Abstract

Objectives

Secondary caries and restoration fracture are the two main challenges facing tooth cavity restorations. The objective of this study was to develop a composite using tetracalcium phosphate (TTCP) fillers and whiskers to be stress-bearing, and to be “smart” to increase the calcium (Ca) and phosphate (PO4) ion release at cariogenic pH.

Methods

TTCP was ball-milled to obtain four different particle sizes: 16.2 μm, 2.4 μm, 1.3 μm, and 0.97 μm. Whiskers fused with nano-sized silica were combined with TTCP as fillers in a resin. Filler level mass fractions varied from 0% to 75%. Ca and PO4 ion release were measured vs. time at pH of 7.4, 6, and 4. Composite mechanical properties were measured via three-point flexure before and after immersion in solutions at the three pH.

Results

TTCP composite without whiskers had flexural strength similar to a resin-modified glass ionomer (Vitremer) and previous Ca-PO4 composites. With whiskers, the TTCP composite had a flexural strength (mean ± sd; n = 5) of (116 ± 9) MPa, similar to (112 ± 14) MPa of a stress-bearing, non-releasing hybrid composite (TPH) (p > 0.1). The Ca release was (1.22 ± 0.16) mmol/L at pH of 4, higher than (0.54 ± 0.09) at pH of 6, and (0.22 ± 0.06) at pH of 7.4 (p < 0.05). PO4 release was also dramatically increased at acidic pH. After immersion, the TTCP-whisker composite matched the strength of TPH at all three pH (p > 0.1); both TTCP-whisker composite and TPH had strengths about 3-fold that of a releasing control.

Significance

The new TTCP-whisker composite was “smart” and increased the Ca and PO4 release dramatically when the pH was reduced from neutral to a cariogenic pH of 4, when these ions are most needed to inhibit caries. Its strength was 2–3 fold higher than previously-known Ca-PO4 composites and resin-modified glass ionomer. This composite may have the potential to provide the necessary combination of load-bearing and caries-inhibiting capabilities.

Keywords: dental composite, tetracalcium phosphate, particle size, mechanical properties, tooth caries inhibition, Ca and PO4 ion release

1. Introduction

Dental polymeric composites are composed of reinforcing inorganic fillers in a dimethacrylate resin monomer matrix that is polymerized to form a solid restoration [1–6]. Resin compositions, fillers and cure conditions have been improved, and composite properties and clinical usefulness have been enhanced [7–11]. However, recent reports on composite restorations still indicate that “The two main challenges are secondary caries and bulk fracture” [12,13]. Secondary caries at the tooth restoration margins is the most frequent reason for replacement of existing restorations [14]. Replacement of existing restorations accounts for more than half of all operative work, and replacement dentistry costs about $5 billion annually in the U. S. alone [15].

Calcium and phosphate (Ca-PO4) particles have been used as fillers in dental resins, and the resulting composite released calcium (Ca) and phosphate (PO4) ions, which can form hydroxyapatite [Ca10(PO4)6(OH)2], the putative mineral in enamel and dentin [16–20]. Ca-PO4composites were shown to remineralize enamel and dentin lesions in vitro [16,19]. However, the Ca-PO4 composites had flexural strengths of about half of that of the unfilled resin [17]. Such low strengths were “inadequate to make these composites acceptable as bulk restoratives” [18]. Recently, nanoparticles of calcium phosphates were synthesized and incorporated into dental resins [21–23]. The high surface area of the nanoparticles, coupled with strong reinforcement fillers, resulted in composites with stress-bearing and Ca and PO4 releasing capabilities. However, these studies used only dicalcium phosphate anhydrous (DCPA: CaHPO4) powders [21–23]. Tetracalcium phosphate [TTCP: Ca4(PO4)2O] is another important compound used in bone cements [24], tissue engineering scaffolds [25,26], and dental composites [19]. TTCP is the most alkaline among all Ca-PO4 compounds [24] and, hence, is promising in buffering harmful acids and inhibiting tooth caries. Previous studies used TTCP with a particle size of about 17 μm [19,24–26]. There has been no investigation on using finer TTCP particles as fillers in dental resins, and no study on the effect of pH of the immersion solution on ion release and mechanical properties of TTCP-based dental composite.

The oral plaque pH after a sucrose rinse can decrease to 4.5 or even 4 [27,28]. A plaque pH of higher than 6 is considered to be the safe area, a plaque pH of 6.0 to 5.5 is the potentially cariogenic area, and pH of 5.5 to 4 is the cariogenic or danger area for cavity formation. Therefore, it is desirable for Ca-PO4 composite to be “smart”, to increase the release of caries-inhibiting ions at lower pH, when the Ca and PO4 ions are most needed. Such ion release triggered by a local pH drop may help prevent demineralization in tooth structures contiguous to the smart composite restoration.

Therefore, the objectives of this study were to develop a composite using fine TTCP particles, and to investigate the effects of solution pH on composite ion release and mechanical properties. It was hypothesized that: (1) Smaller TTCP particle size and co-filler reinforcement will significantly improve the composite mechanical properties; (2) TTCP composite will be “smart” as it will increase its Ca and PO4 release when the pH is lowered; (3) The mechanical properties of the reinforced TTCP composite will match those of a commercial stress-bearing, non-releasing hybrid composite, after immersion in solutions with pH of 7.4, 6, and 4.

2. Materials and methods

2.1 TTCP fillers and whiskers

Tetracalcium phosphate [TTCP: Ca4(PO4)2O] was synthesized from a solid-state reaction between CaHPO4 and CaCO3 (Baker Analyzed Reagents, J. T. Baker Chemical, Phillipsburg, NJ), which were mixed and heated at 1500 °C for 6 h in a furnace (Model 51333, Lindberg, Watertown, WI) [24–26]. The heated mixture was quenched to room temperature, ground in a blender (Dynamics Corp., New Hartford, CT) for approximately 10 min. The powder was then sieved to obtain TTCP particles with sizes ranging from about 1.5 μm to 60 μm, with a median particle size of 16.2 μm. This TTCP powder was similar to those used in previous bone repair materials and dental composite [19,20,24–26].

This TTCP powder was then ground in 95% ethanol with a ball mill (Bel-Alert Products, Pequannock, NJ; 120 balls, 300 rpm) for 3 hrs, 24 hrs, and 72 hrs, respectively, to obtain three finer TTCP powders. The particle size distribution was measured via a sedimentation method with the use of a centrifugal particle analyzer (SA-CP3, Shimazu, Kyoto, Japan).

Silicon nitride whiskers (β-Si3N4, UBE, New York, NY) were used with diameters ranging from 0.1 to 2 μm, witha mean of approximately 0.4 μm. The lengths of whiskers ranged from 2 to 30 μm, with a mean of 5 μm [29,30]. The whiskers were mixed with nano-sized silica (Aerosil-OX50, Degussa, Ridgefield, NJ) having a diameter of about 40 nm, at a whisker:silica mass ratio of 5:1. The mixture was heated in the furnace at 800 °C for 30 min to fuse the nanosilica onto the whiskers. This purpose of this fusion was to roughen the whisker surfaces, as well as to enhance the silanization efficacy, for improved retention in the resin [29,30]. The nanosilica-fused whiskers were then silanized with 4% 3-methacryloxypropyltrimethoxysilane and 2% n-propylamine (mass fractions) [29,30].

2.2 Resin composite fabrication

A monomer consisting of 48.975% Bis-GMA (bisphenol glycidyl dimethacrylate), 48.975% TEGDMA (triethylene glycol dimethacrylate), 0.050% 2,6-di-tert-butyl-4-methylphenol, and 2.000% benzoyl peroxide formed part I, the initiator, of a two-part chemically-activated resin [22]. Part II, the accelerator resin, consisted of 49.5% Bis-GMA, 49.5% TEGDMA, and 1.0% N,N-dihydroxyethyl-p-toluidine.

Four groups of specimens were fabricated. The purpose of group 1 was to examine the effect of TTCP filler level on composite mechanical properties. The finest TTCP powder (0.97 μm) from ball-milling was used, because previous studies showed that smaller particles with a higher surface area yielded more ion release from the composite [23]. The following TTCP filler mass fractions were used in the resin: 0% (unfilled resin), 30%, 40%, 50%, 60%, 70%, and 75%. Equal masses of the two pastes, part I and part II, were mixed and filled into a rectangular stainless steel mold with 2 mm × 2 mm × 25 mm dimensions. The specimens were incubated at 37°C with a relative humidity of approximately 50% for 24 h prior to testing.

The purpose of group 2 was to investigate the effects of TTCP particle size and whisker reinforcement on composite mechanical properties. A 2×4 full factorial design was tested, with 2 levels of whiskers (TTCP:whisker mass ratio of 1:0; TTCP:whisker ratio of 1:1), and 4 levels of TTCP particle sizes (16.2 μm, 2.4 μm, 1.3 μm, 0.97 μm). The total filler level in the resin was fixed at 75% by mass (e.g., the composite with TTCP:whisker of 1:1 had 37.5% TTCP and 37.5% whiskers). Rectangular specimens were made as previously described.

The purpose of group 3 was to measure Ca and PO4 release vs. solution pH. Two composites were made. The first was a TTCP composite without whiskers, at 75% TTCP mass fraction, using the fine TTCP with 0.97 μm particle size. The second composite had a TTCP:whisker ratio of 1:1, at a total filler mass fraction of 75%, using the same fine TTCP. The ion release was measured as described in Section 2.4.

The purpose of group 4 was to investigate the effect of solution pH on mechanical properties of the composite immersed in the solution. Since the composite containing 75% fillers at a TTCP:whisker ratio of 1:1 had a relatively higher strength and good ion release, it was selected for this experiment. The specimens were immersed in solutions at pH of 7.4, 6 and 4 for 28 days, after which their flexural strength and elastic modulus were measured, as described in Section 2.3.

A hybrid composite (TPH, Caulk/Dentsply, Milford, DE) was used as a stress-bearing, non-releasing control for mechanical properties. It consisted of a combination of barium silicate glass particles and fumed silica, with a mean particle size of about 0.8 μm, at 78% filler level by mass in a urethane-modified Bis-GMA-TEGDMA resin. The specimens were photo-cured (Triad-2000, Dentsply, York, PA) for 1 min on each open side of the specimen using the same 2 mm × 2 mm × 25 mm molds. In addition, a resin-modified glass ionomer (Vitremer, 3M, St. Paul, MN) was used as another control for mechanical properties that has ion release. Vitremer was mixed according to the manufacturer’s instructions, placed into the same molds, and cured using visible light (Triad 2000) for 1 min on each open side of the specimen.

2.3 Flexural testing

Flexural strength and elastic modulus were measured using a three-point flexural test with a 20 mm span at a crosshead-speed of 1 mm/min on a computer-controlled Universal Testing Machine (5500R, MTS, Cary, NC). The flexural strength of the composite was calculated by S = 3PmaxL/(2bh2), where Pmax is the maximum load on the load-displacement curve, L is flexure span, b is specimen width, and h is specimen thickness [31]. The elastic modulus was calculated by E = (P/d)(L3/[4bh3]), where the load P divided by the corresponding displacement d is the slope of the load-displacement curve in the linear elastic region [32].

2.4 Ca and PO4 release

A sodium chloride (NaCl) solution (133 mmol/L) was buffered to three different pHs: pH 4 with 50 mmol/L formic acid, pH 6 with 50 mmol/L MES (2-[N-Morpholino] ethanesulfonic acid) monohydrate at a Sigma ultra purity level, and pH 7.4 with 50 mmol/L HEPES. These three solutions were used to immerse the specimens. Following previous studies [21–23], three specimens of approximately 2 mm × 2 mm × 12 mm were immersed in 50 mL solution, yielding a specimen volume/solution of 2.9 mm3/mL. This compared to a specimen volume per solution of approximately 3.0 mm3/mL in a previous study [17]. For each solution, the concentrations of Ca and PO4 released from the specimens were measured vs. immersion time: 6 hours, 1 day (d), 2 d, 4 d, 7 d, 14 d, 21 d, and 28 d. At each time period, aliquots of 0.5 mL were removed and replaced by fresh solution. The aliquots were analyzed for Ca and PO4 via spectrophotometric methods (DMS-80 UV-visible, Varian, Palo Alto, CA) using known standards and calibration curves [17,19,33]. Five calcium standards of 0.08, 0.16, 0.24, 0.32 and 0.4 mmol/L and five phosphate standards of 0.008, 0.016, 0.024, 0.036 and 0.048 mmol/L were respectively prepared and used to form the calibration curves. All solutions were diluted to the ranges of the calcium and phosphate standards.

One-way and two-way ANOVA were performed to detect the significant effects of the experimental variables. Tukey’s multiple comparison test was used to compare the measured data at a p value of 0.05.

3. Results

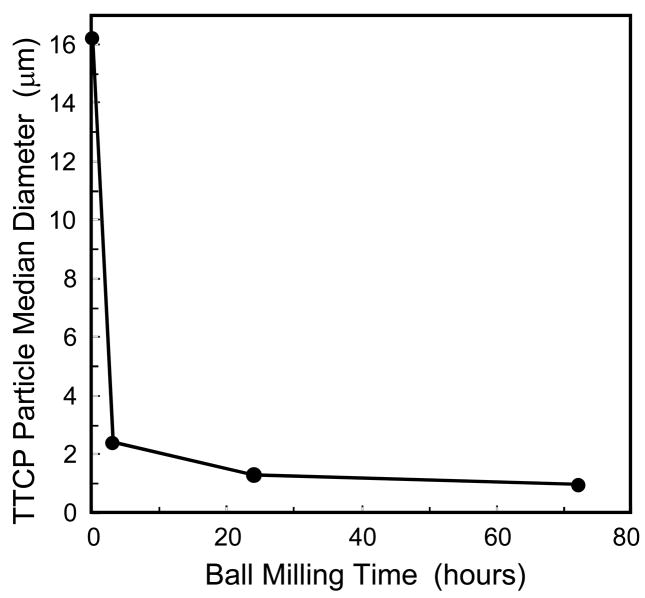

The TTCP particle size vs. ball milling time data are shown in Fig. 1. There was a sharp reduction in TTCP particle size initially, but the then decrease became much slower over longer milling time. The finest TTCP powder obtained at 72 hours had a median (50 percentile) diameter of 0.97 μm, with a particle size range of approximately 0.2 μm to 3.0 μm.

Figure 1.

Tetracalcium phosphate (TTCP), Ca4(PO4)2O, particle diameter vs. ball milling time. The median (50th percentile) particle sizes were 16.2 μm, 2.4 μm, 1.3 μm, and 0.97 μm, respectively. These particles were used as fillers in dental resin to release Ca and PO4 ions to inhibit tooth caries.

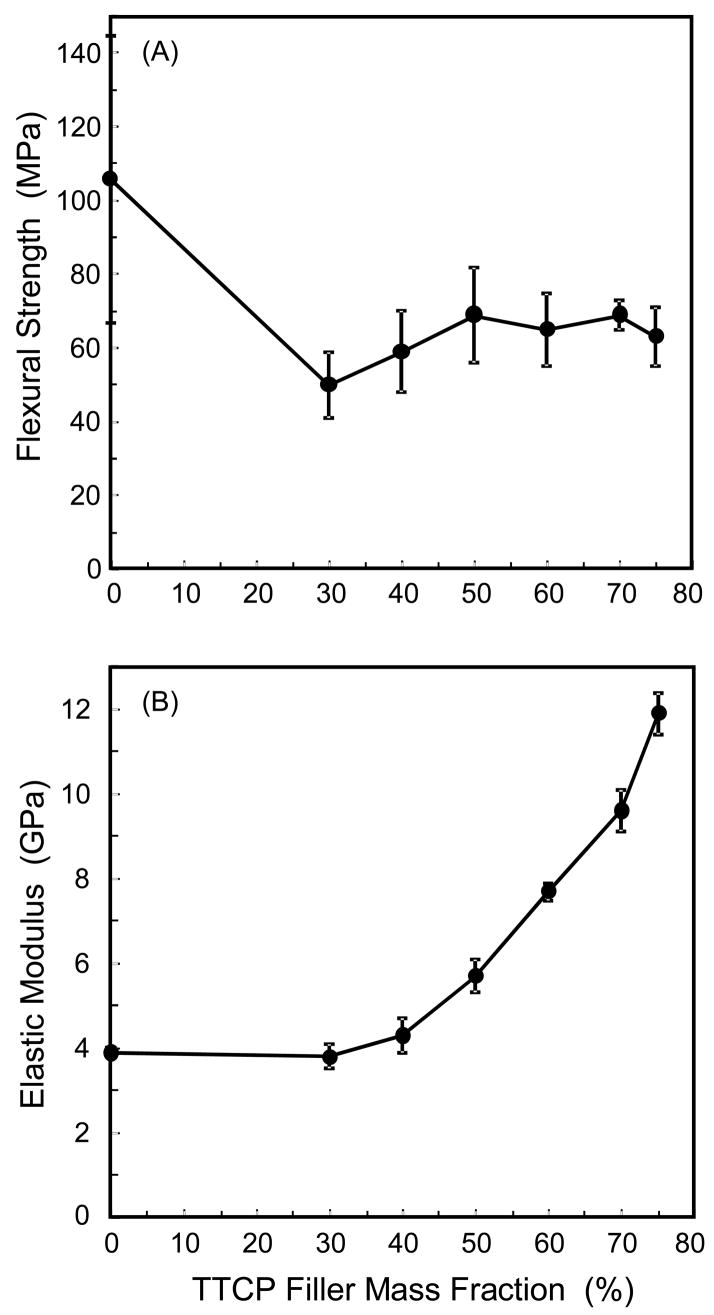

The results of group 1 is plotted in Fig. 2, which shows the effect of TTCP filler level on (A) flexural strength, and (B) elastic modulus (mean ± sd; n = 5). Incorporating TTCP (0.97 μm) into the resin significantly decreased the strength but increased the elastic modulus (p < 0.05). The strength for composites with 30% to 75% fillers was about 60 MPa, not significantly different from each other (p > 0.1). However, the modulus monotonically increased with TTCP filler level, from (3.8 ± 0.3) GPa at 30% TTCP, to (11.9 ± 0.5) GPa at 75% TTCP (p < 0.05).

Figure 2.

Results of group 1 on the effect of TTCP filler level on composite mechanical properties. Each value is the mean of five measurements with the error bar showing one standard deviation (mean ± sd; n = 5). The TTCP particle size was 0.97 μm, and no whiskers were used in the composite.

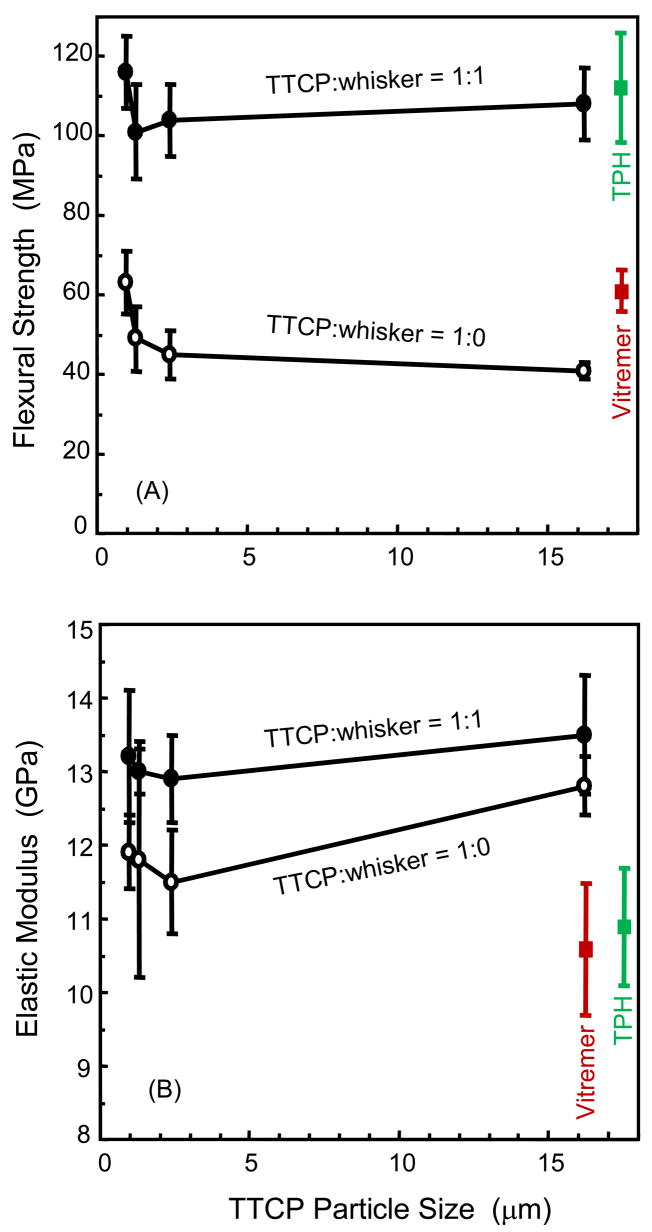

The results of group 2 on the effects of TTCP particle size and whisker reinforcement, at a fixed filler level of 75%, are shown in Fig. 3. For the composite containing 75% TTCP without whiskers, increasing the TTCP particle size from 0.97 μm to 16.2 μm significantly decreased the composite strength (p < 0.05). At a TTCP size of 0.97 μm, the composite strength (mean ± sd; n = 5) was (63 ± 8) MPa, not significantly different from (60 ± 6) of Vitremer (p > 0.1). However, at TTCP:whisker ratio of 1:1, TTCP particle size did not significantly change the composite strength (p > 0.1). The flexural strength at TTCP size of 0.97 μm was (116 ± 9) MPa, similar to (108 ± 9) MPa at TTCP size of 16.2 μm; both are similar to the (112 ± 14) MPa of TPH (p > 0.1). These strengths are nearly 2-fold those of TTCP composite without whiskers, and that of Vitremer.

Figure 3.

Results of group 2 on effects of TTCP particle size and whiskers. Each value is mean ± sd; n = 5. The total filler level was fixed at 75% for each experimental composite. The TTCP particle sizes were 16.2 μm, 2.4 μm, 1.3 μm, and 0.97 μm, respectively. Two commercial controls were also included, which were measured in the same manner. TTCP:whisker ratio of 1:1 means 37.5% of TTCP and 37.5% of whiskers. TTCP:whisker ratio of 1:0 means 75% of TTCP and no whiskers.

The elastic modulus (Fig. 3B) varied from about 11.5 GPa to 13.5 GPa, with the composite containing the 16.2-μm TTCP having a slightly higher modulus. All the TTCP composites at TTCP:whisker ratio of 1:1 had significantly (p < 0.05) higher elastic moduli than the (10.9 ± 0.8) GPa of TPH, and the (10.6 ± 0.9) GPa of Vitremer.

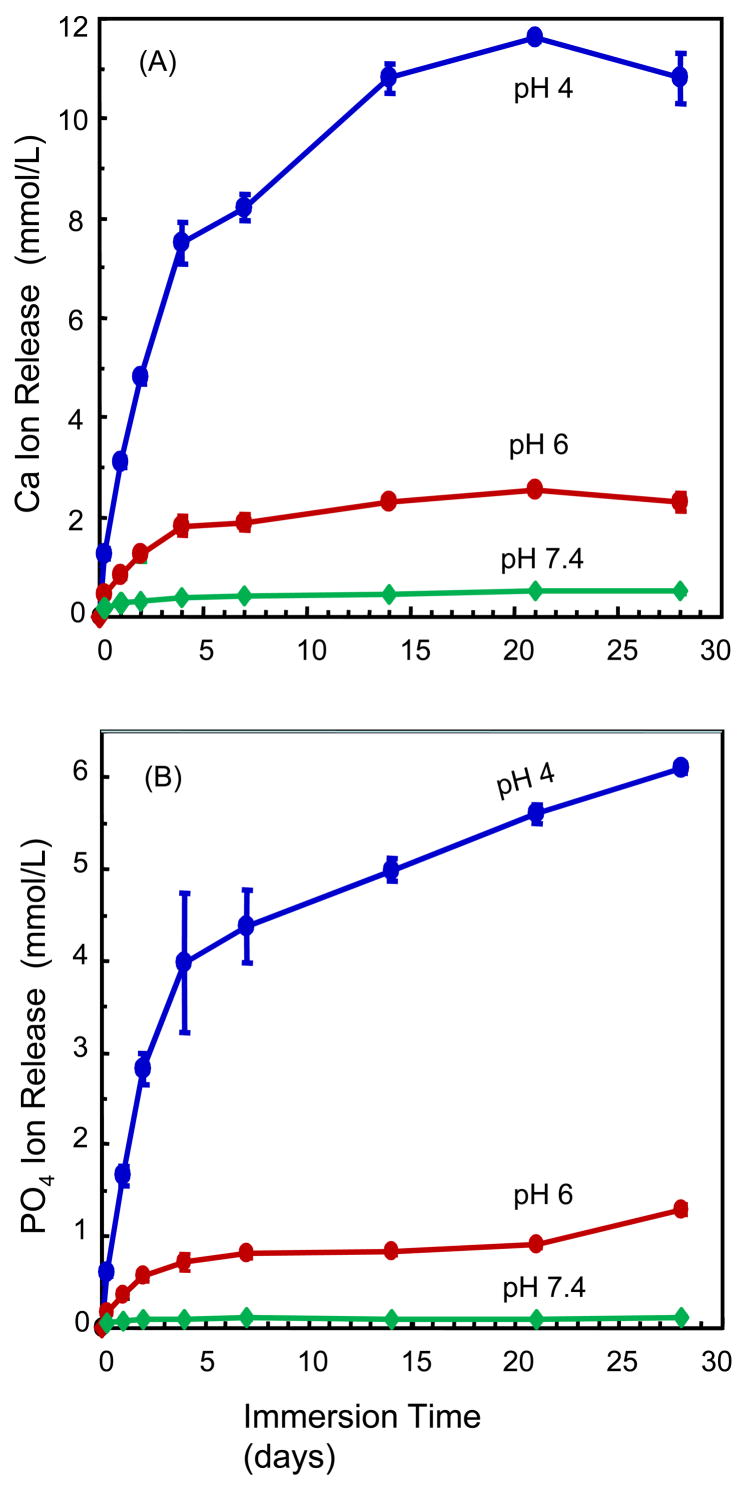

The Ca and PO4 ion release from the first composite in group 3, which was filled with TTCP (0.97 μm) to 75% mass fraction (without whiskers), is plotted in Fig. 4. Two-way ANOVA showed significant effects of solution pH and immersion time, with a significant interaction between the two variables (p < 0.05). Decreasing the solution pH increased the ion release. The Ca concentration at 28 days was (10.76 ± 0.51) mmol/L at pH of 4, significantly higher than (2.29 ± 0.16) mmol/L at pH of 6, and (0.51 ± 0.04) mmol/L at pH of 7.4 (p < 0.05). The PO4 was (6.09 ± 0.05) mmol/L at pH of 4, higher than (1.29 ± 0.06) mmol/L at pH of 6, and (0.12 ± 0.01) mmol/L at pH of 7.4 (p < 0.05).

Figure 4.

Ca and PO4 release for group 3: Composite filled with 0.97-μm TTCP to 75% mass fraction, without whiskers. Each value is mean ± sd; n = 3. Decreasing the solution pH significantly increased the ion release from the composite (p < 0.05).

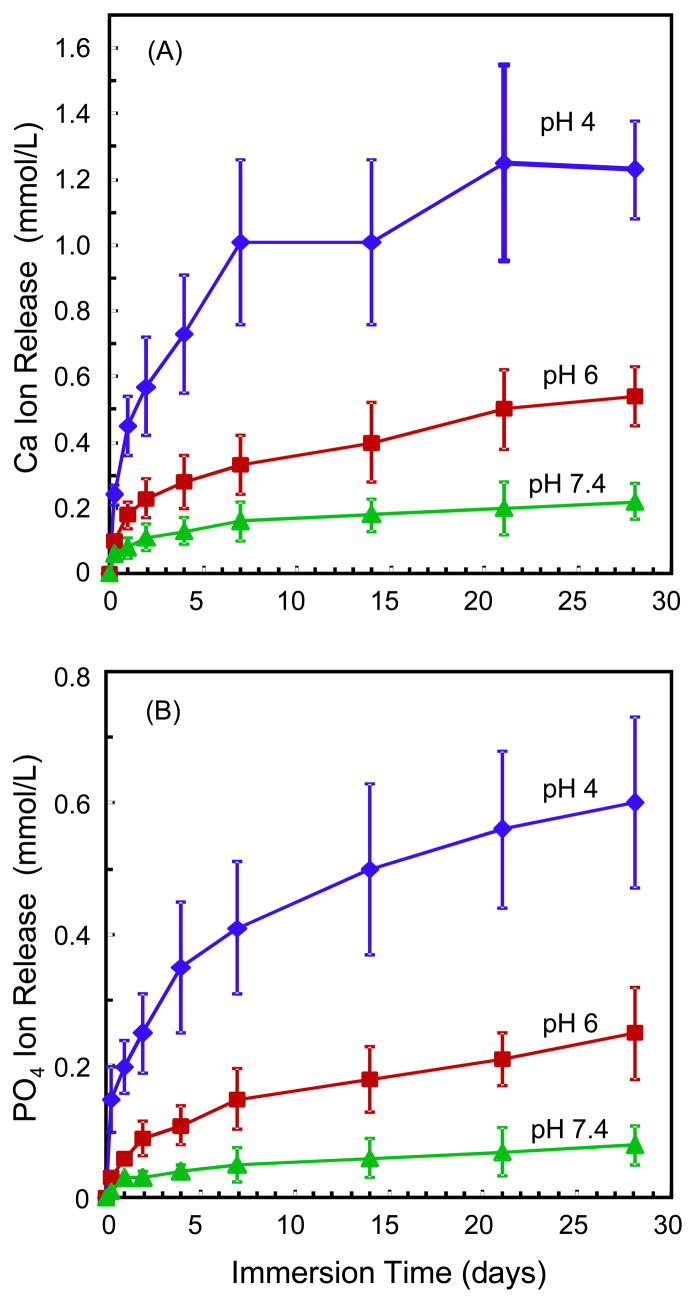

The Ca and PO4 release from the second composite in group 3, at a TTCP:whisker ratio of 1:1 and 75% total filler, is plotted in Fig. 5. Decreasing the solution pH increased the ion release. The Ca concentration at 28 days was (1.22 ± 0.16) mmol/L at pH of 4, significantly higher than (0.54 ± 0.09) mmol/L at pH of 6, and (0.22 ± 0.06) mmol/L at pH of 7.4 (p < 0.05). The PO4 was (0.60 ± 0.12) mmol/L at pH of 4, higher than (0.25 ± 0.07) mmol/L at pH of 6, and (0.08 ± 0.03) mmol/L at pH of 7.4 (p < 0.05). For both Ca and PO4, the release was increased by about 6-fold when the pH was reduced from 7.4 to 4. The amounts of release were significantly lower than the corresponding releases from the composite filled with TTCP particles without whiskers in Fig. 4 (p < 0.05).

Figure 5.

Ca and PO4 release for group 3: TTCP-whisker composite with 37.5% of TTCP (0.97μm TTCP), and 37.5% of whiskers. Each value is mean ± sd; n = 3.

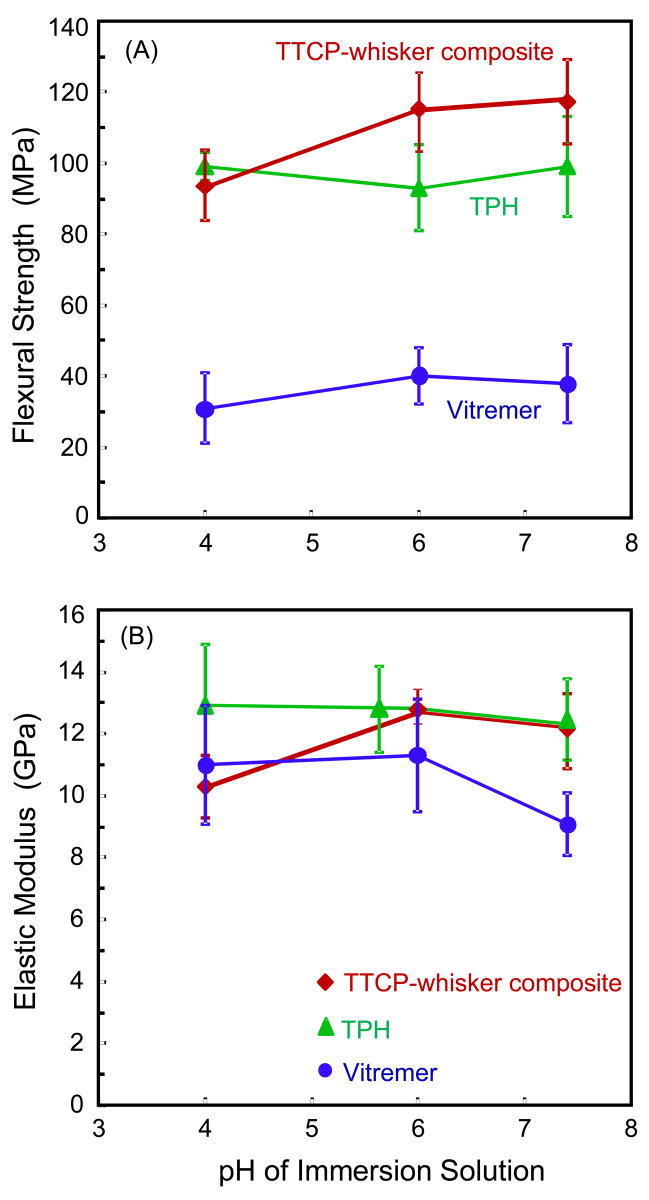

The results of group 4 are shown in Fig. 6. The composite with 75% fillers at a TTCP:whisker ratio of 1:1, TPH, and Vitremer were immersed in solutions at pH of 7.4, 6 and 4 for 28 days. In general, solution pH had only minor effects on the strength and modulus. The main results are: (1) The TTCP-whisker composite matched the strengths of TPH at all three pH; (2) Both TTCP-whisker composite and TPH had strengths about 3-fold the strength of Vitremer; (3) All three materials had similar elastic moduli, with little change vs. solution pH for the range tested. Compared to the mechanical properties without immersion in Fig. 3, both TPH and TTCP-whisker composite showed no significant decrease in strength or modulus in immersion (p > 0.1). Vitremer showed a significant decrease in strength (p < 0.05), but no decrease in modulus during immersion (p > 0.1).

Figure 6.

Results of group 4, showing (A) flexural strength, and (B) elastic modulus, after immersion for 28 days in solutions of pH of 7.4, 6, and 4, respectively. Solution pH had only minor effects on composite strength and modulus. TTCP-whisker composite matched the strengths of TPH at all three pH. Both TTCP-whisker composite and TPH had strengths about 3-fold the strength of Vitremer. Each value is mean ± sd; n = 5. The TTCP-whisker composite had 75% fillers at a TTCP:whisker ratio of 1:1.

4. Discussion

A new composite was developed using ball-milled fine TTCP particles and nanosilica-fused whiskers. The incorporation of TTCP enabled the composite to release Ca and PO4 ions to combat secondary caries, while the whiskers provided the needed load-bearing ability. This new composite had flexural strength and elastic modulus matching those of a commercial stress-bearing, non-releasing composite, both before and after immersion in solutions at pH of 7.4, 6, and 4. The strength of TTCP composite without whiskers was about half of that for the unfilled resin, similar to previous studies showing that the calcium phosphate composites had flexural strengths of about half of that of the unfilled resin [17,18]. TTCP and other calcium phosphate fillers did not reinforce the resin, likely because these fillers are not strong mechanically, and they were not silanized and hence did not bond chemically to the resin matrix. A separate study showed that silanization of Ca-PO4 fillers did not increase the strength of a Ca-PO4 composite [23], likely because the silane did not bond to calcium phosphate fillers. Furthermore, silanization of Ca-PO4 fillers was not desirable because it reduced the Ca and PO4 ion release [23]. Therefore, a more effective approach to increasing the composite mechanical properties would be to use a strong co-filler for reinforcement. In the present study, the TTCP-whisker composite had strengths about 2-fold those of the TTCP composite without whiskers. Moreover, previous studies showed that nanosilica-fused whiskers were effectively silanized and bonded to the resin [29,30]. As a result, immersion in solutions at pH of 7.4, 6 and 4 did not significantly reduce the strength of the TTCP-whisker composite, which was similar to that of a commercial hybrid composite, in contrast to a significant strength loss for a releasing control material.

Both the TTCP composite and the TTCP-whisker composite were “smart” in that they dramatically increased the Ca and PO4 ion release when the pH was reduced from neutral to a cariogenic pH of 4. The local plaque pH of > 6 is the safe area, pH of 6.0 - 5.5 is the potentially cariogenic area, and pH of 5.5 - 4 is the cariogenic area for cavity formation [27,28]. Hence, the ability of the TTCP composite and the TTCP-whisker composite to dramatically increase the release of caries-inhibiting ions at lower pH, when the Ca and PO4 ions are most needed, is highly desirable. Previous studies have examined the release of fluoride ions and chlorhexidine from restoratives at neutral and acidic pH, showing higher releases at lower pH [34–36]. In previous studies, Ca and PO4 ion release from composites for remineralization was measured at neutral pH, but no investigation at cariogenic pH was carried out [17–20]. Based on our literature search, the present study is the first report on Ca and PO4 release at acidic pH for smart Ca-PO4 composites, showing substantial increases in Ca and PO4 release at cariogenic pH.

The TTCP-whisker composite had a flexural strength of 116 MPa, 2–3 fold higher than the strengths of previously-known Ca-PO4 composites before immersion. For example, in one study, amorphous calcium phosphate (ACP) fillers were used to develop an ACP remineralizing composite [16,17]. For dry specimens without immersion, the ACP composite had a flexural strength of (47 ±5) MPa using unmilled ACP, and (56 ±16) MPa using milled ACP [37]. In another study on a novel Ca-PO4 composite, a biaxial flexural strength of 40–60 MPa before immersion was reported; the strength decreased to 10–20 MPa after 90 days of immersion [20]. The strength of the ACP-composite decreased to 40 MPa after 11 days of immersion [17,18]. These strengths are similar to the strength of Vitremer after immersion (Fig. 6), hence these materials have the potential to be useful in low-load-bearing restorations. The strength of the new TTCP-whisker composite is 2–3 fold higher than previously-known Ca-PO4 releasing composites. This was likely because the nanosilica-fused whiskers were tough and stable, and were strongly bonded with the resin matrix [29,30]. Hence the composite is expected to have improved long-term durability than the previously-known Ca-PO4 composites that do not have a stable reinforcement phase. Further studies are needed to investigate the long-term water-aging and wear behavior of the TTCP-whisker composite.

Regarding clinical applications, for deep cavities and other complex-shaped cavities where carious tissues may not be removed completely, the TTCP composite without whiskers may be able to serve as a base or a core buildup material. In these restorations, the high Ca and PO4 release (Fig. 4) should be highly desirable to remineralize remnants of caries and to prevent future caries, while the moderate strength may not be a concern because the base will be covered by a stronger occlusal composite. Previous studies showed that when the Ca and PO4 ions were released from the composite, they reprecipitated to form hydroxyapatite outside the composite and inside the tooth lesions, increasing the mineral content of the lesion [16,19]. On the other hand, the stronger TTCP-whisker composite, with strength and modulus matching a commercial hybrid composite, may be used where hybrid composites are used, including posterior load-bearing restorations. The TTCP-whisker composite increased the Ca and PO4 release by about 6-fold when the pH was reduced from neutral to a cariogenic pH of 4. Such a smart, stress-bearing composite may be highly advantageous for inhibiting secondary caries, which is currently a major reason for the replacement of existing restorations [12–15].

Currently available posterior composites and hybrid composites can be used in stress-bearing restorations, but they generally do not release Ca, PO4 or F ions. On the other hand, restoratives that do release Ca and PO4 ions are relatively weak and cannot be used in large stress-bearing restorations. Therefore, there is a need to develop new composites that are as strong as hybrid composites, while at the same time have sustained release of high levels of Caand PO4 to inhibit caries, with the composite being smart to substantially increase the ion release at cariogenic pH. The TTCP-whisker composite developed in the present study may have the potential to meet this need. Further studies are needed to fully characterize its long-term load-bearing capabilities and in situ tooth caries-inhibition efficacy.

5. Summary

A new composite was developed using ball-milled fine TTCP particles and nanosilica-fused whiskers. The composite had flexural strength and elastic modulus matching those of a commercial stress-bearing, non-releasing composite, both before and after immersion in solutions with neutral and acidic pH.

The TTCP-whisker composite was “smart” and increased the Ca and PO4 ion release by about 6-fold when the pH was reduced from neutral to a cariogenic pH of 4, when these ions are most needed to inhibit caries.

The TTCP-whisker composite had flexural strength 2–3 fold higher than previously-known Ca-PO4 composites, as well as a commercial resin-modified glass ionomer.

The smart, Ca and PO4 releasing composite, with mechanical properties matching those of a commercial hybrid composite, may have the potential to provide the necessary combination of load-bearing and caries-inhibiting capabilities.

Acknowledgments

We thank Dr. Laurence C. Chow, Dr. Shozo Takagi, Dr. Joseph M. Antonucci, Dr. Sabine H. Dickens and Dr. Drago Skrtic for discussions. We are grateful to Esstech (Essington, PA) for providing the resin monomers. This study was supported by NIH R01 DE14190 and DE17974 (HX), Maryland Nano-Biotechnology Initiative Award (HX), the University of Maryland Dental School, NIST, and the ADAF.

Footnotes

DISCLAIMER

Certain commercial materials and equipment are identified to specify the experimental procedure. This does not imply recommendation or endorsement by NIST or ADAF or that the material or equipment identified is necessarily the best available for the purpose.

References

- 1.Söderholm KJ, Zigan M, Ragan M, Fischlschweiger W, Bergman M. Hydrolytic degradation of dental composites. J Dent Res. 1984;63:1248–1254. doi: 10.1177/00220345840630101701. [DOI] [PubMed] [Google Scholar]

- 2.Goldberg AJ, Burstone CJ, Hadjinikolaou I, Jancar J. Screening of matrices and fibers for reinforced thermoplastics intended for dental applications. J Biomed Mater Res. 1994;28:167–173. doi: 10.1002/jbm.820280205. [DOI] [PubMed] [Google Scholar]

- 3.Ferracane JL, Berge HX, Condon JR. In vitro aging of dental composites in water --Effect of degree of conversion, filler volume, and filler/matrix coupling. J Biomed Mater Res. 1998;42:465–472. doi: 10.1002/(sici)1097-4636(19981205)42:3<465::aid-jbm17>3.0.co;2-f. [DOI] [PubMed] [Google Scholar]

- 4.Frankenberger R, García-Godoy F, Lohbauer U, Petschelt A, Krämer N. Evaluation of resin composite materials. Part I: In vitro investigation. Am J Dent. 2005;18:23–27. [PubMed] [Google Scholar]

- 5.Watts DC, Issa M, Ibrahim A, Wakiaga J, Al-Samadani K, Al-Azraqi M, Silikas N. Edge strength of resin-composite margins. Dent Mater. 2008;24:129–133. doi: 10.1016/j.dental.2007.04.006. [DOI] [PubMed] [Google Scholar]

- 6.Junior SAR, Scherrer SS, Ferracane JL, Bona AD. Microstructural characterization and fracture behavior of a microhybrid and a nanofill composite. Dent Mater. 2008;24:1281–1288. doi: 10.1016/j.dental.2008.02.006. [DOI] [PubMed] [Google Scholar]

- 7.Bayne SC, Thompson JY, Swift EJ, Jr, Stamatiades P, Wilkerson M. A characterization of first-generation flowable composites. J Am Dent Assoc. 1998;129:567–577. doi: 10.14219/jada.archive.1998.0274. [DOI] [PubMed] [Google Scholar]

- 8.Ruddell DE, Maloney MM, Thompson JY. Effect of novel filler particles on the mechanical and wear properties of dental composites. Dent Mater. 2002;18:72–80. doi: 10.1016/s0109-5641(01)00022-7. [DOI] [PubMed] [Google Scholar]

- 9.Lim BS, Ferracane JL, Sakaguchi RL, Condon JR. Reduction of polymerization contraction stress for dental composites by two-step light-activation. Dent Mater. 2002;18:436–444. doi: 10.1016/s0109-5641(01)00066-5. [DOI] [PubMed] [Google Scholar]

- 10.Drummond JL, Bapna MS. Static and cyclic loading of fiber-reinforced dental resin. Dent Mater. 2003;19:226–231. doi: 10.1016/s0109-5641(02)00034-9. [DOI] [PubMed] [Google Scholar]

- 11.Lu H, Stansbury JW, Bowman CN. Impact of curing protocol on conversion and shrinkage stress. J Dent Res. 2005;84:822–826. doi: 10.1177/154405910508400908. [DOI] [PubMed] [Google Scholar]

- 12.Sarrett DC. Clinical challenges and the relevance of materials testing for posterior composite restorations. Dent Mater. 2005;21:9–20. doi: 10.1016/j.dental.2004.10.001. [DOI] [PubMed] [Google Scholar]

- 13.Sakaguchi RL. Review of the current status and challenges for dental posterior restorative composites: clinical, chemistry, and physical behavior considerations. Dent Mater. 2005;21:3–6. doi: 10.1016/j.dental.2004.10.008. [DOI] [PubMed] [Google Scholar]

- 14.Mjör IA, Moorhead JE, Dahl JE. Reasons for replacement of restorations in permanent teeth in general dental practice. International Dent J. 2000;50:361–366. doi: 10.1111/j.1875-595x.2000.tb00569.x. [DOI] [PubMed] [Google Scholar]

- 15.Jokstad A, Bayne S, Blunck U, Tyas M, Wilson N. Quality of dental restorations. FDI Commision Projects 2-95 International. Dent J. 2001;51:117–158. doi: 10.1002/j.1875-595x.2001.tb00832.x. [DOI] [PubMed] [Google Scholar]

- 16.Skrtic D, Hailer AW, Takagi S, Antonucci JM, Eanes ED. Quantitative assessment of the efficacy of amorphous calcium phosphate/methacrylate composites in remineralizing caries-like lesions artificially produced in bovine enamel. J Dent Res. 1996;75:1679–1686. doi: 10.1177/00220345960750091001. [DOI] [PubMed] [Google Scholar]

- 17.Skrtic D, Antonucci JM, Eanes ED. Improved properties of amorphous calcium phosphate fillers in remineralizing resin composites. Dent Mater. 1996;12:295–301. doi: 10.1016/s0109-5641(96)80037-6. [DOI] [PubMed] [Google Scholar]

- 18.Skrtic D, Antonucci JM, Eanes ED, Eichmiller FC, Schumacher GE. Physiological evaluation of bioactive polymeric composites based on hybrid amorphous calcium phosphates. J Biomed Mater Res. 2000;53B:381–391. doi: 10.1002/1097-4636(2000)53:4<381::aid-jbm12>3.0.co;2-h. [DOI] [PubMed] [Google Scholar]

- 19.Dickens SH, Flaim GM, Takagi S. Mechanical properties and biochemical activity of remineralizing resin-based Ca-PO4 cements. Dent Mater. 2003;19:558–566. doi: 10.1016/s0109-5641(02)00105-7. [DOI] [PubMed] [Google Scholar]

- 20.Dickens SH, Flaim GM, Floyd CJE. Effect of resin composition on mechanical and physical properties of calcium phosphate filled bonding systems. Polymer Preprints. 2004;45:329–330. [Google Scholar]

- 21.Xu HHK, Sun L, Weir MD, Antonucci JM, Takagi S, Chow LC. Nano dicalcium phosphate anhydrous-whisker composites with high strength and Ca and PO4 release. J Dent Res. 2006;85:722–727. doi: 10.1177/154405910608500807. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Xu HHK, Weir MD, Sun L, Takagi S, Chow LC. Effect of calcium phosphate nanoparticles on Ca-PO4 composites. J Dent Res. 2007;86:378–383. doi: 10.1177/154405910708600415. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Xu HHK, Weir MD, Sun L. Dental nanocomposites with Ca-PO4 release: Effects of reinforcement, dicalcium phosphate particle size and silanization. Dent Mater. 2007;23:1482–1491. doi: 10.1016/j.dental.2007.01.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Chow LC. Calcium phosphate cements: Chemistry, properties, and applications. Mater Res Symp Proc. 2000;599:27–37. [Google Scholar]

- 25.Xu HHK, Quinn JB, Takagi S, Chow LC. Synergistic reinforcement of in situ hardening calcium phosphate composite scaffold for bone tissue engineering. Biomaterials. 2004;25:1029–1037. doi: 10.1016/s0142-9612(03)00608-2. [DOI] [PubMed] [Google Scholar]

- 26.Xu HHK, Weir MD, Simon CG. Injectable and strong nano-apatite scaffolds for cell/growth factor delivery and bone regeneration. Dent Mater. 2008;24:1212–1222. doi: 10.1016/j.dental.2008.02.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Hefferren JJ, Koehler HM. Foods, nutrition and dental health. Pathotox Publishers; Park Forest South, IL: 1981. p. 138. [Google Scholar]

- 28.Thylstrup A, Fejerskov O. Textbook of cariology. Copenhagen; Denmark, Munksgaard: 1986. pp. 145–146. [Google Scholar]

- 29.Xu HHK. Long-term water aging of whisker-reinforced polymer-matrix composites. J Dent Res. 2003;82:48–52. doi: 10.1177/154405910308200111. [DOI] [PubMed] [Google Scholar]

- 30.Xu HHK, Quinn JB, Giuseppetti AA. Wear and mechanical properties of nano-silica-fused whisker composites. J Dent Res. 2004;83:930–935. doi: 10.1177/154405910408301208. [DOI] [PubMed] [Google Scholar]

- 31.ISO/FDIS 4049. Dentistry – polymer-based fillings, restorative and luting materials. 3. Geneva, Switzerland: International Organization for Standardization; 2000. [Google Scholar]

- 32.ASTM D 790-03. Standard test methods for flexural properties of unreinforced and reinforced plastic and electrical insulating materials. West Conshohocken, PA: ASTM International; 2004. [Google Scholar]

- 33.Vogel GL, Chow LC, Brown WE. A microanalytical procedure for the determination of calcium, phosphate and fluoride in enamel biopsy samples. Caries Res. 1983;17:23–31. doi: 10.1159/000260645. [DOI] [PubMed] [Google Scholar]

- 34.Carey CM, Spencer M, Gove RJ, Eichmiller FC. Fluoride release from a resin-modified glass-ionomer cement in a continuous-flow system: effect of pH. J Dent Res. 2003;82:829–832. doi: 10.1177/154405910308201013. [DOI] [PubMed] [Google Scholar]

- 35.Anusavice KJ, Zhang NZ, Shen C. Effect of CaF2 content on rate of fluoride release from filled resins. J Dent Res. 2005;84:440–444. doi: 10.1177/154405910508400508. [DOI] [PubMed] [Google Scholar]

- 36.Anusavice KJ, Zhang NZ, Shen C. Controlled release of chlorhexidine from UDMA-TEGDMA resin. J Dent Res. 2006;85:950–954. doi: 10.1177/154405910608501016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.O’Donnell JNR, Antonucci JM, Skrtic D. Mechanical properties of amorphous calcium phosphate composites. J Dent Res. 2005:84. doi: 10.1177/0883911506064476. IADR Abstract No. 586. [DOI] [PMC free article] [PubMed] [Google Scholar]