Abstract

Engineered Saccharomyces cerevisiae strains overexpressing GPD1, which codes for glycerol-3-phosphate dehydrogenase, and lacking the acetaldehyde dehydrogenase Ald6 display large-scale diversion of the carbon flux from ethanol toward glycerol without accumulating acetate. Although GPD1 ald6 strains have great potential for reducing the ethanol contents in wines, one major side effect is the accumulation of acetoin, having a negative sensory impact on wine. Acetoin is reduced to 2,3-butanediol by the NADH-dependent 2,3-butanediol dehydrogenase Bdh1. In order to investigate the influence of potential factors limiting this reaction, we overexpressed BDH1, coding for native NADH-dependent Bdh1, and the engineered gene BDH1221,222,223, coding for an NADPH-dependent Bdh1 enzyme with the amino acid changes 221 EIA 223 to 221 SRS 223, in a glycerol-overproducing wine yeast. We have shown that both the amount of Bdh1 and the NADH availability limit the 2,3-butanediol dehydrogenase reaction. During wine fermentation, however, the major limiting factor was the level of synthesis of Bdh1. Consistent with this finding, the overproduction of native or engineered Bdh1 made it possible to redirect 85 to 90% of the accumulated acetoin into 2,3-butanediol, a compound with neutral sensory characteristics. In addition, the production of diacetyl, a compound causing off-flavor in alcoholic beverages, whose production is increased in glycerol-overproducing yeast cells, was decreased by half. The production of higher alcohols and esters, which was slightly decreased or unchanged in GPD1 ald6 cells compared to that in the control cells, was not further modified in BDH1 cells. Overall, rerouting carbons toward glycerol and 2,3-butanediol represents a new milestone in the engineering of a low-alcohol yeast with desirable organoleptic features, permitting the decrease of the ethanol contents in wines by up to 3°.

A large number of quality wines produced by modern winemaking practices, which favor harvesting fully ripened grapes, frequently contain an excessive ethanol content. This tendency is observed in the majority of the world's wine-producing areas, and reducing the alcohol levels in wines has become a major concern of the wine industry. Consequently, numerous attempts have been made to engineer Saccharomyces cerevisiae yeast strains with reduced ethanol yields, which would offer faster and less expensive biological alternatives to the current physical processes available for the production of low- and reduced-alcohol wines (29). The biological approaches used so far are all based on diverting sugar metabolism toward by-products other than ethanol by metabolic engineering strategies (7, 8, 18, 19, 21, 22, 30). However, these strategies have so far not satisfied the need to obtain a significant reduction in the ethanol yield without causing the accumulation of undesirable secondary products and/or without affecting yeast physiology. Among these various advances, an efficient strategy is based on the rerouting of the carbon flux toward the production of glycerol. This polyol is a relatively neutral compound from an olfactory perspective, and it is has been demonstrated previously to contribute positively to wine quality through enhanced sweetness and viscosity (27). In yeast, glycerol plays a major role as an osmolyte under osmotic stress conditions and also functions as an essential redox sink in the absence of oxygen, when the reoxidation of excess cytosolic NADH is required (1, 2, 42, 44, 46). This compound is formed by the reduction of dihydroxyacetone phosphate by glycerol-3-phosphate dehydrogenase (encoded by GPD1 and GPD2), followed by dephosphorylation by glycerol-3-phosphatase, which exists as two isoforms: Gpp1 and Gpp2p (see Fig. 1). By overexpressing GPD1 or GPD2, the production of glycerol has been greatly enhanced, making it possible to decrease the ethanol yield as the result of carbon diversion and reduced NADH availability for the alcohol dehydrogenase reaction. This strategy has been used previously to reduce the ethanol yields in wine and brewer's yeast (4, 7, 23, 25, 26, 31). For wine, it was shown that these glycerol-overproducing strains have the potential to reduce the ethanol content by 1 to 2°. Nevertheless, major modifications in the production levels of other metabolites, in particular acetate and acetoin (23, 31), which are undesirable at high concentrations in wine, are generated. The production of acetate in glycerol-overproducing wine yeasts has been reduced to a normal level by the deletion of ALD6, coding for an acetaldehyde dehydrogenase (4, 30). The major problem of the accumulation of acetoin, which was shown to accumulate at several grams per liter in commercial GPD1 ald6 wine yeast strains (4), remains to be overcome. At usual concentrations in wine, which vary from undetectable levels to 80 mg/liter (32, 33, 40), this compound has no negative organoleptic influence. However, at concentrations higher than its threshold level (around 150 mg/liter [11]), acetoin can confer an unpleasant buttery flavor on wines. In contrast, the reduced form of acetoin, 2,3-butanediol (2,3-BD), has neutral sensory qualities (data not shown). It is found in wines at concentrations ranging from 0.2 to 3 g/liter (14, 41).

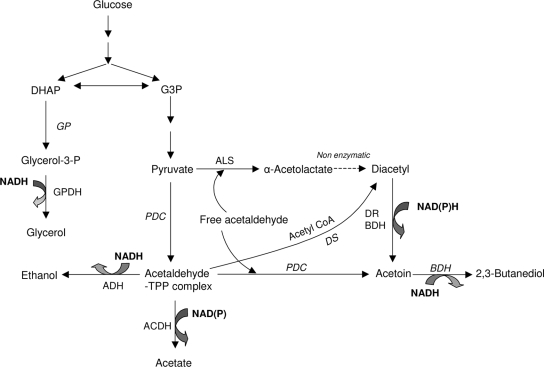

FIG. 1.

Schematic representation of metabolic pathways implicated in our design strategy for a low-alcohol yeast. GP, glycerol phosphatase, encoded by GPP1 and GPP2; GPDH, glycerol phosphate dehydrogenase, encoded by GPD1 and GPD2; PDC, pyruvate decarboxylase, encoded by PDC1, PDC5, and PDC6; ACDH, acetaldehyde dehydrogenase, encoded by ALD4, ALD5, and ALD6; ADH, alcohol dehydrogenase, encoded by ADH1; BDH, Bdh1, encoded by BDH1 (other BDHs exist; however, no other identified gene has been associated with BDH activity); ALS, acetolactate synthase, encoded by ILV2; DS, diacetyl synthetase; DR, diacetyl reductase; G3P, glycerol-3-phosphatase; DHAP, dihydroxyacetone phosphate; acetyl CoA, acetyl coenzyme A; TPP, thiamine PPi.

Bdh1, encoded by BDH1, is the only identified enzyme in yeast catalyzing the reduction of acetoin into 2,3-BD (12). This enzyme has strict stereospecificity for the OHs of carbons in R configuration and acts preferentially as a reductase rather than as a dehydrogenase (11, 12). It is essentially responsible for the formation of (2R,3R)-2,3-BD and part of meso-2,3-BD from (3R)-acetoin and (3S)-acetoin, respectively.

The accumulation of acetoin in strains engineered for glycerol overproduction has been attributed to several factors (4). On one hand, it was assumed that the amount of Bdh1 is a rate-limiting factor in the conversion of acetoin into 2,3-BD. On the other hand, it is possible that the Bdh1 reaction is limited by the low level of available NADH since this coenzyme is preferentially used for glycerol synthesis in these strains.

The aim of the present study was to investigate in detail the metabolic prerequisites for reducing accumulated acetoin in S. cerevisiae overproducing glycerol and exhibiting reduced acetate formation by promoting the conversion of acetoin into the compound 2,3-BD, which has neutral sensory characteristics. In this study, we first determined the role of Bdh1 in the reduction of acetoin into 2,3-BD during wine fermentation. Next, we studied the impact of the overproduction of NADH-dependent Bdh1 or an engineered NADPH-dependent form of Bdh1 in a model wine yeast, V5, overexpressing GPD1 and lacking ALD6 during fermentation in synthetic must with various sugar concentrations. The NADPH-dependent Bdh1 has been obtained previously by the replacement of three amino acids involved in the NADH binding domain, resulting in the complete reversal of the coenzyme specificity from NADH to NADPH (6). The effects on the growth and fermentation properties of the engineered strains and the levels of by-products and key aromatic compounds formed by the strains were determined.

MATERIALS AND METHODS

Strains, plasmids, and growth conditions.

The S. cerevisiae strains used in this study were generated from strain V5 (MATa ura3), derived from a champagne wine yeast, and are described in Table 1. Yeast strains were maintained and grown in YPD medium (1% Bacto yeast extract, 2% Bacto peptone, 2% glucose). The multicopy vector pVT100U-ZEO-GPD1, carrying GPD1 under the control of the ADH1 promoter and terminator, has been described previously (31, 45). Transformants were selected on SD minimal medium (6.7 g/liter yeast nitrogen base without amino acids, 2% glucose) or on YPD medium supplemented with 200 μg/ml of geneticin.

TABLE 1.

S. cerevisiae strains used in this study

| Strain | Genotype | Gene modification(s) | Source or reference |

|---|---|---|---|

| V5 | MATaura3 | None | INRA UMR 1083a |

| V5 ald6 | V5 ald6 | ald6::KanMX | 30 |

| V5 ald6 GPD1 | V5 ald6 pVT100U-ZEO-GPD1 | ADH1p-GPD1-ADH1t | 4 |

| V5 ald6 GPD1 BDH1 | V5 ald6 BDH1 pVT100U-ZEO-GPD1 | TDH3p-BDH1-BDH1t, ADH1p-GPD1-ADH1t | This study |

| V5 ald6 GPD1 BDH1221,222,223 | V5 ald6 BDH1221,222,223 pVT100U-ZEO-GPD1 | TDH3p-BDH1221,222,223-BDH1t, ADH1p-GPD1-ADH1t | This study |

INRA UMR 1083, Microbiologie, Montpellier, France.

Fermentation conditions.

Batch fermentation experiments were carried out in MS synthetic medium that simulates standard grape juice as described previously (3). The MS medium used in this study contained 50 to 240 g/liter glucose, 6 g/liter malic acid, 6 g/liter citric acid, and a nitrogen source composed of 120 mg/liter nitrogen from ammonium and 340 mg/liter nitrogen from amino acids. The medium was supplemented with uracil (50 mg/liter) when required and methionine (115 mg/liter) for the growth of V5. To fulfill the lipid requirement of yeast cells during anaerobic growth, MS medium was supplemented with 7.5 mg/liter ergosterol, 0.21 g/liter Tween 80, and 2.5 mg/liter oleic acid. The pH of the medium was 3.3. Cells were precultured with agitation (150 rpm) for 30 h at 28°C in 100-ml flasks filled with MS medium. The main fermentation culture was inoculated at a density of 106 cells per ml and incubated at 28°C with continuous stirring (350 rpm) in fermentors of 1.0 liter (working volume) equipped with fermentation locks. These conditions give fermentation kinetics similar to those obtained under enological conditions on a pilot scale (3). The amount of CO2 released was determined by an automatic measurement of fermentor weight loss every 20 min. The CO2 production rate, dCO2/dt, is the first derivate of the amount of CO2 produced with respect to time and was automatically calculated by polynomial smoothing of the level of CO2 produced (34). Fermentation experiments were performed in duplicate or triplicate.

DNA manipulation and transformation methods.

DNA was extracted from yeast and purified by standard protocols (37). Oligonucleotides were synthesized by MWG Biotech (MWG, Germany). The lithium acetate procedure was used for the transformation of S. cerevisiae (39).

Construction of the V5 bdh1 mutant.

The BDH1 gene was deleted by the short flanking homology method using the loxP-kanMX4-loxP gene disruption cassette (13). The deletion cassette was amplified from pUG6 by using forward primer 5′-CTTCTTTCTTAAAAAGTCTTAGTACGATTGACCAAGTCAGTTCGT ACGCTGCAGGTCGAC-3′, which includes 20 nucleotides complementary to pUG6 and a 40-nucleotide extension (underlined) corresponding to the region from position −81 to position −121 upstream of the start codon of the BDH1 open reading frame (ORF), and reverse primer 5′-TACAAATGAGCCGCGAGGGGCCCCAAATATTATTTTGTCAGCATAGGCCACTAGTGGATCTG- 3′, which includes 22 nucleotides complementary to pUG6 and 40 nucleotides (underlined) corresponding to the region from position +1238 to position +1198 downstream of the start codon of the BDH1 ORF. The deletion of the BDH1 ORF was confirmed by PCR analysis of genomic DNA extracted from G418r transformants. V5 bdh1 was transformed with pVT100U-ZEO-GPD1.

Overexpression of BDH1 and BDH1221,222,223 in strains V5 and V5 ald6.

BDH1 and BDH1221,222,223, a mutant form of BDH1 engineered to express an NADPH-dependent Bdh1 enzyme with the amino acid changes 221 EIA 223 to 221 SRS 223 (Bdh1221,222,223), were overexpressed in the strain V5 ald6::loxP (36) by using short flanking homology PCR to replace the native promoter in situ by the yeast glyceraldehyde-3-phosphate dehydrogenase TDH3 promoter. In the case of BDH1, coding for the NADH-dependent 2,3-BD dehydrogenase (BDH), a PCR fragment carrying the loxP-kanMX4-loxP and TDH3 promoter cassettes was amplified from pUG6noxE (18) by using forward primer 5′-CTTTCCTCCTTACGGGGTCCTAGCCTGTTTCTCTTGATATGCAGGTCGACAACCCTTAAT-3′, having 20 nucleotides complementary to pUG6noxE and a 40-nucleotide extension (underlined) corresponding to the region from position −224 to position −184 upstream from the start codon of the BDH1 ORF, and reverse primer 5′-AGTGAATATCACCCTTCTTGAAATATGCCAAAGCTCTCATTCGAAACTAAGTTCTTGGTGT-3′, having 20 nucleotides complementary to pUG6noxE and 40 nucleotides (underlined) corresponding to the region from position +1 to position +40 downstream from the start codon of the BDH1 ORF.

For the overexpression of BDH1221,222,223, coding for an NADPH-dependent form of BDH (6), a fragment required to overexpress and to change the coenzyme specificity of the BDH1 enzyme was amplified from genomic DNA of V5 ald6 BDH1. The forward primer 5′-CTTTCCTCCTTACGGGGTCCTAGCCTGTTTCTCTTGATATGCAGGTCGACAACCCTTAAT-3′ was complementary to the loxP-kanMX4-loxP-TDH3 promoter cassette, and the reverse primer GGCCATTTCTATTCTTCTCTCTGATCTTGAAGACACTACAATTTTACTGGCCCCC, complementary to the genomic region from position +639 to position +690 downstream of the start codon of the BDH1 ORF, contained nucleotides (underlined) required to modify the coenzyme specificity. These nucleotides correspond to a change in the native Bdh1 amino acid sequence from 221 EIA 223 to 221 SRS 223. The fragment amplified using these primers was used to transform V5 ald6 in order to obtain V5 ald6 BDH1221,222,223. The integration of the loxP-kanMX4-loxP-TDH3 promoter cassette was checked by PCR with genomic DNA from G418r transformants. BDH1221,222,223 was completely sequenced, and the NADP(H)-dependent activity of the product was verified by enzymatic assays. V5 ald6 overexpressing either BDH1 or BDH1221,222,223 was transformed with pVT100U-ZEO-GPD1.

Analytical methods.

Cells were counted using an electronic particle counter (ZBI model; Coulter Counter Coultronics) fitted with a probe with a 100-μm aperture. Glucose, glycerol ethanol, pyruvate, succinate, acetate, 2-oxoglutarate, and 2-hydroxyglutarate were analyzed by high-pressure liquid chromatography using an HPX-87H ion exclusion column (Bio-Rad), and volatile aromatic compounds acetoin and 2,3-BD were measured by gas chromatography as described previously (23, 28). The acetaldehyde concentration was determined enzymatically according to the method of Lundquist (20).

Diacetyl was analyzed by using solid-phase microextraction with deuterated diacetyl-d6 as an internal standard, followed by gas chromatography-mass spectrometry according to the method of Hayasaka and Bartowsky (16). Diacetyl was purchased from Aldrich, and the diacetyl-d6 used as an internal standard was purchased from CDN Isotopes (Quebec, Canada). The solid-phase microextraction fiber coated with a 70-μm Carbowax-divinylbenzene StableFlex fiber was purchased from Supelco (Bellefonte, PA).

Cell extracts and enzyme assays.

Yeast cell extracts were prepared from a total of 109 cells collected from the bioreactor as described previously (30). Enzyme activities were assayed immediately. BDH-specific activity was assayed spectrophotometrically at 25°C in a total volume of 1 ml containing 33 mM potassium phosphate buffer (pH 7), 0.2 mM NAD(P)H, and 50 mM acetoin. The reaction was initiated by the addition of 20 μl of cell extract and monitored by the decrease in absorbance at 340 nm. The protein concentration was determined with a bicinchoninic acid assay kit (Uptima-Interchim, France).

RESULTS

Role of Bdh1 in metabolism of acetoin during wine fermentation.

Yeast can produce acetoin from pyruvate by three different pathways (33). The major route is the condensation of active acetaldehyde (thiamine PPi-acetaldehyde) with free acetaldehyde, catalyzed by the pyruvate decarboxylase (Fig. 1). An alternative route involves the transformation of pyruvate and free acetaldehyde by a 2-acetolactate synthase into 2-acetolactate, which can be further converted into diacetyl by spontaneous nonenzymatic transformation. In the next step, diacetyl is reduced to acetoin, which in turn is reduced further to 2,3-BD. A final described route is the condensation of active acetaldehyde with acetyl coenzyme A to form diacetyl (5), which is successively reduced to acetoin. Acetoin is converted into the end product 2,3-BD, which exists as optically active [(2R,3R)-2,3-BD and (2S,3S)-2,3-BD] and as meso [(2R,3S)-2,3-BD and (2S,3R)-2,3-BD] forms.

Bdh1 is the main enzyme catalyzing the NADH-dependent reduction of acetoin into 2,3-BD in yeast (E. Gonzalez and J. Biosca, unpublished data). In addition, Bdh1 can use several other substrates in vitro, in particular diacetyl as the second best substrate after acetoin (12).

To investigate more precisely the role of Bdh1 in the reduction of acetoin under wine fermentation conditions, we deleted BDH1 in a model wine yeast strain, V5, and studied the impact of BDH1 disruption during fermentation in MS medium (synthetic must) containing 200 g/liter glucose. The deletion of BDH1 did not affect either the growth or the fermentation rate compared to that of wild-type V5 (data not shown). Under these conditions, when all glucose was exhausted, V5 produced 553 mg/liter of 2,3-BD, as a mixture of about 77% active and 23% meso isomers (Table 2). The bdh1 mutant, on the other hand, did not produce any detectable (2R,3R)-2,3-BD, and its residual production of 2,3-BD, consisting exclusively of the meso form, corresponded to ∼15% of the total 2,3-BD production by wild-type V5. Moreover, while no acetoin was detected in the medium fermented by V5, V5 bdh1 produced ∼400 mg/liter of this compound.

TABLE 2.

Production of acetoin, (2R,3R)-2,3-BD, (2S,3S)-2,3-BD, and meso-2,3-BD during alcoholic fermentation in MS medium containing 200 g/liter glucose

| Strain | Concn (mean ± SD) of:

|

||||

|---|---|---|---|---|---|

| Acetoin (mg/liter) | (2R,3R)-2,3-BD and (2S,3S)-2,3-BD (mg/liter) | meso-2,3-BD (mg/liter) | Total 2,3-BD (mg/liter) | Diacetyl (μg/liter) | |

| V5 | 0 ± 0 | 428 ± 107 | 126 ± 25 | 553 ± 132 | 7.9 ± 0.5 |

| V5 bdh1 | 401 ± 11 | NDa | 84 ± 22 | 84 ± 22 | 15.8 ± 0.3 |

ND, not detected.

Overall, these data indicate that Bdh1 is responsible for ∼85% of the total amount of 2,3-BD produced by yeast cells during wine fermentation, including the entire (2R,3R)-stereoisoform and ∼40% of the meso form.

We additionally investigated the impact of BDH1 deletion on diacetyl formation. The diacetyl level produced by V5 bdh1 (Table 2) increased by ∼2-fold compared to that produced by native V5, indicating that Bdh1 also plays an important role in the reduction of diacetyl.

Identification of factors limiting the reduction of acetoin into 2,3-BD.

In the strains overproducing glycerol, the BDH reaction is limited above a certain level of glycerol production, resulting in a dramatic increase in the production of acetoin (4, 31). The accumulated level is increased further by the disruption of ALD6, coding for the cytosolic acetaldehyde dehydrogenase (4).

In order to investigate the influence of potential factors limiting this reaction, we overexpressed BDH1 and BDH1221,222,223, coding for the native NADH-dependent Bdh1 and an engineered NADPH-dependent Bdh1 enzyme, respectively, in the strains V5 and V5 ald6. Bdh1221,222,223 has the same apparent affinity for and performance efficiency with NADPH as Bdh1 has for NADH (6).

The fermentation behavior of V5, V5 BDH1, and V5 BDH1221,222,223 during wine fermentation in MS medium was examined. BDH1 and BDH1221,222,223 overexpression did not affect growth compared to that of the reference strain, and no differences in the production of 2,3-BD were observed.

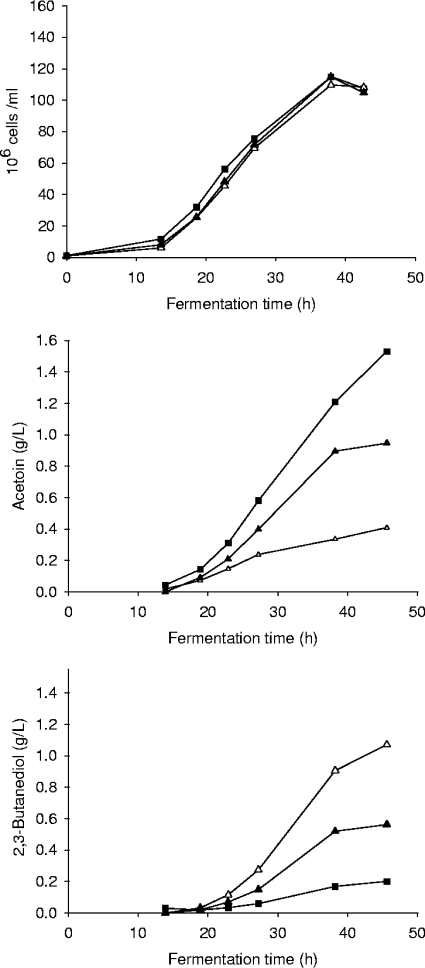

Next, we examined the impacts of BDH1 and BDH1221,222,223 overexpression on the levels of acetoin accumulated by yeast carrying an ALD6 disruption and producing high levels of glycerol. The strains V5 ald6, V5 ald6 BDH1, and V5 ald6 BDH1221,222,223 were transformed by the multicopy plasmid pVT100U-ZEO carrying GPD1 and studied in a preliminary experiment under alcoholic fermentation conditions in MS medium containing 50 g/liter glucose. The growth (Fig. 2) and fermentation (data not shown) rates of the three strains V5 ald6 GPD1, V5 ald6 GPD1 BDH1, and V5 ald6 GPD1 BDH1221,222,223 were identical. Compared to the acetoin formation by strain V5 ald6 GPD1, which accumulates 1.5 g/liter acetoin, the acetoin formation by strains overproducing Bdh1 and Bdh1221,222,223 decreased (Table 3; Fig. 2). However, the overproduction of the NADPH-dependent enzyme resulted in more efficient conversion of acetoin into 2,3-BD than the overproduction of native NADH-dependent Bdh1. Indeed, under these conditions, V5 ald6 GPD1 BDH1 formed 37% less acetoin than the reference strain V5 ald6 GPD1, while V5 ald6 GPD1 BDH1221,222,223 produced 61% less acetoin than V5 ald6 GPD1 BDH1. In both cases, acetoin was reduced to 2,3-BD in a stoichiometric way. These results demonstrate that both the expression level of BDH1 and the NADH availability are limiting factors for the 2,3-BD pathway in glycerol-overproducing yeast. Nevertheless, the NADH availability is the most restricting parameter under these growth conditions.

FIG. 2.

Growth and acetoin and 2,3-BD production profiles of modified wine yeast strains V5 ald6 GPD1 (black squares), V5 ald6 GPD1 BDH1 (black triangles), and V5 ald6 GPD1 BDH1221,222,223 (white triangles) in MS medium containing 50 g/liter glucose. Representative results of one of three independent experiments are shown.

TABLE 3.

Production of acetoin and 2,3-BD during alcoholic fermentation in MS medium containing 50 g/liter glucose

| Strain | Concna (mg/liter) of:

|

|

|---|---|---|

| Acetoin | Total 2,3-BD | |

| V5 ald6 GPD1 | 1,492 ± 55 | 193 ± 10 |

| V5 ald6 GPD1 BDH1 | 935 ± 17 | 559 ± 10 |

| V5 ald6 GPD1 BDH1221,222,223 | 361 ± 68 | 1,042 ± 102 |

Values are means ± standard deviations.

Effects of BDH1 and BDH1221,222,223 overexpression on acetoin levels during wine fermentation.

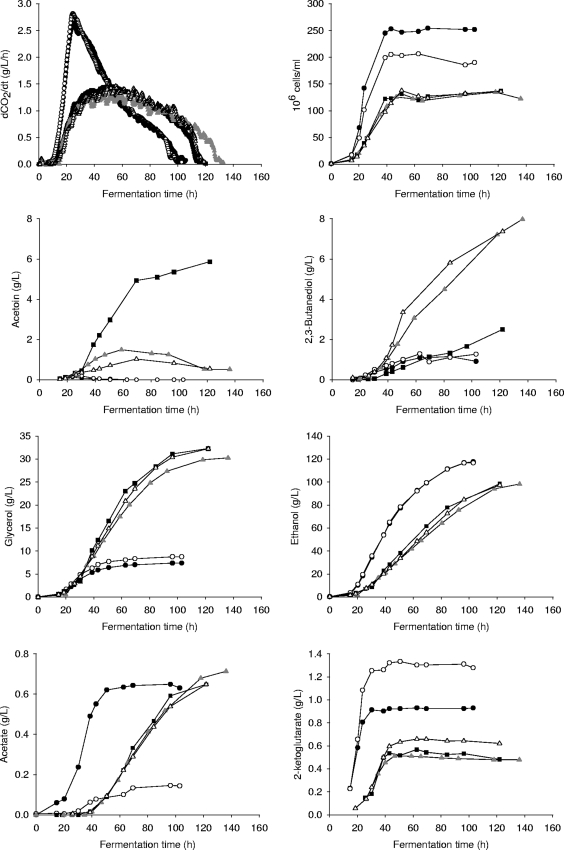

In another step, we performed extensive characterization of the five strains V5, V5 ald6, V5 ald6 GPD1, V5 ald6 GPD1 BDH1, and V5 ald6 GPD1 BDH1221,222,223 in synthetic MS media containing 200 and 240 g/liter of glucose, corresponding to sugar levels commonly found in grape juice (Tables 4 and 5; Fig. 3).

TABLE 4.

Impacts of genetic modifications on ethanol production and corresponding acetoin, acetate, and glycerol levels produced during alcoholic fermentationa

| Strain | Concn (g/liter) of:

|

Ethanol content (°) in:

|

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Acetoin

|

2,3-BD

|

Glycerol

|

Ethanol

|

|||||||

| 200-g/liter- glucose medium | 240-g/liter- glucose medium | 200-g/liter- glucose medium | 240-g/liter- glucose medium | 200-g/liter- glucose medium | 240-g/liter- glucose medium | 200-g/liter- glucose medium | 240-g/liter- glucose medium | 200-g/liter- glucose medium | 240-g/liter- glucose medium | |

| V5 | 0.0 ± 0.0 | 0.0 ± 0.0 | 0.5 ± 0.1 | 1.3 ± 0.4 | 5 ± 0.08 | 7 ± 0.6 | 97 ± 0.3 | 119 ± 1.4 | 12.2 | 15.0 |

| V5 ald6 | 0.0 ± 0.0 | 0.0 ± 0.0 | 0.7 ± 0.1 | 1.4 ± 0.3 | 6.3 ± 0.6 | 8 ± 0.3 | 97 ± 0.3 | 117 ± 1.6 | 12.2 ± 0.03 | 14.8 ± 0.2 |

| V5 ald6 GPD1 | 5.9 ± 1.5 | 7.6 ± 1.7 | 1.3 ± 0.3 | 2.4 ± 0.6 | 27 ± 0.2 | 33 ± 0.4 | 78 ± 0.5 | 99 ± 0.1 | 9.8 | 12.4 |

| V5 ald6 GPD1 BDH1 | 1.0 ± 0.07 | 0.8 ± 0.0 | 6.0 ± 0.9 | 8.9 ± 0.5 | 24 ± 0.14 | 29 ± 1.1 | 80 ± 0.6 | 98 ± 0.2 | 10.1 | 12.4 |

| V5 ald6 GPD1 BDH1221,222,223 | 1.2 ± 0.36 | 0.9 ± 0.14 | 7.0 ± 2.3 | 8.9 ± 1.6 | 26 ± 0.45 | 32 ± 0.0 | 79 ± 0.0 | 97 ± 0.7 | 9.9 | 12.2 |

Experiments were carried out with MS media containing 200 and 240 g/liter glucose. The means ± standard deviations of results from two independent experiments are shown.

TABLE 5.

Metabolite and biomass levels and yields for strains V5, V5 ald6, V5 ald6 GPD1, V5 ald6 GPD1 BDH1, and V5 ald6 GPD1 BDH1221,222,223 in medium with 240 g/liter glucosea

| Compound or material | Concn (g/liter) in V5 culture | Yield (10−3) from V5 | Concn (g/liter) in V5 ald6 culture | Yield (10−3) from V5 ald6 | Concn (g/liter) in V5 ald6 GPD1 culture | Yield (10−3) from V5 ald6 GPD1 | Concn (g/liter) in V5 ald6 GPD1 BDH1 culture | Yield (10−3) from V5 ald6 GPD1 BDH1 | Concn (g/liter) in V5 ald6 GPD1 BDH1221,222,223 culture | Yield (10−3) from V5 ald6 GPD1 BDH1221,222,223 |

|---|---|---|---|---|---|---|---|---|---|---|

| Glucose | 240 | 1,000 | 240 | 1,000 | 240 | 1,000 | 240 | 1,000 | 240 | 1,000 |

| Biomass | 6.10 | 25.4 | 6.7 | 27.9 | 4.4 | 18 | 3.7 | 15.5 | 4.2 | 17.3 |

| Ethanol | 118 | 492 | 117 | 486 | 99 | 410 | 98 | 409 | 97 | 406 |

| CO2 | 113 | 471 | 114 | 473 | 106 | 443 | 107 | 445 | 106 | 443 |

| Acetate | 0.63 | 2.6 | 0.14 | 0.6 | 0.65 | 2.7 | 0.7 | 3.0 | 0.65 | 2.7 |

| Glycerol | 7 | 31 | 9 | 36 | 32 | 130 | 30 | 126 | 32 | 134 |

| Pyruvate | 0.10 | 0.4 | 0.04 | 0.17 | 0.18 | 0.8 | 0.23 | 1.0 | 0.22 | 0.9 |

| 2-Ketoglutarate | 0.93 | 3.9 | 1.3 | 5.3 | 0.5 | 2.0 | 0.5 | 2.0 | 0.6 | 2.6 |

| Succinate | 0.4 | 1.5 | 0.5 | 2.1 | 0.9 | 3.7 | 0.9 | 3.9 | 0.9 | 3.9 |

| Acetaldehyde | 0.01 | 0.04 | 0.01 | 0.04 | 0.14 | 0.56 | 0.12 | 0.5 | 0.12 | 0.5 |

| Acetoin | 0.00 | NDb | 0.00 | ND | 5.9 | 24.4 | 0.5 | 2.2 | 0.6 | 2.3 |

| 2,3-BD | 0.9 | 3.8 | 1.3 | 5.3 | 2.5 | 10.4 | 8.0 | 33.2 | 7.4 | 30.7 |

Yields are expressed as grams per gram of glucose consumed. The levels of carbon recovery were 103% for strain V5 and 104% for strains V5 ald6, V5 ald6 GPD1, V5 ald6 GPD1 BDH1, and V5 ald6 GPD1 BDH1221,222,223. The redox balance, which represents the ratio (expressed as a percentage) between the reductance degree of fermentation products (including biomass) and the reductance degree of glucose, was 104% for all strains. The reductance degree indicates the number of equivalents of available electrons required for the oxidation of a compound to CO2 and H2O. The reductance degree of compound CxHyOz is calculated with the following equation: γ = 4x+ y − 2z.

ND, not detected.

FIG. 3.

Fermentation performances of modified wine yeast strains V5 ald6 (white circles), V5 ald6 GPD1 (black squares), V5 ald6 GPD1 BDH1 (gray triangles), and V5 ald6 GPD1 BDH1221,222,223 (white triangles) in comparison to that of the corresponding reference strain V5 (black circles). Experiments were carried out in MS medium containing 240 g/liter glucose. Sugar was completely consumed by all strains. Representative results of one of three independent experiments are shown.

Detailed results of one experiment in MS medium with 240 g/liter glucose are shown (Fig. 3; Table 5). The specific BDH activities in the different strains were determined at a time point corresponding to the release of 48 g/liter CO2 (∼62 h of fermentation). The NADH-dependent BDH-specific activity in V5 ald6 GPD1 BDH1 was similar to the NADPH-dependent specific activity in V5 ald6 GPD1 BDH1221,222,223 (means ± standard deviations, 2.0 ± 0.06 and 1.8 ± 0.1 U/mg, respectively) and approximately 20-fold higher than the BDH-specific activities in V5 and V5 ald6 (0.1 ± 0.01 and 0.09 ± 0.01 U/mg, respectively).

As described previously (4, 31), the high-glycerol strain V5 ald6 GPD1 exhibited reduced growth (Fig. 3) compared to that of V5. This result may be due to a toxic effect of acetaldehyde, which increased to 0.3 to 0.4 g/liter at the end of growth phase (data not shown), or to a net ATP loss resulting from the diversion of carbons toward glycerol (4, 31). The overexpression of BDH1 or BDH1221,222,223 in V5 ald6 GPD1 did not further influence either growth or the CO2 production rate (Fig. 3). Both gene modifications resulted in a considerable decrease of acetoin production (Fig. 3; Table 5). By the end of the first 60 h, corresponding to the midfermentation point for strains overproducing glycerol, acetoin was efficiently reduced to 2,3-BD by V5 ald6 GPD1 BDH1, and the efficiency of this reaction in V5 ald6 GPD1 BDH1221,222,223 was further increased, as observed previously with MS medium containing 50 g/liter glucose. However, from midfermentation, these differences were attenuated, and the final acetoin concentrations for V5 ald6 GPD1 BDH1221,222,223 and V5 ald6 GPD1 BDH1 were very close (Fig. 3). Similar effects in both MS medium with 200 g/liter glucose and MS medium with 240 g/liter glucose were observed (Table 4). In both media, 83 to 90% of the acetoin produced from pyruvate was reduced into 2,3-BD in a stoichiometric manner, in contrast to the large accumulation of acetoin in the media and the low-level 2,3-BD production observed for V5 ald6 GPD1 (Table 4; Fig. 3).

As shown in Table 5, redox and carbon levels were balanced for all genetically modified strains. Apart from the effects on acetoin and 2,3-BD levels, BDH1 overexpression triggered, additionally, a decrease in the glycerol level by ∼3 g/liter compared to that in V5 ald6 GPD1 (Table 4), which can be explained by more restricted NADH availability for glycerol synthesis, in favor of 2,3-BD production. On the other hand, the overexpression of the NADPH-dependent Bdh1 restored the glycerol level to the one produced by V5 ald6 GPD1, suggesting that this enzyme uses NADPH rather than NADH in vivo. In addition, V5 ald6 GPD1 BDH1221,222,223 produced larger 2-ketoglutarate amounts than V5 ald6 GPD1 BDH1 (Fig. 3; Table 5). This finding also supports the NADPH specificity of this enzyme in vivo. A similar effect was observed for V5 ald6 compared to V5 (Fig. 3, Table 5). Since Ald6 preferentially uses NADP, the deletion of ALD6 results in lower NADPH formation. In both cases, less NADPH will be available for the NADPH-dependent glutamate dehydrogenase Gdh1 reaction, responsible for 2-ketoglutarate conversion into glutamate, thus explaining the observed 2-ketoglutarate accumulation.

The overproduction of the NADH- and NADPH-dependent Bdh1 did not further influence the ethanol formation (Table 4). Compared to that from the wild type, the ethanol yield was considerably reduced, by about 20%, this effect being essentially the result of glycerol overproduction. Depending on the initial glucose concentration, this strategy results in a decrease in the ethanol level of 2.1 to 2.8° (Table 4).

Impacts on volatile aromatic compounds.

In the next step, we compared the effects of the genetic modifications on the production of some key aromatic compounds (Tables 6 and 7).

TABLE 6.

Higher-alcohol, ester, and diacetyl levels produced by genetically modified yeasts during alcoholic fermentation in MS medium containing 240 g/liter glucose

| Compound | Concna produced by strain:

|

||||

|---|---|---|---|---|---|

| V5 | V5 ald6 | V5 ald6 GDP1 | V5 ald6 GDP1 BDH1 | V5 ald6 GDP1 BDH1221,222,223 | |

| Isobutanol | 55.5 ± 2.7 | 94.6 ± 4.5 | 67.4 ± 13.5 | 59.0 ± 3.1 | 63.6 ± 2.7 |

| Isoamyl alcohol | 142.6 ± 7.1 | 209.8 ± 9.9 | 88.4 ± 12.5 | 60.1 ± 1.0 | 88.2 ± 2.1 |

| 2-Phenylethanol | 47.8 ± 5.8 | 54.1 ± 6.8 | 36.6 ± 5.6 | 34.4 ± 4.2 | 40.0 ± 7.9 |

| Isobutyl acetate | 0.6 ± 0.2 | 0.8 ± 0.1 | 0.7 ± 0.4 | 0.6 ± 0.1 | 0.4 ± 0.2 |

| Isoamyl acetate | 2.0 ± 0.1 | 4.2 ± 0.3 | 0.9 ± 0.3 | 0.5 ± 0.0 | 0.7 ± 0.1 |

| Ethyl acetate | 52.7 ± 4.5 | 71.6 ± 5.7 | 62.5 ± 10.2 | 55.1 ± 2.2 | 55.6 ± 3.0 |

| Ethyl butyrate | 0.5 ± 0.0 | 0.6 ± 0.0 | 1.1 ± 0.3 | 0.7 ± 0.0 | 1.0 ± 0.0 |

| Ethyl octanoate | 0.5 ± 0.1 | 0.7 ± 0.1 | 0.3 ± 0.1 | 0.3 ± 0.0 | 0.2 ± 0.0 |

| Diethyl succinate | 1.1 ± 0.8 | 1.0 ± 0.2 | 17.8 ± 0.7 | 19.1 ± 1.9 | 17.0 ± 1.5 |

| Diacetyl | 4.0 ± 2.3 | 4.6 ± 2.7 | 32.7 ± 3.1 | 14.3 ± 0.1 | 16.0 ± 1.7 |

Concentrations are given in milligrams per liter for all compounds except diacetyl, for which concentrations are given in micrograms per liter. Values are means ± standard deviations of results from two experiments.

TABLE 7.

Aroma descriptors for analyzed flavor compounds listed in Table 6

| Compound | Range of concn (mg/liter) in wine | Aroma threshold (mg/liter)a | Aroma description |

|---|---|---|---|

| Isobutanol | 9.0-174 | 40* | Fusel alcohol odor; spirituous; bitter |

| Isoamyl alcohol | 6.0-490 | 30* | Harsh; nail polish, whiskey, and malt odors; burnt |

| 2-Phenylethanol | 4.0-197 | 10* | Floral; rose, honey, and spice scents |

| Isobutyl acetate | 0.01-1.6 | 1.6*** | Banana aroma; fruity |

| Isoamyl acetate | 0.1-3.4 | 0.03* | Banana and pear aromas |

| Ethyl acetate | 22.5-63.5 | 7.5* | Nail polish odor; scent of pineapple; fruity |

| Ethyl butyrate | 0.01-1.8 | 0.02* | Floral; fruity |

| Ethyl octanoate | 0.05-3.8 | 0.02* | Smell of sweet soap and fat; fruity |

| Diethyl succinate | 0.9-9.4 | 1,200* | Wine aroma; fruity; sweet |

| Diacetyl | 0.5-10 | 0.2-2.8**** | Buttery |

*, determined in 10% ethanol; **, determined in water; ***, determined in synthetic wine; and ****, determined in wine.

The deletion of ALD6, coding for the NADP-dependent cytosolic isoform of acetaldehyde dehydrogenase, induced the production of significantly larger amounts of isobutanol and isoamyl alcohol than those produced by the wild type V5 (Table 6). These higher alcohols derive from the metabolism of valine and leucine (17). Increased levels of these compounds may be explained by the slight transient increase of acetaldehyde and pyruvate in V5 ald6 (data not shown) (35), which can favor the production of 2-acetolactate, an intermediary of valine and leucine synthesis. In addition, redox imbalances provoked by the disruption of ALD6 may contribute to these modifications. The deletion of ALD6 induced, additionally, an increase in the isoamyl acetate level, which may be a direct consequence of the higher isoamyl alcohol level produced.

In a general way, the overexpression of GPD1 led to a decreased level of higher alcohols compared to those produced by V5 ald6 (Table 6). A likely explanation for this finding is the lower level of NADH availability for the NADH-dependent higher-alcohol production in this strain (17), as NADH is preferentially used for glycerol synthesis. The production of isoamyl acetate in this strain was also reduced, which can be directly related to the lower level of isoamyl alcohol formation. In contrast, the production of diethyl succinate increased, probably as the direct consequence of the higher succinate levels formed by glycerol-overproducing yeast (4, 31).

The overproduction of Bdh1 or Bdh1221,222,223 had little effect on higher-alcohol and ester synthesis. The only effect was an additional decrease in the formation of isoamyl alcohol compared to that by the ald6 GPD1 strain, which may, again, be explained by a lower level of NADH availability for the NADH-dependent higher-alcohol production. In a similar way, the overproduction of NADPH-dependent Bdh1221,222,223 increased the production of isoamyl alcohol to levels similar to those of production by the ald6 GPD1 strain, as NADH became more available. Altogether, the various levels of all analyzed compounds remained in the range of concentrations found in wine (Table 7), and no significant alteration in aroma traits compared to those obtained with the parental strain V5 can be attributed to the genetically modified strains V5 ald6 GPD1 BDH1 and V5 ald6 GPD1 BDH1221,222,223.

In the final stage, we investigated the consequences of BDH1 and BDH1221,222,223 overexpression for diacetyl production by V5 ald6 GPD1. The overexpression of GPD1 triggers high-level accumulation of diacetyl (Tables 6 and 7), as shown for a previously engineered glycerol-overproducing brewer's yeast (25). This effect can be attributed to the higher levels of pyruvate and acetaldehyde production in this background (4, 25, 31). The overexpression of the two Bdh1 forms decreased the diacetyl level by half. This result emphasizes the limitation of the diacetyl reduction reaction in a GPD1 background, due probably to the level of synthesis of Bdh1 and/or NADH availability, similar to that of the acetoin reaction.

DISCUSSION

Engineered S. cerevisiae GPD1 ald6 strains that produce high glycerol levels also exhibit a large increase in acetoin biosynthesis, which is detrimental for wine quality. In this study, we have provided strong evidence that both the expression level of BDH1 and the availability of NADH, which is used mainly for the synthesis of glycerol, are limiting factors in the reduction of acetoin to 2,3-BD.

The main limiting factor during wine fermentation was the level of synthesis of Bdh1. The NADH effect varied significantly throughout the fermentation. In the first step of wine fermentation (the first 60 h) in MS medium with 240 g/liter glucose or during fermentation with 50 g/liter glucose, the production of acetoin by cells overexpressing BDH1 was decreased by about 39% and that by cells overproducing the NADPH-dependent Bdh1 was decreased by 58%. The limitation of the BDH reaction by NADH availability is consistent with the high NADH demand for glycerol production during this phase. In contrast, from midway in the fermentation reaction, acetoin was reduced to 2,3-BD as efficiently by cells overproducing native Bdh1 as by those overproducing engineered Bdh1. This finding may be explained by the decrease in the glycerol production rate, resulting in the increased availability of NADH for the Bdh1 reaction.

Overall, the two strategies had similar effects on the final level of acetoin and allowed a drastic decrease in the production of this compound by reducing it into 2,3-BD. The introduced modifications triggered only minor alterations in the production of secondary products. The main impact on the production of fusel alcohols and esters was due to the overexpression of GPD1 and to the deletion of ALD6, but most of these effects were in fact compensated for by the combination of the two modifications. In addition to the decreased acetoin accumulation, the most obvious effect of BDH1 or mutated BDH1 overexpression was decreased diacetyl production. Five enzymes having in vitro diacetyl reductase activity in S. cerevisiae, including Bdh1, which reduces diacetyl as the second best substrate after acetoin, have been identified previously (9, 12, 24, 38, 43). We have shown that the overexpression or deletion of BDH1 results in a twofold decrease or increase in diacetyl levels, respectively, suggesting that Bdh1 is a rate-limiting enzyme in diacetyl reduction. However, we cannot exclude that this reaction is subjected to metabolic control. For example, the lower diacetyl levels produced by strains overexpressing BDH1 or BDH1221,222,223 may be due to a release of the inhibition of diacetyl reductase activity by acetoin.

The perception threshold for diacetyl in wine has been estimated to be in the range of 0.2 to 2.8 mg/liter, depending on the wine type (22). At concentrations higher than 5 mg/liter, this compound gives undesirable buttery and butterscotch aromas, similar to those from acetoin (6). In all cases, the amounts of diacetyl produced by ald6 GPD1 and ald6 GPD1 BDH1 strains (14 to 32 μg/liter) remained far below the detection threshold for this compound in wine.

In beer, the detection threshold for diacetyl is much lower than that in wine, around 0.1 to 0.15 mg/liter (15); therefore, this compound represents a much more important problem for beer than for wine. It has been reported previously that a high-glycerol brewing yeast produces diacetyl and acetoin at levels higher than those observed for wine yeast strains (25). One possible explanation is the lower levels of BDH activity in brewing yeasts than in wine yeasts (25). The overexpression of Bdh1 in glycerol-overproducing brewing strains may therefore be an efficient strategy to reduce the production of these compounds. In addition, it may be interesting to compare the effects of the overproduction of the NADH- and NADPH-dependent Bdh1 enzymes in the context of beer fermentation.

Overall, the approach based on the redirection of carbons mainly toward the production of glycerol and 2,3-BD is the most promising one so far on the way to the development of a low-ethanol yeast with desired organoleptic features. We have shown that this strategy has the potential of decreasing the ethanol content by up to 3°, depending on the initial sugar concentration. Sensory analysis studies have demonstrated that glycerol and 2,3-BD, at levels produced by engineered ald6 GPD1 BDH1 yeast, have no negative sensory contribution to wine quality (27; Ehsani et al., unpublished). On the other hand, the assessment of the acetoin threshold in wine showed that detectable levels include the ranges of acetoin amounts produced by this improved strain. Indeed, a compromise between the levels of glycerol (and, consequently, ethanol) and acetoin produced will have to be found. Finally, the impacts of ALD6 deletion and GPD1 and BDH1 overexpression in commercial wine yeasts and the effects on natural grape musts have to be evaluated in order to validate this strategy.

Acknowledgments

We thank L. Dagan and R. Schneider for diacetyl analysis and M. Angenieux (INRA, Pech Rouge) for her help with higher-alcohol and ester analyses. We also thank C. Camarasa for critical reading of the manuscript.

This work was supported in part by a grant from the Ministry of Education and Science (BMC-2003-09606), Spain.

Footnotes

Published ahead of print on 27 March 2009.

REFERENCES

- 1.Ansell, R., K. Granath, S. Hohmann, J. M. Thevelein, and L. Adler. 1997. The two isoenzymes for yeast NAD+-dependent glycerol 3-phosphate dehydrogenase encoded by GPD1 and GPD2 have distinct roles in osmoadaptation and redox regulation. EMBO J. 16:2179-2187. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Bakker, B. M., K. M. Overkamp, A. J. van Maris, P. Kotter, M. A. Luttik, J. P. van Dijken, and J. T. Pronk. 2001. Stoichiometry and compartmentation of NADH metabolism in Saccharomyces cerevisiae. FEMS Microbiol. Rev. 25:15-37. [DOI] [PubMed] [Google Scholar]

- 3.Bely, B., J. M. Sablayrolles, and P. Barre. 1990. Automatic detection of assimilable nitrogen deficiencies during alcoholic fermentation in oenological conditions. J. Ferment. Bioeng. 70:246-252. [Google Scholar]

- 4.Cambon, B., V. Monteil, F. Remize, C. Camarasa, and S. Dequin. 2006. Effects of GPD1 overexpression in Saccharomyces cerevisiae commercial wine yeast strains lacking ALD6 genes. Appl. Environ. Microbiol. 72:4688-4694. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Chuang, L. F., and E. B. Collins. 1968. Biosynthesis of diacetyl in bacteria and yeast. J. Bacteriol. 95:2083-2089. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Davis, C. R., D. Wibowo, R. Eschenbruch, T. H. Lee, and G. H. Fleet. 1985. Practical implications of malolactic fermentation: a review. Am. J. Enol. Vitic. 36:290-301. [Google Scholar]

- 7.de Barros Lopes, M., A. U. Rehman, H. Gockowiak, A. J. Heinrich, P. Langridge, and P. A. Henschke. 2000. Fermentation properties of a wine yeast overexpressing the Saccharomyces cerevisiae glycerol 3-phosphate dehydrogenase gene (GPD2). Aust. J. Grape Wine Res. 6:208-215. [Google Scholar]

- 8.Dequin, S., and P. Barre. 1994. Mixed lactic acid-alcoholic fermentation by Saccharomyces cerevisiae expressing the Lactobacillus casei L(+)-LDH. Bio/Technology (New York) 12:173-177. [DOI] [PubMed] [Google Scholar]

- 9.Ehsani, M., M. R. Fernández, J. A. Biosca, and S. Dequin. Reversal of coenzyme specificity of 2,3-butanediol dehydrogenase from Saccharomyces cerevisiae and in vivo functional analysis. Biotechnol. Bioeng., in press. [DOI] [PubMed]

- 10.Reference deleted.

- 11.Gonzalez, E., M. R. Fernandez, C. Larroy, X. Pares, and J. A. Biosca. 2001. Characterization and functional role of Saccharomyces cerevisiae 2,3-butanediol dehydrogenase. Chem. Biol. Interact. 130-132:425-434. [DOI] [PubMed] [Google Scholar]

- 12.Gonzalez, E., M. R. Fernandez, C. Larroy, L. Sola, M. A. Pericas, X. Pares, and J. A. Biosca. 2000. Characterization of a (2R,3R)-2,3-butanediol dehydrogenase as the Saccharomyces cerevisiae YAL060W gene product. Disruption and induction of the gene. J. Biol. Chem. 275:35876-35885. [DOI] [PubMed] [Google Scholar]

- 13.Guldener, U., S. Heck, T. Fielder, J. Beinhauer, and J. H. Hegemann. 1996. A new efficient gene disruption cassette for repeated use in budding yeast. Nucleic Acids Res. 24:2519-2524. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Guymon, J. F., and E. A. Crowell. 1967. Direct gas chromatographic determination of levo- and meso-2,3-butanediols in wines and factors affecting their formation. Am. J. Enol. Vitic. 18:200-209. [Google Scholar]

- 15.Hammond, J. R. M. 1995. Genetically modified brewing yeasts for the 21st century. Progress to date. Yeast 11:1613-1627. [DOI] [PubMed] [Google Scholar]

- 16.Hayasaka, Y., and E. J. Bartowsky. 1999. Analysis of diacetyl in wine using solid-phase microextraction combined with gas chromatography-mass spectrometry. J. Agric. Food Chem. 47:612-617. [DOI] [PubMed] [Google Scholar]

- 17.Hazelwood, L. A., J. M. Daran, A. J. van Maris, J. T. Pronk, and J. R. Dickinson. 2008. The Ehrlich pathway for fusel alcohol production: a century of research on yeast metabolism. Appl. Environ. Microbiol. 74:2259-2266. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Heux, S., R. Cachon, and S. Dequin. 2006. Cofactor engineering in Saccharomyces cerevisiae: expression of a H2O-forming NADH oxidase and impact on redox metabolism. Metab. Eng. 8:303-314. [DOI] [PubMed] [Google Scholar]

- 19.Heux, S., J. M. Sablayrolles, R. Cachon, and S. Dequin. 2006. Engineering a Saccharomyces cerevisiae wine yeast that exhibits reduced ethanol production during fermentation under controlled microoxygenation conditions. Appl. Environ. Microbiol. 72:5822-5828. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Lundquist, F. 1974. Acetaldehyd: Bestimmung mit Aldehyd-dehydrogenase, p. 1509-1513. In H. U. Bermeyer (ed.), Methods of enzymatic analysis. Academic Press, Inc., New York, NY.

- 21.Malherbe, D. F., M. du Toit, R. R. Cordero Otero, P. van Rensburg, and I. S. Pretorius. 2003. Expression of the Aspergillus niger glucose oxidase gene in Saccharomyces cerevisiae and its potential applications in wine production. Appl. Microbiol. Biotechnol. 61:502-511. [DOI] [PubMed] [Google Scholar]

- 22.Martineau, B., T. E. Acree, and T. Henick-Kling. 1995. Effect of wine type on the detection threshold for diacetyl. Food Res. Int. 28:139-143. [Google Scholar]

- 23.Michnick, S., J. L. Roustan, F. Remize, P. Barre, and S. Dequin. 1997. Modulation of glycerol and ethanol yields during alcoholic fermentation in Saccharomyces cerevisiae strains overexpressed or disrupted for GPD1 encoding glycerol 3-phosphate dehydrogenase. Yeast 13:783-793. [DOI] [PubMed] [Google Scholar]

- 24.Nakamura, K., S. I. Kondo, N. Nakajima, and A. Ohno. 1997. Amino acid sequence and characterization of aldo-keto reductase from bakers yeast. Biosci. Biotechnol. Biochem. 61:375-377. [DOI] [PubMed] [Google Scholar]

- 25.Nevoigt, E., R. Pilger, E. Mast-Gerlach, U. Schmidt, S. Freihammer, M. Eschenbrenner, L. Garbe, and U. Stahl. 2002. Genetic engineering of brewing yeast to reduce the content of ethanol in beer. FEMS Yeast Res. 2:225-232. [DOI] [PubMed] [Google Scholar]

- 26.Nevoigt, E., and U. Stahl. 1996. Reduced pyruvate decarboxylase and increased glycerol-3-phosphate dehydrogenase [NAD+] levels enhance glycerol production in Saccharomyces cerevisiae. Yeast 12:1331-1337. [DOI] [PubMed] [Google Scholar]

- 27.Noble, A. C., and G. F. Bursick. 1984. The contribution of glycerol to perceived viscosity and sweetness in white wine. Am. J. Enol. Vitic. 35:110-112. [Google Scholar]

- 28.Ortega, C., R. Lopez, J. Cacho, and V. Ferreira. 2001. Fast analysis of important wine volatile compounds development and validation of a new method based on gas chromatographic-flame ionisation detection analysis of dichloromethane microextracts. J. Chromatogr. A 923:205-214. [DOI] [PubMed] [Google Scholar]

- 29.Pickering, G. H. 2000. Low- and reduced-alcohol wine: a review. J. Wine Res. 11:129-144. [Google Scholar]

- 30.Remize, F., E. Andrieu, and S. Dequin. 2000. Engineering of the pyruvate dehydrogenase bypass in Saccharomyces cerevisiae: role of the cytosolic Mg2+ and mitochondrial K+ acetaldehyde dehydrogenases Ald6p and Ald4p in acetate formation during alcoholic fermentation. Appl. Environ. Microbiol. 66:3151-3159. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Remize, F., J. L. Roustan, J. M. Sablayrolles, P. Barre, and S. Dequin. 1999. Glycerol overproduction by engineered Saccharomyces cerevisiae wine yeast strains leads to substantial changes in by-product formation and to a stimulation of fermentation rate in stationary phase. Appl. Environ. Microbiol. 65:143-149. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Romano, P., L. Granchi, M. Caruso, G. Borra, G. Palla, C. Fiore, D. Ganucci, A. Caligiani, and V. Brandolini. 2003. The species-specific ratios of 2,3-butanediol and acetoin isomers as a tool to evaluate wine yeast performance. Int. J. Food Microbiol. 86:163-168. [DOI] [PubMed] [Google Scholar]

- 33.Romano, P., and G. Suzzi. 1996. Origin and production of acetoin during wine yeast fermentation. Appl. Environ. Microbiol. 62:309-315. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Sablayrolles, J. M., P. Barre, and P. Grenier. 1987. Design of laboratory automatic system for studying alcoholic fermentations in anisothermal enological conditions. Biotechnol. Technol. 1:181-184. [Google Scholar]

- 35.Saint-Prix, F. 2004. Production d'acétate chez S. cerevisiae en fermentation oenologique. Université Montpellier II, Montpellier, France.

- 36.Saint-Prix, F., L. Bonquist, and S. Dequin. 2004. Functional analysis of the ALD gene family of Saccharomyces cerevisiae during anaerobic growth on glucose: the NADP+-dependent Ald6p and Ald5p isoforms play a major role in acetate formation. Microbiology 150:2209-2220. [DOI] [PubMed] [Google Scholar]

- 37.Sambrook, J., E. F. Fritsh, and T. Maniatis. 1989. Molecular cloning: a laboratory manual. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY.

- 38.Sánchez, B., L. Reverol, I. Galindo-Castro, A. Bravo, R. Rangel-Aldao, and J. L. Ramírez. 2003. Brewer's yeast oxidoreductase with activity on Maillard reaction intermediates of beer. Tech. Q. 40:204-212. [Google Scholar]

- 39.Schiestl, R. H., and R. D. Gietz. 1989. High efficiency transformation of intact yeast cells using single stranded nucleic acids as a carrier. Curr. Genet. 16:339-346. [DOI] [PubMed] [Google Scholar]

- 40.Shinohara, T., Y. Shimazu, and M. Watanabe. 1979. Dosage de l'acétoïne et du lactate d'éthyle dans les vins par chromatographie en phase gazeuse, et étude de leur formation dans les vins. Agric. Biol. Chem. 43:2569-2577. [Google Scholar]

- 41.Sponholz, W. R., H. H. Dittrich, and H. Muno. 1993. Diols in wine. Wine Vitic. Enol. Sci. 49:23-26. [Google Scholar]

- 42.Valadi, A., K. Granath, L. Gustafsson, and L. Adler. 2004. Distinct intracellular localization of Gpd1p and Gpd2p, the two yeast isoforms of NAD+-dependent glycerol-3-phosphate dehydrogenase, explains their different contributions to redox-driven glycerol production. J. Biol. Chem. 279:39677-39685. [DOI] [PubMed] [Google Scholar]

- 43.van Bergen, B., R. Strasser, N. Cyr, J. D. Sheppard, and A. Jardim. 2006. α,β-Dicarbonyl reduction by Saccharomyces d-arabinose dehydrogenase. Biochim. Biophys. Acta 1760:1636-1645. [DOI] [PubMed] [Google Scholar]

- 44.van Dijken, J. P., and W. A. Scheffers. 1986. Redox balances in the metabolism of sugars by yeasts. FEMS Microbiol. Lett. 32:199-224. [Google Scholar]

- 45.Vernet, T., D. Dignard, and D. Y. Thomas. 1987. A family of yeast expression vectors containing the phage f1 intergenic region. Gene 52:225-233. [DOI] [PubMed] [Google Scholar]

- 46.Wang, Z. X., J. Zhuge, H. Fang, and B. A. Prior. 2001. Glycerol production by microbial fermentation: a review. Biotechnol. Adv. 19:201-223. [DOI] [PubMed] [Google Scholar]