Abstract

The full set of material constants for relaxor-based ternary single crystals Pb(In1∕2Nb1∕2)O3–Pb(Mg1∕3Nb2∕3)O3–PbTiO3 (PIN-PMN-PT) were determined and compared to binary Pb(Mg1∕3Nb2∕3)O3–PbTiO3 (PMNT) crystals. The Curie temperature for rhombohedral compositions of PIN-PMN-PT was found to be in the range of 160–200 °C with ferroelectric rhombohedral to tetragonal phase transition on the order of 120–130 °C, more than 30 °C higher than that found for PMNT. The piezoelectric coefficients (d33) were in the range of 1100–1500 pC∕N, with electromechanical coupling factors (k33) about 89%–92% comparable to PMNT crystals. The coercive field of the ternary crystal was found to be 5.5 kV∕cm, double the value of the binary counterparts. The dielectric behavior under varying dc bias exhibited a similar trend as observed in PMNT with a much broader usage temperature range. Together with its enhanced field induced phase transition level, the ternary PIN-PMN-PT crystals are promising candidates for high temperature and high drive transducer applications.

INTRODUCTION

Relaxor-based single crystals, such as (1−x)Pb(Mg1∕3Nb2∕3)O3−xPbTiO3 (PMNT) (x=0.28–0.32) with morphotropic phase boundary (MPB) composition have attracted much attention over the past decade owing to its ultrahigh piezoelectric coefficients (d33=1500–2500 pC∕N) and electromechanical coupling factors (k33>90).1, 2, 3 However, their relatively low Curie temperatures (130–170 °C) limit their application in transducers and actuators, in which thermal stability is expected in relation to dielectric and piezoelectric property variations and depolarization as a result of postfabrication processes. In addition, the strongly curved MPB results in rhombohedral to tetragonal phase transformation temperature of only 60–95 °C, further limiting their applicability. A broader temperature and∕or electric field operating range would allow for greater device design flexibility and therefore a wider range of potential applications. Thus, new single crystal piezoelectric compositions that will operate at higher temperature and∕or higher electric field than current state-of-the-art PMNT single crystals are desirable. Extensive investigations have been carried out on single crystals with high Curie temperature over the past few years4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17 in order to find the possibility of single crystals for the next generation of transduction devices.

In the reported relaxor-PbTiO3 systems, Pb(Sc1∕2Nb1∕2)O3–PbTiO3, Pb(In1∕2Nb1∕2)O3–PbTiO3, and Pb(Yb1∕2Nb1∕2)O3–PbTiO3 (PYNT) were found to possess relative high Curie temperatures near their respective MPBs, being on the order of 260–360 °C.4, 5, 6 The PYNT single crystals are very promising with the highest Curie temperature of 350 °C and rhombohedral to tetragonal phase transition temperature is on the order of ∼160 °C. However, it was reported that the PYNT crystals can only be obtained from high temperature solution method due to its poor perovskite stability with crystal sizes only on the order of few millimeters.7, 8 Bismuth based perovskite ferroelectric single crystals BiScO3–PbTiO3 (BSPT) were reported to possess much higher Curie temperatures, being on the order of 400 °C. Of particular interest is its high ferroelectric phase transition temperature of 350 °C with excellent piezoelectric properties (d33∼1200 pC∕N and k33=90%), expanding its temperature usage range significantly.9, 10 As for the PYNT system, BSPT crystals can only be grown using the flux method, with crystals on the order of few millimeters obtained.

Recently, it was reported that large ternary PIN-PMN-PT single crystals (>50 mm in diameter) can be grown from the melt directly by the Bridgman method, with Curie temperatures on the order of ∼200 °C, while maintaining the excellent piezoelectric properties.15, 16, 17 In this work, the dielectric permittivity, piezoelectric coefficient, elastic constant, and electromechanical coupling factors of PIN-PMN-PT crystals were measured and∕or derived. The ability to utilize the ternary crystals over a wider temperature and external electric field range is demonstrated in contrast to the binary PMNT counterpart.

EXPERIMENTAL

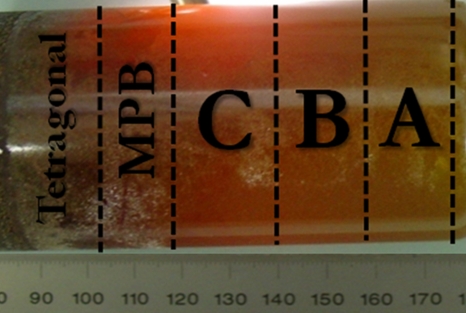

Ternary PIN-PMN-PT single crystals were grown by the Bridgman technique using the [011] oriented seed crystals. The starting composition was selected as [xPIN−(1−x−y)PMN−yPT] with x>0.25–0.35 and y>0.30–0.32. An obtained crystal boule with 50 mm in diameter and 100 mm in length is shown in Fig. 1. As reported for PMNT crystals, the composition along the growth direction is varied due to the segregation of titanium in PIN-PMN-PT crystals, with lower PT content at the bottom part of the crystals and the crystal near the top of the boule was found to be in tetragonal phase. The obtained crystal boule was divided into five parts, rhombohedral A, B, and C, and MPB region, and tetragonal, as shown in Fig. 1. All the samples for characterization in this work belong to the rhombohedral phase, considering the low ferroelectric phase transition temperature associated with the MPB composition(s), the MPB region was not studied in this work. The full set of material constants were determined using the resonance method and five types of Z-cut samples were prepared according to IEEE standards.10, 11, 18, 19, 20, 21, 22 All the samples were oriented along their crystallographic directions [001] and [110] using real-time Laue and sputtered with gold on the parallel [001] faces. The samples were poled at 20 kV∕cm at room temperature. High field polarization and strain measurements at room temperature were performed on the [001] oriented plate samples using a modified Sawyer–Tower circuit and linear variable differential transducer driven by a lock-in amplifier. The resonance and antiresonance frequencies were obtained by an HP 4194A impedance-phase gain analyzer. The Curie temperature and ferroelectric phase transition temperatures were determined from the dielectric temperature dependence using a multifrequency LCR meter (HP4284A), connected to a computer controlled temperature chamber. Dielectric behavior under external dc bias was measured as a function of temperature on the [001] oriented samples, with dc bias varying from 0 to 20 kV∕cm and in 1 kV∕cm step, with a blocking circuit to protect the LCR meter under high dc bias field, which was supplied by a Trek609C-6 high-voltage dc amplifier.

Figure 1.

Photo of as grown PIN-PMN-PT crystal with 50 mm in diameter.

RESULTS AND DISCUSSIONS

Material constants at room temperature

Tables 1, 2, 3 list the full set of elastic constants, piezoelectric coefficients, electromechanical coupling factors, and dielectric permittivity for PIN-PMN-PT and compared to PMNT, respectively. As found in PMNT crystal boules, the PT content in PIN-PMN-PT was found to vary along the growth direction, with lower PT observed in the early growth stage and higher PT in the final growth stage. As shown in Fig. 1, parts A–C are in the rhombohedral region, with the highest PT found in part C. The elastic compliance constants were found to increase slightly with increasing PT, while the elastic stiffness constants (c11, c33, and c44) exhibited similar values, demonstrating that the rhombohedral PIN-PMN-PT crystals have similar longitudinal and shear wave sound velocities related to the above constants regardless of the variation in PT content. However, the elastic stiffness c66 were found to decrease slightly with increasing PT, indicating slower shear wave (with both the propagation and displacement perpendicular to the poling direction) sound velocity due to the domain wall motion, which makes extrinsic contribution to the dielectric and piezoelectric properties.21 The piezoelectric strain coefficients d33 were found to increase with increasing PT. The piezoelectric stress coefficient e33 values were found to decrease with increasing PT contents, associated with a decrease in clamped dielectric permittivity. All the piezoelectric properties are comparable to PMNT29 single crystals.

Table 1.

Measured and derived elastic compliance constants sij (10−12 m2∕N) and elastic stiffness constants cij (1010 N∕m2) for PIN-PMN-PT crystals, compared to PMNT29.

| Material | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part A | 42.3 | −18.4 | −20.9 | 45.7 | 15.6 | 33.0 | 33.9 | −26.7 | −3.6 | 9.9 | 14.4 | 33.0 |

| Part B | 49.0 | −20.0 | −26.5 | 57.3 | 15.2 | 39.4 | 38.2 | −30.8 | −4.0 | 10.3 | 14.3 | 39.4 |

| Part C | 51.2 | −18.3 | −31.3 | 68.4 | 15.8 | 43.0 | 38.2 | −31.3 | −3.7 | 10.0 | 14.5 | 43.0 |

| PMNT29 | 52.1 | −24.6 | −26.4 | 59.9 | 16.0 | 28.3 | 41.8 | −34.8 | −3.9 | 10.3 | 14.0 | 28.3 |

| Material | ||||||||||||

| Part A | 11.2 | 9.6 | 9.5 | 10.9 | 6.4 | 3.0 | 11.7 | 10.1 | 7.9 | 15.9 | 6.9 | 3.0 |

| Part B | 11.9 | 10.5 | 10.4 | 11.4 | 6.6 | 2.5 | 12.3 | 10.9 | 9.0 | 16.7 | 7.0 | 2.5 |

| Part C | 12.2 | 10.7 | 10.5 | 11.0 | 6.4 | 2.3 | 12.7 | 11.2 | 8.8 | 16.4 | 6.9 | 2.3 |

| PMNT29 | 12.4 | 11.1 | 10.4 | 10.8 | 6.3 | 3.5 | 12.6 | 11.3 | 9.3 | 16.8 | 7.1 | 3.5 |

Table 2.

Piezoelectric coefficients, dij (pC∕N), eij (C∕m2), gij (10−3 Vm∕N), and hij (108 V∕m), and electromechanical coupling factors, kij, for PIN-PMN-PT crystals, compared to PMNT29.

| Material | d33 | d31 | d15 | e33 | e31 | e15 |

|---|---|---|---|---|---|---|

| Part A | 1130 | −544 | 119 | 19.1 | −6.1 | 7.6 |

| Part B | 1320 | −634 | 105 | 18.6 | −4.8 | 6.9 |

| Part C | 1510 | −712 | 119 | 17.1 | −5.4 | 7.6 |

| PMNT29 | 1540 | −699 | 164 | 22.3 | −3.9 | 10.3 |

| Material | g33 | g31 | g15 | h33 | h31 | h15 |

| Part A | 31.8 | −15.4 | 9.9 | 26.2 | −8.4 | 7.0 |

| Part B | 35.6 | −17.0 | 8.8 | 28.9 | −7.4 | 6.5 |

| Part C | 38.7 | −18.3 | 10.2 | 31.4 | −9.8 | 7.9 |

| PMNT29 | 32.2 | −14.6 | 11.9 | 27.7 | −4.8 | 8.7 |

| Material | k33 | k31 | k15 | kt | k31 (45 °C) | |

| Part A | 0.89 | 0.44 | 0.27 | 0.56 | 0.77 | |

| Part B | 0.91 | 0.47 | 0.25 | 0.57 | 0.80 | |

| Part C | 0.92 | 0.50 | 0.28 | 0.57 | 0.82 | |

| PMNT29 | 0.91 | 0.44 | 0.35 | 0.60 | 0.81 |

Table 3.

Dielectric constants εij (ε0) and dielectric impermeability constants β (10−4∕ε0) for PIN-PMN-PT crystals, compared to PMNT29.

| Material | ||||||||

|---|---|---|---|---|---|---|---|---|

| Part A | 4000 | 1360 | 822 | 1230 | 2.50 | 7.35 | 12.17 | 8.13 |

| Part B | 4200 | 1335 | 729 | 1200 | 2.38 | 7.49 | 13.72 | 8.33 |

| Part C | 4400 | 1320 | 617 | 1080 | 2.27 | 7.58 | 16.21 | 9.26 |

| PMNT29 | 5400 | 1560 | 910 | 1340 | 1.85 | 6.41 | 10.99 | 7.46 |

Ferroelectric properties at room temperature

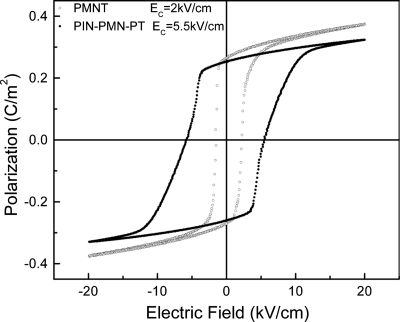

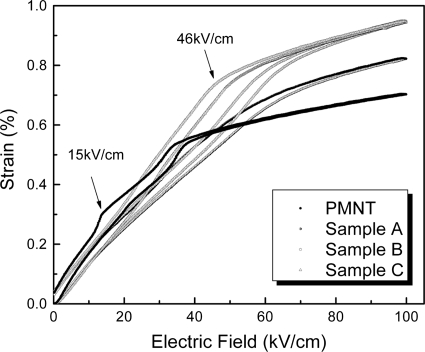

Figure 2 shows the bipolar polarization hysteresis for PIN-PMN-PT crystals and compared to PMNT. The remnant polarization was found to be on the order of 0.25 C∕m2 for PIN-PMN-PT, comparable to PMNT (∼0.265 C∕m2). Of particular interest is the high coercive field of PIN-PMN-PT, being on the order of 5.5 kV∕cm, more than twice of the value of PMNT (∼2 kV∕cm). The high field strain behavior as a function of electric field is given in Fig. 3, in which the electric field induced phase transformation field level of PMNT crystals was found to be ∼15 kV∕cm, while the induced transition field level was on the order of 46 kV∕cm for the ternary system. The piezoelectric coefficients obtained from the low-field slope were found to be 1100–1500 pm∕V, corresponding to the d33 value of the rhombohedral crystals obtained from the resonance method. Upon strain saturating, i.e., tetragonal phase induced, the piezoelectric d33 was found to drop significantly, being on the order of 250 pm∕V for PMNT crystal and ∼400 pm∕V for PIN-PMN-PT system.

Figure 2.

Polarization hysteresis measured at a field of 20 kV∕cm for PIN-PMN-PT crystals and compared to PMNT.

Figure 3.

Unipolar strain as a function of electric field for PIN-PMN-PT and compared to PMNT.

Properties as a function of temperature

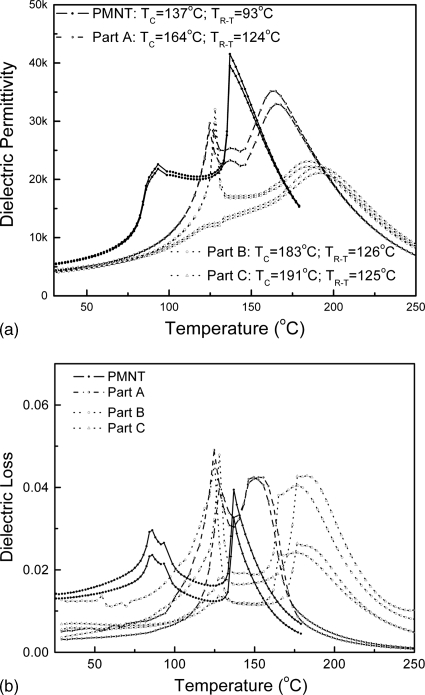

Figure 4 shows the dielectric permittivity and dielectric loss as functions of temperature for rhombohedral PIN-PMN-PT with different PT contents, and compared to PMNT29, respectively. The room temperature dielectric permittivity was found to be ∼4000 for part A, increasing to ∼4400 for part C, lower than binary PMNT29 crystal (∼5400). The Curie temperature increased from 164 to 191 °C, depending on the different PT contents. Of particular interest is the rhombohedral to tetragonal phase transition temperature for most of the rhombohedral region, being on the same order of ∼125 °C, 30 °C higher than the binary counterpart. The dielectric permittivity variation for PIN-PMN-PT in the range of room temperature to 100 °C was found to be on the order of 50–90∕K, much lower when compared to PMNT crystal (∼220∕K), exhibiting a much flatter and more stable dielectric behavior. The dielectric loss for PIN-PMN-PT crystals, as shown in Fig. 4b, exhibited similar trend as dielectric permittivity, with peak values located at the phase transition temperature.

Figure 4.

Dielectric permittivity (a) and dielectric loss (b) as a function of temperature for PIN-PMN-PT and compared to PMNT.

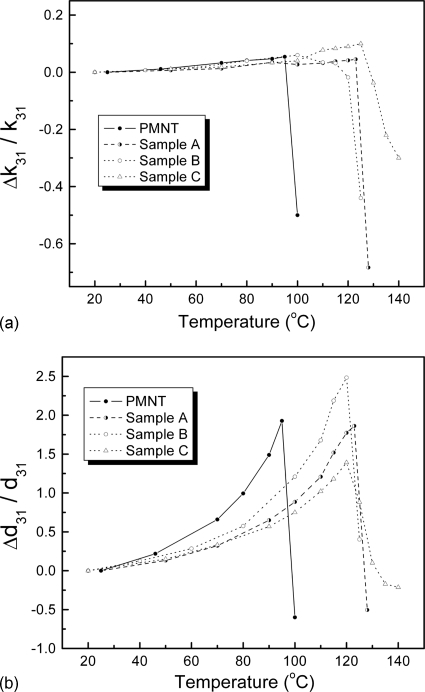

Figure 5 shows the variation in electromechanical coupling k31 and piezoelectric coefficient d31 as functions of temperature for PIN-PMN-PT crystals, compared to PMNT. It was observed that the electromechanical coupling factor maintained similar values with increasing temperature, decreasing sharply above the phase transition temperature (∼125 °C for PIN-PMN-PT) due to the partial depolarization of the crystals in the tetragonal phase. The piezoelectric coefficients were found to increase with increasing temperature and reach a maxima at the phase transition temperature, whereupon they decrease significantly.

Figure 5.

Variation in lateral electromechanical coupling factor (a) and variation in lateral piezoelectric coefficient (b) as a function of temperature for PIN-PMN-PT and compared to PMNT.

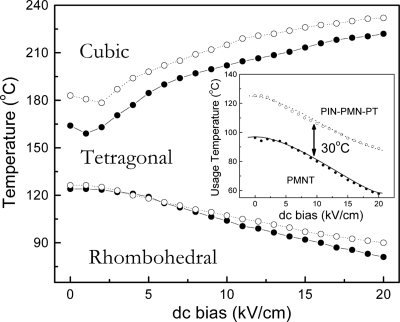

Usage temperature range under dc bias

Usage temperature range for a ferroelectric single crystal is not only limited by their ferroelectric phase transition temperature but to the applied external electric fields, which results in lower phase transition temperatures. Thus, it is important to understand the behavior of crystals under dc bias field. Figure 6 presents the Curie temperature and rhombohedral to tetragonal phase transition temperatures for PIN-PMN-PT crystals with different PT contents as a function of dc bias. As found for other ferroelectric crystal systems,14 the Curie temperature was found to shift to lower temperatures when the dc bias was lower than a specific threshold field, which is related to the magnitude of the random internal field in relaxor systems. Above the critical field, the Curie temperature increased with increasing dc bias; meanwhile, the rhombohedral to tetragonal phase transition temperatures were found to decrease linearly with increasing dc bias. This behavior reflects the stabilizing of the tetragonal phase, owing to the fact that the spontaneous polarization direction [001] in tetragonal phase is along the dc bias direction. The small inset in Fig. 6 shows the usage temperature range (phase transition temperature) for PIN-PMN-PT under different dc biases compared to PMNT. The usage temperature range for PIN-PMN-PT was found to be on the order of 125 °C (zero bias) and decreases to 90 °C at an applied field of 20 kV∕cm, being 30 °C higher than PMNT counterpart.

Figure 6.

Curie temperature and rhombohedral to tetragonal phase transition temperature as a function of external dc bias for PIN-PMN-PT crystals. (The inset shows the usage temperature range of PIN-PMN-PT and compared to PMNT crystal.)

SUMMARY

In summary, large size (50 mm in diameter) PIN-PMN-PT crystals were grown directly from the melt using the Bridgman technique. Of the obtained crystal boule, 70% of which belongs to the rhombohedral phase, with modest PT segregation along the growth direction. The piezoelectric properties of rhombohedral PIN-PMN-PT crystals are comparable to binary PMNT crystals. Of particular interest, the ferroelectric phase transition temperatures observed, being on the order of 125 °C, were 30 °C higher than PMNT29 crystals. Due to the higher Curie temperature, PIN-PMN-PT crystals were found to possess higher coercive field of ∼5.5 kV∕cm, more stable dielectric and piezoelectric properties, and much broader usage temperature range, when compared to PMNT crystals, which make the ternary crystals promising candidates for wider range of potential transducer applications.

ACKNOWLEDGMENTS

This work was supported by the ONR and NIH under Contract No. P41-RR11795. Thanks are due to Ms. Ru Xia for the sample preparation.

References

- Park S. E. and Shrout T. R., J. Appl. Phys. 10.1063/1.365983 82, 1804 (1997). [DOI] [Google Scholar]

- Zhang S. J., Luo J., Xia R., Rehrig P. W., Randall C. A., and Shrout T. R., Solid State Commun. 10.1016/j.ssc.2005.10.023 137, 16 (2006). [DOI] [Google Scholar]

- Damjanovic D., Budimir M., Davis M., and Setter N., J. Mater. Sci. 10.1007/s10853-005-5925-5 41, 65 (2006). [DOI] [Google Scholar]

- Zhang S. J., Luo J., Snyder D. W., and Shrout T. R., in Handbook of Advanced Dielectric, Piezoelectric, and Ferroelectric Mater: Synthesis Characterization and Applications, edited by Ye Z. G. (Woodhead, Cambridge, 2008), p. 130. [Google Scholar]

- Yamashita Y. J. and Hosono Y., in Handbook of Advanced Dielectric, Piezoelectric, and Ferroelectric Mater: Synthesis Characterization and Applications, edited by Ye Z. G. (Woodhead, Cambridge, 2008), p. 205. [Google Scholar]

- Bing Y. H. and Ye Z. G., in Handbook of Advanced Dielectric, Piezoelectric, and Ferroelectric Mater: Synthesis Characterization and Applications, edited by Ye Z. G. (Woodhead, Cambridge, 2008), p. 173. [Google Scholar]

- Zhang S. J., Lebrun L., Rhee S., Randall C. A., and Shrout T. R., Appl. Phys. Lett. 10.1063/1.1497435 81, 892 (2002). [DOI] [Google Scholar]

- Zhang S. J., Rhee S., Randall C. A., and Shrout T. R., Jpn. J. Appl. Phys., Part 1 10.1143/JJAP.41.722 41, 722 (2002). [DOI] [Google Scholar]

- Zhang S. J., Randall C. A., and Shrout T. R., Appl. Phys. Lett. 10.1063/1.1619207 83, 3150 (2003). [DOI] [Google Scholar]

- Zhang S. J., Randall C. A., and Shrout T. R., J. Appl. Phys. 10.1063/1.1682694 95, 4291 (2004). [DOI] [Google Scholar]

- Zhang S. J., Lee S. M., Kim D. H., Lee H. Y., and Shrout T. R., J. Appl. Phys. 10.1063/1.2817641 102, 114103 (2007). [DOI] [Google Scholar]

- Zhang S. J., Lee S. M., Kim D. H., Lee H. Y., and Shrout T. R., Appl. Phys. Lett. 10.1063/1.2746055 90, 232911 (2007). [DOI] [Google Scholar]

- Amin A., Lee H. Y., and Kelly B., Appl. Phys. Lett. 10.1063/1.2748857 90, 242912 (2007). [DOI] [Google Scholar]

- Zhang S. J., Lee S. M., Kim D. H., Lee H. Y., and Shrout T. R., J. Am. Ceram. Soc. 90, 3859 (2007). [Google Scholar]

- Guo Y. P., Luo H. S., He T., and Yin Z. W., Solid State Commun. 10.1016/S0038-1098(02)00311-3 123, 417 (2002). [DOI] [Google Scholar]

- Xu G. S., Chen K., Yang D. F., and Li J. B., Appl. Phys. Lett. 10.1063/1.2431706 90, 032901 (2007). [DOI] [Google Scholar]

- Tian J., Han P. D., Huang X. L., and Pan H. X., Appl. Phys. Lett. 10.1063/1.2817743 91, 222903 (2007). [DOI] [Google Scholar]

- ANSI/IEEE Std. 176-1987, IEEE Standard on Piezoelectricity.

- Cao W. W., in Handbook of Advanced Dielectric Piezoelectric and Ferroelectric Mater: Synthesis Characterization and Applications, edited by Ye Z. G. (Woodhead, Cambridge, 2008), p. 235. [Google Scholar]

- Zhang S. J., Lee S. M., Kim D. H., Lee H. Y., and Shrout T. R., J. Am. Ceram. Soc. 10.1111/j.1551-2916.2007.02190.x 91, 683 (2008). [DOI] [Google Scholar]

- Zhang R., Jiang B., and Cao W., J. Appl. Phys. 10.1063/1.1390494 90, 3471 (2001). [DOI] [Google Scholar]

- Geng X. C., Ritter T. A., and Park S. E., IEEE Ultrasonics Symposium (IEEE, New York, 1998), p. 571.