Abstract

The influence of the mechanical bending, rolling and crimping of flexible screen-printed electrodes upon their electrical properties and electrochemical behavior has been elucidated. Three different flexible plastic substrates, Mylar, polyethylene naphthalate (PEN), and Kapton, have been tested in connection to the printing of graphite ink working electrodes. Our data indicate that flexible printed electrodes can be bent to extremely small radii of curvature and still function well, despite a marginal increase the electrical resistance. Below critical radii of curvature of ~8 mm, full recovery of the electrical resistance occurs upon strain release. The electrochemical response is maintained for sub-mm bending radii and a 180° pinch of the electrode does not lead to device failure. The electrodes appear to be resistant to repeated bending. Such capabilities are demonstrated using model compounds, including ferrocyanide, trinitrotoluene (TNT) and nitronaphthalene (NN). These printed electrodes hold great promise for widespread applications requiring flexible, yet robust non-planar sensing devices.

Keywords: Screen-printing, Flexible substrates, Mechanical bending, Electrodes

1. Introduction

Large-scale sensor fabrication of modern electrochemical sensors, such as disposable glucose strips or environmental gas sensors, is commonly accomplished by modern screen-printing (thick-film) processes [1–3]. Since the mid 1980s, the screen-printing technology has offered mass production of highly reproducible yet inexpensive electrode systems. The screen printing process involves the patterned deposition of conducting and insulating inks onto planar substrates by pressing the ink through a stencil or screen mask [4,5]. The basic composition for these inks includes a conductive material (i.e. graphite, gold, silver, etc), a polymer or resin or epoxy, a binding agent, and a solvent. Post-printing treatment varies by the formulation, but typically these thick films are annealed (cured) at high temperatures or dried at room temperature for a period of time. The electrodes can be easily modified through addition of specific functional materials to the ink formulation or in connection to different surface coatings.

Another variable in these thick-film electrodes, besides the material being printed, is the substrate itself. Rigid solid supports (e.g. alumina ceramic), that were used initially [6], are not suitable for use as wearable on-body sensors and are not compatible with current flexible electronics and display systems. Polymeric substrates, such as flexible polyimides [7,8] or plastic PVC [9], have thus been introduced to meet the growing biomedical and industrial demands for more flexible less rigid electrodes. These initial studies using polymeric substrates have spawned the recent development of flexible solar cells [10], implantable Kapton-based biomedical sensing devices [11], chemical sensors on flexible polyester films [12], or pressure sensors on flexible polyethylene naphthalate (PEN) [13]. Indeed, flexible devices are now widely sought in connection to flexible electronics [14], organic field effect transistors [15], optical organic light emitting diodes [16], or flexible displays [17]. The major challenge to this surge is not only their manufacture, but in the stability of these devices in terms of mechanical [18], electrical [19], or electrochemical properties. The practical utility of flexible thick-film sensing devices has been developed despite the fact that little is known about the influence of mechanical stress (associated with their bending or rolling) upon their operation and overall performance.

The aim of the present work was to examine the influence of the mechanical bending on the electrochemical behavior of flexible thick-film sensors. A carbon ink was screen printed onto three different flexible plastic substrates: Mylar, polyethylene naphthalate (PEN), and Kapton. The electrochemical behavior and electrical parameters were examined before and after rolling, bending, and crimping the corresponding electrodes. Our data indicate that flexible printed electrodes can be bent to extremely small radii of curvature (including repeated mechanical wear) and still function well. The implications of such mechanical stress upon the operation of flexible thick-film devices as on-body wearable sensors or in flexible-electronic applications are discussed.

2. Experimental

2.1 Regents and materials

A standard solution of 2,4,6-trinitrotoluene (TNT) in acetonitrile (ACN) (1000 μg/mL) was obtained from Cerilliant (Round Rock, TX). 1-Nitronaphthalene was obtained from Sigma-Aldrich (St. Louis, MO). Note that 1-nitronaphthalene is carcinogenic and care should be taken when utilizing. Potassium ferrocyanide was purchased from Sigma Aldrich (St Louis, USA). Deionized water from a Milli-Q system (Millipore, Bedford, MA) was used to prepare all solutions. Most electrochemical measurements were measured in the mixture of 5 % of acetonitrile (ACN) (Sigma, St. Louis) in 0.1M phosphate buffer (PBS) pH 6.5 containing potassium phosphate monobasic and dibasic (both from Sigma, St. Louis). Some cyclic voltammograms were carried out in 0.8M KCl (Sigma, St. Louis). The carbon ink [G-449(I)] used in screen printing was obtained from Ercon (Wareham, MA).

2.2 Apparatus and measurement

A semi-automatic screen printer (Model TF 100; MPM, Franklin, MA) was used to print ~50 μm thick film carbon electrodes (1.5 × 18 mm). For the screen printed electrodes (SPE), the carbon ink was printed through a patterned stencil on four different substrates: ceramic (alumina) (Coorstek, Golden, CO), polyethylene naphthalate (PEN) (DuPont Teijin Films, Hopewell, VA), Kapton (CS Hyde Co., Lake Villa, IL) and biaxially-oriented polyethylene terephthalate polyester (Mylar) plates (HP Company, Palo Alto, CA) (See Fig. 1). Subsequently, the carbon thick film was heated for 10 min at 100 °C to drive off the solvent from the applied paste and to cure the patterned paste.

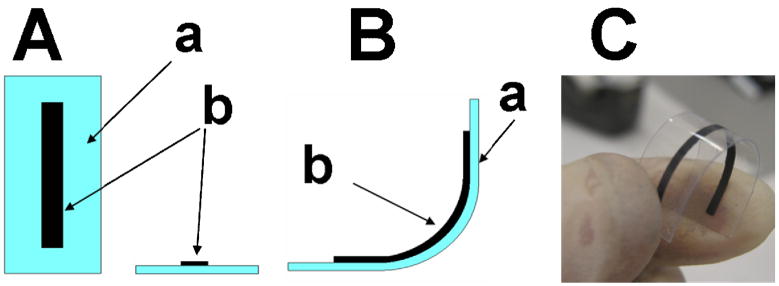

Figure 1.

Schematic of screen-printed electrode (SPE) (A) on a flexible substrate (a) with a thick-film carbon working electrode (b). (B) Schematic of the 90° longitudinal inward bend of the flexible SPE. (C) Photo of the 180° longitudinal inward bend of a SPE on a Mylar substrate.

The effect of cyclic strain on the resistance of the electrodes was measured using a digital multimeter Elenco LCM-1950 (Elenco Electronics, Wheeling, Il). The resistance of the electrode was measured in its flat position from the end to end. The electrode was then bent inward to 45° for 5 min, and resistance was measured again. This 5 min bend followed by resistance measurement was repeated for bend angles of 90°, 180°, and 180° pinched (Illustration in Fig. 1). This was repeated for 5 electrodes for each type of substrate.

The resistivity of each sample was determined using a four-point-probe system (SP4-40045TFS, Lucas Labs) attached to a Semiconductor Characterization System (Keithley 4200-SCS) through a custom built stage. The SCS was programmed to source voltage and measure current through the probes according to typical protocols. The resistivity, ρ, of each sample was determined as

| (1) |

where V is the applied voltage, I is the measured current, and G is the correction factor based on the thickness and geometry of the sample being measured. As the thickness of the printed carbon lines was more than an order of magnitude larger than the probe spacing, G was calculated based on a semi-infinite rectangular slab with finite width [20]. This factor corrects for the narrow structure of the printed sample. The printed carbon electrodes were tested individually in triplicate as a function of annealing time. The impact of bending or flexing of the electrode on electrical properties was examined using a series of fixed bending radii. The resistivity of each electrode was first measured in unperturbed state and then while bent. The reversibility of the changes in the electrical performance was assessed by flattening the electrode post bending to determine if the initial resistivity is recovered.

Optical images of the electrodes were acquired on a Nikon Eclipse 801i microscope (Nikon Corp., Tokyo, Japan) equipped with an X-Cite 120 fluorescence illumination system (EXFO, Mississauga, Ontario, Canada) as a light source. Digital images from the microscope were acquired with a Photometrics CoolSnap CF camera (Roper Scientific, Duluth, GA) and MetaMorph 7 software (Molecular Devices Corp., Sunnyvale, CA). Pictures were taken using a stereoscope (Caltex Systems 3D Digital-Video Measurement Inspection, model infinity 1-1c).

All electrochemical measurements were performed using an Autolab Electrochemical Analyser (Eco Chemie BV, Type Π, The Netherlands) and CHI 1220A Electrochemical Analyzers (CH Instruments, Austin, TX) with the general purpose electrochemical software operating system GPES 4.9. All measurements were performed at room temperature (~ 23 °C). To understand the electrochemical behavior of flexible electrodes under strain, the electrochemical response of the flexible substrate electrodes was measured upon bending inward to angles of 0°, 90°, 180°, and 180° pinched. To facilitate these measurements, three-electrode electrochemical cell was used in all the experiments with a screen-printed thick film carbon electrode as working electrode, Ag/AgCl (3 M KCl) as reference electrode and 0.25 mm diameter platinum wire as counter electrode. Both square-wave voltammetry (SWV) and cyclic voltammetry (CV) were used to study the strain effect on flexible printed electrodes.

To test the impact of mechanical strain on the sensing capabilities of flexible electrodes, a solution of 50 ppm TNT in phosphate buffer (PBS; pH 6.5) containing 5% ACN was prepared for the SWV measurements. Main SWV parameters included a 30 Hz frequency, 4 mV step potential and an amplitude of 25 mV. The potential was swept from 0.0 V to −1.2 V. For cyclic voltammetry, the supporting electrolyte were 0.1M phosphate buffer (pH 6.5) or 0.8M KCl for the background and ferrocyanide measurements, respectively. A scan rate of 0.1 V/s was applied.

3. Results and Discussion

We examined the influence of the rolling, bending, and crimping of flexible screen printed electrodes (SPEs) upon their electrochemical behavior and electrical parameters. Figure 1 illustrates the bending of the 1.5×18 mm carbon-based SPE that was used to characterize the robustness of these flexible sensors. An inward bend, illustrated in Figure 1B, results in compressive strains, whilst an outward bend yields a tensile stress in the electrically active film. While a Mylar substrate was used here, similar stresses were applied to PEN and Kapton based electrodes.

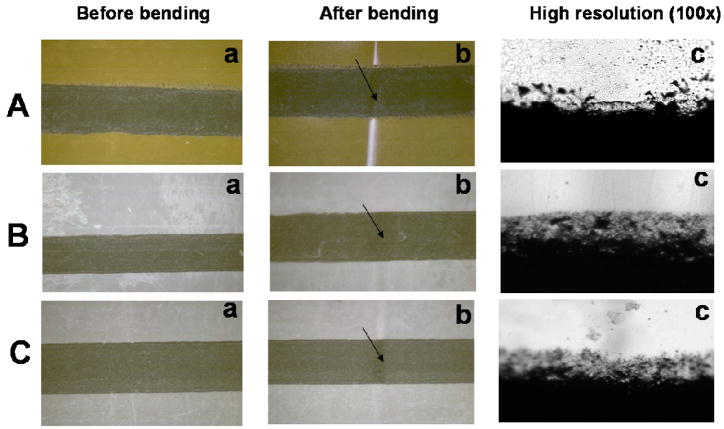

As illustrated in Figure 2, such SPEs can be bent on top of itself to extremely small radii of curvature without any visual signs of failure. Three substrate materials are presented: Kapton (A), PEN (B), and Mylar (C). These substrates were initially tested with high resolution microscopy to evaluate print results. For a-Si:H based transistors, a tensile strain of ~ 0.5% was sufficient to physically crack the active layer, leading to device failure [21]. In contrast, Figure 2 indicates that a significantly greater strain can be imparted to the flexible SPEs without visible damage (a vs. b). These SPEs have been subjected to sub-mm bending radii to the point of crimping the substrate. No apparent visual damage of the printed carbon surface is indicated at the place where the bend was taken (arrow in b), although it is clearly indicated - as the white line from the crimping -in the substrate (especially using Kapton). The higher magnification images (of Figure 2C) further indicate that the printed carbon surface was not deteriorated during the bending.

Figure 2.

Optical images of strain test of printed electrodes on different flexible plastic substrates: Kapton (A), PEN (B), and Mylar (C) before (a) and after (b) bending, along with a x100 zoom after bending (c). The arrow in images (b) indicates the place where bending took place.

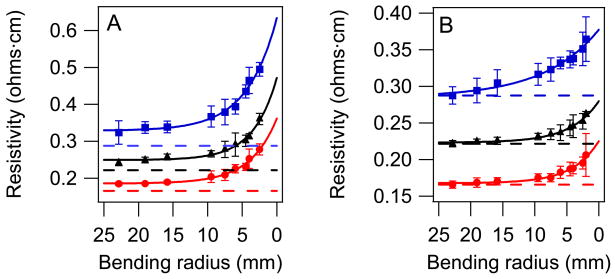

To test the electrical robustness of the carbon composite SPEs, the electrodes were bent to varying radii of curvature to induce tensile stresses. Their changes in resistivity during and after bending are illustrated in Figure 3 (A and B, respectively). The resistivity of the unstressed electrodes is illustrated by the dashed horizontal lines. In all cases, the application of a tensile stress decreased the conductivity of the electrode. As the radius of curvature decreases and the tensile strain increases, the deviation from the unstrained case (dashed line) increases, especially for a bending radius smaller than 8 mm. This is similar to the 7.5 mm critical radius obtained by Loo et al for organic thin film transistors (TFTs) [22]. However, even at a curvature radius of 1.5 mm, the SPEs remain highly conductive with less than 50 % increase in the resistivity.

Figure 3.

Impact of controlled bending of SPE cured for 3 min (●), 10 min (▲) and 60 min (■) on the resistivity during (A) and after (B) bending. The dashed lines represent the resistivity of the unstressed electrodes. Solid lines are provided as a guide for the reader’s eyes.

The annealing (curing) of the carbon electrodes, following the screen printing step, does impact the electrical response as illustrated in Figure 3A. As the electrode is annealed at 120 °C, the resistivity of the SPE increases presumably from loss of the solvent, which is more conductive than the polymeric binder. The resistivity of the SPE increases from 0.155 ohm·cm to 0.222 ohm·cm to 0.288 ohm·cm as the annealing time is varied from 3 min to 10 min to 60 min, in comparison to 0.0035 ohm·cm for pure carbon [23]. Due to the nature (mixture) of the polymeric ink (with solvent and binder) a difference between SPE ink and pure carbon is expected, as well as among SPE ink with different curing times or temperatures. These data are the average of 3 electrodes with less than 5 % variability. This illustrates one of the advantages of these SPEs over conjugated polymers, namely reproducibility. Orders of magnitude variability in the electrical properties of semiconducting polymers on a single wafer have been reported [24]. Thus, it appears that our flexible SPEs combine the advantages of inorganic electronic materials (narrow variance in electronic properties) and conjugated polymers (small bending radii). At large bending radii, a slightly larger increase in resistivity is observed for the 60 min cured SPEs in comparison to the shorter annealing times. However, the radii (~8 mm) where the conductivity decreases significantly more is independent of the annealing conditions. This suggests that the strain associated with this radius is sufficient to substantially decrease the number of carbon-carbon contacts in the composite and therefore the structure of the composite electrode is not significantly altered by the annealing condition. However, the modulus of the SPE will be altered by the loss of solvent during annealing.

The change in the mechanical properties of the SPE will impact the recovery of the initial structure following release of the tensile strain. To test the impact of the mechanical properties of the SPE as altered through annealing, the reversibility of the changes in the electrical resistivity was examined by flattening the electrode following the bending (Figure 3B). Using large bending radii (>10 mm), the initial conductivity of the SPEs is fully recovered. However, an irreversible increase in resistance is observed for smaller bending radius. Additionally, this change is greater at long annealing times, consistent with a decrease in the composite relaxation associated with the solvent loss. Nonetheless, all SPEs tested remained highly conductive during and after all bending radii examined.

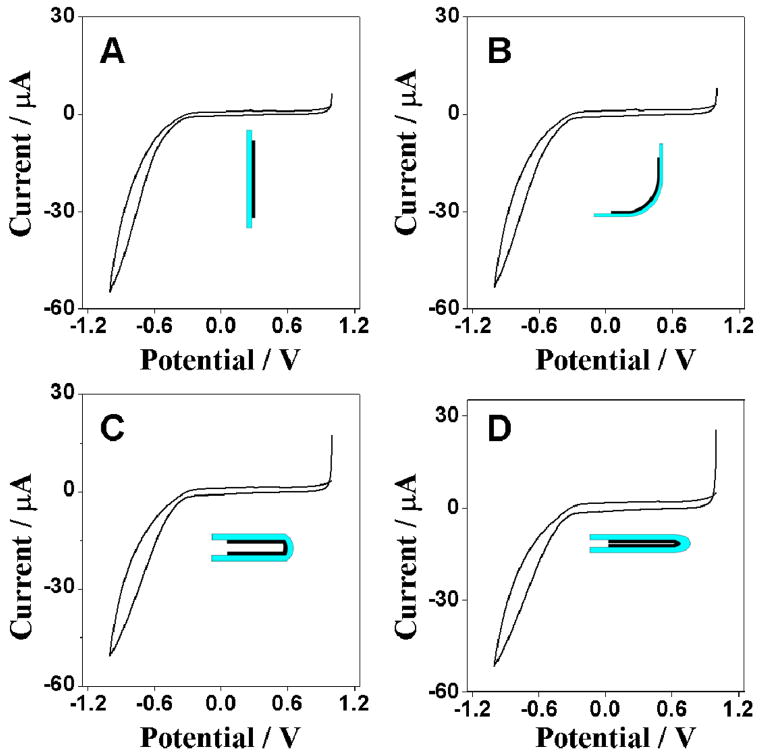

The stability in the conductivity of these electrodes through bending suggests that the electrodes will remain effective for electrochemical sensing and detection. Such electrochemical testing were carried out using electrode cured at 120 °C for 10 min. Background (phosphate buffer) cyclic voltammograms of unstressed and stressed are illustrated in Figure 4 (A vs. B–D). In the unstressed state, the voltammogram is relatively featureless as would be expected for phosphate buffer on these carbon based electrodes. Solvent evolution is observed above +1.0V with oxygen reduction negative to −0.45V. Bending the SPE at different curvatures has a negligible impact upon the background signal and potential window (B–D). Even a severe abuse of the electrode to the point of folding the substrate on top of itself and creating a pinched electrode does not result in electrical failure. The voltammogram at this SPE with a near zero radius of curvature is not significantly altered from the unstressed SPE (D vs. A). These background voltammograms illustrate the robustness of the SPE on flexible substrates.

Figure 4.

Background cyclic voltammograms of a 0.1M PBS (pH 6.5) solution recorded at a flexible PEN substrate SPE before (A) and after (B–D) inward longitudinal bending at different angles: 90° (B), 180° (C), and 180° pinched (D). Bending time, 5 min; scan rate, 0.1 V/s.

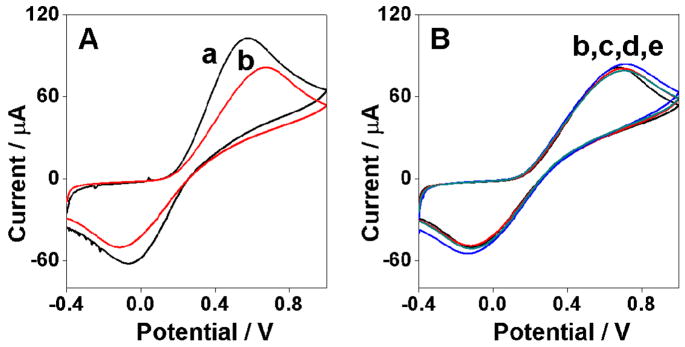

The redox behavior of potassium ferrocyanide has been used for testing the electrochemical performance of the flexible SPEs following a mechanical stress. Figure 5A compares cyclic voltammograms for 5 mM potassium ferrocyanide recorded using carbon electrodes printed on a rigid alumina (a) and flexible PEN (b) substrates. The SPE on both substrates show two characteristic redox peaks. However, a slight decrease in the peak current and a larger peak separation (ΔEp = 710 vs. 642 mV) are observed for the flexible substrate. These changes, however, do not impede the electrochemical detection. As illustrated in Figure 5B, the flexible SPE on PEN can be bent to extremely small radii of curvature and still function well. Well-defined redox peaks, with no apparent change in the peak currents or peak separations, are observed after inward longitudinal bending at different angles (b vs c–e). Note that even bending the electrode to a pinched state has minimal effect upon the response (e). Overall, Figure 5B indicates negligible changes in the cyclic voltammetric response following bending to extremely small radii of curvature. In contrast, bending the rigid alumina substrate to any appreciable extent leads to a catastrophic failure of the substrate and thus of the electrode.

Figure 5.

Cyclic voltammograms of 5mM potassium ferrocyanide recorded (A): using SPEs based on alumina (a) and flexible PEN (b) substrates; (B): using flexible PEN substrate SPE before (b) and after inward longitudinal bending at different angles: 90° (c), 180° (d), and 180° pinched (e). Bending time, 5 min; scan rate, 0.1 V/s; electrolyte, 0.8M KCl.

The attributes of flexible SPEs make them attractive for demanding sensing applications. For demonstration purposes, TNT has been selected as a model analyte. Figure 6 illustrates the square-wave voltammograms for a 50 ppm TNT solution using different SPEs. The distinct electrochemical signature of TNT is clearly present for sensors fabricated on alumina, PEN (A,d) and Kapton (C,d). The current from the alumina-based SPE supported is larger than for the flexible printed sensors, consistent with the cyclic voltammetric results for potassium ferrocyanide (Figure 5). Bending the flexible PEN (B) and Kapton (D) based electrodes at different curvatures does not significantly impact the sensing capabilities of the SPEs for TNT. There is a decrease in the current as the bending radius is decreased (B,D; d vs. d2–d4), but the peaks associated with the TNT reduction remain clearly visible in the voltammograms. These changes are more pronounced using the PEN substrate. Yet, the signal remains well above the background (b), enabling convenient trace measurements at the flexible sensor.

Figure 6.

SW voltammograms of 50 ppm TNT in 5 % of ACN/0.1 M PBS (pH 6.5) recorded at alumina (A, C), PEN (A, B) and Kapton (C, D) SPEs. Background voltammograms at alumina (A,C; a), PEN (A,B; b) and Kapton (C,D;b) based SPEs; TNT response at the alumina (A,C; d), flexible PEN (A,B; d) and flexible Kapton (C,D; d), including TNT signals at different bending angles of the flexibles SPE (B,D): 90° (d2), 180° (d3) and 180° pinched (d4). SWV parameters: amplitude, 25 mV; potential step, 4 mV and frequency of 30 Hz.

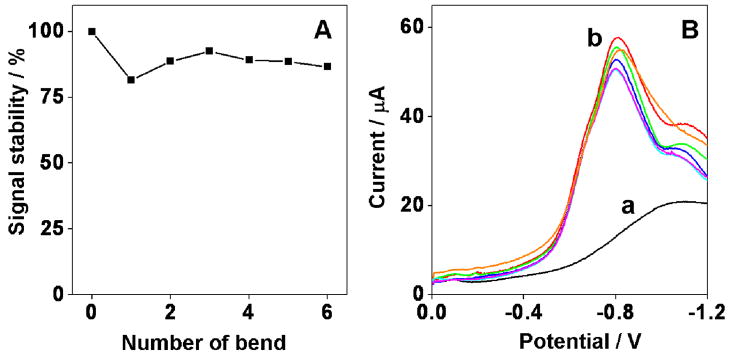

One additional concern with flexible electronics is cyclical fatigue that can occur from repeated bending [25]. Sensing of 1-nitronaphalene (1 NNP, 20 ppm) was used for testing the robustness of these SPEs to repeated 5 min bending. As illustrated in Figure 7, initial bending of the electrode results in a small decrease in the signal. However, the signal is stabilized at this level with repeated 5-min bending having a negligible effect upon the voltammetric signal. Apparently, these SPEs appear to be resistant to short cyclical fatigue. Additional testing, over hundreds to thousands of cycles, is necessary to determine the resiliency of these electrodes.

Figure 7.

Stability of the SWV response of 1-NNP (20 ppm in 1M NaCl) measured at a PEN flexible SPE before and after repeated 5 min 180° bending. The average signal stability is counted from the heights of the peaks and represents measurements at 5 electrodes where 100% corresponds to the unstressed electrode (A). The SW voltammograms of the supporting electrolyte and of 20 ppm 1-NNP before and after bend are shown in Fig. 7B (a and b, respectively). SWV parameters, as in Figure 6.

4. Conclusions

We have discussed the influence of mechanical stress upon the operation of flexible thick-film electrochemical sensors. Bending the electrodes to extremely small radii of curvature has minimal effect upon the electrochemical behavior, reflecting a small increase in their electrical resistance Additionally, the electrochemical signal was not adversely impacted from cyclic bending. These results illustrate the robust nature of screen printed electrodes on flexible substrates and their promise for sensing with non-planer geometries in connection to various on-body wearable sensors or flexible-electronic and display applications.

Acknowledgments

This work was supported by the Office of Naval Research (Award Number N000140811202), the National Institute of Health (Grants No. S000256 and EB002189), and the Army Research Laboratory (ARL; Cooperative Agreement W911NG-04-2-0005). The views contained in this document are those of the authors and should not be interpreted as representing the official policies of the U.S. Government.

Biographies

Jiaying Cai (BS,2005, Nanjing University of Technology) is a graduate student in Chemical Engineering at ASU, currently working on high temperature polymer electrolyte membrane fuel cell.

Karel Cizek (PhD, 2007, Charles University in Prague) is a post-doctoral fellow at UCSD, with research interests involving the development and applications of electrochemical methods for environmental analysis

Brenton Long (undergraduate, ASU) is studying bioengineering with interests in medicine and disease marker research.

Kenyon McAferty (undergraduate, ASU) is a bioengineering major whose research has focused on quality control and process evaluation.

Casey G. Campbell (undergraduate, ASU) is a student in Electrical Engineering whose research interests include structure-property relationships in polymer thin films.

David R. Allee (PhD, 1990, Stanford University) is an associate professor in the Department of Electrical Engineering at ASU whose research interests focus on flexible thin film transistors and circuits.

Bryan D. Vogt (PhD, 2003, University of Massachusetts-Amherst) is an assistant professor of chemical engineering at ASU whose research interests focus interfacial characterization of soft materials.

Jeffrey T. La Belle (PhD, 2001, ASU) is a biomedical engineer whose research interests include the development of biomedical devices, including biosensors for personalized medicine.

Joseph Wang (PhD, 1978, Technion) is a professor in the Department of Nanoengineering at UCSD, with research interests in nanobiotechnology and electrochemical sensors for biomedical, environmental and security applications.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Hart JP, Wring SA. Screen-printed voltammetric and amperometric electrochemical sensors for decentralized testing. Electroanalysis. 1994;6:617. [Google Scholar]

- 2.Wang J, Tian BM, Nascimento VB, Angnes L. Performance of screen-printed carbon electrodes fabricated from different carbon inks. Electrochimica Acta. 1998;43:3459. [Google Scholar]

- 3.Galandival C, Munoz J, Dominguez C, Alegret S. Chemical sensors, biosensors and thick-film technology. Trend Anal Chem. 1995;14:225. [Google Scholar]

- 4.Wang J. Analytical Electrochemistry. 3. Wiley; New York: 2006. [Google Scholar]

- 5.Renedo OD, Alonso-Lomillo MA, Martinez MJA. Recent development in the field of screen-printed electrodes and their related applications. Talanta. 2007;73:202. doi: 10.1016/j.talanta.2007.03.050. [DOI] [PubMed] [Google Scholar]

- 6.Craston D, Jones C, Williams D, El Murr N. Microband electrodes fabricated by screen printing processes – Applications in electroanalysis. Talanta. 1991;38:17. doi: 10.1016/0039-9140(91)80005-k. [DOI] [PubMed] [Google Scholar]

- 7.Johnson KW, Mastrototaro JJ, Howey DC, Brunelle RL, Burden-Brady PL, Noffke NA, McMahan WC, Morff RJ, Lipson D, Nevin RS. Invivo evaluation of an electroenzymatic glucose sensor implanted in subcutaneous tissue. Biosens Bioelectron. 1992;7:709. doi: 10.1016/0956-5663(92)85053-d. [DOI] [PubMed] [Google Scholar]

- 8.Buck RP, Cosofret VV, Lindner E, Ufer S, Madaras MB, Johnson TA, Ash RB, Neuman MR. Microfabrication technology of flexible membrane-based sensors for in-vivo applications. Electroanalysis. 1995;7:846. [Google Scholar]

- 9.Hart AL, Turner APF, Hopcroft D. On the use of screen-and ink-jet printing to produce amperometric enzyme electrode for lactate. Biosens Bioelectron. 1996;11:263. [Google Scholar]

- 10.Gleskova H, Cheng IC, Wagner S, Sturm JC, Suo Z. Mechanics of thin-film transistors and solar cells on flexible substrates. Solar Energy. 2005;80:687. [Google Scholar]

- 11.Kagie A, Bishop DK, Burdick J, La Belle JT, Dymond R, Felder R, Wang J. Flexible rolled thick-film miniaturized flow-cell for minimally invasive amperometric sensing. Electroanalysis. 2008;14:1610. [Google Scholar]

- 12.Nilsson D, Kugler T, Svensson PO, Berggren M. An all-organic sensor-transistor based on a novel electrochemical transducer concept printed electrochemical sensors on paper. Sens Actuators B. 2002;86:193. [Google Scholar]

- 13.Noguchi Y, Sekitani T, Someya T. Organic-transistor-based flexible pressure sensors using ink-jet-printed electrodes and gate dielectric layers. Appl Phys, Lett. 2006;89:253. [Google Scholar]

- 14.Sekitani T, Iba S, Kato Y, Noguchi Y, Sakurai T, Someya T. Submillimeter radius bendable organic field-effect transistors. J Non-Crystalline Solids. 2006;352:1769. [Google Scholar]

- 15.Stutzmann N. Self-Aligned, Vertical-Channel, Polymer Field-Effect Transistors. Science. 2003;299:1881. doi: 10.1126/science.1081279. [DOI] [PubMed] [Google Scholar]

- 16.Calvert P. Inkjet printing for materials and devices. Chem Mater. 2001;13:3229. [Google Scholar]

- 17.Rogers JA, Bao Z. Printed plastic electronics and paperlike displays. J Polym Sci A. 2002;40:3327. [Google Scholar]

- 18.Lacour SP, Jones J, Wagner S, Li T, Suo ZG. Stretchable interconnects for elastic electronic surfaces. Proceedings of the IEEE. 2005;93:1459. [Google Scholar]

- 19.Allee DR, Clark LT, Vogt BD, Shringarpure R, Venugopal SM, Gopalan Uppili S, Kaftanoglu H, Shivalingaiah H, Li ZP, Ravindra Fernando JJ, Bawolek EJ, O’Rourke S. Degradation effects in a-Si:H thin film transistors and their impact on circuit performance. submitted to IEEE Transactions. [Google Scholar]

- 20.Smith FM. Measurement of sheet resistivity with the four-point probe. The Bell System Technical Journal. 1958:711. [Google Scholar]

- 21.Gleskova H, Wagner S. Failure resistance of amorphous silicon transistors under extreme in-plane strain. Appl Phys Lett. 1999;75:3011. [Google Scholar]

- 22.Loo YL, Someya T, Baldwin KW, Bao Z, Ho P, Dodabalapur A, Katz HE, Rogers JA. Soft, conformable electrical contacts for organic semiconductors: High-resolution plastic circuits by lamination. Proc Natl Acad Sci USA. 2002;99:10252. doi: 10.1073/pnas.162128299. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Cutnell JD, Johnson KW. Physics. 4. Wiley; New York: 2004. Resistivity of Various Materials. [Google Scholar]

- 24.DeLongchamp DM, Vogel BM, Jung Y, Gurau MC, Richter CA, Kirillov OA, Obrzut J, Fischer DA, Sambasivan S, Richter LJ, Lin EK. Variations in semiconducting polymer microstructure and hole mobility with spin-coating speed. Chem Mater. 2005;17:5610 – 5612. Note that the variance in electrical properties is shown in supplemental materials. [Google Scholar]

- 25.Gray DS, Tien J, Chen CS. High conductivity elastomeric electronics. Adv Mater. 2004;16:393. [Google Scholar]