Abstract

The effect of MnO2 addition on the dielectric and piezoelectric properties of 0.4Pb(Mg1∕3Nb2∕3)O3–0.25PbZrO3–0.35PbTiO3 single crystals was investigated. Analogous to acceptor doping in “hard” Pb(Zr,Ti)O3 based polycrystalline materials, the Mn doped crystals exhibited enhanced mechanical Q (∼1050) with low dielectric loss (∼0.2%), while maintaining ultrahigh electromechanical coupling k33>90%, inherent in domain engineered single crystals. The effect of acceptor doping was also evident in the build-up of an internal bias (Ei∼1.6 kV∕cm), shown by a horizontal offset in the polarization-field behavior. Together with the relatively high usage temperature (TR-T∼140 °C), the Mn doped crystals are promising candidates for high power and broad bandwidth transducers.

High power ultrasonic transducers generally use “hard” piezoelectric ceramics Pb(Zr,Ti)O3 (PZT), including PZT4 and PZT8 (DOD types I and III)1. These materials are characterized by low dielectric (tan δ) and mechanical losses (high mechanical quality factor Q). In general, to achieve the “hardening” effect, these materials are acceptor doped, e.g., Fe3+,2+, Mn3+,2+ substitution for Zr4+∕Ti4+, resulting in the development of acceptor-oxygen vacancy defect dipoles. These dipoles align parallel to the polarization direction, leading to an internal bias, as evident in a horizontal offset in the polarization-electric field (P-E) behavior. This offset effectively increases the coercive field (EC) and reduces or clamps domain wall motion∕mobility.2, 3 A consequence of these dopants, however, is a reduction in electromechanical coupling and piezoelectric activity, with k33 values less than 70% and piezoelectric strain coefficients d33’s on the order of 200–350 pC∕N,4 so limits the bandwidth of transducer since the power and bandwidth capabilities of the transducer are functions of the mechanical quality and electromechanical coupling factors5, 6. Recently, domain engineered ⟨001⟩ oriented single crystal perovskites have been demonstrated to possess ultrahigh electromechanical couplings k33>90% and high piezoelectric coefficients d33>1500 pC∕N. However, the relaxor-PbTiO3 (PT) crystals exhibit low mechanical quality Q’s (<100) and coercive fields (EC∼2–3 kV∕cm), typical of “soft” piezoelectric behavior.7, 8, 9 Numerous efforts have been made to piezoelectrically harden the crystals through the addition of acceptor dopants. To date, only moderate mechanical Q values in the range of 200–300 have been achieved in flux grown Pb(Zn1∕3Nb2∕3)O3–PbTiO3 crystals.10, 11, 12

In this work, the effect of acceptor doping with MnO2 in solid state crystal grown (SSCG) 0.4Pb(Mg1∕3Nb2∕3)O3–0.25PbZrO3–0.35PbTiO3 (PMN-PZT) crystals was investigated. The SSCG method was selected owing to its inherent benefit of maintaining dopant uniformity in a solid solution, unlike the melt Bridgman process. The PMN-PZT composition was selected owing to its relatively high coercive field (EC∼5 kV∕cm) and high temperature usage range (TR-T>140 °C).13, 14, 15, 16

Pure and manganese modified PMN-PZT single crystals were grown by the SSCG method. Sample geometries were determined for the full set of material constants measurement according to IEEE Standards.17, 18, 19, 20 Prior to the measurements, the samples were poled and aged for 24 h. The Curie temperature TC and ferroelectric phase transition temperature (TR-T) were determined from the dielectric temperature dependence. High field measurements including polarization electric field hysteresis and strain loops were performed on [001] oriented plate samples.

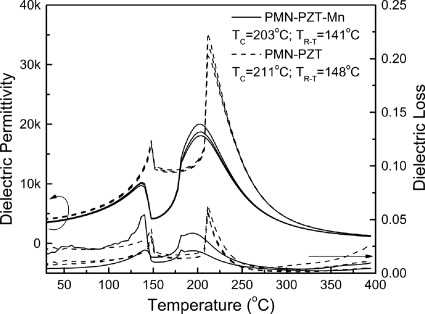

Figure 1 shows the dielectric behavior as a function of temperature for pure and modified PMN-PZT crystals. The Curie temperature TC and rhombohedral to tetragonal phase transition temperature TR-T were found to be on the order of 203 and 141 °C, respectively. For the Mn-modified PMN-PZT crystals, both transition temperatures were shifted downward a few degrees. The dielectric permittivity was found to be suppressed for the modified crystals due to domain wall pinning. As in acceptor doped hard PZT ceramics, Mn3+,2+ cations are believed to be substituted into the Zr4+∕Ti4+ sites, resulting in oxygen vacancies, leading to the development of acceptor-oxygen vacancy defect dipoles. Since there are no grain boundaries, the defect dipoles in hard PMN-PZT single crystals can occupy energetically preferred sites in the lattice, forming anisotropic centers, locally or within a domain. The dipoles thus align themselves along a preferential direction for the spontaneous polarization, and∕or move to the high-stressed areas of domain walls by diffusion, pin the walls, and stabilize the domains.2 The build-up of these parallel defect dipoles to the local polarization vector leads to an offset of P-E behavior or internal bias, as shown in Fig. 2, being on the order of 1.6 kV∕cm, about one-forth the level of the coercive field. The introduction of this internal bias effectively increases the EC by 40% when compared to the undoped crystal, being ∼6.3 kV∕cm. The remnant polarization was found to be reduced from 0.29 to 0.18 C∕m2 for the modified PMN-PZT crystals, demonstrating that the degree of “switchable” polarization is significantly reduced, owing to domain clamping.

Figure 1.

Dielectric permittivity and dielectric loss as a function of temperature for pure and Mn modified PMN-PZT single crystals, measured at frequencies of 1 k–100 kHz.

Figure 2.

Bipolar polarization hysteresis of pure and Mn modified PMN-PZT single crystals, measured at 20 kV∕cm field.

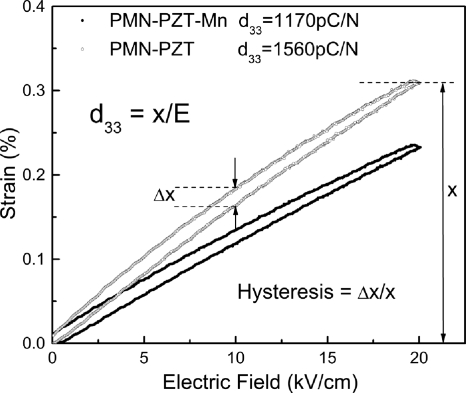

Figure 3 presents the unipolar strain curves (x-E) as a function of electric field for pure and modified crystals. As expected, low hysteresis (obtained by the ratio of Δx∕x, as shown in Fig. 3), being on the order of 5%–6%, was observed for both crystals, similar to the value of hard PZT8 ceramics. The piezoelectric strain coefficients determined from the slope of x-E curve, resulted in d33 values of 1560 and 1170 pC∕N for pure and modified crystals, respectively.

Figure 3.

Unipolar strain-electric field curves for pure and Mn modified PMN-PZT single crystals.

Table 1 lists characteristic properties for Mn modified PMN-PZT crystals as compared to undoped crystals and hard PZT ceramics. The coercive field and mechanical Q were found to increase and the dielectric loss decreased for the modified crystals, a consequence of the formation of internal bias and associated domain wall pinning, a particularly characteristic of hard piezoelectric materials. Although both the piezoelectric and dielectric properties decreased, the electromechanical coupling factor k33 remained greater than 90%, significantly higher than that of the hard PZTs (∼70%).

Table 1.

Application parameters of pure and Mn-modified PMN-PZT single crystals, compared to hard PZT ceramics.

| Material | TC(°C) | TR−T(°C) | Pr(C∕m2) | EC(kV∕cm) | Ei(kV∕cm) | Loss(%) | d33(pC∕N) | k33 | Q | FOM1(pC∕N) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PMN-PZT | 211 | 148 | 0.29 | 4.5 | ∕ | 4850 | 0.5 | 1530 | 0.93 | 100 | 1.5×105 |

| PMN-PZT-Mn | 203 | 141 | 0.18 | 6.3 | 1.6 | 3410 | 0.2 | 1140 | 0.92 | 1050 | 1.2×106 |

| PZT4 | 328 | ∕2 | 0.36 | 14.2 | 3.0 | 1300 | 0.4 | 300 | 0.70 | 500 | 1.5×105 |

| PZT8 | 300 | ∕2 | 0.26 | 18.7 | 7.0 | 1000 | 0.4 | 230 | 0.64 | 1000 | 2.3×105 |

FOM=Qd33.

Usage temperature range of ferroelectric ceramic is limited by (Ref. 21).

For high power applications that require high piezoelectric properties and low loss (high mechanical quality factor), the figure of merit (FOM), product of Q and d, is an important factor to evaluate piezoelectric materials.4 As anticipated, the FOM of Mn modified PMN-PZT was found to be one order of magnitude higher than both the undoped crystal and hard PZT ceramics. Though there is no ferroelectric-ferroelectric phase transformation for PZT4 and PZT8 polycrystalline ceramics prior to their respective Curie temperatures, their usage temperature range is generally limited to less than half of the Curie temperature,21 which is on the same order of TR-T of the crystals.

Table 2 lists the full set of material constants, including piezoelectric coefficients, electromechanical coupling factors, dielectric permittivities, elastic compliance and stiffness constants for both undoped and Mn-modified PMN-PZT crystals. As presented, the piezoelectric coefficients were found to decrease with doping, but the electromechanical coupling factors maintained similar values, demonstrating that the domain wall clamping has no effect on the coupling factors. The dielectric was found to decrease for Mn-modified crystals, while the dielectric increased, exhibiting less anisotropic behavior for the modified crystals when compared to the undoped crystals. Also from Table 2, the elastic compliance constants were found to decrease with Mn doping, whereas the elastic stiffness constants increased, indicating a higher acoustic velocity when compared to the undoped counterpart.

Table 2.

Measured and derived piezoelectric coefficients dij (pC∕N), eij (C∕m2), gij (10−3 Vm∕N), hij (108 V∕m), Electromechanical coupling factors kij, dielectric permittivity εij (ε0), dielectric impermeability βij (10−4∕ε0), elastic compliance constants sij (10−12 m2∕N), elastic stiffness constants cij (1010 N∕m2), for pure and Mn-modified PMN-PZT crystals.

| Material | d33 | d31 | d15 | g33 | g31 | g15 | e33 | e31 | e15 | h33 | h31 | h15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PMN-PZT | 1530 | −718 | 133 | 35.6 | −16.7 | 21.6 | 17.7 | −7.4 | 7.5 | 34.0 | −14.1 | 14.5 |

| PMN-PZT-Mn | 1140 | −513 | 107 | 37.8 | −17.0 | 12.5 | 17.0 | −6.1 | 7.1 | 37.7 | −13.4 | 9.1 |

| Material | k33 | k31 | k15 | kt | ||||||||

| PMN-PZT | 0.93 | 0.44 | 0.40 | 0.60 | 4850 | 697 | 590 | 580 | 2.06 | 14.35 | 16.95 | 17.24 |

| PMN-PZT-Mn | 0.92 | 0.45 | 0.30 | 0.59 | 3410 | 970 | 510 | 880 | 2.93 | 10.31 | 19.61 | 11.36 |

| Material | ||||||||||||

| PMN-PZT | 62.0 | −31.8 | −28.4 | 62.8 | 17.8 | 26.1 | 50.0 | −43.8 | −2.9 | 8.1 | 15.0 | 26.1 |

| PMN-PZT-Mn | 42.6 | −19.9 | −22.1 | 51.3 | 15.2 | 29.9 | 33.9 | −28.6 | −2.7 | 8.1 | 13.9 | 29.9 |

| Material | ||||||||||||

| PMN-PZT | 11.7 | 10.6 | 10.1 | 10.7 | 5.6 | 3.8 | 12.7 | 11.6 | 7.6 | 16.7 | 6.7 | 3.8 |

| PMN-PZT-Mn | 14.3 | 12.7 | 11.7 | 12.0 | 6.6 | 3.3 | 15.2 | 13.6 | 9.4 | 18.4 | 7.2 | 3.3 |

Of particular interest is the “soft shear acoustic wave” that propagates along ⟨110⟩ with displacement along the direction. Experimental results reported that domain wall motion results in a large effective ,18 with low soft shear acoustic velocity. From Table 2, the value of was found to drop by 33% for the Mn-modified PMN-PZT crystals, from which the velocity was calculated to be on the order of 1000 m∕s, higher than the value of pure crystals (∼830 m∕s), indicative of the reduced domain wall motion owing to the domain wall pinning by defect dipoles.

In summary, pure and Mn-modified PMN-PZT crystals were grown using the SSCG method. The modified crystals exhibited higher coercive field and Q, with reduced dielectric and piezoelectric properties, typical of hard behavior. The internal bias field in the Mn modified PMN-PZT crystal is believed to play an important role in the pinning and∕or clamping of domain walls. The FOM Qd for the Mn modified PMN-PZT crystals was found to be one order of magnitude higher than both pure crystals and hard PZT ceramics. Together with its comparable temperature usage range and ultra high electromechanical coupling factor, make Mn-modified PMN-PZT crystals promising candidates for high power and broad bandwidth transducers.

Acknowledgments

This work was supported by the Office of Naval Research (ONR) and National Institutes of Health (NIH) under Grant No. P41-RR11795.

References

- Pohanka R. C. and Smith P. L., Electronic Ceramics: Properties, Devices and Applications, edited by Levinson L. M. (Marcel Dekker, New York, 1987), Chap. 2. [Google Scholar]

- Carl K. and Hardtl K. H., Ferroelectrics 17, 473 (1978). [Google Scholar]

- Takahashi S., Ferroelectrics 41, 143 (1982). [Google Scholar]

- Zhang S. J., Xia R., Lebrun L., Anderson D., and Shrout T. R., Mater. Lett. , 59, 3471 (2005). [Google Scholar]

- Meyer R. J., Montgomery T. C., and Hughes W. J., Oceans ’02 MTS∕IEEE Proceeding, Mississippi, 29–31 October 2002. (unpublished), p. 2328.

- Montgomery T. C., Meyer R. J., and Bienert E. M., Oceans ’07 MTS∕IEEE Proceeding, Vancouver, 29 September–4 October, 2007. (unpublished).

- Park S. E. and Shrout T. R., J. Appl. Phys. 10.1063/1.365983 82, 1804 (1997). [DOI] [Google Scholar]

- Zhang S. J., Luo J., Xia R., Rehrig P. W., Randall C. A., and Shrout T. R., Solid State Commun. 10.1016/j.ssc.2005.10.023 137, 16 (2006). [DOI] [Google Scholar]

- Damjanovic D., Budimir M., Davis M., and Setter N., J. Mater. Sci. 10.1007/s10853-005-5925-5 41, 65 (2006). [DOI] [Google Scholar]

- Priya S., Kim H. W., Ryu J., Zhang S. J., Shrout T. R., and Uchino K., J. Appl. Phys. 10.1063/1.1503411 92, 3923 (2002). [DOI] [Google Scholar]

- Zhang S. J., Lebrun L., Randall C. A., and Shrout T. R., J. Cryst. Growth 10.1016/j.jcrysgro.2004.03.063 267, 204 (2004). [DOI] [Google Scholar]

- Kobor D., Lebrun L., Sebald G., and Guyomar D., J. Cryst. Growth 10.1016/j.jcrysgro.2004.12.010 275, 580 (2005). [DOI] [Google Scholar]

- Zhang S. J., Lee S. M., Kim D. H., Lee H. Y., and Shrout T. R., Appl. Phys. Lett. 10.1063/1.2746055 90, 232911 (2007). [DOI] [Google Scholar]

- Amin A., Lee H. Y., and Kelly B., Appl. Phys. Lett. 10.1063/1.2748857 90, 242912 (2007). [DOI] [Google Scholar]

- Zhang S. J., Lee S. M., Kim D. H., Lee H. Y., and Shrout T. R., J. Appl. Phys. 10.1063/1.2817641 102, 114103 (2007). [DOI] [Google Scholar]

- Zhang S. J., Lee S. M., Kim D. H., Lee H. Y., and Shrout T. R., J. Am. Ceram. Soc. 90, 3859 (2007). [Google Scholar]

- IEEE Standard on Piezoelectricity (ANSI/IEEE Standard, New York, 1987), p. 176. [Google Scholar]

- Zhang R., Jiang B., and Cao W., J. Appl. Phys. 10.1063/1.1390494, 90, 3471 (2001). [DOI] [Google Scholar]

- Zhang S. J., Randall C. A., and Shrout T. R., J. Appl. Phys. 10.1063/1.1682694, 95, 4291 (2004). [DOI] [Google Scholar]

- Geng X. C., Ritter T. A., and Park S. E., Proc.-IEEE Ultrason. Symp. ,571 (1998). [Google Scholar]

- Shrout T. R., Eitel R., and Randall C. A., Piezoelectric Materials in Devices, edited by Setter N. (EPFL Swiss Federal Institute of Technology, Switzerland, 2002), p. 413. [Google Scholar]