Abstract

Eliminating post-irradiation melting and stabilizing the residual free radicals of radiation crosslinked ultra-high molecular weight polyethylene (UHMWPE) with Vitamin-E resulted in improved fatigue crack propagation resistance without compromising wear resistance. We designed a cantilever post bending test to determine the bending fatigue resistance of vitamin E-doped, irradiated UHMWPE (α-TPE) in comparison to conventional UHMWPE. The bending fatigue behavior of α-TPE was comparable to conventional UHMWPE. Upon accelerated aging the fatigue resistance of α-TPE was substantially better than that of conventional UHMWPE. α-TPE has shown improved wear and oxidation resistance, migration stability of vitamin E, and improved mechanical properties. The use of this material may be beneficial in total knee arthroplasty where its improved fatigue properties may be an advantage under high stresses.

Keywords: Total knee arthroplasty, highly cross-linked polyethylene, oxidation resistance, fatigue resistance, vitamin E, biomaterials

Introduction

One of the major factors limiting the long-term performance of total hips is the peri-prosthetic osteolysis secondary to the wear of the ultra-high molecular weight polyethylene (UHMWPE) in acetabular components. In total knees, wear and mechanical damage initiated by fatigue, such as delamination and fatigue fracture are additional concerns. Radiation cross-linking and melting of UHMWPE has successfully been used to decrease UHMWPE wear [1–6] .Early clinical studies for these improved UHMWPEs, which have been in clinical use since 1998, show significantly reduced wear rates in comparison with conventional UHMWPEs [7–9]. These novel UHMWPE materials are promising in markedly reducing the occurrence of osteolysis.

Cross-linking of UHMWPE is achieved through the use of ionizing radiation [10]. Ionizing radiation forms free radicals in polyethylene, most of which recombine with each other and form crosslinks in the amorphous portion of the polymer. However, the free radicals generated during irradiation in the crystals are trapped in this phase. The molecular weight of the polymer is reduced through oxidation reactions of these residual free radicals, leading to deterioration of mechanical properties [11, 12]. Achieving oxidative stability of irradiated UHMWPE is therefore necessary to avoid compromised long-term performance.

Post-irradiation melting has been used in stabilizing radiation cross-linked UHMWPE against oxidation; melting converts crystalline structure to amorphous and allows elimination of the trapped free radicals by recombination reactions [1, 2, 6]. However, post-irradiation melting reduces the crystallinity of irradiated UHMWPE, in turn reducing its mechanical properties and fatigue strength [13]. It may not be beneficial to use this highly wear resistant UHMWPE in applications where the polyethylene component may be subjected to adverse conditions; such as the use of thin components, and adverse loading of the polyethylene post in posterior-stabilized knees.

Our research in the past five years has been focused on replacing post-irradiation melting with an alternative method to address the issue of oxidative stability following radiation crosslinking while improving mechanical strength. We developed a second generation highly cross-linked UHMWPE, namely radiation crosslinked and vitamin E stabilized UHMWPE (α-TPE) to address these concerns caused by loss of fatigue strength in irradiated and melted UHMWPEs [13–15]. Vitamin E (α-tocopherol) was used to stabilize the residual free radicals in radiation cross-linked UHMWPE instead of post-irradiation melting due to its antioxidant free-radical scavenging ability. Since vitamin E is known to decrease the cross-linking efficiency of UHMWPE when present during irradiation [16], not resulting in optimum reduction in wear [17], it was incorporated in cross-linked UHMWPE by diffusion. This preserved the natural cross-linking efficiency of UHMWPE and resulted in the desired decrease in wear [13, 14].

Recently, we have shown that, as hypothesized, vitamin E-doped, irradiated UHMWPE showed wear resistance superior to conventional UHMWPE using a hip simulator in both clean serum and in serum with third body bone cement particles [14]. The wear rate of conventional UHMWPE has been shown to increase with increasing femoral head size due to the increase in the wear path for each simulated gait cycle [18]; in contrast, we showed that the wear rate of the vitamin E-doped, irradiated UHMWPE was not affected by the larger femoral head size, also reported previously for cross-linked and melted UHMWPE [18]. The hip simulator wear rates of vitamin E-doped, irradiated UHMWPE were comparable to those reported for cross-linked and melted UHMWPE [2, 18].

We have shown that the mechanical strength and fatigue crack propagation resistance of vitamin E-doped, irradiated UHMWPE was improved compared to irradiated and melted UHMWPE [14]. However, it is very important to evaluate the fatigue strength of this UHMWPE under clinically relevant adverse conditions, which may give rise to fatigue initiation, crack growth and ultimately, failure. In this study, we report the fatigue strength of vitamin E-doped UHMWPE in a test simulating the adverse case of impingement of the post on a posterior-stabilized total knee implant design. The fatigue strength was quantified as the total number of cycles to failure under specified peak loads; unaged and accelerated aged vitamin E-doped, irradiated UHMWPE was compared to unaged and accelerated aged gamma sterilized conventional UHMWPE.

Materials and Methods

Preparation of vitamin E-doped, irradiated UHMWPE and conventional UHMWPE for bending fatigue testing

All specimens were manufactured from isostatically molded UHMWPE bar stock. The UHMWPE resin utilized was GUR1050 (Ticona, Bishop TX). Two different groups of test samples, namely vitamin E-doped, irradiated UHMWPE and conventional UHMWPE were prepared. Both groups of test samples were terminally gamma sterilized in argon gas before testing.

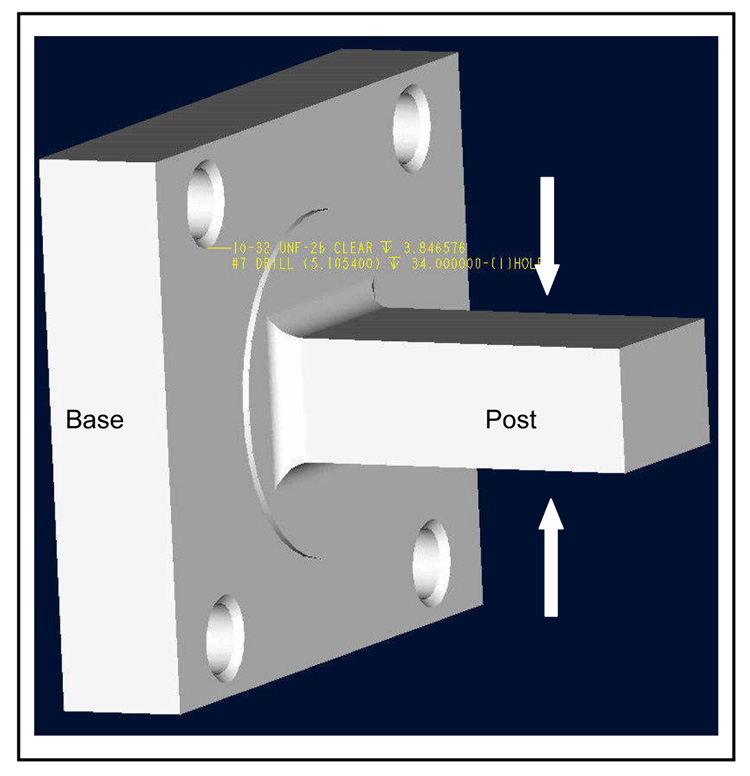

The vitamin E-doped, irradiated UHMWPE samples were machined into a shape with a cantilevered post (Fig 1) using annealed GUR1050 UHMWPE stock. The annealing of the stock UHMWPE was to reduce the thermal stresses resulting in greater dimensional stability at elevated temperatures. These samples were packaged under argon gas and the packages were gamma-irradiated to 85 kGy. The irradiated samples were then doped with vitamin E (D,L-α-tocopherol, Alfa Aesar, Ward Hill, MA) by immersion into vitamin E at 120 °C for 5 hours and subsequently homogenized at 120 °C in argon for 64 hours. The samples were then packaged under argon gas and gamma sterilized (25–40kGy).

Fig 1.

3D model of a bending specimen used in crack initiation studies. The post was cyclically loaded in both directions at a per-determined peak bending load.

Control conventional UHMWPE samples were machined from a GUR1050 UHMWPE stock, packaged in argon gas, and gamma sterilized (25–40kGy).

Bending Fatigue Testing

Resistance to bending fatigue failures was quantified by cyclically loading a post with a rectangular cross-section of 14×9 mm (Fig 1). The tests were conducted on an MTS 858 Bionix test system (Eden Prairie, MN). The post was centered vertically between two load applicators. A distance of 9.5 ± 0.2 mm was maintained between the edges of the load applicators. The testing was done in an aqueous chamber maintained at 40°C to simulate joint temperature. The load was applied as a sinusoidal waveform symmetrical about the zero load line at 0.5 Hz. This frequency simulated the load frequencies typically encountered by total joints in vivo [19].

The displacement corresponding to the maximum and minimum loads for each load cycle was recorded. Failure initiation was defined as sudden increase in displacement, and in most cases the post sheared off and separated from the base within 10–100 cycles of crack initiation. The materials tested were compared on an S-N curve. At least 5 samples of each group was tested of each group at loads from 400–900N, constructing a S-N curve over 4 decades on a logarithmic scale.

Groups tested were unaged and aged conventional UHMWPE and α-tocopherol-doped, irradiated UHMWPE. Accelerated aging was performed at 70°C for 2 weeks in 5 atm. of pure oxygen.

Determination of vitamin E concentration profiles by Fourier Transform Infrared Spectroscopy (FTIR)

Thin (~150 µm) sections were cut from one doped and homogenized bending sample using a sledge microtome (Model 90-91-1177, LKB-Produkter AB, Bromma Sweden) for analysis. FTIR (Bio-Rad FTS155, Natick MA) analysis was performed on these thin sections. Infrared spectra were collected from one edge of the sample to the other in 100 µm and 500 µm intervals, with each spectrum recorded as an average of 32 individual scans. The infrared spectra were analyzed to calculate a vitamin E index [17].

Determination of oxidation profiles by FTIR

Blocks (30×30×5 mm) were used to determine oxidation levels following accelerated aging. These samples were packaged under argon gas and the packages were gamma-irradiated to 85 kGy. The irradiated samples were then doped with vitamin E by immersion into vitamin E at 120 °C for 2 hours and subsequently homogenized at 120 °C in argon for 24 hours. The samples were then packaged under argon gas and gamma sterilized.

Following accelerated aging at 70°C in 5 atm. of oxygen for 2 weeks, samples were cut in half and thin (~150 µm) sections were cut from the inside of the half-samples using a sledge microtome. These thin films were boiled in hexane for 16 hours to remove extractable species and dried in vacuum for 8 hours to remove all absorbed species. Oxidation levels were quantified as a function of depth from a free surface. Oxidation levels were expressed as an oxidation index, which was calculated by normalizing the absorbance over 1680 cm−1 – 1780 cm−1 to the absorbance over 1330 cm−1 – 1390 cm−1. The surface oxidation index (SOI) was calculated as the average of the oxidation indices over the first 3 mm of the sample as per ASTM F 2102-01ε1.

Statistical Analysis

Statistical analysis was performed on the bending fatigue data using the Cox proportional hazards regression model for accelerated lifetime analysis using a 2-parameter Weibull distribution [20]. Maximum likelihood estimation was used to derive time to failure as well as to estimate Weibull parameters. Data analysis was performed using ALTA 7 (ReliaSoft Corporation, Tucson, AZ). The minimum number of cycles (lower bound of 95% confidence) at which 90% survivorship is expected was evaluated at each load. For example, at 500 N, there is a 95% probability that 90% of aged vitamin E-doped, irradiated UHMWPE will survive at least 770 cycles whereas this value for aged conventional UHMWPE is 32 cycles. This translates into an acceleration factor of 24 (770/32).

Results

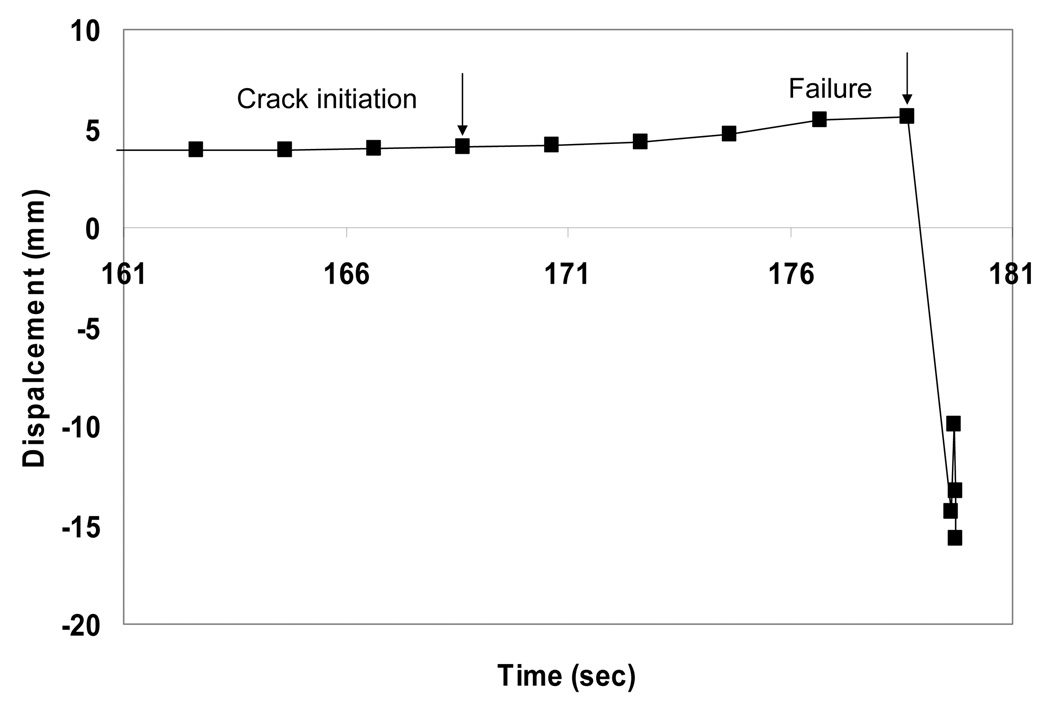

Bending fatigue crack initiation, propagation and failure are shown in a representative plot of displacement versus time (Fig 2). Maximum positive displacement was plotted for this particular sample since the crack was initiated on the bottom surface of the post. Fatigue initiation was marked on the curve as the point at which the maximum displacement started increasing. The initiated crack propagated for several cycles after initiation until the displacement sharply decreased. If the crack had initiated on the top surface, at the point of failure, the displacement would have drastically increased rather than decreasing.

Fig 2.

Displacement as a function of time for a representative bending fatigue test. Only the data points close to the end of the test are shown.

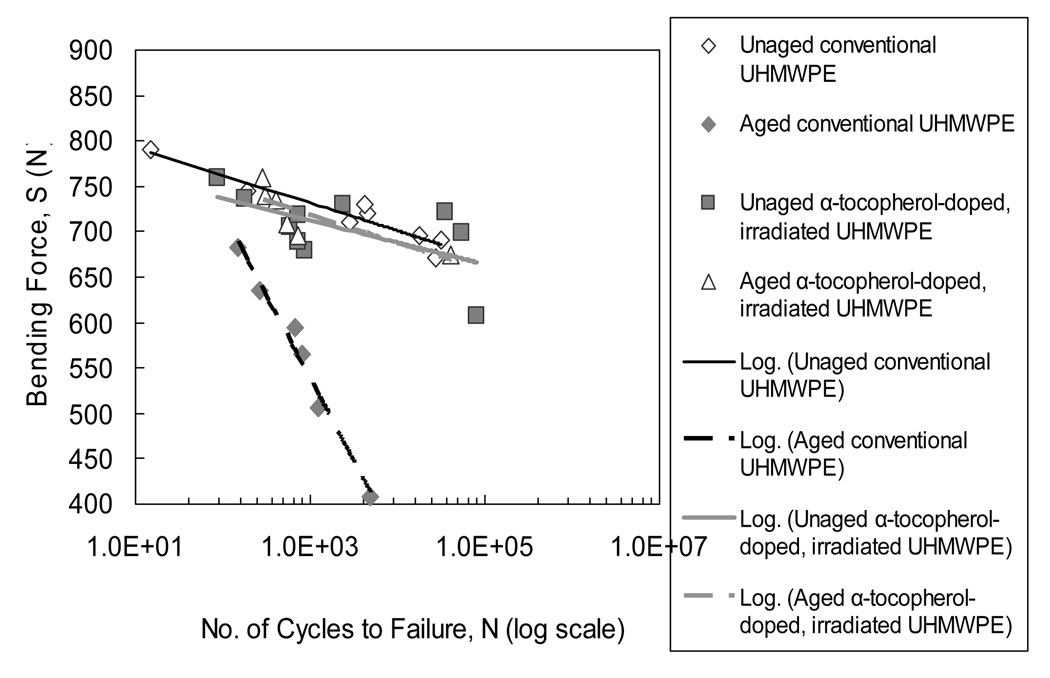

The α-tocopherol doped, irradiated UHMWPE showed comparable bending fatigue strength to conventional UHMWPE (Fig 3). For example, at a peak load of 740N, conventional UHMWPE failed in 190 cycles and vitamin E-doped, irradiated UHMWPE failed in 180 cycles. When the load was decreased, the fatigue life of the specimens increased logarithmically. At a peak load of 690N, conventional UHMWPE failed in 31,178 cycles and vitamin E-doped, irradiated UHMWPE failed in 53,391 cycles. As the load was decreased to lower than 600N, the total number of cycles for both conventional and vitamin E-doped, irradiated UHMWPE exceeded 1 million-cycles.

Fig 3.

Bending fatigue initiation resistance of Vitamin E doped, irradiated UHMWPE compared to conventional gamma-sterilized UHMWPE. Accelerated aging was performed in pure oxygen at 70°C for 2 weeks. Lines are regression fits to the logarithmic curve.

Accelerated aging drastically reduced the bending fatigue strength of conventional UHMWPE (Fig 3). Even at a peak load of 400N, aged conventional UHMWPE failed in less than 5,000 cycles whereas aged vitamin E-doped, irradiated UHMWPE was loaded without failure until at least 100,000 cycles.

Using statistical analysis, the life expectancy was similar for unaged conventional and vitamin E-doped, irradiated UHMWPE (p>0.5), but life expectancy of aged vitamin E-doped, irradiated UHMWPE was significantly higher than aged conventional UHMWPE at each applied load (p<0.001). Over the load range where the analysis was performed (400–750 N), the average acceleration factor for vitamin E-doped, irradiated UHMWPE over conventional UHMWPE is 0.92 in their unaged state and is 26.4 after aging, suggesting a significantly extended life expectancy in cycles for vitamin E-doped, irradiated UHMWPE 28 times greater, on the average than aged conventional UHMWPE.

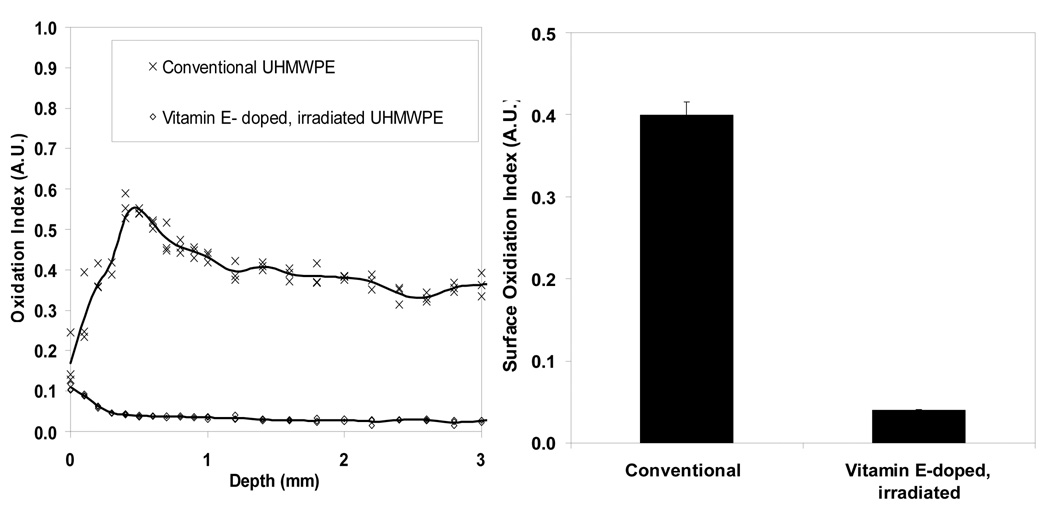

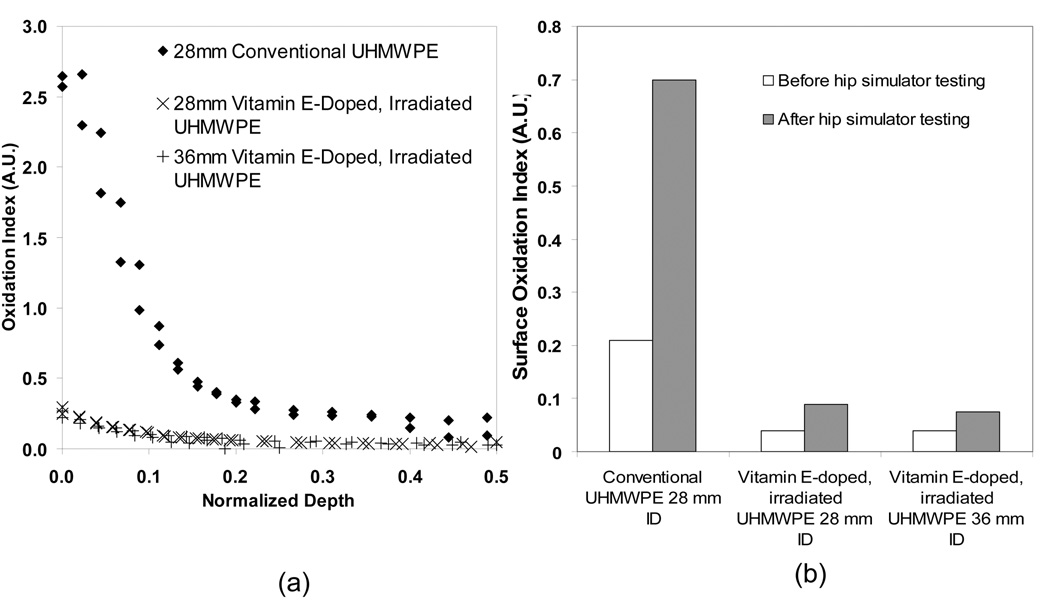

Conventional UHMWPE showed a subsurface oxidation peak whereas vitamin E-doped, irradiated UHMWPE showed a higher oxidation index on the surface with decreasing index values towards the bulk of the sample (Fig 4a). The average surface oxidation levels as a result of accelerated aging were significantly higher for conventional UHMWPE than vitamin E-doped, irradiated UHMWPE (p<0.0001, Fig 4b).

Fig 4.

The oxidation profiles of (a) and surface oxidation indices (b) of accelerated aged conventional, gamma sterilized UHMWPE and vitamin E-doped, irradiated UHMWPE. Lines shown are spline averages.

Discussion

Early clinical studies, aimed to determine the in vivo wear behavior of total hip implants manufactured from cross-linked and melted UHMWPE, corroborate the decrease in wear rate compared to conventional, gamma-sterilized UHMWPE observed in these materials using in vitro techniques such as bi-directional pin-on-disc and simulator testing [21, 22]. Based on these studies, it is highly probable that the incidence of osteolysis caused by UHMWPE wear debris in total joints will be reduced. However, it would be beneficial to improve the fatigue strength of radiation cross-linked and melted UHMWPEs [23]. In the development of a new generation of cross-linked UHMWPE joint implants, we aimed to increase fatigue strength while preserving the wear and oxidation resistance established for cross-linked and melted UHMWPE. This new UHMWPE had to possess improved mechanical properties and fatigue resistance compared to cross-linked and melted UHMWPE; equivalent wear resistance as determined by in vitro simulator studies, oxidative stability determined by accelerated and real-time aging studies, and preservation of its properties upon exposure to oxygen.

We have previously shown that the wear resistance obtained by radiation cross-linking is not compromised by subsequent vitamin E diffusion and terminal gamma sterilization in hip simulator studies performed in clean bovine serum and in bovine serum with third-body bone cement particulate [14]. We have also proven that oxidation is eliminated in UHMWPE in regions where vitamin E is detectable by our FTIR detection method [13, 24]. Thus, the wear and oxidation resistance of this new vitamin E-doped UHMWPE was shown to be equivalent to cross-linked and melted UHMWPE.

The mechanical and fatigue strength of UHMWPE is a function of its crystallinity and crosslink density. There is a decrease in mechanical and fatigue strength of cross-linked and melted UHMWPEs, caused by cross-linking and separately by the loss of crystallinity that occurs during the melting step, which quenches the residual free radicals [23]. We showed that the loss of crystallinity during post-irradiation melting could be avoided by doping irradiated UHMWPE with vitamin E instead of melting it after irradiation, resulting in an UHMWPE with equivalent crystallinity to conventional, gamma sterilized UHMWPE [23]. The ultimate tensile strength, a good indicator of overall mechanical strength, was 46 MPa for this UHMWPE compared to 35 MPa for cross-linked and melted UHMWPE (Table 1, [1]). Likewise, the fatigue crack propagation resistance of this UHMWPE, as hypothesized, showed a 38% increase (Table 2, [14]).

Table 1.

Tensile properties for conventional and α-tocopherol doped, irradiated UHMWPE [14]

| Sample | UTS (MPa) | YS (MPa) | EAB (%) |

|---|---|---|---|

| Unaged conventional UHMWPE | 52 ± 5 | 24 ± 1 | 347 ± 35 |

| Aged conventional UHMWPE | 33 ± 1 | 28 ± 1 | 434 ± 40 |

| Unaged vitamin E-doped, irradiated UHMWPE | 46 ± 3 | 25 ± 1 | 230 ± 9 |

| Aged vitamin E-doped, irradiated UHMWPE | 45 ± 2 | 25 ± 1 | 234 ± 21 |

Table 2.

Stress factor range at fatigue crack inception for conventional UHMWPE and vitamin E-doped, irradiated UHMWPE

When comparing the strength of vitamin E-doped, irradiated UHMWPE to conventional, gamma irradiated UHMWPE, oxidative stability should be addressed. Because of unstabilized residual free radicals, terminally gamma sterilized UHMWPE is prone to oxidation and has been shown to oxidize in vitro and in vivo, causing increased wear and delamination in total knee joints [12, 25–31]. Although the mechanical strength and fatigue resistance of unoxidized conventional UHMWPE is higher than that of vitamin E-doped, irradiated UHMWPE [14], that of oxidized conventional UHMWPE is very poor in comparison (Table 1 and Table 2).

Fatigue failure of UHMWPE joint implants is of major concern in two adverse cases: impingement on the thin rim of a vertically aligned acetabular liner used with a large femoral head in total hip implants and the impingement of the cam on the post of a posterior stabilized tibial insert in total knee implants. In a recent publication [14], we performed a cyclic impingement test of the femoral neck on the lip of vitamin E-doped, irradiated UHMWPE acetabular liners with 28 and 40 mm inner diameters under 125lbs for 2 million cycles at a frequency of 0.5 Hz. These liners showed no fracture and the observed deformation caused by the femoral head was not different from conventional UHMWPE, indicating that the improved fatigue strength of vitamin E-doped, irradiated UHMWPE might decrease the incidence of liner fracture under such adverse loading conditions.

The bending fatigue test, presented in this study, aimed at comparing the bending fatigue behavior of vitamin E-doped, irradiated UHMWPE to conventional UHMWPE under high load, low cycle fatigue, which may be encountered under adverse conditions such as that involving the impingement on the post of a posterior-stabilized tibial insert. Fatigue crack initiation resistance from a defect-free surface is believed to be a strong function of molecular weight and not of cross-link density [32]. Since it is very likely that there are minute defects on the surface of the bending samples, which grow with cyclic loading to propagating cracks; true fatigue crack initiation from a defect-free surface is unlikely. Therefore, this test might still be viewed as a fatigue crack initiation and propagation study. We have developed this study to compare the fatigue resistance of different materials and did not intend to simulate in vivo conditions. However, this situation is also clinically relevant since there may be microscopic defects on the surfaces of UHMWPE introduced during manufacturing or during surgery. For unaged vitamin E-doped, irradiated UHMWPE, the S-N curve was similar to that of conventional UHMWPE (Fig 3), suggesting that the radiation dose was not a major factor in the bending fatigue resistance.

After aging, the bending fatigue strength of vitamin E-doped UHMWPE was significantly higher than that of aged conventional UHMWPE. We attribute the decrease in the bending fatigue strength of conventional UHMWPE following accelerated aging tested in the present study to oxidation. While conventional UHMWPE oxidizes heavily, vitamin E-doped, irradiated UHMWPE is stable against oxidation (Figs 4a and 4b). This result corroborates the effect of molecular weight on bending fatigue resistance since oxidation is accompanied by molecular weight degradation. In contrast, upon exposure to oxygen in accelerated aging studies, the mechanical strength (Table 1, [14]) and bending fatigue resistance of vitamin E-doped, irradiated UHMWPE were preserved. This is presumably due to the stabilization of residual free radicals by vitamin E. Therefore, the presence of vitamin E should ensure the oxidative stability and the preservation of mechanical properties in the long-term.

In order to ensure the presence of vitamin E throughout UHMWPE samples, we have used a doping step to obtain a high surface concentration followed by a homogenization step to diffuse the high surface concentration to the bulk of the samples. As a result, by adjusting doping and homogenization durations, one can achieve the same vitamin E penetration through samples of desired thickness.

While discussing the preservation of mechanical properties in the long-term, one potential concern is the risk of elution of vitamin E out of the UHMWPE. We have shown that cleaning with isopropyl alcohol during manufacturing did not cause the elution of α-tocopherol [15]. Also, we analyzed hip simulator-tested acetabular liners following 5 million-cycles of normal gait and accelerated aging under oxygen for 2 weeks at 70°C. While the conventional UHMWPE showed high oxidation levels with a subsurface oxidation peak (Fig 5a), the oxidation levels of vitamin E-doped irradiated UHMWPEs were unchanged from non-tested samples and significantly less than gamma sterilized UHMWPE tested under the same conditions (Fig 5b), suggesting that the extent of elution, if any, of vitamin E out of the acetabular liners did not compromise the oxidative stability of these components during accelerated aging [14]. These results were corroborated by a real-time aging study on the shelf, at 40°C in air and at 40°C in water, where vitamin E-doped, irradiated UHMWPE showed no appreciable oxidation and superior oxidation resistance compared to 100-kGy irradiated UHMWPE at 7 months [33].

Fig 5.

(5a to be reproduced from Biomaterials 27: 2434–2439) Oxidation profiles (a) and surface oxidation indices (b) of conventional and vitamin E doped, irradiated UHMWPE accelerated aged after hip simulator testing in clean serum for 5 million-cycles. Accelerated aging was performed at 80°C in air for 5 weeks.

In conclusion, irradiated, vitamin E-doped and terminally gamma sterilized second-generation highly crosslinked UHMWPE has better mechanical properties than irradiated and melted first-generation highly crosslinked UHMWPE and better bending fatigue resistance than that of aged conventional UHMWPE. In addition, the oxidation resistance and wear resistance of vitamin E-doped, irradiated UHMWPE are comparable to those of irradiated and melted first-generation highly crosslinked UHMWPE. All of these properties should remain substantially unchanged due to the presence and tested migration stability of vitamin E in UHMWPE. Therefore, vitamin E-doped, irradiated UHMWPE may be used as an improved cross-linked bearing surface for the fabrication of acetabular liners and tibial inserts for total joint arthroplasty.

Acknowledgments

This work was funded by NIH AR051142 and a research grant by Biomet Inc‥ The authors would especially like to thank Dr. David Zurakowski (Harvard Medical School) for help and guidance with the statistical analysis.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Muratoglu OK, Bragdon CR, O'Connor DO, Jasty M, Harris WH, Gul R, McGarry F. Unified Wear Model for Highly Crosslinked Ultra-high Molecular Weight Polyethylenes (UHMWPE) Biomaterials. 1999;20:1463. doi: 10.1016/s0142-9612(99)00039-3. [DOI] [PubMed] [Google Scholar]

- 2.Muratoglu OK, Bragdon CR, O'Connor DO, Jasty M, Harris WH. 1999 HAP Paul Award. A novel method of crosslinking UHMWPE to improve wear, reduce oxidation and retain mechanical properties. Journal of Arthroplasty. 2001;16:149. doi: 10.1054/arth.2001.20540. [DOI] [PubMed] [Google Scholar]

- 3.Muratoglu OK, O'Connor DO, Bragdon CR, Delaney J, Jasty M, Harris WH, Merrill EW, Venugopalan P. Gradient crosslinking of UHMWPE using irradiation in molten state for total joint arthroplasty. Biomaterials. 2001;23:717. doi: 10.1016/s0142-9612(01)00176-4. [DOI] [PubMed] [Google Scholar]

- 4.Muratoglu OK, Merrill EW, Bragdon CR, O'Connor DO, Hoeffel D, Burroughs B, Jasty M, Harris WH. Effect of Radiation, Heat, and Aging on In Vitro Wear Resistance of Polyethylene. Clinical Orthopaedics & Related Research. 2003;417:253. doi: 10.1097/01.blo.0000093004.90435.d1. [DOI] [PubMed] [Google Scholar]

- 5.Muratoglu OK, Bragdon CR, O'Connor DO, Jasty M, Harris WH, Gul R, McGarry F. Erratum to Unified wear model for highly crosslinked ultra-high molecular weight polyethylene (UHMWPE) Biomaterials. 2003;24:1527. doi: 10.1016/s0142-9612(99)00039-3. [DOI] [PubMed] [Google Scholar]

- 6.McKellop H, Shen F-W, Lu B, Campbell P, Salovey R. Development of an extremely wear resistant ultra-high molecular weight polyethylene for total hip replacements. Journal of Orthopaedic Research. 1999;17:157. doi: 10.1002/jor.1100170203. [DOI] [PubMed] [Google Scholar]

- 7.Nivbrant B, Roerhl S, Hewitt B, Li M. In vivo wear and migration of high cross linked poly cups: A RSA study; 49th Annual Orthopaedic Research Society; New Orleans, LA. 2003. [Google Scholar]

- 8.Martell JM, Incavo SJ. Clinical performance of a highly crosslinked polyethylene at two years in total hip arthroplasty; A randomized prospective trial; 49th Annual Orthopaedic Research Society; New Orleans, LA. 2003. [DOI] [PubMed] [Google Scholar]

- 9.Digas G, Karrholm J, Malchau H, Bragdon CR, Herberts P, Thanner J, Estok DM, Plank GR, Harris WH. RSA evaluation of wear of conventional versus cross-linked polyethylene acetabular components in vivo; 49th Annual Meeting Orthopaedic Research Society; New Orleans, LA. 2003. [Google Scholar]

- 10.Charlesby A. Cross-linking of polythene by pile radiation. Proc. Roy. Soc. Lond. 1952;A215:187. [Google Scholar]

- 11.Sutula L, et al. The Otto Aufranc Award. Impact of gamma sterilization on clinical performance of polyethylene in the hip. Clinical Orthopaedics & Related Research. 1995;319:28. [PubMed] [Google Scholar]

- 12.Collier JP, Sperling DK, Currier JH, Sutula LC, Saum KA, Mayor MB. Impact of gamma sterilization on clinical performance of polyethylene in the knee. J. Arthroplasty. 1996;11:377. doi: 10.1016/s0883-5403(96)80026-x. [DOI] [PubMed] [Google Scholar]

- 13.Oral E, Wannomae KK, Hawkins NE, Harris WH, Muratoglu OK. α-Tocopherol Doped Irradiated UHMWPE for High Fatigue Resistance and Low Wear. Biomaterials. 2004;25:5515. doi: 10.1016/j.biomaterials.2003.12.048. [DOI] [PubMed] [Google Scholar]

- 14.Oral E, Christensen S, Malhi A, Wannomae K, Muratoglu O. Wear resistance and mechanical properties of highly crosslinked UHMWPE doped with vitamin E. Journal of Arthroplasty. 2006;21:580. doi: 10.1016/j.arth.2005.07.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Oral E, Rowell S, Wannomae K, Muratoglu O. Migration stability of alpha-tocopherol in irradiated UHMWPE. Biomaterials. 2006;27:2434. doi: 10.1016/j.biomaterials.2005.11.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Parth M, Aust N, Lederer K. Studies on the effect of electron beam radiation on the molecular structure of ultra-high molecular weight polyethylene under the influence of alpha-tocopherol with respect to its application in medical implants. J Mater Sci-Mater Med. 2002;13:917. doi: 10.1023/a:1019892004830. [DOI] [PubMed] [Google Scholar]

- 17.Oral E, Greenbaum E, Malhi A, Muratoglu O. Characterization of blends of α-Tocopherol with UHMWPE. Biomaterials. 2005;26:6657. doi: 10.1016/j.biomaterials.2005.04.026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Muratoglu OK, Bragdon CR, O'Connor DO, Perinchief RS, Estok DM, Jasty M, Harris WH. Larger diameter femoral heads used in conjunction with a highly cross-linked ultra-high molecular weight polyethylene: A new concept. Journal of Arthroplasty. 2001;16:24. doi: 10.1054/arth.2001.28376. [DOI] [PubMed] [Google Scholar]

- 19.Kokshenev V. Dynamics of Human Walking at Steady Speeds. Physical Review Letters. 2004;93:208101. doi: 10.1103/PhysRevLett.93.208101. [DOI] [PubMed] [Google Scholar]

- 20.Leemis L. Reliability-Probabilistic Models and Statistical Methods. Englewood Cliffs, NJ: Prentice-Hall; 1995. [Google Scholar]

- 21.Digas G, Karrholm J, Thanner J, Malchau H, Herberts P. Highly cross-linked polyethylene in total hip arthroplasty: randomized evaluation of penetration rate in cemented and uncemented sockets using radiostereometric analysis. Clinical Orthopaedics & Related Research. 2004;429:16. [PubMed] [Google Scholar]

- 22.Martell JM, Verner JJ, Incavo SJ. Clinical performance of a highly cross-linked polyethylene at two years in total hip arthroplasty: a randomized prospective trial. Journal of Arthroplasty. 2003;18:9. doi: 10.1016/s0883-5403(03)00341-3. [DOI] [PubMed] [Google Scholar]

- 23.Oral E, Malhi A, Muratoglu O. Mechanisms of decrease in fatigue crack propagation resistance in irradiated and melted UHMWPE. Biomaterials. 2006;27:917. doi: 10.1016/j.biomaterials.2005.06.025. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Oral E, Wannomae K, Muratoglu O. The effect of doping conditions on α-tocopherol stabilized UHMWPE. Transactions; 51st Annual Meeting of the Orthopaedic Research Society; Washington, D.C. 2005. [Google Scholar]

- 25.Muratoglu O, Mark A, Vittetoe D, Harris W, Rubash H. Polyethylene damage in total knees and use of highly crosslinked polyethylene. Journal of Bone & Joint Surgery. 2003;85-A:7. doi: 10.2106/00004623-200300001-00003. [DOI] [PubMed] [Google Scholar]

- 26.Eyerer P, Ke Y. Property changes of UHMW polyethylene hip cup endoprostheses during implantation. J Biomed Mater Res. 1984;18:1137. doi: 10.1002/jbm.820180915. [DOI] [PubMed] [Google Scholar]

- 27.Muratoglu OK, Bragdon CR, Jasty M, Harris WH. An oxidation mechanism in gamma-sterilized ultra-high-molecular-weight-polyethylene components; Fifth World Biomaterials Congress; Toronto, Canada. 1996. [Google Scholar]

- 28.Premnath V, Harris WH, Jasty M, Merrill EW. Gamma sterilization of UHMWPE articular implants: an analysis of the oxidation problem. Biomaterials. 1996;17:1741. doi: 10.1016/0142-9612(95)00349-5. [DOI] [PubMed] [Google Scholar]

- 29.Bell CJ, Walker PS, Abeysundera M, Simmons JMH, King PM, W.Blunn G. Effect of oxidation on delamination of ultrahigh-molecular-weight polyethylene tibial components. J. Arthroplasty. 1998;13:280. doi: 10.1016/s0883-5403(98)90173-5. [DOI] [PubMed] [Google Scholar]

- 30.Young SK, Greer KW, Gorhan MC, Keller TS. Wear testing of UHMWPE tibial components: influence of oxidation. 2000 [Google Scholar]

- 31.Costa L, Jacobson K, Bracco P, Brach del Prever EM. Oxidation of orthopaedic UHMWPE. Biomaterials. 2002;23:1613. doi: 10.1016/s0142-9612(01)00288-5. [DOI] [PubMed] [Google Scholar]

- 32.Baker DA, Bellare A, Pruitt L. The effect of degree of crosslinking on the fatigue crack initiation and propagation resistance of orthopedic-grade polyethylene. J Biomed Mater Res. 2003;66A:146. doi: 10.1002/jbm.a.10606. [DOI] [PubMed] [Google Scholar]

- 33.Oral E, Rowell S, Muratoglu O. The effect of alpha-tocopherol on the oxidation and free radical decay in irradiated UHMWPE. Biomaterials. 2006;27:5580. doi: 10.1016/j.biomaterials.2006.07.017. [DOI] [PMC free article] [PubMed] [Google Scholar]