Abstract

Eucalyptus species are native to Australia but grown extensively worldwide as short rotation hardwoods for a variety of products and as ornamentals. We describe their general importance with specific emphasis on existing and emerging markets as energy products and the potential to maximize their productivity as short rotation woody crops. Using experience in Florida USA and similar locations, we document their current energy applications and assess their productivity as short-term and likely long-term energy and related products.

Keywords: Eucalyptus; Eucalyptus grandis; Eucalyptus amplifolia; Corymbia torelliana; short rotation woody crops; ethanol; biofuels, silvichemicals

1. Introduction

Interest in renewable, CO2 neutral, and sulfur-free biomass as a clean source of fuel, chemicals and materials is accelerating [1]. Many products currently derived from petrochemicals can be produced from biomass feedstocks: lubricants, polymers, high matrix composites, textiles, biodegradable plastics, paints, adhesives, thickeners, stabilizers and a range of cellulosics [2]. Biomass can be converted into a variety of energy products and chemicals [3], including liquid fuels and electricity. Methanol, ethanol, and hydrogen may be used in advanced (fuel cell–powered) vehicles. Advanced technologies may increase alcohol conversion by fermenting cellulose. Biomass pyrolysis produces charcoal, bio-oil, and gases in varying proportions, depending on the technology and raw material. Charcoal is used for the production of pig iron and high quality steel and for the production of iron alloys, particularly in Brazil and Australia. Charcoal is also widely used as activated carbon, with some 130,000 tons of wood annually transformed into activated carbon worldwide. Phenolic derivatives from bio-oil can partly replace petrochemical phenol in phenolformaldehyde resins. Fractionating woody biomass for a wide range of products and materials has been demonstrated by a closed loop pilot plant in New Zealand [4]. After washing and pre-heating biomass, hemicellulose was hydrolyzed and the lignin and cellulose dried to produce “value-added” chemicals, hardboards, activated carbon, animal feed, or bioenergy feedstock.

Biomass and biofuels have been identified by the US Department of Energy as critical technologies for minimizing the costs of reducing carbon emissions [4]. Cofiring in coal-fired power plants, integrated gasification combined-cycle units for the forest industry, and ethanol from the hydrolysis of lignocellulosics have the most potential, with estimated annual carbon offsets in the US alone ranging between 16–24 Mt, 4–8 Mt, and 12.6–16.8 Mt, respectively, by the year 2010. The near term energy savings from the implementation of each of these technologies should cover the associated costs with cofiring giving the highest return and lowest technical risk.

Potential biomass species include some of over 700 Eucalyptus species, commonly known as eucalypts, that are native to Australia and its northerly islands. Eucalypts have been successful as exotics because of their capacity for fast growth and tolerance of harsh environments involving many effective adaptations: indeterminate growth, coppicing, lignotubers, drought, fire, insect resistance, and tolerance of soil acidity and low fertility. Many eucalypts have wood properties, such as high density, suitable for fuel and charcoal production, pulp and paper manufacturing, and sawn wood.

Eucalyptus is the most valuable and widely planted hardwood in the world (18 million ha in 90 countries [5]. Eucalypts are grown extensively as exotic plantation species in tropical and subtropical regions throughout Africa, South America, Asia, and Australia, and, in more temperate regions of Europe, South America, North America, and Australia. In 2000, India had 8.0 million mostly low productivity ha followed by Brazil with 3.0 million mostly intensively cultivated ha reaching average productivities of 45–60 m3/ha/year.

Of the 12.751 million ha of eucalypt plantations reported to FAO in 2005, the almost 12 million ha classified as productive forest [6] was nearly all accounted for by 12 countries (Table 1). Eucalypt planting has intensified in recent years and continues to do so, especially in tropical countries. In these regions of faster growth, rotations were as short as 5 years with yields as high as 70 m3/ha/yr. Eucalypts are also commercially planted in the Congo, Indonesia, Malaysia, Thailand, France, Portugal, New Zealand, and the US. China has perhaps the largest current commitment to establishing eucalypt plantations at a rate of 3,500–43,000 ha/year. Plantation area in southern China increased more than threefold from 325,000 to 1.1 million ha in 20 years.

Table 1.

Area of productive eucalypt plantations and semi-natural forests (*) in 2005 by country, species, and age class [6].

| Area (1,000 ha) by Age Class (years) | |||||||

|---|---|---|---|---|---|---|---|

| Country | Species | 0–5 | 5–10 | 10–20 | 20–30 | 30–40 | >40 |

| RSA | nitens | 109.7 | 99.3 | 19.4 | 0.7 | 1.8 | |

| grandis | 144.1 | 140.7 | 44.9 | 3.7 | 1.7 | ||

| Sudan | spp | 118.2 | 189.1 | 165.5 | 8.0 | ||

| China | spp | 683.0 | 576.4 | 982.7 | 154.4 | ||

| India | spp | 43.0 | 64.4 | 103.2 | |||

| spp* | 656.1 | 984.2 | 1,576.0 | ||||

| Myanmar | camaldulensis | 1.1 | 2.1 | 2.2 | 1.1 | 0.5 | |

| Vietnam | spp | 222.4 | 286.5 | 67.1 | 7.0 | 3.0 | |

| Iran | spp | 24.6 | 6.2 | ||||

| Italy | spp | 7.0 | 8.2 | 8.2 | |||

| Australia | regnans | 5.2 | 0.2 | 2.8 | 3.7 | 4.7 | 1.1 |

| globulus | 131.2 | 260.1 | 48.7 | 1.1 | 0.4 | ||

| pilularis | 5.2 | 5.5 | 0.5 | 1.4 | 4.6 | 0.4 | |

| dunnii | 5.3 | 12.2 | 0.2 | ||||

| grandis | 5.2 | 5.5 | 0.5 | 1.4 | 4.6 | 0.4 | |

| Argentina | grandis | 15.8 | 32.6 | 34.5 | 11.8 | 3.9 | |

| Brazil | spp | 2118.1 | 756.5 | 121.0 | 30.3 | ||

| Chile | spp | 353.4 | 204.1 | 85.4 | 7.2 | 2.0 | |

| Subtotal | 4,648.6 | 3,633.8 | 3,262.8 | 231.8 | 27.2 | 1.9 | |

| Total | 11,806.1 | ||||||

A few eucalypt species and hybrids constitute the majority of these plantations. Most domesticated eucalypts are from the subgenus Symphyomyrtus, the largest of the 10 subgenera currently recognized within Eucalyptus, containing over 75% of the species. Four species and their hybrids from this subgenus, Eucalyptus grandis (EG), E. urophylla (EU), E. camaldulensis, and E. globulus, account for about 80% of the eucalypt plantations worldwide. EG is the most widely used species in plantation forestry worldwide in tropical and subtropical areas not only as a pure species, but also as a parental species in hybrid breeding. It has the fastest growth and widest adaptability of all Eucalyptus species. The greatest area of plantations of EG and its hybrids with other species is in Brazil and several other Central and South American countries. It has been planted extensively in India, South Africa, Zambia, Zimbabwe, Tanzania, Uganda, and Sri Lanka and is grown in California, Florida, and Hawaii in the United States. EU has been widely planted in the tropics for many years. E. globulus is the premier species for temperate zone plantations in Portugal, Spain, Chile, and Australia. For pulp production and increasingly for solid wood, EG, EU, and the EGxEU hybrid are the most favored in tropical and subtropical regions.

Numerous Eucalyptus species have been evaluated in various edaphic and climatic sites in Florida. From 1965 to 1984, US Forest Service research focused on the best of 156 seed sources of 67 species for southern Florida, resulting in >1,500 selected EG. Since 1979, the University of Florida evaluated nine species [7]. Current tested Eucalyptus genetic resources have been largely defined by major freezes from 1982 to 1989, e.g., as low as –6°C for more than 18 hours in southern Florida in January 1985. For areas of frequent freezes, testing has produced desirable genotypes of E. amplifolia (EA).

Vegetative propagation of superior clones is one key to enhancing Eucalyptus productivity [8–15]. Rooted cuttings commenced in the 1960s and provide adaptation to local sites with cost and wood property advantages. In Brazil, for example, 3.5 million ha of plantations support many domestic and industrial activities. In the pulpwood sector, forest productivity has increased from 12 to 40 m3/ha/year through breeding and silvicultural practices. Optimized and efficient transformation and recovery procedures exist for some Eucalyptus genotypes. Transgenic plantlets of various Eucalyptus species and hybrids have been regenerated from stem or leaf segments. Micropropagation and transformation have combined with efforts to engineer novel traits (exogenous genes) or to alter existing traits (modified endogenous genes or transferred homologous genes from related species). Elite hybrid clones with superior wood quality, rapid growth, and disease resistance are used extensively in tropical and subtropical regions of Brazil, South Africa, Congo, and China.

Short Rotation Woody Crop (SRWC) systems may be implemented in Florida and elsewhere. On suitable sites and/or with intensive culture, fast growing hardwoods such as EG and EA may reach harvestable size in as few as three years [16, 17]. EG is the most productive, largely because of the genetic improvement conducted since the late 1960s [8]. EG is now grown commercially in southern Florida for mulchwood [18] and can be used in central Florida, while EA is suitable from central Florida into the lower Southeast. Corymbia torelliana (CT) has been used as a windbreak for vegetable crops in southern Florida and is now being utilized widely for citrus windbreaks.

Eucalypts are utilized worldwide for a wide array of products including pulp for high quality paper [14], lumber, plywood, veneer, solid and engineered flooring, fiberboard [19, 20], wood cement composites [21, 22], mine props, poles, firewood, charcoal, essential oils [23–26], honey, tannin, and landscape mulch [18] as well as for shade, windbreaks, and phytoremediation [17, 27, 28]. The expansion of eucalypt plantations throughout the world is largely attributable to eucalypts’ superior fiber and pulping properties and the increased global demand for short-fiber pulp.

Elite hybrid clones are extensively used by the cellulose and paper industry because of wood quality and rapid growth. In many developing countries, eucalypt wood is important for fuel and building material in rural communities. Eucalyptus wood is a precursor for the preparation of activated carbon adsorbents for use in liquid-phase applications, such as water and wastewater treatment [29]. In the Congo, Eucalyptus is primarily grown for firewood and pulp, but is also used for round poles or sawn timber. In China, eucalypt plantations are harvested for pulpwood, fiberboard, sawlogs, roundwood, veneer, fuelwood and oil. As new high-yielding plantations mature, some 50–60% may be used for pulp and paper production. The rest will be used for plywood, medium density fiberboard (MDF) and sawn timber. Residues and leaf litter are used for fuelwood. Eucalypt oil production is primarily confined to cooler, temperate regions, where up to 150,000 ha of plantations are used for oil.

Eucalyptus SRWCs have shown suitability for some traditional products and may be suitable for many biofuels in Florida. Of the energy in dry whole-tree chips of 9-year-old EG in southwest Florida, 70% was recovered as char and oil, which could be transported and stored, and 21% was converted to noncondensed volatile oil and low-energy gas that could only be used on site or sold to an adjacent user [30]. EA and EG SRWCs are promising for cofiring in coal-based power plants in central Florida [31], but little is known about their suitability for a wider range of value-added products. Opportunities for developing technology to produce renewable bioenergy (biofuels and biopower) have recently gained momentum in the State’s public policy, research, and media.

Accordingly, the general objective of this review and the Florida-based research reported here was to determine forest biorefinery\bioenergy product opportunities for these SRWCs. The specific objectives were to evaluate and compare the broad suitability of eucalypts and specifically EG, EA, and CT, and estimate their suitability for a range of products.

2. Experimental Section

EA, EG, and CT from Florida were assessed for their suitability to make bioenergy products. The genotypes that were evaluated included three very good EG (2805, 2814, and 2817) clones and four well-tested EA progenies based on statewide genetic tests (Table 2). The 26.9cm DBH EG 2805 tree in a 11.8-year-old clonal test near Haines City, and the 19.7cm 6.7-year-old coppiced 2814 and 29.5cm 13.3-year-old 2817 in a study at Tampa were represented by 2.4m long basal logs. Four 8.3-year-old EA trees averaging 19.2cm in DBH in a study near Old Town were compared by basal logs; five 2.4m logs in the tree of 4836 estimated within tree variability. Four approximately 15-year-old CT trees in a windbreak near Clewiston with average DBH of 23.6cm were also represented by basal logs. The logs were harvested and shipped to the USFS Forest Products Laboratory (FPL) in Madison, WI, on June 27, 2007, where they were cut into 1.3m lengths to remove a midlog disk, debarked and sectioned to chippable size if needed, and put in storage at 4°C on July 2.

Table 2.

EG, EA, and CT genotypes (their age in years, number of trees, and number of logs per genotype) and resulting numbers of stem disks and batch numbers in the FPL study.

| Species | Genotype (Age, No of trees, No of Logs) | Disks | Batches |

|---|---|---|---|

| EG | 2805 (11.8,1,1), 2814(6.7,1,1), 2817(13.3,1,1) | 3 | EG1, EG2, EG3 |

| EA | 4836 (8.3,1,5), 4543 (8.3,1,1), 4853 (8.3,1,1), 4875 (8.3,1,1) | 6 | EA1, EA2, EA3, EA4, EA5, EA6 |

| CT | ? (∼15,1,1), ? (∼15,1,1), ? (∼15,1,1), ? (∼15,1,1) | 4 | CT1, CT2, CT3, CT4 |

2.1. Wood and Fiber Properties

Various properties of the disks and process batches were then determined. The disks, or sections of large disks, were saturated in water, weighed green, and dried at 38°C to determine wood moisture content (MC) and specific gravity (SG) using a water displacement method. Each of the resulting 13 batches (Table 2) was chipped, usually the day before refining. Thermomechanical pulps (TMP) were prepared in a Sprout-Bauer Model 12–1CP (Andritz, Inc., Muncy, PA) 305-mm single-disk refiner with the chips held at 58 kPa for 10 minutes prior to refining. The feed rate was set to 1kg/min, and the plate gap was 0.15 mm (Sprout-Bauer refiner plates D2B503). Specific energy consumption averaged 200–250 Wh/kg. Fiber characteristics such as percent fines, pH, and fiber length were next assessed.

2.2. Silvichemicals

Condensates from steam pretreatment of wood chips of the 13 batches were collected and analyzed by 13C NMR. Approximately 50 ml of each condensate was air dried to constant weight. Dried solids (∼70 mg) were dissolved in 400 μl of DMSO-d6. The central solvent peak served as the internal reference, DMSO at δH 2.50, δC 39.5 ppm. Samples were run with standard Bruker pulse sequences on a Bruker DPX–250 (62.9 MHz 13C) spectrometer fitted with a quadranuclear 5-mm Z-gradient coil probe. Qualitative 13C spectral experiments were acquired with a standard power-gated sequence with a 1.0 s delay.

2.3. Biofuels

Chemical composition analysis of batches EG1 and EA4 (Table 2) were conducted by FPL’s Analytical and Microscopy Laboratory using an improved high performance anion exchange chromatography with pulsed amperometric detection (HPAEC-PAD) method [18]. The hydrolytic reaction was followed by measuring the carbohydrates in the hydrolyzates. For fast analysis, only glucose in the hydrolyzates was measured using a commercial glucose analyzer (YSI 2700S, YSI Inc., Yellow Springs, OH).

To evaluate the potential for bioconversion, Batch EG1 was pretreated using four processes: standard sulfuric acid method at 180°C with acid charge on oven dry wood of 1.84%, hot water at 180°C, and two FPL proprietary processes (patent pending). The pretreatment was conducted in 1-liter sealed stainless steel cylinders (pulping digesters) in an autoclave-type arrangement using steam heat. About 130 gram (od) wood chips were used under a liquid to wood ratio of 5. The duration time of pretreatment was fixed at 30 min. At the end of the pretreatment, the solid was collected and directly transferred to size reduction using a laboratory 8-inch disk refiner. Solid loss was determined from the measured wet weight and moisture content of the collected solid. Enzymatic hydrolysis was carried out at 2% of substrate (w/v) in 50-mL sodium acetate buffer using a shaker/incubator (Thermo Fisher Scientific, Model 4450, Waltham, MA) at 200 rpm. The pH and temperature were adjusted to 4.8 and 50°C, respectively. A mixture of Celluclast 1.5 L with an activity loading of approximately 15 FPU/g substrate and Novozyme 188 with an activity loading of approximately 22.5 CBU/g was made.

3. Results and Discussion

3.1. Wood and Fiber Properties

For ethanol and methanol production regardless of technology used, certain wood properties are almost universally favored: higher wood density, lower moisture content, and higher extractives content [33]. Among and within Florida-grown EG, EA, and CT, differences were noted for some of these properties (Table 3). EG was densest and EA lightest based on the limited genotypes and ages represented. Considerable within species variation for wood properties was evident in each species, suggesting that deployment of favorable clones would be advantageous in producing energy products. Similar variation in the characteristics of refined fibers also emphasized the importance of genetic variation in making other products.

Table 3.

Variation in log specific gravity (kg/m3) and moisture content (%) and batch fines (%), pH, and fiber length (mm) from Florida-grown EG, EA, and CT basal logs.

| Species | Genotype (Batch) | Age (yrs) | No of Trees | Specific Gravity | Moisture Content | Fines | pH | Fiber Length |

|---|---|---|---|---|---|---|---|---|

| EG | 3 clones | 10.6 | 3 | 544 | 107 | 38.9 | 4.05 | |

| 2805 (EG1) | 11.8 | 1 | 522 | 104 | 30.3 | 3.96 | - | |

| 2814 (EG2) | 6.7 | 1 | 470 | 129 | 32.1 | 4.30 | .673 | |

| 2817 (EG3) | 13.3 | 1 | 640 | 89 | 54.1 | 3.92 | - | |

| EA | 4 progenies | 8.3 | 4 | 508 | 108 | 59.5 | 3.97 | |

| 4836 (EA5) | 8.3 | 1 | 527 | 107 | 53.1 | 3.89 | - | |

| 4843 (EA6) | 8.3 | 1 | 469 | 115 | 53.5 | 3.89 | - | |

| 4853 (EA1) | 8.3 | 1 | 506 | 109 | 70.7 | - | - | |

| 4875 (EA4) | 8.3 | 1 | 529 | 88 | 60.5 | 4.11 | .502 | |

| CT | 4 trees | 15 | 4 | 526 | 101 | 50.0 | 4.20 | |

| ? (CT1) | 15 | 1 | 526 | 80 | 48.6 | 4.17 | - | |

| ? (CT2) | 15 | 1 | 610 | 98 | 52.6 | 4.20 | - | |

| ? (CT3) | 15 | 1 | 555 | 94 | 37.1 | 4.23 | .472 | |

| ? (CT4) | 15 | 1 | 411 | 131 | 61.5 | 4.21 | - |

Wood quality of the EG x EU hybrid can be evaluated at 5 years [10]. Basic density and age were positively correlated. Fiber length and wall thickness tended to increase with age. Width, lumen diameter, and chemical composition did not vary with age. Screened yield was directly related to age up to 5 and 6 years; for kappa number, an inverse relation with age was observed with a trend until 4–5 years. Different Eucalyptus woods had constant polysaccharide and lignin contents but differing extractive levels [36].

Small variations of pulp yield and basic density can be predicted from some chemical parameters [37]. Woods with higher pulp yield had very distinctive syringyl/guaiacyl (S/G), syringaldehyde/vanillin (S/V), and total phenols, independent of basic density. Woods with higher basic density and lower pulp yield were identical for S/V, S/G, methoxyl group, and total sugars. Methoxyl group and total sugars content were the best parameters for woods with lower density.

Wood quality traits are primary targets for genetic modification. Because lignin removal is costly and energy-consuming, reducing lignin content and modifying its composition for increased pulping efficiency are important objectives of tree engineering as an alternative to adjusting bleaching and delignification processing technologies [38]. Substantial progress has been made, aided by a growing understanding of lignin biosynthesis and its genetic control.

3.2. Silvichemicals

While Eucalyptus species contain many silvichemicals, their cost effective capture is critical to commercial use. Capturing them as an incidental byproduct of other wood processing would be advantageous.

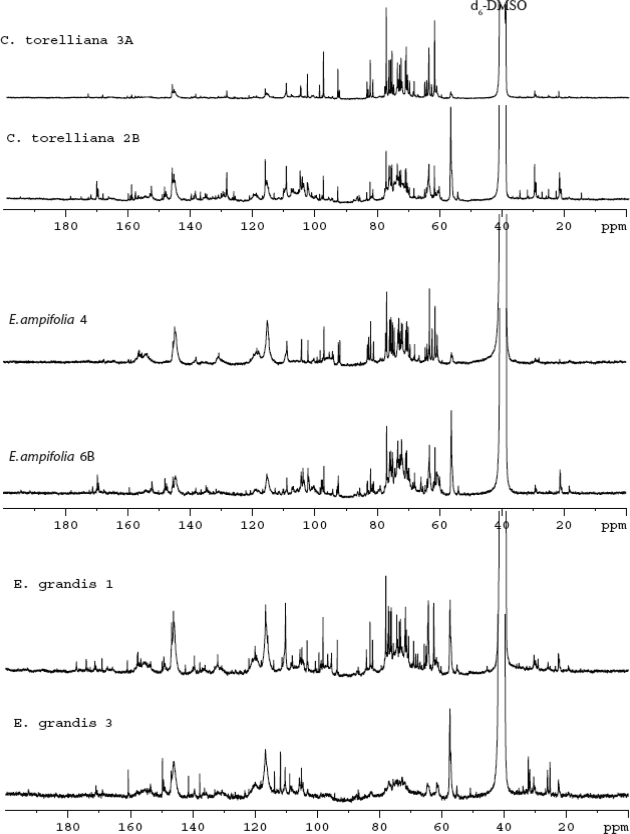

Condensate extracts from steam pretreatment of wood chips of EA, EG, and CT contained a multitude of components with no one compound in sufficient quantity to make separation and recovery a viable commercial option. The samples ranged from 1.59 to 0.16 grams of dry material per 50 milliliters of condensate, with most between 0.3 and 1 gram. The chemical makeup differed among species, trees within species, and within trees. Figure 1 illustrates the compositional range found in select condensates from EA, EG and CT. From the literature [39, 40], we would expect to see chemical shift signals due to lignin/lignan moieties, and the signal at ∼ 56 ppm is generally indicative of the aromatic methoxyl for these types of compounds. The EG condensates all showed similar methoxyl content; however, the EA and CT condensate examples show the extremes for methoxyl content.

Figure 1.

3C NMR spectra for condensates from two CT samples (top), two E. amplifolia samples (middle), and two EG samples (bottom).

Eucalyptus in general are also known to contain significant amounts of polyphenols of the condensed (proanthocyanidins) and hydrolysable tannin (ellagitannin and gallotannin) varieties. A comparison of the chemical shifts of authentic catechin, the base structure for condensed proanthocyanidins, shows consistent data for two of the CT condensates. This catechin type structure was not significant in the extracts of EA or EG.

Spectra for ellagic acid (ellagitannin aglycone) compared most favorably with the EG condensates but was less obvious in the EA and CT extracts. The most predominant and common features for all of the condensates may be attributed to catechol and gallol type structures. Most notably the signals clustered around 145 ppm for the carbons bearing adjacent hydroxyl groups, the 118–114 ppm grouping for the protanated carbons of the catechol group, and more sharply around 110 ppm for protonated gallol carbons.

It is possible that the sharp signals indicative of carbohydrate units between 100 and 60 ppm are part of the hydrolysable tannin components and/or they may be small, water-soluble oligomers not associated with phenolic units. All of the condensates showed substantial amounts of carbohydrate signals with the exception of EG 3 (Figure 1). Fatty acids of potential value for biodiesel should show a pattern of aliphatic signals in the 40 to 20 ppm region which is not apparent in the condensates.

Eucalyptus compounds often have several roles [23], including defense against insect and vertebrate herbivores and protection against UV radiation and cold stress. Best-known are the terpenoids, which give Eucalyptus foliage its characteristic smell. Eucalyptus is also a rich source of phenolics such as tannins. While some phenolics have been the basis of past industries, the most recent interest is newly identified formylated phloroglucinol compounds (FPCs), which include euglobal, macrocarpal, and sideroxylonal subtypes. All FPCs have the same fully substituted, formylated, aromatic moiety, but vary in side chain structure. FPCs have a wide range of biological actions and play a major ecological role as powerful antifeedants.

FPCs appear to be concentrated in subgenus Symphyomyrtus, are absent from subgenera Monocalyptus and Idiogenes (E. cloeziana), and occur sparingly and at low concentrations in Corymbia and Blakella [41]. In subgenus Eudesmia, E. phoenicia appeared rich in euglobals. Of 39 Eucalyptus species and four Melaleuca species that are or could be planted in low-rainfall areas, rich sources of FPCs are some Western Australian oil mallees, most notably E. loxophleba, with sideroxylonal concentrations as high as 9% of the dry leaf mass. Sideroxylonal was most abundant, with high concentrations also observed in E. cinerea, E. pulverulenta and E. mannifera. Large quantities of macrocarpals occurred in E. kartzoffiana and E. pulverulenta as well as in some E. viminalis. In species with sideroxylonals, concentrations of 1,8-cineole and FPCs are strongly associated, suggesting that selection for cineole will result also in selection for FPCs. A strong correlation between foliar concentrations of 1,8-cineole and sideroxylonal in E. polyanthemos is important ecologically because marsupial folivores use cineole concentration as a cue to the concentration of the FPCs; if they detect high concentrations of cineole, they will eat little, if any, of the foliage. Likewise, low cineole concentrations suggest that the foliage is palatable. If confirmed in other Eucalyptus species, selection increasing the concentrations of essential oils might also yield similar increases in the FPCs. In contrast, eucalypts selected for rapid growth rate may contain lower concentrations of FPCs.

Conversion of 1, 8-cineole by a strain of Aspergillus niger produced two novel alcohols, 3-exo- and 3-endo-hydroxycineole [24]. Furthermore, hydrogenolysis of 3-endo-hydroxycineole afforded p-methane-3, 8-e″-diol which has been isolated as a plant growth inhibitor from E. citriodora.

With integrated tree crop systems in Western Australia, large volumes of high-cineole eucalyptus oil could be produced from mallee eucalypts well below current market prices [25]. Large industrial solvent markets are currently in transition following withdrawal of 1,1,1-trichloroethane due to international measures to control ozone depletion. Although penetration of these markets would need prices about half those in traditional eucalyptus oil markets, this may be achievable with economies of scale, genetic advances, and improved harvesting and processing technologies.

3.3. Biofuels

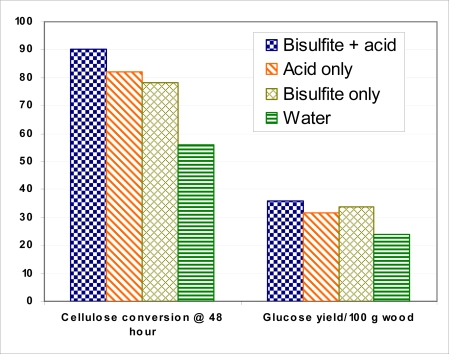

Two Eucalyptus species grown in Florida are suitable for biofuel and bioenergy production. As is the case with all hardwoods, the major chemicals in EG1 and EA4 are lignin, glucan, and xylan (Table 5). Glucan contents are about 40%, lower than other hardwood species. However, mannan contents are very low. Mannose from mannan is difficult to ferment. The main hemicellulose is xylan of 11%. Xylan can be easily removed in pretreatment and fermented. Lignin content at about 34% is higher than most hardwood species, which suggests that SRWC Eucalyptus species can be ideal for bioenergy production through thermoconversion. Our experiments with EG1 indicate that Eucalyptus species can be readily converted biologically for biofuel and byproduct production. Under mild pretreatment conditions, such as sulfuric acid pretreatment, over 80% cellulose conversion can be achieved, and over 30g glucose can be obtained from 100 grams od wood when using the two FPL processes (Figure 2).

Table 5.

Carbohydrate characterization for two Florida eucalypts.

| Species Batch | AI Ash | K. Lignin | ASL | Arabinan | Galactan | Rhamnan | Glucan | Xylan | Mannan |

|---|---|---|---|---|---|---|---|---|---|

| EG1 | −0.001 | 0.324 | 0.034 | 0.003 | 0.009 | 0.002 | 0.397 | 0.114 | 0.003 |

| EA4 | −0.002 | 0.345 | 0.034 | 0.004 | 0.013 | 0.002 | 0.374 | 0.111 | 0.005 |

Figure 2.

Cellulose conversion efficiency by four methods for EG1.

Hemicellulose can be reduced to sugar by acid or enzymatic hydrolysis and then fermented to produce ethanol [2]. Solid energy crops such as SRWC willow, poplar, and eucalyptus can be utilized whole to produce heat and electricity directly through combustion or indirectly through conversion for use as biofuels like methanol and ethanol. The synthesis of lower viscosity methylcellulose from juvenile eucalyptus is feasible and suitable [42]. Pulping severity is an important factor for the preparation of methylcellulose. Autohydrolysis to fractionate biomass into soluble sugar oligomers and a solid residue mainly made up of cellulose and lignin followed by posthydrolysis of autohydrolysis liquors allows the generation of xylose solutions with low inhibitor content [43]. The concentrations of furfural and other sugars obtained as reaction byproducts (glucose and arabinose) were below the threshold leading to problems in further bioconversion of the liquors. Considerable ethanol production alternatives are under investigation [44–48], e.g., ethanol may be generated from spent sulfite liquor.

The use of organic liquids from carbonization of wood to produce biopitches, which can then be mixed with charcoal to make electrodes, may replace both pitch and coke from fossil sources [1]. Biomass-derived carbons may have important and successful applications. Silicon for semiconductors, new batteries, aircraft structures and composite-like metal intercalated with graphite are some specific applications where a high degree of purity is required and metal or sulfur impurities from oil and coal can contaminate the final product. Some Brazilian companies have already begun biooil recovery at a competitive price. Mild hydropyrolysis in deeper beds may be more likely to produce lighter, less oxygenated and more stable tars/oils than liquids produced at atmospheric pressure [49]. Direct liquefaction of mallee biomass is lower cost and higher efficiency transportation of the liquid biofuel to a central user or processing facility [50]. Complex xylo-oligosaccharides may be obtained by hydrothermally treated Eucalyptus wood [51]. Polycyclic aromatic hydrocarbons may be obtained by partitioning the liquid products of the slow pyrolysis of E. grandis wood [52].

Gasification of biomass residues and spent pulping liquors into syngas is expected to produce new value streams [54, 55]. Syngas could be converted into biofuels, power, chemicals and other high value materials. Growth in biomass markets worldwide is anticipated to double between 2004 and 2013. The greatest percentage growth of biomass thermal plants is expected in Asia and Latin America. Biofuels (both ethanol and biodiesel) are rapidly increasing in the US, EU, and Brazil [56]. Key drivers for worldwide biomass expansion are: 1) meeting increasing energy demands where indigenous fossil fuel sources are non-existent or in decline, 2) meeting greenhouse gas emission targets, 3) supporting domestic and industrial waste management projects, 4) utilizing forest, crop and livestock residues, 5) rising fossil fuel prices.

Methanol can be produced from biomass by gasification, gas upgrading, and eventual synthesis over a copper-zinc oxide catalyst [57]. Woody species including Eucalyptus tend to be less favorable for methane production because of higher cell wall constituents (86.1%) and lignin (22.6%) and lower nitrogen (0.43%) and phosphorous (0.05%) [58, 59]. Methanol, like ethanol, can be used to store chemical energy for use in fuel cells, avoiding the storage and transportation problems inherent in the direct use of hydrogen in such systems. Methanol could be an attractive transportation fuel, provided effective methanol-powered fuel cells and fuel-cell/electric vehicles are developed.

Using catalytic upgrading of pyrolytic biomass oils, yields of up to 75% oil have been obtained by low-pressure liquefaction of a variety of woody and nonwoody materials, although the resultant oils contain about 20% water and are poor fuels. Catalytic upgrading can generate a useful product [ e.g., 60], but little work has been done on scale-up.

Given the prominence of current and future Eucalyptus plantations (Table 1) in areas with large energy needs and biomass energy crop production potential (Table 6), Eucalyptus can be a significant contributor of a range of energy products. In tropical and subtropical areas where Eucalyptus species are already widely planted, their deployment for energy products is likely, especially when grown on non-agricultural land and without environmental impact. In Florida, EG, EA, and CT utilization may expand from the current mulchwood market to pulps and biofuels.

Table 6.

Projected energy crop areas in 2025 by region and globally [2].

| Region | Energy crop area (ha × 103) under four IPCC scenarios | |||

|---|---|---|---|---|

| B1 | A1b | B2 | A2 | |

| North America | 14992 | 31004 | 41132 | 34985 |

| Central America | 3406 | 6489 | 10047 | 7550 |

| South America | 8521 | 8722 | 15687 | 8219 |

| Northern Africa | 182 | 0 | 0 | 0 |

| Western Africa | 182 | 257 | 142 | 102 |

| Eastern Africa | 101 | 137 | 80 | 53 |

| Southern Africa | 549 | 791 | 1376 | 706 |

| OECD Europe | 7266 | 19681 | 17886 | 15092 |

| Eastern Europe | 514 | 1826 | 2715 | 1647 |

| Former USSR | 3534 | 8916 | 7296 | 6092 |

| Middle East | 526 | 0 | 0 | 0 |

| South Asia | 5788 | 12469 | 12726 | 5171 |

| East Asia | 10068 | 18097 | 21609 | 12163 |

| Southest Asia | 1854 | 4501 | 7406 | 3521 |

| Oceania | 198 | 537 | 1594 | 1057 |

| Japan | 650 | 1150 | 1510 | 855 |

| World | 58332 | 114577 | 141206 | 97212 |

For example, the “Integrated Oil Mallee” project in Western Australia involves more than heat and power generation [2]. Biomass will come from growing SRWC eucalyptus mallee in 4–5m wide strips to help solve the dryland salinity problem on crop lands. Harvesting trees on a 3–4 year cycle will provide pharmaceutical oils, activated carbon, heat and power, tradeable renewable energy certificates, and even carbon credits. Larger scale plants may follow since the salinity problem extends over millions of hectares of arable land. Planting eucalypts for leaf oil may simultaneously provide: 1) a commercial incentive for vegetative restoration, 2) sustainable control of groundwater and salinity, 3) an environmentally benign substitute for a widely used solvent damaging to the ozone layer, 4) specialty chemical products, 5) biomass fuels, and 6) carbon sequestration.

Biomass-derived electricity and liquid fuels may be able to compete with fossil fuels [61–63]. The most likely short-term technology to convert biomass to electricity is integrated gasifier/gas turbine cycles, which may be more efficient than conventional coal electric power generation and coal gasification and have lower capital costs. Nevertheless, the techniques and technologies for growing biomass and converting it into modern energy carriers must be more fully developed. Suitable policy options include a reallocation of agricultural subsidies and a review of energy subsidies to create a more level playing field, internalizing external negative costs of fossil fuels by methods such as carbon taxes, and using these taxes to support bioenergy and other alternative carbon mitigation options.

Overall, bioenergy will likely be the highest contributor to global renewable energy in the short to medium term with dedicated energy crops, such as SRWC Eucalyptus, providing a larger proportion of the biomass feedstock in the coming decades [2]. Opportunities for energy crops include development of biorefineries, carbon sequestration, and the growing trend towards small, distributed energy systems.

4. Conclusions

Eucalyptus is widely planted and produces abundant biomass. Many conversion technologies are well understood, and several are being developed. Biomass characteristics, difficulty in securing adequate and cost effective supplies early in project development, and planning constraints currently prevent Eucalyptus bioenergy from reaching its full potential. However, increased biomass productivity and quality, prospects for carbon trading, distributed energy systems and hydrogen, multiple products from biorefining, and government incentives should foster Eucalyptus biomass use for bioenergy.

Acknowledgments

We gratefully acknowledge the significant contributions of Research Work Units 4706 and 4709 at the FPL and the following associated staff: C Hillary, G Cook, R. Gleisner, D. Mann, J Muehl, N Gribbins, P Walsh, J O’Dell, K Rosenberger, R Foss, J Balczewski, S Fishwild, M Begel, T Nelson, K Hirth, N Ross-Sutherland, D Foster, D Schulenburg, R Simonsen, S Schmeiding, GS Wang, Visiting Scientist from TianJin Key Laboratory Pulp and Paper of TianJin University of Science and Technology, XJ Pan, Dept of Biological Systems Engineering of University of Wisconsin, Madison. University of Florida (UF) staff having substantial involvement in the study included B Becker, B Tamang, P Proctor, W McKinstry. The Tampa Port Authority and D Mason supplied the EG logs, R Hodges the EA logs, and C & B Farms the CT logs. This review was initiated and contributing research conducted while the senior author was at the FPL on sabbatic leave from UF.

References

- 1.Rocha JD, Coutinho AR, Luengo CA. Biopitch produced from eucalyptus wood pyrolysis liquids as a renewable binder for carbon electrode manufacture. Braz. J. Chem. Eng. 2002;19:127–132. [Google Scholar]

- 2.Sims REH, Hastings A, Schlamadinger B, Taylor G, Smith P. Energy crops: current status and future prospects. Global Change Biology. 2006;12(11):2054–2076. [Google Scholar]

- 3.Kheshgi HS, Prince RC, Marland G. The potential of biomass fuels in the context of global climate change: Focus on transportation fuels. Ann. Rev. Energy Environ. 2000;25:199–244. [Google Scholar]

- 4.Sims REH. Bioenergy to mitigate for climate change and meet the needs of society, the economy and the environment. Mitigation and Adaptation Strategies for Global Change. 2003;8(4):349–370. [Google Scholar]

- 5.FAO. Global forest resources assessment 2005 - main report. FAO Forestry Paper, 2005; available online: ftp://ftp.fao.org/docrep/fao/008/A0400E/A0400E00.pdf

- 6.FAO. Global planted forests thematic study: results and analysis. Planted forests and trees. FAO Working Paper FP38E, 2006; available online: http://www.fao.org/forestry/webview/-media?mediaId=12139&langId=1

- 7.Rockwood DL.Eucalyptus genetic resources in Florida USA. FAO Forest Genetics Resources Information, 19881640–41.available online: http://www.fao.org/docrep/006/s9280e/S9280E19.htm#ch19

- 8.Meskimen GF, Rockwood DL, Reddy KV. Development of Eucalyptus clones for a summer rainfall environment with periodic severe frosts. New Forests. 1987;3:197–205. [Google Scholar]

- 9.Campinhos E., Jr Sustainable plantations of high-yield shape Eucalyptus trees for production of fiber: the Aracruz case. New Forests. 1999;17(1–3):129–143. [Google Scholar]

- 10.Alencar GSBde, Ernestro L, Barrichelo G, da Silva FG., Jr Wood quality of a E. grandis x E. urophylla hybrid for genetic selection. ABTCP 35th Annual Pulp and Paper Conference; São Paulo - Brasil. October 14–17, 2002. [Google Scholar]

- 11.Gion J-M, Rech P, Grima-Pettenati J, Verhaegen D, Plomion C. Mapping candidate genes in Eucalyptus with emphasis on lignification genes. Molecular Breeding. 2000;6:441–449. [Google Scholar]

- 12.MacRae S, van Staden J. Transgenic Eucalyptus. In: Bajaj YPS, editor. Transgenic Trees: Biotechnology in Agriculture and Forestry. Vol. 44. Springer-Verlag; Berlin: 2000. pp. 88–114. [Google Scholar]

- 13.McComb JA, Oddie RLA, Chapman SR, Calver MC, Rasmussen GF, Hingston TL, et al. Salt tolerant hybrid eucalypts for wood fibre production. In: Dungey HS, Dieters MJ, Nikles DG, editors. Hybrid Breeding and Genetics of Forest Trees; Proceedings of QFRI/CRC-SPF Symposium; Noosa, Queensland, Australia. Brisbane: Department of Primary Industries; 2000. pp. 252–258. [Google Scholar]

- 14.Tournier V, Grat S, Marque C, El Kayal W, Penchel R, de Andrade G, Boudet AM, Teulieres C. An efficient procedure to stably introduce genes into an economically important pulp tree (Eucalyptus grandis x Eucalyptus urophylla) Transgenic Research. 2003;12(4):403–411. doi: 10.1023/a:1024217910354. [DOI] [PubMed] [Google Scholar]

- 15.Valério L, Carter D, Rodrigues JC, Tournier V, Gominho J, Marque C, Boudet A-M, Maunders M, Pereira H, Teulières C. Down regulation of Cinnamyl Alcohol Dehydrogenase, a lignification enzyme, in Eucalyptus camaldulensis. Molecular Breeding. 2003;12(2):157–167. [Google Scholar]

- 16.Rockwood DL.Eucalyptus - pulpwood, mulch, or energywood? Florida Cooperative Extension Service Circular No. 1194, 19976available online: http://edis.ifas.ufl.edu/FR013

- 17.Langholtz M, Carter D, Alavalapati J, Rockwood D. The economic feasibility of reclaiming phosphate mined lands with short-rotation woody crops in Florida. J. For. Econ. 2007;12(4):237–249. [Google Scholar]

- 18.Aaction Mulch, Inc., http://www.aactionmulch.com/ (accessed 2007).

- 19.Gorrini B, Poblete H, Hernandez G, Dunn F. Particleboard and MDF using Eucalyptus nitens: Industrial scale experiments. Bosque. 2004;25(3):89–97. [Google Scholar]

- 20.Krzysik AM, Muehl JH, Youngquist JA, Franca FS. Medium density fiberboard made from Eucalyptus saligna. Forest Products Journal. 2001;51(10):47–50. [Google Scholar]

- 21.Eusebio D, Cabangon R, Soriano F, Evans PD. Manufacture of low-cost wood-cement composites in the Philippines using plantation grown Australian species I. Eucalypts. Proceedings 5th Pacific Rim Biobased Composites Symposium; Canberra, Australia. 10–13 December, 2000; p. 9. [Google Scholar]

- 22.Coutts RSP. A review of Australian research into natural fibre cement composites. Cement and Concrete Composites. 2005;27(5):518–526. [Google Scholar]

- 23.Foley W, Lassak E.The potential of bioactive constituents of Eucalyptus foliage as non-wood products from plantations Rural Industries Research and Development Corporation. Publication 20041544available online: http://www.rirdc.gov.au/reports/AFT/04-154.pdf [Google Scholar]

- 24.Nishimura H, Noma Y, Mizutani J. Eucalyptus as biomass. Novel compounds from microbial conversion of 1, 8-Cineole. Agricultural and Biological Chemistry. 1982;46(10):2601–2604. [Google Scholar]

- 25.Barton A.Industrial uses of eucalyptus oil. White Paper, 2007; available online: http://www.oilmallee.com.au/docs/BARTON.doc

- 26.Ogunwande IA, Olawore NO, Schmidt JM, Setzer WN, Walker TM, Silifat JT, Olaleye ON, Aboaba SA. In vitro cytotoxicity activities of essential oils of Eucalyptus torreliana F. v. Muell (leaves and fruits) Journal of Essential Oil-Bearing Plants. 2005;8(2):110–119. [Google Scholar]

- 27.Rockwood DL, Naidu CV, Carter DR, Rahmani M, Spriggs T, Lin C, Alker GA, Isebrands JG, Segrest SA.Short-rotation woody crops and phytoremediation: Opportunities for agroforestry? New Vistas in Agroforestry, A Compendium for the 1st World Congress of Agroforestry, Nair PKR, Rao MR, Buck LE.Kluwer Academic Publishers; Dordrecht, The Netherlands: 2004 [Google Scholar]

- 28.Langholtz M, Carter DR, Rockwood DL, Alavalapati JRR, Green AES. Effect of dendroremediation incentives on the profitability of short-rotation woody cropping of Eucalyptus grandis. Forest Policy and Economics. 2005;7(5):806–817. [Google Scholar]

- 29.Tancredi NC, Cordero T, Rodriguez-Mirasol J, Rodriguez JJ. Activated carbons from Uruguayan eucalyptus wood. Fuel. 1996;75(15):1701–1706. [Google Scholar]

- 30.Purdy KR, Elston LW, Hurst DR, Knight JA. Georgia Institute of Technology, Engineering Experiment Station; Atlanta: 1978. Pyrolysis of Eucalyptus grandis and melaleuca whole-tree chips. Final report, project A-2148; p. 34. [Google Scholar]

- 31.Segrest SA, Rockwood DL, Carter DR, Smith WH, Green AES, Stricker JA.Short rotation woody crops for cofiring in central Florida Proc. 29th International Technical Conference on Coal Utilization & Fuel SystemsApril 18–22, 2004Clearwater, FL; Coal Technology AssociationPaper 12. [Google Scholar]

- 32.Davis MW. A rapid modified method for compositional carbohydrate analysis of lignocellulosics by HPAEC/PAD. J. Wood Chem. Technol. 1998;18:235–252. [Google Scholar]

- 33.Rockwood DL, Squillace AE. Increasing alcohol production from wood by utilizing genetic variation in wood characteristics. Proc. 1981 TAPPI Ann. Meet.; 1981. pp. 307–316. [Google Scholar]

- 34.Rockwood DL, Dinus RJ, Kramer JM, McDonough TJ, Raymond CA, Owen JV, Devalerio JT. Genetic variation for rooting, growth, frost hardiness, and wood, fiber, and pulping properties in Florida-grown Eucalyptus amplifolia. Proceedings 22nd. Southern Forest Tree Improvement Conference; 14–17 June 1993; Atlanta, GA. pp. 81–88. [Google Scholar]

- 35.Rockwood DL, Dinus RJ, Kramer JM, McDonough TJ. Genetic variation in wood, pulping, and paper properties of Eucalyptus amplifolia and E. grandis grown in Florida USA. Proceedings CRC-IUFRO Conference Eucalypt Plantations: Improving Fibre Yield and Quality; 19–24 February 1995; Hobart, Australia. pp. 53–59. [Google Scholar]

- 36.Mori FA, Mendes LM, Trugilho PF, Cardoso MG. Use of wood of Eucalyptus sp and native in the storage of the sugar cane spirit. Ciênc. Tecnol. Aliment. 2003;23(3):396–400. [Google Scholar]

- 37.Seca AML, Domingues FMJ. Basic density and pulp yield relationship with some chemical parameters in eucalyptus trees. Pesq. Agropec. Bras. 2006;41(12):1687–1691. [Google Scholar]

- 38.Christensen JH, Baucher M, O’Connell A, van Montagu M, Boerjan W. Control of lignin biosynthesis. In: Jain SM, Minocha SC, editors. Molecular biology of woody plants. Vol. 1. Kluwer Academic Publishers; Dordrecht, Netherlands: 2000. pp. 227–267. [Google Scholar]

- 39.Hillis WE. Eucalypts: Chemistry, Uses. Proceedings of the 6th International Symposium on Wood and Pulping Chemistry; 1991. [Google Scholar]

- 40.Jewell IJ, Cavell KJ, Blackman AJ. The chemistry of Eucalyptus regnans extractives and effects on peroxide bleaching. Proceedings of the 6th International Symposium on Wood and Pulping Chemistry; 1991. [Google Scholar]

- 41.Eschler BM, Pass DM, Willis M, Foley WJ. Distribution of foliar formylated phloroglucinol derivatives amongst Eucalyptus species. Biochem. Syst. Ecol. 2000;28(90):813–824. doi: 10.1016/s0305-1978(99)00123-4. [DOI] [PubMed] [Google Scholar]

- 42.Ye D, Montané D, Farriol X. Preparation and characterisation of methylcellulose from annual cardoon and juvenile eucalyptus. Carbohydr. Polym. 2005;61(4):446–454. [Google Scholar]

- 43.Garrote G, Domínguez H, Parajó JC. Generation of xylose solutions from Eucalyptus globulus wood by autohydrolysis-posthydrolysis processes: posthydrolysis kinetics. Bioresour. Technol. 2001;79(2):155–164. doi: 10.1016/s0960-8524(01)00044-x. [DOI] [PubMed] [Google Scholar]

- 44.Felipe MGA, Alves LA, Silva SS, Roberto IC, Mancilha IM, Almeida e silva JB. Fermentation of eucalyptus hemicellulosic hydrolysate to xylitol by Candida guilliermondii. Biores. Technol. 1996;56:281–283. [Google Scholar]

- 45.Ferrari MD, Neirotti E, Albornoz C, Saucedo E. Ethanol production from eucalyptus wood hemicellulose hydrolysate by Pichia stipitis. Biotechnol. Bioeng. 1992;40(7):753–759. doi: 10.1002/bit.260400702. [DOI] [PubMed] [Google Scholar]

- 46.Gregg DJ, Saddler JN. Factors affecting cellulose hydrolysis and the potential of enzyme recycle to enhance the efficiency of an integrated wood to ethanol process. Biotechnol. Bioeng. 1996;51(4):375–383. doi: 10.1002/(SICI)1097-0290(19960820)51:4<375::AID-BIT1>3.0.CO;2-F. [DOI] [PubMed] [Google Scholar]

- 47.Parajó JC, Santos V, Vázquez M. Production of carotenoids by Phaffia rhodozyma growing on media made from hemicellulosic hydrolysates of Eucalyptus globulus wood. Biotechnol. Bioeng. 1998;59(4):501–506. doi: 10.1002/(sici)1097-0290(19980820)59:4<501::aid-bit13>3.0.co;2-c. [DOI] [PubMed] [Google Scholar]

- 48.Sun Y, Cheng J. Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour. Technol. 2002;83(1):1–11. doi: 10.1016/s0960-8524(01)00212-7. [DOI] [PubMed] [Google Scholar]

- 49.Pindoria RV, Lim JY, Hawkes JE, Lazaro M-J, Herod AA, Kandiyoti R. Structural characterization of biomass pyrolysis tars/oils from eucalyptus wood waste: effect of H2 pressure and sample configuration. Fuel. 1997;76(11):1013–1023. [Google Scholar]

- 50.Bridgwater AV, Carson P, Coulson M. A comparison of fast and slow pyrolysis liquids from mallee. Int. J. Global. Energ. Issues. 2007;27(2):204–216. [Google Scholar]

- 51.Kabel MA, Schols HA, Voragen AGJ. Complex xylo-oligosaccharides identified from hydrothermally treated Eucalyptus wood and brewery’s spent grains. Carbohydr. Polym. 2002;50(2):191–200. [Google Scholar]

- 52.Pimentaa AS, Vitala BR, Bayonabr JM, Alzagab R. Characterisation of polycyclic aromatic hydrocarbons in liquid products from pyrolysis of Eucalyptus grands by supercritical fluid extraction and GWMS determination. Fuel. 1998;77(11):1133–1139. [Google Scholar]

- 53.Silva MC, Lopes OR, Colodette JL, Porto AO, Rieumont J, Chaussy D, Belgacem MN, Silva GG. Characterization of three non-product materials from a bleached eucalyptus kraft pulp mill, in view of valorising them as a source of cellulose fibres. Industrial Crops and Products. 2008;27:288–295. [Google Scholar]

- 54.Wright L. Worldwide commercial development of bioenergy with a focus on energy crop-based projects. Biomass and Bioenergy. 2006;30:706–714. [Google Scholar]

- 55.Overend R. Biomass gasification - the enabling technology. Renewable Energy World. 2000;3(3):42–47. [Google Scholar]

- 56.Pinatti DG, Couto L, Soares ÁG, Vieira CA, Conte RA.Report on bioenergy in Brazil. White Paper, 1991; available online: http://www.p2pays.org/ref/17/16274/pinatti.pdf

- 57.Hamelinck CN, Faaij APC. Future prospects for production of methanol and hydrogen from biomass. Proceedings of 12th European Conference on “Biomass for Energy, Industry and Climate Protection”; 17–21 June 2002; Amsterdam, ETA-Florence and WIP-Munich. pp. 1170–1173. [Google Scholar]

- 58.Bjorndal KA, Moore JE. Prediction of fermentability of biomass feedstocks from chemical characteristics. In: Smith WH, editor. Biomass Energy Development. Plenum Press; N.Y.: 1985. pp. 497–454. [Google Scholar]

- 59.Bjorndal KA, Moore JE. Chemical characteristcs and their relation to fermentability of potential biomass feedstocks. In: Smith WH, Frank JR, editors. Methane from Biomass: A Systems Approach. Elsevier Applied Science; N.Y.: 1988. pp. 355–365. [Google Scholar]

- 60.Zhang S, Yan Y, Li T, Ren Z. Upgrading of liquid fuel from the pyrolysis of biomass. Bioresour. Technol. 2005;96(5):545–550. doi: 10.1016/j.biortech.2004.06.015. [DOI] [PubMed] [Google Scholar]

- 61.Rexen F, Blicher-Mathiesen U. Energy and Industry. James & James; London: 1998. Whole crop utilisation - biorefineries. Sustainable agriculture for food; pp. 825–828. [Google Scholar]

- 62.Sims REH, Rogner H-H, Gregory K. Carbon emission and mitigation cost comparisons between fossil fuel, nuclear and renewable energy resources for electricity generation. Energy Policy. 2003;31:1315–1326. [Google Scholar]

- 63.Hall DO. Biomass energy in industrialised countries-a view of the future. Forest Ecology and Management. 1997;91(1):17–45. [Google Scholar]