523 | APS | I | MnP | Mx− | 0.003 | V | 0.404 | |

| 474 | APS | I | MxS | 0.001 | X | 0.404 | 524 | APS | I | MnP | Mx− | 0.002 | V | 0.404 | |

| 475 | APS | I | MxP | Mx+ | 0.001 | X | 0.404 | 525 | APS | I | MnP | Mx− | 0.001 | V | 0.404 |

| 476 | APS | I | “M” | 0.0005 | X | 0.404 | 526 | APS | I | MnP | Mx− | 0.0005 | V | 0.404 | |

| 477 | APS | I | “E” | 0.0005 | X | 0.404 | 527 | APS | I | 23 | Mx− | 0 | V | 0.404 | |

| 478 | APS | I | MxS | 0.0005 | X | 0.404 | 528 | APS | I | 13 | Mx− | 0 | V | 0.404 | |

| 479 | APS | I | MxP | Mx+ | 0.0005 | X | 0.404 | 529 | APS | I | 12 | Mx− | 0 | V | 0.404 |

| 480 | APS | I | “M” | 0 | X | 0.404 | 530 | APS | I | MnP | Mx− | 0 | V | 0.404 | |

| 481 | APS | I | “E” | 0 | X | 0.404 | 531 | APS | I | MxP | Mx− | 0 | V | 0.404 | |

| 482 | APS | I | MxS | 0 | X | 0.404 | 532 | APS | I | 33 | Mx− | 0 | V | 0.404 | |

| 483 | APS | I | 23 | Mx+ | 0 | X | 0.404 | 533 | APS | I | 22 | Mx− | 0 | V | 0.404 |

| 484 | APS | I | 13 | Mx+ | 0 | X | 0.404 | 534 | APS | I | 11 | Mx− | 0 | V | 0.404 |

| 485 | APS | I | 12 | Mx+ | 0 | X | 0.404 | 535 | APS | I | “E” | 0.005 | V | 0.404 | |

| 486 | APS | I | MnP | Mx+ | 0 | X | 0.404 | 536 | APS | I | “M” | 0.004 | V | 0.404 | |

| 487 | APS | I | MxP | Mx+ | 0 | X | 0.404 | 537 | APS | I | “E” | 0.004 | V | 0.404 | |

| 488 | APS | I | 33 | Mx+ | 0 | X | 0.404 | 538 | APS | I | “M” | 0.003 | V | 0.404 | |

| 489 | APS | I | 22 | Mx+ | 0 | X | 0.404 | 539 | APS | I | “E” | 0.003 | V | 0.404 | |

| 490 | APS | I | 11 | Mx+ | 0 | X | 0.404 | 540 | APS | I | MxS | 0.003 | V | 0.404 | |

| 491 | APS | I | “M” | Res | 0 | V | 0.404 | 541 | APS | I | MxP | Mx+ | 0.003 | V | 0.404 |

| 492 | APS | I | “E” | Res | 0 | V | 0.404 | 542 | APS | I | “M” | 0.002 | V | 0.404 | |

| 493 | APS | I | MxS | Res | 0 | V | 0.404 | 543 | APS | I | “E” | 0.002 | V | 0.404 | |

| 494 | APS | I | 23 | Res | 0 | V | 0.404 | 544 | APS | I | MxS | 0.002 | V | 0.404 | |

| 495 | APS | I | 13 | Res | 0 | V | 0.404 | 545 | APS | I | MxP | Mx+ | 0.002 | V | 0.404 |

| 496 | APS | I | 12 | Res | 0 | V | 0.404 | 546 | APS | I | “M” | 0.001 | V | 0.404 | |

| 497 | APS | I | MnP | Res | 0 | V | 0.404 | 547 | APS | I | “E” | 0.001 | V | 0.404 | |

| 498 | APS | I | MxP | Res | 0 | V | 0.404 | 548 | APS | I | MxS | 0.001 | V | 0.404 | |

| 499 | APS | I | 33 | Res | 0 | V | 0.404 | 549 | APS | I | MxP | Mx+ | 0.001 | V | 0.404 |

| 500 | APS | I | 22 | Res | 0 | V | 0.404 | 550 | APS | I | “M” | 0.0005 | V | 0.404 | |

| 501 | APS | I | 11 | Res | 0 | V | 0.404 | 551 | APS | I | “E” | 0.0005 | V | 0.404 | |

| 502 | APS | I | MnP | |M| | 0.004 | V | 0.404 | 552 | APS | I | MxS | 0.0005 | V | 0.404 | |

| 503 | APS | I | MnP | |M| | 0.003 | V | 0.404 | 553 | APS | I | MxP | Mx+ | 0.0005 | V | 0.404 |

| 504 | APS | I | MxP | |M| | 0.003 | V | 0.404 | 554 | APS | I | “M” | 0 | V | 0.404 | |

| 505 | APS | I | MnP | |M| | 0.002 | V | 0.404 | 555 | APS | I | “E” | 0 | V | 0.404 | |

| 506 | APS | I | MxP | |M| | 0.002 | V | 0.404 | 556 | APS | I | MxS | 0 | V | 0.404 | |

| 507 | APS | I | 22 | |M| | 0.002 | V | 0.404 | 557 | APS | I | 23 | Mx+ | 0 | V | 0.404 |

| 508 | APS | I | MnP | |M| | 0.001 | V | 0.404 | 558 | APS | I | 13 | Mx+ | 0 | V | 0.404 |

| 509 | APS | I | MxP | |M| | 0.001 | V | 0.404 | 559 | APS | I | 12 | Mx+ | 0 | V | 0.404 |

| 510 | APS | I | 22 | |M| | 0.001 | V | 0.404 | 560 | APS | I | MnP | Mx+ | 0 | V | 0.404 |

| 511 | APS | I | MnP | |M| | 0.0005 | V | 0.404 | 561 | APS | I | MxP | Mx+ | 0 | V | 0.404 |

| 512 | APS | I | MxP | |M| | 0.0005 | V | 0.404 | 562 | APS | I | 33 | Mx+ | 0 | V | 0.404 |

| 513 | APS | I | 22 | |M| | 0.0005 | V | 0.404 | 563 | APS | I | 22 | Mx+ | 0 | V | 0.404 |

| 514 | APS | I | 23 | |M| | 0 | V | 0.404 | 564 | APS | I | 11 | Mx+ | 0 | V | 0.404 |

| 515 | APS | I | 13 | |M| | 0 | V | 0.404 | 565 | APS | I | 23 | |M| | 0.001 | X | 0.404 |

| 516 | APS | I | 12 | |M| | 0 | V | 0.404 | 566 | APS | I | 11 | Res | 0.001 | X | 0.403 |

| 517 | APS | I | MnP | |M| | 0 | V | 0.404 | 567 | APS | I | 23 | |M| | 0.004 | V | 0.403 |

| 518 | APS | I | MxP | |M| | 0 | V | 0.404 | 568 | APS | I | 23 | Mx− | 0.004 | V | 0.403 |

| 519 | APS | I | 33 | |M| | 0 | V | 0.404 | 569 | APS | I | 22 | Mx+ | 0.008 | X | 0.403 |

| 520 | APS | I | 22 | |M| | 0 | V | 0.404 | 570 | PS | I | “M” | PV | V | 0.403 | |

| 571 | PS | I | MxS | PV | V | 0.402 | 621 | APS | I | 11 | Res | 0.003 | X | 0.389 | |

| 572 | APS | I | 33 | |M| | 0.004 | V | 0.402 | 622 | S | H | 13 | (+) | V | 0.389 | |

| 573 | PS | I | 23 | PV | V | 0.401 | 623 | APS | I | 22 | Mx− | 0.005 | X | 0.389 | |

| 574 | APS | I | 13 | Mx+ | 0.002 | V | 0.401 | 624 | APS | I | MxP | |M| | 0.007 | V | 0.389 |

| 575 | APS | I | 23 | |M| | 0.07 | X | 0.400 | 625 | APS | I | MxP | Mx+ | 0.007 | V | 0.389 |

| 576 | APS | I | 23 | Mx− | 0.07 | X | 0.400 | 626 | TSE | I | Shr | V | 0.389 | ||

| 577 | APS | I | 33 | Mx+ | 0.004 | V | 0.400 | 627 | APS | I | 33 | |M| | 0.008 | V | 0.389 |

| 578 | S | H | 33 | V | 0.400 | 628 | M*A | I | 22 | Mx+ | 0 | X | 0.388 | ||

| 579 | S | I | 13 | |M| | V | 0.400 | 629 | APS | I | 33 | Mx− | 0.002 | V | 0.387 | |

| 580 | S | H | 11 | (+) | X | 0.400 | 630 | APS | I | 13 | Mx+ | 0.003 | X | 0.387 | |

| 581 | PS | I | MnP | |M| | X | 0.398 | 631 | APS | I | 22 | |M| | 0.007 | X | 0.387 | |

| 582 | PS | I | MnP | Mx− | X | 0.398 | 632 | S | H | 22 | V | 0.387 | |||

| 583 | PS | H | 12 | (+) | X | 0.397 | 633 | S | H | MnP | V | 0.387 | |||

| 584 | APS | I | 33 | Mx+ | 0.008 | V | 0.396 | 634 | PS | I | MxP | PV | V | 0.387 | |

| 585 | APS | I | 23 | |M| | 0.004 | X | 0.396 | 635 | APS | I | 33 | |M| | 0.0005 | X | 0.386 |

| 586 | APS | I | 23 | Mx− | 0.004 | X | 0.396 | 636 | APS | I | 33 | Mx+ | 0.0005 | X | 0.386 |

| 587 | APS | I | 22 | Mx+ | 0.009 | X | 0.395 | 637 | S | H | 11 | V | 0.386 | ||

| 588 | PS | H | 23 | (−) | X | 0.395 | 638 | APS | I | 11 | |M| | 0.003 | X | 0.386 | |

| 589 | APS | I | 22 | |M| | 0.006 | X | 0.395 | 639 | TS | H | 33 | (−) | X | 0.386 | |

| 590 | APS | I | 23 | |M| | 0.005 | X | 0.394 | 640 | APS | I | 11 | Res | 0.002 | X | 0.385 |

| 591 | APS | I | 23 | Mx− | 0.005 | X | 0.394 | 641 | APS | I | 11 | Mx+ | 0.002 | X | 0.385 |

| 592 | APS | I | 22 | Mx+ | 0.007 | X | 0.394 | 642 | PS | I | 12 | PV | V | 0.385 | |

| 593 | APS | I | MxP | |M| | 0.004 | V | 0.394 | 643 | APS | I | 23 | |M| | 0.001 | V | 0.385 |

| 594 | APS | I | “M” | 0.005 | V | 0.394 | 644 | PS | I | 22 | |M| | X | 0.385 | ||

| 595 | APS | I | MxS | 0.004 | V | 0.394 | 645 | APS | I | 23 | |M| | 0.0005 | V | 0.384 | |

| 596 | APS | I | MxP | Mx+ | 0.004 | V | 0.394 | 646 | APS | I | 23 | Mx− | 0.0005 | V | 0.384 |

| 597 | APS | I | 23 | |M| | 0.006 | X | 0.393 | 647 | PSE | I | Shr | X | 0.384 | ||

| 598 | APS | I | 23 | Mx− | 0.006 | X | 0.393 | 648 | S | H | vM | V | 0.384 | ||

| 599 | APS | I | 33 | |M| | 0.009 | V | 0.392 | 649 | APS | I | 23 | Mx− | 0.001 | V | 0.384 |

| 600 | APS | I | 23 | Mx+ | 0.0005 | X | 0.392 | 650 | TS | H | MnP | V | 0.384 | ||

| 601 | APS | I | “M” | 0.04 | V | 0.392 | 651 | APS | I | MxP | Mx− | 0.007 | V | 0.383 | |

| 602 | M*A | I | 22 | |M| | 0 | X | 0.392 | 652 | APS | I | 23 | |M| | 0.002 | V | 0.383 |

| 603 | APS | I | 22 | Mx− | 0.007 | V | 0.391 | 653 | APS | I | 23 | Mx− | 0.002 | V | 0.383 |

| 604 | PS | I | MxP | |M| | V | 0.391 | 654 | S | H | MxS | V | 0.383 | |||

| 605 | PS | I | MxP | Mx+ | V | 0.391 | 655 | S | H | Tca | V | 0.383 | |||

| 606 | TS | H | 22 | (−) | X | 0.391 | 656 | APS | I | 11 | |M| | 0.002 | X | 0.382 | |

| 607 | S | H | prs | V | 0.391 | 657 | APS | I | 33 | Mx+ | 0.006 | V | 0.381 | ||

| 608 | S | H | 11 | (−) | V | 0.391 | 658 | APS | I | 23 | |M| | 0.003 | V | 0.381 | |

| 609 | APS | I | MnP | |M| | 0.008 | X | 0.391 | 659 | APS | I | 23 | Mx− | 0.003 | V | 0.381 |

| 610 | APS | I | MnP | Mx− | 0.008 | X | 0.391 | 660 | M*A | I | MxP | Mx− | 0 | V | 0.381 |

| 611 | APS | I | MxS | 0.008 | X | 0.391 | 661 | APS | I | 13 | Mx+ | 0.004 | X | 0.381 | |

| 612 | APS | I | 11 | Mx+ | 0.003 | X | 0.390 | 662 | APS | I | 22 | |M| | 0.008 | V | 0.381 |

| 613 | APS | I | 33 | Mx+ | 0.007 | V | 0.390 | 663 | APS | I | 13 | |M| | 0.0005 | X | 0.380 |

| 614 | APS | I | MxP | |M| | 0.008 | X | 0.390 | 664 | M*A | I | “E” | 0 | V | 0.380 | |

| 615 | APS | I | MxP | Mx+ | 0.008 | X | 0.390 | 665 | TS | H | MxS | V | 0.380 | ||

| 616 | TSE | H | Gnl | V | 0.390 | 666 | S | H | 3rd | (−) | V | 0.380 | |||

| 617 | APS | I | 22 | Mx+ | 0.003 | X | 0.390 | 667 | S | I | 12 | |M| | V | 0.380 | |

| 618 | PS | H | 33 | (−) | V | 0.390 | 668 | APS | I | 22 | Mx+ | 0.001 | X | 0.379 | |

| 619 | S | H | MxP | V | 0.390 | 669 | APS | I | MnP | Mx+ | 0.007 | V | 0.379 | ||

| 620 | APS | I | 33 | Mx+ | 0.009 | V | 0.389 | 670 | S | I | 13 | Mx+ | V | 0.378 | |

| 671 | APS | I | 12 | |M| | 0.005 | X | 0.378 | 721 | APS | I | 23 | |M| | 0.008 | X | 0.363 |

| 672 | APS | I | 12 | Mx+ | 0.005 | X | 0.378 | 722 | APS | I | 23 | Mx− | 0.008 | X | 0.363 |

| 673 | TSE | H | Nml | V | 0.378 | 723 | APS | I | 22 | Mx− | 0.006 | X | 0.363 | ||

| 674 | APS | I | 13 | |M| | 0.002 | V | 0.378 | 724 | APS | I | 22 | Mx+ | 0.01 | X | 0.362 |

| 675 | APS | I | 33 | |M| | 0.007 | V | 0.377 | 725 | APS | I | 11 | |M| | 0.004 | X | 0.361 |

| 676 | S | I | 12 | Mx− | V | 0.377 | 726 | APS | I | 33 | Mx+ | 0.01 | V | 0.361 | |

| 677 | APS | I | 13 | Mx+ | 0.002 | X | 0.376 | 727 | PS | I | 11 | PV | V | 0.360 | |

| 678 | M*A | I | MnP | Mx+ | 0 | V | 0.376 | 728 | M*A | I | 12 | |M| | 0 | X | 0.360 |

| 679 | APS | I | 22 | Mx− | 0.002 | V | 0.376 | 729 | M*A | I | 12 | Mx+ | 0 | X | 0.360 |

| 680 | APS | I | “E” | 0.01 | X | 0.376 | 730 | APS | I | 13 | |M| | 0.004 | V | 0.359 | |

| 681 | TS | H | 23 | (−) | X | 0.376 | 731 | APS | I | 11 | Mx+ | 0.004 | X | 0.358 | |

| 682 | PS | H | 13 | (+) | X | 0.376 | 732 | APS | I | 22 | Mx− | 0.001 | V | 0.358 | |

| 683 | PSE | I | Shr | V | 0.376 | 733 | APS | I | 22 | Mx− | 0.0005 | V | 0.358 | ||

| 684 | PS | I | 13 | PV | X | 0.375 | 734 | APS | I | 22 | |M| | 0.009 | X | 0.358 | |

| 685 | APS | I | 22 | Mx+ | 0.004 | X | 0.375 | 735 | S | I | MnP | Mx+ | V | 0.358 | |

| 686 | M*A | I | 11 | Res | 0 | X | 0.375 | 736 | APS | I | 22 | Mx+ | 0.005 | X | 0.357 |

| 687 | APS | I | 22 | Mx− | 0.008 | X | 0.374 | 737 | S | H | 23 | |m| | X | 0.357 | |

| 688 | TS | H | MxP | V | 0.373 | 738 | S | I | 12 | |M| | X | 0.357 | |||

| 689 | TS | I | 22 | |M| | V | 0.372 | 739 | APS | I | “M” | 0.02 | V | 0.357 | ||

| 690 | M*A | I | 11 | Mx+ | 0 | X | 0.371 | 740 | TS | H | MxP | X | 0.357 | ||

| 691 | S | H | 23 | (+) | X | 0.371 | 741 | APS | I | 22 | Mx+ | 0.0005 | X | 0.357 | |

| 692 | APS | I | 12 | |M| | 0.009 | X | 0.371 | 742 | APS | I | 12 | |M| | 0.004 | V | 0.357 |

| 693 | APS | I | 12 | Mx+ | 0.009 | X | 0.371 | 743 | APS | I | 12 | Mx+ | 0.004 | V | 0.357 |

| 694 | APS | I | MxP | Mx− | 0.005 | X | 0.370 | 744 | APS | I | “E” | 0.08 | X | 0.356 | |

| 695 | APS | I | 12 | |M| | 0.007 | X | 0.370 | 745 | PS | H | 23 | (−) | V | 0.356 | |

| 696 | APS | I | 12 | Mx+ | 0.007 | X | 0.370 | 746 | APS | I | 33 | Mx− | 0.008 | V | 0.356 |

| 697 | S | H | 23 | (−) | X | 0.369 | 747 | M*A | I | 23 | Mx− | 0 | X | 0.355 | |

| 698 | APS | I | 13 | Mx+ | 0.005 | X | 0.369 | 748 | M*A | I | 23 | |M| | 0 | X | 0.355 |

| 699 | APS | I | 33 | |M| | 0.006 | V | 0.368 | 749 | TS | I | MnP | PV | V | 0.355 | |

| 700 | PS | I | 22 | |M| | V | 0.368 | 750 | PS | H | 11 | X | 0.355 | |||

| 701 | PS | I | 22 | Mx+ | V | 0.368 | 751 | APS | I | 12 | |M| | 0.006 | X | 0.355 | |

| 702 | PS | H | 33 | V | 0.368 | 752 | APS | I | 12 | Mx+ | 0.006 | X | 0.355 | ||

| 703 | APS | I | 23 | Mx+ | 0.01 | V | 0.368 | 753 | TS | I | MxP | |M| | V | 0.354 | |

| 704 | APS | I | 13 | Mx− | 0.002 | V | 0.367 | 754 | TS | I | MxP | Mx+ | V | 0.354 | |

| 705 | APS | I | “M” | 0.009 | X | 0.367 | 755 | APS | I | 23 | Mx+ | 0.001 | X | 0.354 | |

| 706 | APS | I | 33 | Mx− | 0.005 | V | 0.367 | 756 | TS | I | MxP | PV | V | 0.354 | |

| 707 | APS | I | 33 | |M| | 0.01 | V | 0.367 | 757 | M*A | I | 22 | Mx− | 0 | X | 0.354 |

| 708 | APS | I | 12 | |M| | 0.01 | X | 0.367 | 758 | TS | I | MxS | V | 0.354 | ||

| 709 | APS | I | 12 | Mx+ | 0.01 | X | 0.367 | 759 | TS | I | 13 | |M| | X | 0.353 | |

| 710 | APS | I | 12 | |M| | 0.004 | X | 0.367 | 760 | TS | I | 13 | Mx+ | X | 0.353 | |

| 711 | APS | I | 12 | Mx+ | 0.004 | X | 0.367 | 761 | S | I | 13 | |M| | X | 0.353 | |

| 712 | S | H | 22 | (+) | V | 0.367 | 762 | APS | I | MxS | 0.02 | V | 0.353 | ||

| 713 | APS | I | 12 | |M| | 0.008 | X | 0.366 | 763 | TS | H | 33 | |m| | X | 0.353 | |

| 714 | APS | I | 12 | Mx+ | 0.008 | X | 0.366 | 764 | PS | H | 13 | |m| | X | 0.352 | |

| 715 | TS | H | 11 | (+) | V | 0.365 | 765 | APS | I | 12 | |M| | 0.002 | X | 0.352 | |

| 716 | TS | H | 12 | V | 0.365 | 766 | APS | I | 12 | Mx+ | 0.002 | X | 0.352 | ||

| 717 | TS | I | MxS | PV | V | 0.364 | 767 | APS | I | 23 | |M| | 0.01 | X | 0.352 | |

| 718 | APS | I | 13 | Mx− | 0.0005 | X | 0.364 | 768 | APS | I | 23 | Mx− | 0.01 | X | 0.352 |

| 719 | APS | I | 23 | |M| | 0.007 | X | 0.363 | 769 | APS | I | 13 | Mx+ | 0.0005 | X | 0.352 |

| 720 | APS | I | 23 | Mx− | 0.007 | X | 0.363 | 770 | TS | I | 13 | |M| | V | 0.352 | |

| 771 | TS | I | 13 | Mx+ | V | 0.352 | 821 | APS | I | 22 | Mx− | 0.01 | X | 0.345 | |

| 772 | S | H | 23 | V | 0.351 | 822 | PS | H | 11 | |m| | X | 0.345 | |||

| 773 | APS | I | 23 | |M| | 0.009 | X | 0.351 | 823 | PSE | H | Gnl | X | 0.345 | ||

| 774 | APS | I | 23 | Mx− | 0.009 | X | 0.351 | 824 | S | I | 12 | PV | V | 0.345 | |

| 775 | APS | I | 13 | Mx+ | 0.001 | V | 0.351 | 825 | APS | I | MxP | |M| | 0.007 | X | 0.345 |

| 776 | APS | I | 22 | |M| | 0.01 | X | 0.351 | 826 | APS | I | MxP | Mx+ | 0.007 | X | 0.345 |

| 777 | APS | I | 23 | |M| | 0.04 | V | 0.351 | 827 | PS | I | 11 | Mx− | V | 0.345 | |

| 778 | APS | I | 23 | Mx− | 0.04 | V | 0.351 | 828 | PS | H | 12 | X | 0.344 | ||

| 779 | APS | I | 13 | Mx+ | 0.004 | V | 0.351 | 829 | PSE | H | Nml | X | 0.344 | ||

| 780 | APS | I | 22 | Mx− | 0.002 | X | 0.351 | 830 | TS | H | 11 | X | 0.343 | ||

| 781 | APS | I | 12 | |M| | 0.003 | X | 0.350 | 831 | S | H | 13 | |m| | X | 0.343 | |

| 782 | APS | I | 12 | Mx+ | 0.003 | X | 0.350 | 832 | TS | H | 13 | (+) | X | 0.343 | |

| 783 | APS | I | 13 | Mx+ | 0.005 | V | 0.350 | 833 | APS | I | 11 | Res | 0.004 | X | 0.343 |

| 784 | PS | I | 12 | Mx− | X | 0.350 | 834 | TS | H | MnP | X | 0.343 | |||

| 785 | S | H | Tca | X | 0.349 | 835 | TS | I | 12 | Mx− | V | 0.342 | |||

| 786 | S | H | MxS | X | 0.349 | 836 | M*A | I | 11 | |M| | 0 | X | 0.342 | ||

| 787 | TS | H | MxS | X | 0.349 | 837 | APS | I | 33 | Mx− | 0.004 | V | 0.341 | ||

| 788 | APS | I | 22 | Mx− | 0.007 | X | 0.349 | 838 | S | H | prs | X | 0.341 | ||

| 789 | S | H | vM | X | 0.349 | 839 | PS | H | 33 | X | 0.340 | ||||

| 790 | TS | I | 11 | |M| | X | 0.349 | 840 | APS | I | 22 | Mx+ | 0.005 | V | 0.340 | |

| 791 | TS | I | 11 | Mx− | X | 0.349 | 841 | APS | I | 13 | Mx+ | 0.003 | V | 0.339 | |

| 792 | PS | H | “E” | X | 0.349 | 842 | TS | H | 12 | |m| | X | 0.338 | |||

| 793 | S | H | 12 | (−) | X | 0.349 | 843 | APS | I | MnP | Mx+ | 0.002 | X | 0.337 | |

| 794 | PS | H | 12 | |m| | X | 0.349 | 844 | APS | I | MxP | Mx− | 0.002 | X | 0.337 | |

| 795 | APS | I | 33 | |M| | 0.001 | X | 0.348 | 845 | M*A | I | MnP | Mx+ | 0 | X | 0.337 |

| 796 | PS | H | MnP | X | 0.348 | 846 | S | H | prs | (−) | V | 0.336 | |||

| 797 | PS | H | MxS | X | 0.348 | 847 | M*A | I | 33 | Mx− | 0 | V | 0.336 | ||

| 798 | PS | H | “M” | X | 0.348 | 848 | M*A | I | MxP | Mx− | 0 | X | 0.336 | ||

| 799 | TS | I | MnP | |M| | V | 0.348 | 849 | APS | I | 23 | |M| | 0.06 | V | 0.335 | |

| 800 | TS | I | MnP | Mx− | V | 0.348 | 850 | APS | I | 23 | Mx− | 0.06 | V | 0.335 | |

| 801 | APS | I | 13 | |M| | 0.003 | V | 0.348 | 851 | APS | I | 13 | Mx+ | 0.006 | X | 0.335 |

| 802 | PS | H | 22 | |m| | X | 0.348 | 852 | S | I | 13 | Mx+ | X | 0.335 | ||

| 803 | APS | I | 22 | Mx− | 0.009 | X | 0.347 | 853 | PS | H | 23 | X | 0.335 | ||

| 804 | TS | H | 11 | |m| | X | 0.347 | 854 | APS | I | “E” | 0.009 | X | 0.334 | ||

| 805 | APS | I | “E” | 0.01 | V | 0.347 | 855 | APS | I | 13 | |M| | 0.006 | V | 0.334 | |

| 806 | PS | H | MxP | X | 0.347 | 856 | APS | I | “M” | 0.01 | V | 0.334 | |||

| 807 | APS | I | 33 | Mx+ | 0.001 | X | 0.347 | 857 | APS | I | 13 | |M| | 0.005 | V | 0.333 |

| 808 | TS | H | 11 | (−) | X | 0.347 | 858 | S | H | 13 | X | 0.333 | |||

| 809 | APS | I | 13 | Mx+ | 0.006 | V | 0.347 | 859 | APS | I | “M” | 0.009 | V | 0.333 | |

| 810 | TS | I | MxP | Mx− | X | 0.347 | 860 | PS | H | 23 | V | 0.333 | |||

| 811 | PS | I | 11 | |M| | X | 0.347 | 861 | APS | I | MnP | Mx+ | 0.003 | X | 0.333 | |

| 812 | TSE | H | Shr | X | 0.346 | 862 | APS | I | MxP | Mx− | 0.003 | X | 0.332 | ||

| 813 | PSE | I | Gnl | PV | V | 0.346 | 863 | PS | H | 33 | |m| | X | 0.332 | ||

| 814 | APS | I | 22 | Mx− | 0.001 | X | 0.346 | 864 | APS | I | 33 | Mx− | 0.007 | V | 0.332 |

| 815 | APS | I | 22 | Mx− | 0.0005 | X | 0.346 | 865 | PS | H | 23 | |m| | X | 0.332 | |

| 816 | APS | I | 33 | Mx− | 0.003 | V | 0.346 | 866 | PS | H | “E” | V | 0.332 | ||

| 817 | PS | I | 11 | |M| | V | 0.346 | 867 | PS | I | 23 | Mx+ | X | 0.331 | ||

| 818 | PSE | H | Shr | X | 0.346 | 868 | APS | I | MnP | Mx+ | 0.004 | X | 0.331 | ||

| 819 | S | I | 13 | Mx− | X | 0.346 | 869 | APS | I | 11 | Mx− | 0.002 | X | 0.331 | |

| 820 | APS | I | 22 | Mx+ | 0.002 | V | 0.346 | 870 | M*A | I | “M” | 0 | V | 0.331 | |

| 871 | PS | I | 12 | |M| | X | 0.331 | 921 | APS | I | 22 | Mx+ | 0.01 | V | 0.320 | |

| 872 | PS | I | 12 | Mx+ | X | 0.331 | 922 | S | H | prs | |m| | X | 0.320 | ||

| 873 | APS | I | 13 | Mx+ | 0.007 | V | 0.330 | 923 | APS | I | 33 | |M| | 0.002 | X | 0.319 |

| 874 | TS | I | 12 | PV | V | 0.330 | 924 | APS | I | MxP | Mx− | 0.006 | X | 0.319 | |

| 875 | APS | I | MxP | Mx− | 0.004 | X | 0.330 | 925 | APS | I | 11 | Mx− | 0.005 | X | 0.319 |

| 876 | APS | I | 33 | Mx− | 0.009 | V | 0.330 | 926 | S | H | 12 | |m| | X | 0.319 | |

| 877 | TS | H | 23 | (+) | X | 0.330 | 927 | M*A | I | MxP | |M| | 0 | V | 0.318 | |

| 878 | APS | I | 11 | Mx− | 0.003 | X | 0.330 | 928 | M*A | I | MxP | Mx+ | 0 | V | 0.318 |

| 879 | S | H | 3rd | |m| | X | 0.330 | 929 | APS | I | 33 | Mx− | 0.006 | V | 0.318 | |

| 880 | S | I | MnP | Mx+ | X | 0.329 | 930 | APS | I | 13 | |M| | 0.005 | X | 0.317 | |

| 881 | PS | H | 11 | (−) | X | 0.329 | 931 | M*A | I | 13 | Mx+ | 0 | X | 0.317 | |

| 882 | PS | I | 23 | |M| | X | 0.329 | 932 | APS | I | MnP | Mx+ | 0.005 | X | 0.317 | |

| 883 | PS | I | 23 | Mx− | X | 0.329 | 933 | APS | I | 11 | |M| | 0.005 | X | 0.317 | |

| 884 | PS | I | “E” | X | 0.329 | 934 | APS | I | MxP | |M| | 0.01 | V | 0.315 | ||

| 885 | TS | H | 13 | (+) | V | 0.329 | 935 | APS | I | MxP | Mx+ | 0.01 | V | 0.315 | |

| 886 | M*A | I | MxS | 0 | V | 0.328 | 936 | M*A | I | 12 | Mx− | 0 | X | 0.315 | |

| 887 | M*A | I | MnP | |M| | 0 | V | 0.328 | 937 | APS | I | 13 | |M| | 0.004 | X | 0.314 |

| 888 | M*A | I | MnP | Mx− | 0 | V | 0.328 | 938 | APS | I | 11 | Mx− | 0.004 | X | 0.314 |

| 889 | APS | I | 23 | Mx+ | 0.01 | X | 0.328 | 939 | APS | I | 12 | |M| | 0.007 | V | 0.314 |

| 890 | APS | I | MxP | |M| | 0.008 | V | 0.327 | 940 | APS | I | 12 | Mx+ | 0.007 | V | 0.314 |

| 891 | APS | I | MxP | Mx+ | 0.008 | V | 0.327 | 941 | APS | I | 33 | Mx− | 0.0005 | X | 0.314 |

| 892 | APS | I | MnP | |M| | 0.008 | V | 0.327 | 942 | PS | H | 11 | (+) | X | 0.313 | |

| 893 | APS | I | MnP | Mx− | 0.008 | V | 0.327 | 943 | APS | I | 23 | |M| | 0.02 | X | 0.313 |

| 894 | APS | I | MxS | 0.008 | V | 0.327 | 944 | APS | I | 23 | Mx− | 0.02 | X | 0.313 | |

| 895 | S | H | MnP | X | 0.327 | 945 | APS | I | MnP | Mx+ | 0.007 | X | 0.313 | ||

| 896 | APS | I | 12 | |M| | 0.03 | X | 0.327 | 946 | S | H | 12 | (+) | V | 0.313 | |

| 897 | APS | I | 12 | Mx+ | 0.03 | X | 0.327 | 947 | TS | H | 11 | (+) | X | 0.312 | |

| 898 | PS | I | 11 | Mx+ | X | 0.326 | 948 | APS | I | 23 | |M| | 0.03 | X | 0.312 | |

| 899 | TSE | H | Gnl | X | 0.325 | 949 | APS | I | 23 | Mx− | 0.03 | X | 0.312 | ||

| 900 | S | H | 23 | X | 0.325 | 950 | APS | I | MxS | 0.01 | V | 0.312 | |||

| 901 | APS | I | 12 | |M| | 0.006 | V | 0.325 | 951 | APS | I | 13 | Mx+ | 0.008 | V | 0.312 |

| 902 | APS | I | 12 | Mx+ | 0.006 | V | 0.325 | 952 | APS | I | MxP | Mx− | 0.007 | X | 0.312 |

| 903 | TS | I | 22 | Mx+ | V | 0.324 | 953 | TS | H | 12 | (+) | V | 0.311 | ||

| 904 | S | H | 13 | (−) | X | 0.324 | 954 | M*A | I | 23 | Mx+ | 0 | X | 0.311 | |

| 905 | TS | I | 11 | Mx+ | V | 0.324 | 955 | M*A | I | 11 | Mx− | 0 | X | 0.311 | |

| 906 | APS | I | 13 | Mx− | 0.003 | V | 0.324 | 956 | M*A | I | 12 | Mx− | 0 | V | 0.310 |

| 907 | APS | I | 22 | |M| | 0.007 | V | 0.323 | 957 | S | H | 13 | (+) | X | 0.310 | |