Abstract

Studies to determine baseline levels of microbial contaminants and foodborne bacterial pathogens are needed to evaluate the effectiveness of Hazard Analysis Critical Control Point (HACCP) programs, Good Manufacturing/Production Practices, and various interventions. In 2004 and 2005 poultry carcass rinses from provincially inspected abattoirs in Alberta, Canada, were tested to determine the levels of aerobic plate count bacteria, coliform bacteria, and generic Escherichia coli, the prevalence and levels of Campylobacter spp., and the prevalence of Salmonella spp. and Shiga toxin-producing E. coli (STEC). Samples were collected from 3 high volume and 62 low volume abbatoirs. All samples (1296) were positive for aerobic plate count bacteria, with 98.8% of samples having counts of 100 000 or less colony forming units (CFU)/cm2. Coliform bacteria were isolated from 99.7% of the 1296 carcasses and were recovered at levels of ≤ 1000 CFU/cm2 for 98.3% of the samples. Generic E. coli were recovered from 99.1% of the 1296 carcasses at levels of ≤ 1000 CFU/cm2 for 98.6% of the samples. Seventy five percent of 1234 samples that were tested for Campylobacter were positive; 37.5% of 1295 samples that were tested for Salmonella were positive; and only 2 of 1296 samples tested for STEC were positive (0.15%).

Résumé

Étude sur les valeurs microbiologiques de base chez des volailles abattues dans des établissements sous juridiction provinciale en Alberta, au Canada. Des études visant à déterminer les valeurs de base des contaminants microbiens et des pathogènes bactériens d’origine alimentaire sont nécessaires pour évaluer l’efficacité des programmes d’analyse du risque et contrôle des points critiques (HACCP), de bonnes pratiques de fabrication/ production et d’interventions diverses. En 2004 et 2005 les eaux de rinçage de carcasses de volailles des abattoirs inspectés par les autorités provinciales de l’Alberta, au Canada, ont été testées par comptage sur gélose pour déterminer les niveaux de bactéries aérobiques, de bactéries coliformes et d’Escherichia coli génériques. La prévalence et les niveaux de Campylobacter spp et la prévalence de Salmonella spp et de E. coli producteur de toxine Shiga (ECTS) ont aussi été analysés. Les échantillons ont été recueillis dans 3 abattoirs à grand débit et 62 à petit débit. Tous les échantillons (1296) étaient positifs au comptage sur gélose pour les bactéries aérobiques et 98,8 % des échantillons avaient un comptage de 100 000 unités formant colonies ou moins (UFC)/cm2. Les bactéries coliformes ont été isolées de 99,7 % des 1296 carcasses et recouvrées à des niveaux de 1000 UFC/cm2 ou moins dans 98,3 % des échantillons. E. coli générique a été recouvré dans 99,1 % des 1296 carcasses à des niveaux de 1000 UFC/cm2 ou moins dans 98,6 % des échantillons. Soixante-quinze pourcent des 1234 échantillons testés pour Campylobacter étaient positifs, 37,5 % des 1295 échantillons testés pour Salmonella étaient positifs et seulement 2 des 1296 échantillons testés pour le ECTS étaient positifs (0,15 %).

(Traduit par Docteur André Blouin)

Introduction

Food safety is of utmost importance to consumers, regulatory agencies, governments, and the food industry. Hazard Analysis Critical Control Point (HACCP) programs, Good Manufacturing/Production Practices, and various interventions play a large role in enhancing the safety of food products. To evaluate the effectiveness of these programs and interventions, baseline studies are needed to determine levels of indicator organisms and prevalence of pathogens. The United States Department of Agriculture, Food Safety and Inspection Service (USDA/FSIS) has conducted several baseline studies of meat and poultry products to determine the prevalence and levels of bacteria of public health concern. These studies included testing 1297 rinses from chicken carcasses that were collected from July 1994 to June 1995 and analyzed for aerobic plate count bacteria (APC), total coliforms, Escherichia coli (biotype I), Salmonella spp., Campylobacter jejuni, C. coli, Listeria monocytogenes, E. coli O157:H7, Staphylococcus aureus, and Clostridium perfringens (1). From 1997 to 2000 the USDA/FSIS analyzed 1225 rinses from young chicken carcasses, 1881 sponge samples from cattle carcasses, and 2127 sponge samples from swine carcasses from federally inspected establishments for Salmonella spp. and generic E. coli (2). In Canada, the Canadian Food Inspection Agency (CFIA) performed a baseline study during 1997–1998 to determine the prevalence and levels of Salmonella, E. coli (bio-type 1) and APC in broiler chicken and young turkey carcasses from federally registered abattoirs (3). The Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) conducted baseline studies of poultry, beef, and pork carcasses from provincially inspected abattoirs from 1999 to 2002 to determine the APC, coliform and E. coli counts, the prevalence and levels of Salmonella spp. and Campylobacter spp., and the prevalence of L. monocytogenes and verotoxigenic E. coli (4).

The need to obtain baseline information on prevalence of pathogens and levels of commensal bacteria was also recognized in Alberta. The Food Safety Division of Alberta Agriculture and Rural Development initiated baseline studies of poultry, beef, and pork carcasses slaughtered in provincially inspected abattoirs starting in November 2004. Poultry carcass rinses, and beef and pork carcasses were tested to determine APC, coliform, and E. coli counts, the prevalence and levels of Campylobacter spp., and the prevalence of Salmonella spp. and Shiga toxin-producing E. coli (STEC). The results of the baseline study for poultry carcass rinses collected from provincially inspected Alberta abattoirs are reported herein.

Materials and methods

Experimental design

Samples were collected from provincially inspected poultry slaughter facilities between November 22, 2004 and July 21, 2005. The slaughter facilities were categorized into 2 strata (high or low numbers of animals slaughtered) using a dividing line of 100 000 based on annual slaughter numbers from the previous year (2003). The total number of birds killed in 2003 was considered the study population for sample size estimation, which used an allowable error of 4% and a 95% confidence interval. Within each stratum, the number of chickens sampled in each abattoir was proportional to the number of birds that had been slaughtered at that abattoir in the preceding calendar year. A random stratified sampling strategy was employed and adjusted on a weekly basis due to the unpredictability of poultry slaughter in the lower volume facilities. This maximized the number of abattoirs and samples collected. Abattoirs that were selected to be sampled but did not slaughter during a given week were put on a pending list and were sampled on their next slaughter date. No more than 14 samples were collected from an abattoir in 1 day. If more than 14 samples were randomly chosen, those taken after the 14th sample were put on the pending list until the next slaughter date.

Sample collection

Chicken carcass rinses were collected according to the USDA/ FSIS sample collection guidelines (5). The carcass rinses were collected in sterile plastic bags, put on ice in coolers, and sent to the laboratory for testing. Samples received at the laboratory at temperatures > 10°C or more than 48 h after collection were rejected.

Culture methods

All media used were Difco (Difco Laboratories, Becton Dickinson Microbiology Systems, Sparks, Maryland, USA) brand unless otherwise indicated. Aerobic plate count bacteria (APC), coliform bacteria, and generic E. coli were enumerated using the pour plate technique. Ten-fold serial dilutions of chicken rinse samples were made using 0.1% peptone water, 1-mL aliquots were dispensed into sterile Petri dishes, and molten agar was added. Aerobic plate count bacteria were enumerated on plate count agar and incubated at 35°C for 48 h. Coliform bacteria and E. coli were enumerated on Violet Red Bile agar with 4-methylumbelliferyl-β-D-glucuronide (MUG) after incubation at 35°C for 24 h. Coliform bacteria were confirmed by the production of gas after incubation in 2% Brilliant Green Bile broth at 35°C for 48 h. Generic E. coli were confirmed by the production of gas and fluorescence after incubation in EC medium with MUG at 45°C for 48 h. Incubated EC medium with MUG that had gas production but no fluorescence was streaked onto Columbia Blood Agar plates (BAP) (Oxoid, Nepean, Ontario) and incubated at 35°C for 24 h. The identity of at least 1 colony was determined by a Vitek instrument (bioMéreiux Canada, St. Laurent, Quebec) using a GNI+ card.

Salmonella spp. were identified using the USDA/FSIS method (5) with modifications. Briefly, 30 mL of Buffered Peptone Water (BPW) was added to 30 mL of chicken rinse. The sample was mixed thoroughly and incubated at 35°C for 24 h. One milliliter and 0.1 mL of BPW pre-enrichment culture were transferred to 10 mL of tetrathionate (TT) broth and 10 mL of Rappaport Vassiliadis (RV) broth (EM Science, Merck, Darmstadt, Germany), respectively, and incubated at 42°C for 24 h. One hundred and fifty microliters of each selective enrichment broth (TT and RV) culture were combined for DNA extraction followed by real-time polymerase chain reaction (RT-PCR) (6). Culture was continued on samples that were positive by RT-PCR. Enrichment cultures (TT and RV) from positive samples were streaked onto Brilliant Green Sulfa agar (BGS), Xylose-Lysine-Tergitol 4 agar (XLT4), and Rambach agar (Merck) plates and incubated at 35°C. The plates were examined after 24 h of incubation and suspect colonies were selected for biochemical testing. The plates were incubated for an additional 24 h and re-examined for additional suspect colonies. Suspect colonies were streaked on BAP and MacConkey agar plates and inoculated into urea agar, Triple Sugar Iron agar, and Lysine Iron agar slants. The plates were examined for purity and reactions of the slants and the MacConkey agar plates were noted. Isolates which had biochemical reactions typical of Salmonella were tested for agglutination in polyvalent O and O1 antisera (Denka Seiken Co., Tokyo, Japan). Samples that were positive by the RT-PCR assay but negative by the culture method were re-tested using immunomagnetic separation (IMS). One milliliter of each enrichment broth (BPW, TT, and RV) was mixed with immunomagnetic beads (Dynabeads anti-Salmonella; Dynal, Lake Success, New York, USA) on a semi-automated magnetic particle processor (Kingfisher mL, Thermo Scientific, Milford, Massachusetts, USA) according to the manufacturer’s instructions. The bead-bacteria complexes were added to TT, incubated and then plated onto XLT4 and Rambach agar plates, these were incubated and then examined for typical Salmonella colonies. Typical colonies were tested using the biochemical and serological tests described previously.

Campylobacter spp. were isolated and enumerated using a modification of the FDA method (7). Briefly, 0.1 mL of chicken rinse was plated onto each of Campy-line agar (CLA) (Dalynn Biologicals, Calgary, Alberta) and Modified Campylobacter Blood-Free Selective agar (CCDA) (Oxoid) plates. Additionally, 90 mL of Campylobacter Enrichment Broth, Bolton formula (Oxoid) with laked horse blood was added to 10 mL of chicken rinse. The plates and enrichment broth were placed in an anaerobic jar filled with 10% CO2, 5% O2, 85% N2 and incubated microaerobically at 42°C for 48 h. After 24 h and 48 h of incubation, the enrichment broth was plated onto CLA and CCDA plates using a 10-μL loop and the plates were incubated microaerobically at 42°C. Plates from directly plated samples and from subculture of enrichment samples were examined for typical colonies after 24 h and 48 h incubation. Typical smooth, convex, translucent, colorless to cream-colored colonies on CCDA plates and deep red to magenta, smooth, shiny, and convex colonies with a defined edge or flat colonies with an irregular edge on CLA plates, were streaked onto BAP. The BAP were incubated microaerobically at 42°C for 24 h. Campylobacter species were identified by wet mount, oxidase, catalase, hippurase, and naladixic acid/cephalothin susceptibility tests.

Shiga toxin-producing E. coli (STEC) were identified following the method cited in Renter et al (8). The DNA was extracted from BPW enrichment broths used for the isolation of Salmonella spp. Enrichment broths positive for the stx1 and/or stx2 genes were streaked onto MacConkey and Violet Red Bile Agar with MUG and incubated at 42°C for 24 h. Twenty isolated colonies from each plate were stab inoculated onto a MacConkey plate and incubated at 35°C for 24 h. The isolates were tested for the stx1 and stx2 genes. If no positive isolates were identified, the enrichment broth was restreaked and an additional 40 colonies were tested. Only samples in which a positive isolate could be identified were reported as positive. The STEC isolates were further characterized for O157 antigen using Prolex E. coli O157 latex test kit (Pro-Lab Diagnostics, Richmond Hill, Ontario) and verotoxin production using GLISA Duopath Verotoxin test kit (EM Science, Merck).

For all analyses, positive and negative controls were included with each set of samples. Positive controls were ATCC strains (S. Typhimurium ATCC 14028, C. jejuni ATCC 33250, and E. coli O157:H7 ATCC 35150) inoculated into the appropriate enrichment broths. Negative controls were uninoculated enrichment broths.

Enumeration data was recorded as colony forming units (CFU)/mL and then converted to CFU/cm2 using the conversion formula described by Thomas (9):

Statistical analysis

The chi-squared (χ2) test was used to compare the proportion of positive samples for Salmonella and Campylobacter across the 2 strata. Similarly, 2-sample Wilcoxon rank-sum (Mann-Whitney) tests were used to compare microbial counts. The statistical analyses were carried out using Stata software (Stata Statistical Software, Version 9; StataCorp, College Station, Texas, USA).

Results

From November 22, 2004 to July 21, 2005, 1474 samples were collected from 65 provincially inspected poultry abattoirs in Alberta. Three high volume abattoirs accounted for 56.1% (827) of the samples collected. Samples were rejected (n = 178) because they did not meet the criteria for microbiological testing to commence. Test results on an additional 62 samples were rejected because problems were detected during testing. These included problems with media, incubator failure, contamination, or if the positive control for a batch of samples did not give expected results then the results from that batch of samples were not included in the final analyses.

All tested samples (1296) were positive for APC; coliform bacteria were recovered from 99.7% of the carcasses and E. coli from 99.1%. Table 1 displays descriptive statistics for counts of commensal organisms and Campylobacter spp. in positive samples, for both high- and low-volume abattoirs. The log means for APC were significantly higher in low-volume abattoirs irrespective of whether the units used were CFU/mL (P < 0.01) or CFU/cm2 (P = 0.03). The opposite was observed for Campylobacter spp., for which the log mean counts were significantly higher in high-volume abattoirs (P < 0.01), irrespective of units. For coliforms and E. coli, log mean counts expressed as CFU/mL were significantly higher (P < 0.01) in low-volume abattoirs compared with high-volume abattoirs. When CFU/cm2 were used, the results were reversed, with high-volume abattoirs having significantly higher (P < 0.01) log mean counts than low-volume abattoirs. This discrepancy could be explained by the difference in carcass weights between low- and high-volume abattoirs; the average weight for low- and high-volume abattoirs was 2.77 kg and 1.50 kg, respectively.

Table 1.

Descriptive statistics of microbiological counts of poultry carcasses from high and low volume abattoirs

| CFU/mL of carcass rinse fluid

|

CFU/cm2 of carcass rinse fluid

|

||||

|---|---|---|---|---|---|

| Bacteria | Summary statistics | Low-volume abattoirs | High-volume abattoirs | Low-volume abattoirs | High-volume abattoirs |

| Aerobic plate | Geometric mean | 5588 | 2993 | 796 | 627 |

| count bacteria | CIa geometric mean | 4918–6349 | 2731–3280 | 697–910 | 572–687 |

| Log10 mean | 3.75 | 3.48 | 2.90 | 2.80 | |

| CI log10 mean | 3.69–3.80 | 3.44–3.52 | 2.84–2.96 | 2.76–2.84 | |

| Median value | 4500 | 2800 | 649 | 578 | |

| 10th percentile | 1360 | 760 | 172 | 159 | |

| 90th percentile | 21 000 | 11 000 | 2989 | 2330 | |

| Coliform bacteria | Geometric mean | 337 | 246 | 48 | 52 |

| CI geometric mean | 304–373 | 224–269 | 43–53 | 47–57 | |

| Log10 mean | 2.53 | 2.39 | 1.68 | 1.71 | |

| CI log10 mean | 2.48–2.57 | 2.35–2.43 | 1.63–1.72 | 1.67–1.75 | |

| Median value | 290 | 250 | 41 | 53 | |

| 10th percentile | 80 | 45 | 12 | 10 | |

| 90th percentile | 1800 | 1200 | 249 | 246 | |

| Generic E. coli | Geometric mean | 310 | 227 | 44 | 48 |

| CI geometric mean | 280–344 | 207–250 | 39–49 | 43–53 | |

| Log10 mean | 2.49 | 2.36 | 1.64 | 1.68 | |

| CI log10 mean | 2.45–2.54 | 2.32–2.40 | 1.60–1.69 | 1.64–1.72 | |

| Median value | 270 | 230 | 38 | 50 | |

| 10th percentile | 77 | 41 | 12 | 8 | |

| 90th percentile | 1500 | 1100 | 212 | 236 | |

| Campylobacter spp. | Geometric mean | 48 | 87 | 7 | 18 |

| CI geometric mean | 41–56 | 75–101 | 6–9 | 15–21 | |

| Log10 mean | 1.68 | 1.94 | 0.85 | 1.25 | |

| CI log10 mean | 1.61–1.75 | 1.88–2.00 | 0.77–0.93 | 1.19–1.32 | |

| Median value | 40 | 80 | 7 | 15 | |

| 10th percentile | 10 | 10 | 1 | 2 | |

| 90th percentile | 307 | 650 | 51 | 140 | |

95% confidence intervals

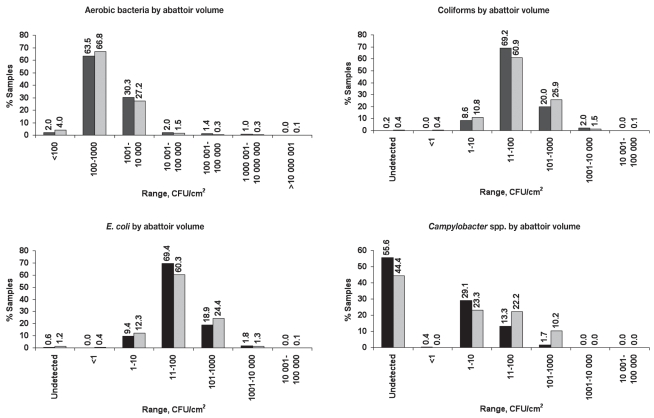

The frequency distribution of samples according to the levels of these organisms is shown in Figure 1. Viable aerobic bacteria were recovered from 100% of the samples tested, and of these, 98.8% had counts of 100 000 or less CFU/cm2 with the majority (65.2%) of the samples having counts of 100 to 1000 CFU/cm2. Coliform bacteria and generic E. coli were recovered at levels of ≤ 1000 CFU/cm2 from 98.3% and 98.6% of the samples, respectively. The majority (65.1% and 64.9%) of the samples had coliforms and E. coli, respectively, at levels of 11 to 100 CFU/cm2. Campylobacter spp. isolated from samples from both high- and low-volume abattoirs using direct plating methodology were at levels of ≤ 1000 CFU/cm2 with 50% of the samples falling below the detection limit of the method. Approximately 26.2% and 17.8% of the samples had levels of Campylobacter spp. at 1 to 10 CFU/cm2 and 11 to 100 CFU/cm2, respectively.

Figure 1.

Frequency distribution of aerobic bacteria, coliforms, generic E. coli and Campylobacter spp. in broiler carcass rinse fluids by abattoir volume. Low-volume abattoirs are shown with black bars and high-volume abattoirs are shown with grey bars.

For foodborne pathogens, the overall weighted results and 95% confidence intervals (CI) for samples from low-volume abattoirs were as follows: 75.0% (95% CI: 72.5 to 77.5) of the 1234 samples tested for Campylobacter spp. were positive; 37.5% (95% CI: 34.6 to 40.3) of 1295 samples that were tested for Salmonella spp. were positive; and 2 of 1296 samples that were tested for STEC were positive (0.15%). Neither isolate tested positive for the O157 antigen and verotoxin production (VT1) was detected in only 1 of the isolates. The prevalence of Salmonella and Campylobacter according to plant volume is shown in Table 2. The difference in Campylobacter prevalence between high- and low-volume abattoirs was statistically significant (P < 0.01). This was not the case with Salmonella (P = 0.11). Isolates from samples that were positive for Campylobacter were characterized to the species level with 90.7% of the isolates identified as C. jejuni and 9.3% as C. coli.

Table 2.

Proportion of samples positive for Campylobacter and Salmonella from high- and low-volume abattoirs

| Abattoir | Campylobacter (Number of samples) | CIa | Salmonella (Number of samples) | CIa |

|---|---|---|---|---|

| High-volume | 78.2 (729) | 75.0–81.2 | 38.4 (762) | 35.0–42.0 |

| Low-volume | 64.4 (505) | 60.0–68.5 | 34.2 (533) | 30.1–38.3 |

| Totalb | 75.0 (1234) | 72.5–77.5 | 37.5 (1295) | 34.6–40.3 |

95% confidence intervals

Weighted averages

Discussion

There is a paucity of information on the levels of commensal bacteria and the prevalence of pathogens on poultry carcasses slaughtered in Alberta. To evaluate the effectiveness of changes in good manufacturing and food safety practices in the future it is necessary to conduct baseline studies. In 2004 and 2005, a baseline study was conducted to determine levels of aerobic plate count bacteria, coliform bacteria, generic E. coli and Campylobacter spp. and the prevalence of STEC, Salmonella spp. and Campylobacter spp. on poultry carcasses from provincially inspected abattoirs in Alberta.

The levels of viable aerobic bacteria recovered from the samples in this study are very similar to those found in a Canadian baseline study of poultry carcasses slaughtered in federally inspected abattoirs in 1997 to 1998 (3) and in the USDA baseline study conducted in 1994 to 1995 (1). The majority of samples had coliform bacteria and generic E. coli at levels of 11 to 100 CFU/cm2, which is also the range for coliforms found in the USDA baseline study for the majority of the samples (1). The level of E. coli isolated in this study, however, was higher than the levels reported in the previous Canadian and USDA baseline studies in which most samples had E. coli in the range of 1 to 10 CFU/cm2 (1,3).

The overall prevalence of Campylobacter spp. was 75.0% when an enrichment method was used. This is lower than the 88.2% reported for the 1994 to 1995 USDA baseline study (1) but somewhat higher than the 63.9% prevalence found in the Ontario baseline study (4). There is wide variation in the positive rates reported for Campylobacter in regions throughout the world. For example, in the United Kingdom, approximately 80% of raw chickens sold are contaminated with Campylobacter (10). A 2001 study of US broiler operations reported that 84.7% of carcass rinses were positive for Campylobacter spp. (11). However, a positive rate of only 26% was reported in a study of poultry carcasses from 13 US commercial poultry processing facilities in 2003 to 2004 (12), but the low level reported in this study may be due to the use of a direct plating method without any enrichment of samples. A 1998 study of selected US processing operations reported that the proportions of carcasses that were positive for Campylobacter averaged 29.1% (13). The authors acknowledged that the low positive rate may have been influenced by delays in testing samples after collection, or by handling conditions, or prolonged contact of carcasses with chlorinated water at 50 ppm in the immersion chilling systems (13). In a baseline study of broiler chickens at Swedish slaughterhouses in 2002 to 2003, 15% of carcasses tested were positive when an enrichment method was used (14). A study conducted in Quebec, Canada, in 2003 to 2004, reported that the prevalence of Campylobacter-positive carcasses sampled prior to chilling was 35.8%; however, variations in laboratory methodology could account for the lower positive rate since some carcass rinses were frozen prior to bacteriological analysis (15). The prevalence of Campylobacter spp. was significantly higher in high-volume compared with low-volume abattoirs in Alberta and this is in contrast to the Ontario study where Campylobacter was significantly lower in high-volume abattoirs (4).

The prevalence rate for Salmonella spp. on chicken carcasses in Alberta abattoirs was 37.5%. This rate is higher than the 21.1% reported for the Canadian Food Inspection Agency (CFIA) baseline survey (3), the 20.0% found in the 1994 to 1995 USDA baseline study (1), and the 31.6% positive rate found in the OMAFRA baseline study (4). The positive rate reported here is also higher than the 21.2% reported for chicken carcasses that were sampled prior to chilling in abattoirs in Quebec, Canada (15). Very low prevalence rates (0 to 0.8%) have been reported for a baseline study of broiler chickens slaughtered in Sweden; however, because of the Swedish Salmonella control program Salmonella is rarely found on Swedish poultry (14). The higher Salmonella-positive rate reported in this study may be due in part to differences in methodology. A PCR screening method followed by immunomagnetic separation with broth culture supernatants from PCR-positive culture negative samples increased the efficiency of isolation of Salmonella (6). Caution should be exercised when comparing results from different studies because of the many factors that may influence results. Variations in results may be due to actual differences in contamination rates or variations in sampling technique, study design, seasonal or yearly effects, or differences in laboratory methodologies.

The results of this baseline study indicate that improvements need to be made in Alberta’s provincially inspected abattoirs or other sections of the poultry production chain to reduce the prevalence of pathogenic bacteria and lower the levels of bacteria on poultry carcasses. Efforts are currently underway in Alberta to improve Good Manufacturing Practices and implement HACCP-type processes in provincially inspected abattoirs and subsequent studies using the same or equivalent methodologies will determine the effectiveness of these efforts in reducing microbial levels and pathogen prevalence.

Acknowledgments

The contributions of Colleen Annett, Mike Bouma, Archie Clark, Darlene Dietrich, Ken Fahner, Becky Goulding, Rod Halmrest, Dr. Jim Henderson, Dr. Robert Holowaychuk, Tom Ivans, Mark Miller, Dan Morris, and Mary Vanderkop are acknowledged. We are grateful to the inspectors of the Regulatory Services Division for collection of the samples. We also thank Barbara Dakin, Sandra Dyal, Suzanne Gibson, Kyla Kennedy, Robin King, Pat Layton, Wayne Lazaroff, Patricia Lu, Sonja Marshall, Denise Patterson, Deana Rolheiser, Cathy Sheppard, Catherine Taylor, Cheryl Turner, and Cassandra Vermeulen for their technical support. CVJ

References

- 1.USDA. United States Department of Agriculture, Food Safety and Inspection Service, Nationwide Broiler Chicken Microbiological Baseline Data Collection Program, July 1994 – June 1995. [Last accessed on November 23, 2006]; Available from http://www.fsis.usda.gov/OPHS/baseline/broiler1.pdf.

- 2.USDA. United States Department of Agriculture, Food Safety and Inspection Service. [Last accessed October 21, 2008];Baseline Data. Available from http://www.fsis.usda.gov/science/Baseline_Data/index.asp.

- 3.CFIA. Canadian Food Inspection Agency. [Last accessed October 21, 2008];Canadian Microbiological Baseline Survey of Chicken Boiler and Young Turkey Carcasses, June 1997 – May 1998. Available from http://www.inspection.gc.ca/english/fssa/meavia/man/mane.shtml.

- 4.Johnson P, Mahdi A, Baker T, Odumeru J. Microbiological analysis of raw chicken carcasses in Ontario abattoirs — A summary report. Guelph, Ontario: Food Inspection Branch, Ontario Ministry of Agriculture and Food; 2003. [Google Scholar]

- 5.USDA. United States Department of Agriculture, Food Safety and Inspection Service. Appendix E — FSIS Sample Collection Guidelines and Procedure for Isolation and Identification of Salmonella from Raw Meat and Poultry Products. [Last accessed October 21, 2008];Federal Register. 1996 61:144. Rules and Regulations. Available from http://www.fsis.usda.gov/OA/fr/rule3.pdf#Appendix%20E.

- 6.Bohaychuk VM, Gensler GE, McFall ME, King RK, Renter DG. A real-time PCR assay for the detection of Salmonella spp. in wide variety of food and food-animal matrices. J Food Prot. 2007;70:1080–1087. doi: 10.4315/0362-028x-70.5.1080. [DOI] [PubMed] [Google Scholar]

- 7.Hunt JM, Abeyta C, Tran T. Isolation of Campylobacter Species from Food and Water. [Last accessed October 21, 2008];Bacteriological Analytical Manual Online. Available from http://www.cfsan.fda.gov/~ebam/bam-mm.html#about.

- 8.Renter DG, Bohaychuk VM, Van Donkersgoed J, King RK. Presence of shiga toxin-producing Escherichia coli in feces from feedlot cattle in Alberta and absence on corresponding beef carcasses. Can J Vet Res. 2006;71:230–235. [PMC free article] [PubMed] [Google Scholar]

- 9.Thomas NL. Observations of the relationship between surface area and weight of eviscerated carcasses of chickens, ducks and turkeys. J Food Technol. 1978;13:81–86. [Google Scholar]

- 10.Corry JE, Atabay HI. Poultry as a source of Campylobacter and related organisms. Symp Ser Soc Appl Microbiol. 2001:96S–114S. doi: 10.1046/j.1365-2672.2001.01358.x. [DOI] [PubMed] [Google Scholar]

- 11.Stern NJ, Robach MC. Enumeration of Campylobacter spp. in broiler feces and in corresponding processed carcasses. J Food Prot. 2003;66:1557–1563. doi: 10.4315/0362-028x-66.9.1557. [DOI] [PubMed] [Google Scholar]

- 12.Stern NJ, Pretanik S. Counts of Campylobacter spp. on U.S. broiler carcasses. J Food Prot. 2006;69:1034–1039. doi: 10.4315/0362-028x-69.5.1034. [DOI] [PubMed] [Google Scholar]

- 13.Stern NJ, Fedorka-Cray P, Bailey JS, et al. Distribution of Campylobacter spp. in selected U.S. poultry production and processing operations. J Food Prot. 2001;64:1705–1710. doi: 10.4315/0362-028x-64.11.1705. [DOI] [PubMed] [Google Scholar]

- 14.Lindblad M, Lindmark H, Lambertz ST, Lindqvist R. Microbiological baseline study of broiler chickens at Swedish slaughterhouses. J Food Prot. 2006;69:2875–2882. doi: 10.4315/0362-028x-69.12.2875. [DOI] [PubMed] [Google Scholar]

- 15.Arsenault J, Letellier A, Quessy S, Boulianne M. Prevalence and risk factors for Salmonella and Campylobacter spp. carcass contamination in broiler chickens slaughtered in Quebec, Canada. J Food Prot. 2007;70:1820–1828. doi: 10.4315/0362-028x-70.8.1820. [DOI] [PubMed] [Google Scholar]